Patents

Literature

95results about How to "Meet the processing technology requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

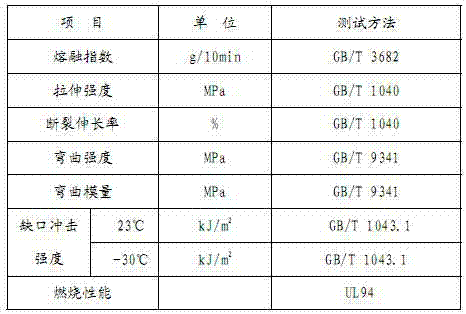

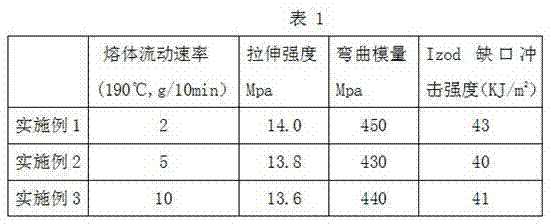

High-fluidity environmental protection halogen-free flame-retardant HIPS composite material and its preparation method

The invention belongs to the technical field of macromolecular compound combination and relates to a high-fluidity environmental protection halogen-free flame-retardant HIPS composite material, which is composed of the following components of: by weight, 29-50 parts of high impact polystyrene (HIPS), 15-35 parts of polyphenylene oxide (PPO), 3-12 parts of a flexibilizer, 5-20 parts of a phosphorus flame retardant, 1-7 parts of a flame-retardant synergistic agent, 0.2-1.0 part of a heat stabilizer, 0.2-0.8 part of an antioxidant and 0.5-1.2 parts of a processing aid. The invention also discloses a preparation method of the HIPS composite material. The composite material provided by the invention is a halogen-free flame retardation HIPS / PPO alloy with high fluidity and excellent mechanical properties.

Owner:深圳市比克新材科技有限公司

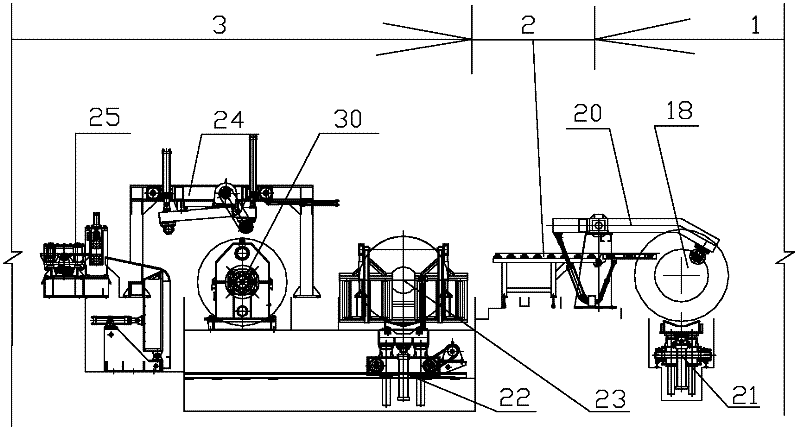

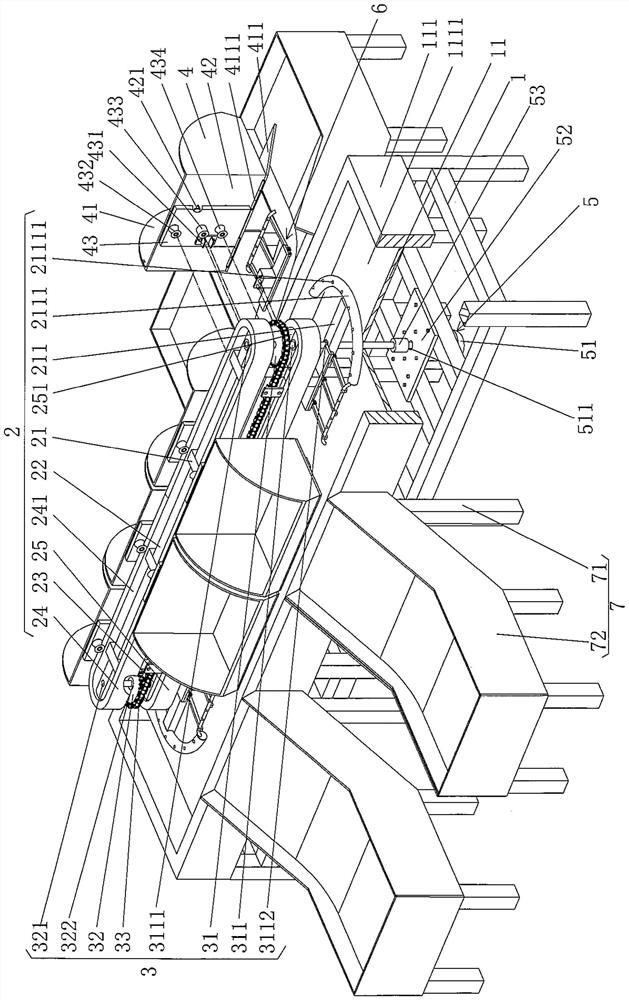

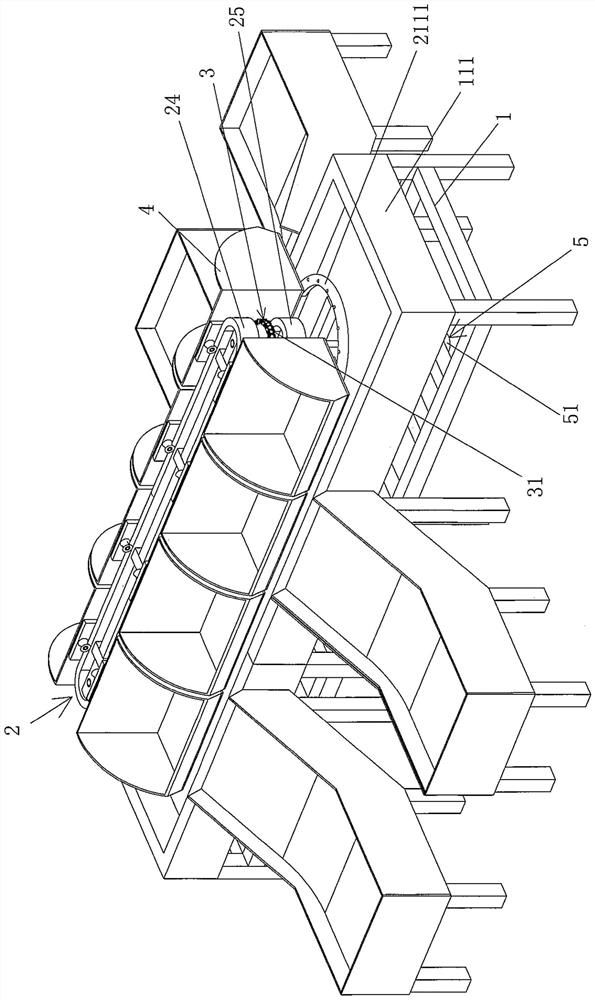

Vertical and horizontal shearing combination production line for high-strength thick steel plates

InactiveCN102490009AMeet the processing technology requirementsIncrease profitOther manufacturing equipments/toolsProduction lineIndependent function

The invention provides a vertical and horizontal shearing combination production line for high-strength thick steel plates based on the advantage of multifunction of an existing vertical and horizontal shearing combination production line, so that vertical shearing and horizontal shearing functions are organically combined, various machining processes are realized, and production requirements on high efficiency and high quality are met. The vertical and horizontal shearing combination production line for the high-strength thick steel plates comprises a vertical shearing line and a horizontal shearing line which are controlled by an electric control system and a hydraulic pneumatic lubricating system, a second uncoiler is arranged on the horizontal shearing line, and a transition bench is arranged between the vertical shearing line and the horizontal shearing line. The vertical shearing line has independent functions of uncoiling, vertical shearing and coiling, the horizontal shearing line has independent functions of uncoiling, leveling, horizontal shearing and stacking, the whole vertical and horizontal shearing combination production line has the functions of uncoiling, leveling, vertical shearing and coiling, leveling and horizontal shearing, multi-strip horizontal shearing and automatic stacking, the requirements of various high-strength thick steel plates on various machining processes are met, the vertical and horizontal shearing combination production line is high in utilization rate, multifunctional and high in automation degree, and the production requirements on high efficiency and high quality are met.

Owner:佛山市南海力丰机床有限公司

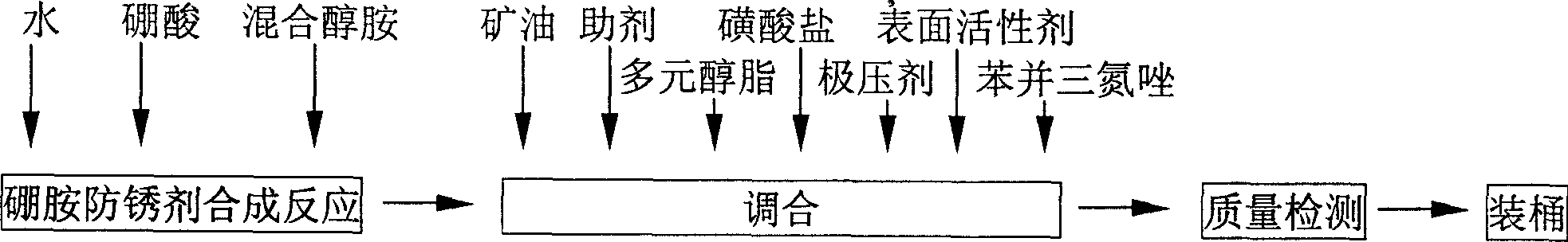

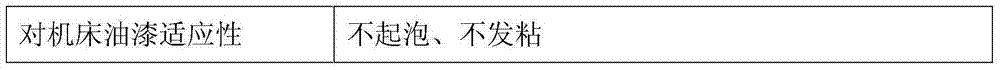

Extreme pressure cutting fuild microemulsion free of chlorine and its preparation method and uses

InactiveCN1730634AReduce emulsificationExtended service lifeLubricant compositionActive agentSurface-active agents

The invention provides a fluoro-free extreme-pressure microemulsion cutting liquid, whose constituents by weight percentage include water 20-40, mixed alkylolamide 6-12, boracic acid 2-6, sulfonates rust-preventing agent 8-12, auxiliary agent 1-5%, anionic surface active agent 8-12, polybasic alcohol 2-6, sulfurized grease 4-10, mineral oil 15-30, benzotrizaole 0.1-0.3. The invention also provides a process for preparing the liquid.

Owner:GUANGZHOU MECHANICAL ENG RES INST

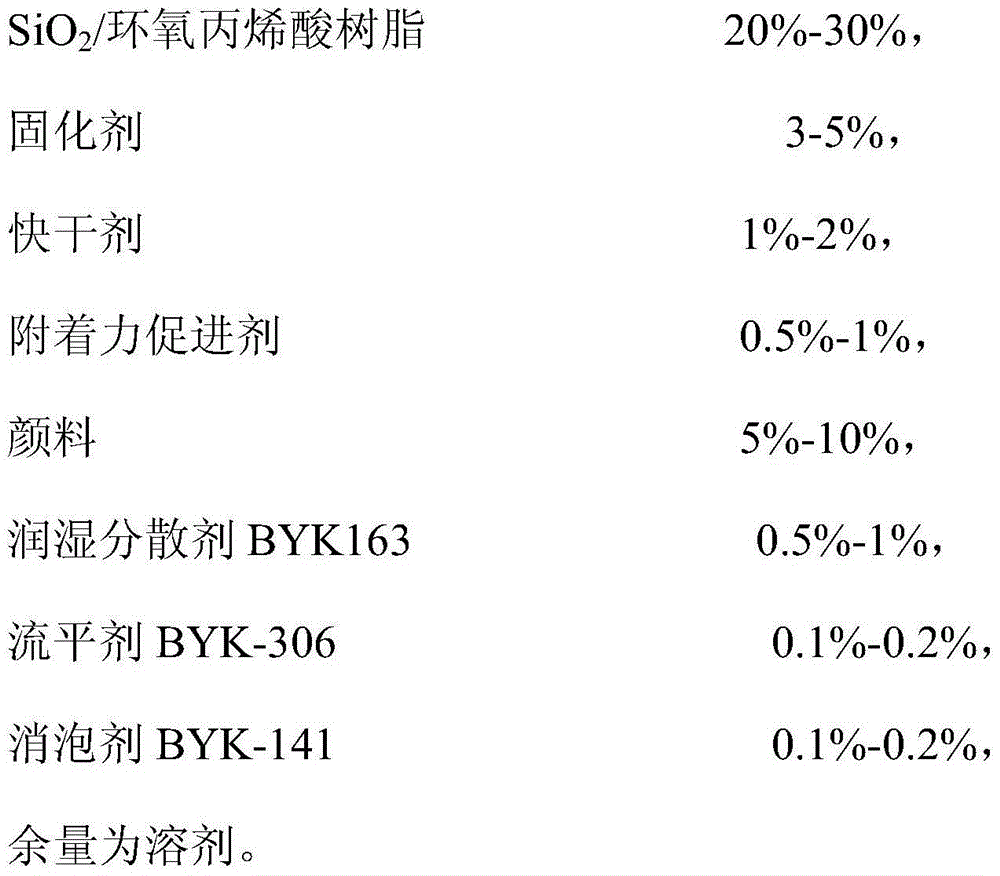

Nanometer modified SiO2/epoxy acrylic acid composite resin, IMD ink and preparation method thereof

InactiveCN104311757AMeet the processing technology requirementsGood flexibilityInksIn situ polymerizationResin-Based Composite

The present invention discloses a nanometer modified SiO2 / epoxy acrylic acid composite resin, an IMD ink and a preparation method thereof. The preparation method comprises: (1) adopting an organic solvent as a co-solvent and adopting tetraethyl orthosilicate as a precursor to prepare a SiO2 sol through alkali-catalyzed hydrolysis condensation polymerization; (2) adopting a vinyl silane coupling agent to carry out surface modification on the nanometer SiO2 to obtain the modified nanometer SiO2 sol; and (3) adopting the modified nanometer SiO2 sol, and carrying out in situ polymerization of the modified nanometer SiO2 sol, an epoxy acrylate and an acrylic acid monomer to prepare the SiO2 / epoxy acrylic acid resin. Compared with the existing ink, the ink of the present invention can not produce the color change for 3 min at the temperature of 300 DEG C, has characteristics of good flexibility, good impact resistance, good adhesion, and good water-acid-alkali-resistance comprehensive performance, and can meet the IMD product processing requirements. In addition, the IMD ink is the special ink for plastic product inside-mold decoration thermal transfer printing technology, and can be widely used for finishing of notebook cases, mobile phone housings, vehicle panels, appliance parts and other plastic products.

Owner:GUANGZHOU UNIVERSITY

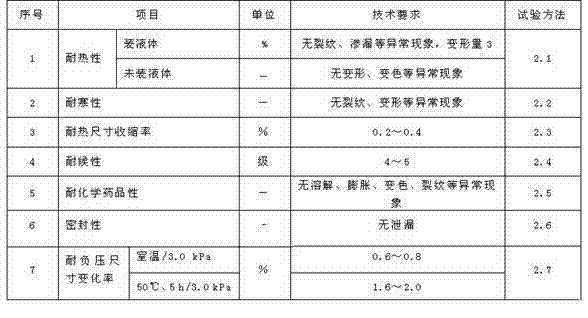

High-rigidity steel belt reinforced polyethylene spiral corrugated pipe and preparation method thereof

ActiveCN104534192AMeet the processing technology requirementsAvoid breakingRigid pipesPropanoic acidPhosphoric acid

The invention discloses a high-rigidity steel belt reinforced polyethylene spiral corrugated pipe and a preparation method thereof. The high-rigidity steel belt reinforced polyethylene spiral corrugated pipe comprises an inner polyethylene pipe, formed steel belts and an outer polyethylene pipe. The formed steel belts are wound around the outer surface of the inner polyethylene pipe at equal intervals and wrapped by the outer polyethylene pipe. The inner polyethylene pipe and the outer polyethylene pipe respectively comprise, by weight, 80-86 parts of high density polyethylene, 8-10 parts of magnesium hydrate, 4-6 parts of compatilizers, 3-4 parts of dibutyltin dilaurate, 2-4 parts of calcium hypophosphite, 2-3 parts of polyoxyethylene, 5-6 parts of polyethylene-graft-maleic anhydride, 7-9 parts of alkyl phosphoric acid, 3-6 parts of superfine talcum powder, 5-7 parts of lustering agents for plastic, 6-8 parts of aluminium-zirconium coupling agents, 4-5 parts of vinyltriethoxysilane, 4-7 parts of beta (3,5 di-tert-butyl-4-hydroxycyclohexyl phenyl ketone) propionic acid octadecyl ester, 5-8 parts of color master batches and 10-12 parts of assistant master batches. According to the high-rigidity steel belt reinforced polyethylene spiral corrugated pipe and the preparation method of the high-rigidity steel belt reinforced polyethylene spiral corrugated pipe, the technology is simple, the production cost is low, pipes are not likely to be fractured, adhesive bonding is firm, the layering problem is not likely to be produced, and using is safe and reliable.

Owner:HANGZHOU TONGYU IND

Marbleized rotational moulding special material and preparation method thereof

ActiveCN102010542AMeet the processing technology requirementsBeautiful appearanceLow-density polyethyleneLinear low-density polyethylene

The invention relates to a rotational moulding special material and a preparation method thereof, in particular to a marbleized rotational moulding special material and a preparation method thereof. The marbleized rotational moulding special material comprises the following components by weight percent: 40-70% of basic resin and 30-60% of marbleized resin, wherein the basic resin is linear low density polyethylene; and the marbleized resin comprises the following components by weight percent: 98% of high density polyethylene, 0.1-1% of pigment, 0.1-0.5% of antioxidant, 0.1-0.5% of light stabilizer, 0.1-0.5% of lubricant and 0.1-1.0% of antistatic agent. In the preparation method in the invention, the differences of the flow rate and melting point of the high density polyethylene melt and low density polyethylene melt are utilized to control the partical size and particle size distribution of the basic resin and marbleized fancy particles and ensure that the marbleized particles are distributed on the product clearly and evenly; and the marbleized particles can be combined with the basic resin well, thus the marbleizing effect can be achieved, the subsequent rotational moulding technology of the product can not be affected and the performance of the product can not be reduced.

Owner:NANJING JULONG SCI&TECH CO LTD +1

Brittle capsule with ginseng characteristic aroma as well as preparation method and application thereof

InactiveCN104172471AHave mechanical strengthMeet the processing technology requirementsTobacco smoke filtersSolventCigarette filter

The invention relates to a brittle capsule with ginseng characteristic aroma as well as a preparation method and an application thereof. The method comprises steps as follows: spice with ginseng characteristic aroma is dissolved in an ester solvent to serve as a core material solution, the core material solution and a wall material solution are co-extruded by dripping equipment to prepare an original capsule, and a target capsule is obtained through dyeing, curing and drying. The wall material solution comprises gelatinizer composition, a filling agent, a plasticizer and a divalent metal chelate agent. The prepared capsule has sufficient mechanical strength and better compactness, uniformity, roundness and stability, one or more capsules are arranged in a cigarette filter stick in a bundling and wrapping manner and pinched to be broken by hands when used, and aroma can be released. The capsule can endow the cigarette with ginseng characteristic aroma and taste, the cigarette aroma is improved, and the cigarette smoking quality is improved.

Owner:CHINA TOBACCO JIANGXI IND CO LTD

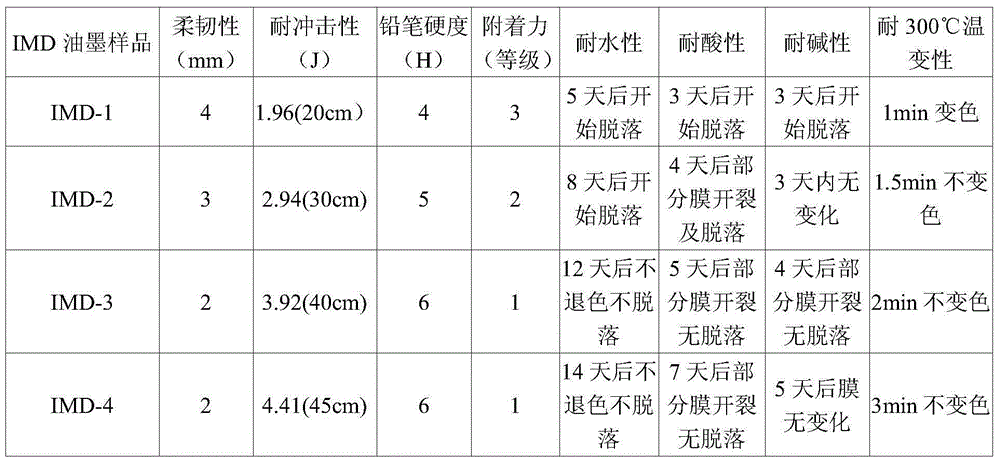

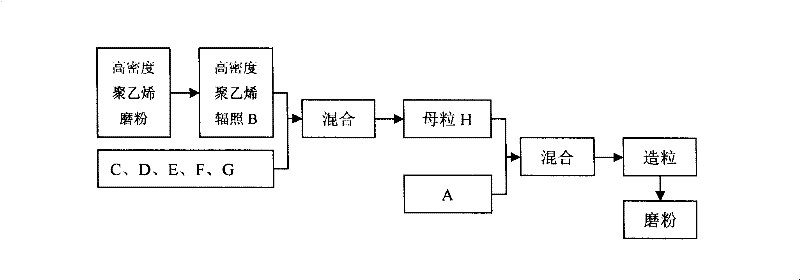

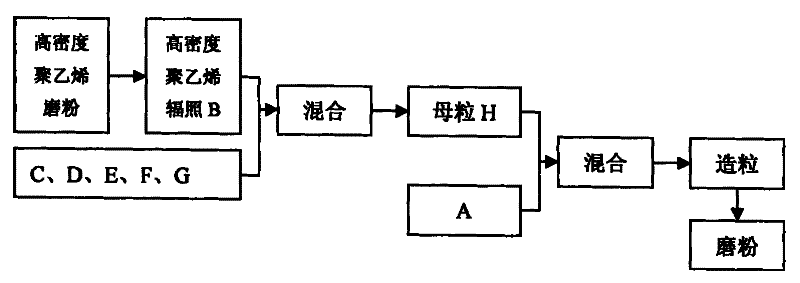

Special-purpose material for high-strength high-ductility high-fluidity rotational molding and preparation method thereof

The invention discloses a high-strength, high-tenacity and high-flow special-purpose material for rotational molding, and a preparation method thereof. The special-purpose material for rotational molding consists of the following components by weight percentages as follows: linear low density polyethylene 60%-90%; irradiated HDPE 9.5%-19.2%; nanometer montmorillonite 0.5%-20%; and a nucleating agent 0%-0.8%. The high strength, high-tenacity and high-flow special-purpose material for rotational molding can meet the requirement of the manufacturing process of rotational molding with the tensile strength reaching 20 to 28.2MPa, the flexural modulus reaching 810MPa to 1460MPa, the impact strength reaching 40KJ / m<2> to 70KJ / m<2>, and the melt flow rate reaching 6.1g / 10 minutes to 14.5g / 10 minutes. The special-purpose material for rotational molding provides a novel raw material with excellent overall performance for the rotational molding field, and is vital in the application field of large rotational molded products and rotational molded products in complicated shapes. The process flow adopted by the invention is simple with controllable cost, and has wide application prospect.

Owner:NANJING JULONG SCI&TECH CO LTD +1

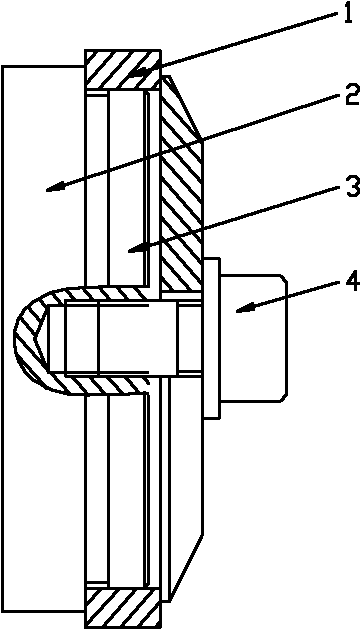

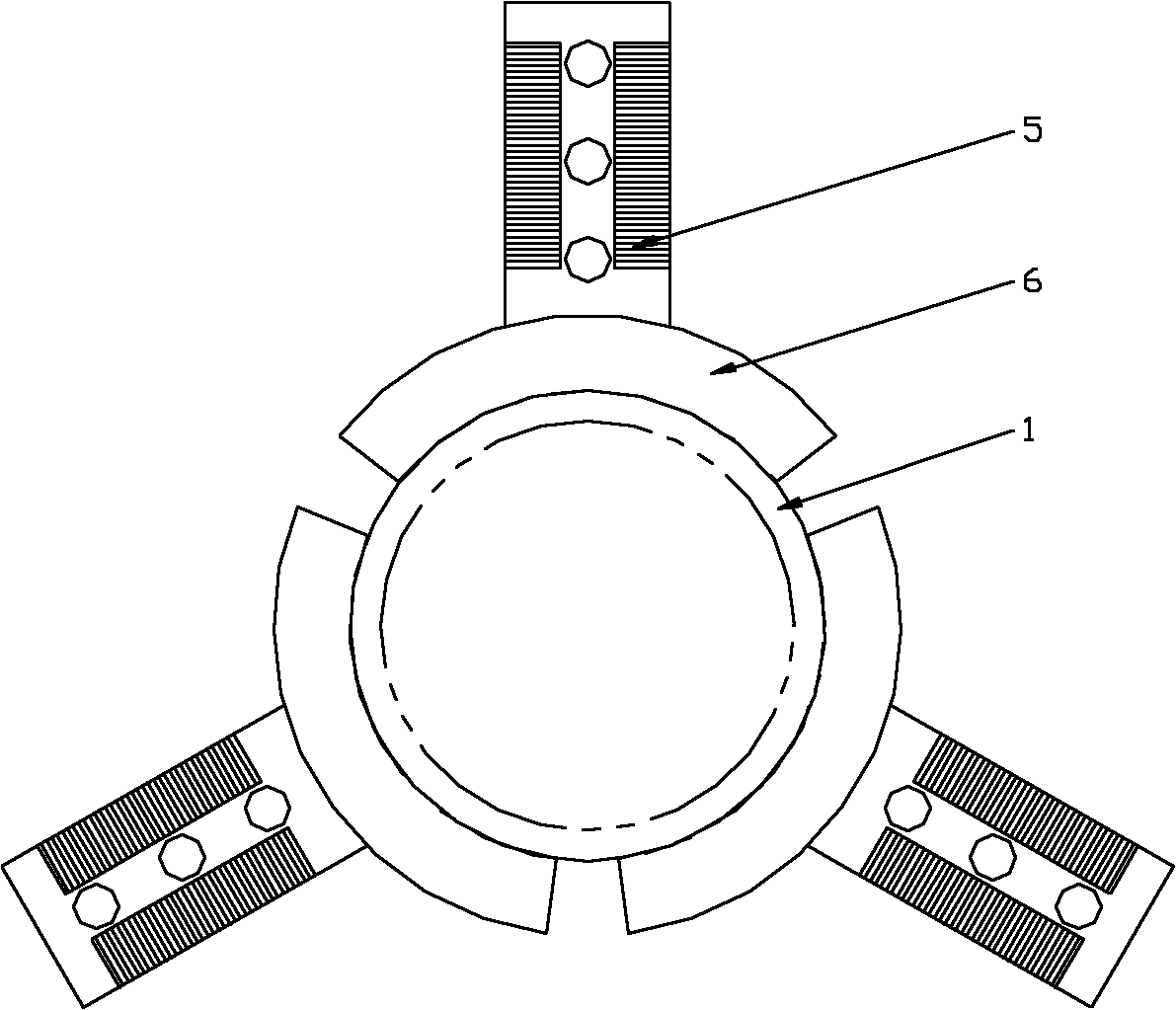

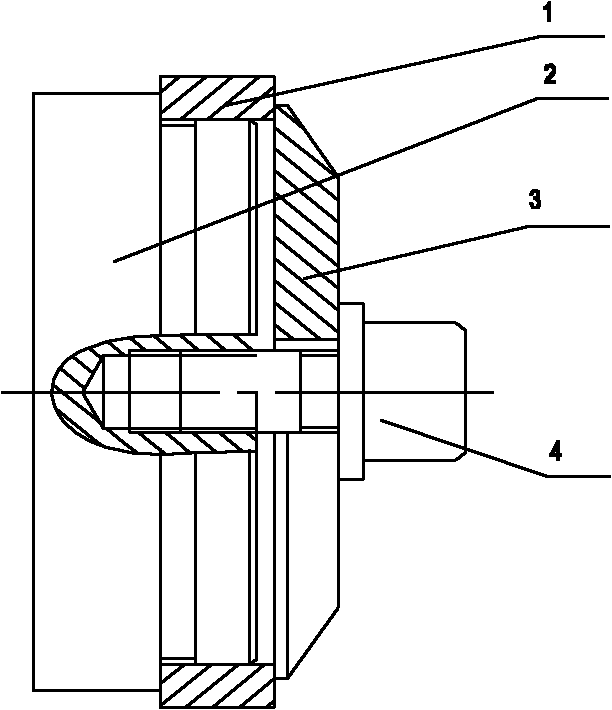

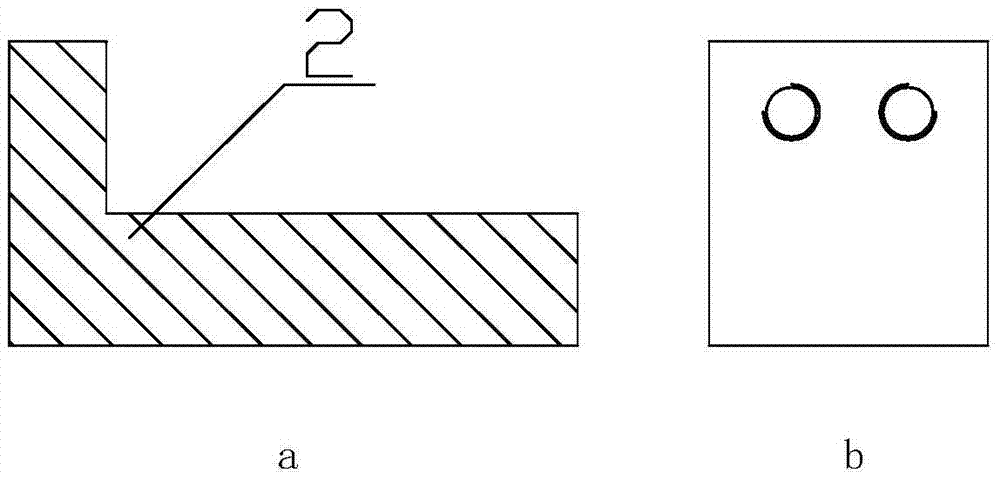

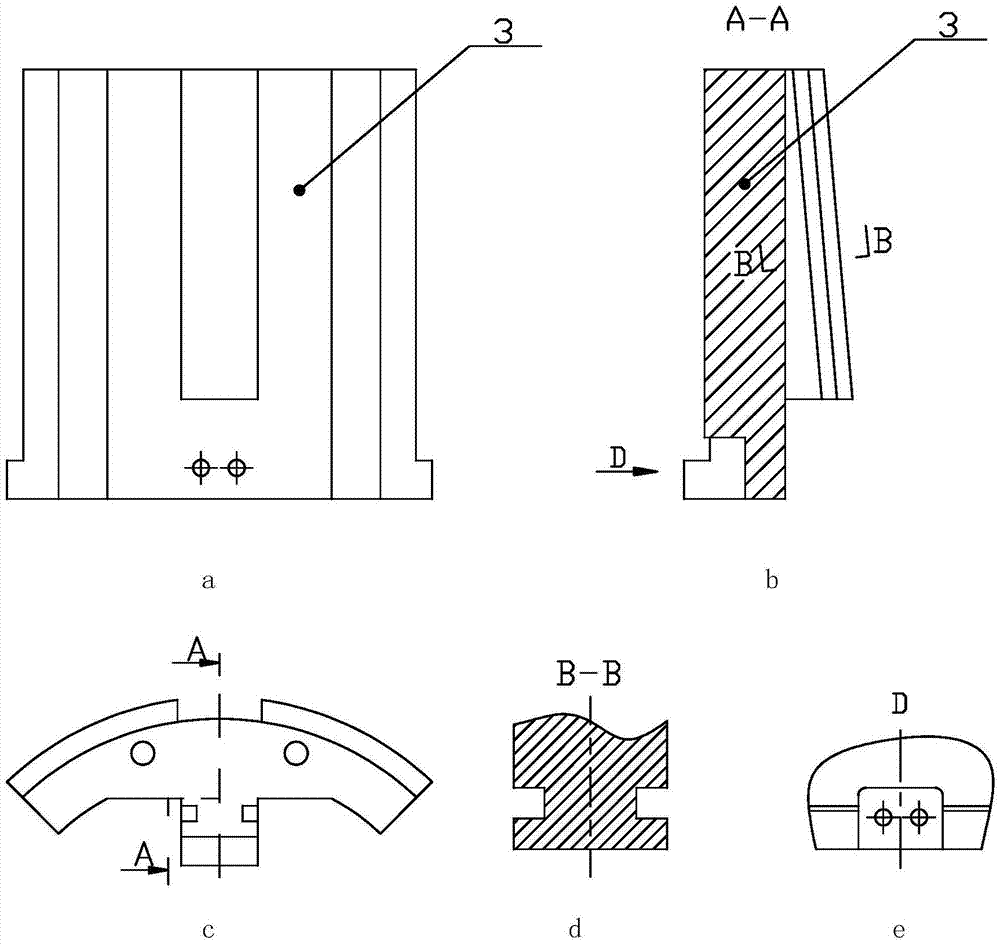

Thin-wall piece lathe clamp

InactiveCN102009363AMeet the processing technology requirementsPositioning apparatusMetal-working holdersThin walledEngineering

The invention discloses a thin-wall piece lathe clamp which is used for solving the problem of workpiece deformation. The thin-wall piece lathe clamp comprises two clamps, namely a turning clamp and a lathe inner hole clamp, wherein the turning clamp is pressed on the end surface of a workpiece through a gland by taking the end surface of the workpiece as a reference surface, and the diameter of the gland is less than the nominal diameter of the workpiece. The lathe inner hole clamp is characterized in that a clamp body tightly clamps the excircle of the workpiece, and the clamp body is welded on a chuck jaw. The invention has the beneficial effects that the thin-wall workpiece does not deform, which satisfies processing technical requirements.

Owner:DALIAN MINGYANG IND

Chloride-free extreme pressure microemulsion cutting fluid and preparation method therefor

InactiveCN103710121AImprove the lubrication effectOvercoming perishable and smellyLubricant compositionHazardous substanceKerosene

Provided is a chloride-free extreme pressure microemulsion cutting fluid. The cutting fluid is prepared from the following raw materials, by weight, 4-5 parts of boric acid, 1-2 benzotriazole, 1-2 parts of octyl decanoic acid, 1-2 parts of lauryl sodium sulfate, 3-4 parts of polyacrylamide, 2-3 parts of urea, 0.8-1.2 parts of span 40, 0.5-1 part of lanthanum nitrate, 12-15 parts of kerosene, 6-8 parts of auxiliary agents and 200 parts of water. The cutting fluid contains no harmful substances of sodium nitrite, phenol, chlorine, mercury and the like, and is safe and environmentally friendly. Through application of boric acid and lanthanum nitrate, the cutting fluid has excellent extreme pressure performances, and workpieces are not easy to damage. The cutting fluid is advantaged by stable emulsification, no delamination, no coacervation, long service time and low cost. The cutting fluid is suitable for processing of a plurality of materials such as cast iron, steel, aluminum, copper, magnesium alloy and the like, and can meet a plurality of processing technology requirements of turning, drilling, grinding, center processing and the like.

Owner:MAANSHAN HENGYI MACHINERY MFG

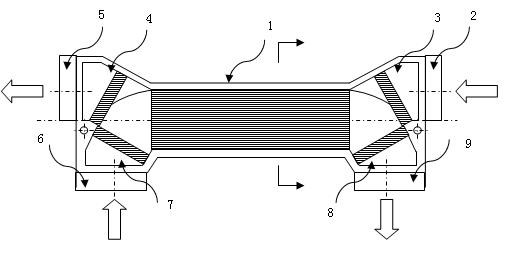

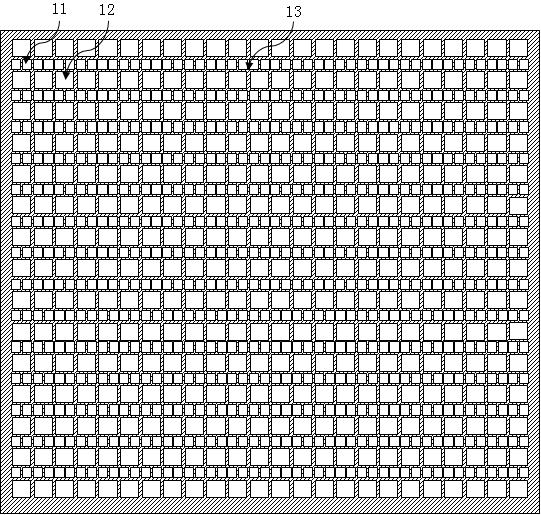

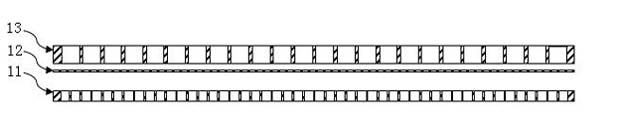

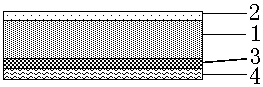

Microchannel heat exchanger

InactiveCN102116545ATaking into account rationalityIncreased forced convection heat transfer coefficientEvaporators/condensersWorking fluidHeat transfer efficiency

The invention discloses a microchannel heat exchanger belonging to the technical field of heat transfer and heat exchange. The microchannel heat exchanger comprises a fluid channel, wherein a working fluid inlet (2) and a refrigerating medium outlet (9) are molded at one end of the fluid channel, and a working fluid outlet (5) and a refrigerating medium inlet (6) are molded at the other end. A heat exchange segment (1) is arranged in the fluid channel and is formed by alternately superposing a refrigerating medium layer (11) and a working fluid layer (13), the refrigerating medium layer (11) and the working fluid layer (13) are isolated through a baffle plate layer (12), and the refrigerating medium layer (11), the baffle plate layer (12) and the working fluid layer (13) are homogenously bonded. A plurality of parallel microchannels are respectively arranged on the refrigerating medium layer (11) and the working fluid layer (13), the heat exchange units are in homogenous structures, and the ratio of the hydraulic diameter of the microchannels of the refrigerating medium layer (11) to the hydraulic diameter of the microchannels of the working fluid layer (13) is 1:(0.25-15). In the invention, according to the use conditions of the heat pump system, a group of optimized hydraulic diameter values of the refrigerating medium microchannels and the working fluid microchannels are obtained through the heat transfer theory and fluid mechanics calculation and analysis. The heat transfer efficiency of microchannel heat exchanger is higher than that of the traditional heat exchange product.

Owner:HANGZHOU SHENSHI ENERGY CONSERVATION TECH

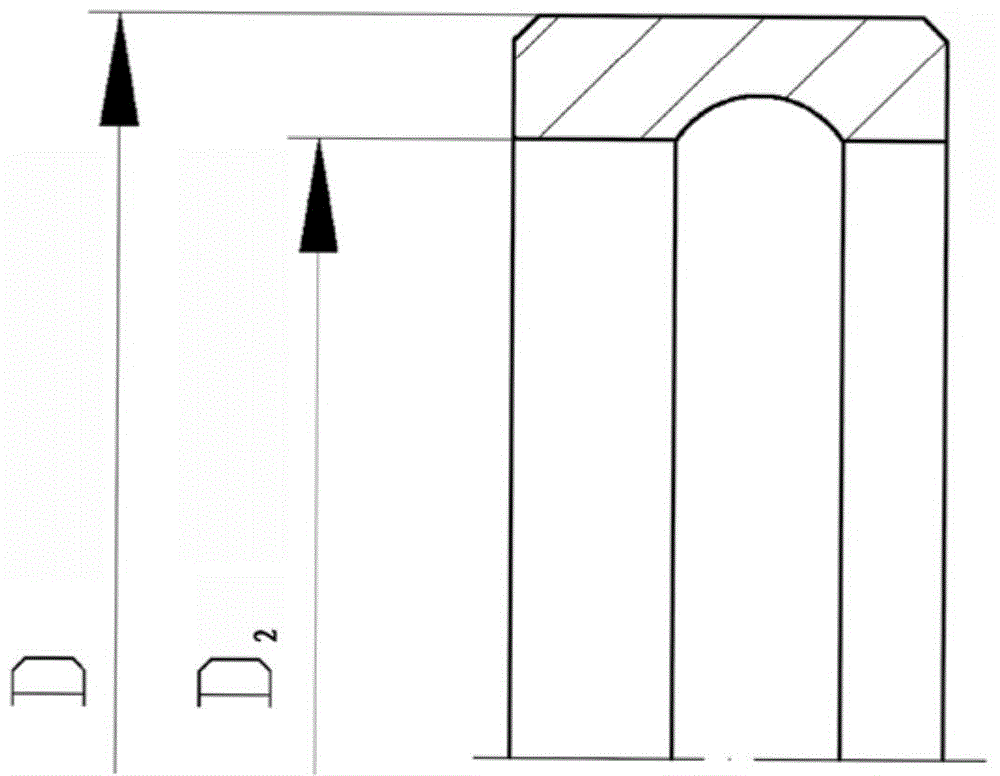

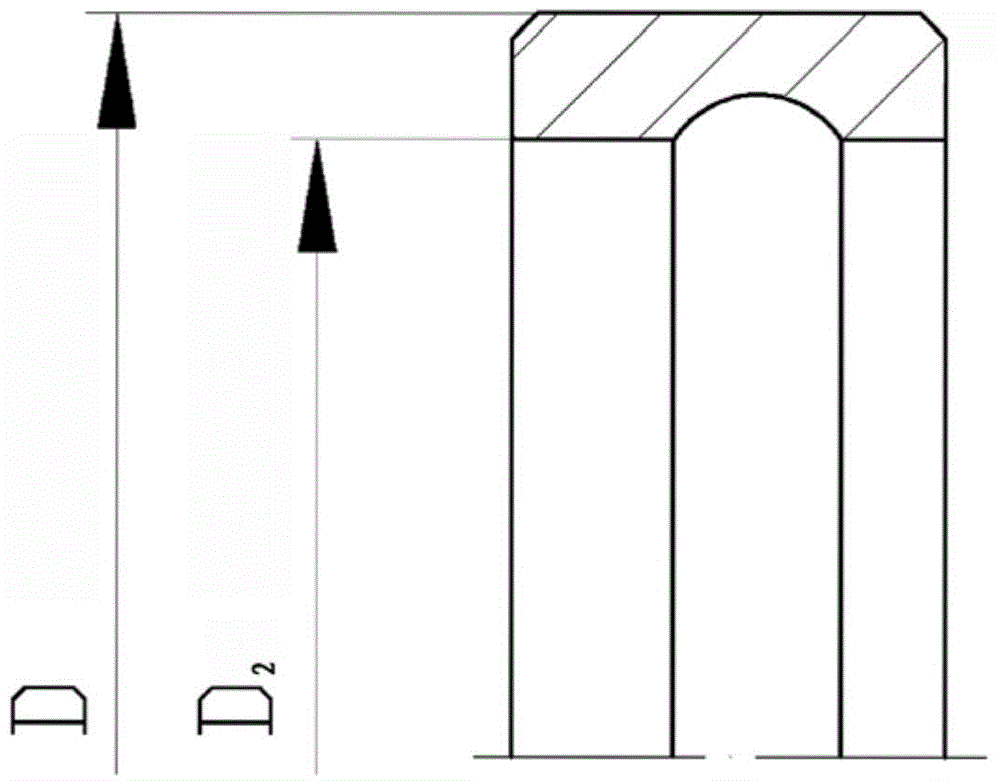

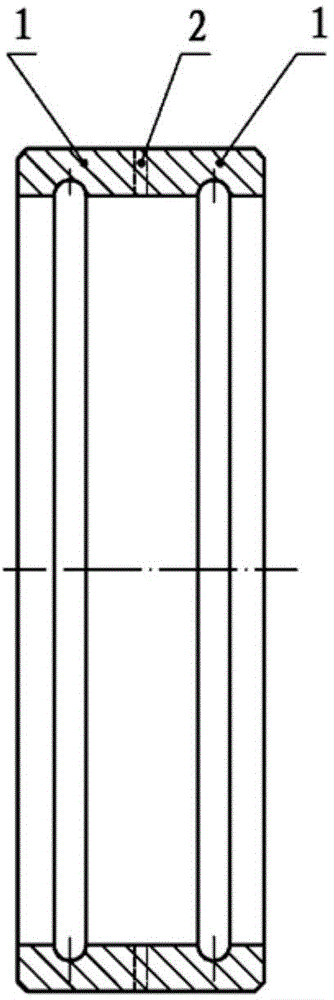

Uniform-section ultra-thin-wall bearing ring turning machining technique

The invention relates to a uniform-section ultra-thin-wall bearing ring turning machining technique. The machining technique is completed on a lathe with a commonly-used three-jaw chuck. According to the shape, the size and the intensity of a bearing ring finished product part, the structure, the shape and the size of a turning part are selected. When the ratio of the outer diameter D2 to the inner diameter D2 of the bearing ring part is smaller than or equal to 1.08, the fact that the intensity of a machined part is improved should be considered. According to the uniform-section ultra-thin-wall bearing ring turning machining technique, the structure is reasonable, the technology is applicable, product quality is good, production efficiency is high, and the requirements for machining performance and detecting performance can be met.

Owner:LUOYANG VSG BEARING

Cracking resistance modified polyethylene material and preparation method therefor

InactiveCN105237853AFormula refiningSolve the problem of poor environmental cracking resistanceLinear low-density polyethyleneElastomer

The invention discloses a cracking resistance modified polyethylene material and a preparation method therefor. The cracking resistance modified polyethylene material is prepared from linear low-density polyethylene, high-density polyethylene, POE (Polyolefin Elastomer) and modified masterbatch. Through polyethylene material modification and a micro cross-linking technology, the problem that polyethylene outer layers of composite metal plastic pipes crack is solved.

Owner:山东融汇管通股份有限公司

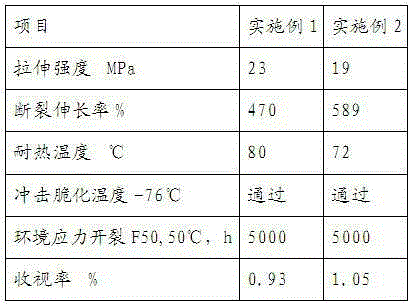

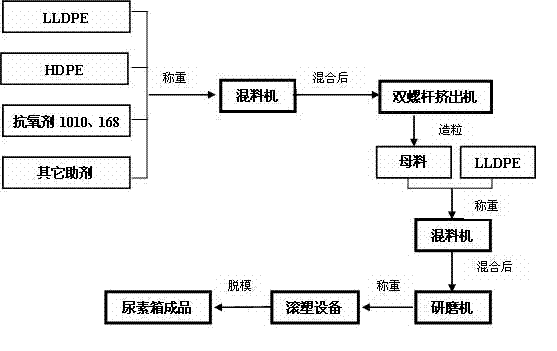

High-strength durable type rotational-molded automobile urea box

The invention relates to a high-strength durable type rotational-molded automobile urea box, belongs to the field of chemical industry, and relates to a material for an automobile urea box. The invention aims at solving the durability problem of the high-strength durable type rotational-molded automobile urea box by changing the urea box material. The urea box master batch is prepared from the following materials in parts by weight: linear low-density polyethylene, high-density polyethylene, POE (Polyoxyethylene), calcium stearate, antioxidant 1010, antioxidant 168, and ethoxyl alkylamine serving as an antistatic agent. The urea box is prepared from the following materials in parts by weight: the master batch and linear low-density polyethylene. According to the invention, the rotational-molded urea box material is advanced in formula and strong in popularization property, and solves the problem that the urea box material has poor environmental stress resistance; the urea box material satisfies the rotational molding processing process requirements; the service life of the manufactured automobile urea box is prolonged by 30%, and the manufactured automobile urea box is applicable to use environments in high-temperature and cold areas; and the preparation method is simple and feasible, and easy for mass production.

Owner:FAW GROUP

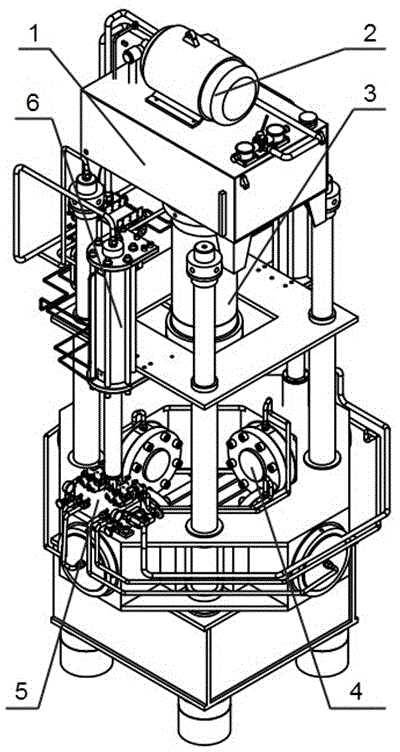

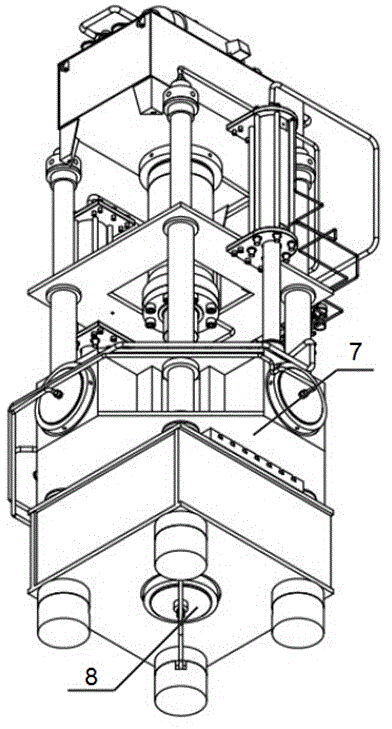

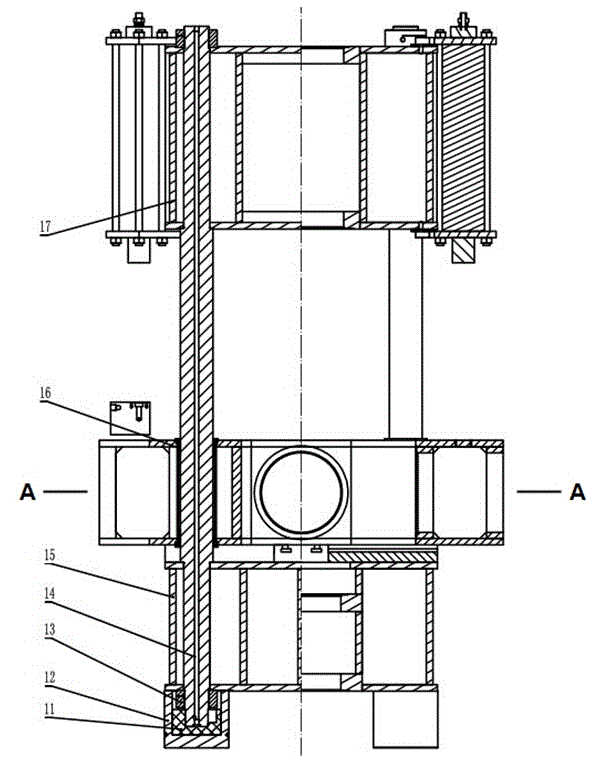

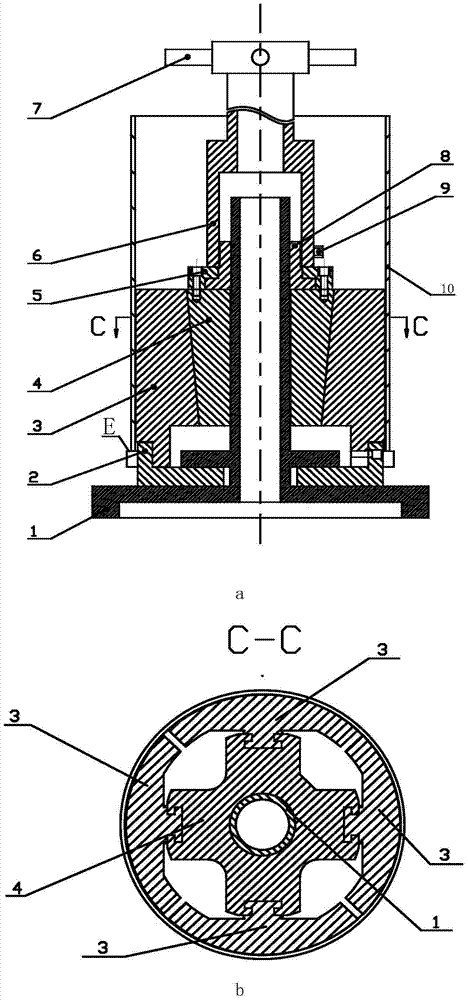

Multi-directional die forging process testing device

InactiveCN104384412AMeet the processing technology requirementsGuarantee forging precisionForging/hammering/pressing machinesForging press drivesHydraulic pumpMulti directional

The invention provides a multi-directional die forging process testing device, and relates to the technical field of machinery manufacturing. The multi-directional die forging process testing device comprises a main machine frame, a hydraulic pump station, an upper main press cylinder, a front oil cylinder, a back oil cylinder, a left oil cylinder, a right oil cylinder, a valve group, a lifting oil cylinder, a movable transverse beam and a lower main press cylinder, wherein the main machine frame comprises a nylon cushion, support leg bodies, a pull rod, a lower transverse beam, an upper transverse beam and a worktable, the upper main press cylinder is fixedly arranged in an inner hole which is formed in the upper transverse beam, the lower main press cylinder is fixedly connected with the lower transverse beam, a piston rod of the lower main press cylinder penetrates through a center hole which is formed in the worktable, the front oil cylinder, the back oil cylinder, the left oil cylinder and the right oil cylinder are respectively and fixedly arranged in inner holes which are formed in the movable transverse beam through flanges, a cylinder body of the lifting oil cylinder is fixedly arranged on the upper surface and the lower surface of the upper transverse beam through screws, lug rings of the lifting oil cylinder are connected with the upper surface of the movable transverse beam, and the hydraulic pump station is connected with the upper main press cylinder, the front oil cylinder, the back oil cylinder, the left oil cylinder, the right oil cylinder, the lifting oil cylinder and the lower main press cylinder through the valve group and pipelines. The multi-directional die forging process testing device has the advantage that the forging press point positions in the horizontal direction are adjusted through the vertical movement of the movable transverse beam.

Owner:YANGZHOU JIANGDU YONGJIAN

Marbleized rotational moulding special material and preparation method thereof

InactiveCN102010542BMeet the processing technology requirementsBeautiful appearanceLow-density polyethyleneLinear low-density polyethylene

Owner:NANJING JULONG SCI&TECH CO LTD +1

Milling inner profile expanding tool of thin-wall variable-wall-thickness cylinder

The invention relates to a milling inner profile expanding tool of a thin-wall variable-wall-thickness cylinder. Limiting blocks are arranged at the lower end of a mandrel in a sleeving manner and embedded between the upper surface of a base of the mandrel and an annular baffle of the mandrel, and an inner conical block is arranged on the mandrel in a sleeving manner. Outer arc blocks are arranged on the inner conical block in a sleeving manner, and the lower end faces of the outer arc blocks are arranged on the upper surfaces of the limiting blocks. A large outer hexagonal nut is arranged on the mandrel in a sleeving manner and attached to the upper end face of the inner conical block. A conduction disc is located on the upper surface of a locating disc at the lower end of the large outer hexagonal nut, and fixedly connected with the inner conical block through a screw. A sleeve is located above the mandrel, and an inner hexagon at the lower end of the sleeve and the large outer hexagonal nut match. The milling inner profile expanding tool is arranged in the spinning cylinder, and correction, rounding and clamping of the spinning cylinder can be achieved; the milling inner profile expanding tool has the beneficial effects that matching precision is high, tool errors are small, and product stress is even in the use process; the rigidity and machining precision of the cylinder are effectively improved; and the technical problems in thin-wall cylinder milling are solved.

Owner:XIAN AEROSPACEMOTOR MACHINE FACTORY

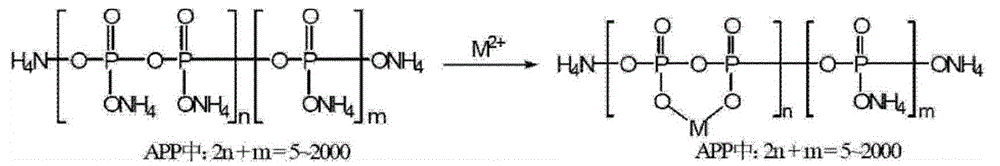

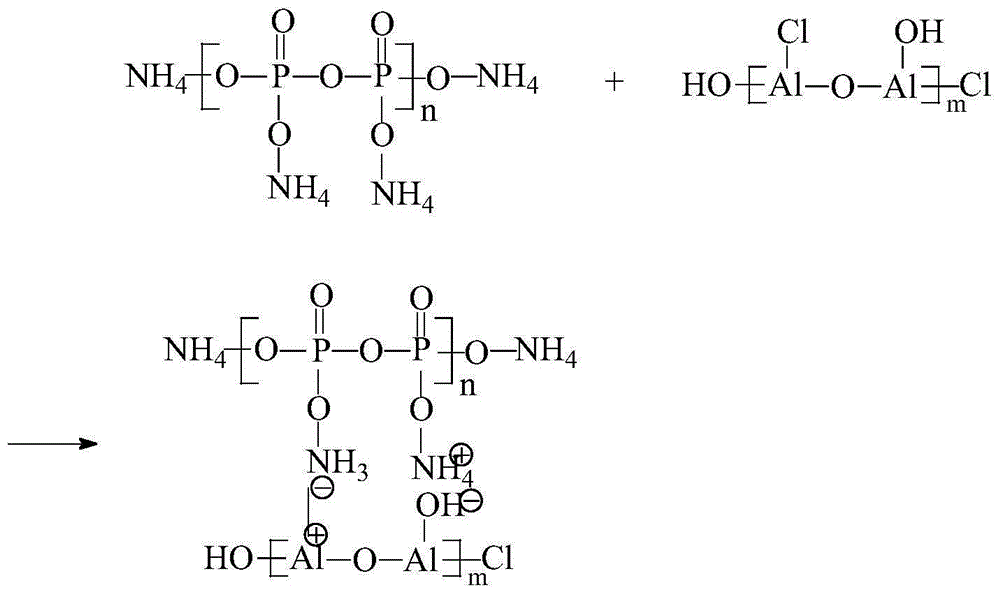

Inorganic polymer modification insoluble halogen-free flame retardant and preparation method and application thereof

The invention discloses an inorganic polymer modification insoluble halogen-free flame retardant, discloses a preparation method of the inorganic polymer modification insoluble halogen-free flame retardant and application in the field of superfine fiber synthetic leather and textile polyurethane coatings, and belongs to the technical field of fire retardants. The inorganic polymer modification insoluble halogen-free flame retardant is a body crosslinked product formed by water-soluble ammonium polyphosphate with the polymerization degree of 20-1000 and inorganic polymer of the polymerization metal salt through a chemical reaction according to the weight ratio being 100:50-100, the solubility in water at the temperature of 25 DEG C is smaller than 0.01 g / 100 ml, and the inorganic polymer modification insoluble halogen-free flame retardant has the advantage of being insoluble, and can meet the requirement of the flame retardant type synthetic leather processing technology. The inorganic polymer modification insoluble halogen-free flame retardant is applied to superthin fiber synthetic leather and textile polyurethane coatings, can be used for preparing the superfine fiber synthetic leather or textiles with the efficient fire resistance, and has the advantages of being small in additive amount, not affecting the characteristics of textiles and the like.

Owner:烟台蓝海博隆超纤新材料有限公司

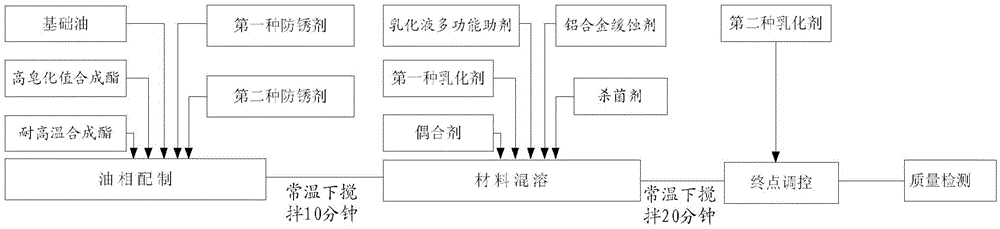

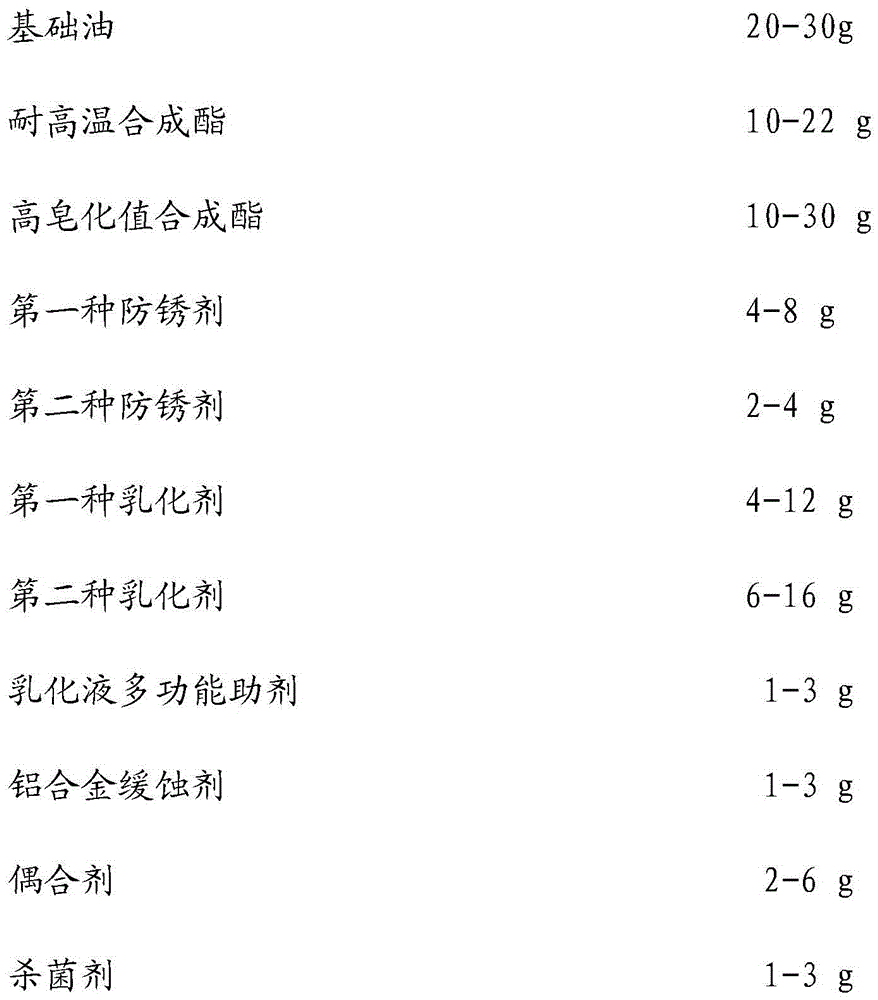

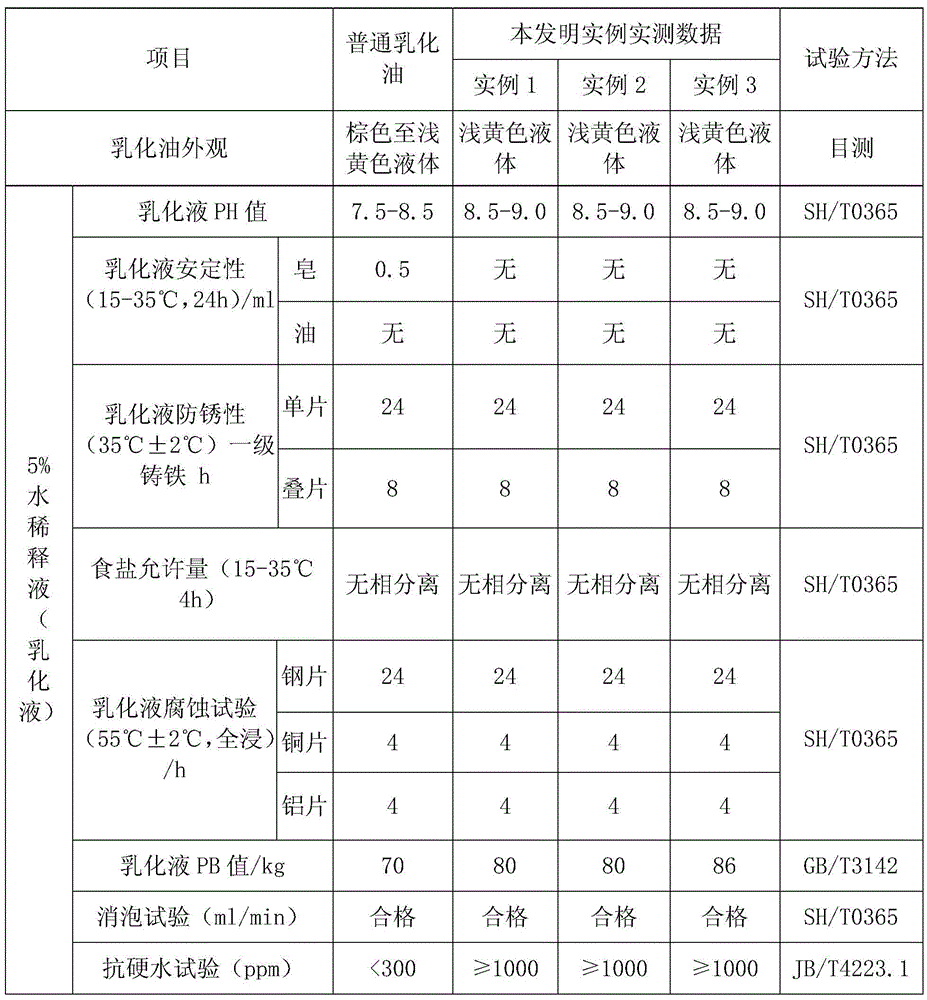

Synthetic ester environment-friendly type aluminum alloy cutting emulsified oil and preparing method thereof

ActiveCN105623809AImprove rust resistanceImprove hard water resistanceAdditivesEmulsionTemperature resistance

The invention relates to the field of cutting fluid for machining, in particular to synthetic ester environment-friendly type aluminum alloy cutting emulsified oil and a preparing method thereof. The synthetic ester environment-friendly type aluminum alloy cutting emulsified oil is prepared from, by weight, 20-30 g of base oil, 10-22 g of high-temperature resistance synthetic ester, 10-30 g of high-saponification value synthetic ester, 4-8 g of a first anti-rusting agent, 2-4 g of a second anti-rusting agent, 4-12 g of an emulsifying agent with the HLB value higher than or equal to 10, 6-16 g of an emulsifying agent with the HLB value lower than or equal to 6, 1-3 g of an emulsion multifunctional assistant, 1-3 g of an aluminum alloy corrosion inhibiting agent, 2-6 g of a coupling agent and 1-3 g of a sterilizing agent.

Owner:DONGGUAN PENGRUN CHEM PROD

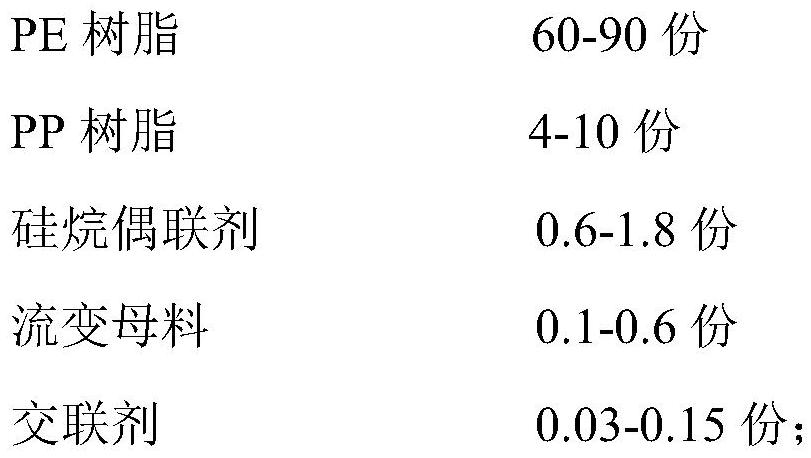

Cross-linked polyethylene insulating material universal for large and small wires of 3KV and below, and preparation method thereof

PendingCN112375284AExtrusion stabilityEasy to processPlastic/resin/waxes insulatorsPolymer sciencePtru catalyst

The invention discloses a cross-linked polyethylene insulating material universal for large and small lines of 3KV and below, and a preparation method thereof. The cross-linked polyethylene insulatingmaterial comprises PE resin, PP resin, a silane coupling agent, a rheological master batch, a cross-linking agent and a catalyst, wherein extruding by a double-step screw, extruding granulation by asingle screw, conveying with water, drying and packaging are performed to obtain a finished product. According to the cross-linked polyethylene insulating material universal for large and small linesof 3KV and below, and the preparation method thereof, the PE resin and the PP resin are compounded to improve the problem of unqualified thermal shrinkage of the small wire, the reaction rate is reduced and the extrusion processability of the small-wire-diameter cable is optimized through the vinyltrimethoxyethoxysilane, the dibutyltin dilaurate catalyst can catalyze a hydrolytic condensation reaction of the grafted material A and water to generate a three-dimensional reticular structure, and the obtained silane cross-linked polyethylene insulating material has more excellent processability, is universal for large and small lines, is stable in extrusion and good in surface extrusion, and meets JB / T 10437-2004 standard requirements and customer processing technology requirements.

Owner:SUZHOU HENGLI COMM MATERIAL

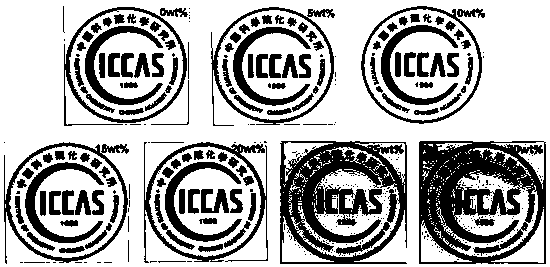

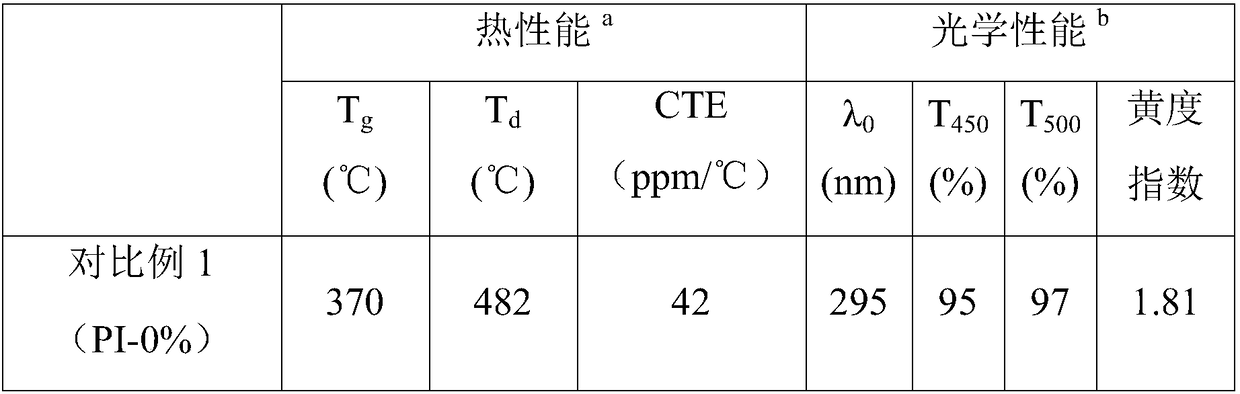

High-transparence low-expansibility polyimide film as well as preparation method and application thereof

The invention relates to a high-transparence low-expansibility polyimide film as well as a preparation method and the application thereof, belongs to the technical field of polyimide films, and aims at solving the problem that a polyimide film prepared by the conventional doping method cannot have both high light transmittance and low thermal expansion coefficients. The preparation method comprises the following steps: uniformly mixing a polyimide resin solution and a perhydropolysilazane solution to obtain a perhydropolysilazane-doped polyimide resin solution; coating the surface of a base plate with the perhydropolysilazane-doped polyimide resin solution; hydrolyzing the perhydropolysilazane into silica; drying the film; curing to obtain the silica-doped polyimide hybrid film. The polyimide film prepared according to the abovementioned method is outstanding in optical performance, high in light transmittance rate of a visible area, and obviously low in thermal expansion coefficient;the polyimide film can be used as a flexible polymer base plate material to be applied to production of photoelectric devices.

Owner:INST OF CHEM CHINESE ACAD OF SCI +1

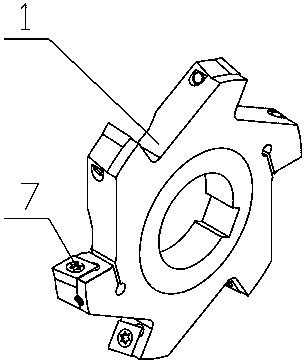

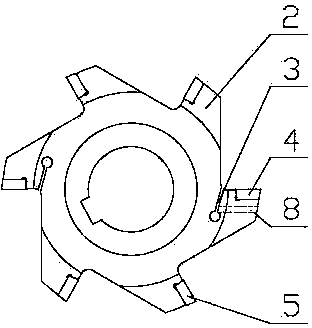

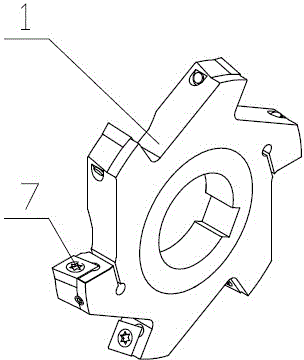

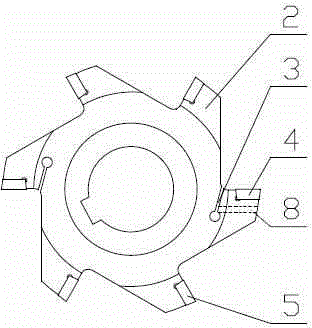

Rough-finish multi-blade boring tool

The invention discloses a rough-finish multi-blade boring tool comprising a tool body (1), rough boring blades (5) and finish boring blades (4). The tool body (1) at least comprises two radial projections (2). At least one radial projection (2) is provided with one finish boring blade (4), and an open slot (3) forms at the junction of each radial projection and the tool body (1). Each radial projection (2) with one open slot (3) is provided with a threaded through hole (8) which fits an adjusting screw (6). Each rough boring blade (5) is mounted on the corresponding radial projection (2) with no open slot (3) through a screw (7). Each finish boring blade (4) is mounted on the corresponding radial projection (2) with one open slot (3) through another screw (7). Horizontal plane of the finish boring blades (4) is lower than the horizontal plane of the rough boring blades (5). The rough-finish multi-blade boring tool is available for simultaneous completion of rough boring and finish boring, so that work time is reduced and work efficiency is improved.

Owner:NINGBO CHUANJINGYU MECHANICAL TECH DEV

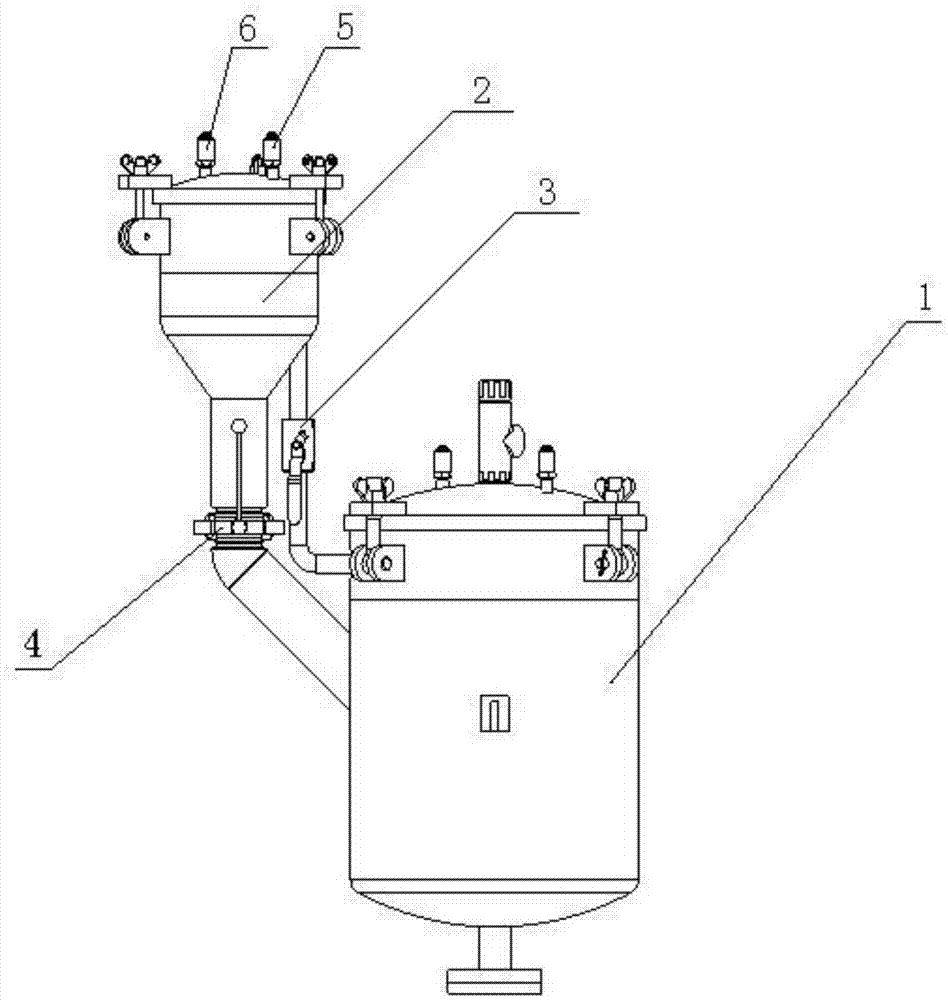

Micropressure type traditional Chinese medicine decoction machine with secondary medicine addition device

ActiveCN105434171AAvoid churnEasy fillingPharmaceutical product form changeDomestic articlesTraditional Chinese medicinePressure sensor

The invention discloses a micropressure type traditional Chinese medicine decoction machine with a secondary medicine addition device, and belongs to the field of pharmaceutical apparatuses. The decoction machine comprises a main container, a secondary medicine feeding container, a pressurizing valve, a medicine feeding valve, a temperature sensor and a pressure sensor. The secondary medicine feeding container is fixedly connected with the main container in a sealed mode through two pipelines, wherein one pipeline is provided with the pressurizing valve, and the other pipeline is provided with the medicine feeding valve. The temperature sensor is arranged on the top of the secondary medicine feeding container. The temperature sensor is connected with the pressurizing valve and the medicine feeding valve through circuits respectively. The pressure sensor is arranged on the top of the secondary medicine feeding container and connected with the pressurizing valve and the medicine feeding valve through circuits respectively. Compared with the prior art, the working procedure of carrying out decoction and feeding successively in the micropressure state in the traditional Chinese medicine decoction process is achieved, the requirement of the traditional processing technology of traditional Chinese medicine is met, the condenser effect is achieved, effective constituent in steam is prevented from running off, medicine liquid is cooled as soon as possible, and filling is facilitated.

Owner:JILIN ACAD OF AGRI MACHINERY

Rough and fine composite multi-edged boring tool

Owner:NINGBO CHUANJINGYU MECHANICAL TECH DEV

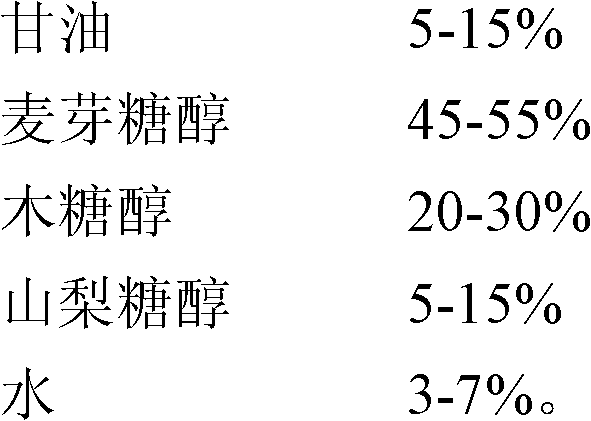

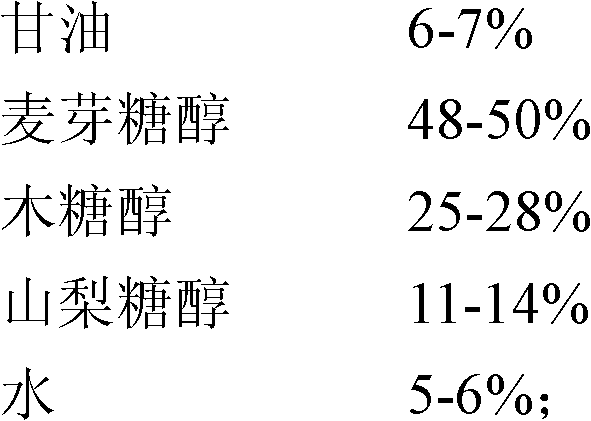

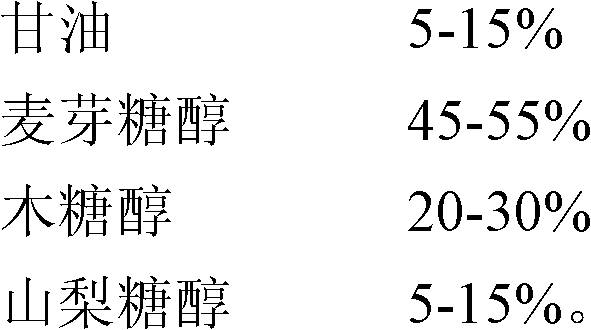

Compound moisturizing agent for foods and preparation method thereof

The invention discloses a compound moisturizing agent for foods. The compound moisturizing agent consists of the following components in percentage by weight: 5 to 15 percent of glycerol, 45 to 55 percent of maltitol, 20 to 30 percent of xylitol, 5 to 15 percent of sorbitol and 3 to 7 percent of water. The invention also discloses a method for preparing the compound moisturizing agent for foods. The method comprises the following steps of: (1) adding solid materials such as the maltitol, the xylitol and the sorbitol into water in a ratio, heating for dissolution, adding the glycerol, and uniformly stirring; and (2) filtering the obtained mixture, ensuring that insoluble matters in the filtrate is less than 10 milligrams / kilogram, and concentrating the filtrate until the water in the concentrated solution is 3 to 7 weight percent. The compound moisturizing agent for foods can be directly added into various foods according to requirements of processing technologies, and has a good moisturizing property, low sugar, low heat and rich health-care effects; and compound moisturizing agent meets the requirements of food processing technologies, and is convenient to use.

Owner:ZHEJIANG HUAKANG PHARMA

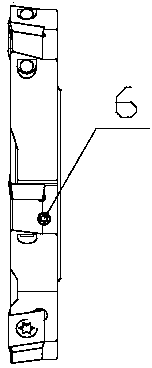

Object circulation conveying device with selectable stations

PendingCN112896970AReduce power consumptionMeet the processing technology requirementsMechanical conveyorsEngineeringAssembly line

The invention discloses an object circulation conveying device with selectable stations, and belongs to the technical field of light industrial product assembly line production equipment. The object circulation conveying device comprises a rack table, a turnover basket conveying guide rail mechanism, a turnover basket conveying mechanism, a set of turnover baskets and a turnover basket operation driving mechanism, wherein a rack table is arranged at the upper part of the rack; the turnover basket conveying guide rail mechanism is arranged on the rack table; the turnover basket conveying mechanism is arranged on the turnover basket conveying guide rail mechanism; the turnover baskets are connected with the turnover basket conveying mechanism and form a rolling pair with the turnover basket conveying guide rail mechanism; and the turnover basket operation driving mechanism is arranged at one end of a rack and connected with the turnover basket conveying mechanism, and the device is characterized by further comprising a set of turnover basket cavity bottom plate opening and closing control mechanisms which are arranged on the turnover basket conveying guide rail mechanism. One side of a turnover basket cavity bottom plate is hinged to the lower edge of a turnover basket back plate, the other side of the turnover basket cavity bottom plate forms a free side for opening or closing the bottom of a turnover basket cavity, and object receiving mechanisms are arranged at the positions corresponding to the front side and the rear side of the rack. Power consumption is reduced, and electric energy is saved. And the processing technology requirements of various types of small-batch garments are met, and flexible fast reverse production is embodied.

Owner:江苏优易智能科技有限公司

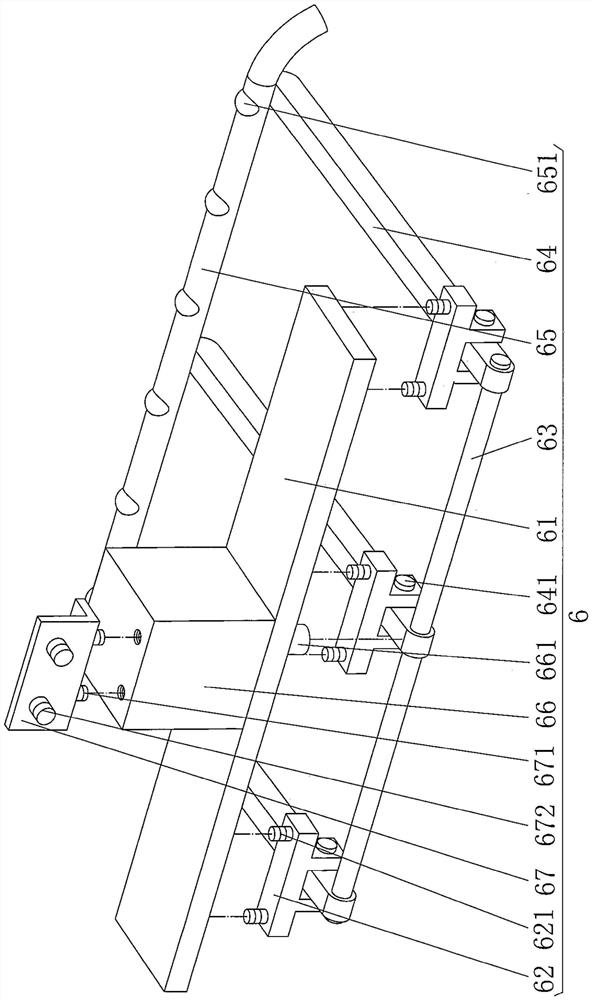

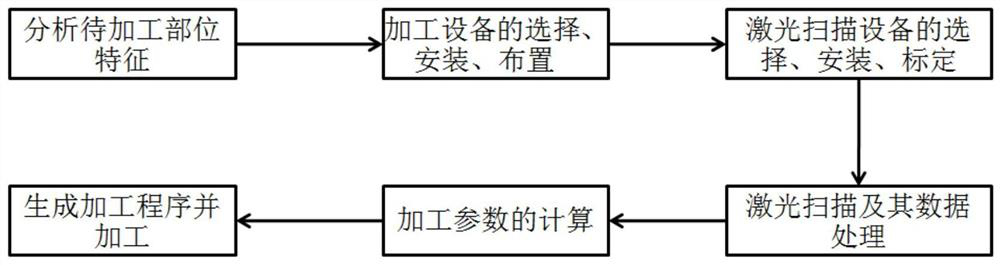

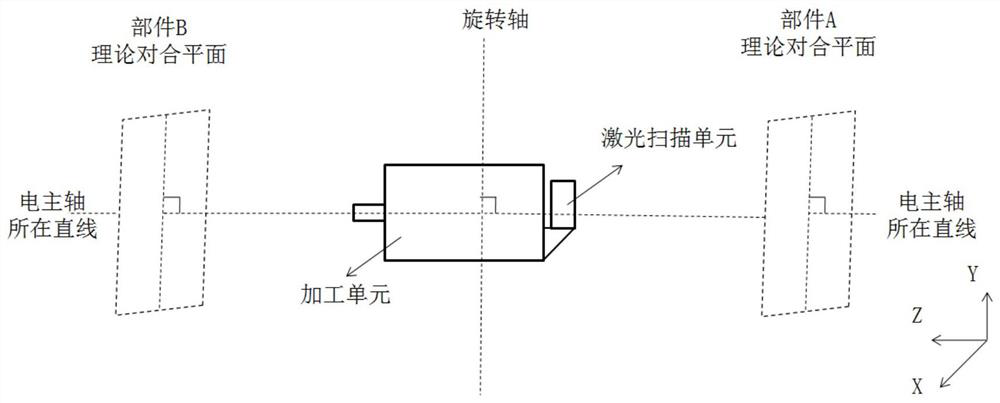

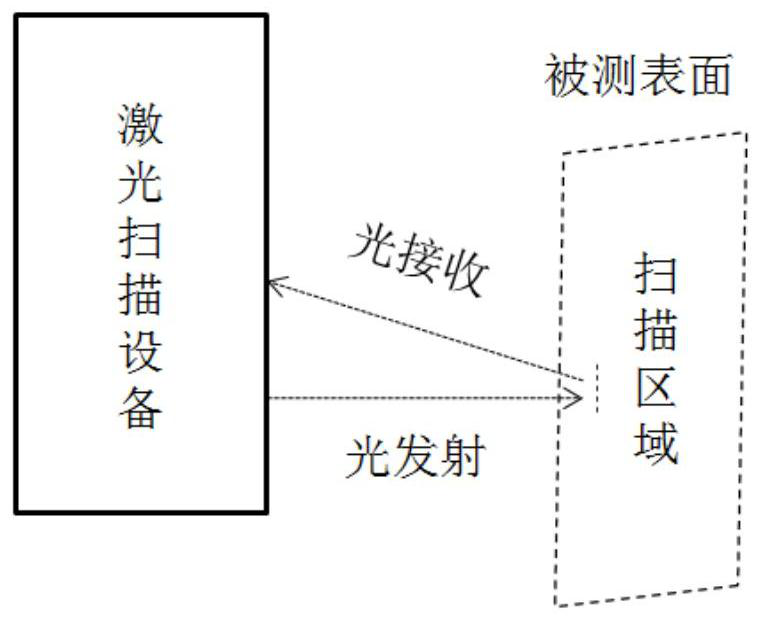

Assembly butting part end face automatic finishing process method

ActiveCN111702490ARealize visual displayMeet the processing technology requirementsOther manufacturing equipments/toolsAirplaneProcess engineering

The invention belongs to component butting assembly technology, and relates to a butting part end face automatic finishing process method. The invention combines laser scanning equipment with a numerical control machine tool according to the production requirements for the coordinated assembly of assembly bonding surfaces in an aircraft component production and assembly site, obtains three-dimensional graphics by scanning the processing surfaces, and automatically calculates the processing volume by applying a software algorithm to generate a processing program, so as to complete the automaticprocessing of the bonding surfaces.

Owner:SHAANXI AIRCRAFT CORPORATION

Steel belt and reinforced polyvinyl chloride helical bellow and production method thereof

ActiveCN104500874AMeet the processing technology requirementsAvoid breakingFlexible pipesRigid pipesO-Phosphoric AcidAntioxidant

The invention discloses a steel belt and reinforced polyvinyl chloride helical bellow and a production method thereof. The helical bellow comprises an inner polyvinyl chloride tube, a molded steel belt and an outer polyvinyl chloride tube. The molded steel belt is wound between the inner polyvinyl chloride tube and the outer polyvinyl chloride tube at equal intervals. Each of the inner polyvinyl chloride tube and the outer polyvinyl chloride tube comprises, by weight, 180-200 parts of polyvinyl chloride resin, 10-12 parts of nano-silica, 5-6 parts of isocyanate compatilizers, 4-7 parts of dibutyltin maleate, 5-7 parts of cubic boron nitride micro powder, 8-12 parts of calcium stearate, 2-4 parts of potassium hypophosphite, 5-7 parts of epoxidized soybean oil, 5-6 parts of maleic anhydride grafted polyethylene, 7-9 parts of alkyl phosphoric acid, 8-10 parts of polyethylene wax, 7-8 parts of jade powder, 6-8 parts of conductive black, 7-11 parts of aluminum-zirconium coupling agents, 4-5 parts of tribasic lead sulfate, 8-14 parts of antioxidants CA, 10-14 parts of color master batches and 7-9 parts of assistant master batches. The steel belt and reinforced polyvinyl chloride helical bellow and the production method thereof have the advantages of simple process, low production cost, less proneness to fracture during bellow forming, firmness in adhesion, less proneness to layering and safety and reliability in use.

Owner:南通皇城新型建材有限公司

Oil-saving rotational molding diesel oil tank material and preparation method thereof

ActiveCN101260209BMeet the processing technology requirementsSimple manufacturing methodUnderstructuresMachines/enginesLinear low-density polyethyleneAntioxidant

The invention discloses an oil-saving rotational-molding diesel oil tank material and a preparation method thereof. The formula of the oil-saving rotational-molding diesel oil tank material comprises the components in mass percent that: 50 percent of linear low density polyethylene, 21 to 47.7 percent of irradiation high density polyethylene; 1 to 10 percent of tourmaline powder, 1 to 10 percent of negative ion powder, 0.1 to 5 percent of antistatic agent, 0.1 to 2 percent of antioxidant and 0.1 to 2 percent of flatting agent. Moreover, the oil-saving rotational-molding diesel oil tank material, which meets the technological requirements of rotational-molding processing, can reach the effect of saving 2 to 5 percent of oil as compared with the prior diesel oil tank when made into an automobile diesel oil tank; moreover, because the preparation method is simple and easy to implement, the oil-saving rotational-molding diesel oil tank material is easy to realize batch production.

Owner:NANJING JULONG SCI&TECH CO LTD +1

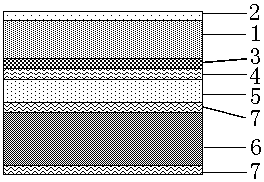

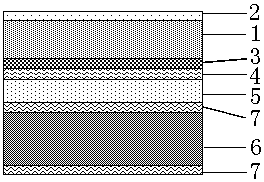

An aluminized film and film-coated color steel plate with wire drawing effect

ActiveCN107538864BHigh surface finishLow yield pointVacuum evaporation coatingSputtering coatingResin coatingSteel plates

The invention provides an aluminized film with wire drawing effects and a film-coated colored steel plate. The aluminized film comprises a PET wire drawing film, the upper surface of the PET wire drawing film is provided with a scratch-resistant coating, the lower surface of the PET wire drawing film is provided with a vacuum aluminized layer and the surface of the vacuum aluminized layer is provided with an adhesion-enhanced resin coating. The aluminized film has metal wire drawing effects, production processes are simplified, economy and practicability are obtained and environmental influence caused by a PVC film is avoided. The film-coated colored steel plate comprises a cold-roll steel sheet and the aluminized film which has wire drawing effects and is bonded to the cold-roll steel sheet through a composite adhesive layer. The composite adhesive layer provides good high temperature resistance and water boiling resistance to the film-coated colored steel plate and satisfies processing and use requirements of the film-coated colored steel plate. Through change of the anti-rust paint color of the surface of the cold-roll steel sheet and combination with the tungsten steel color ofthe aluminized film with wire drawing effects, the appearance of different colors is realized through color superposition.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com