Construction method for revolving digging cast-in-place pile

A construction method and cast-in-place pile technology, applied in sheet pile wall, foundation structure engineering, construction and other directions, can solve the problems of affecting the bearing capacity of engineering piles, slow ballast removal at the end hole, secondary pollution, etc., and achieve fast pile formation. , The effect of clearing the ballast quickly and reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

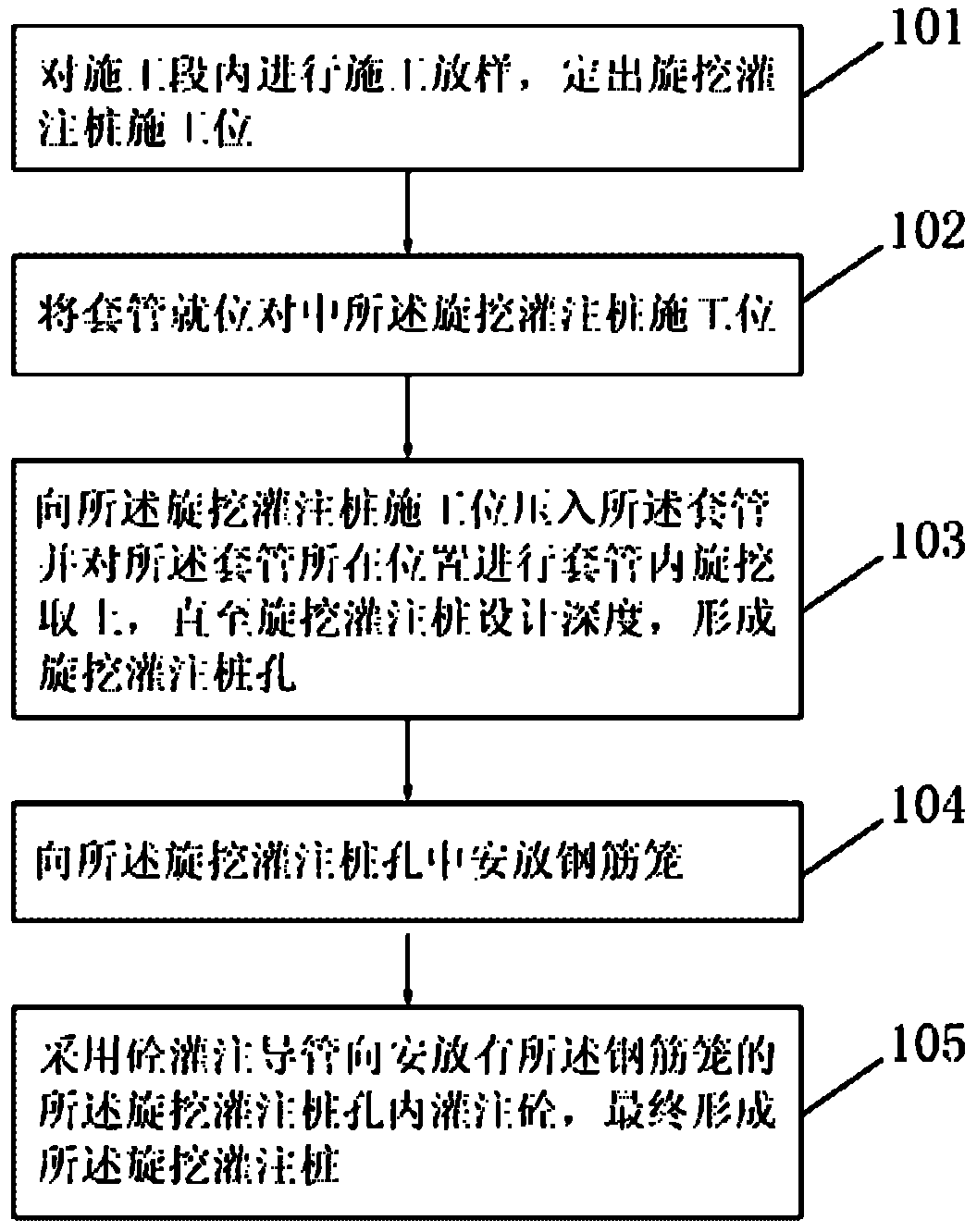

[0028] Such as figure 1 As shown, the rotary-dug cast-in-place pile construction method of the embodiment of the present invention mainly comprises:

[0029] 101, carry out construction lofting in the construction section, and determine the construction position of the rotary excavation grouting pile;

[0030] 102. Put the casing 1 in place and center the construction position of the rotary-dug cast-in-place pile;

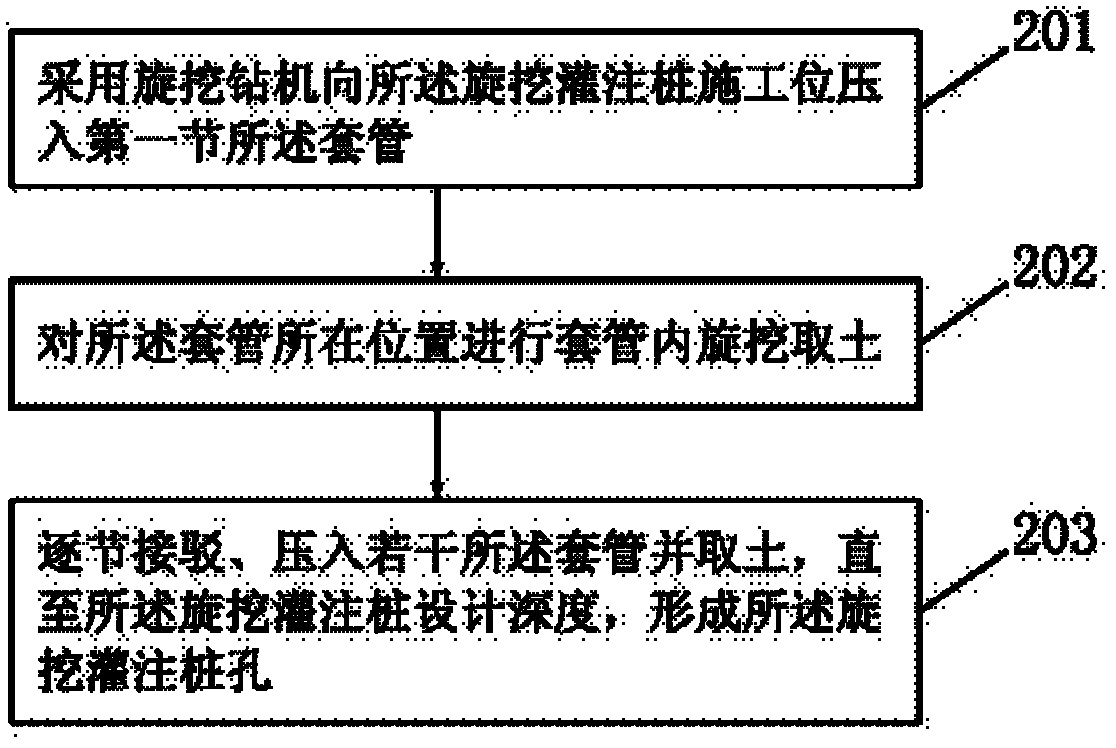

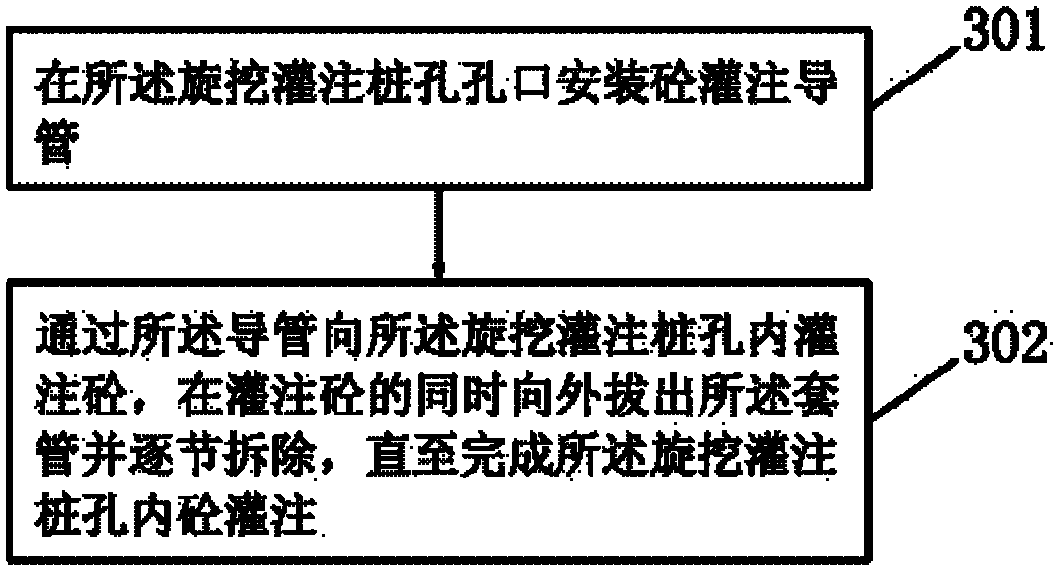

[0031] 103. Press the casing 1 into the construction position of the rotary-dug cast-in-place pile, and carry out rotary digging and soil extraction from the position of the casing 1 until the design depth of the rotary-dug cast-in-place pile is formed to form a rotary-dug cast-in-place pile hole. Specifically, step 103 may include as figure 2 Process shown:

[0032] 201, using a rotary drilling rig 2 to press the casing 1 in the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com