Multifunctional plate bending machine with plate shearing mechanism

A plate bending machine, multi-functional technology, applied in the direction of metal rolling mill stands, manufacturing tools, metal rolling racks, etc., can solve the problems of single function, large volume, high price, etc., and achieve the effect of reducing the occupied space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

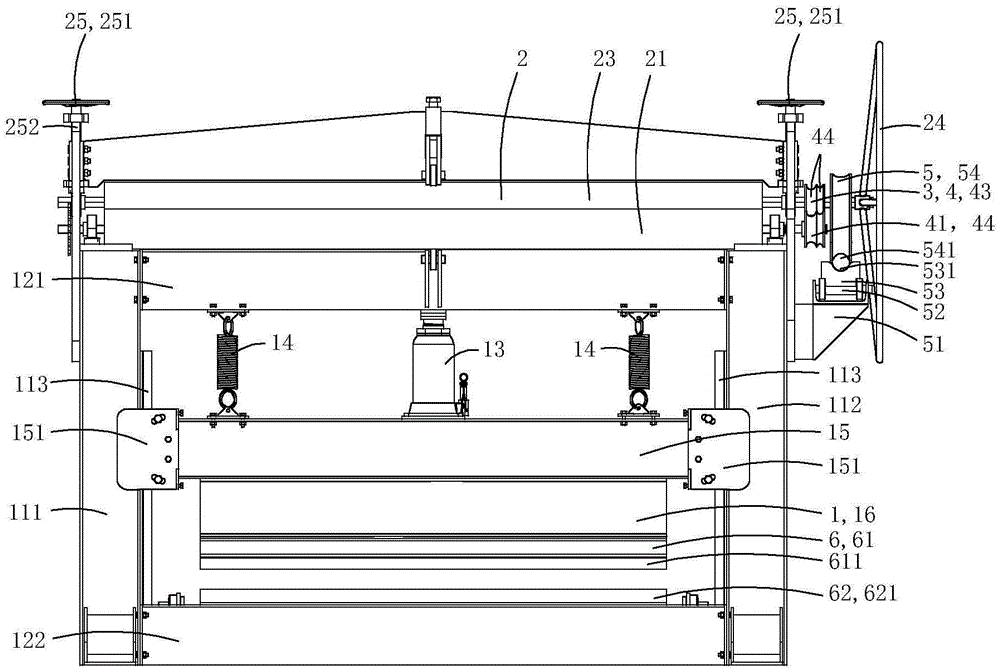

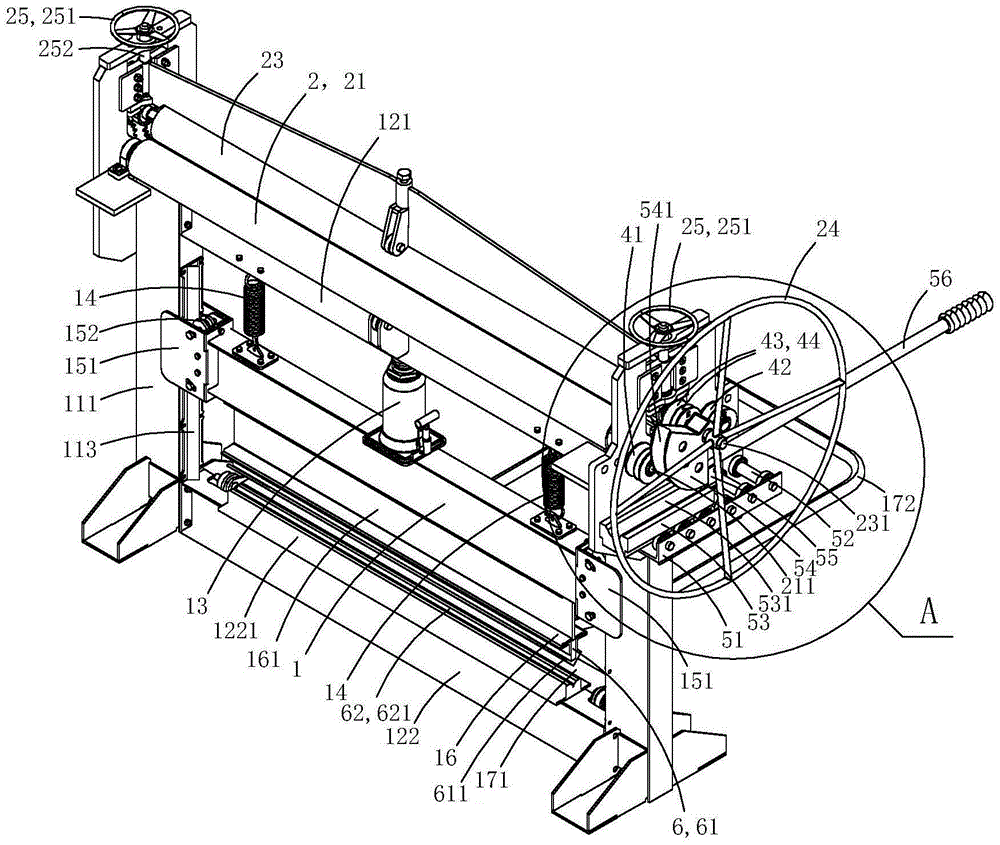

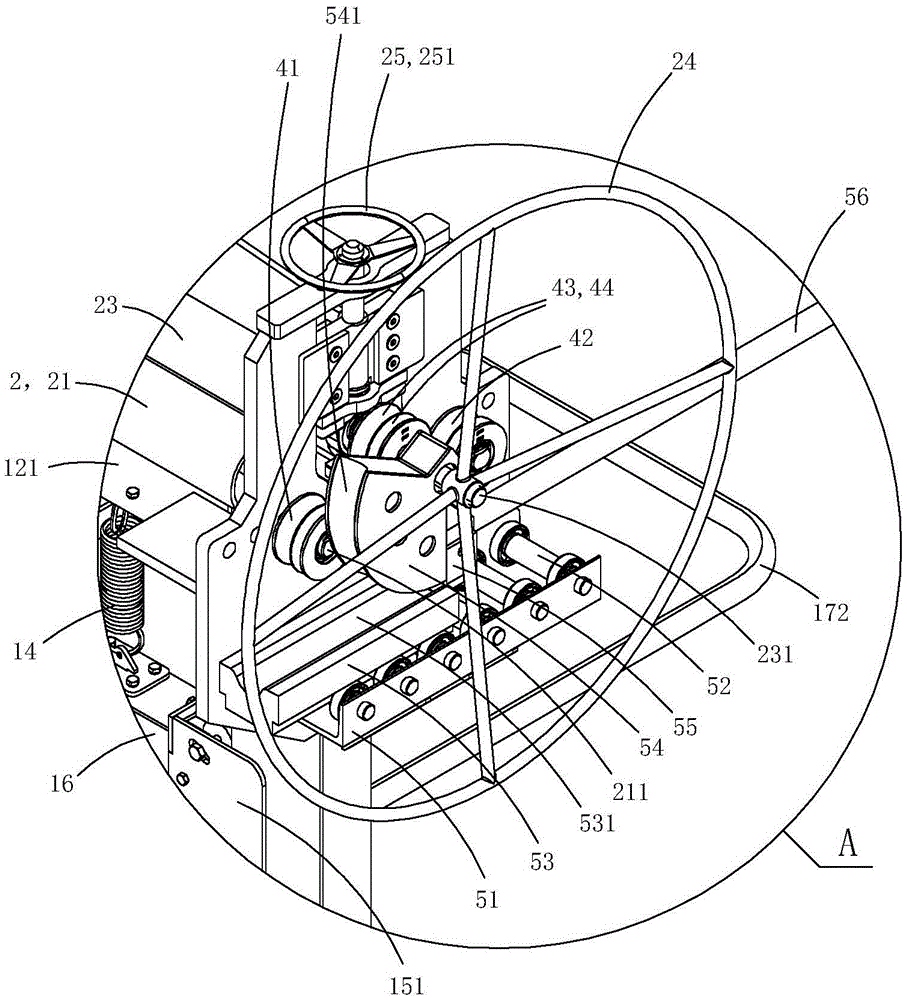

[0012] Figure 1 to Figure 5 A specific embodiment of the present invention is shown, in which, figure 1 Is a schematic diagram of the first structure of the present invention; figure 2 Yes figure 1 A schematic diagram of a three-dimensional structure of the plate bending machine shown; image 3 Yes figure 2 The partial enlarged schematic diagram of A in the plate bending machine shown; Figure 4 Yes figure 1 A schematic diagram of a three-dimensional structure of the plate bending machine shown from another angle; Figure 5 Yes Figure 4 The partial enlarged schematic diagram of B in the plate bending machine shown.

[0013] This embodiment is a multifunctional plate bending machine, see Figure 1 to Figure 5 As shown, it includes a plate bending mechanism 1, a plate rolling mechanism 2 and a pipe bending mechanism 3. The bending mechanism includes a left pillar 111, a right pillar 112, a first horizontal fixed beam 121, a second horizontal fixed beam 122, a cylinder 13, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com