Deep hole forming tool

A technology of forming knives and deep holes, used in drilling/drilling equipment, drilling accessories, transportation and packaging, etc., can solve the problems of reamer or forming knives being easily broken, affecting the surface quality of the hole wall, and deep hole processing. and other problems, to avoid tool breakage, facilitate control, and prolong service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

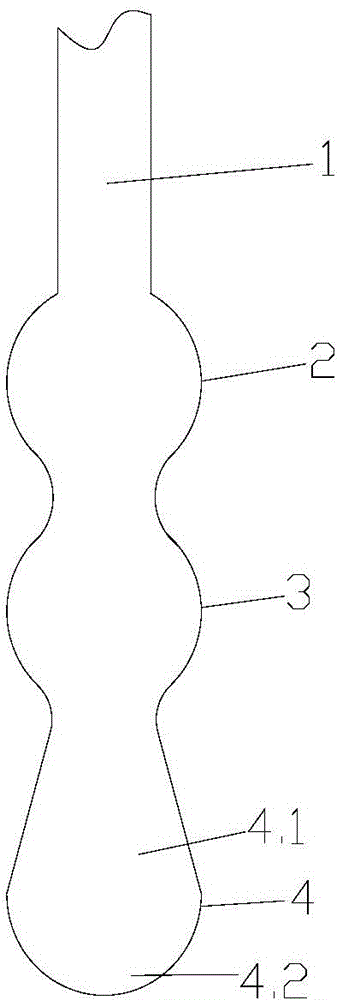

[0012] Such as figure 1 A forming knife for deep holes is shown, which includes a handle 1 and a cutting part at the front end of the handle 1. The handle 1 and the cutting part are integrally formed. The diameter of the handle 1 is smaller than the maximum diameter of the cutting part. The third cutting part 2 connected with the shank 1, the second cutting part 3 at the front end of the third cutting part 2 and the first cutting part 4 at the front end of the second cutting part 3 are composed of the third cutting part 2 and the second cutting part 3. It is spherical, and the third cutting part 4 and the second cutting part 3 meet with a smooth curved surface transition. The first cutting part 4 is composed of a conical part 4.1 connected with the second cutting part 3 and a spherical part 4.2 at the front end of the conical part 4.1. , the end of the small diameter of the tapered part 4.1 is smoothly connected with the second cutting part 3, the part where the tapered part 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com