Drill tip and drill bit

A blade and drill bit technology, which is applied in the direction of drill bits, earthwork drilling, drilling equipment, etc., can solve problems such as hardness damage, hard layer chipping, and reduced operating efficiency, so as to achieve wear resistance and defect resistance. Effective use of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

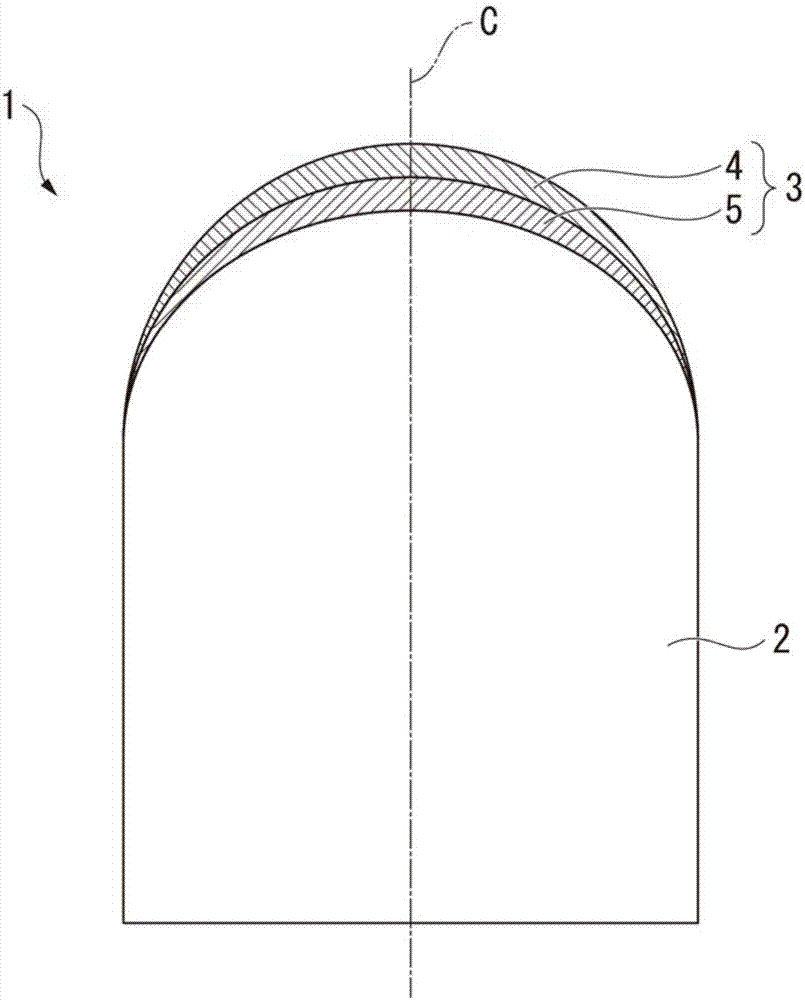

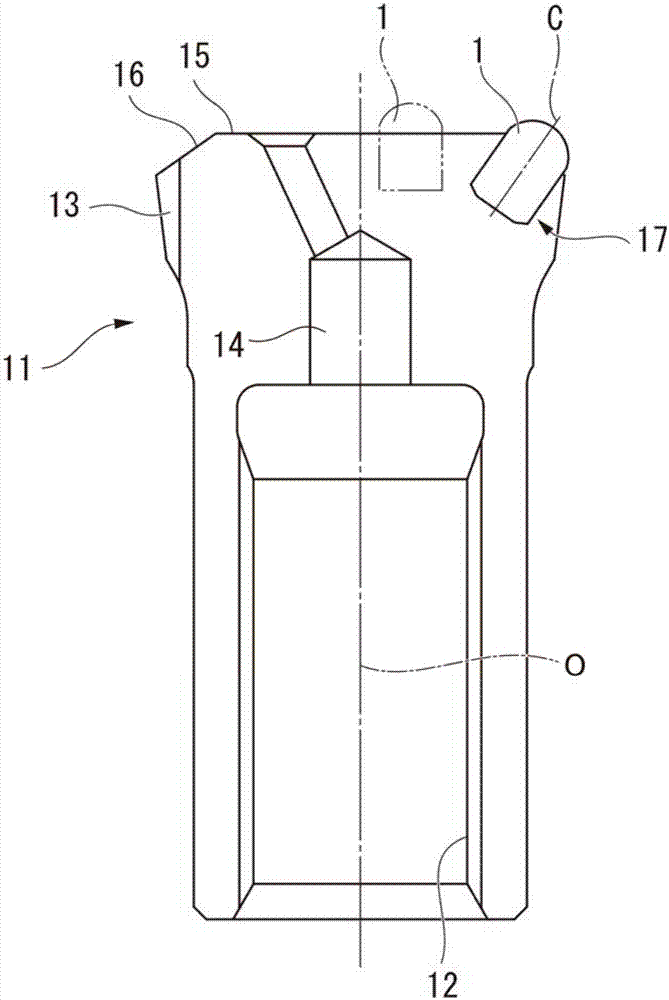

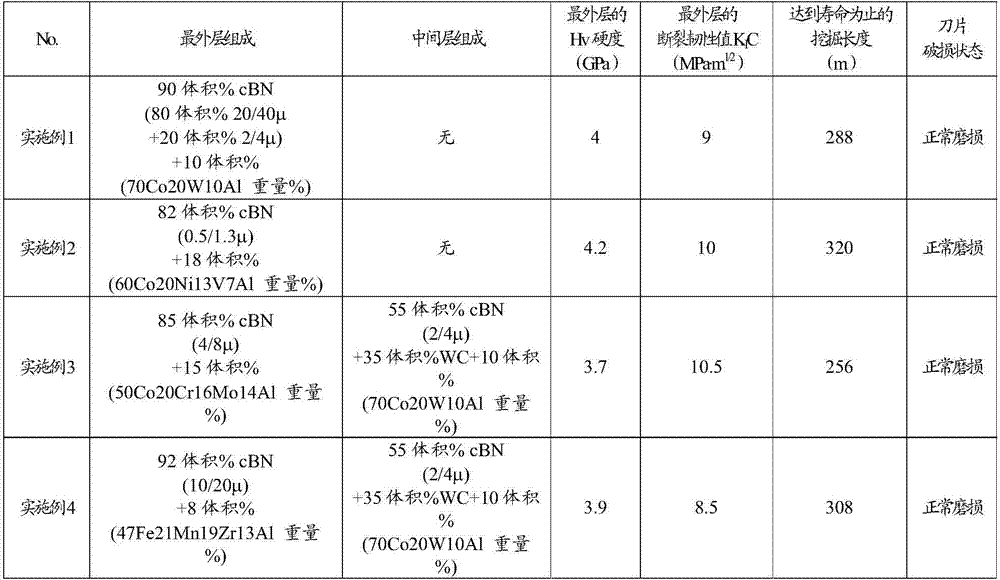

[0054] Next, the effects of the invention of the present application will be demonstrated by giving examples of the excavating blade and the excavating bit of the invention of the present application. In this example, according to the above-mentioned embodiment, the cubic boron nitride (cBN) content of the polycrystalline cubic boron nitride sintered body, the type of catalyst metal, the hard layer composed of WC: 94% by weight, Co: 6% by weight of cemented carbide substrates are sintered together under the conditions of 5.8GPa sintering pressure, 1600°C sintering temperature and 30 minutes sintering time to produce 10 pieces with a radius of 5.5mm and a length of 16mm in the centerline direction of the blade. A button blade. In addition, the radius of the hemisphere formed by the front end portion of the blade body was 5.75 mm. In addition, the thickness of the hard layer in the insert centerline direction was 1.5 mm. In addition, embodiments 1, 2, 5, 6, 9, 10, and 11 are s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com