Vertical and horizontal shearing combination production line for high-strength thick steel plates

A production line, thick steel plate technology, applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve problems such as low equipment utilization, surface scratches, and many sheet metal equipment links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The content of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

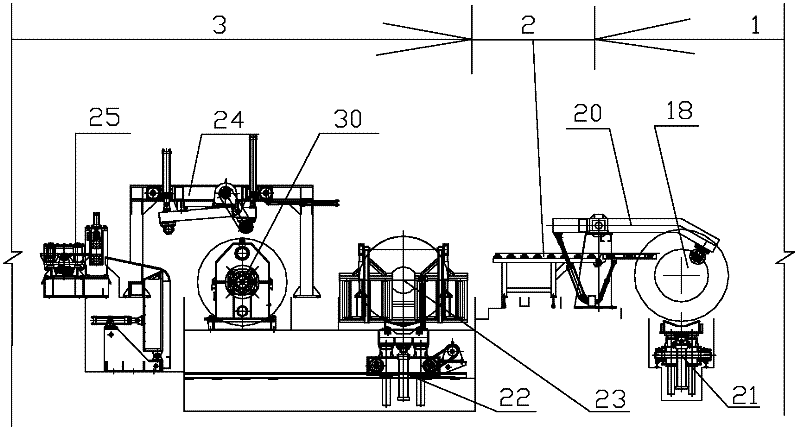

[0046] like figure 1 , 2 , 3, the present invention consists of a slitting line 1, a transition table 2 and a cross-cutting line 3. The slitting line 1 is composed of a feeding trolley 4 with a preparation table, a first uncoiler 5, a pinch guide device 6, a first nine-roller leveler 7, a feeding roller 8, a hydraulic shearing machine 9, a scrap car 10, The first looper device 11, the guide pressing device 12, the slitting machine 13, the second looper device 14, the side material winder 15, the tension roller 16, the auxiliary support 17 and the winder 18 are formed, and in the first unwinding A first unwinding and guiding device 19 is installed on the machine 5, a material distributing device 20 is provided on the winding machine 18, and a discharge trolley 21 is also provided on the corresponding position of the winding machine 18. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com