Patents

Literature

75 results about "Cross shear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Greenhouse suspended self-propelled target-oriented sprayer system and operation method thereof

InactiveCN102017938AAvoid bodily harmImprove labor efficiencySpraying apparatusInsect catchers and killersSprayerEngineering

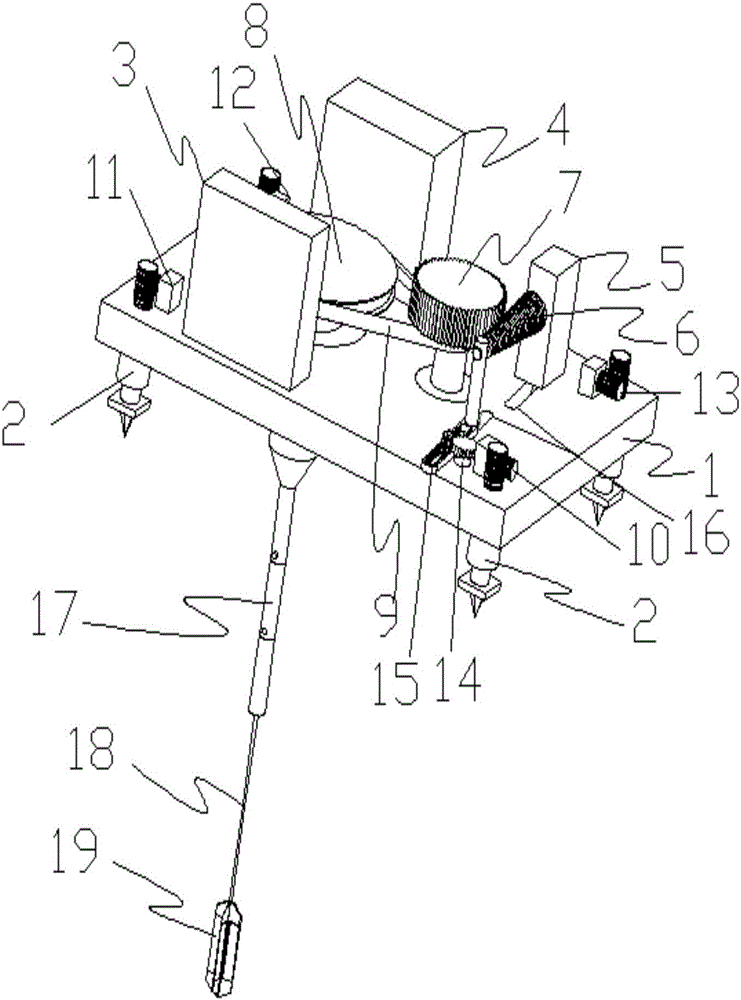

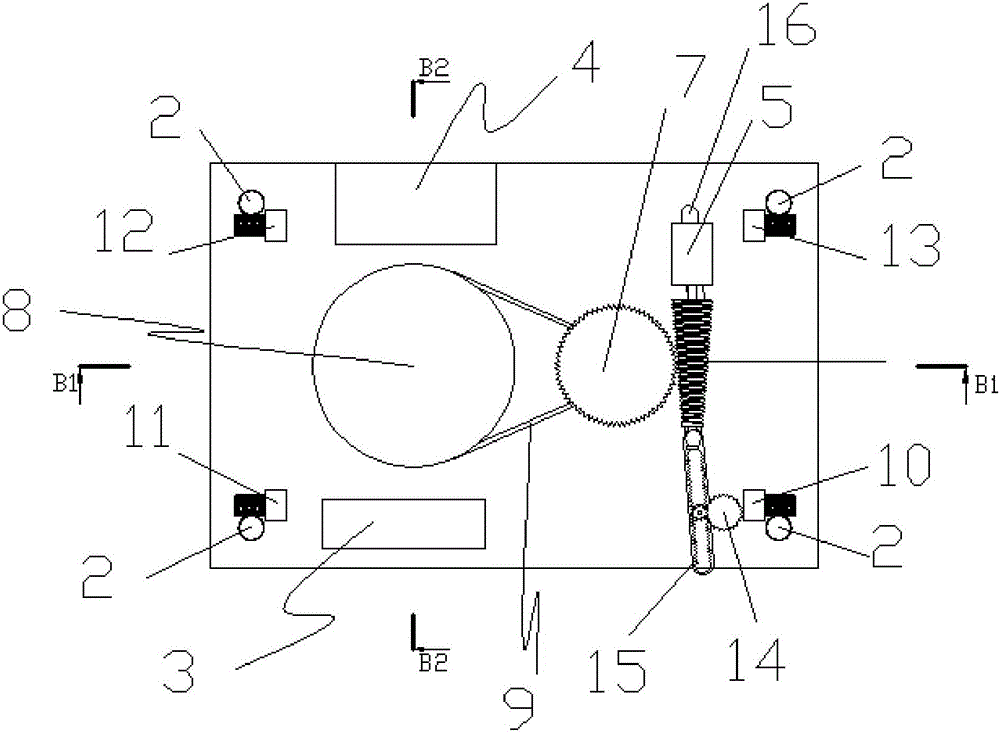

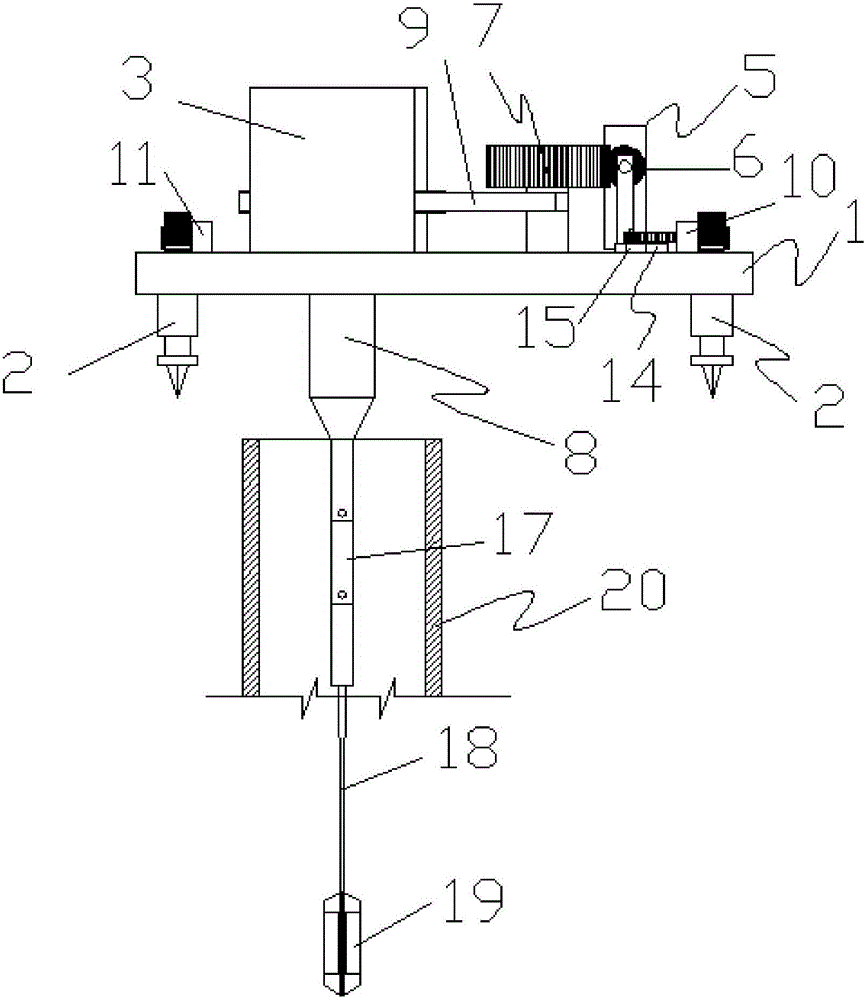

The invention relates to a greenhouse suspended self-propelled target-oriented sprayer system and an operation method thereof. The greenhouse suspended self-propelled target-oriented sprayer system is characterized by comprising a guide way, a self-propelled mobile platform, a hall sensor, a spraying manipulator device, a binocular vision system and a PLC (Programmable Logic Controller), wherein a plurality of magnetic positioning marks are preinstalled on the guide way; the self-propelled mobile platform is arranged on the guide way through a walking mechanism and provided with the hall sensor; the spraying manipulator device comprises a Z direction cross-shear hanger which is arranged on a rack; a spray rod is horizontally arranged below the hanger through a rotary positioning mechanism; a spray pipe is fixedly arranged on the spray rod; a plurality of spray heads are arranged on the spray pipe at intervals and independently controlled by electromagnetic valves; the hanger has the functions of extension and retraction; the binocular vision system comprises two CCD (Charge-Coupled Device) video cameras; the two CCD video cameras are fixedly installed on both ends of the spray rod respectively and connected with an upper computer in which control software is prearranged; and the PLC is electrically connected with the upper computer, the hall sensor, a frequency converter, a drive controller, the electromagnetic valves and the CCD video cameras respectively.

Owner:CHINA AGRI UNIV

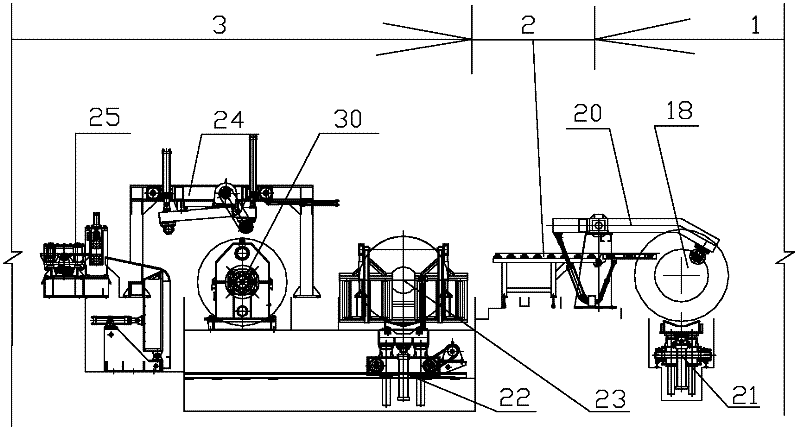

Vertical and horizontal shearing combination production line for high-strength thick steel plates

InactiveCN102490009AMeet the processing technology requirementsIncrease profitOther manufacturing equipments/toolsProduction lineIndependent function

The invention provides a vertical and horizontal shearing combination production line for high-strength thick steel plates based on the advantage of multifunction of an existing vertical and horizontal shearing combination production line, so that vertical shearing and horizontal shearing functions are organically combined, various machining processes are realized, and production requirements on high efficiency and high quality are met. The vertical and horizontal shearing combination production line for the high-strength thick steel plates comprises a vertical shearing line and a horizontal shearing line which are controlled by an electric control system and a hydraulic pneumatic lubricating system, a second uncoiler is arranged on the horizontal shearing line, and a transition bench is arranged between the vertical shearing line and the horizontal shearing line. The vertical shearing line has independent functions of uncoiling, vertical shearing and coiling, the horizontal shearing line has independent functions of uncoiling, leveling, horizontal shearing and stacking, the whole vertical and horizontal shearing combination production line has the functions of uncoiling, leveling, vertical shearing and coiling, leveling and horizontal shearing, multi-strip horizontal shearing and automatic stacking, the requirements of various high-strength thick steel plates on various machining processes are met, the vertical and horizontal shearing combination production line is high in utilization rate, multifunctional and high in automation degree, and the production requirements on high efficiency and high quality are met.

Owner:佛山市南海力丰机床有限公司

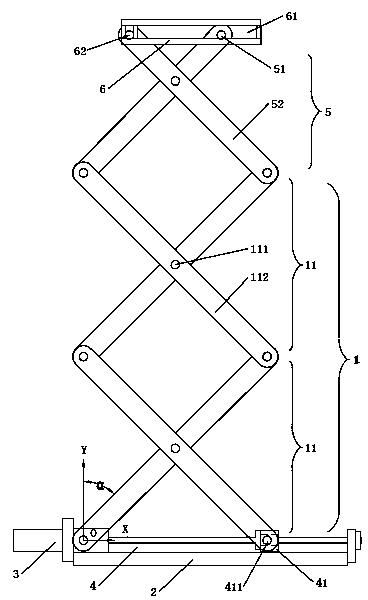

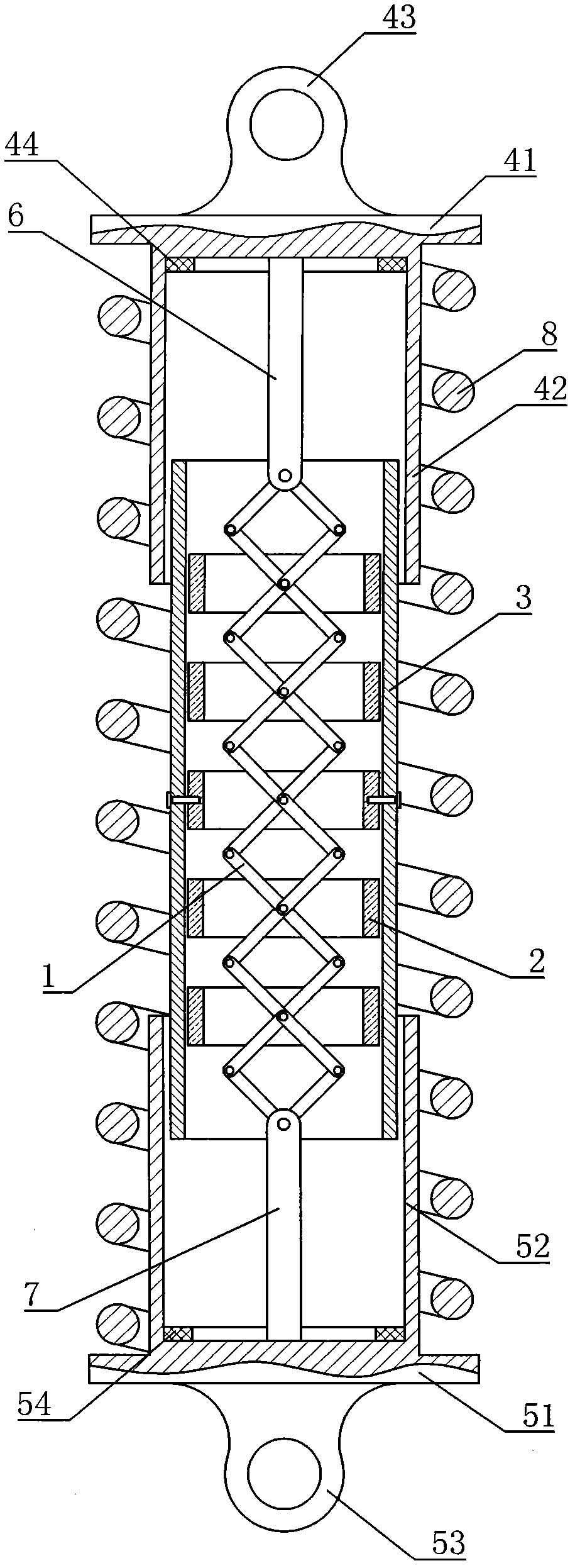

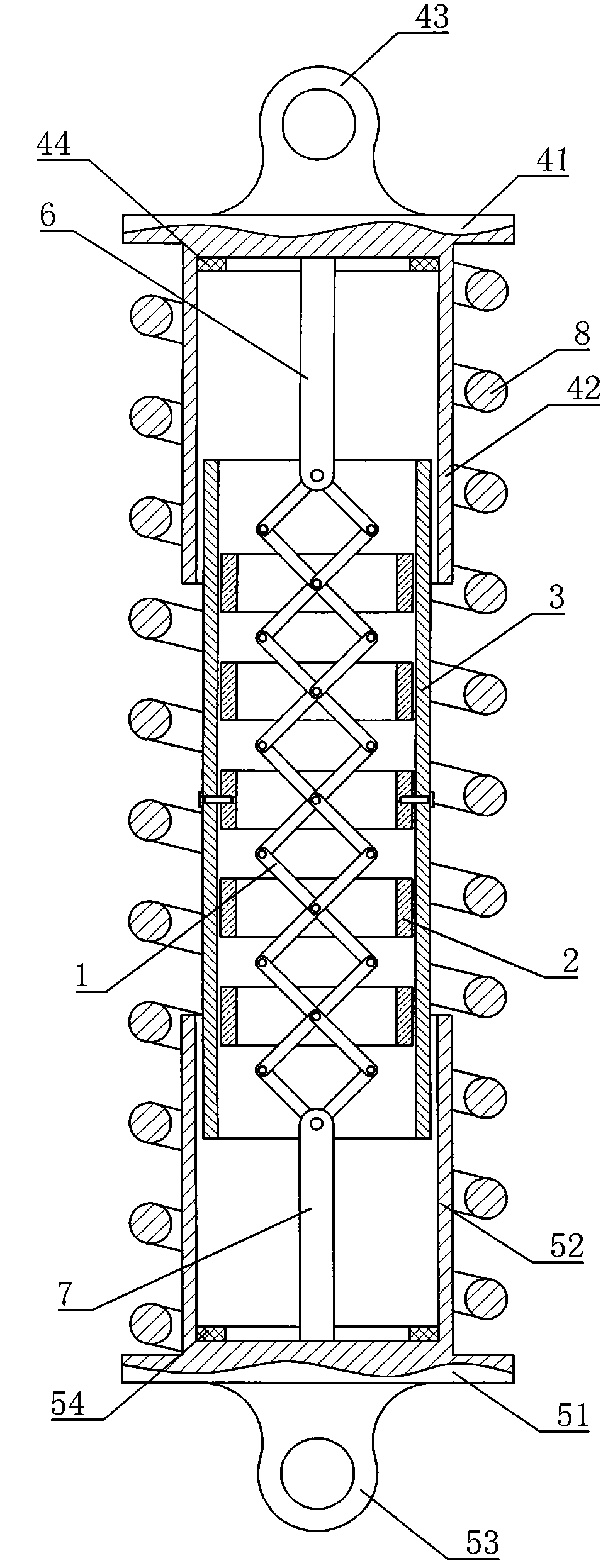

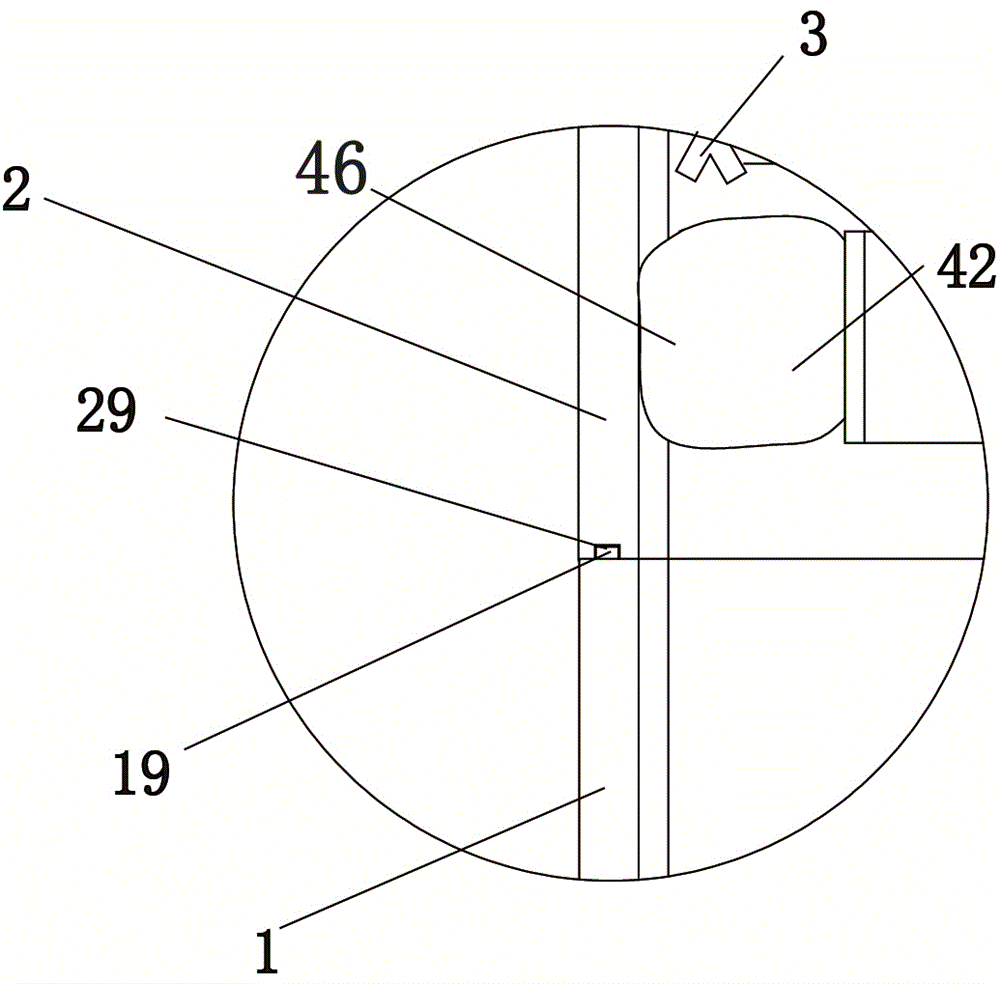

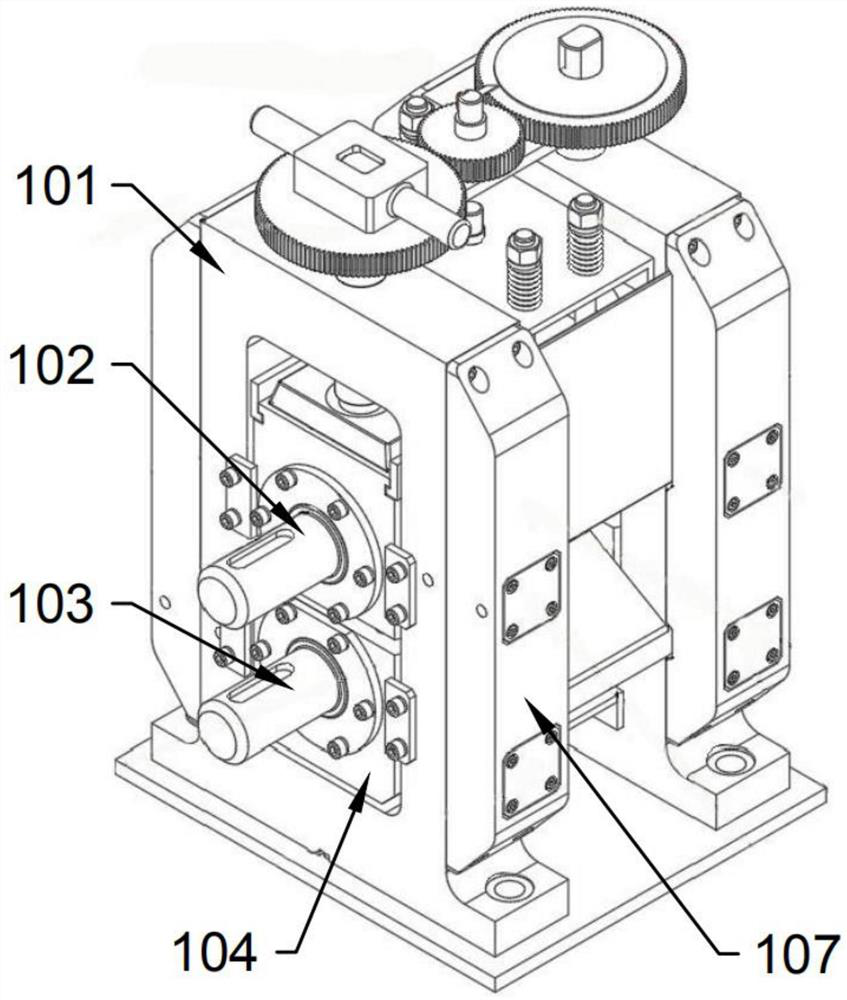

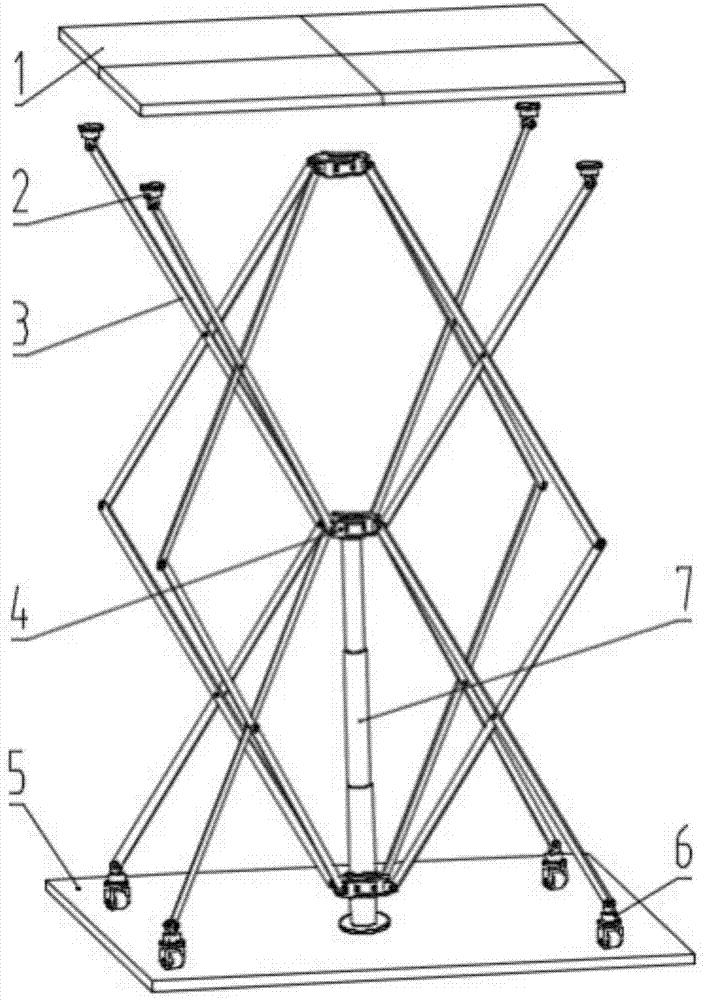

Shear mode mechanism capable of being controlled in numerical mode and shear mode mechanism drive system formed by shear mode mechanisms in combined mode

InactiveCN103523707AAccurate telescopic positioningLarge expansion ratioLifting framesNumerical controlBall screw drive

A shear mode mechanism capable of being controlled in a numerical mode comprises a support unit and further comprises a machine base, a numerical control motor arranged on the machine base, and a ball screw driven by the numerical control motor. End portions of multiple pairs of crossed shear mode supports are sequentially hinged to one another to form the support unit, one of the two ends of the bottoms of the nethermost pair of shear mode supports of the support unit is used as the original point and hinged to the machine base, the other of the two ends of the bottoms of the nethermost pair of shear mode supports of the support unit is hinged to a nut of the ball screw, and therefore the displacement of the shear mode mechanism in the vertical direction can be accurately calculated according to the travel of the numerical control motor, and the aim of controlling the displacement of the shear mode mechanism in the numerical mode is achieved. The shear mode mechanism is accurate in stretching positioning and large in stretching ratio in comparison with a shear mode mechanism, driven by a servo motor, of a joint type mechanical arm. In addition, when the shear mode mechanisms are combined in series or in parallel or in series and in parallel to form a shear mode mechanism drive system, the loading capacity and the stability of the shear mode mechanisms can be greatly improved.

Owner:唐易平

Stable-type damping device

ActiveCN102619926AReduce impactShock absorption stabilityNon-rotating vibration suppressionMagnetic springsVehicle frameMagnetic poles

The invention discloses a stable-type damping device, which comprises at least two magnets. Opposite magnetic poles of the magnets are adjacent, the magnets are hinged on a cross shear-type expansion bracket, retaining-and-guiding inner sleeves are sleeved outside the magnets, upper end seats and lower end seats are disposed at both ends of the retaining-and-guiding inner sleeves respectively andconnected with both ends of the cross shear-type expansion frame respectively, and damping springs are installed between the upper end seats and the lower end seats. Since opposite magnetic poles of adjacent magnets are arranged oppositely, the closer the distance, the greater the attraction; when severe vibration occurs, the damping springs are compressed and deformed greatly, the elasticity of the damping springs increases linearly with the deformation; when the deformation of the damping springs increases, the distance between adjacent magnets decreases, the attraction increases geometrically, a part of increased elasticity is offset, in other words, impact force to car frames is decreased. By the stable-type damping device, stable damping can be realized when the elasticity of damperscan be kept changing mildly and nonlinearly within a bigger deformation range.

Owner:JIANGSU DEPENG AIR CONDITION CO LTD

Method for improving wearability of wearable high manganese steel by using asymmetrical rolling

InactiveCN101003876AImprove initial use hardnessReduce initial wearArc welding apparatusChemical compositionWear resistant

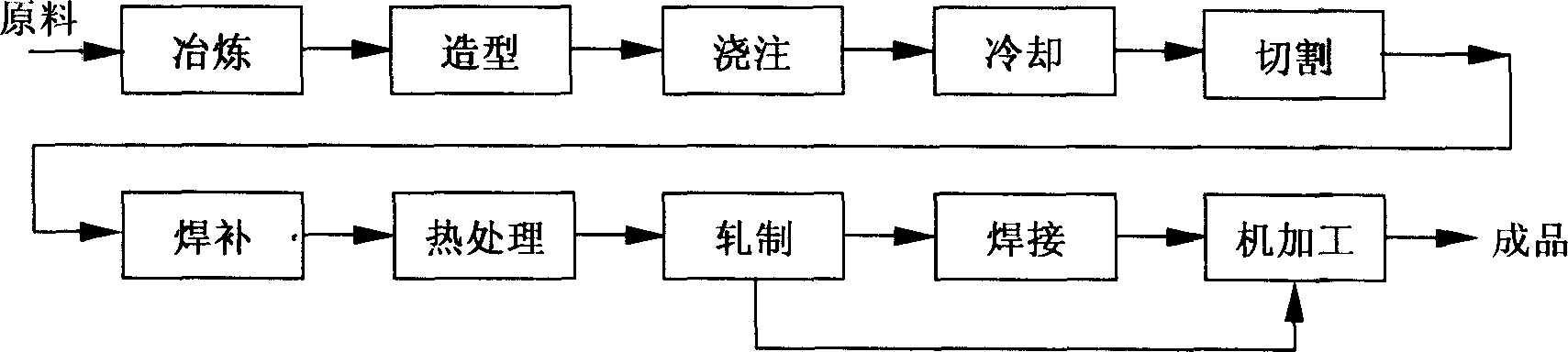

This invention discloses a method for improving wear resistance of wear-resistant high-Mn steel by cross-shear rolling. The high-Mn steel comprises: C 1.1-1.3 wt.%, Mn 11-14 wt.%, Si 0.3-0.8 wt.%, S less than 0.013 wt.%, and P less than 0.027 wt.%. The method comprises: casting high-Mn steel, performing water-toughening treatment on the cast (sigmab greater than 700 MPa, epsiv greater than 15%, ak greater than 180 J / cm3, and HB less than 250), performing cross-shear rolling on the cast plates (sigmab greater than 900 MPa, epsiv greater than 12%, ak greater than 120 J / cm3, and HB less than 350), and welding or machining to obtain qualified product. The method increases initial hardness and decreases initial wear of high-Mn steel, makes plastic processing much easier than common rolling, and maintains good impact toughness of high-Mn steel.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Feeding guide rail for cross shearing machine

The invention discloses a feeding guide rail for a cross shearing machine. The feeding guide rail comprises a base, wherein supports and a screw rod are arranged on the base; a left guide rail and a right guide rail are arranged on the support in a slidable manner; a screw nut a is arranged at the lower end in the middle of the left guide rail and is matched with the screw thread at one end of the screw rod; a screw nut b is arranged at the lower end in the middle of the right guide rail and is matched with the screw thread at the other end of the screw rod; and the directions of the screw threads at the two ends of the screw rod are reverse. According to the feeding guide rail for the cross shearing machine, the positions of the left guide rail and the right guide rail are regulated by rotating the screw rod, so as to position a belt and prevent the belt from deflection; and the feeding guide rail has the advantages of simple structure, easiness in implementation, convenience and simplicity in operation and higher production efficiency.

Owner:无锡中浦电气有限公司

Glass fiber reinforced plastic grating hollow plate and production method thereof

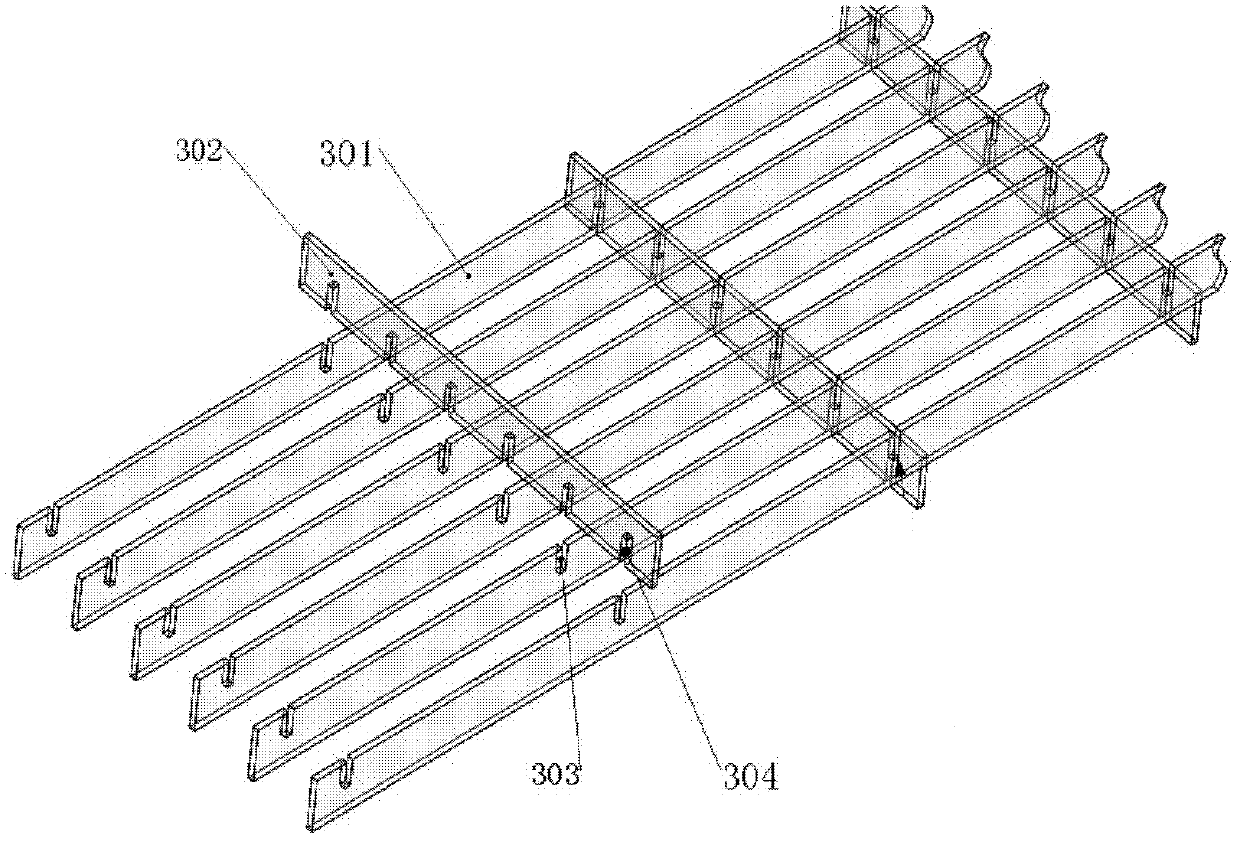

ActiveCN103286994AStable structureImprove adhesionSynthetic resin layered productsLaminationGlass fiberGrating

The invention belongs to the technical field of plates for building containment, and specifically relates to a glass fiber reinforced plastic grating hollow plate and a production method of the glass fiber reinforced plastic grating hollow plate. The glass fiber reinforced plastic grating hollow plate comprises an outside plate, a grating and an inside plate, the grating comprises a longitudinal rib plate and a cross diaphragm plate in latticed structure. The production method comprises the steps of preparing the grating, preparing the inside plate and bonding the grating, preparing the outside plate and bonding the grating and the inside plate, and cutting. The technical problems that the existing glass fiber reinforced plastic hollow plate is easily subjected to the cross shearing strength damage parallel to a panel, the existing glass fiber reinforced plastic production method is low in production efficiency and bad in product stability, are solved. The glass fiber reinforced plastic grating hollow plate provided by the invention is stable in structure, secure in bonding and strong in cross anti-shearing ability. The production method provided by the invention is capable of adopting the intermittent production process to manufacture one by one, and adopting the continuous production process to cut according to the specified size, the production efficiency is high and the product is stable.

Owner:秦皇岛耀华新材料有限公司

Airing clothes hanger with automatic rain-proof function

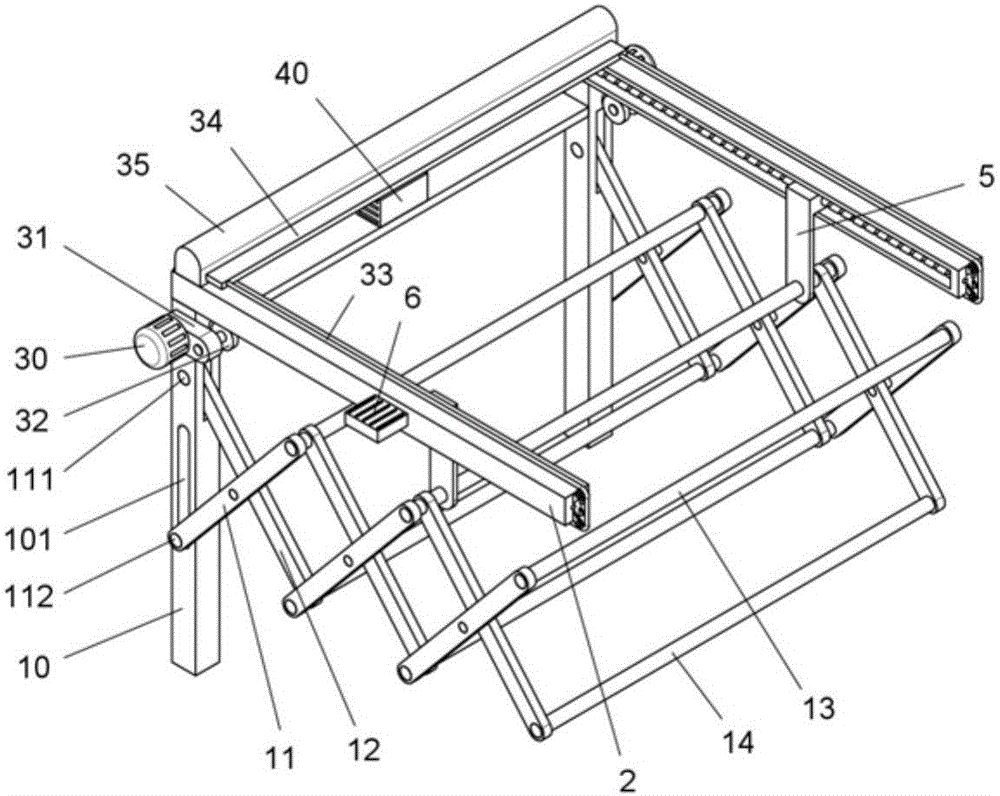

The invention discloses an airing clothes hanger with an automatic rain-proof function. The airing clothes hanger comprises two opposite installing frames. The installing frames are fixed to an external wall of a building. The upper portions of the installing frames are connected with a connecting plate. Multiple cross shear fork structures are connected to the outer side faces of the installing frames. Each cross shear fork structure comprises a left leaning rod and a right leaning rod, wherein the middle of the first left leaning rod is hinged to the middle of the first right leaning rod. Groove bodies facing outwards are formed in the upper ends of the installing frames, lifting grooves are formed in the side faces of the middles of the installing frames, the left leaning rods are hinged into the groove bodies through first pin shafts, the right leaning rods are hinged into the lifting grooves through second pin shafts, and a first cross rod is connected between every two opposite left leaning rods. Two telescopic mechanisms vertical to the installing frames stretch from the connecting plate. Whether precipitation occurs or not can be sensed, once precipitation occurs, a raindrop inductive sensor can transmit an actuating signal to a roller blind driving mechanism, the roller blind driving control mechanism acts to wind a tension rope to pull out of rain shielding cloth, and clothes are covered with the rain shielding cloth.

Owner:DONGGUAN LIANZHOU INTPROP OPERATION MANAGEMENT CO LTD

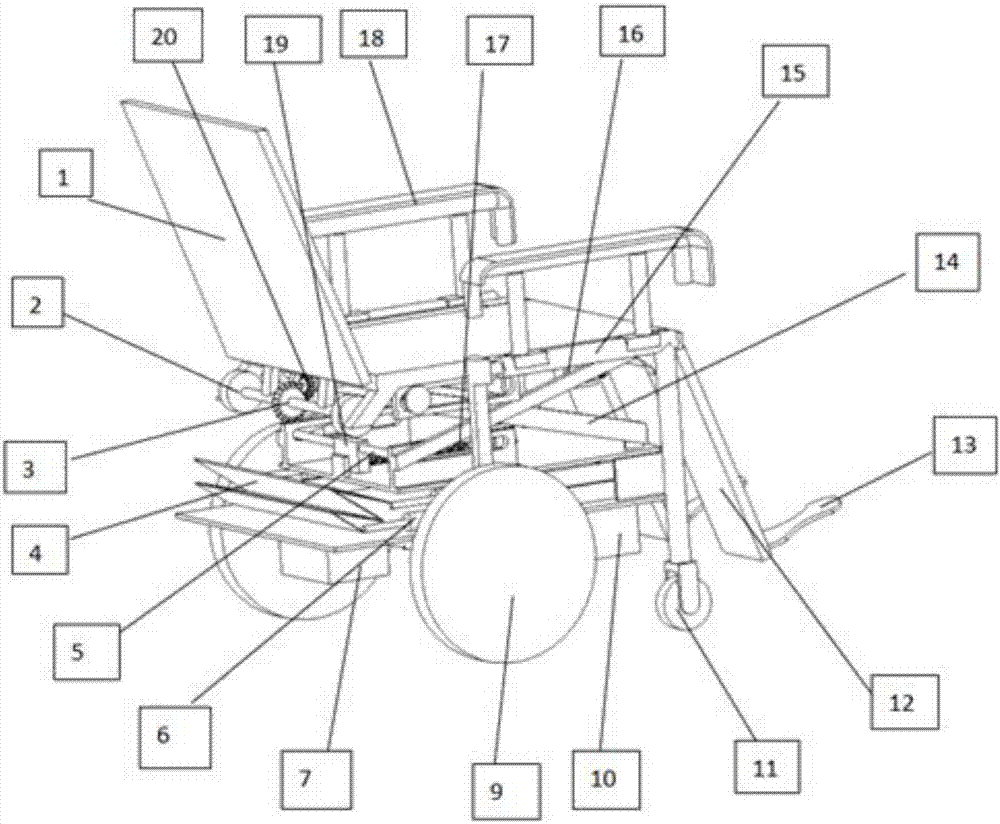

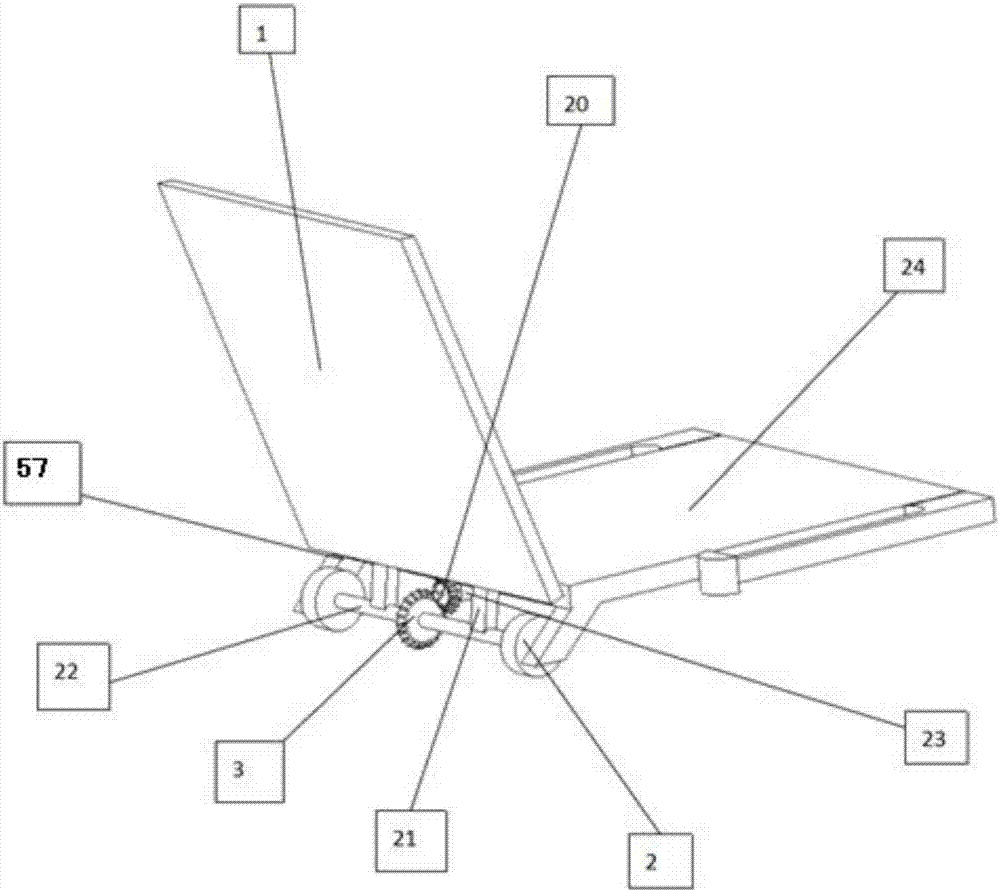

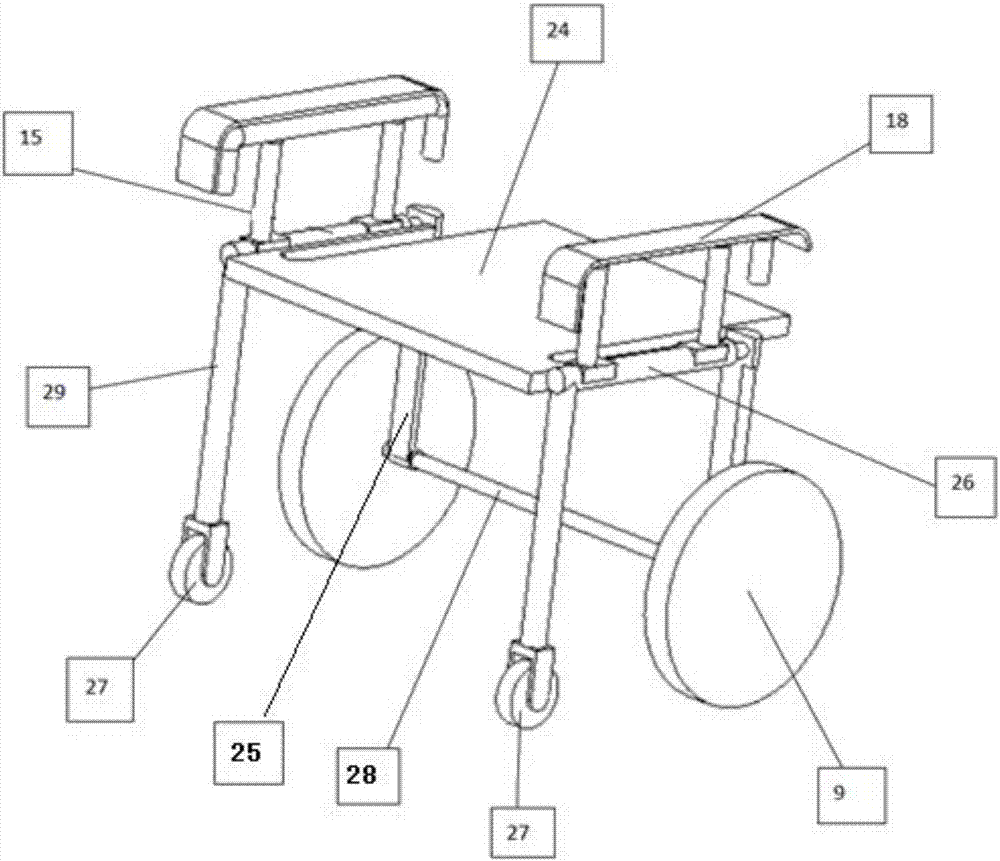

Novel multifunctional wheelchair

ActiveCN107007404ASolve everyday problemsReduce the burden onWheelchairs/patient conveyanceWheelchairOlder people

The invention discloses a novel multifunctional wheelchair, and solves the technical problems that getting on and getting out of the bed, going to the toilet and going out are difficult for old people and disabled people which are mentioned in the background technology. According to the technical scheme, the novel multifunctional wheelchair comprises a seat back transmission mechanism, wherein a support mechanism is arranged below the seat back transmission mechanism and arranged on the ground, and can assist people in going to the toilet and getting on the bed; a double-cross shear-type lifting mechanism used for driving the seat back transmission mechanism to move up and down is arranged below the support mechanism; an awning mechanism used for preventing sunshine and rain is arranged below the double-cross shear-type lifting mechanism, and a storage cabinet mechanism is arranged below the awning mechanism. The novel multifunctional wheelchair has the advantages of solving the problems for the middle aged and elderly people with mobility problems in daily life, and has the functions of assisting in getting on the bed, going to the toilet and preventing sunshine and rain.

Owner:JIANGSU INTCO MEDICAL PROD CO LTD

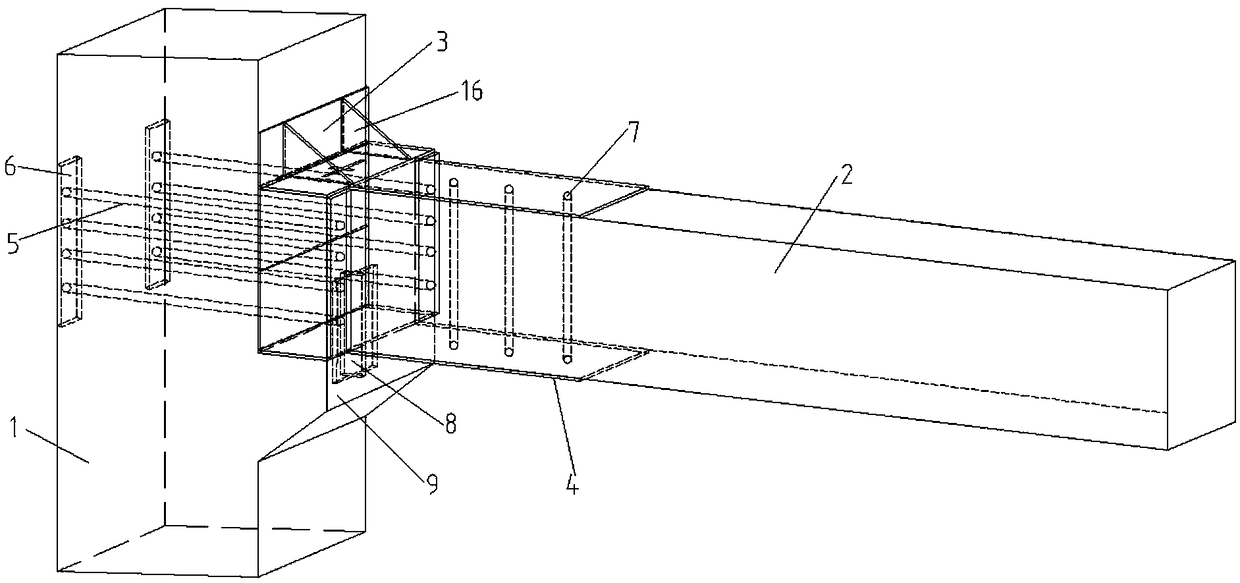

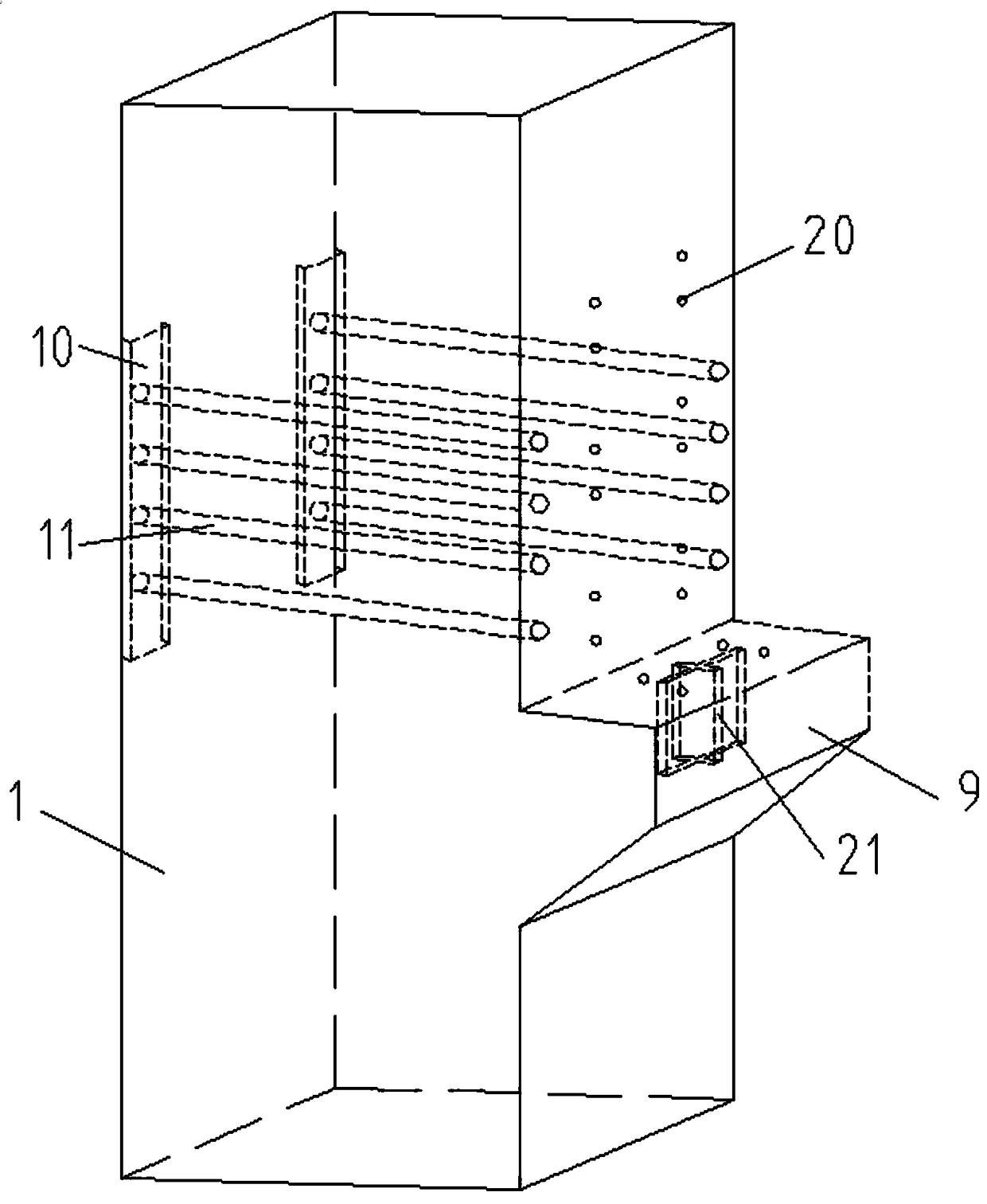

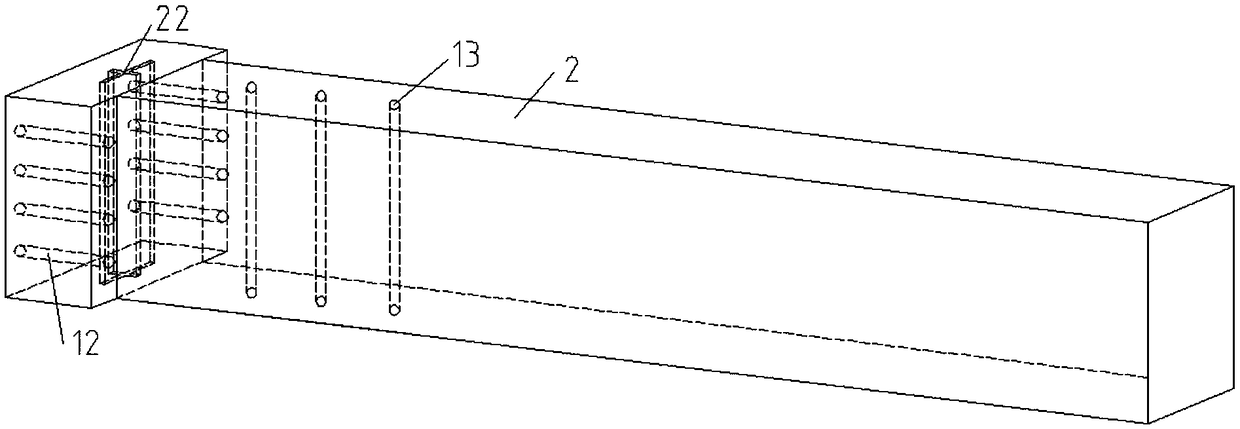

Prefabricated concrete anti-seismic joint

PendingCN108951886AGuaranteed shear resistanceHigh strengthProtective buildings/sheltersShock proofingSheet steelPre stress

Owner:ANHUI UNIVERSITY OF ARCHITECTURE

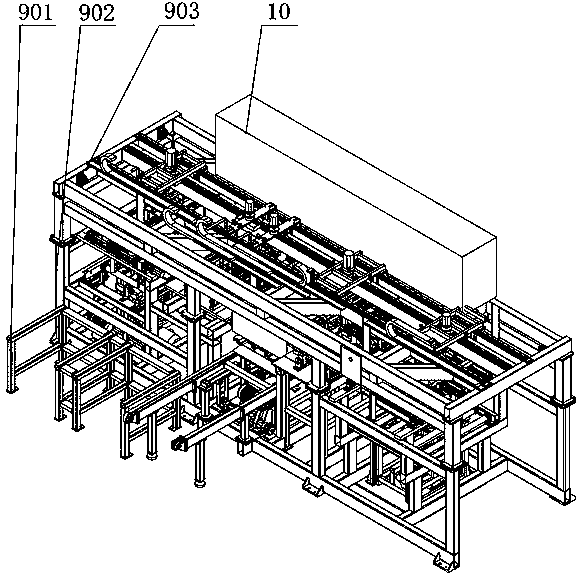

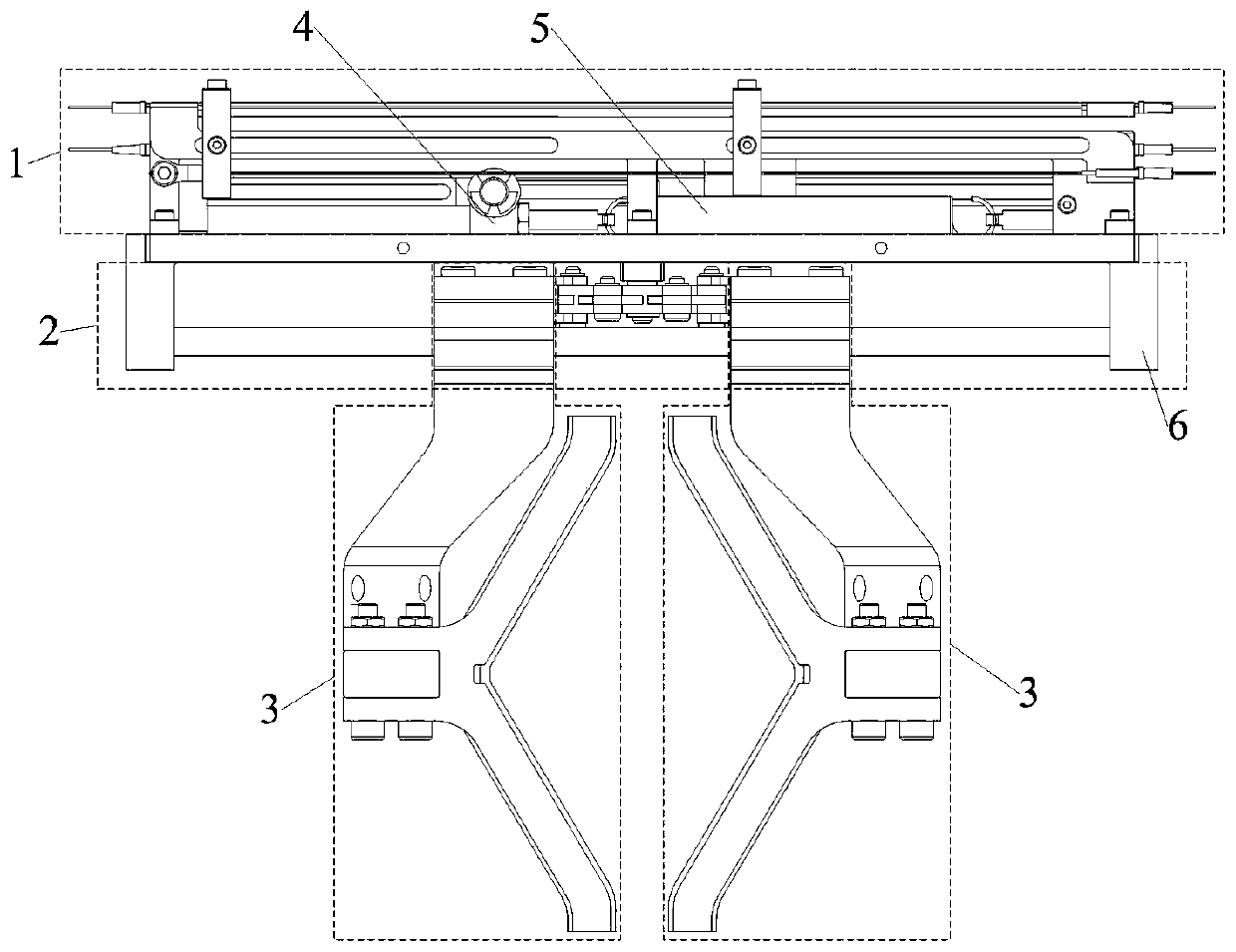

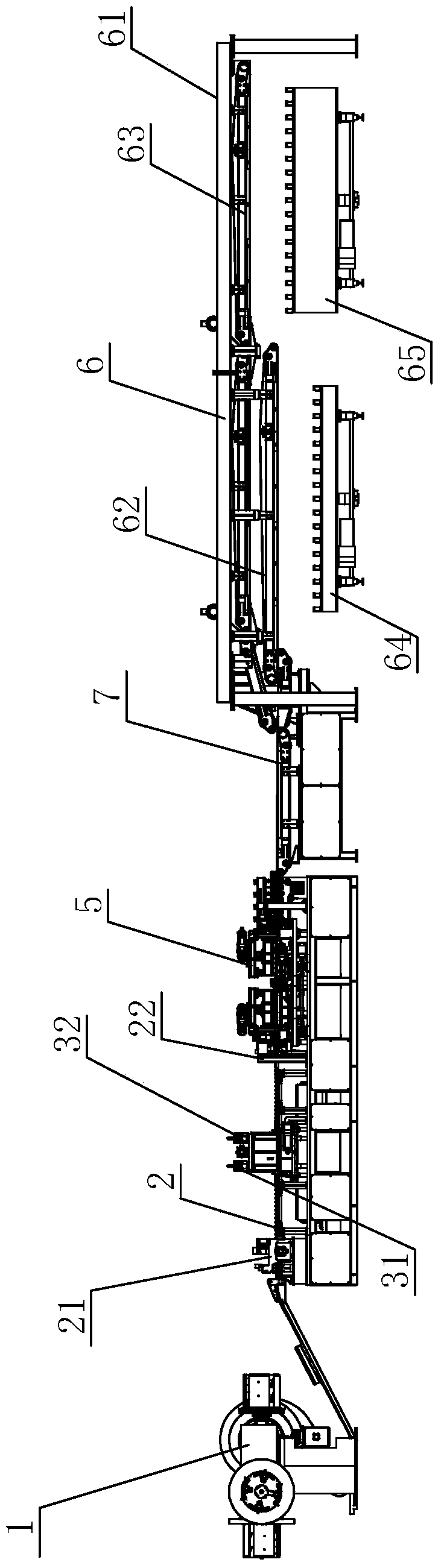

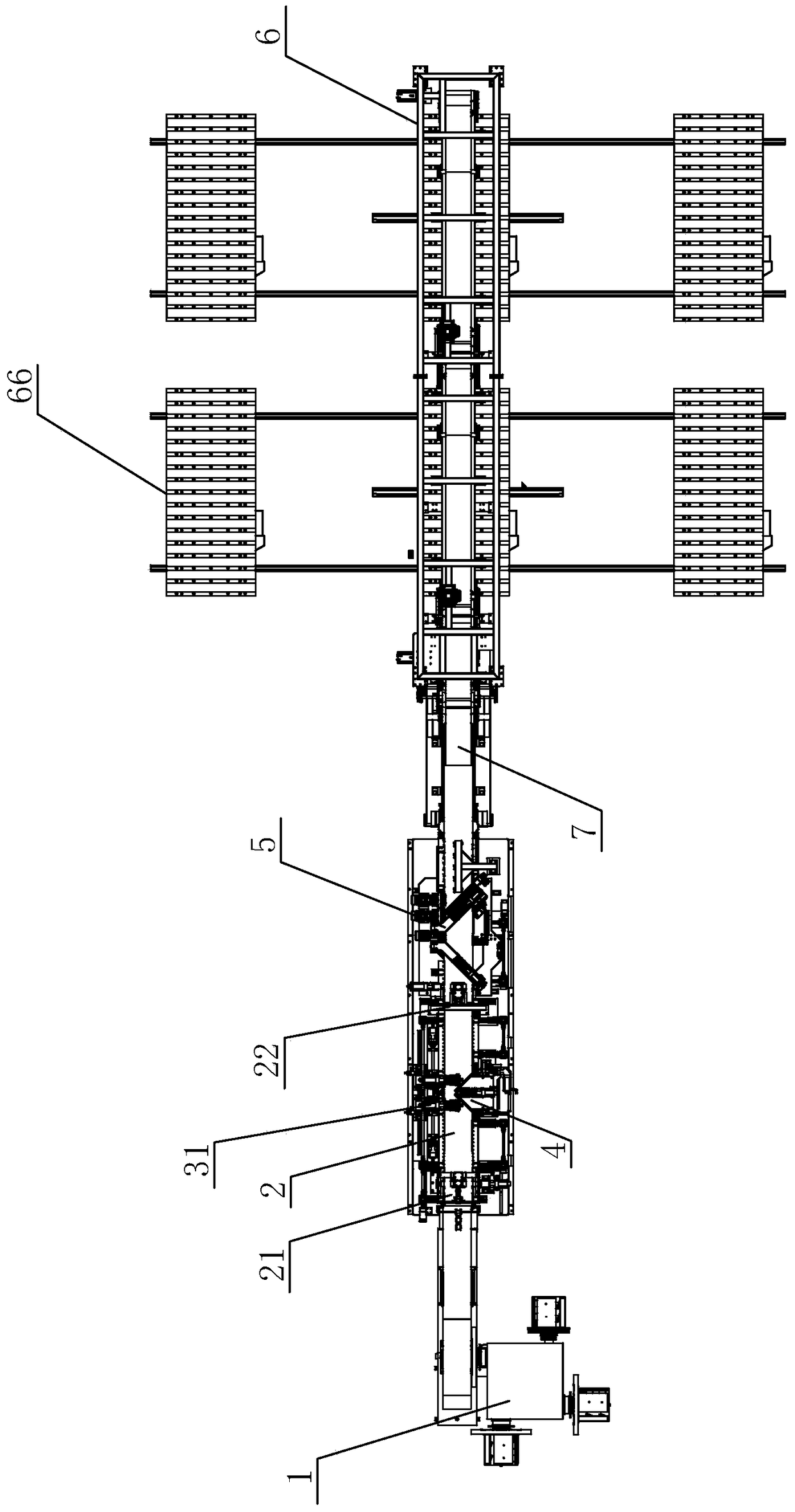

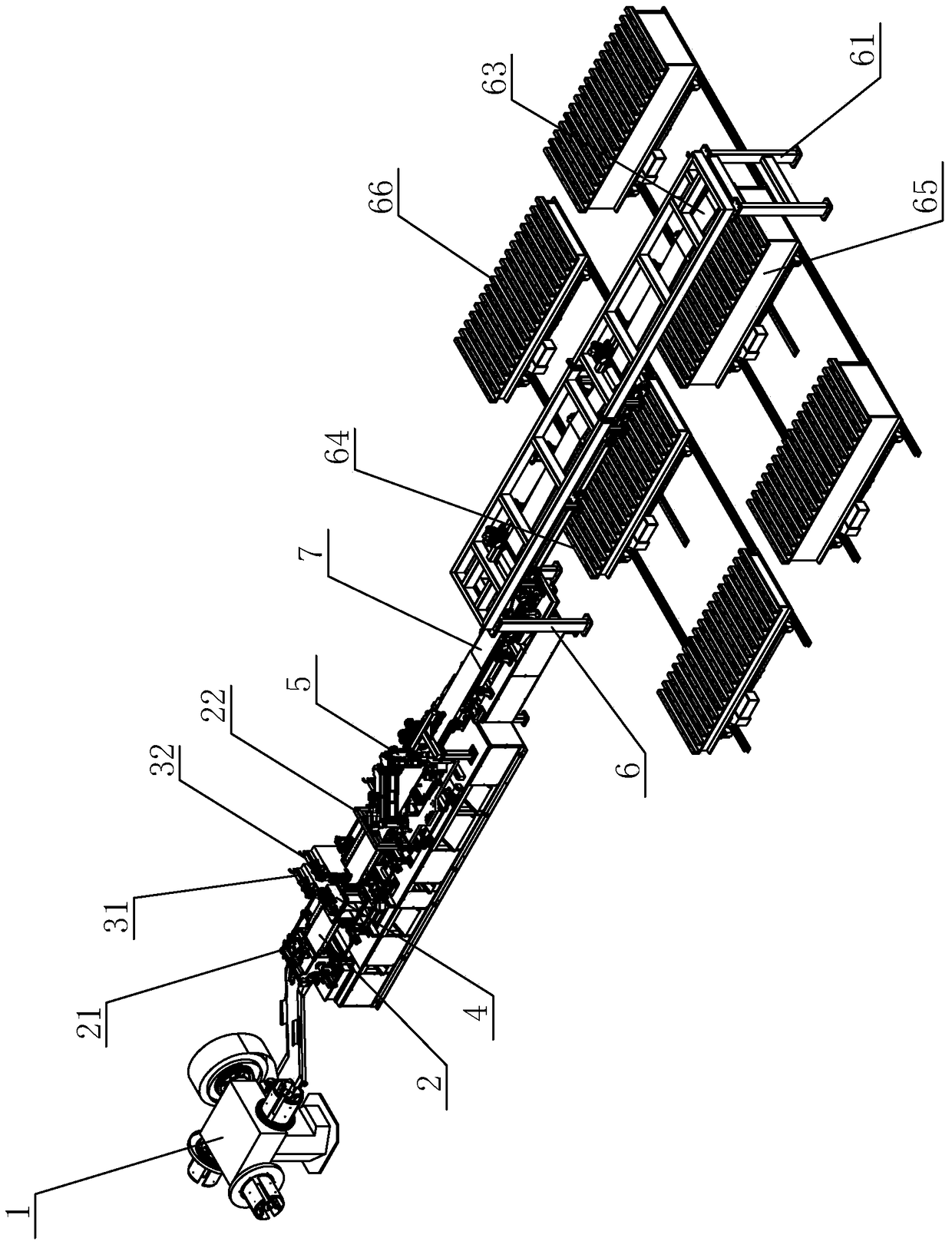

A transformer iron core automatic lamination production device

PendingCN109192496ACompact structureImprove efficiencyInductances/transformers/magnets manufactureTransformerOutput device

The invention provides a transformer iron core automatic laminating production device, which at least comprises a laminating device, a three-column slicing device, a three-column pre-positioning device, a yoke post pre-positioning device, a yoke post slicing device, a finished product output device, a coding table, other auxiliary devices and a machine frame. The three-column slicing device, the three-column pre-positioning device, the finished product output device, the yoke post pre-positioning device and the yoke post slicing device are sequentially installed on the machine frame in the order from right to left in the transverse X-axis direction. The laminating device is located on the upper part of the frame. The other auxiliary devices are arranged above the rack. The encoding table is located on one side of the frame. The invention is mechanized and intelligently improved, and the lamination speed can reach 3600 sheets per hour. The lamination adopts the linear stacking mode alternately between the left and right feeding, which has high compact structure and high efficiency. Can be applied to all types of cross-shear line shear products, strong versatility. The structure is stable and reliable, and the maintenance cost is low.

Owner:CECEP XIAN QIYUAN MECHANICAL & EIECTRICAL EQUIP CO LTD

Space capture manipulator driven by SMA (shape memory alloy) wires

ActiveCN111452030AHigh speedIncrease clamping forceProgramme-controlled manipulatorGripping headsDrive by wireClassical mechanics

The invention provides a space capture manipulator driven by SMA (shape memory alloy) wires. A slide rod retainer is installed on a driver rack, and a plurality of slide rods are slidably connected with the slide rod retainer through a plurality of slide rod pins. A fixed end and the plurality of slide rods are sequentially connected by the SMA wires. The end slide rod of the slide rods, a drivingrod and an offset spring are sequentially connected. Guide rails are arranged below the rack and parallel to an output end slide rod. Two linear bearings are both slidably connected with the guide rails, the two linear bearings on one side are connected with the lower surfaces of clamping arms, the upper surfaces of the clamping arms are fixedly connected with the lower surface of the driving rod, and the clamping arms on two sides are connected through a cross shear hinge coupling transmission mechanism, which is fixedly connected with the rack through a fixing hinge. Two groups of mechanical claws are installed on two clamping arms respectively. Capture is performed in a parallel clamping manner, the driving part performs drive linearly through the SMA wires, so that the linear actuation characteristic of the memory alloys is fully exerted, and capture speed and clamping force of the manipulator are improved.

Owner:HARBIN INST OF TECH

Blunt detacher

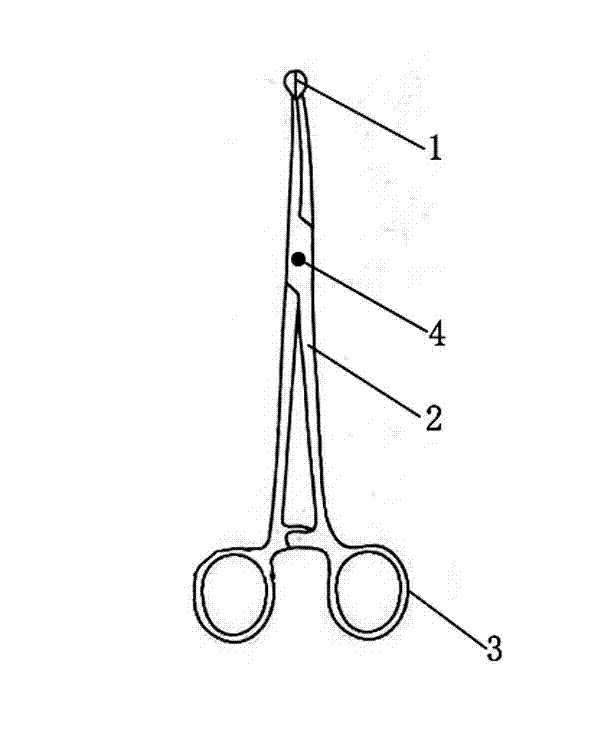

InactiveCN103494630ANot easy to damageImprove the success rate of surgeryIncision instrumentsBlunt dissectorsEngineeringCross shear

The invention discloses a blunt detacher which comprises a head, a connection rod and a handle. The connection rod is used for connecting the head and the handle, the connection rod is composed of two cross shear arms, and the head is composed of two semispherical bodies arranged on the end portions of the shear arms. Due to the fact that the head is composed of the two semispherical bodies arranged on the end portions of the shear arms, detached tissue can not be easily hurt in a surgery, if detachment is complete can be easily confirmed, and the surgery achievement ratio is improved. The blunt detacher is simple in structure, and convenient to use.

Owner:NANJING QINHUAI HOSPITAL

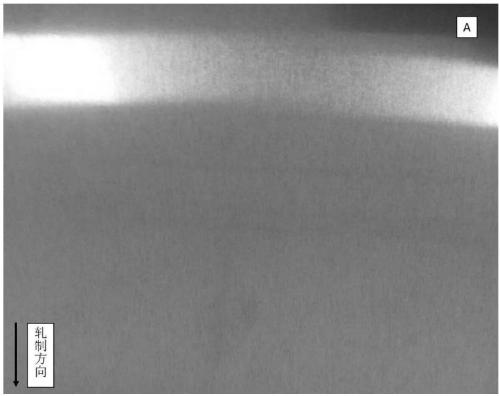

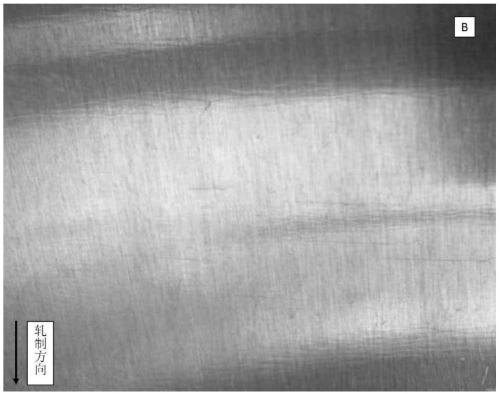

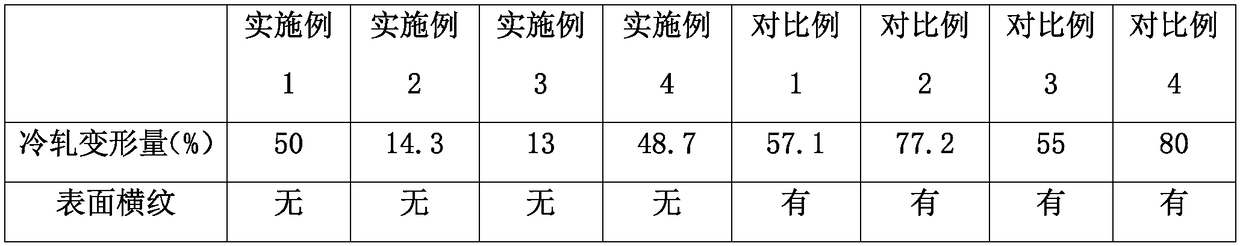

Preparation technology for removing cross grain from surface of 5xxx aluminum alloy sheet

InactiveCN109055788AImprove surface qualityImprove performanceMetal rolling arrangementsIngotHot rolled

The invention belongs to the technical filed of aluminum alloy, and relates to a preparation technology for removing a cross grain from the surface of a 5xxx aluminum alloy sheet. The preparation technology comprises the steps of holding an aluminium alloy ingot after melt casting for 3-5h at 500+ / -5 DEG C, and then tapping off and rolling the aluminium alloy ingot; controlling the hot rolling finishing temperature to be 325+ / -10 DEG C, and reserving 10%-50% deformation between hot-rolled billets and a cold-rolled product; for a product with more than 50% deformation between the hot-rolled billets and the cold-rolled finished product, performing intermediate annealing for one time in the material cold-rolling process; reserving 10%-50% deformation after intermediate annealing of the sheet,and preforming recrystallization annealing to the cold-rolled product for 2-5h at 300-350 DEG C; and finally performing cross shear and parting off to obtain the aluminum alloy sheet. According to the technology, the cross grain on the surface of a 5xxx aluminum alloy O-state sheet is removed, and the surface quality of the sheet is improved effectively.

Owner:TIANJIN ZHONGWANG ALUMINUM IND CO LTD

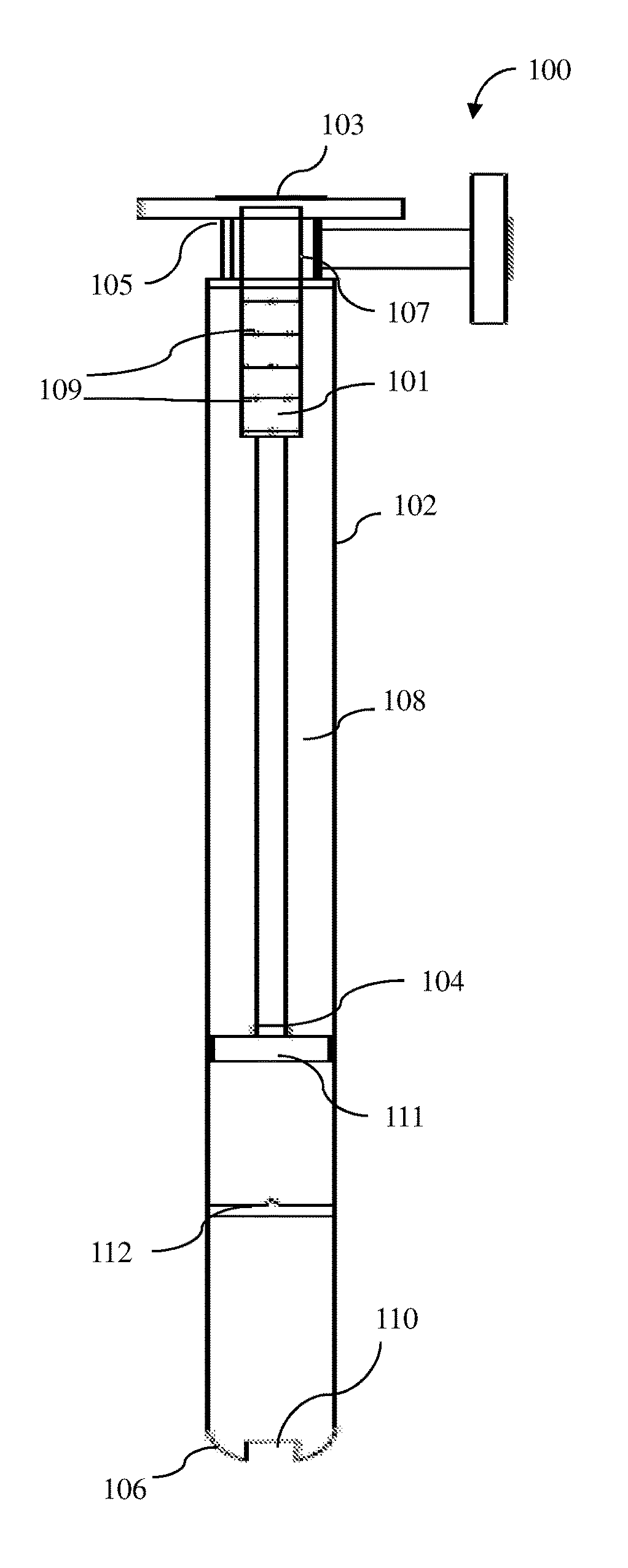

Cross plate shearing apparatus

InactiveCN105973720AAccurate measurementHandy and preciseMaterial strength using steady shearing forcesElectricityLow speed

The invention relates to a cross plate shearing apparatus, and belongs to the an engineering test apparatus used for in situ shearing of soil layer test. The baseboard of the cross plate shearing apparatus is provided with a control bench and a power supply box; a power device is arranged on the baseboard, and the bottom end of the baseboard is supported by supporting legs; the bottom of the power device is connected with a drilling rod, and the drilling rod is formed through connecting a plurality of drilling rod segments; the lower end of the drilling rod is provided with a cross shearing plate shaft lever, and the bottom end of the cross shearing plate shaft lever is provided with a cross plate; the power device drives the cross shearing plate shaft lever to rotate; the supporting legs can adjust the levelness of the baseboard; and the power supply box supplies power to the power device and the control bench, and the control bench controls the power device and the supporting legs. The cross plate shearing apparatus is a mechanical apparatus executing a balance instruction based on gyroscope measured level feedback, is a mechanical apparatus being able to provide multiple speed reduction and to carry out low-speed accurate control based on a common motor, is a measured force feedback apparatus based on a piezoelectric sensing element, and is a cross shearing apparatus for obtaining soil layer shearing destroy intensity peak data.

Owner:HOHAI UNIV

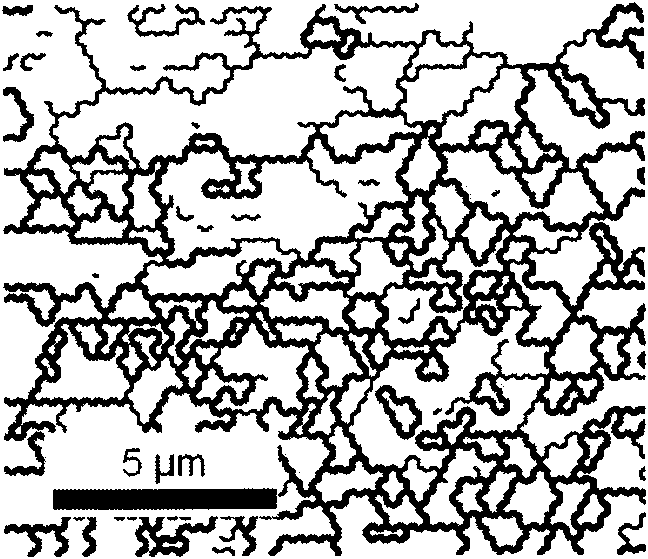

Superfine crystalline pure iron preparation method

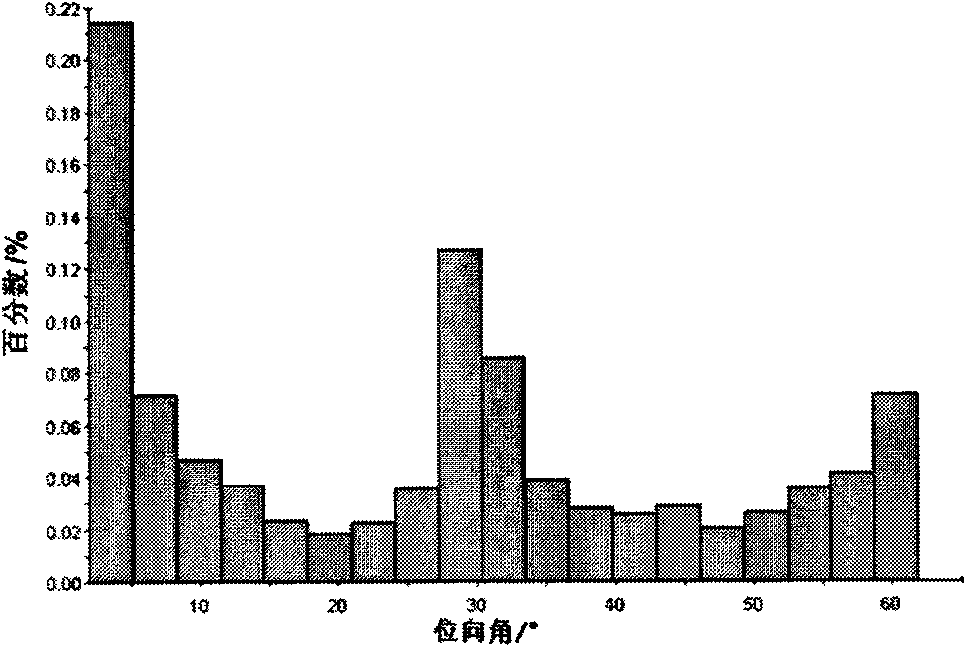

A superfine crystalline pure iron preparation method in the metal rolling technical field comprises the following steps: selecting material to be rolled, keeping temperature for 5h at 900 DEG C; performing synchronous rolling and cross shear friction speed rolling; after keeping temperature, performing secondary synchronous rolling at room temperature and obtaining superfine crystalline pure iron. By adopting the solution of in the invention, the superfine grain structure can be prepared through the simple steps, wherein, the particle size is 0.9mu m and the content of high angle grain boundary (theta is not less than 15 DEG C) can reach more than 65%. Uniaxial tensile test shows that the yield strength of the material is improved remarkablely after the cross shear rolling.

Owner:SHANGHAI JIAO TONG UNIV

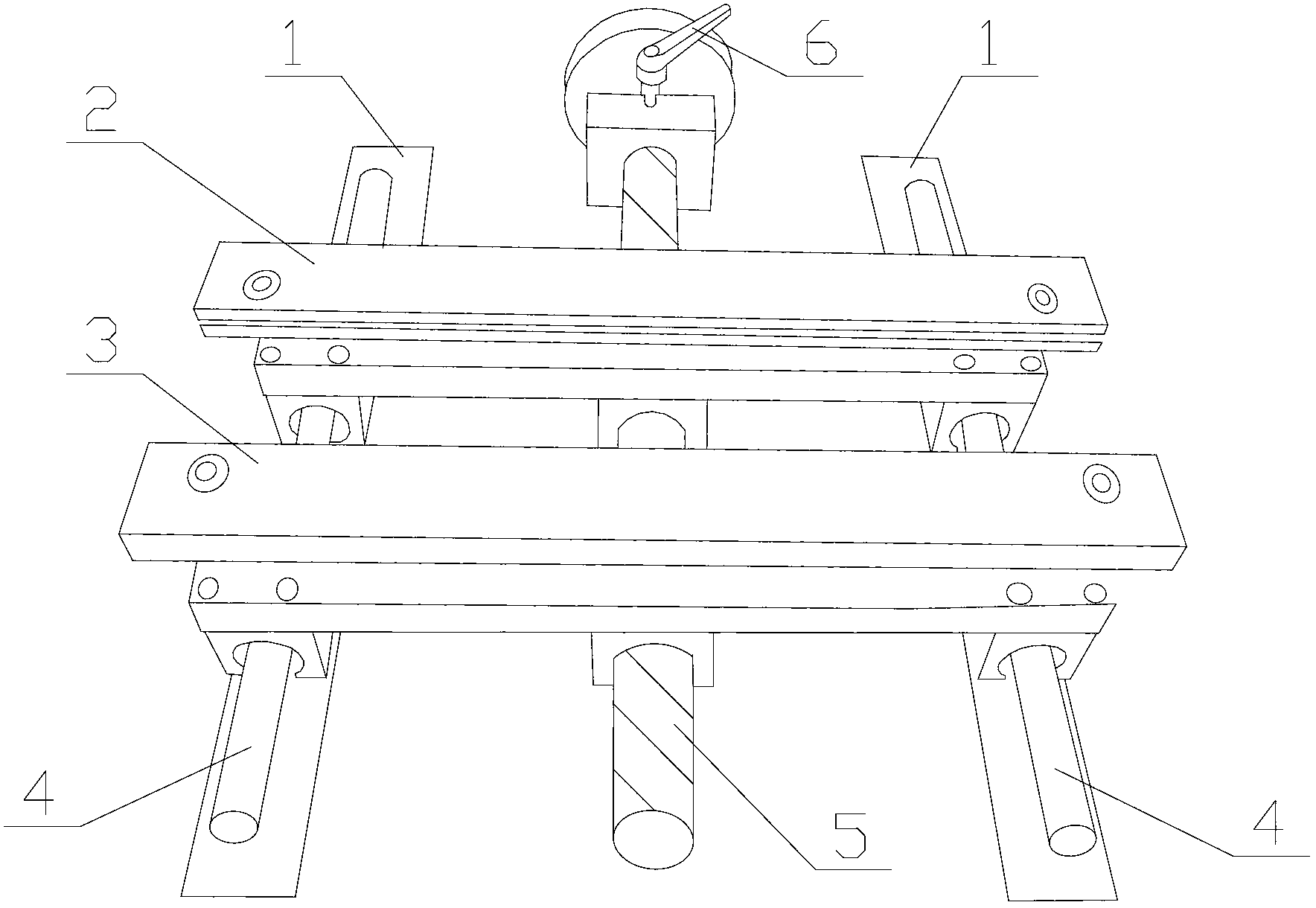

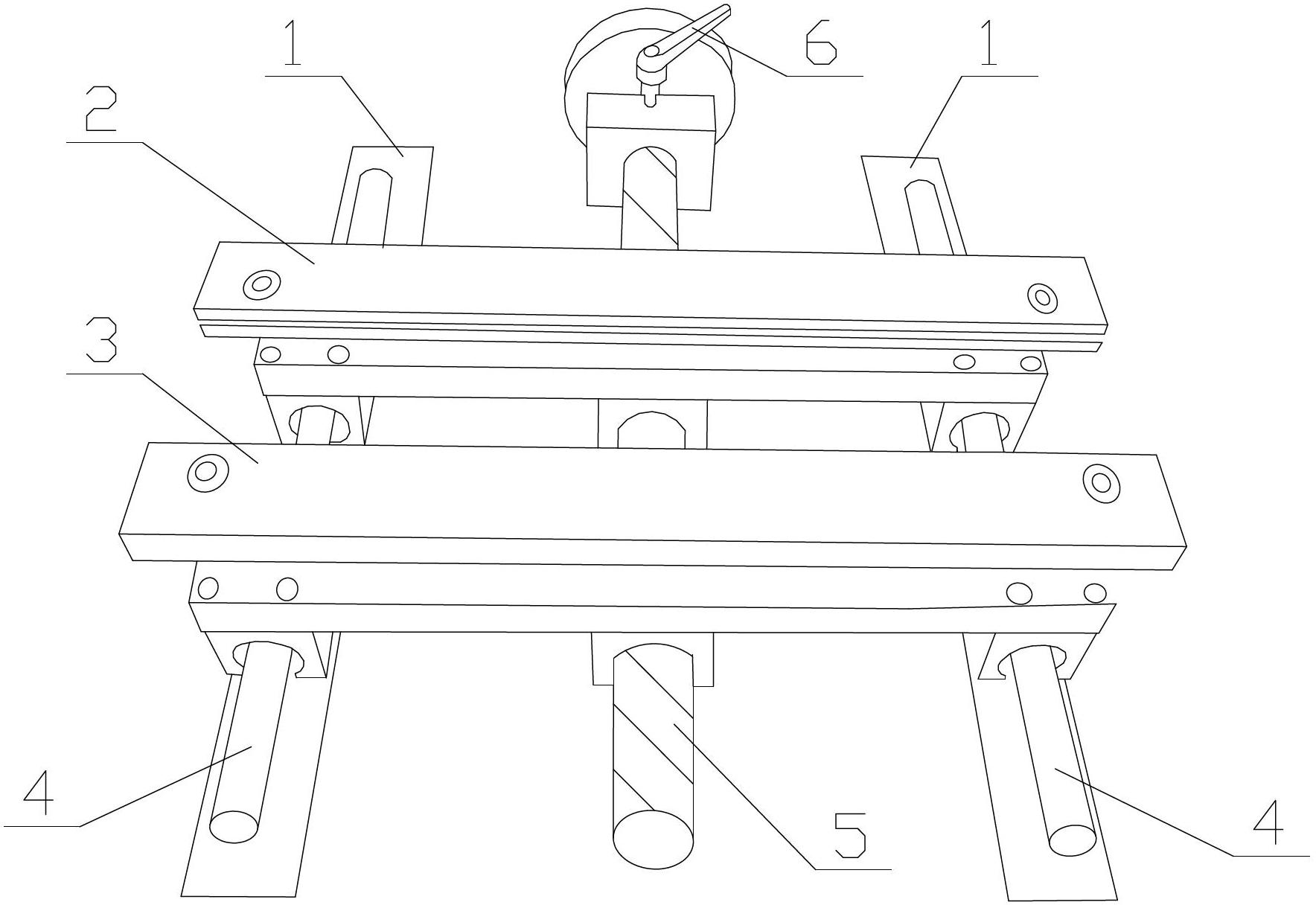

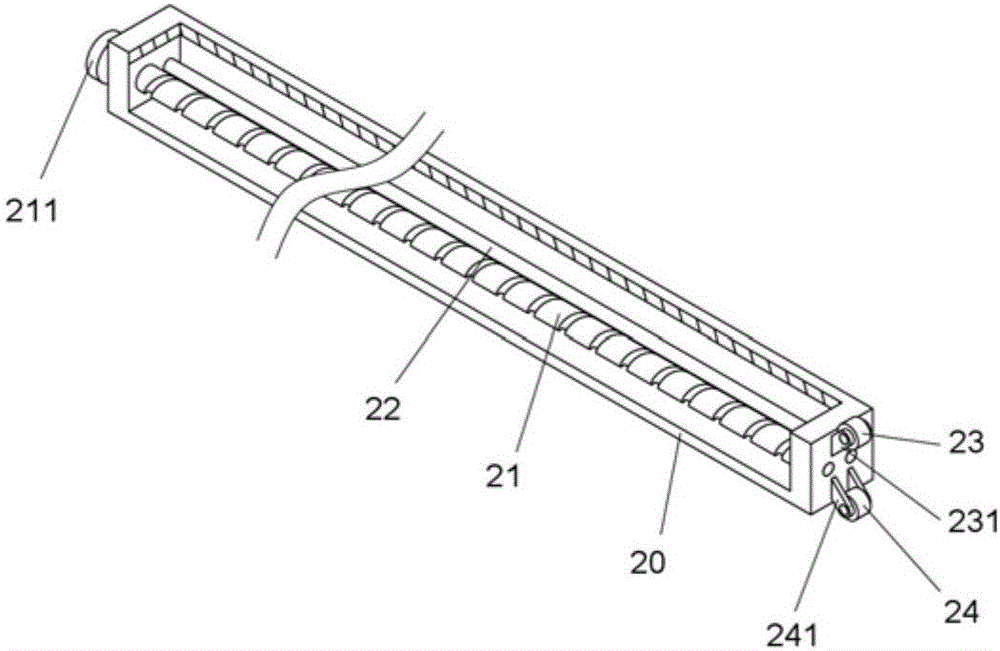

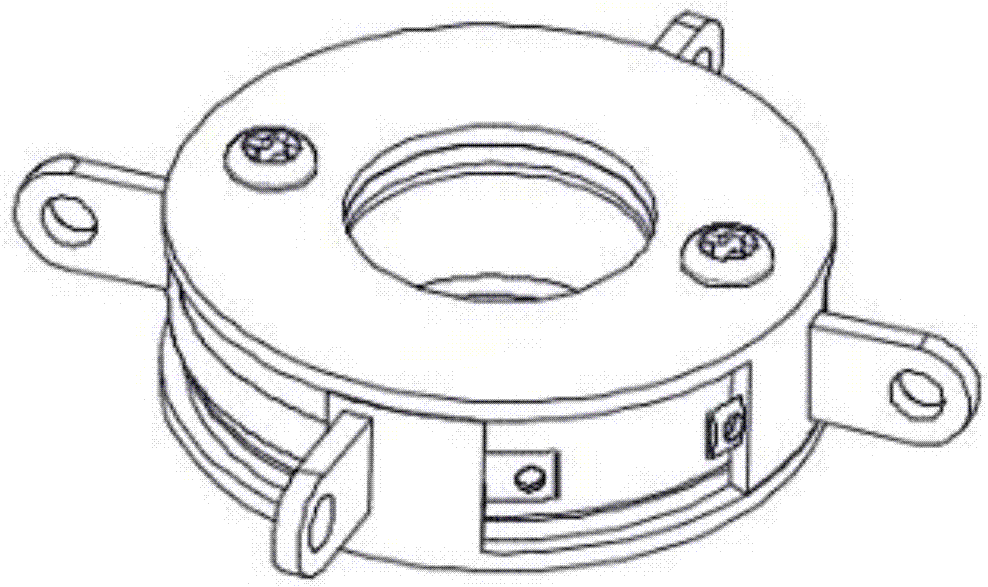

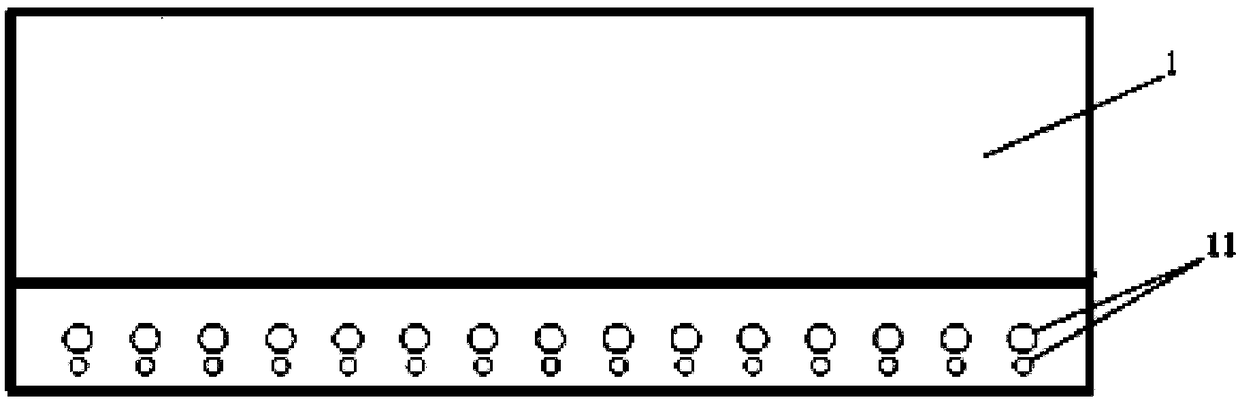

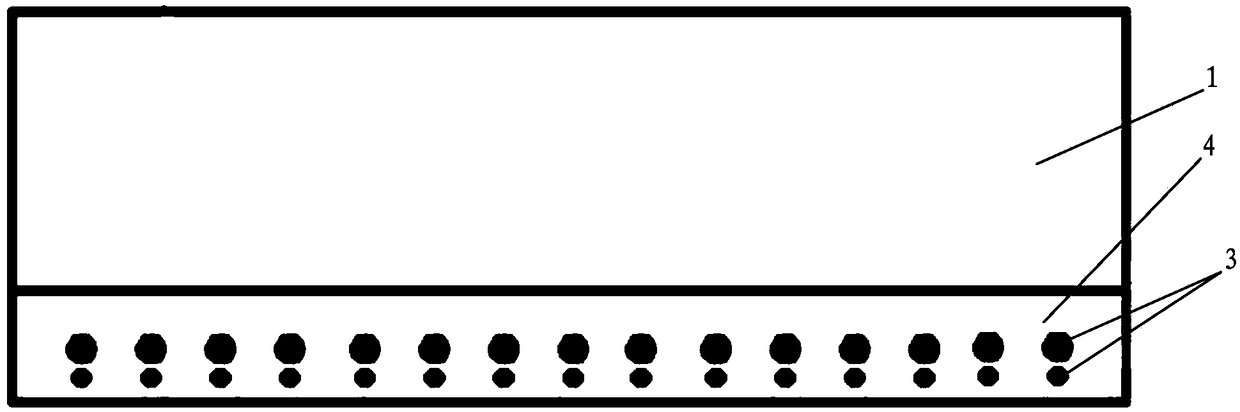

Cross shearing receiving platform for silicon steel sheets

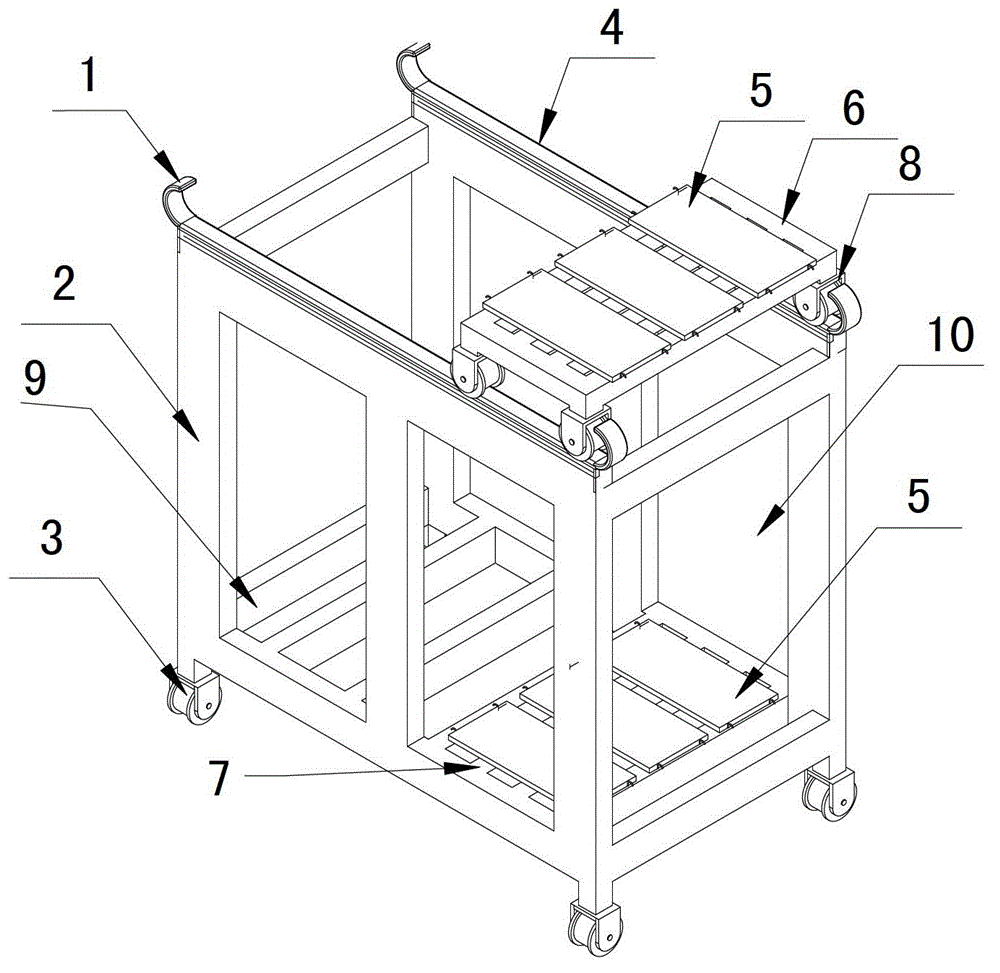

The invention relates to a receiving platform and provides a cross shearing receiving platform for continuously receiving materials, in order to solve the problem that the conventional receiving platform can carry out the next round of shearing only after a silicon steel sheet cross shearing machine is stopped and sheared silicon steel sheets are moved. The cross shearing receiving platform for silicon steel sheets comprises a frame and receiving plates, wherein the frame is a square frame which is vertically separated into a left half part and a right half part from the middle, at least one receiving plate is respectively laid on the top and the bottom of one of the half parts, the bottom receiving plate is laid on a bottom crosspiece, the top receiving plate is laid on a receiving trolley, at least three rollers which are not on the same line are installed on the bottom of the receiving trolley, at least two rails are installed on the top frame and correspond to the at least three rollers, and the receiving trolley can slide on the at least two rails back and forth. The receiving platform can be used continuously and the silicon steel sheet cross shearing machine does not need to be stopped, so the working efficiency of the silicon steel sheet cross shearing machine can be effectively improved.

Owner:WUXI PUTIAN IRON CORE CO LTD

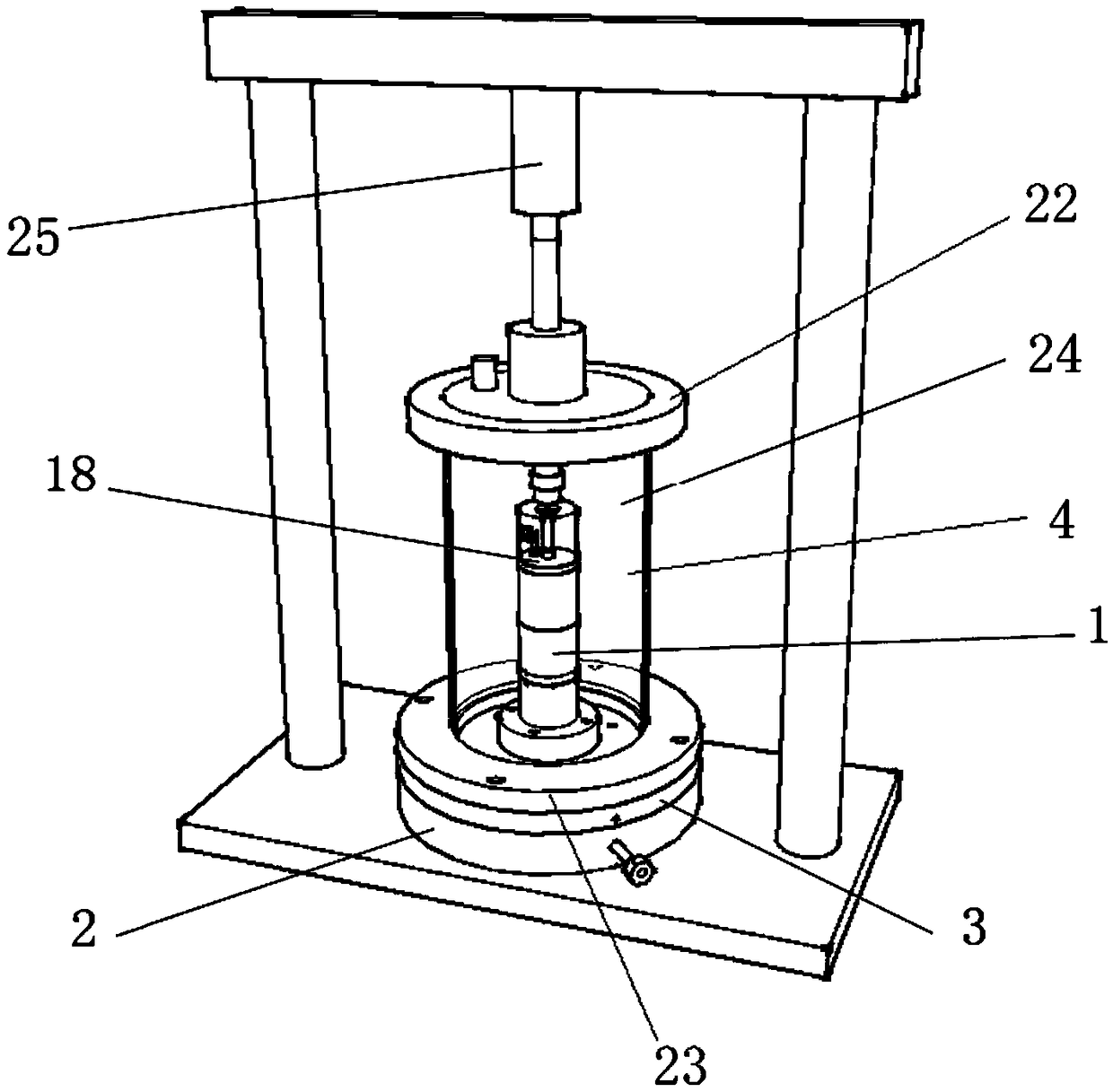

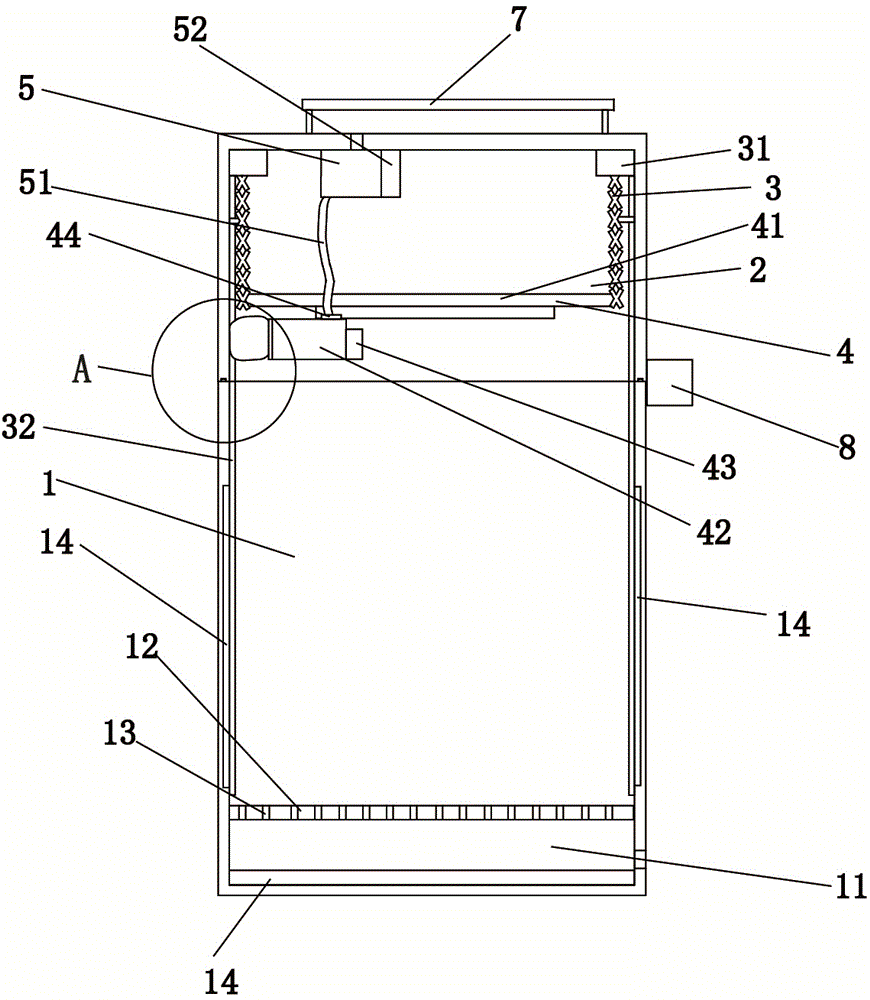

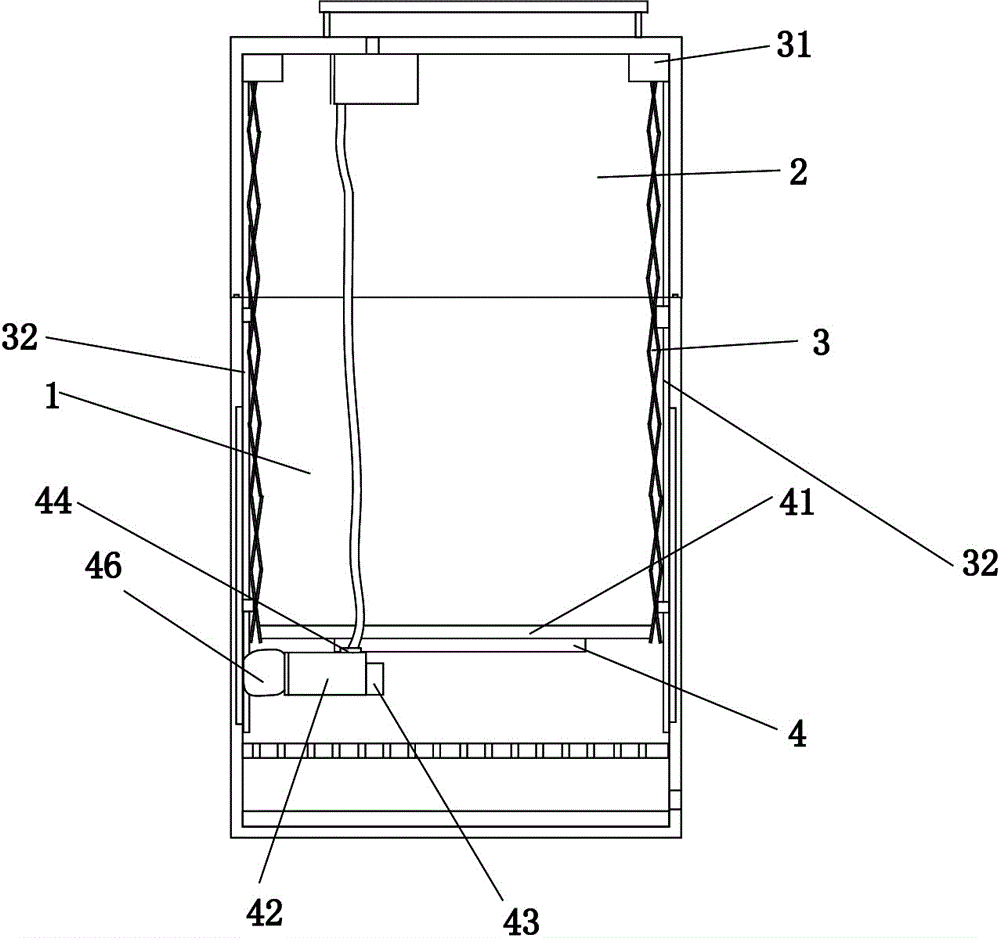

Novel column shear permeation testing device and testing method thereof

ActiveCN109187312AFlow rate limitingPromote healingPermeability/surface area analysisStress conditionsEngineering

The invention relates to a novel column shear permeation testing device and a testing method thereof, and belongs to the technical field of earth-rock dam seepage test devices. The testing device comprises a driving base, a pipeline base, a sample assembly, an axial force system, and a pressure chamber. The sample assembly comprises a sample base, a core wall clay sample, an upstream material sample, a downstream material sample, and a cross shear column. The axial force system comprises an axial force rod, an axial force sensor, an actuator, and a reaction force bracket. The sample top cap iscoaxially arranged at the upper end of the sample assembly. The driving base, the pipeline base, the axial force rod and the pressure chamber form an enclosed space to seal the sample assembly. According to the novel column shear permeation testing device and the testing method thereof, the sample preparation efficiency is high, and the use cost is low; the influence of the combination of the shearing surface generated by the inner column shearing of the clay sample and the upstream and downstream material samples on the permeability characteristics of the sample under different triaxial stress conditions can be researched; and more extensive research can be conducted by researchers to assist in the in-depth research of the seepage prevention theory of earth-rock dams.

Owner:CHONGQING UNIV

Gas cleaning type garbage can

Owner:NINGBO JIANGBEI RUICHEN HANDICRAFT DESIGN

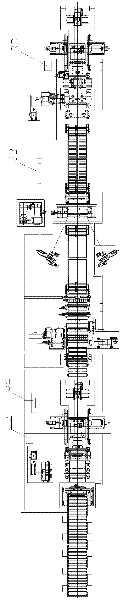

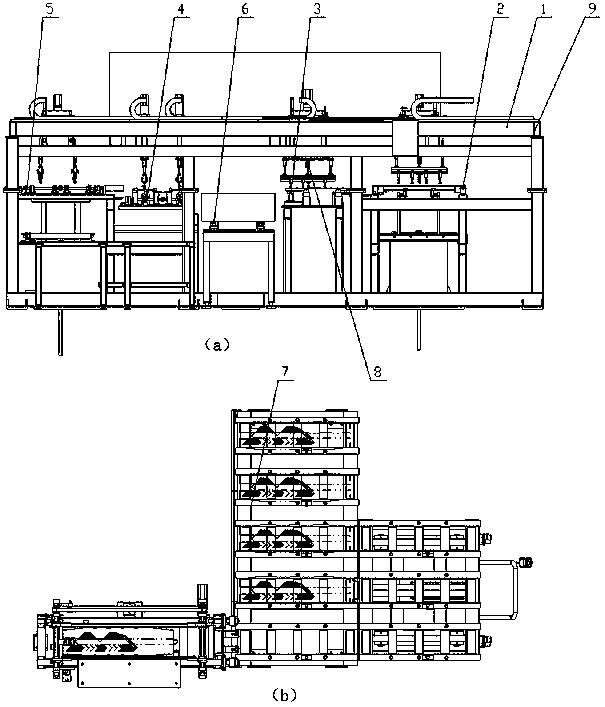

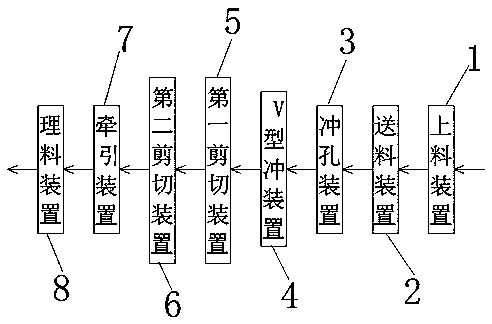

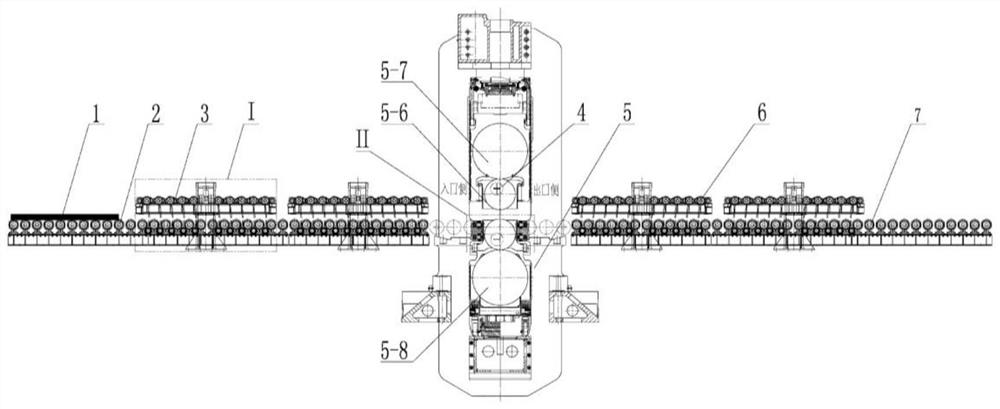

A new CNC silicon steel sheet cutting line equipment

ActiveCN105397495BReduce distanceShorten the lengthOther manufacturing equipments/toolsShearing machine accessoriesNumerical controlPunching

Owner:CANWIN AUTOMATIC EQUIP CO LTD

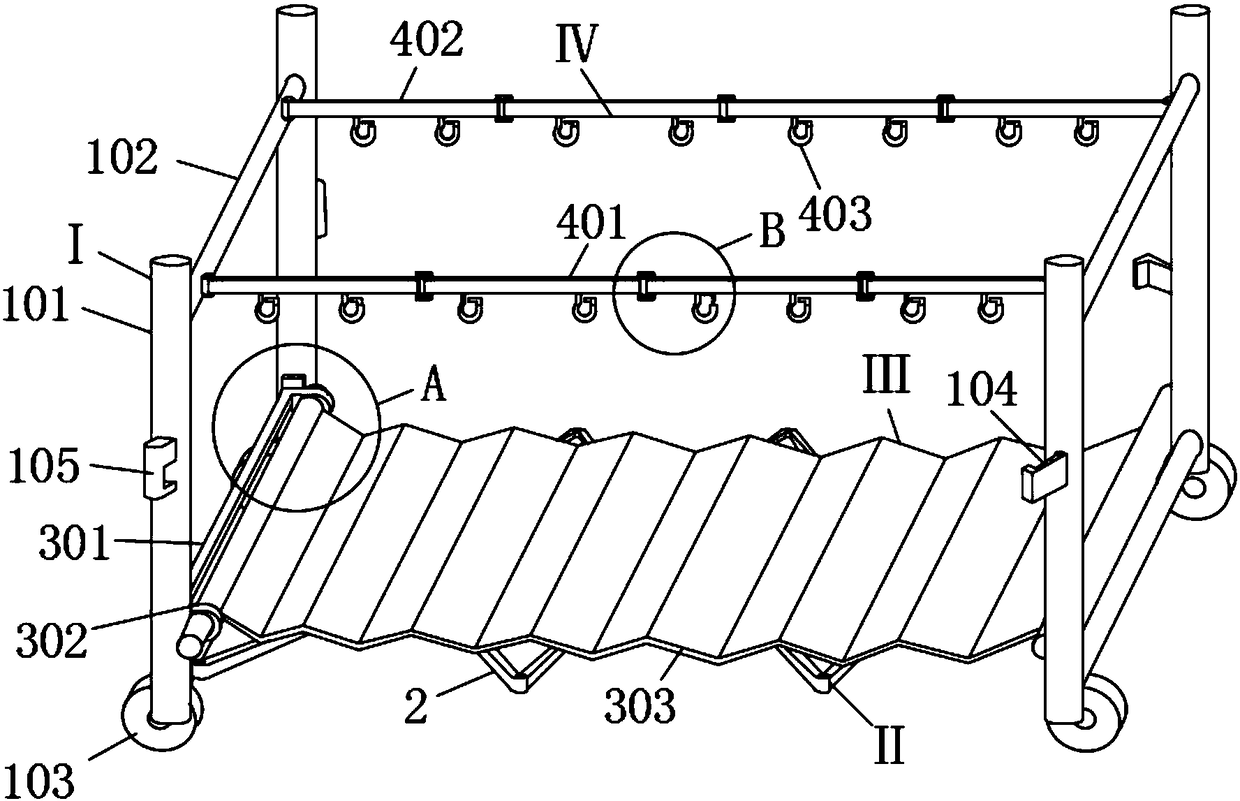

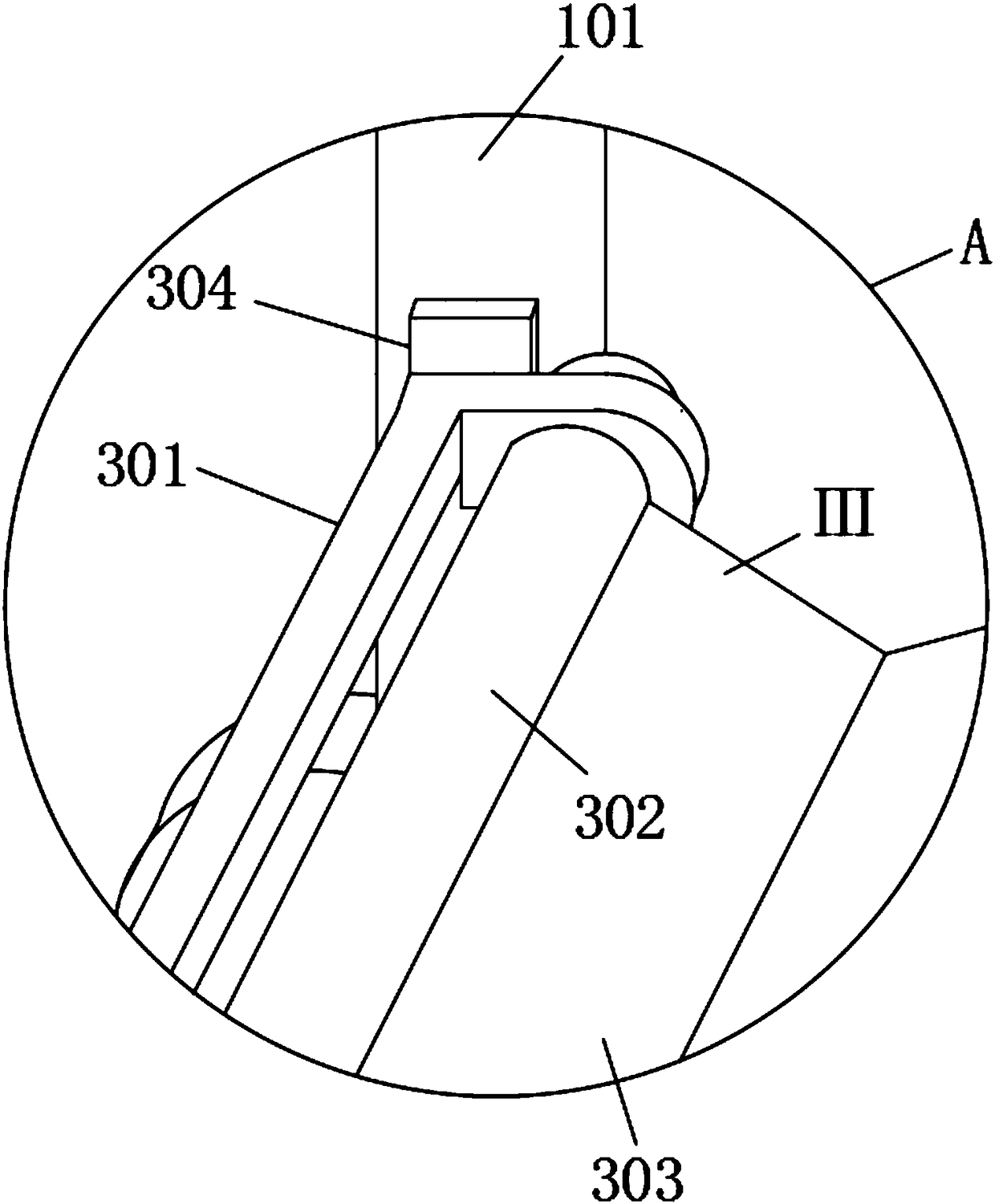

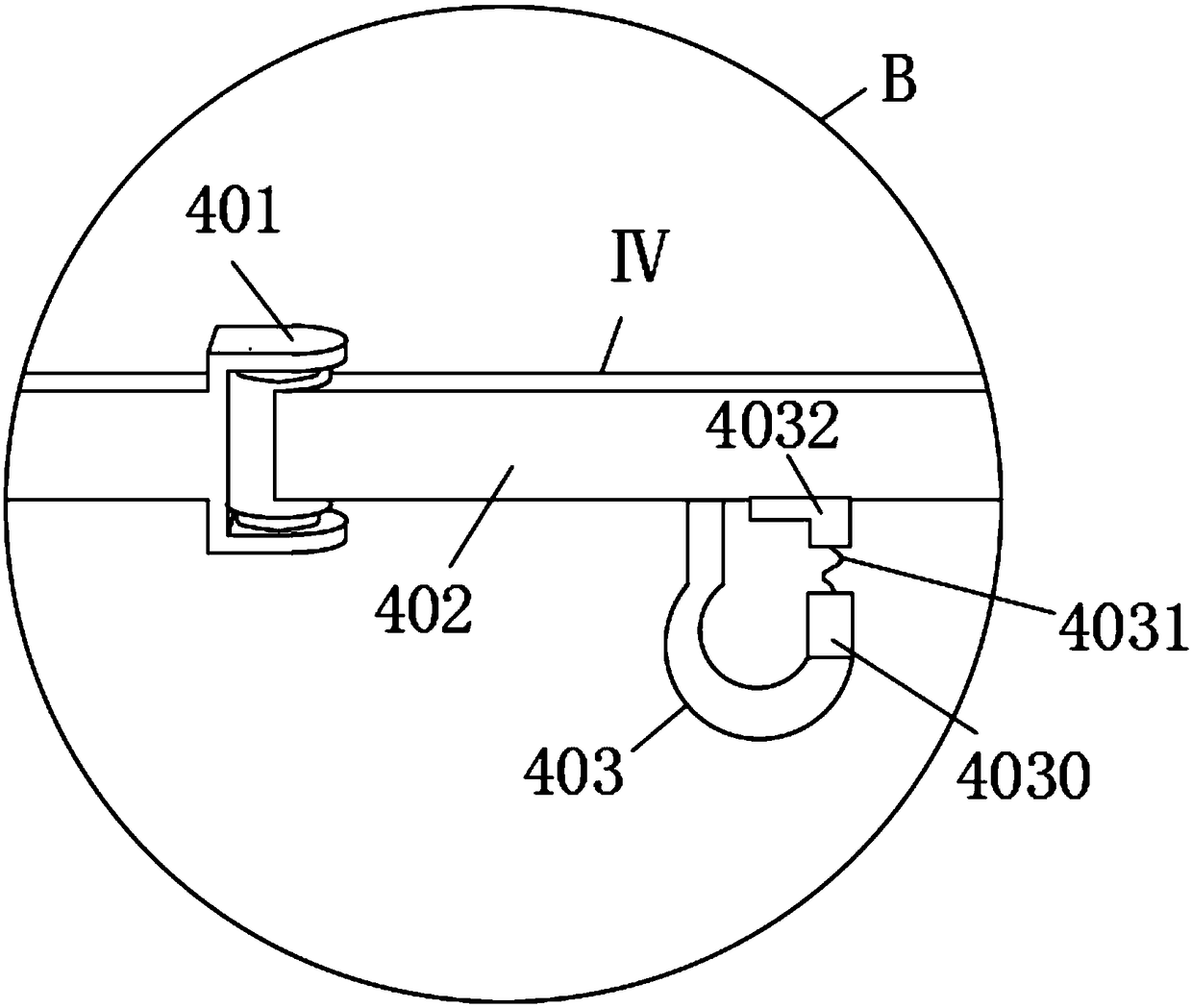

Conveniently moving foldable airing rack for agricultural production

InactiveCN108344267AEasy to moveDoes not take up spaceDrying chambers/containersDrying machines with local agitationAgricultural engineeringCross shear

Owner:竺秋君

Metal composite plate rolling device capable of applying horizontal vibration

PendingCN113787095ARealize horizontal reciprocating motionGuaranteed stabilityMetal rolling stand detailsMeasuring devicesHydraulic cylinderComposite strength

The invention provides a metal composite plate rolling device capable of applying the horizontal vibration. The metal composite plate rolling device capable of applying the horizontal vibration comprises an upper roller system and a lower roller system, bearing seats are fixed to the two ends of the upper roller system and the two ends of the lower roller system, and horizontal vibration mechanisms composed of excitation hydraulic cylinders and dampers are arranged on the outer sides of the bearing seats so as to drive the upper roller system and the lower roller system to do high-frequency micro-stroke horizontal reverse reciprocating motion; and meanwhile, a self-adaptive spherical pad and a dovetail guide block cooperatively act, so that the reciprocating motion stability of the upper roller system and the lower roller system is ensured. The device can effectively promote accelerated dislocation of metal on the surface difficult to deform and an oxidation film, and the interface bonding rate is increased; meanwhile, a ' cross shear rolling area ' is promoted to be formed at a bonding interface, the interface bonding strength is improved through relative sliding, the critical deformation force required by rolling and compounding is reduced, and a composite plate with high compounding strength is produced; and in addition, a reciprocating cross shear rolling effect is formed in a plastic deformation area, bidirectional shearing force is applied to the composite layer, diffusion of atoms on a composite interface is accelerated, and physical combination of the composite interface is strengthened.

Owner:TAIYUAN UNIV OF TECH

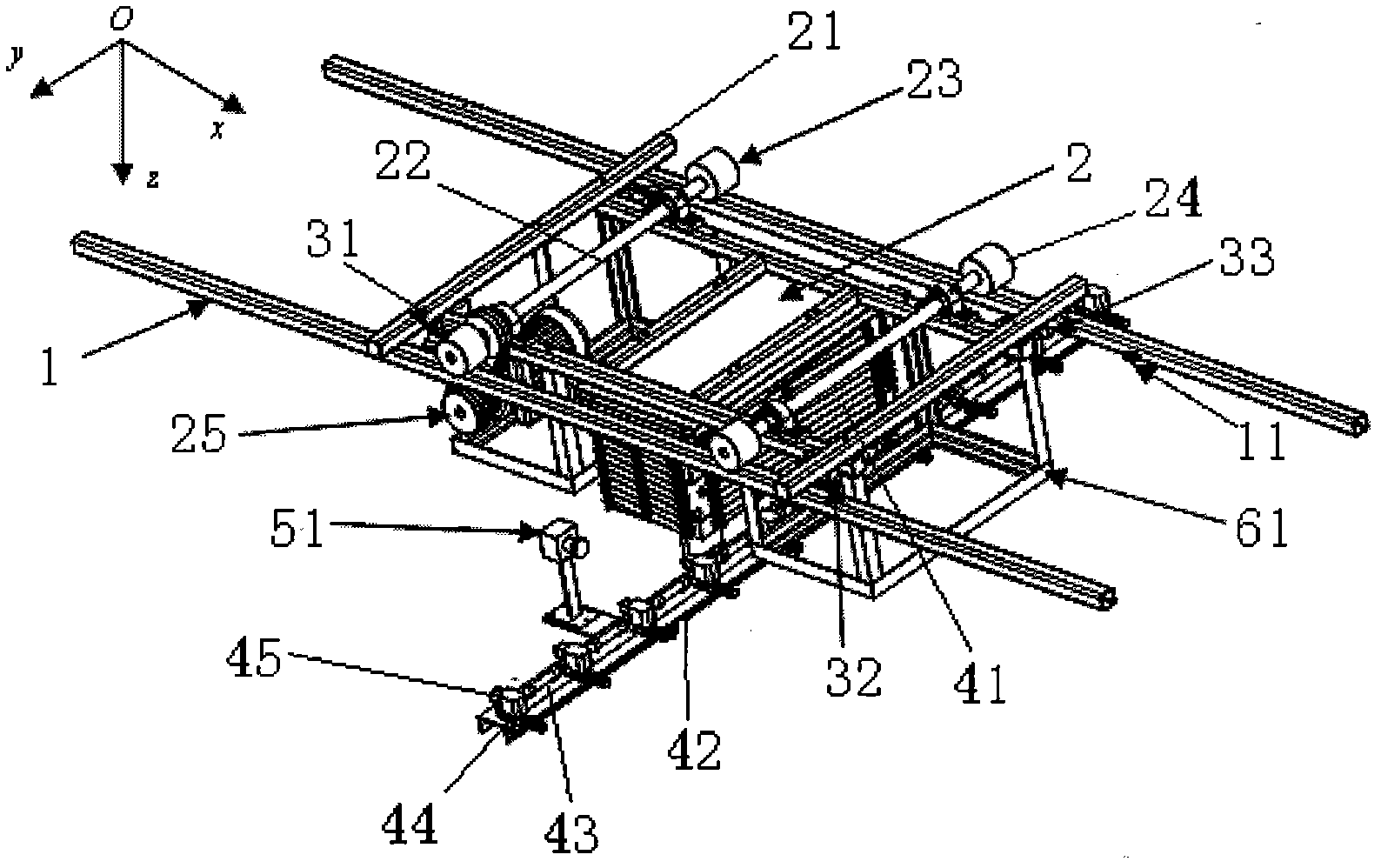

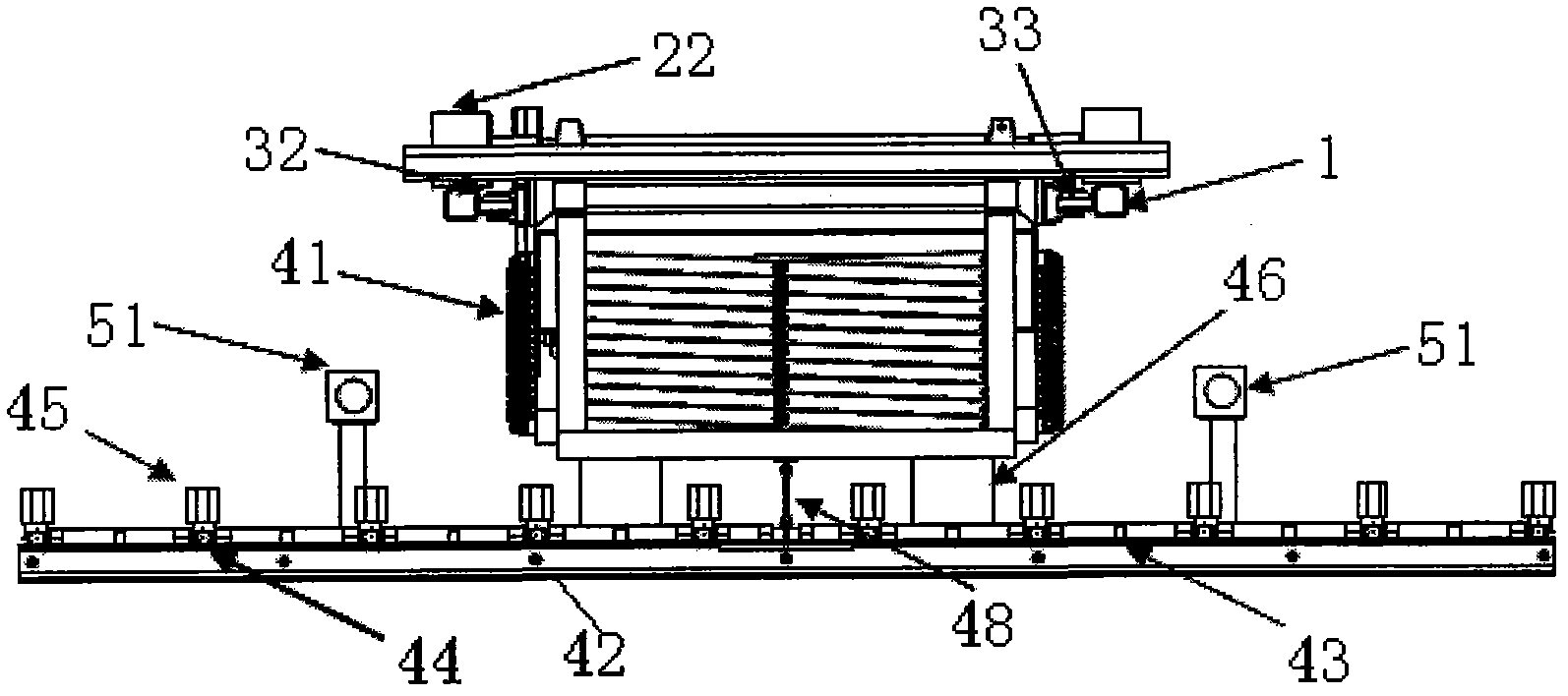

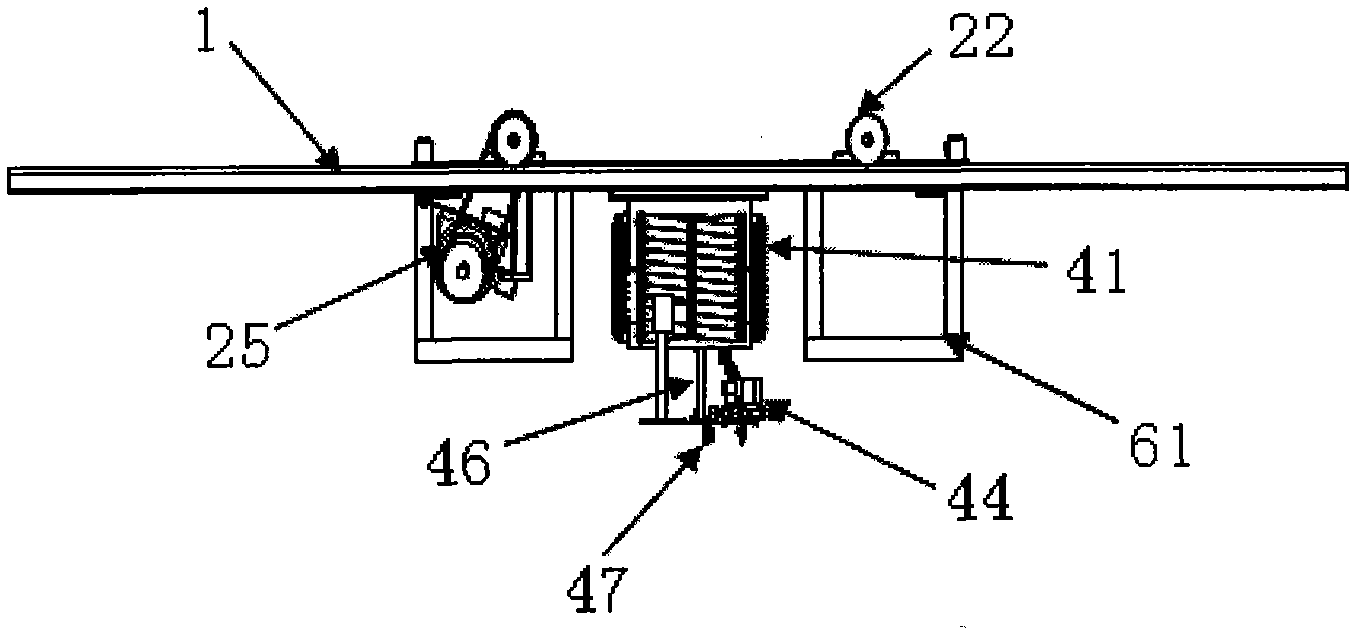

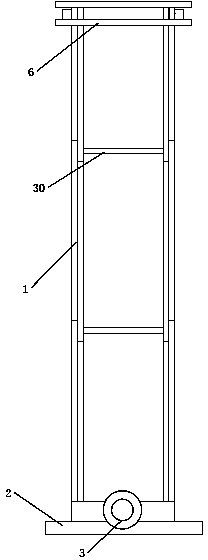

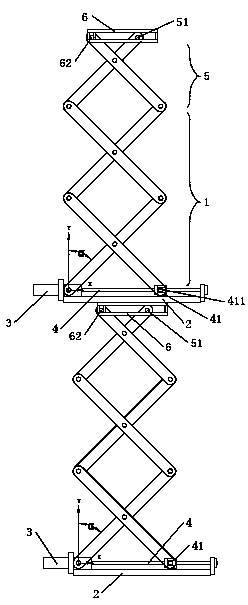

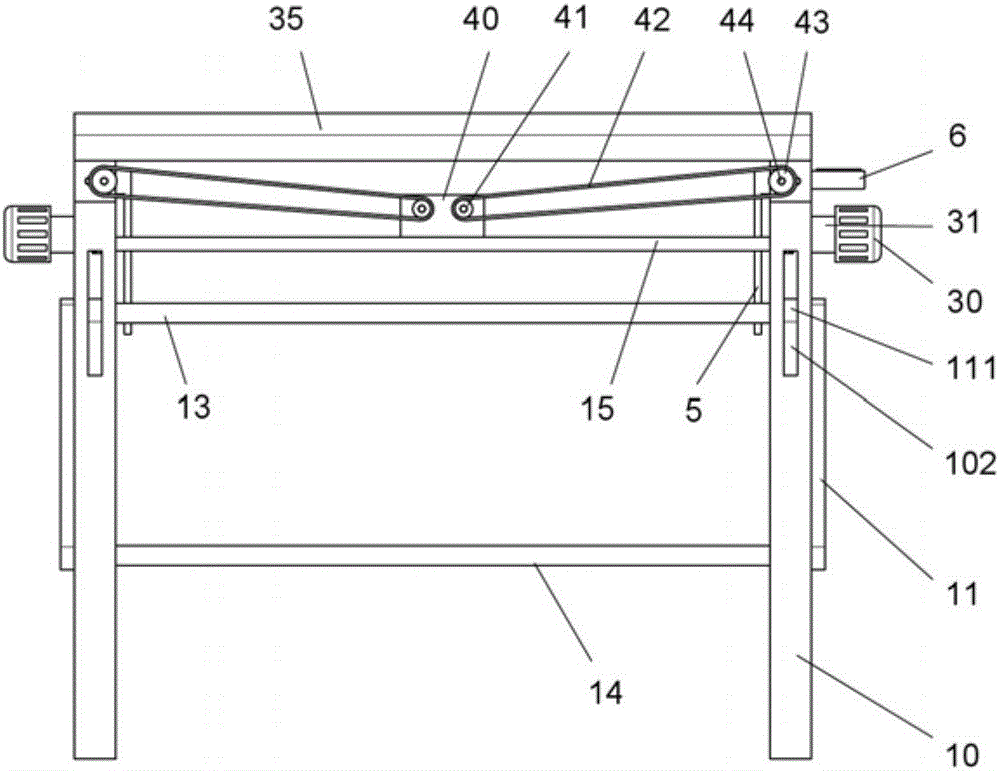

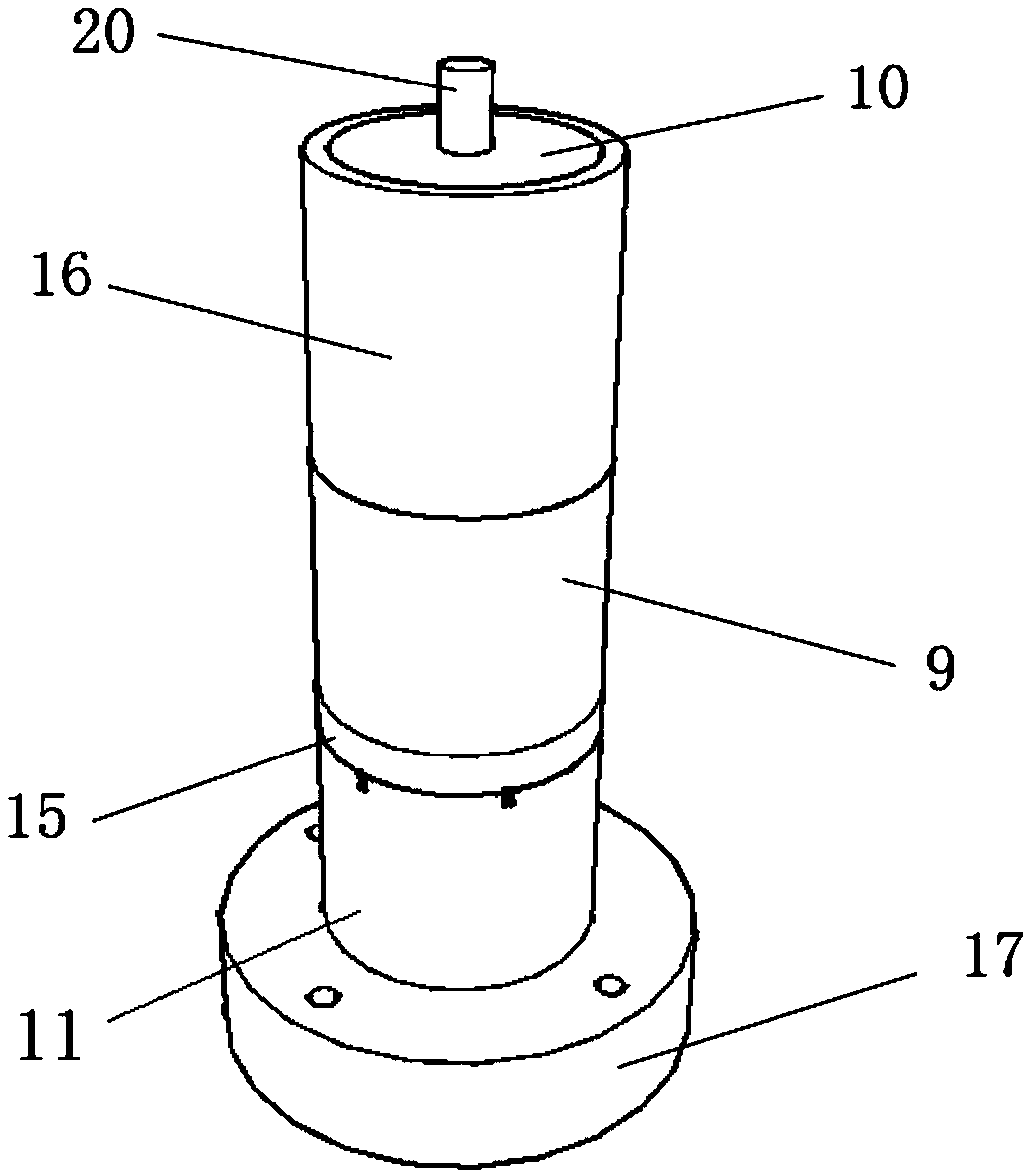

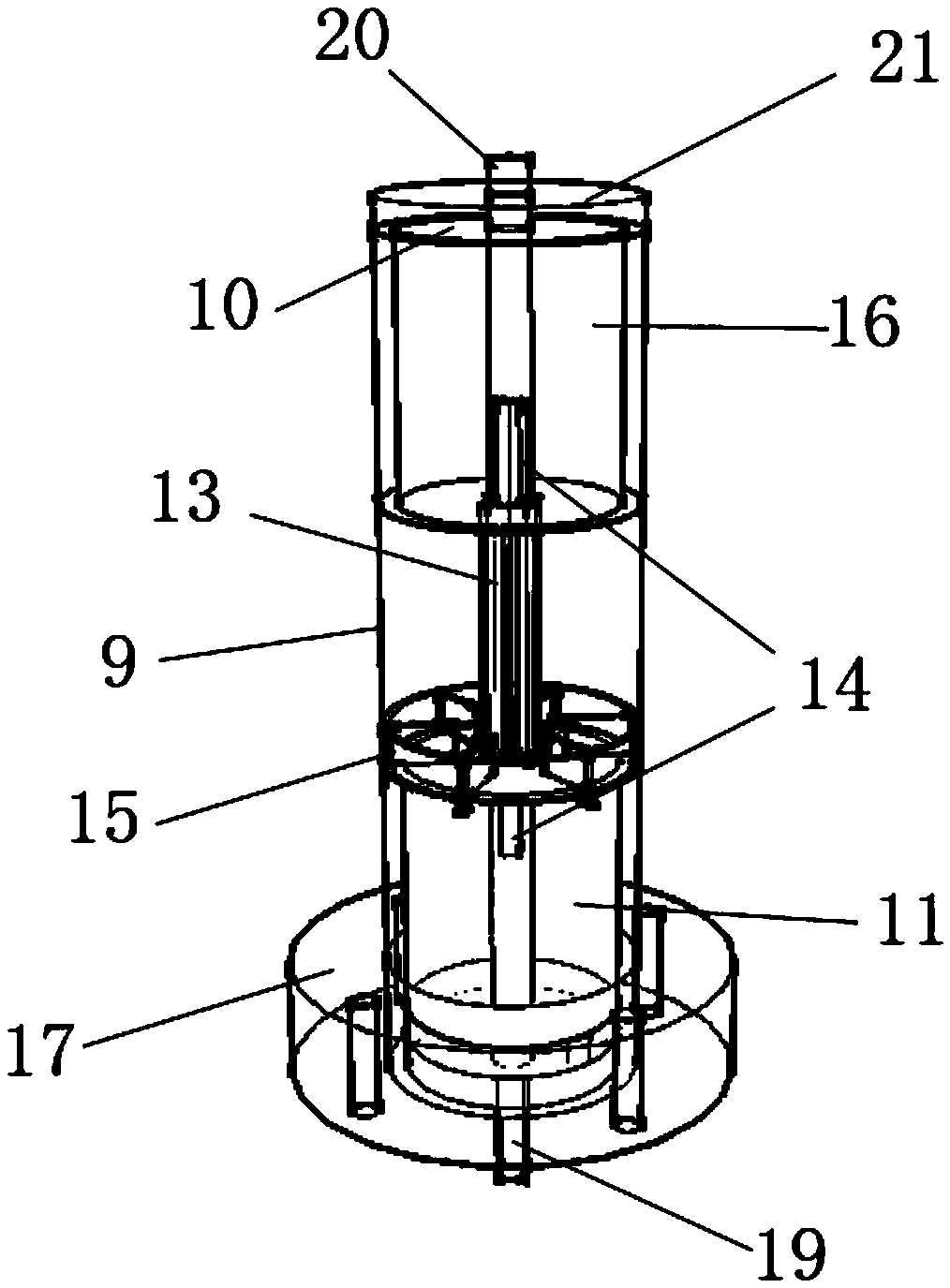

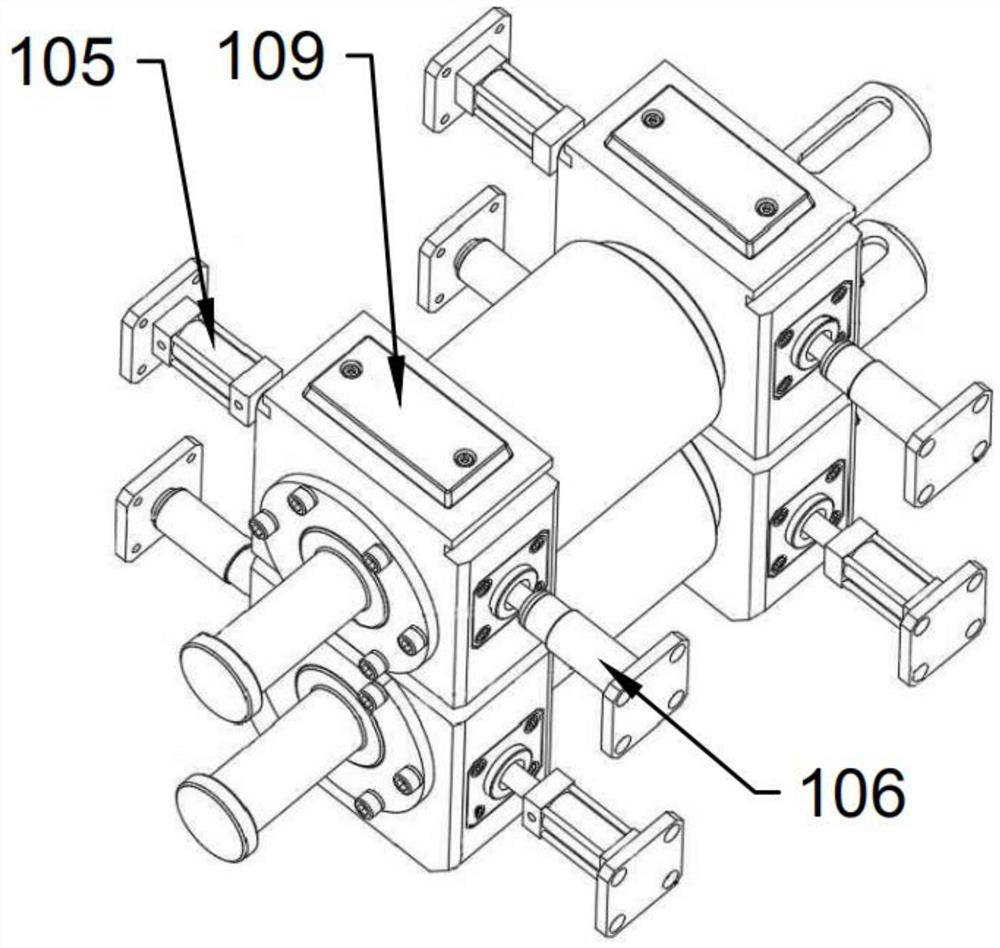

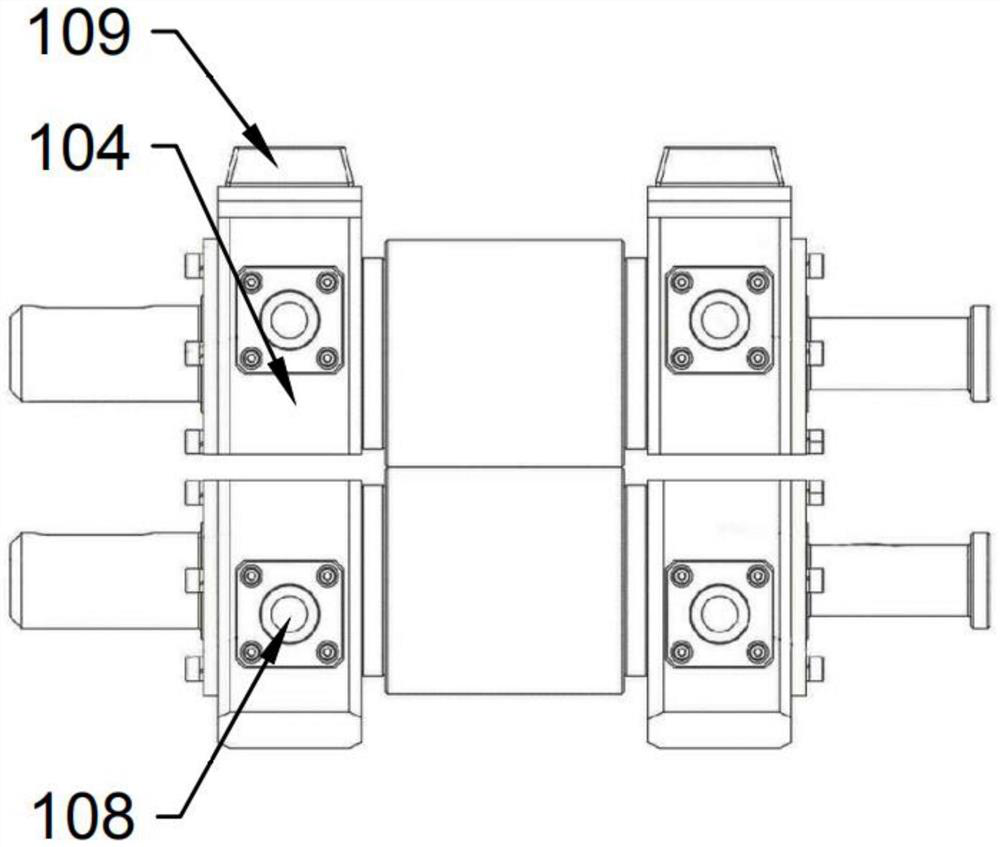

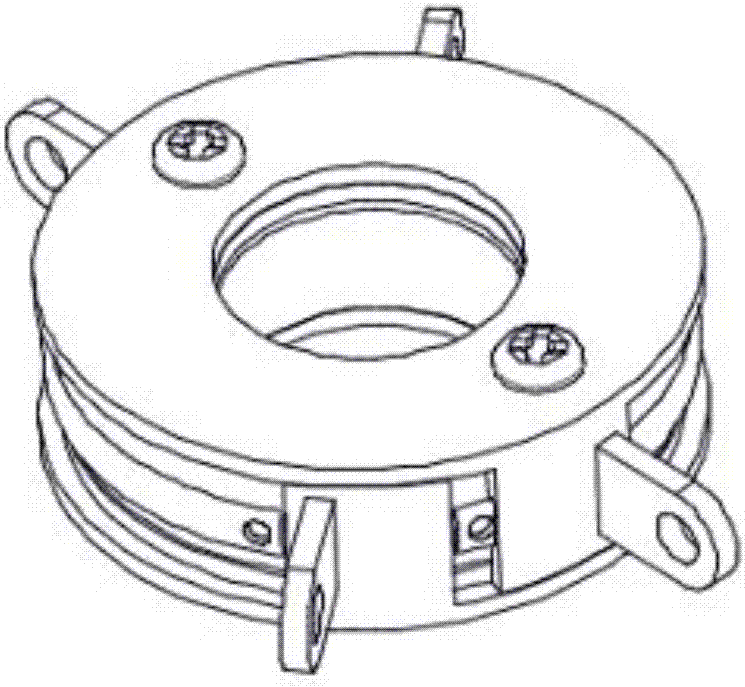

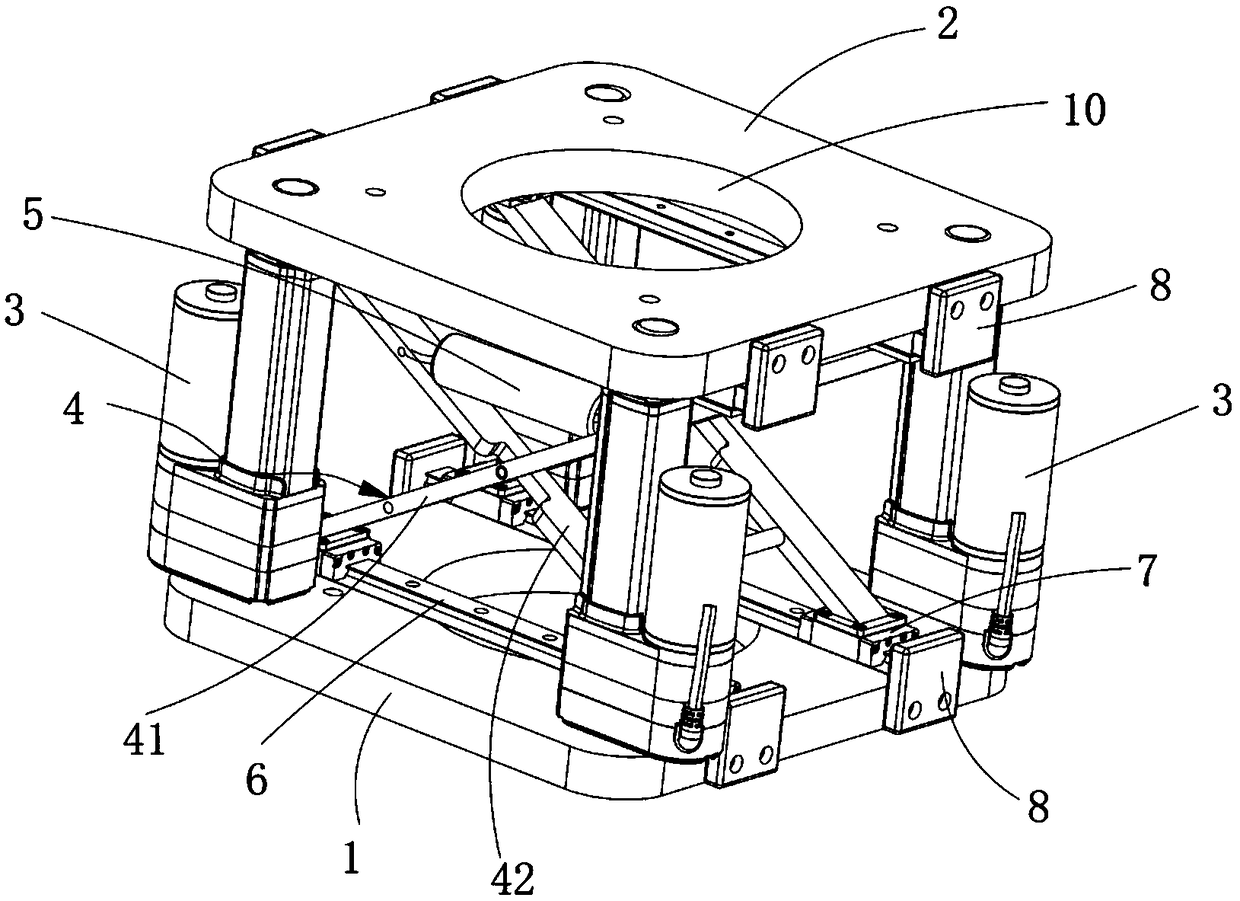

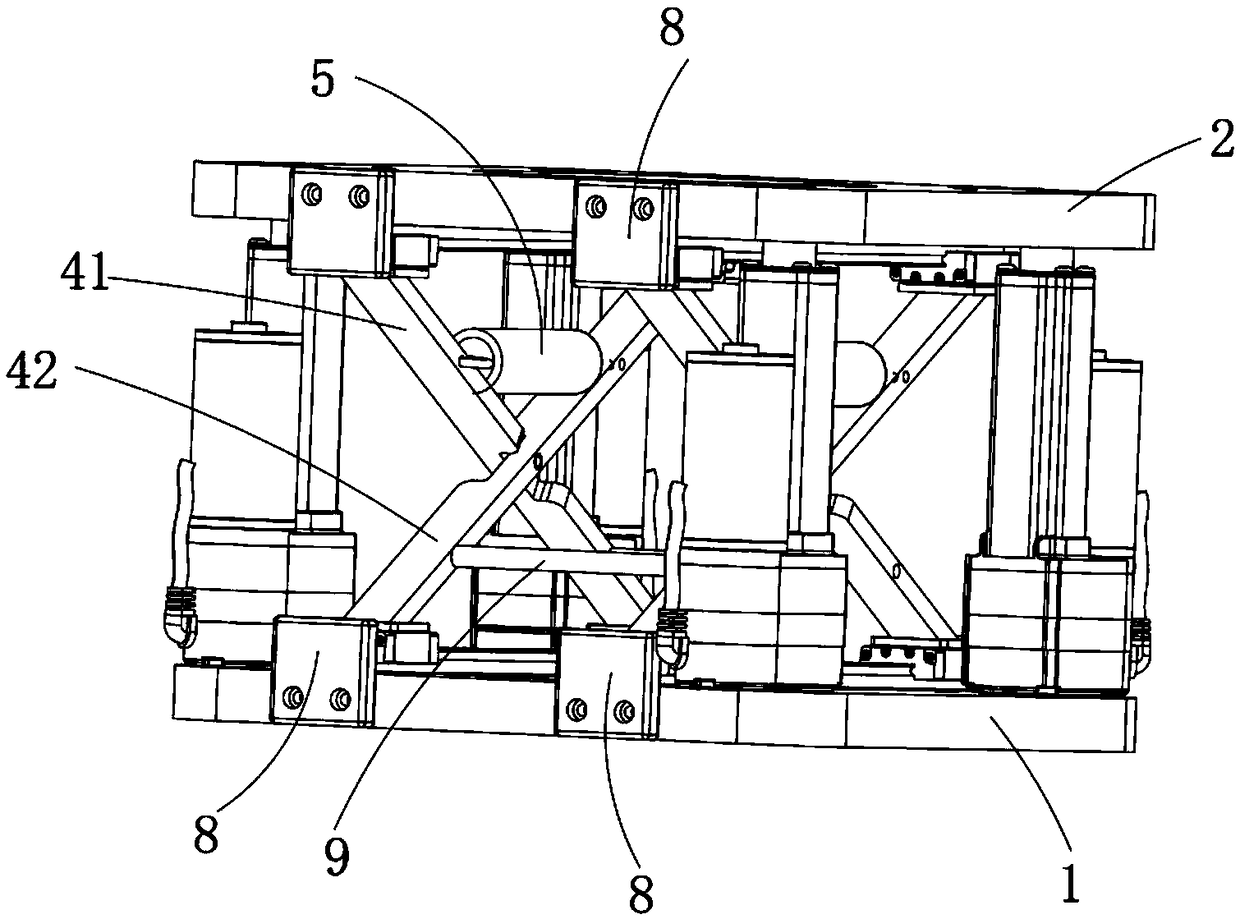

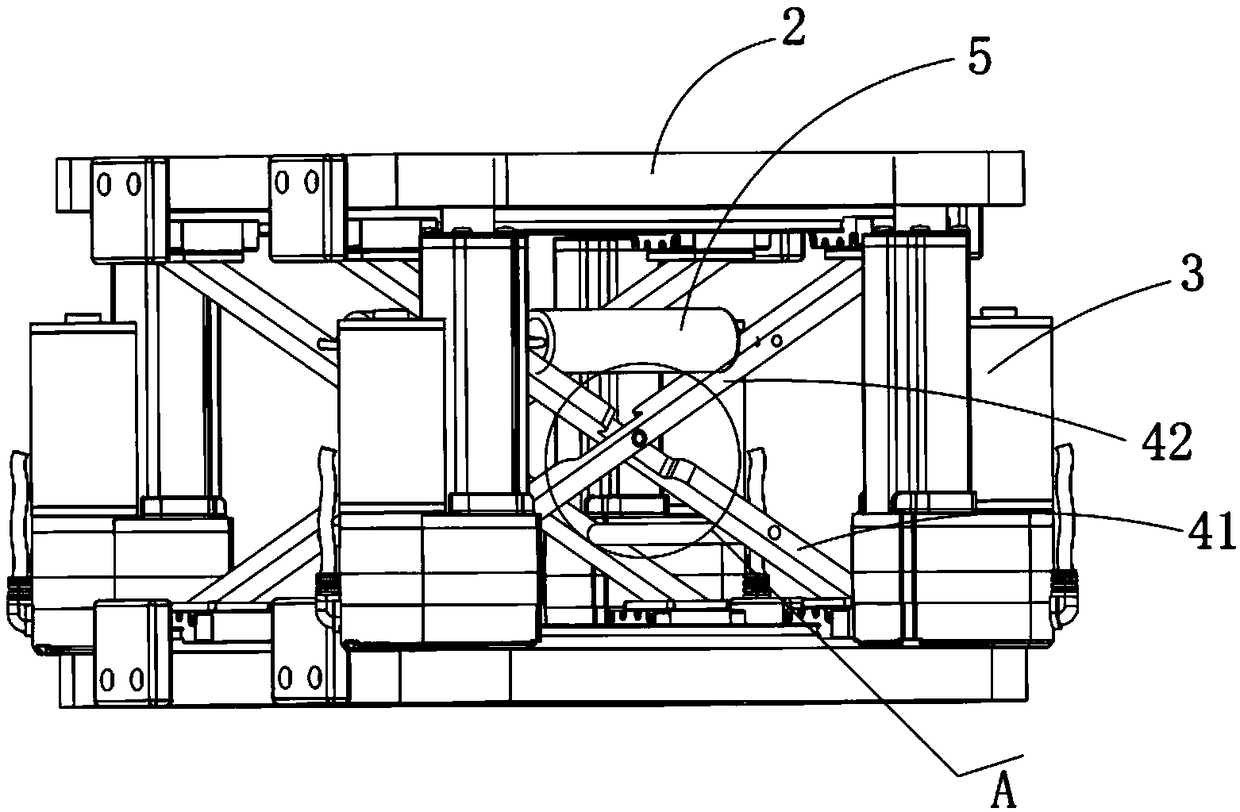

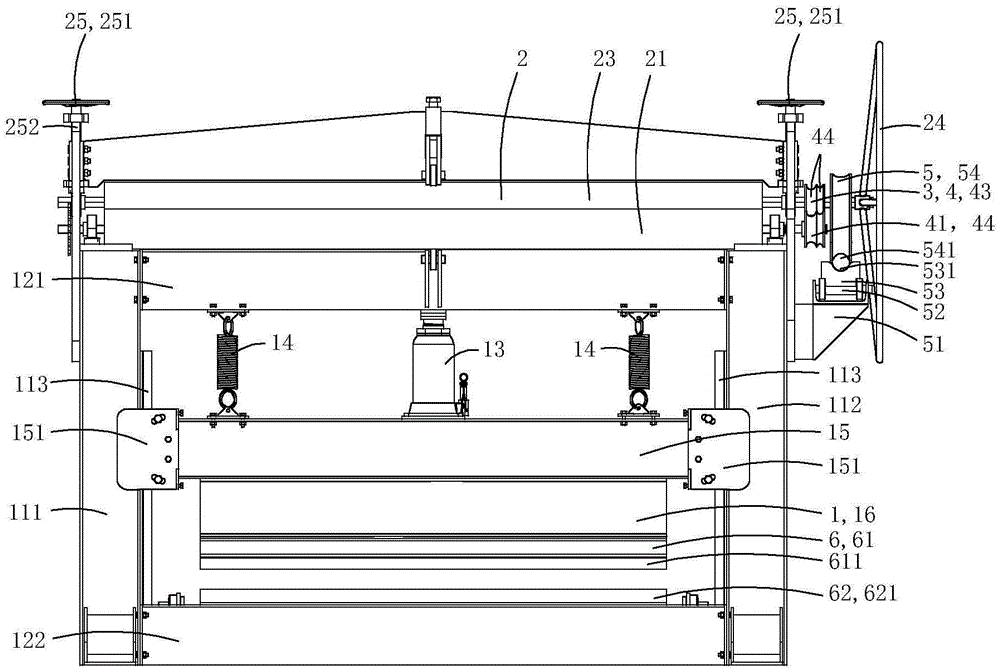

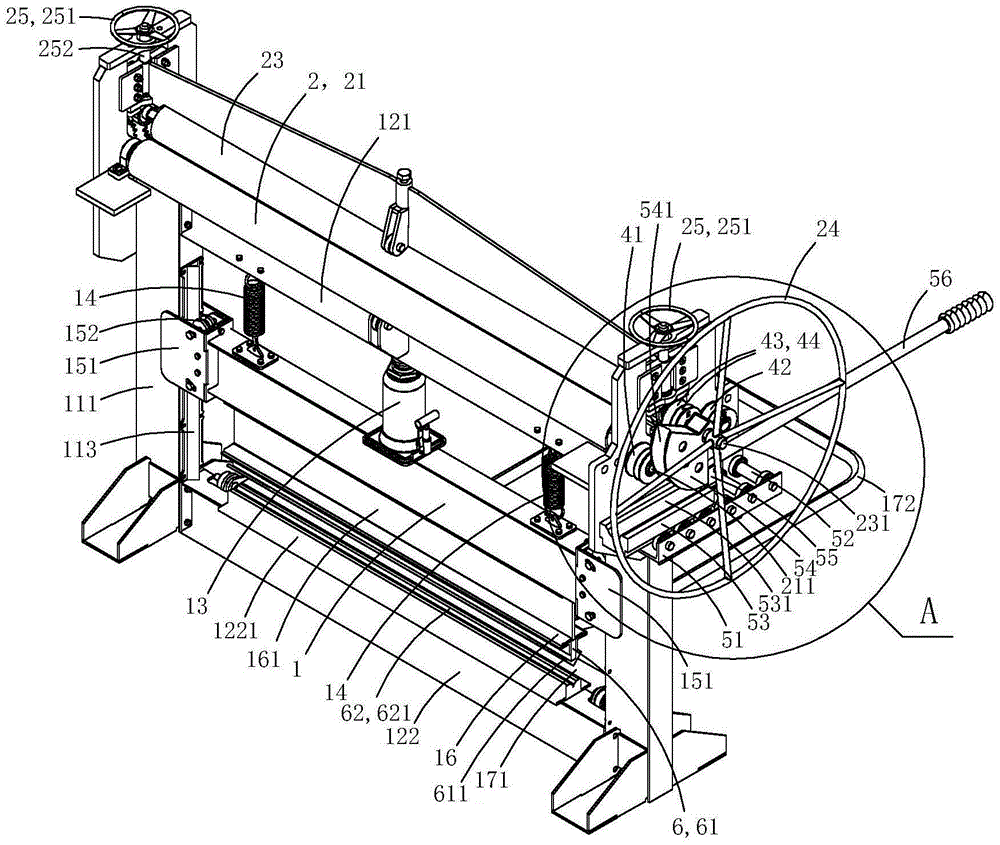

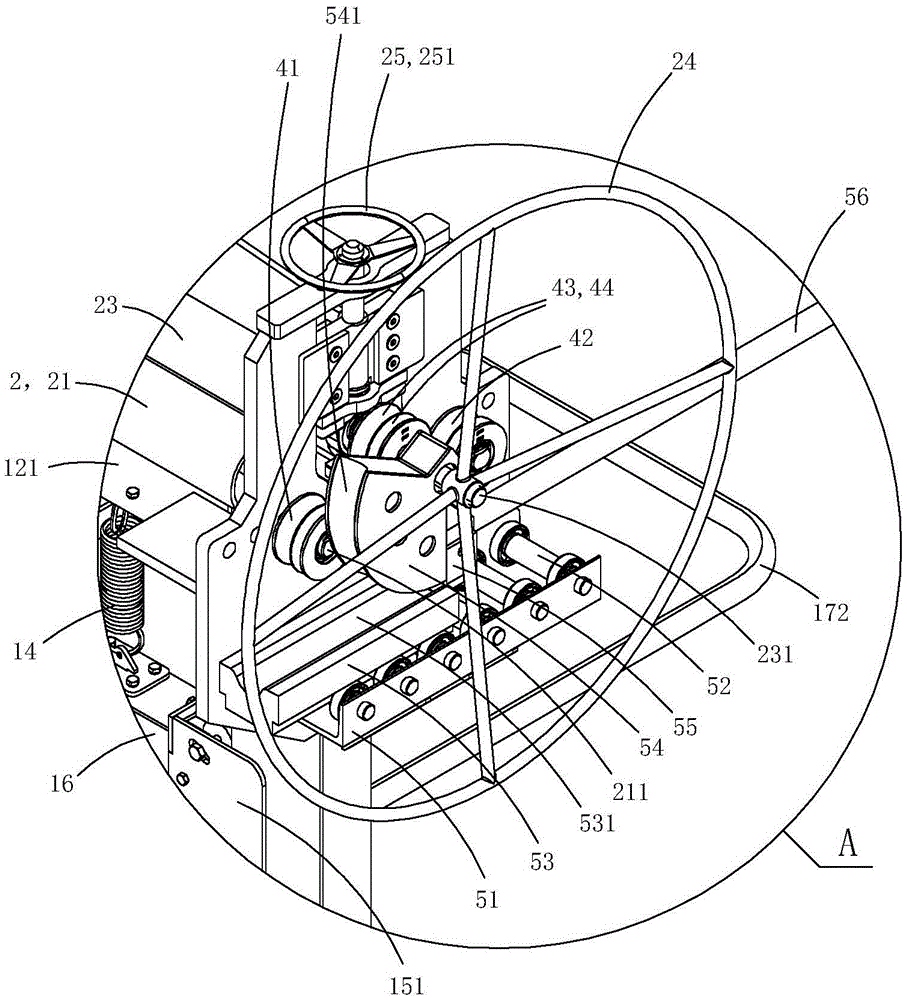

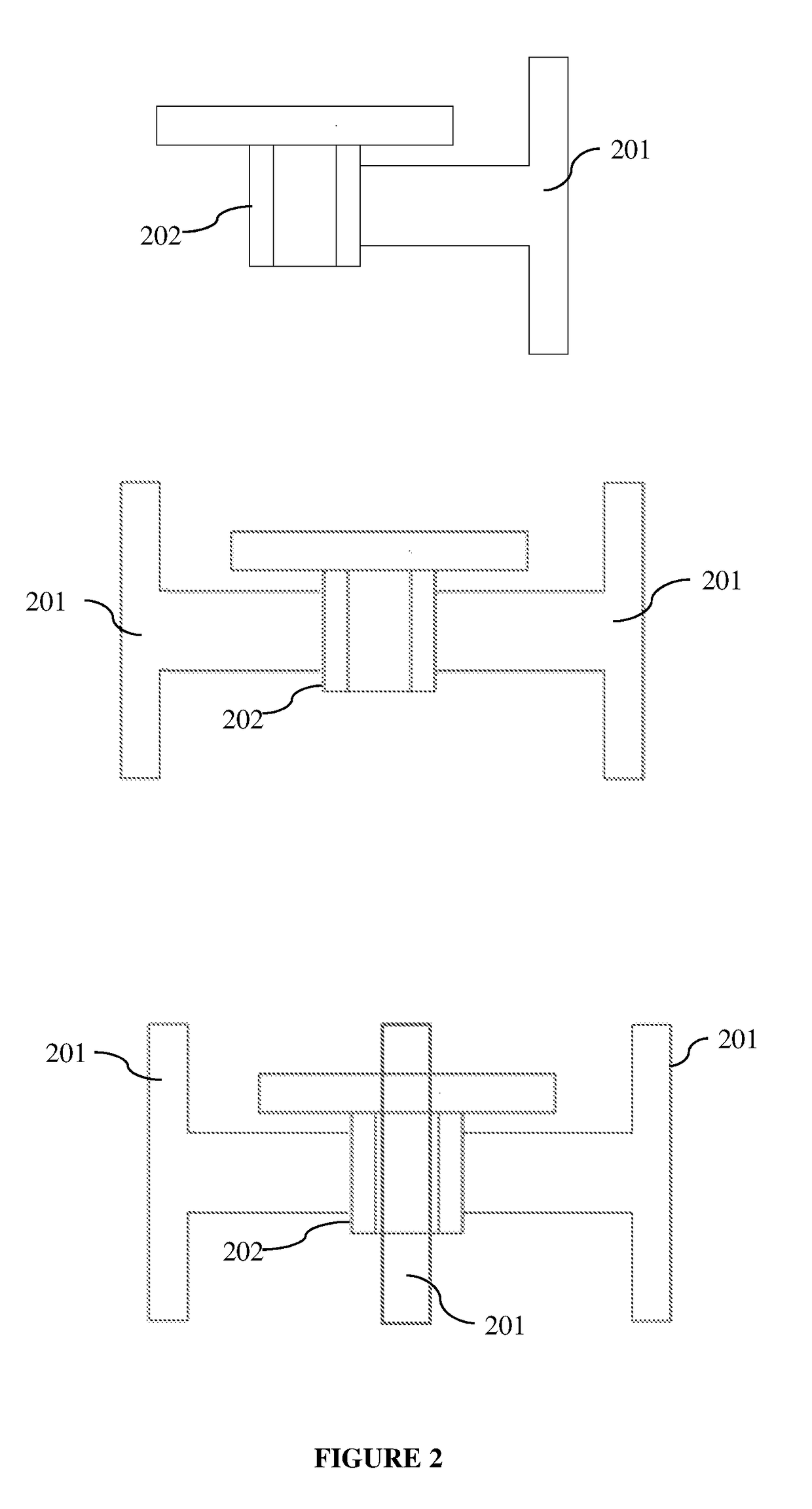

Amplitude angle adjustable mast drive type cross shear fork lifting mechanism

ActiveCN107572442AAdjustable scissor angleSimplify workLifting framesMechanical engineeringCross shear

The invention discloses an amplitude angle adjustable mast drive type cross shear fork lifting mechanism. The amplitude angle adjustable mast drive type cross shear fork lifting mechanism comprises across shear fork mechanism, a masts drive mechanism, an angle adjusting mechanism and a supporting board; the cross shear fork mechanism comprises a plurality of shear fork modules sequentially spliced; each shear fork module comprises a plurality of inner connection rods and a plurality of outer connection rods; the inner connection rods and the outer connection rods correspond to one another oneby one and are crossed and hinged correspondingly; the angle adjusting mechanism can achieve adjustment of the amplitude angle of the cross shear fork mechanism through switching of connection of bearings; and the mast drive mechanism is a telescopic rod arranged between the adjacent angle adjusting mechanisms and can drive the cross shear fork mechanism to ascend or descend and improve the bearing capacity. The lifting mechanism of the structure has the advantages of being adjustable in amplitude angle, low in weight and large in bearing capacity, and meets the lifting requirements of large-bearing high-altitude operation on narrow entrances and areas with complex environments.

Owner:CENT SOUTH UNIV

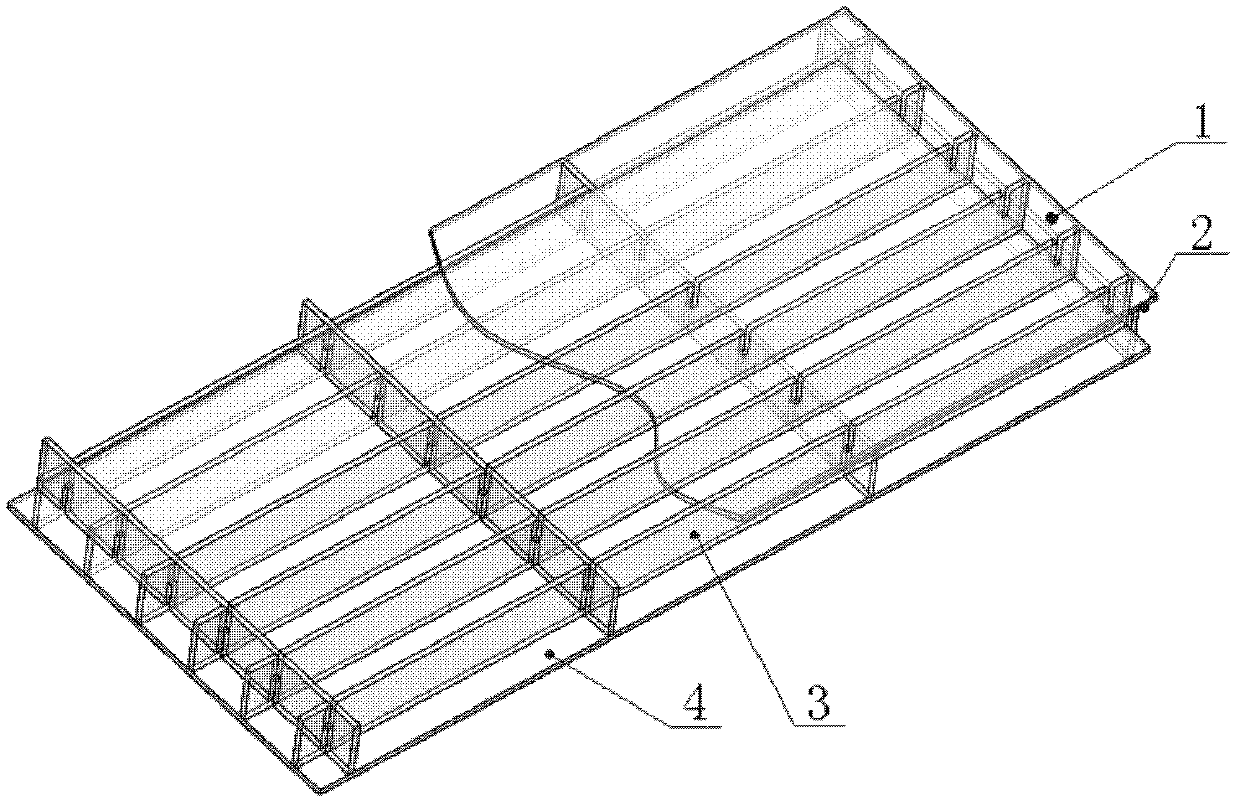

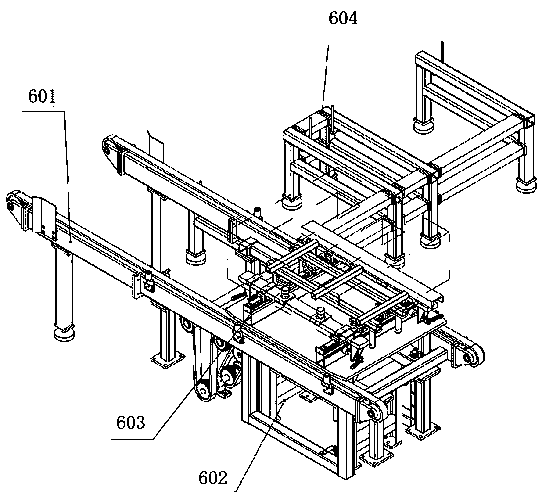

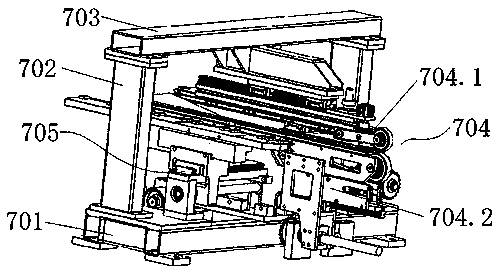

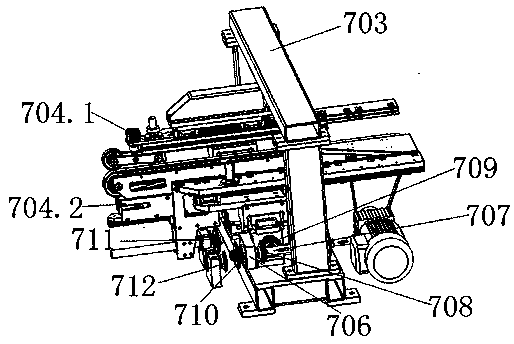

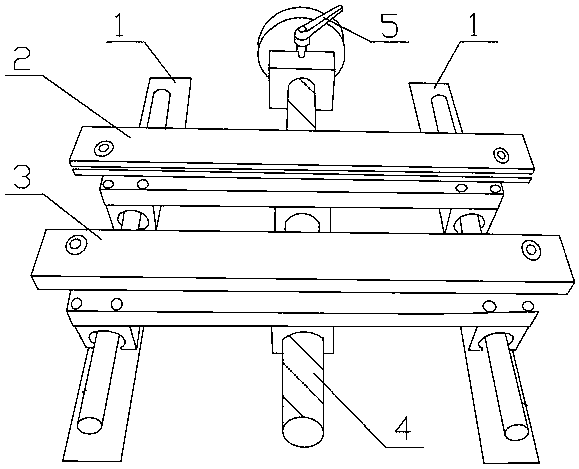

Material arrangement device for cross shear production line

InactiveCN111071804AAvoid shakingIncrease profitConveyorsOther manufacturing equipments/toolsProduction lineIndustrial engineering

The invention relates to a material arrangement device for a cross shear production line. The material arrangement device includes a material dividing mechanism, a lifting mechanism and two material collecting mechanisms. The material dividing mechanism includes a material dividing mechanism machine frame, and the material dividing mechanism machine frame is provided with two material dividing mechanism conveying assemblies which are arranged in an up-down mode, wherein a material dividing assembly is arranged between the feed ends of the two material dividing mechanism conveying assemblies. The lifting mechanism includes a lifting mechanism frame, and the lifting mechanism frame is provided with a lifting frame and a lifting assembly which controls the lifting frame to be lifted and descend up and down. The two material collecting mechanisms are arranged in an up-down mode, and include material collecting mechanism supporting frames, and the material collecting mechanism supporting frames are internally provided with material collecting mechanism conveying assemblies and material collecting assemblies. The discharge ends of the material dividing mechanism conveying assemblies areconnected with the lifting frame, and the material collecting mechanism supporting frames are fixedly connected with the lifting frame. The material arrangement device for the cross shear production line has the advantages of stable operation, improved material conveying efficiency, neatly stacked silicon steel sheets after shearing without manual rearrangement and reduced labor cost.

Owner:JIANGYIN HONGHENG ELECTROMECHANICAL TECH CO LTD

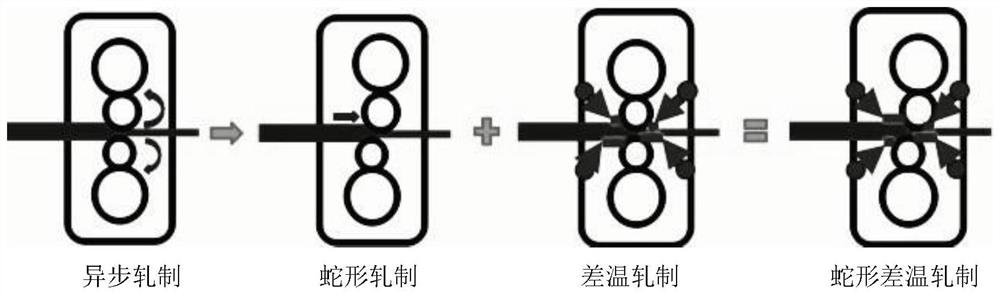

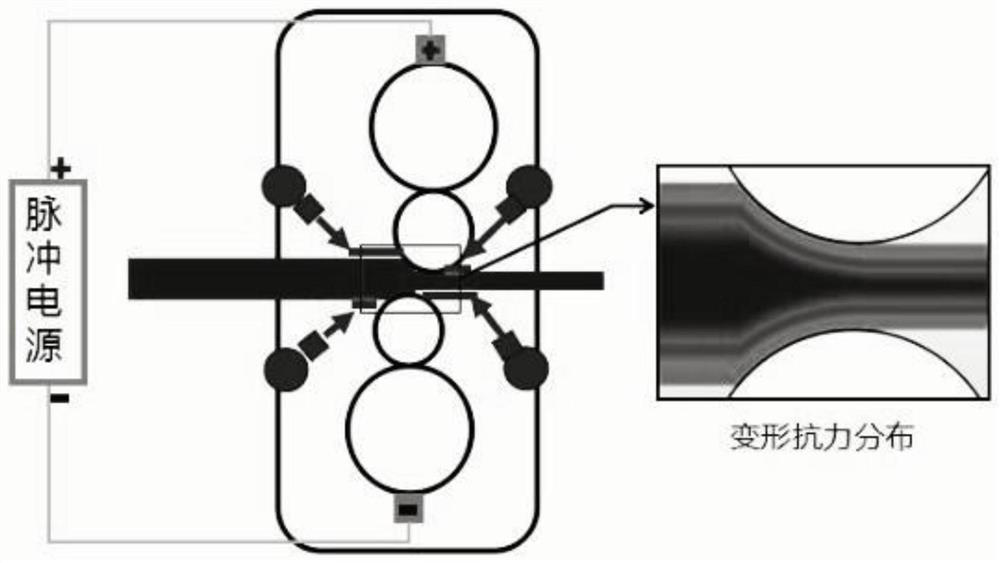

Serpentine differential-temperature rolling method for improving deformation uniformity of hot-rolled plate strip steel

ActiveCN111644464AImprove completenessImprove uniformityWork cooling devicesWork heating devicesShear stressEngineering

The invention discloses a serpentine differential-temperature rolling method for improving the deformation uniformity of hot-rolled plate strip steel. The method comprises the steps that a cross shearzone is formed in a deformation zone through cross shear rolling, and the shear stress generated by the cross shear zone facilitates transfer of the deformation from the surface layer to the center;on the basis of cross shear rolling, a slow working roller moves in the rolling direction or moves a rapid working roller in the opposite direction to form a cross shear zone and an anti-bend zone, and the bending of plate strip steel is restrained by utilizing the anti-bend force of the anti-bend zone to form serpentine rolling; steel plates are subjected to ultra-rapid cooling before rolling toform an outer-hard and inner-soft deformation resistance distribution, and differential temperature rolling is additionally arranged on the basis of serpentine rolling to form serpentine differential-temperature rolling; and a rolling deformation zone is formed in the serpentine differential-temperature rolling zone, and a high-frequency pulse current is applied in the rolling deformation zone. According to the serpentine differential-temperature rolling method, the combined effect of the cross shear rolling, the serpentine rolling, the differential-temperature rolling and the pulse current isfully utilized to improve the deformation uniformity of the plate strip steel in the thickness direction, and meanwhile a good plate shape after rolling is ensured.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Micro-texture surface coating self-lubricating cross-shear cutter embedded with solid lubricants

InactiveCN109482958AExpand the scope of useEasy to useMaintainance and safety accessoriesShearing toolsLow speedMicro texture

The invention discloses a micro-texture surface coating self-lubricating cross-shear cutter embedded with solid lubricants. The micro-texture surface coating self-lubricating cross-shear cutter comprises a cutter body, a plurality of grooves are formed in a contact surface of the cutter body which is in contact with a metal plate, and the grooves are filled with the solid lubricants. A lubricatingcoating is disposed on the contact surface of the cutter body which is in contact with the metal plate, and the lubricating coating covers the solid lubricants filling the grooves. When the lubricating coating is run out, the solid lubricants are released to lubricate the contact surface between the metal plate and the cutter body, so that the lubrication time is greatly increased and the duration and stability of lubrication are ensured. Since the solid lubricants are softened and released by the high temperature action generated during processing, the lubricating effect of the solid lubricants is poor when the cutter body shears at a low speed; and according to the micro-texture surface coating self-lubricating cross-shear cutter embedded with the solid lubricants, the lubricating lubricants are covered with the lubricating coating, so that the cutter body is better lubricated during low-speed shearing, and the range of application of the cutter body is enlarged and the performanceof the cutter body is improved.

Owner:GUANGDONG UNIV OF TECH

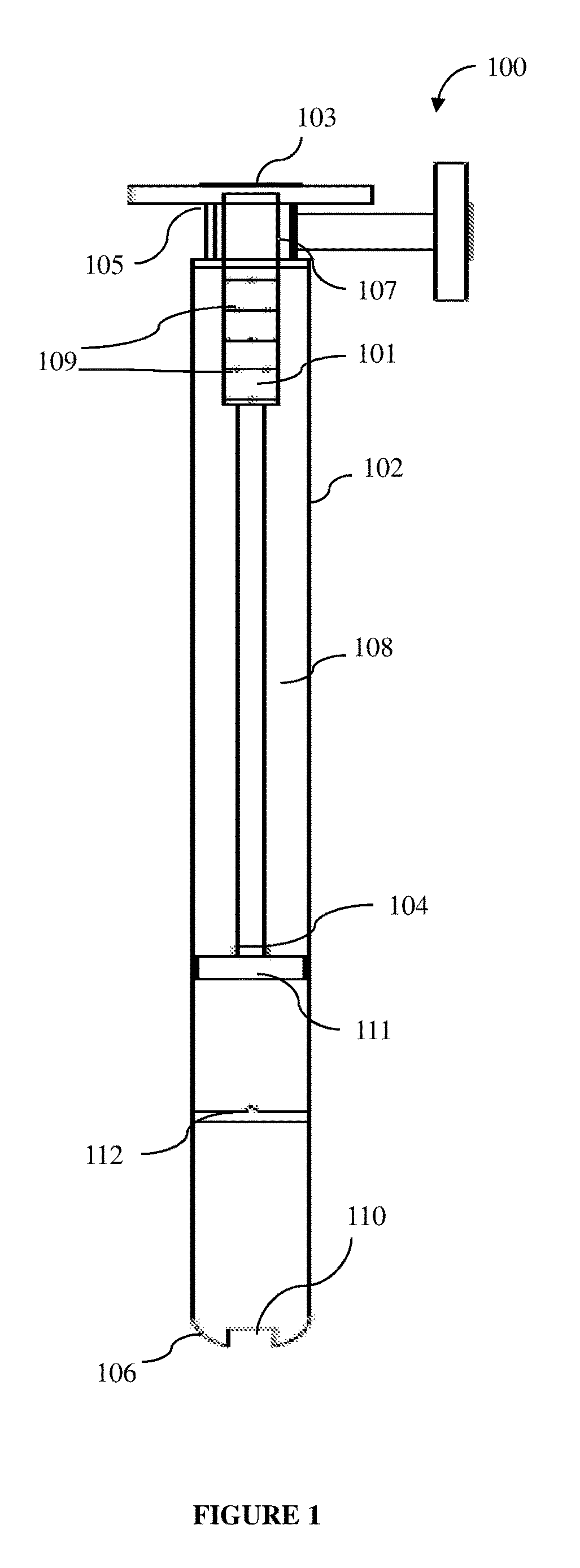

Lifting device and robot

PendingCN109291043AImprove stabilityAvoid the phenomenon of lower lifting accuracyProgramme-controlled manipulatorIndustrial engineeringCross shear

The invention discloses a lifting device and a robot, and belongs to the technical field of industrial robots. The lifting device comprises a bottom plate and a top plate which are parallel to each other, a lifting driving part and a supporting part are arranged between the bottom plate and the top plate, and a base of the lifting driving part is fixed on the bottom plate, and a telescopic rod ofthe lifting driving part is connected to the top plate; the supporting part comprises a cross shearing mechanism, and the cross shearing mechanism comprises a first connecting rod and a second connecting rod which are arranged in a crossed mode; and the middle parts of the first connecting rod and the second connecting rod are hinged, one end of the first connecting rod and one end of the second connecting rod are in sliding connection with the top plate, and the other end of the first connecting rod and the other end of the second connecting rod are in sliding connection with the bottom plate. The robot comprises the lifting device. According to the lifting device and the robot, ascending and descending can be carried out directly through the lifting driving part, accurate and visual effects are realized, and the phenomenon that the lifting precision is low due to driving of other mechanical lifting mechanisms is avoided; and meanwhile, the lifting device is provided with the supporting part, so that the lifting stability of the top plate is improved.

Owner:SIASUN CO LTD

Multifunctional plate bending machine with plate shearing mechanism

InactiveCN105414976ASmall footprintRealize one machine with multiple functionsMetal rolling stand detailsOther manufacturing equipments/toolsShaped beamEngineering

The invention discloses a multifunctional plate bending machine with a plate shearing mechanism. The multifunctional plate bending machine with the plate shearing mechanism comprises a plate bending mechanism and the plate shearing mechanism. The plate bending mechanism comprises a left supporting pillar, a right supporting pillar, a first horizontal fixed beam and a second horizontal fixed beam. The plate shearing mechanism comprises a cross shearing cutter and a auxiliary shearing cutter, wherein the cross shearing cutter is rotationally arranged on an I-shaped beam and can rotates around a rotary shaft of the cross shearing cutter to abut against the bottom wall of the I-shaped beam; the auxiliary shearing cutter is rotationally arranged on the second horizontal fixed beam or rotationally arranged on the left supporting pillar and the right supporting pillar and can rotate around a rotary shaft of the auxiliary shearing cutter to abut against the second horizontal fixed beam. The position is a shearing position, and at the time a V-shaped blade groove opening of the auxiliary shearing cutter is upward. The auxiliary shearing cutter further rotates to the front side of the second horizontal fixed beam, and the position is a storage position. The multifunctional plate bending machine with the plate shearing mechanism achieves multiple functions in one machine.

Owner:CHUZHOU PINZHIDA ELECTRIC TECH

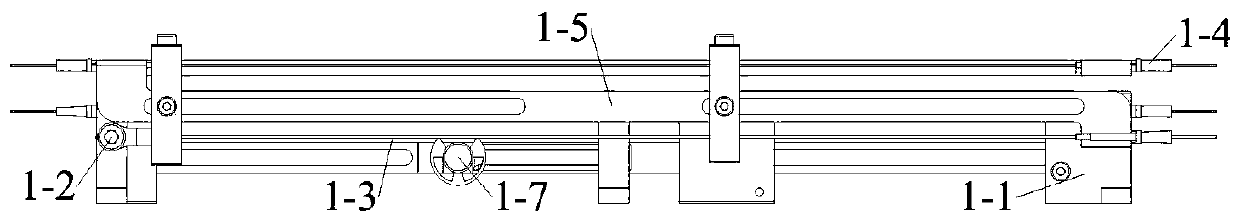

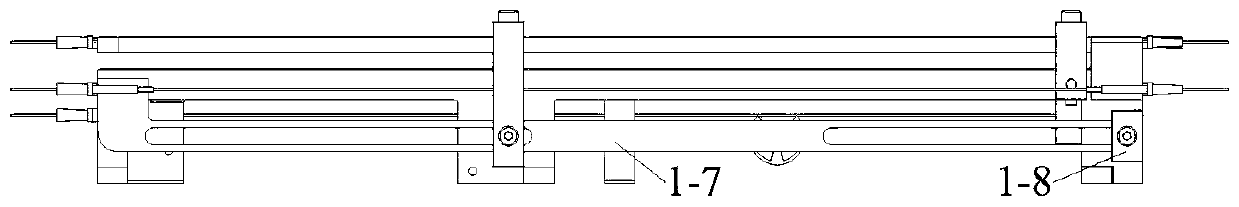

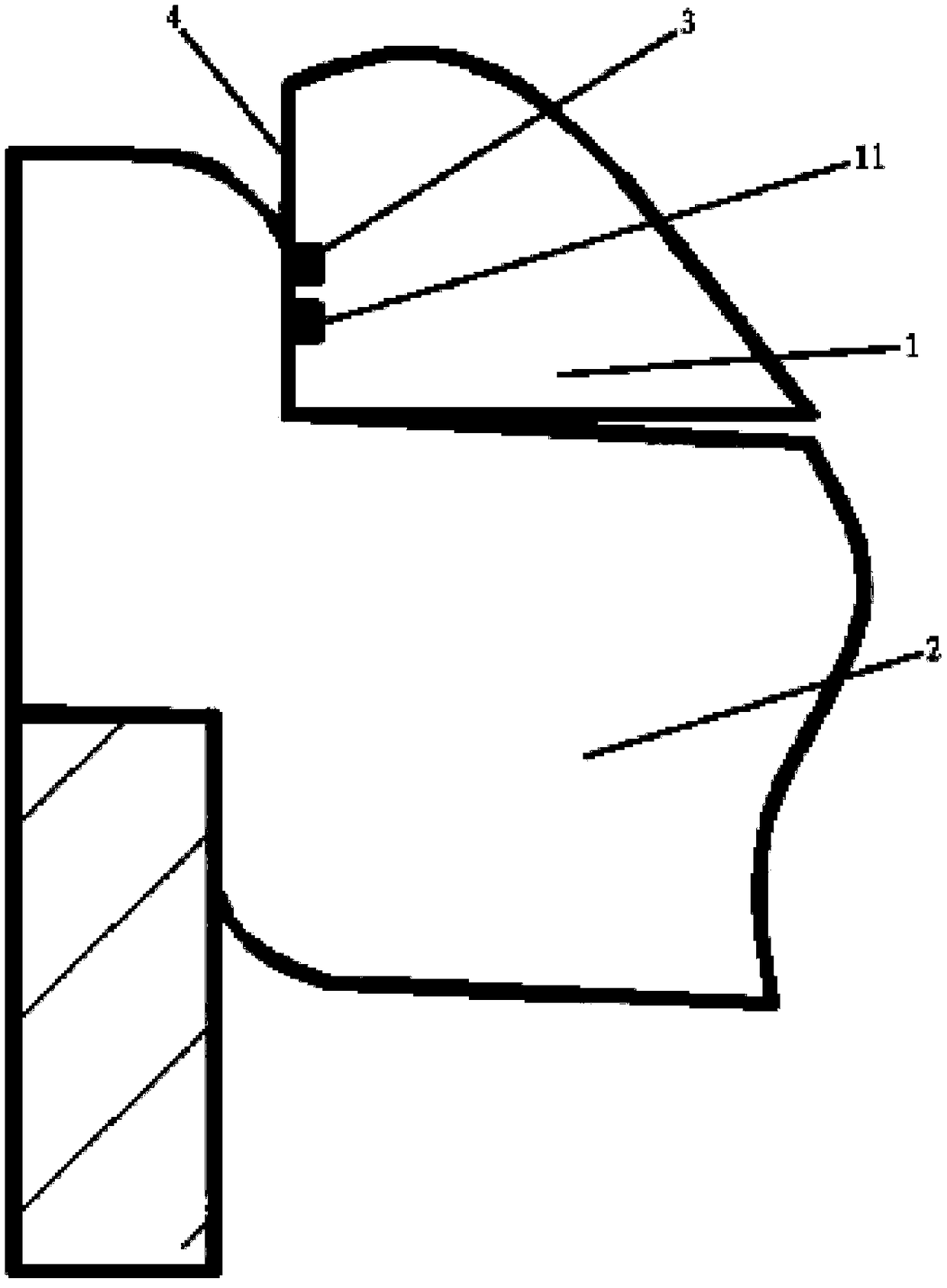

Feeding guiderails of cross cut shear and with magnetic force proximity switches

InactiveCN107661932AAvoid offsetSimple structureMetal-working feeding devicesPositioning devicesEngineeringMechanical engineering

The invention relates to a feed guide rail of a transverse shearing machine with a magnetic proximity switch, which is characterized in that: it comprises a base, a bracket (1) is fixed on the base by bolts, and a left The guide rail (2) and the right guide rail (3), the inner sides of the left guide rail (2) and the right guide rail (3) are provided with guide wheels, and the bottom of the left guide rail (2) and the right guide rail (3) are provided with a guide wheel The screw rod (4), the top of the screw rod (4) is matched with the bottom thread of the left guide rail (2) and the right guide rail (3) through the nut, the two ends of the bracket (1) are equipped with magnetic proximity switches, and the left guide rail is equipped with magnetic proximity switches. (2) and the surface of the right guide rail (3) are provided with protective covers. The feed rail of the cross shearing machine with magnetic proximity switch adjusts the position of the left and right rails by rotating the screw, so as to realize the positioning of the belt material and prevent the belt material from shifting. It is not only simple in structure, easy to implement, but also easy to operate. It is convenient and simple, and improves the production efficiency.

Owner:JIANGYIN RUYI SCI & TECH DEV

Method and apparatus for mixing and atomizing a hydrocarbon stream using a diluent/dispersion stream

The present invention relates to an apparatus and method for mixing and atomizing a hydrocarbon stream using a diluent / dispersion stream. The apparatus includes an inner conduit having an inlet for receiving the diluent / dispersion stream; an outer conduit having an inlet for receiving the hydrocarbon stream and an outlet for dispensing a mixture including the hydrocarbon and the dispersion / diluent streams; the outer conduit concentric to the inner conduit to define at least a first annular space and a second annular space; the first annular space being located downstream of the inlet of the outer conduit, the first annular space enabling formation of a thin film of the hydrocarbon stream between an outer surface of the inner conduit and an inner surface of the outer conduit; the second annular space being located downstream of the first annular space, the second annular space having a width greater than a width of the first annular space; and the inner conduit located at about the second annular space includes a first set orifices disposed on a periphery thereof for dispensing a first portion of the dispersion / diluent stream into the thin film of hydrocarbon stream to cross-shear the thin film and form the mixture including the hydrocarbon and the dispersion / diluent streams.

Owner:INDIAN OIL CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com