Diversion valve

A diversion valve and valve body technology, applied in the field of diversion valves, can solve the problems of no filtering function, easy corrosion and damage of the valve body, complicated operation of the diversion valve, etc., achieving simple structure, reducing cleaning costs, and increasing the number of times. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

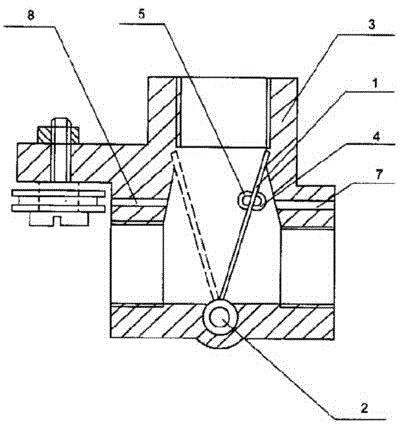

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0021] A diversion valve, characterized in that: the diversion valve has a steel valve body 3, the valve body 3 has a three-way inner cavity including an upper inner cavity, a left inner cavity and a right inner cavity, and the inner cavity is provided with There is a flap 1 located between the left inner cavity and the right inner cavity and below the upper inner cavity. The lower end of the flap 1 is hinged to the bottom wall of the valve body 3 through the flap shaft 2. There are sleeves on both sides of the upper end of the flap 1 respectively. Ring one 4 and ferrule two 5, the two sides of the valve body 3 are respectively provided with a hole one 7 and a hole two 8 for wearing a glass rope, the ferrule one 4 is connected with the glass rope in the hole one 7, the Ferrule two 5 is connected with the glass rope in hole two 8;

[0022] The upper lumen is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com