Assembly butting part end face automatic finishing process method

A process method and technology of butt surface, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., can solve the problems of difficult manual reaming, broken grinding discs, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

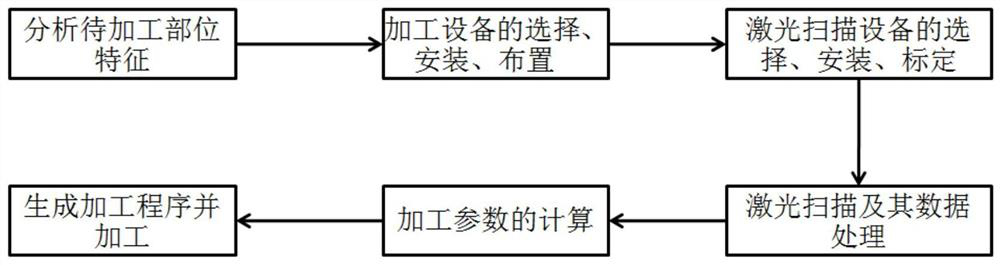

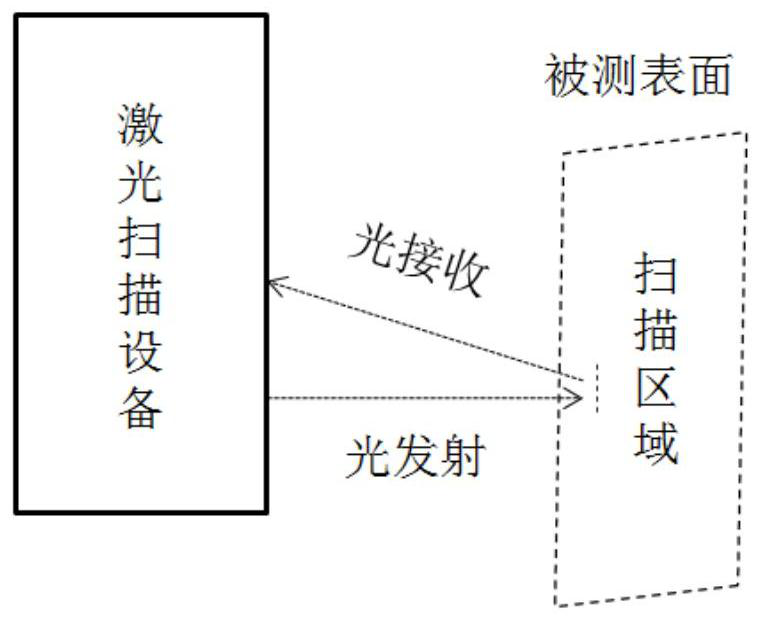

[0045] Below by the combination of accompanying drawing and example, further illustrate this process method.

[0046] 1) Analyze the characteristics of the part to be processed

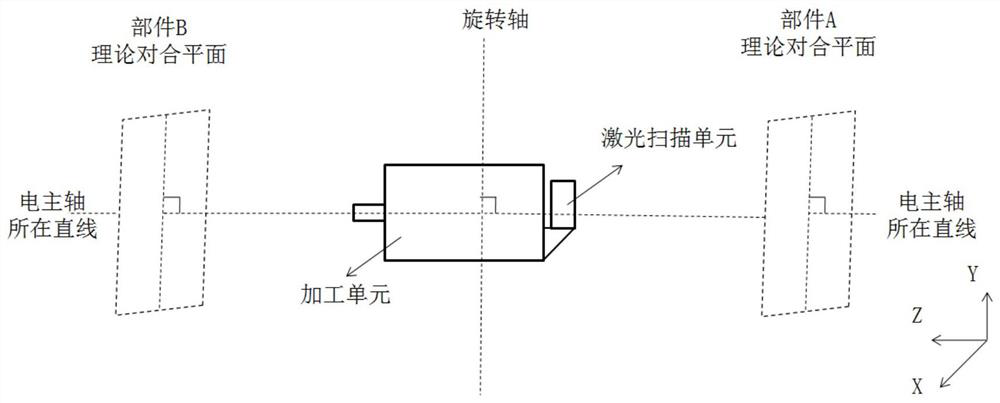

[0047] A product has two parts A and B, and the 4 faces of part A need to be attached to the 4 faces of part B at the same time and connected with bolts. There is a machining allowance on the butt joint surface of part A and part B, and there are several initial butt joint small holes on the butt joint face of part A. When assembling, the milling and cutting process of the butt joint surface must be completed first to ensure that the two parts fit together. Next, the butt hole should be processed to ensure the accuracy and coaxiality of the butt joint hole of the two parts. Finally, bolts and nuts should be installed to assemble the two parts.

[0048] There is a machining allowance on the butt joint surface of part A and part B, and the butt joint surface can be automatically milled; there are sever...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com