Self-heat-preservation prefabricated outer wall board with frame net rack

An external wall panel, self-insulation technology, applied in building components, buildings, building structures, etc., can solve the problem that the impact of the infill wall on the seismic performance of the frame body cannot be fundamentally and effectively solved, the quality of masonry construction is difficult to effectively guarantee, and the construction quality Can not be absolutely guaranteed and other problems, to achieve the effect of easy control of building quality, reduction of thermal insulation workload, and avoidance of common quality problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

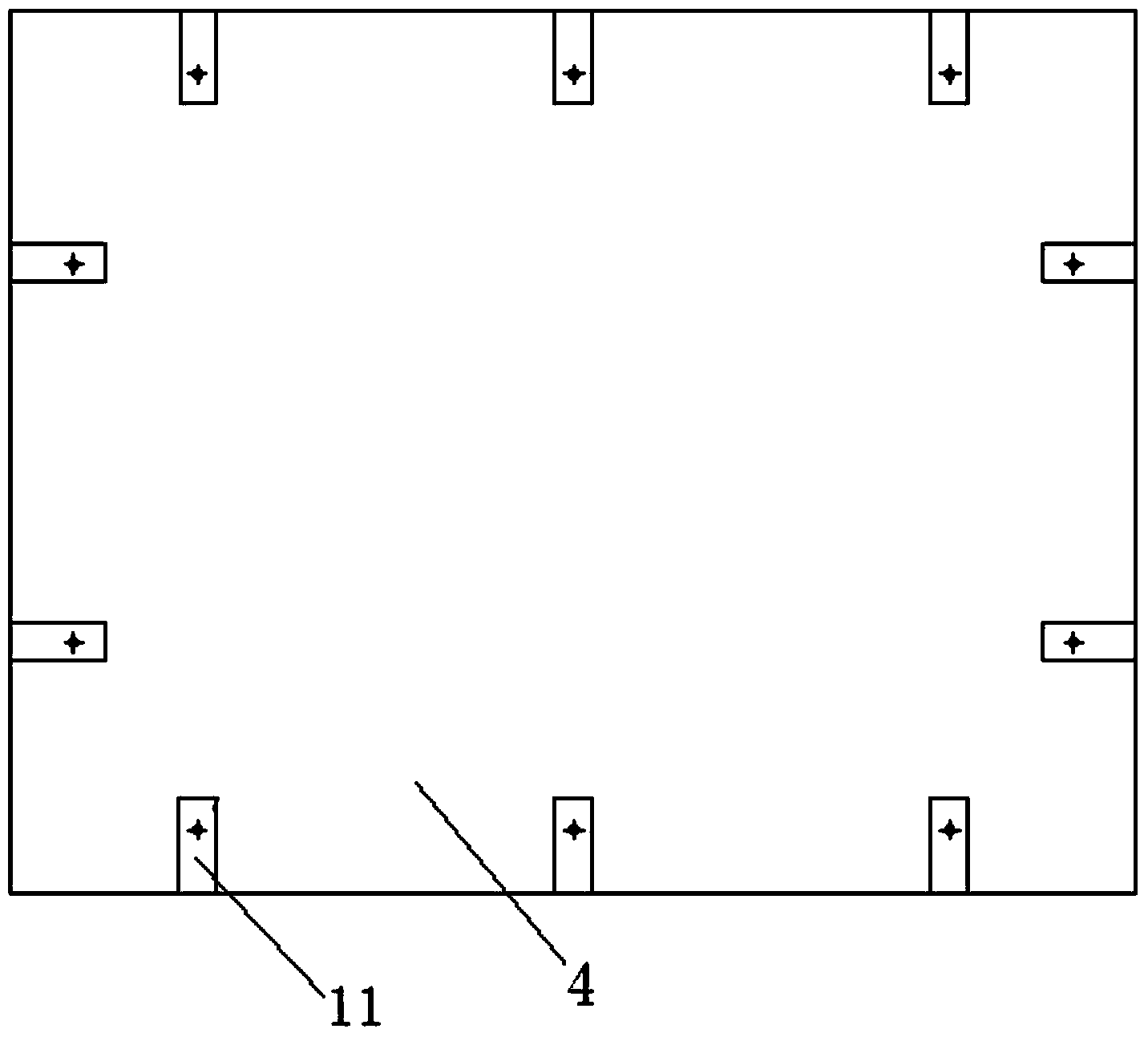

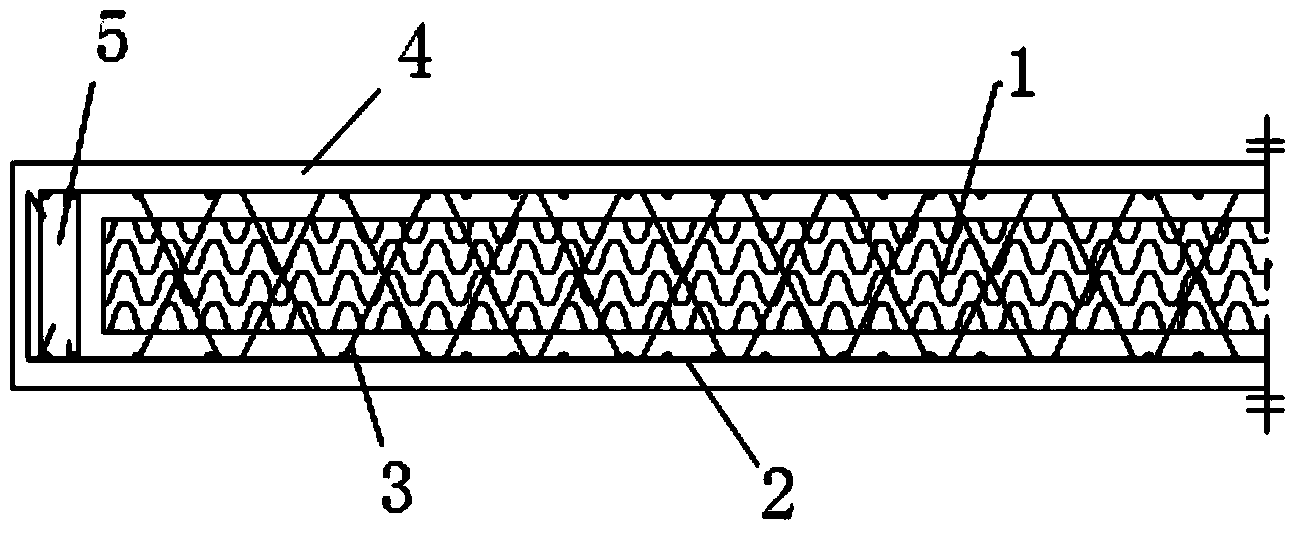

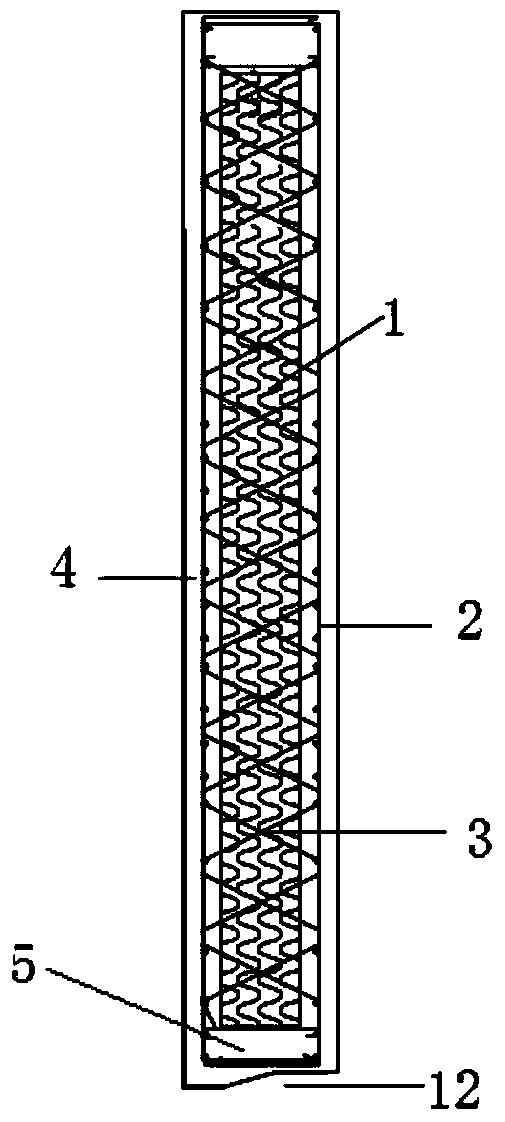

[0026] like figure 1 , figure 2 , image 3 As shown, the upper and lower two pieces of steel wire mesh 2 and the obliquely inserted ribs 3 are welded to form a space steel wire grid, the insulation sandwich panel 1 is placed in the space steel wire grid, and the upper and lower two pieces of steel wire mesh 2 The edges around the core board 1 are divided into two rows of inward bending and additional tension bars are added to form a frame reinforcement cage 5. The insulation sandwich board 1 can be made of foam board or extruded plastic board, or a sandwich combination of two materials, that is, extruded plastic board - foam board - extruded polystyrene board. The steel wire mesh 2 is welded by crisscross steel wires, the diameter of the steel wire is 3-5mm, the oblique rib 3 is made of stainless steel wire, the diameter of the steel wire is 3-5mm, the vertical and horizontal intersection points of the steel wire mesh 2 are all connected by the oblique rib 3 Connect the up...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com