Milling inner profile expanding tool of thin-wall variable-wall-thickness cylinder

A technology of milling and changing wall thickness, applied in the direction of expanding the mandrel, etc., can solve the problem of low machining accuracy, and achieve the effects of uniform force on the product, small tooling error, and improved rigidity and machining accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

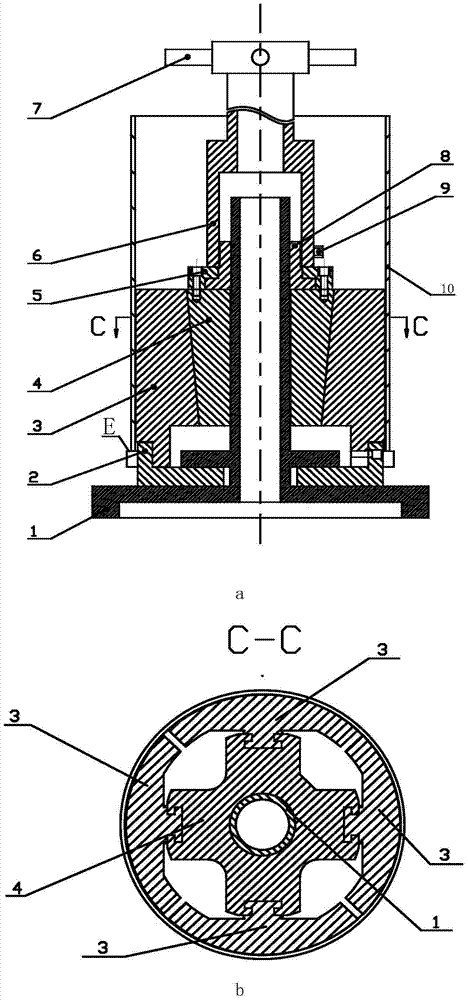

[0031] This embodiment is an inner brace used for milling at the thickened annular zone of a φ750×δ3×1450 thin-walled cylinder. The wall thickness at the thickened ring is 6 mm, and the distance from one end of the cylinder is 38 mm. There is a 218° weight-reducing belt along the circumferential direction at the thickened ring, and the wall thickness of the weight-reducing belt is required to be

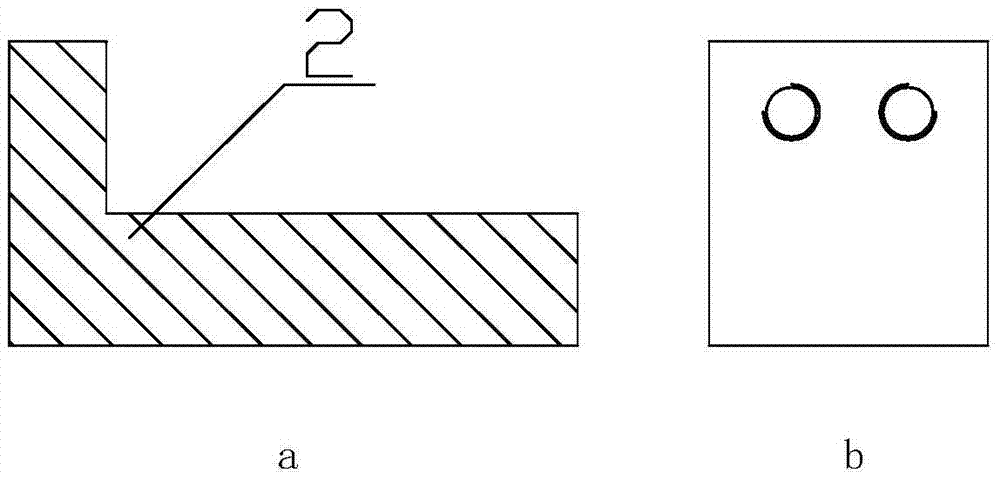

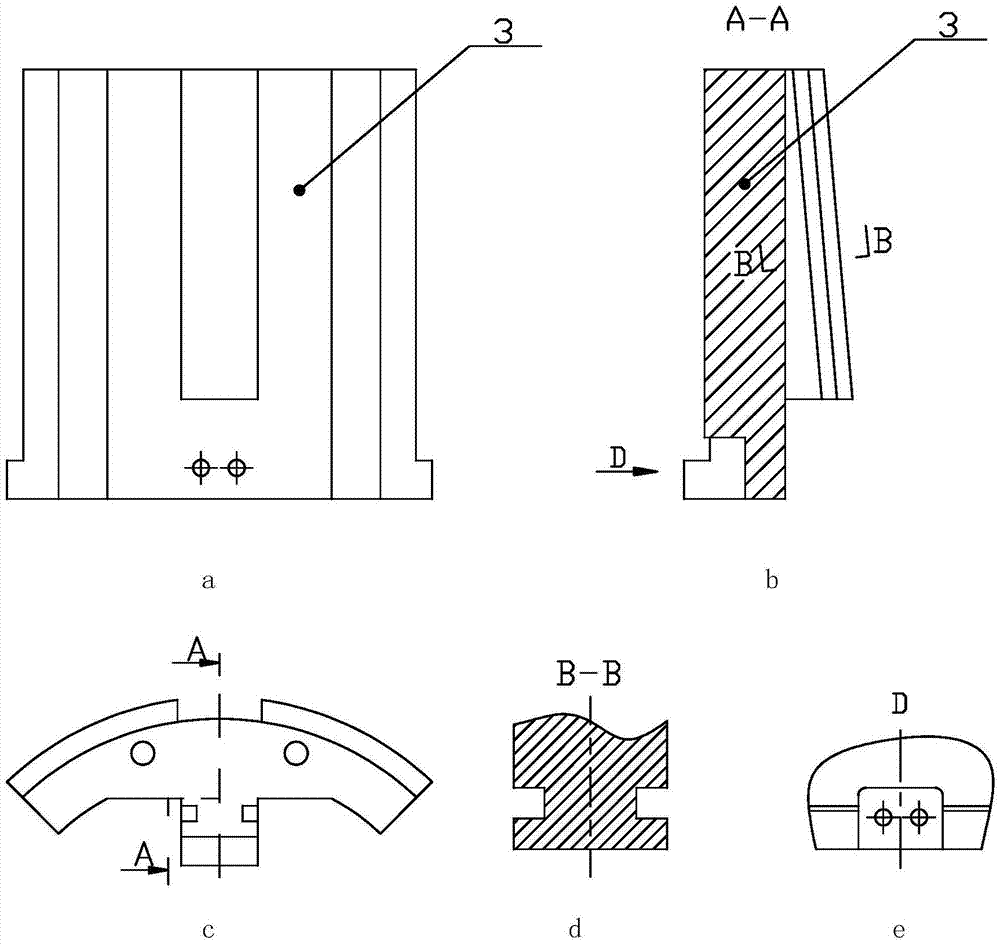

[0032]The inner brace includes a mandrel 1, a limit block 2, an outer arc block 3, an inner cone block 4, a conduction plate 5, an outer hexagonal large nut 8 and a sleeve. Wherein: the bottom end of the mandrel 1 has a base, the lower end of the mandrel has a radially protruding annular baffle, and the distance between the upper surface of the base and the lower surface of the annular baffle is the same as that of the limit block 2 The thickness is the same; the outer peripheral surface of the upper end of the mandrel 1 is a threaded surface. The limiting block 2 is sleeved on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com