Special-purpose material for high-strength high-ductility high-fluidity rotational molding and preparation method thereof

A high-fluidity, high-strength and high-toughness technology, applied in the chemical industry, can solve the problems of less special materials for rotomolding, brittle products, and reduced material toughness, etc., and achieve the effects of excellent comprehensive performance, simple process flow and broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] formula:

[0045] (A) linear low-density polyethylene PE500U of 60% by mass;

[0046] (B) irradiated high-density polyethylene PE5000S with a mass percentage of 19.2%;

[0047](C) Nano-montmorillonite DK-4 of 20% by mass;

[0048] (D) MDBS TM-5 with a mass percentage of 0.8%.

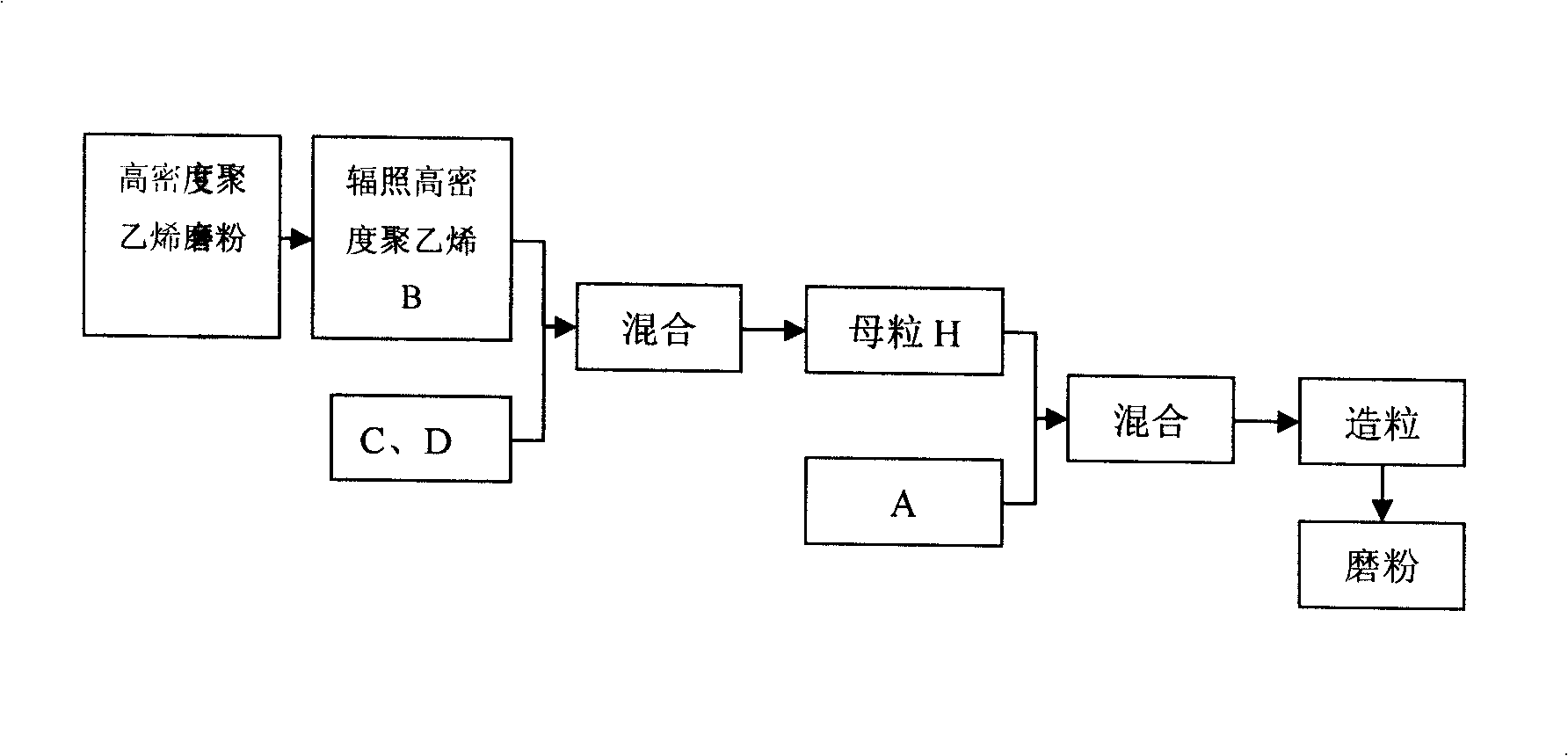

[0049] The above-mentioned components are prepared by the following process methods for rotomolding special materials:

[0050] 1. Raw material processing

[0051] Under the process conditions of rotating speed of 5000 rpm and grinding disc temperature of 65°C, grind high-density polyethylene PE5000S in a plastic mill into a powder of 35 mesh or more, put it in a closed container, and heat it to 60°C At the same time, the air in the container was replaced by ozone, and the ultraviolet irradiation device was turned on for 20 minutes to obtain irradiated high-density polyethylene PE5000S.

[0052] 2. Masterbatch manufacturing

[0053] Pour the B, C and D weighed according to the above ratio i...

Embodiment 2

[0060] formula:

[0061] (A) linear low-density polyethylene PE500U of 90% by mass;

[0062] (B) 9.5% by mass irradiated high-density polyethylene PE5000S;

[0063] (C) Nano-montmorillonite DK-4 with a mass percentage of 0.5%.

[0064] The above-mentioned components are prepared by the following process methods for rotomolding special materials:

[0065] 1. Raw material processing

[0066] Under the process conditions of rotating speed of 3200 rpm and grinding disc temperature of 50°C, grind high-density polyethylene PE5000S in a plastic mill into a powder of 35 mesh or more, put it in a closed container, and heat it to 40°C , and at the same time replace the air in the container with ozone, turn on the ultraviolet irradiation device and treat for 10 minutes to obtain irradiated high-density polyethylene PE5000S.

[0067] 2. Masterbatch manufacturing

[0068] Pour the B and C weighed according to the above ratio into a plastic mixer, fully mix under the process conditions...

Embodiment 3

[0075] formula:

[0076] (A) 65% linear low density polyethylene PE500U by mass percent;

[0077] (B) irradiated high-density polyethylene PE5000S with a mass percentage of 27.65%;

[0078] (C) Nano-montmorillonite DK-4 of 7% by mass;

[0079] (D) MDBS TM-5 with a mass percentage of 0.35%.

[0080] The above-mentioned components are prepared by the following process methods for rotomolding special materials:

[0081] 1. Raw material processing

[0082] Under the process conditions of rotating speed of 4000 rpm and grinding disc temperature of 55°C, grind high-density polyethylene PE5000S in a plastic mill into a powder of 35 mesh or more, put it in an airtight container, and heat it to 50°C At the same time, the air in the container was replaced by ozone, and the ultraviolet irradiation device was turned on for 20 minutes to obtain irradiated high-density polyethylene PE5000S.

[0083] 2. Masterbatch manufacturing

[0084] Pour the B, C and D weighed according to the abo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com