Patents

Literature

269results about How to "Avoid unqualified" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Apparatus for repairing circuit pattern and method for manufacturing display apparatus using the same

InactiveCN1755437AImprove correction accuracyImprove display qualityNon-linear opticsDisplay deviceLaser exposure

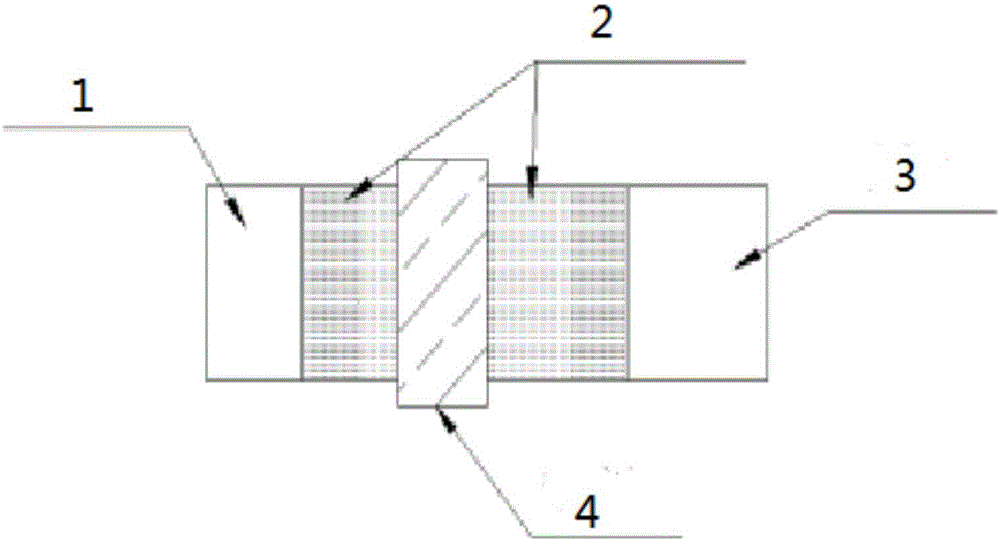

The invention relates to a manufacturing method of a graph amendment device and a display device. Pixels are arranged in the area which is enclosed with two grid wirings and two leakage wirings; as to the short-circuit defect of an adjacent pixel electrode, a laser exposure is caused to eliminate the short-circuit part through the mask of a transmission graph which corresponds to the grid wiring and leakage wiring of the short-circuit part and the graph of the pixel electrode. The elimination of the short-circuit part can be known by utilizing the information sent out by an inspection device to be compared with the normal graph, and the graph defect formed on a substrate can be automatically amended. Thus, the display device with a high-quality absorption characteristic can be realized by causing the method to be applied to the manufacturing process of the display device, in particular to the photoresist graph forming process.

Owner:JAPAN DISPLAY INC

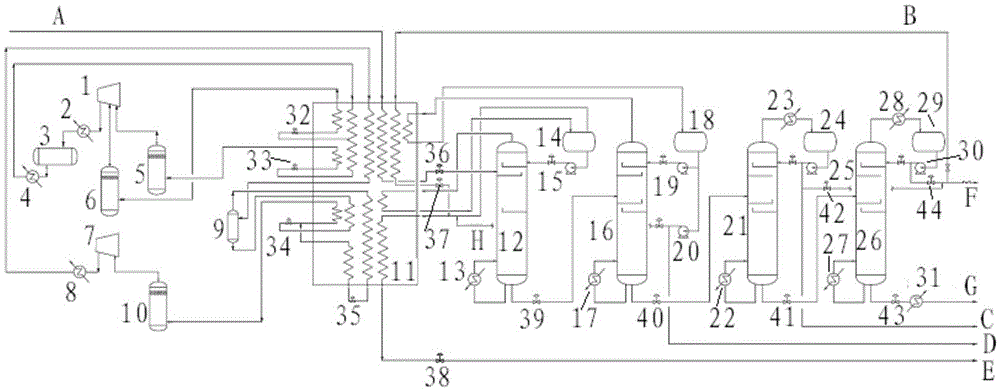

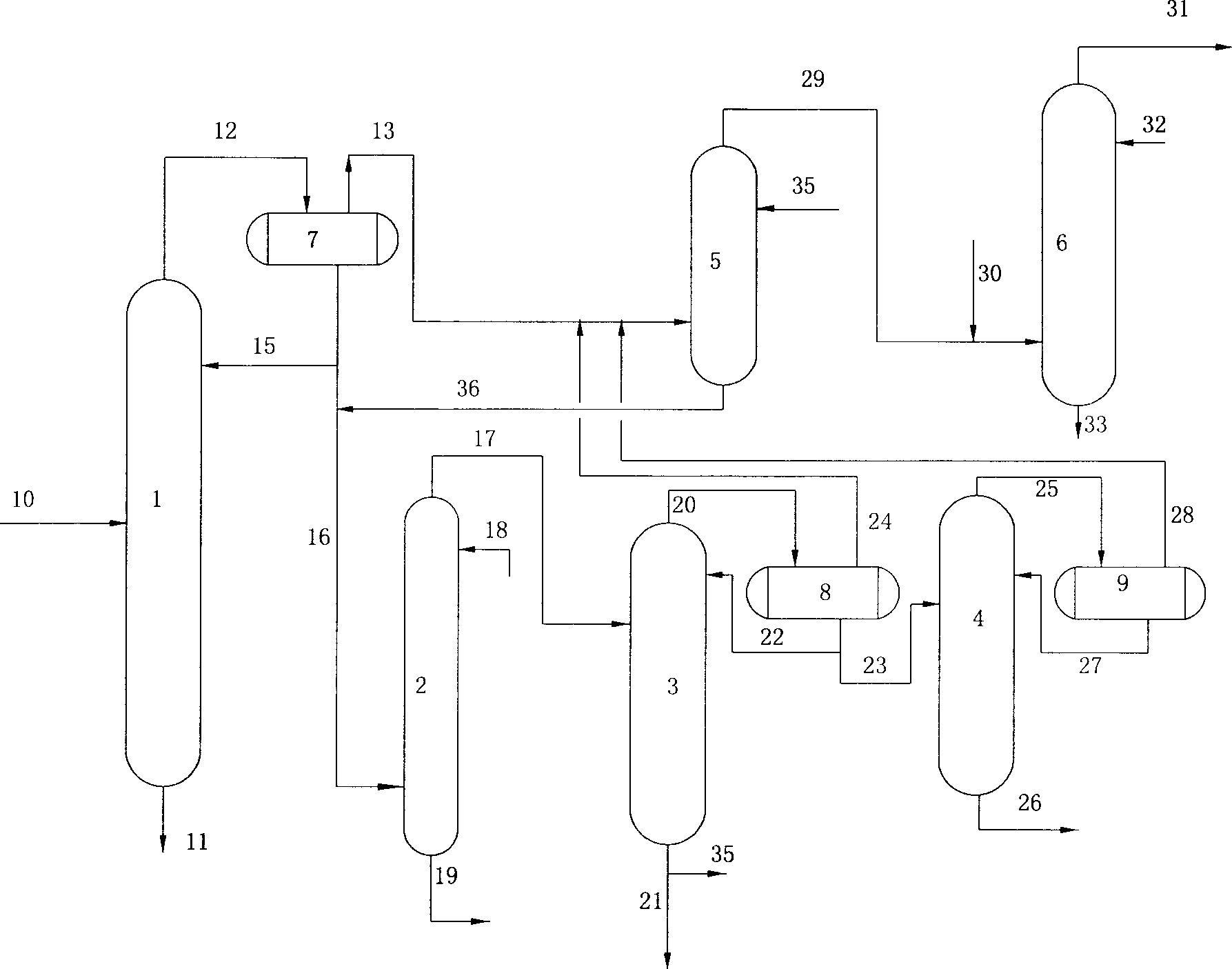

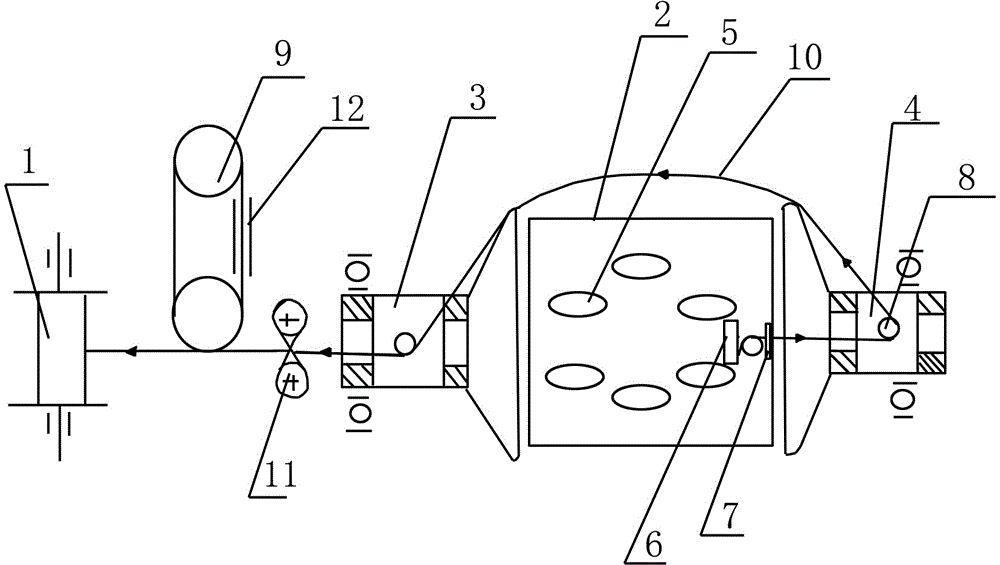

Natural gas liquefaction and light dydrocarbon separation integrated process system and technology

The invention discloses a natural gas liquefaction and light dydrocarbon separation integrated process system and process. The process comprises the steps that after natural gas is subjected to precooling, a gas phase and a liquid phase are drawn out of a main heat exchange cold box and enter a washing tower, the tower top gas phase enters the main heat exchange cold box to be cooled, gas-liquid separation is carried out through a washing tower return tank, the liquid phase enters the washing tower to provide the cold reflux for the washing tower, and the gas phase returns to a liquefaction section of the main heat exchange cold box; after being subjected to throttling pressure reduction, the bottom stream of the washing tower enters a dethanizing column, the top gas phase of the dethanizing column enters a precooling section of the main heat exchange box to be cooled, and gas-liquid separation is carried out through a return tank of the dethanizing column; according to low-temperature liquid-phase ethane, on one hand, the cold reflux is provided for the dethanizing column, and on the other hand, part of the low-temperature liquid-phase ethane is extracted to serve as ethane refrigerant to be stored, and the rest is pressurized and conveyed to the liquidation section of the main heat exchange cold box through a pump; propane and butane are pressurized through a propane pump and a butane pump respectively and then mixed to be conveyed to the cold box, extraction is carried out after precooling, methane and ethane stream is combined after throttling, then propane, butane, methane and ethane return to the main heat exchange cold box to be liquefied together, and LNG is produced.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

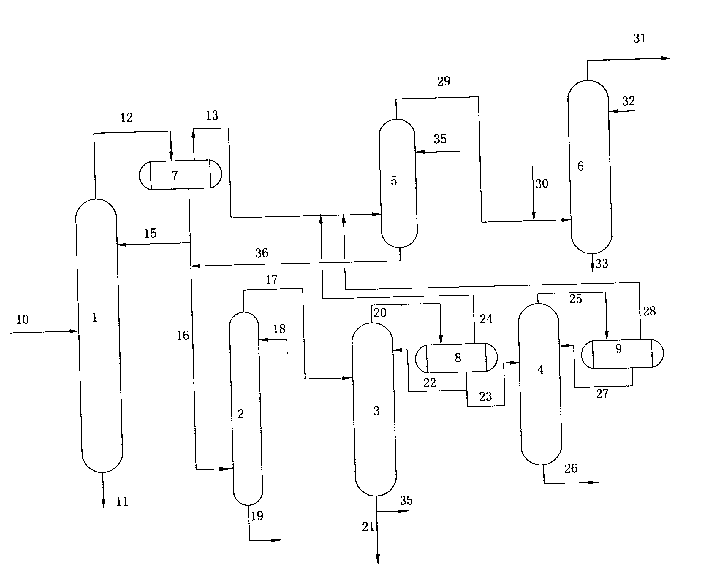

Method for separating hydrocarbon hydrocracking products

The separation method of hydrocracked product of hydrocarbons incldudes stabilization tower, hydrogen sulfide washing tower, debutanizing tower, deethanizing column and light hydrocarbon absorption tower. The stabilizatino tower is designed according to cutting portion or all C6 component, the absorption oil of light hydrocarbon absorption tower is from tower bottom product flow of debutanizing tower, the overhead gas of stabilizaltion tower, overhead gas of debutanizing tower and overhead gas of deethanizing column are mixed, and fed into light hydrocarbon absorption tower to recover light hydrocarbon, and the tower bottom rich absorption oi lof light-hydrocarbon absorption tower and hydrogen sulfide washing tower feeding material coming from stabilizatino tower and mixed, and fed into hydrogen sulfide washing tower. The C3 and C4 components can be completely recovered, and its liquified gas yield is high.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC

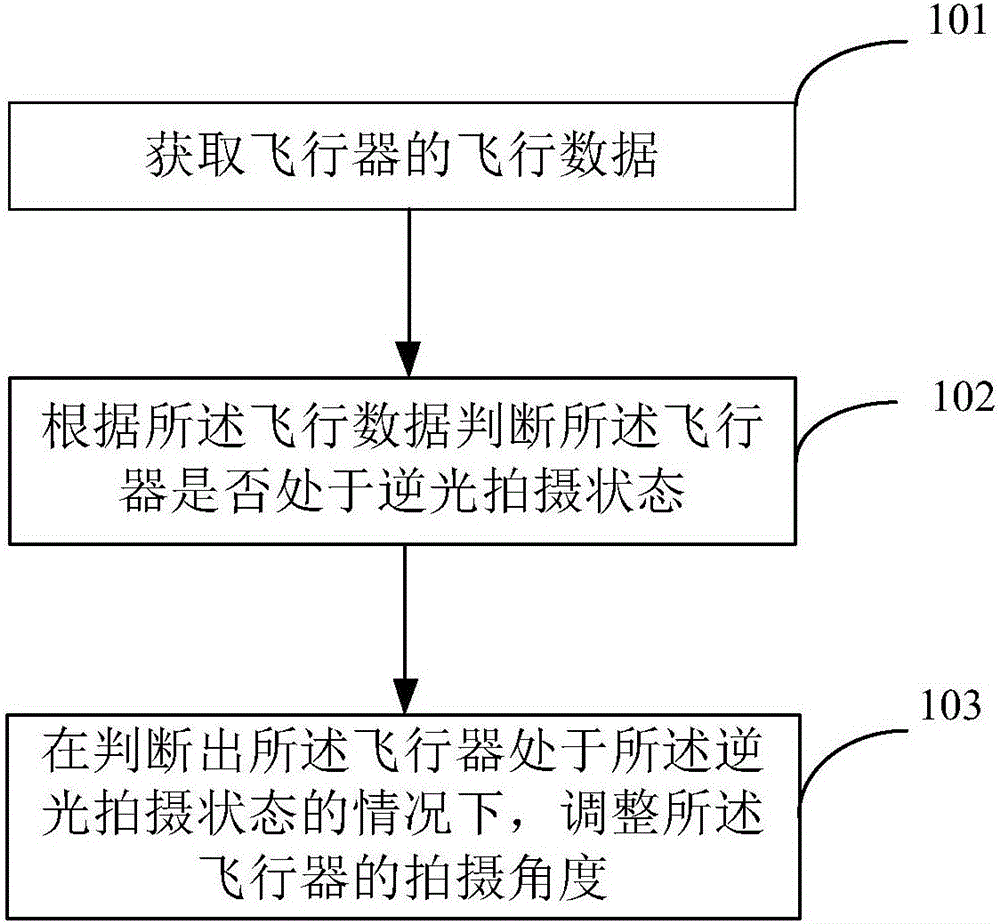

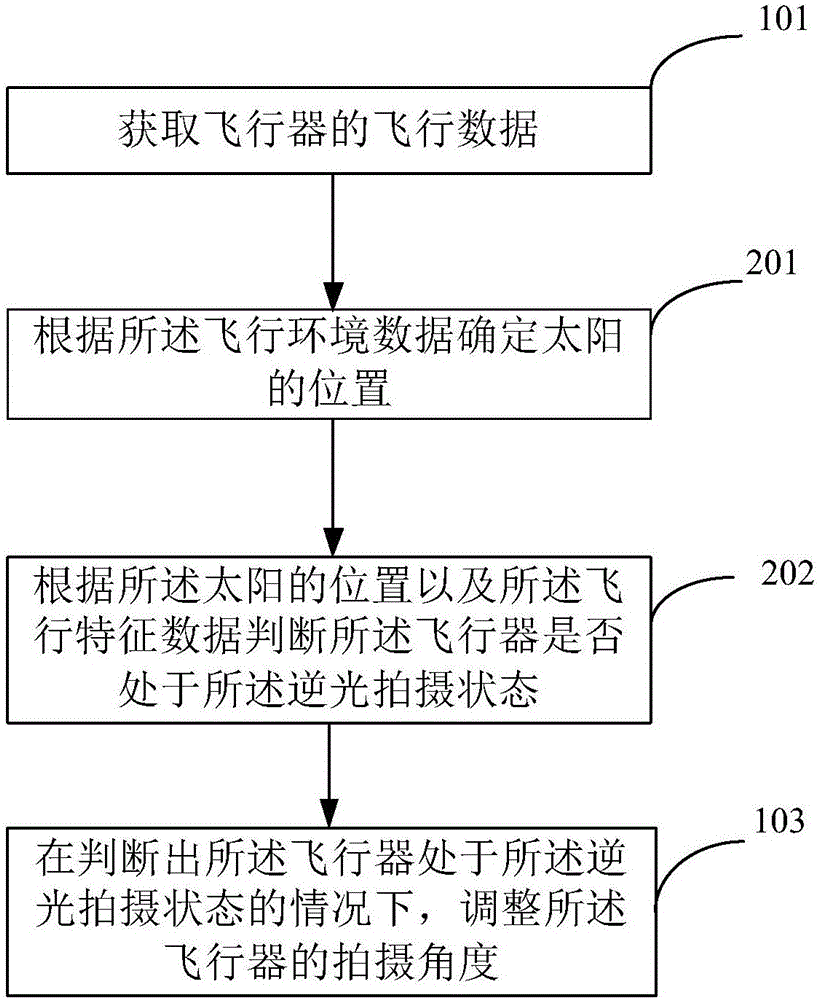

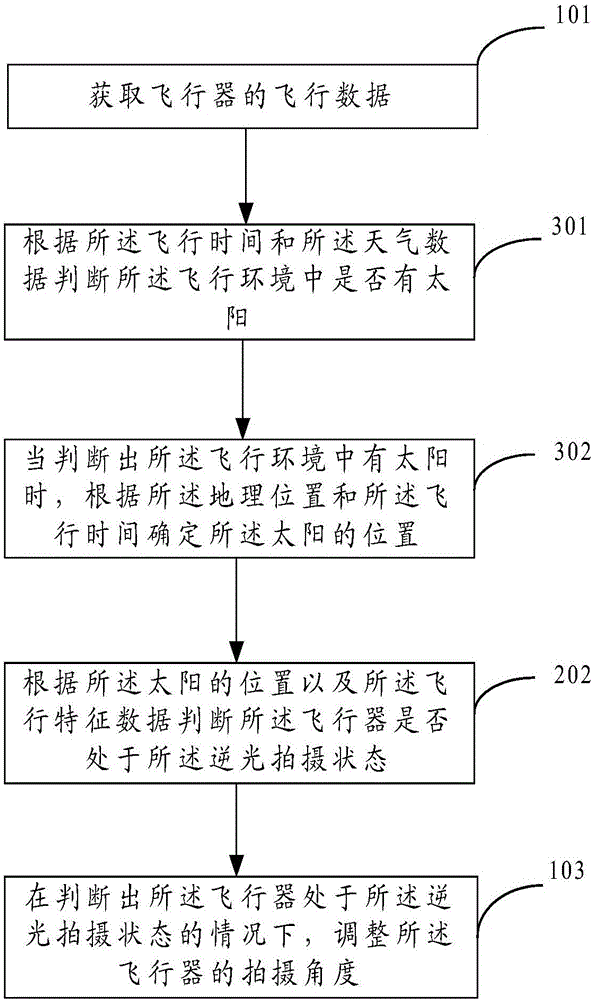

Aircraft control method and device and aircraft

ActiveCN106125767AAvoid unqualifiedThe shooting picture is reasonablePosition/course control in three dimensionsFlight vehicleFlight data

The invention relates to an aircraft control method and device and an aircraft. The method comprises the steps: obtaining the flight data of the aircraft; judging whether the aircraft is in a backlight photographing state or not according to the flight data; and adjusting the photographing angle of the aircraft when the aircraft is judged to be in the backlight photographing state. The method automatically adjusts the flight or photographing angle when the aircraft is judged to be in the backlight photographing state, and avoids a condition that a photographed image is not qualified because of the backlight when the aircraft executes a flight task, thereby guaranteeing that a reasonable photographed image can be obtained.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

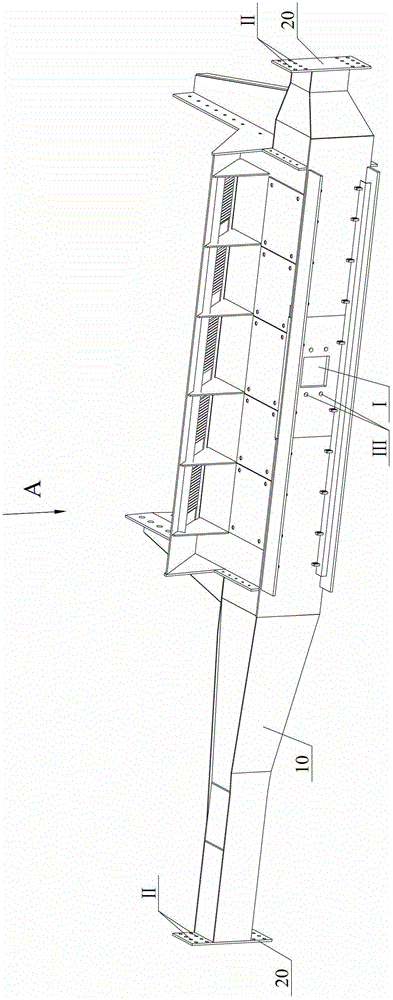

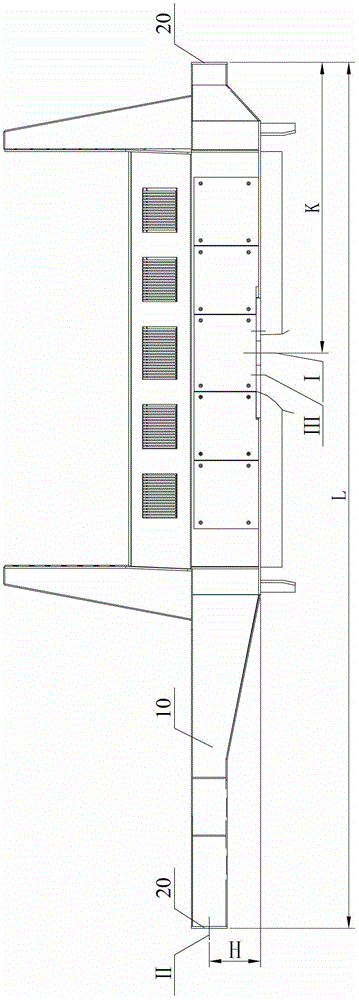

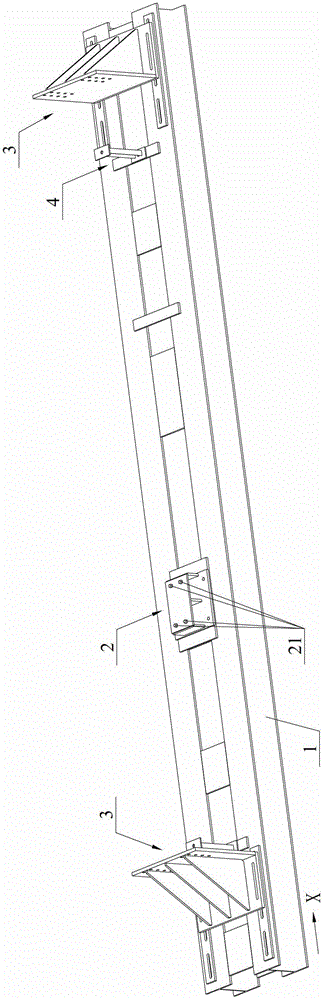

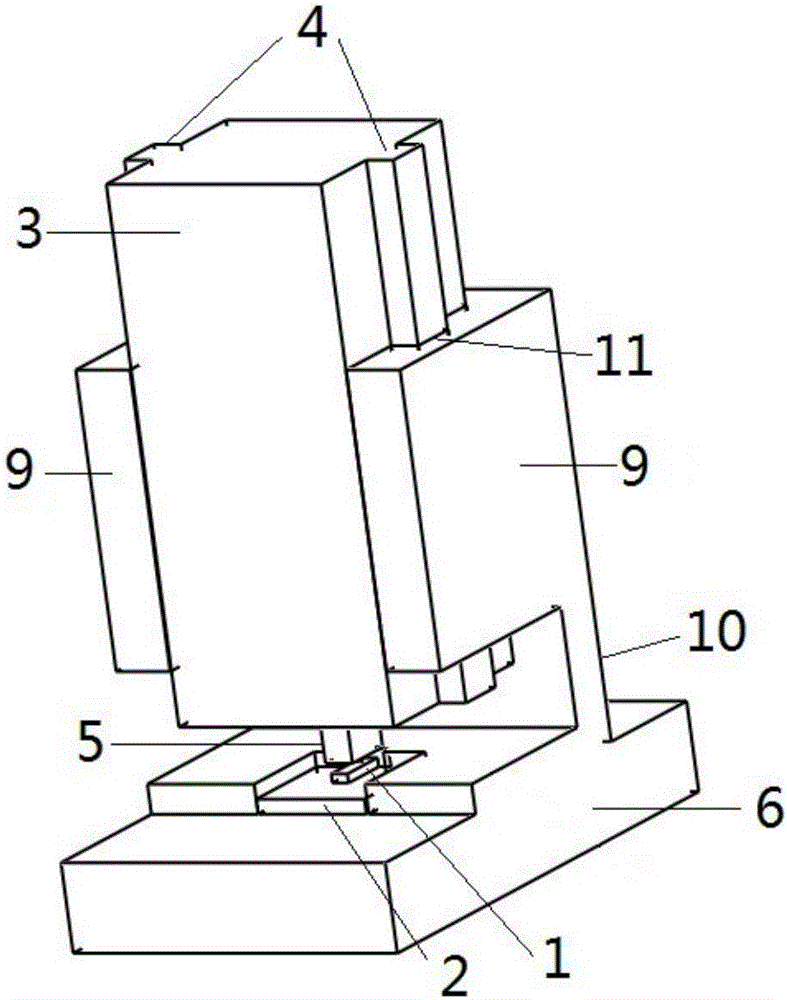

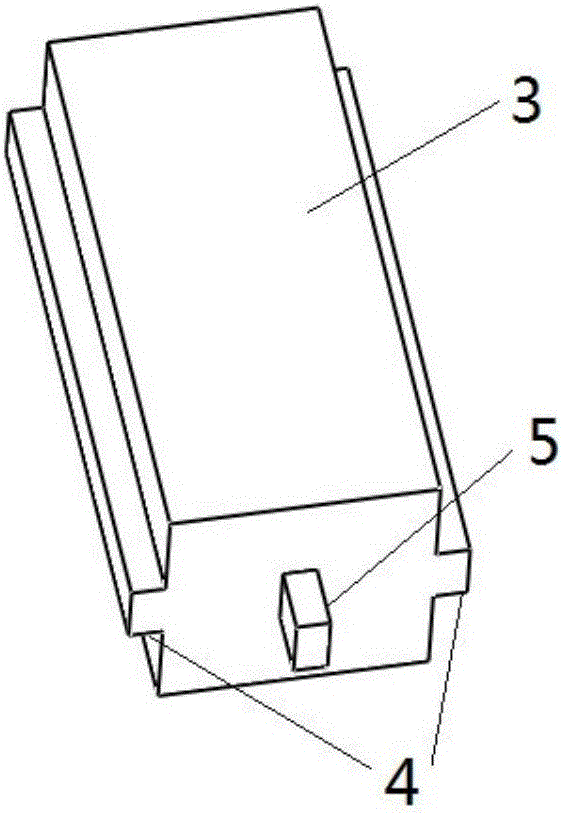

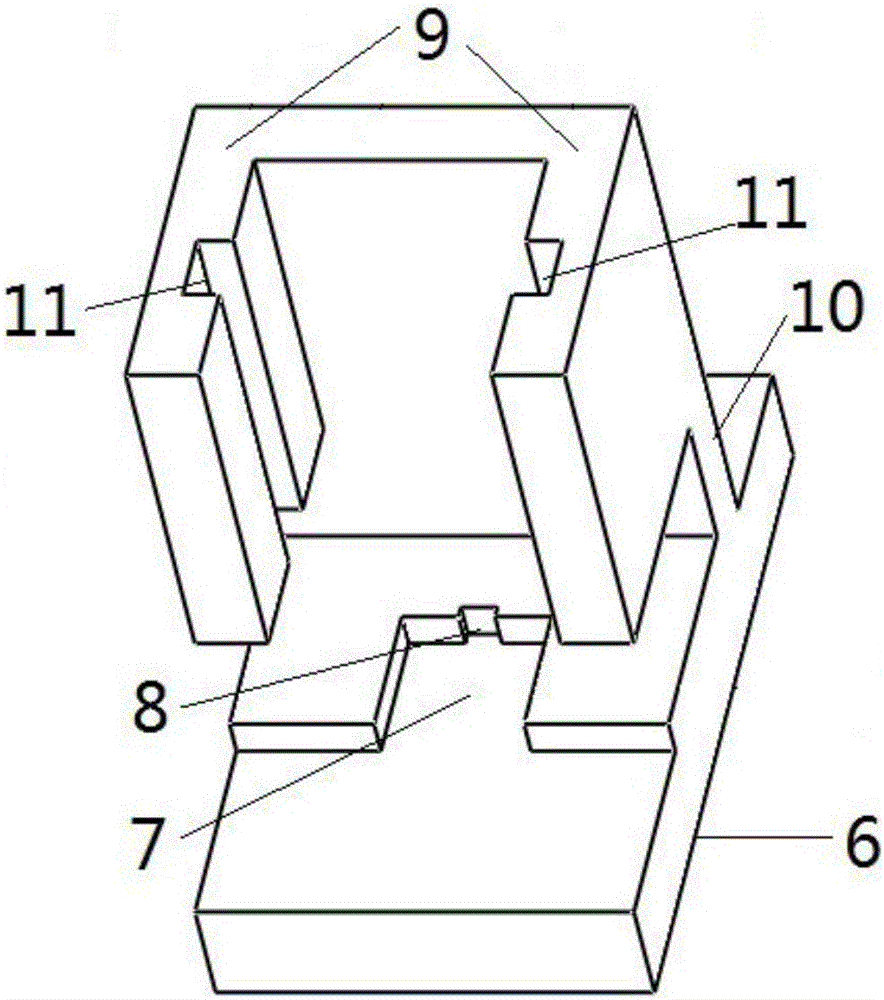

Processing technology and exclusive welding tool for annular cooler special-shaped beam

ActiveCN103143874AAvoid unqualifiedAvoid unqualified defectsWelding/cutting auxillary devicesAuxillary welding devicesShaped beamEngineering

The invention discloses an exclusive welding tool for an annular cooler special-shaped beam. A beam body bearing thereof is used to bear and position the beam body of the special-shaped beam; an upper surface thereof is provided with a first position limitation part adapted with an adapter positioning hole in the bottom of the beam body; two flange end plate bearings thereof are respectively used to bear the inside and outside flange end plates of the special-shaped beam; the opposing side surfaces of the two flange end plate bearings are respectively provided with a second position limitation part adapted with the flange hole group of the corresponding flange end plate; the height from the upper surface of the beam body bearing to the second position limitation part is consistent with the height from the bottom surface of the beam body to the flange hole group on the corresponding flange end plate; and the lengths from the first position limitation part on the beam body bearing to the opposing side surfaces of the two flange end plate bearings are respectively consistent with the lengths from the adapter positioning hole in the bottom of the beam body to the flange surfaces of the inside and outside flange end plates. The exclusive welding tool greatly improves operating efficiency while ensuring processing accuracy for the special-shaped beam. Based on the exclusive welding tool, the invention also provides a processing technology for an annular cooler special-shaped beam.

Owner:HUNAN ZHONGZHI CHANGTIAN HEAVY IND TECH

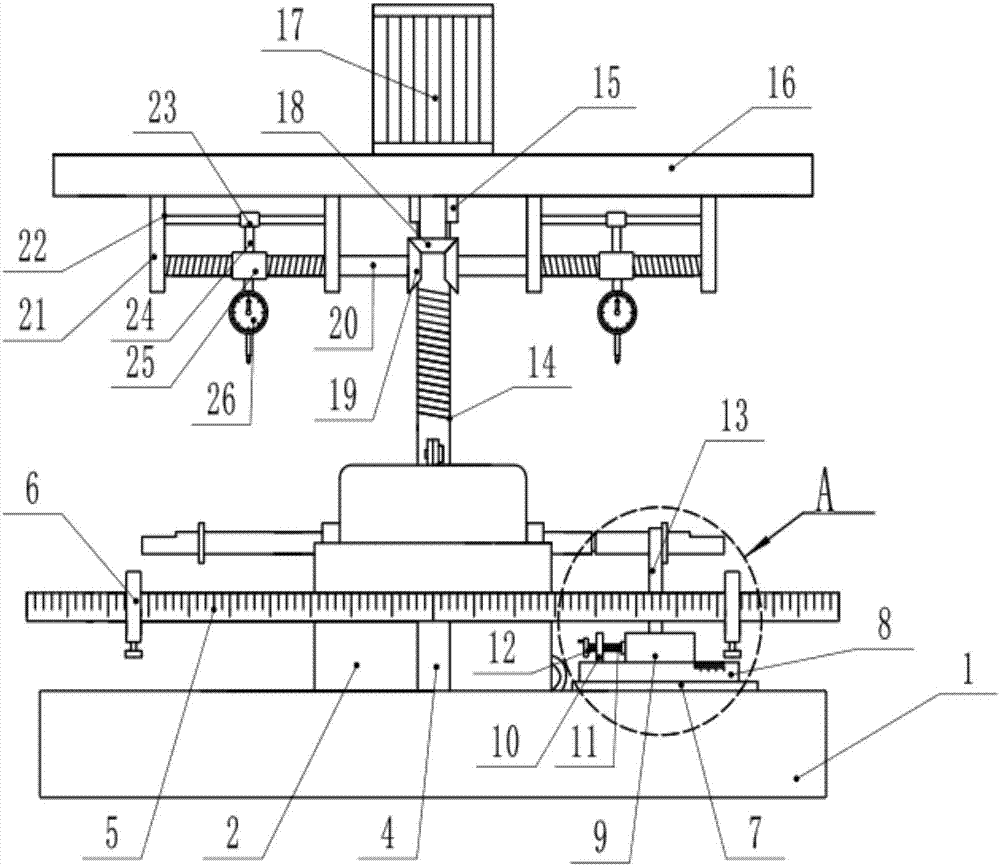

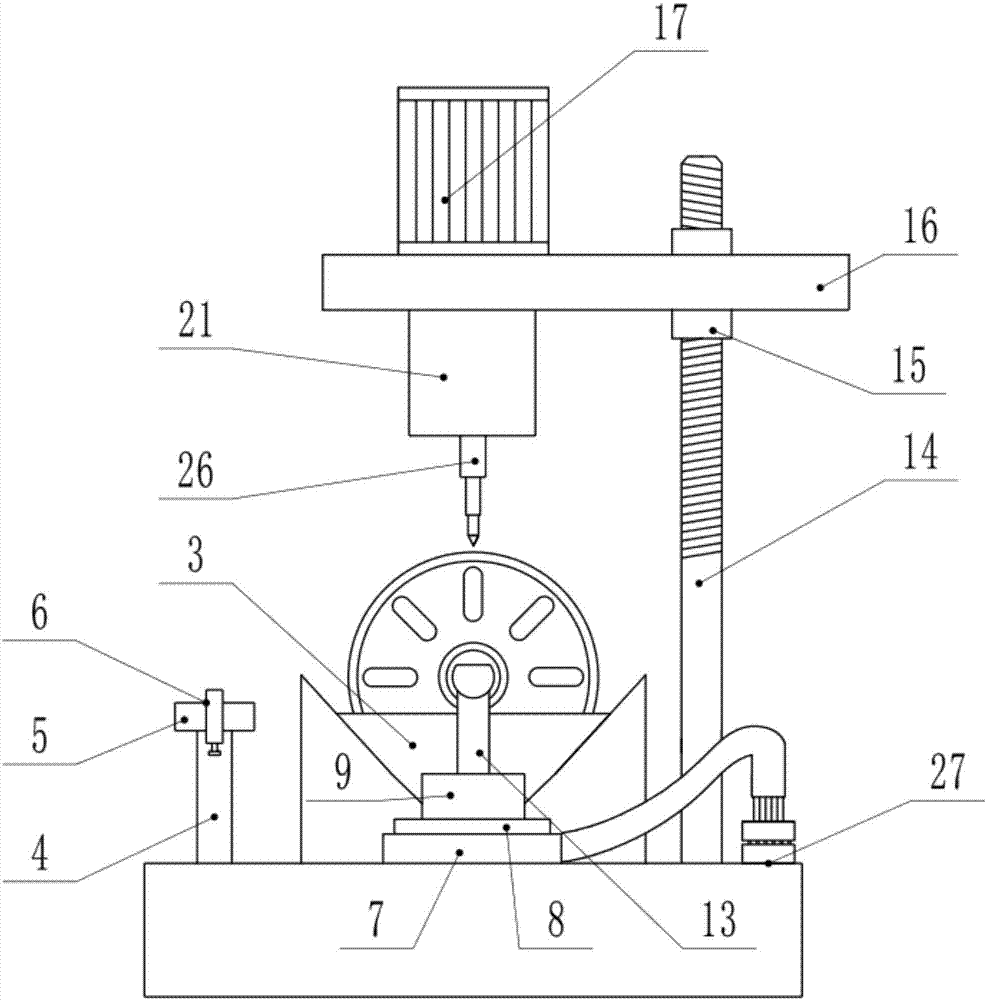

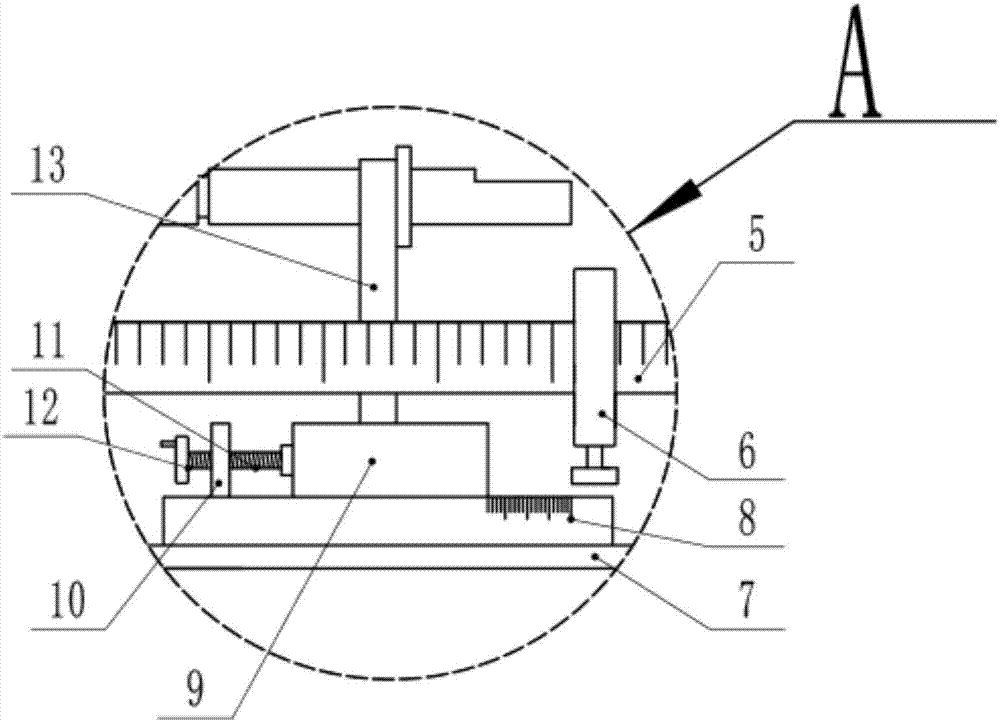

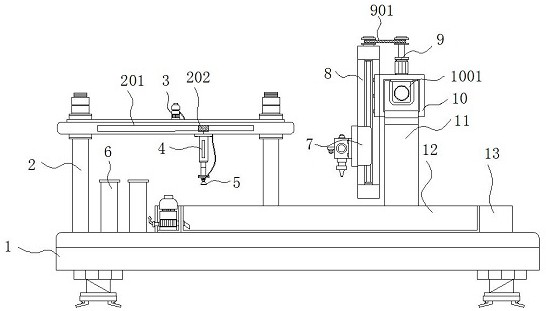

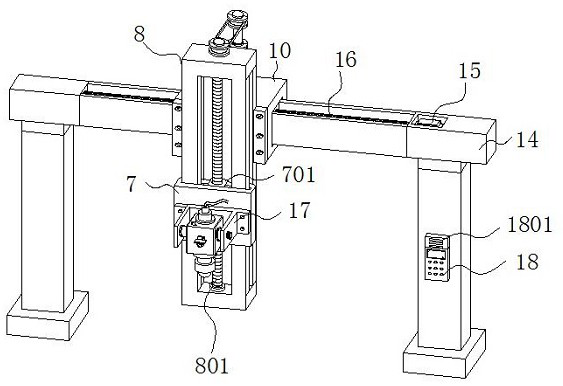

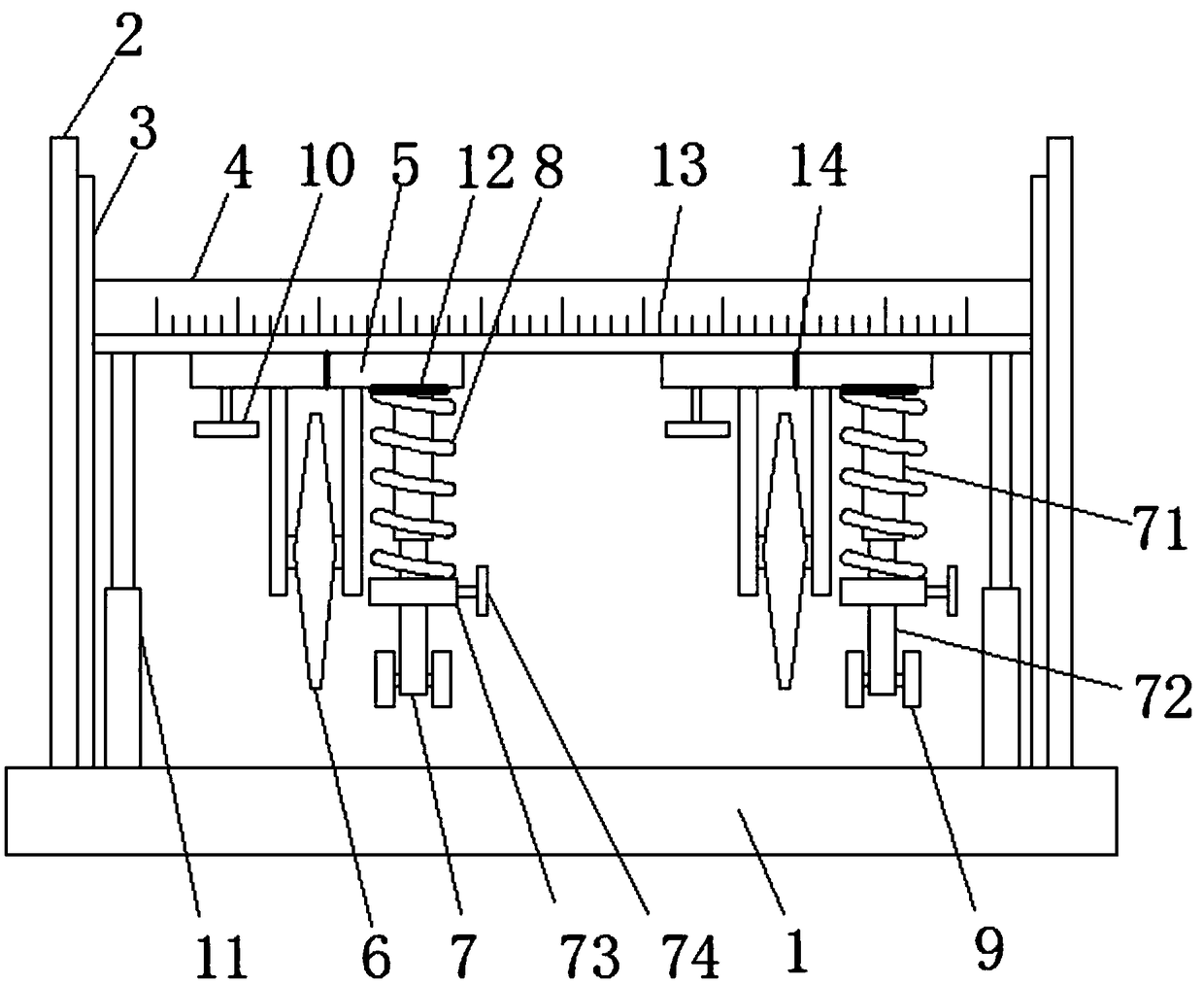

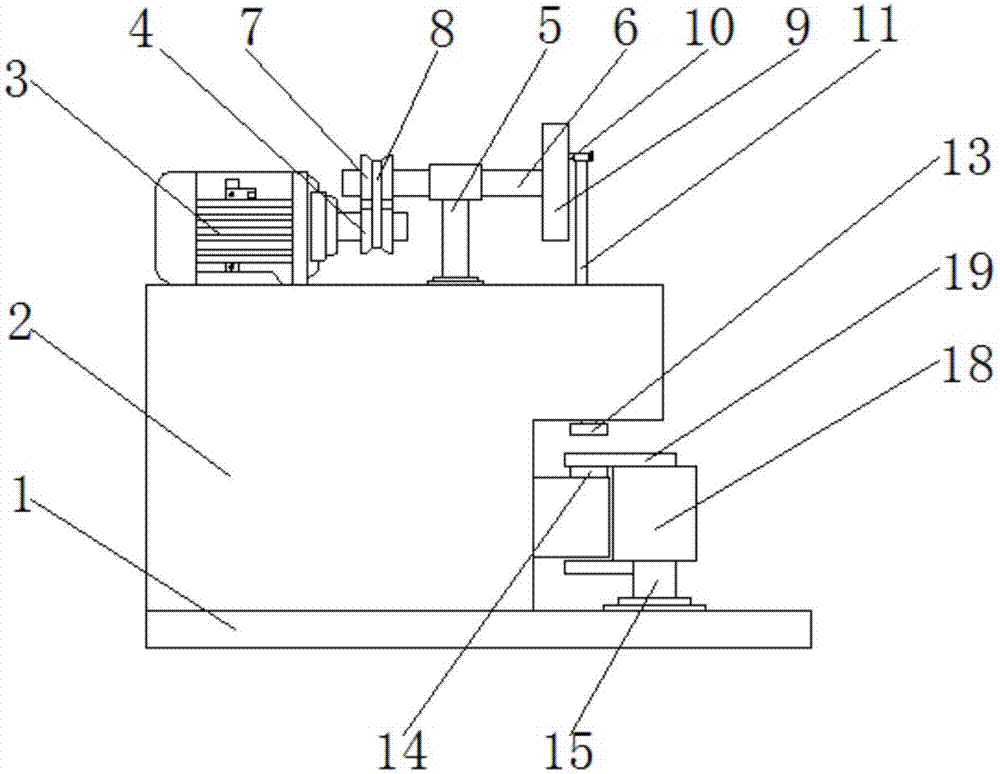

Central air-conditioning wind pipe motor pre-pressure and run-out detection device

InactiveCN107289843AAvoid unqualifiedImprove pass rateMechanical measuring arrangementsYarnEngineering

The invention discloses a central air-conditioning air duct motor preloading and beating detection device, which includes a base, a V-shaped clamp block, a length ruler, a slide rail, a translation platform, a translation block, a rotating shaft fixture, a support rod, a drive motor, a screw and A jumping instrument, a V-shaped clamp block is fixedly installed on the base, a translation platform is slidably installed on the slide rail, a translation block is also slidably installed on the translation platform, and a rotating shaft is fixedly installed at the center of the upper surface of the translation block Fixture; a wire sleeve is threaded on the lead screw, and a run-out meter is fixedly installed under the wire sleeve; setting a length gauge can prevent the motor from being unqualified due to wrong use of the rotating shaft or reverse installation of the rotor during production; motor preloading is added to the device The detection can effectively reduce the phenomenon of motor jamming and noise caused by unqualified motor preloading; the device can also perform full detection of the end face and axial runout of the rotating shaft at the same time, reducing the situation of the fan blade running due to excessive runout of the motor shaft, etc. Improve the qualification rate of the motor.

Owner:苏清凉

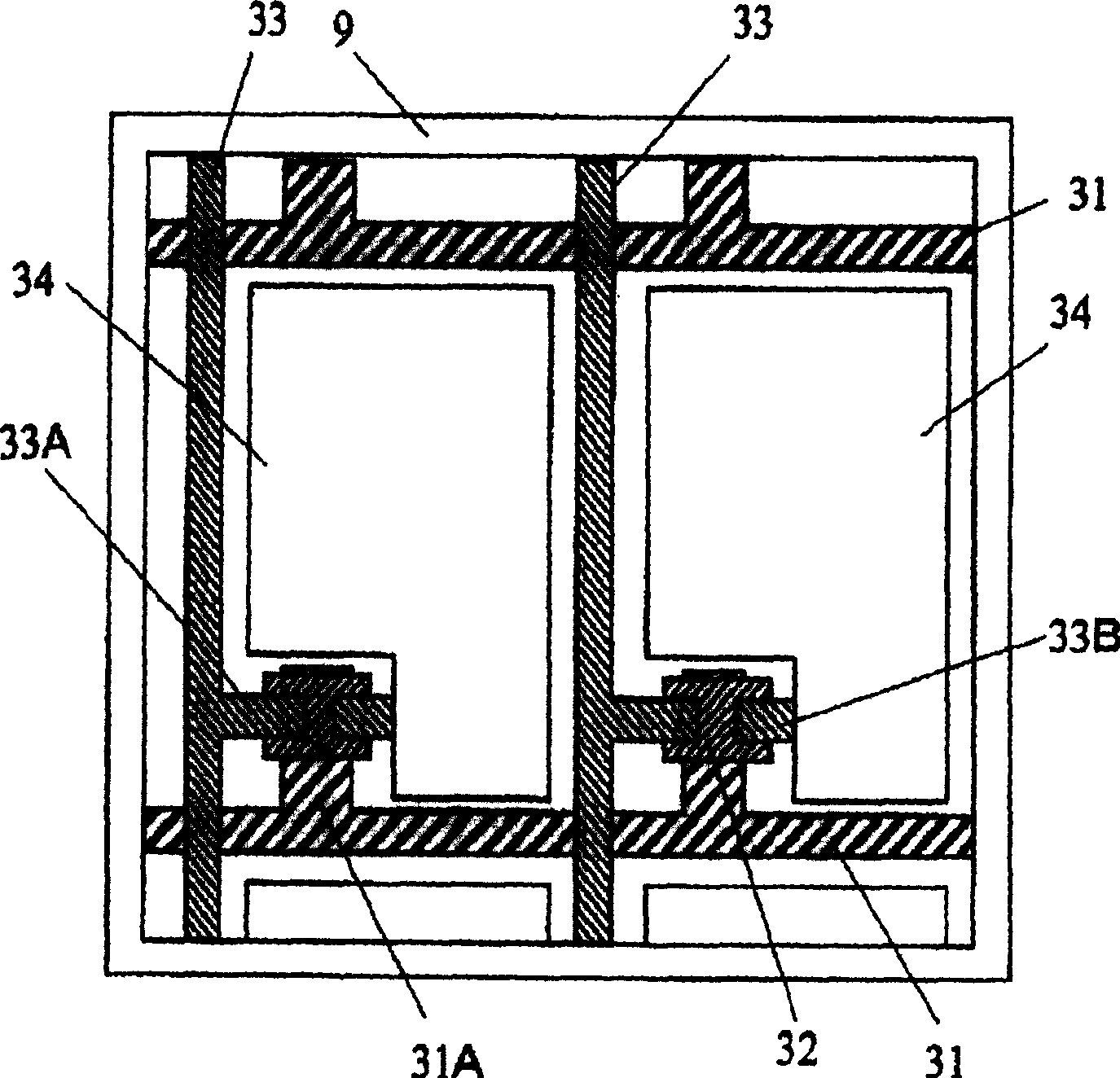

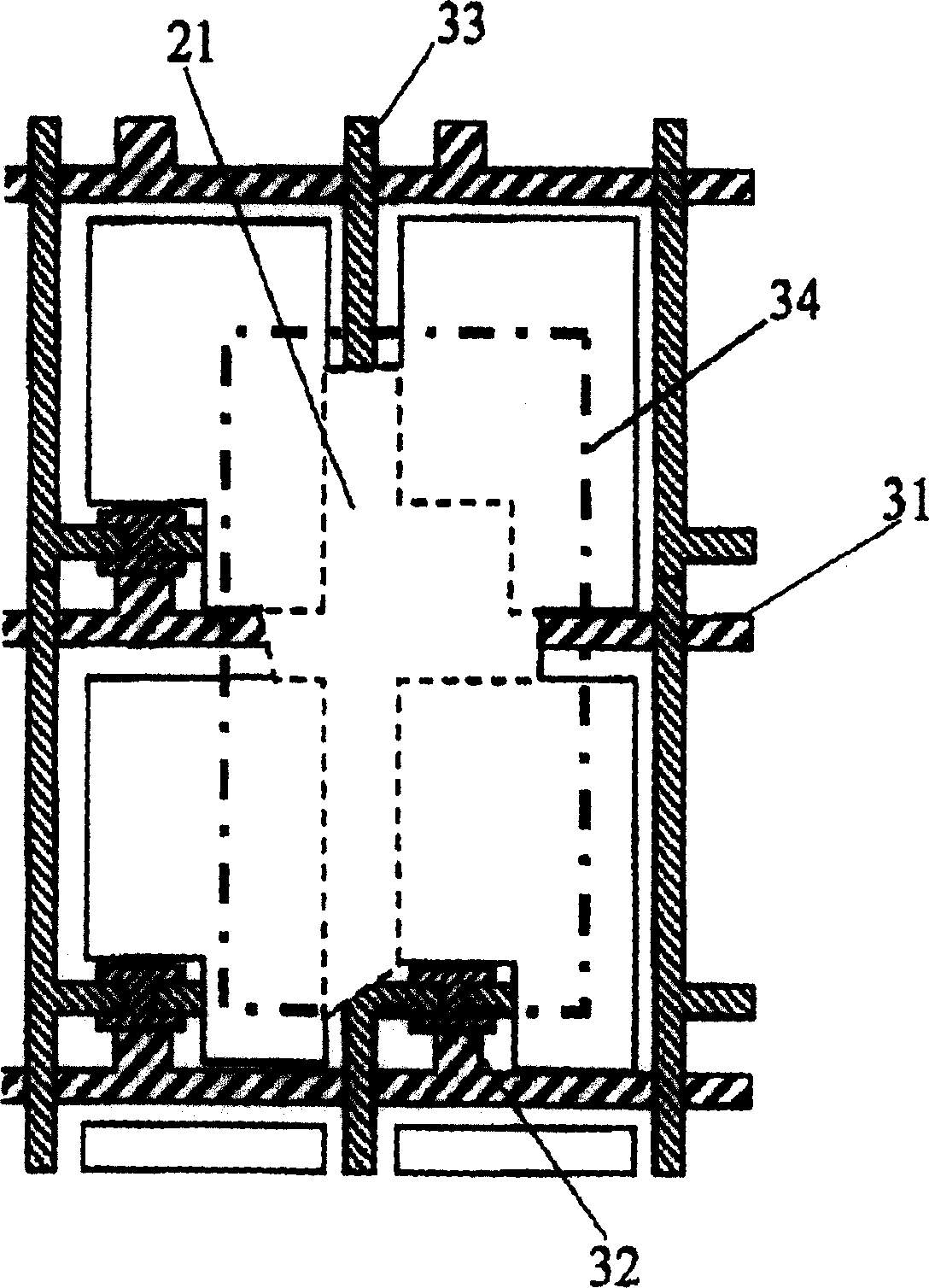

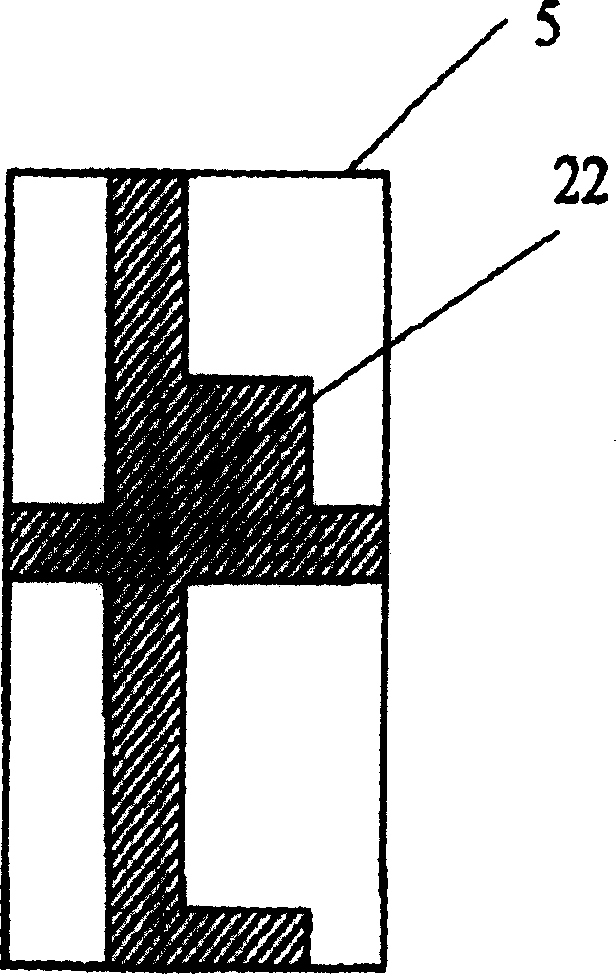

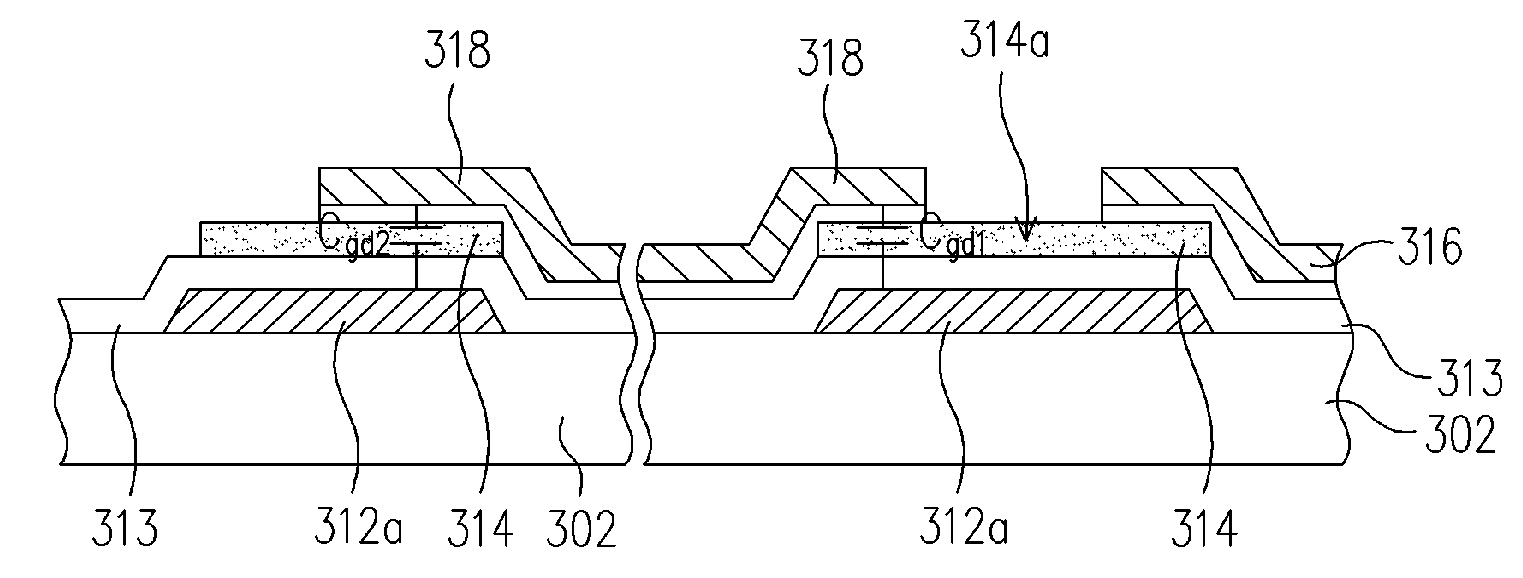

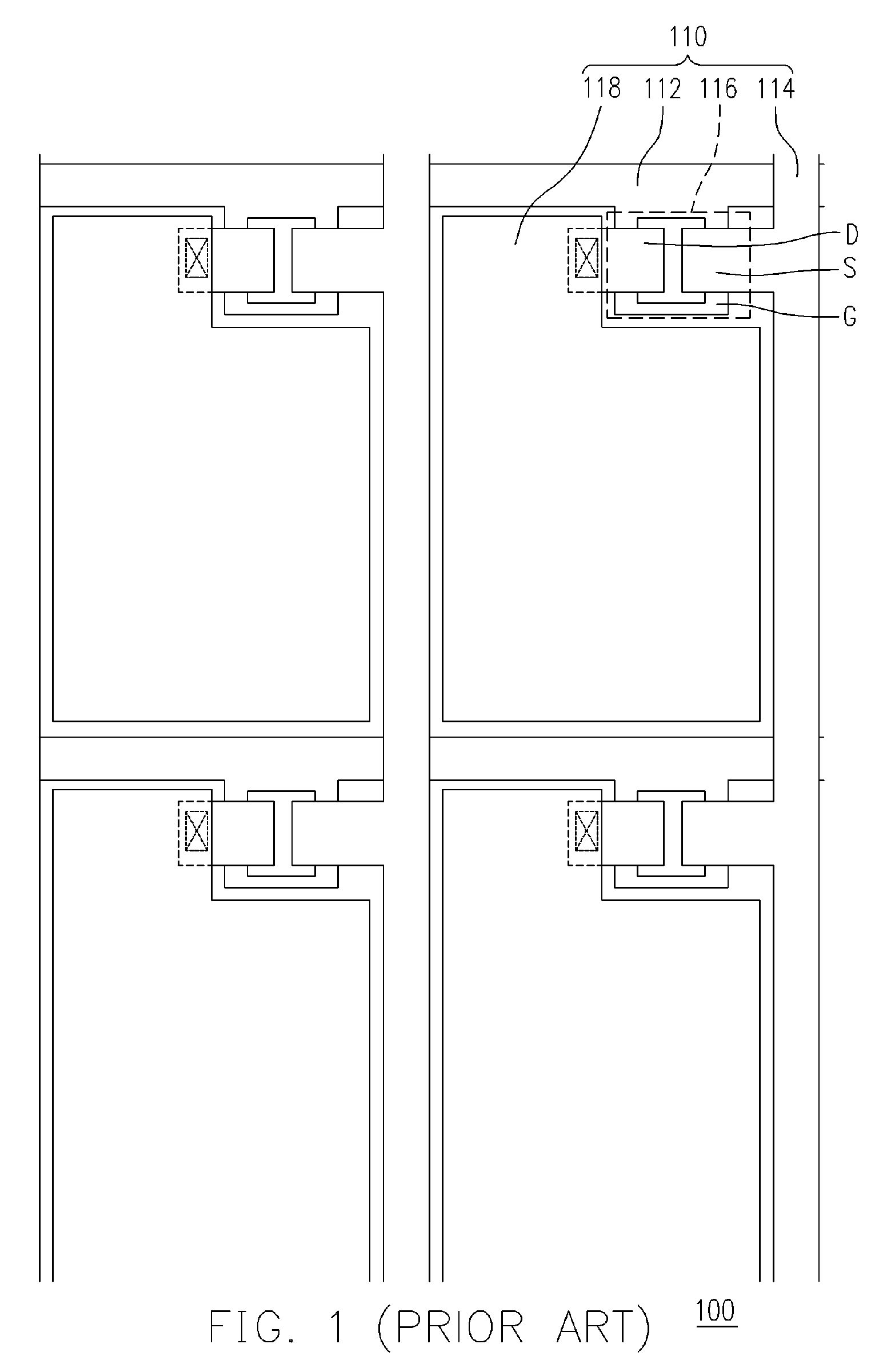

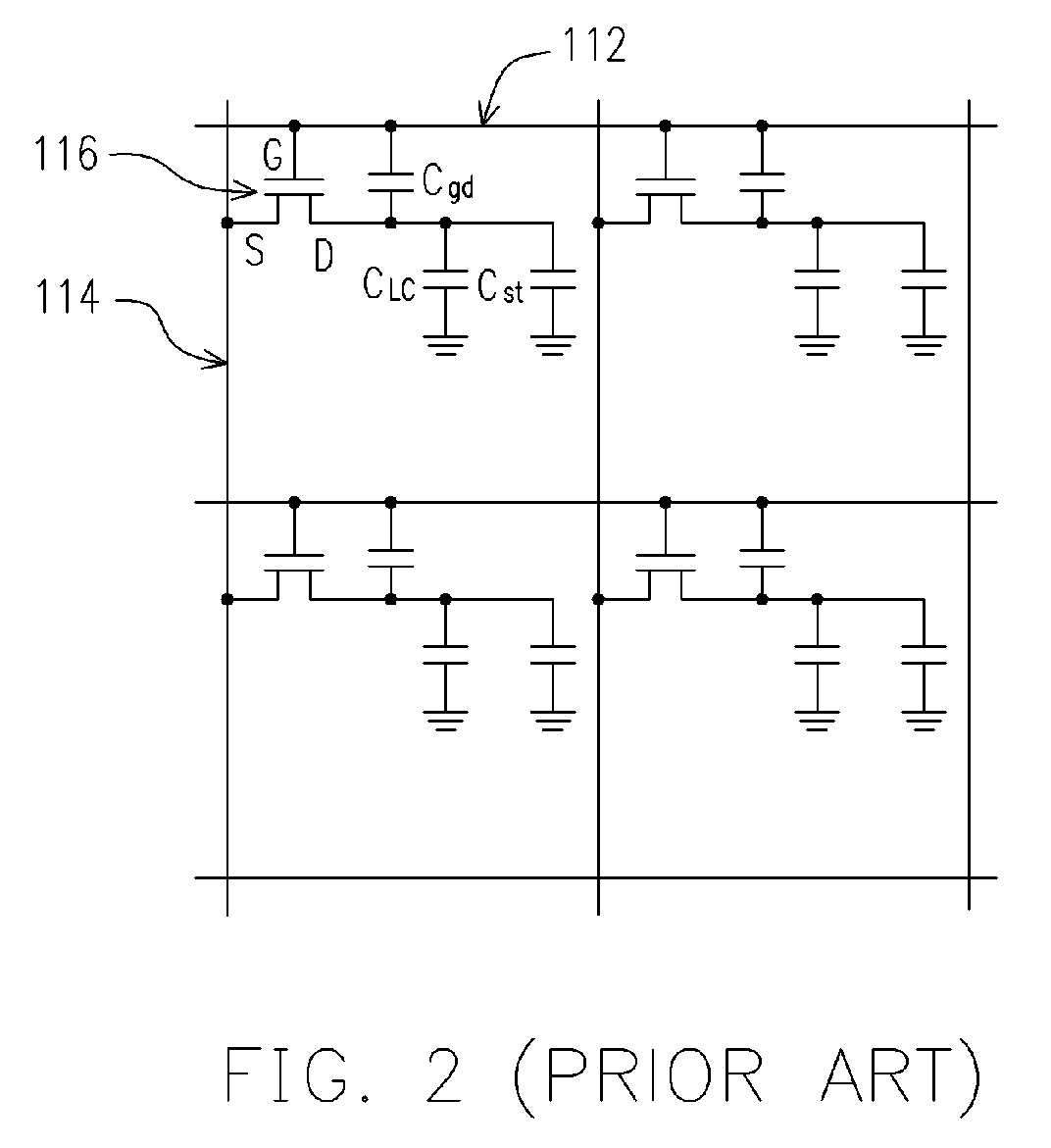

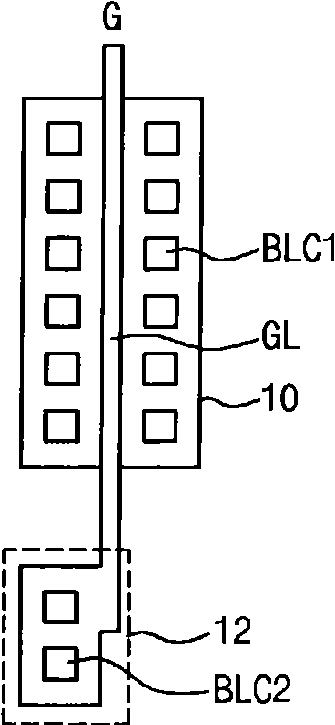

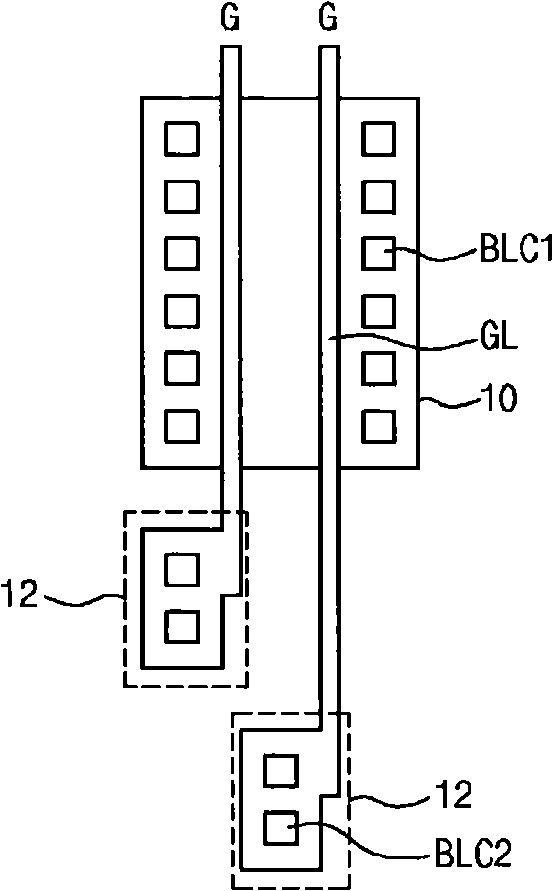

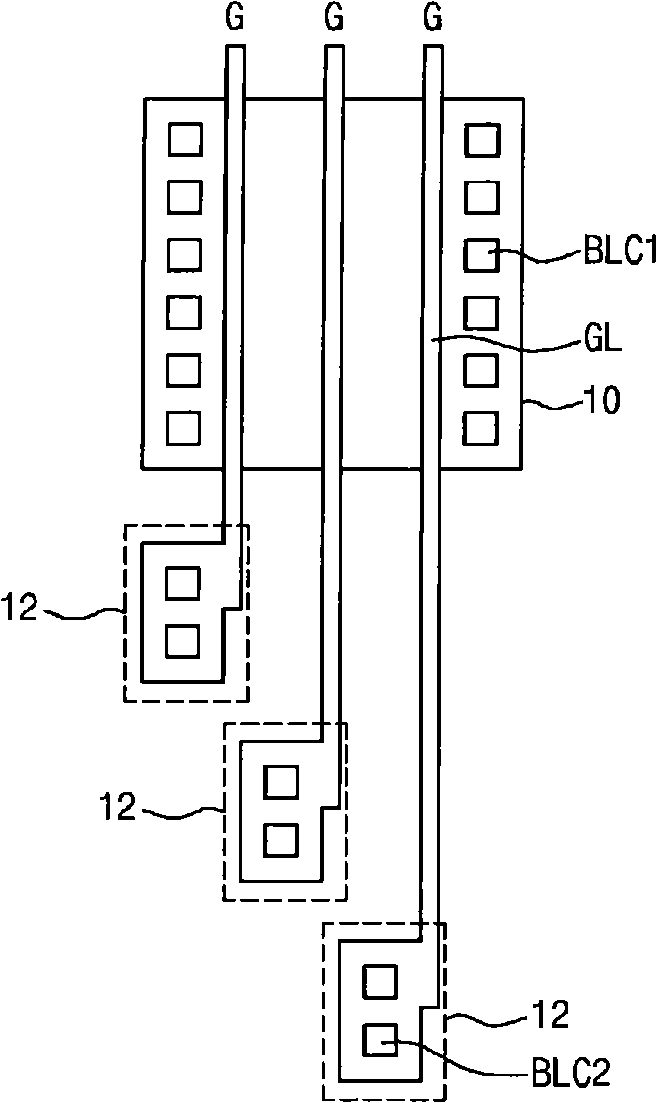

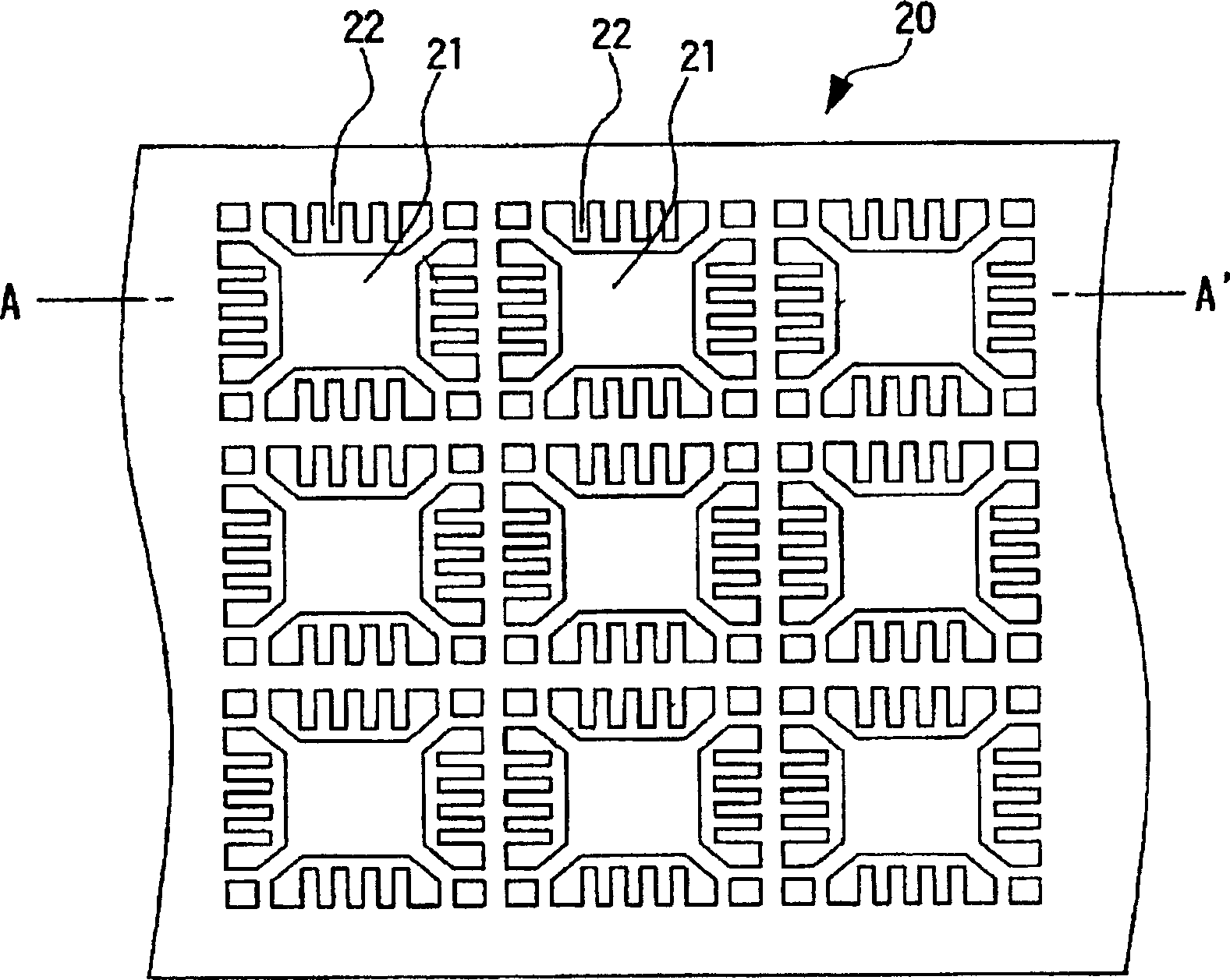

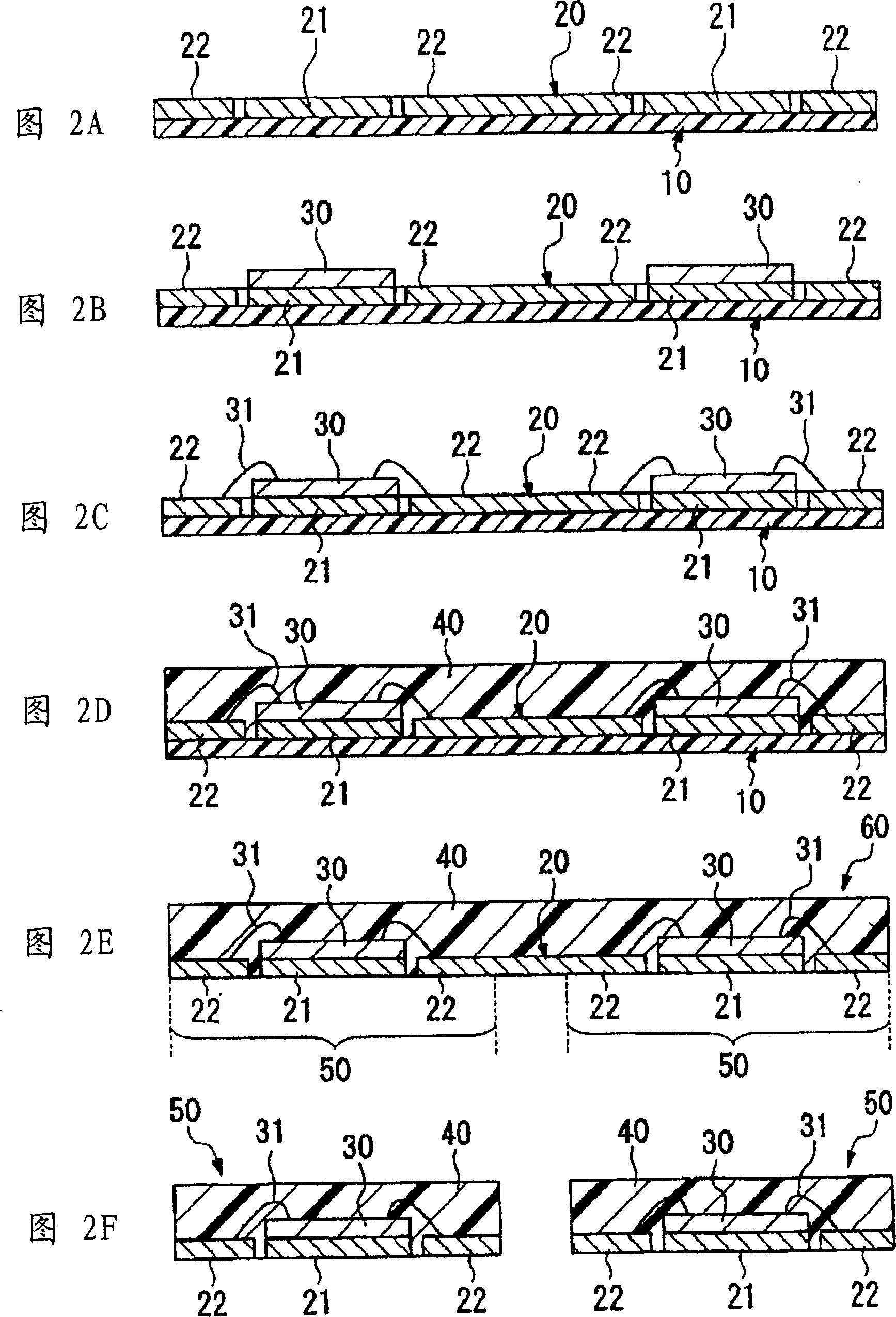

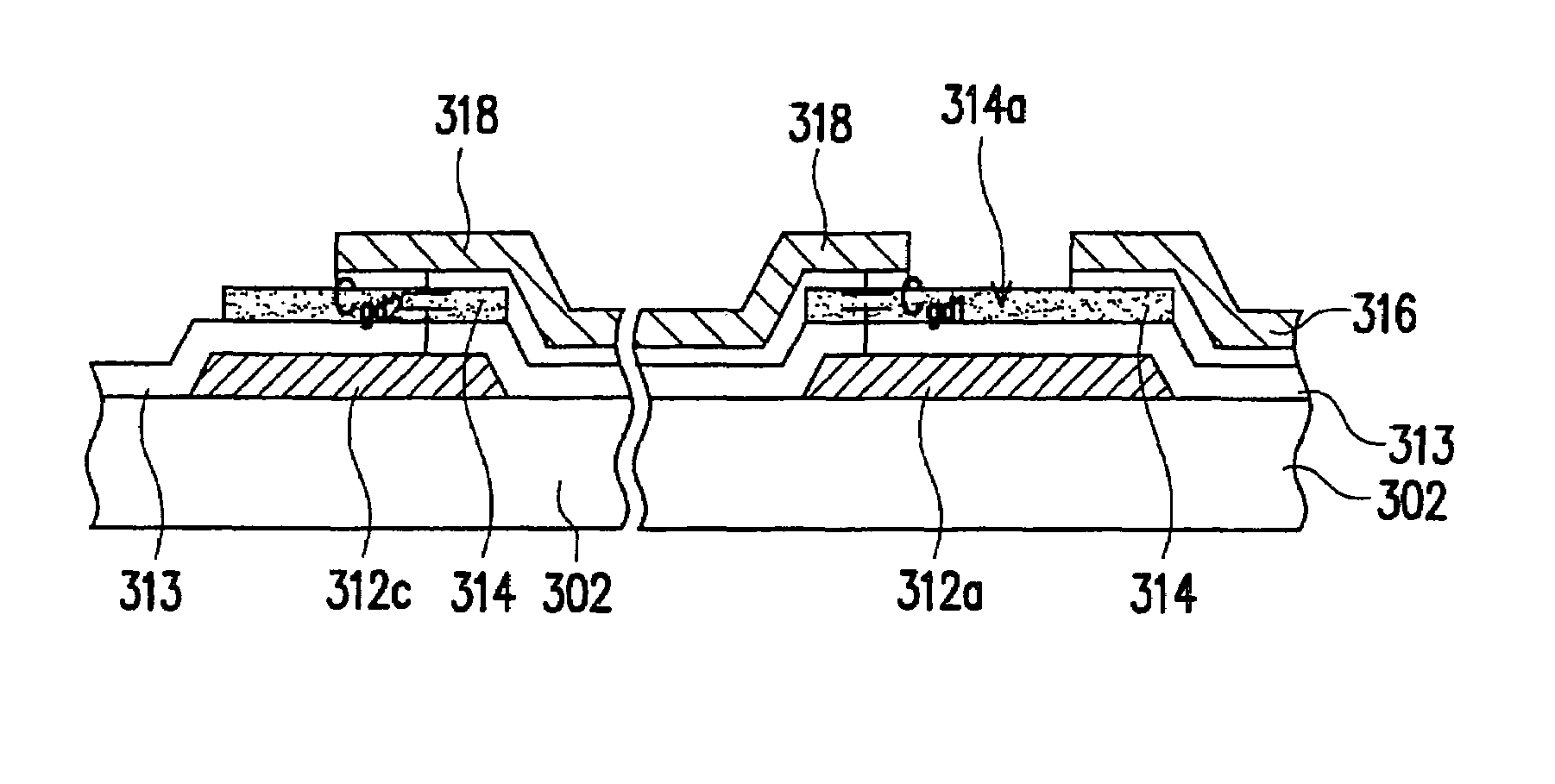

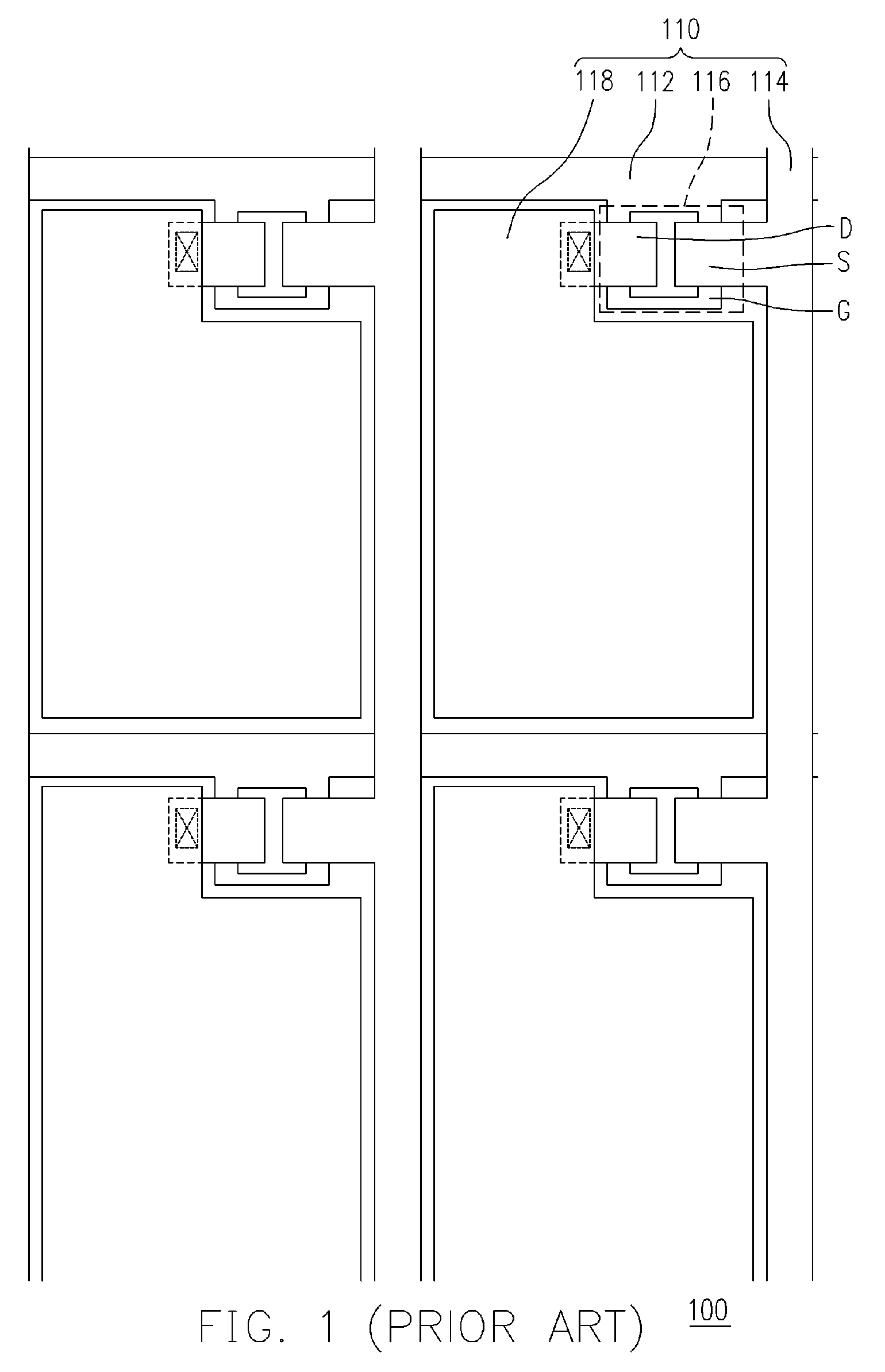

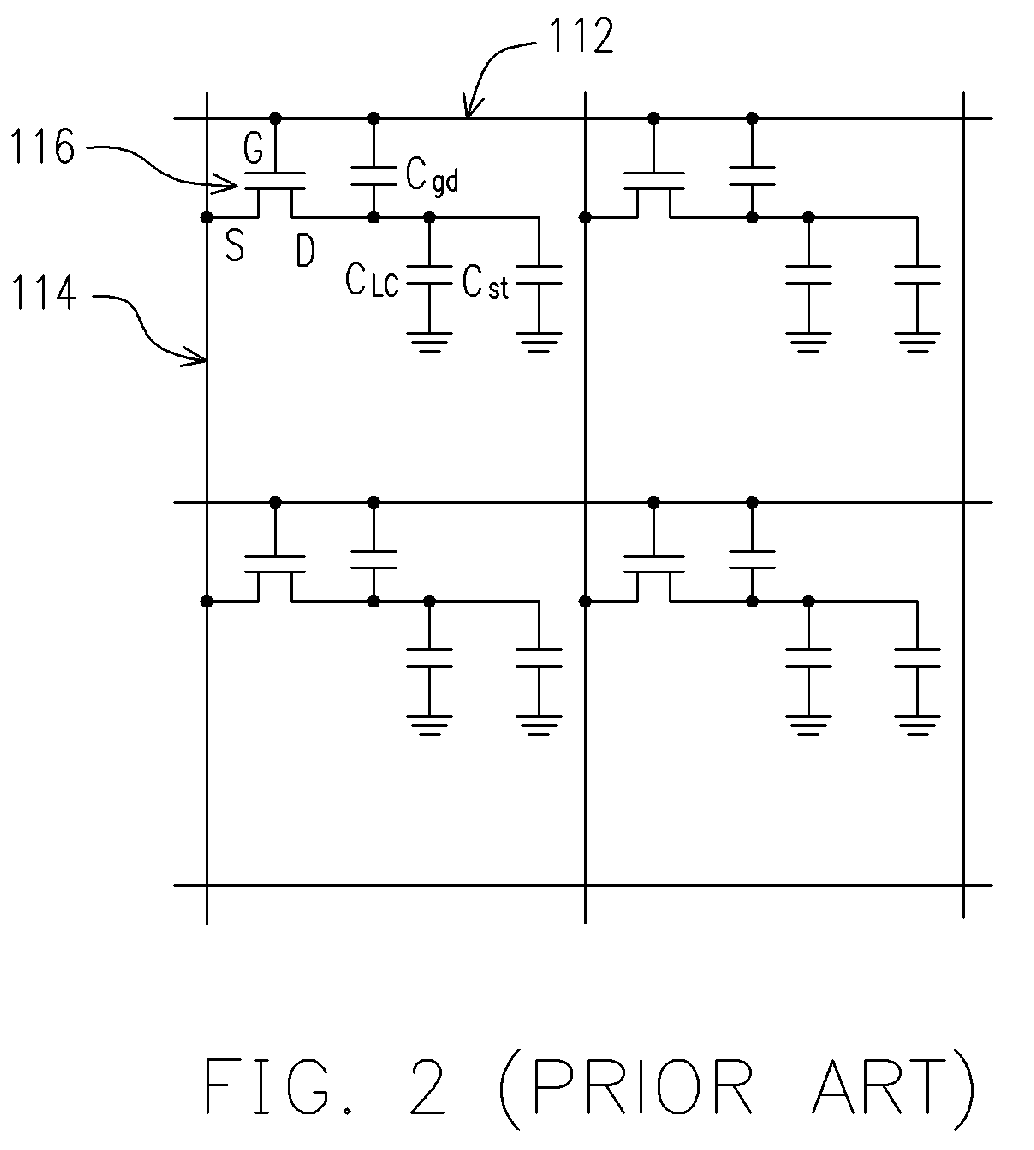

Thin film transistor, thin film transistor array and repairing method thereof

ActiveUS20070187686A1Avoid unqualifiedSolid-state devicesNon-linear opticsTransistor arrayParasitic capacitance

A thin film transistor (TFT) including a gate, a semiconductor layer, a source and a drain is provided. The gate has a control part, a connection part and a capacitance compensation part. The connection part is disposed between the control part and the capacitance compensation part for joining the two parts together. The semiconductor layer is disposed over the gate, the source and the drain are disposed on the semiconductor layer. An end of the drain overlaps the control part of the gate with a first region for composing a first parasitic capacitance; while another end of the drain overlaps the capacitance compensation part of the gate with a second region for composing a second parasitic capacitance. In a TFT array with the TFT, the sum of the first parasitic capacitance and the second parasitic capacitance is a constant.

Owner:NYTELL SOFTWARE LLC

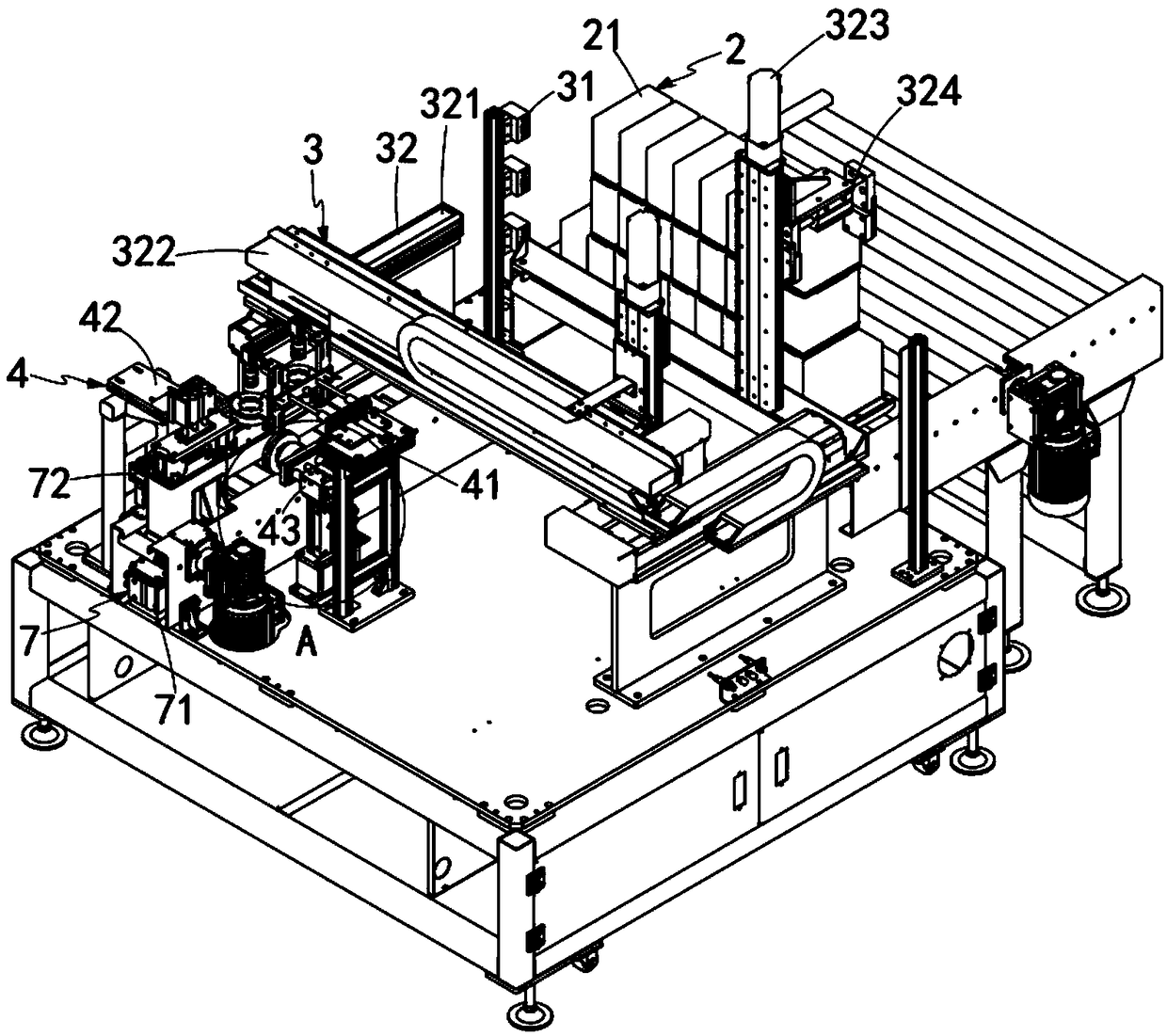

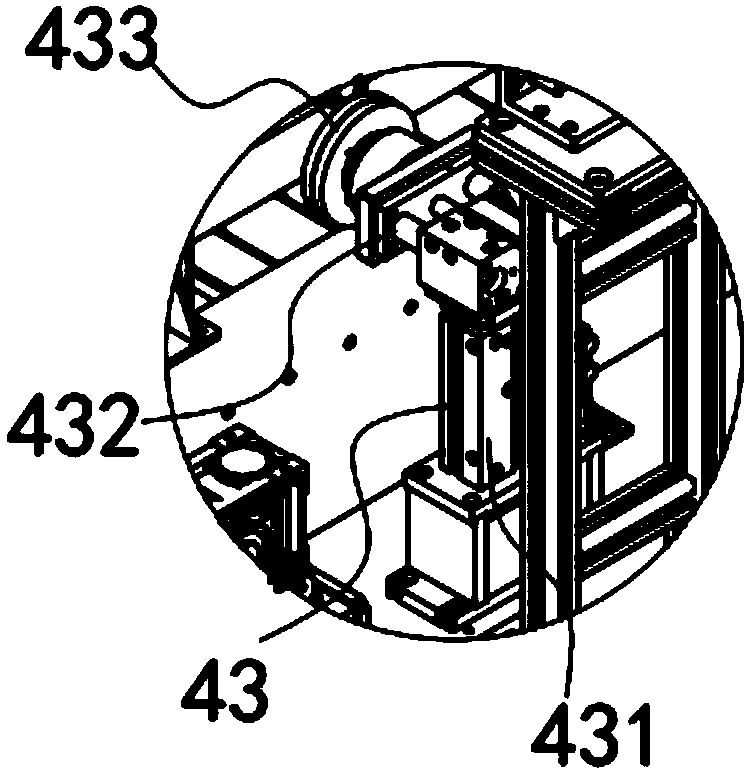

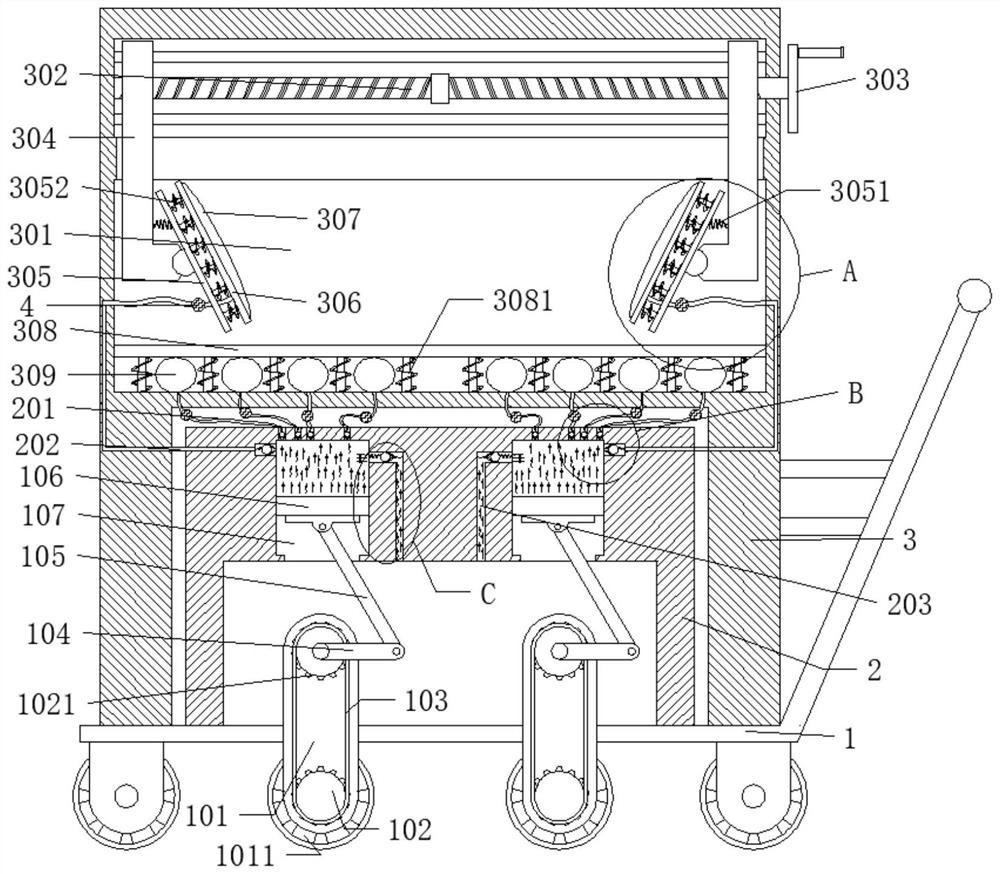

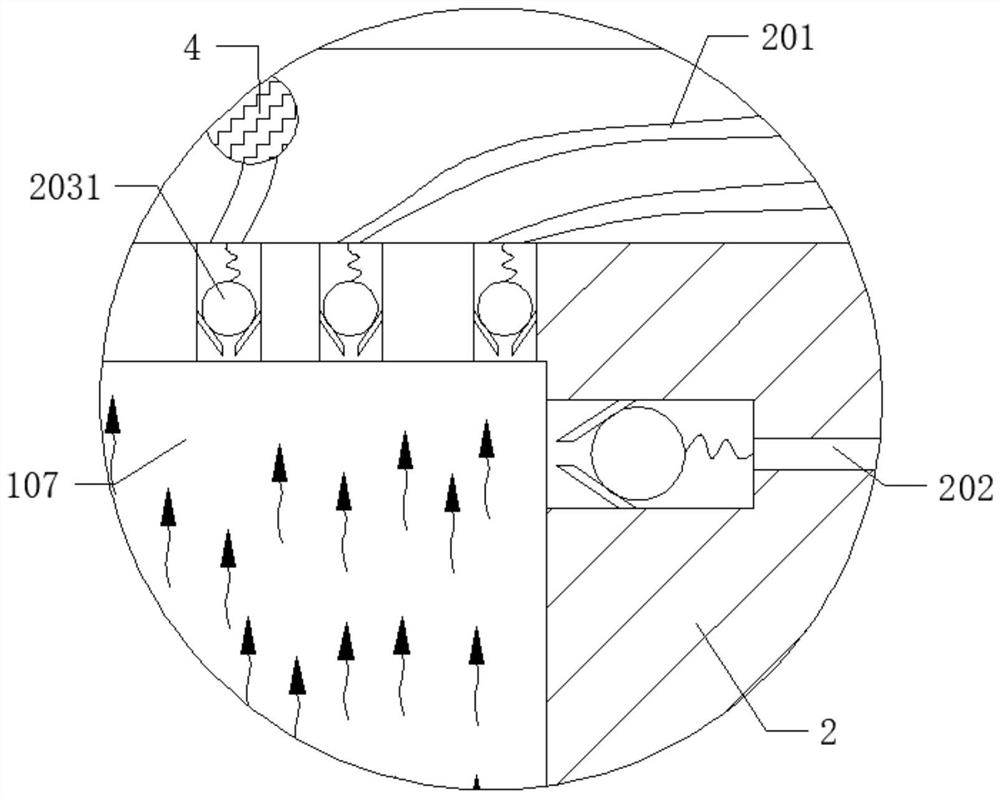

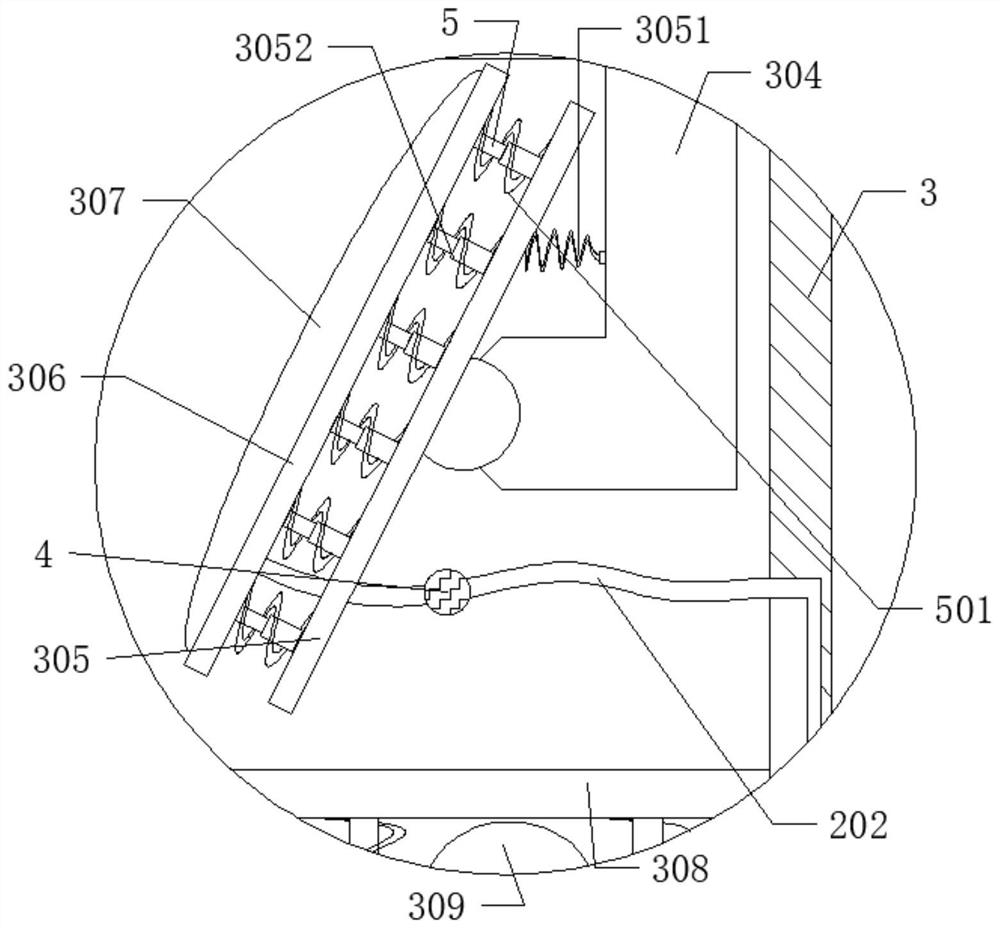

Automatic seal ring loading system for lead-acid battery after cover closure

ActiveCN108511782ASolve the technical problem of poor loading accuracySolve technical problems with poor accuracyAssembling battery machinesFinal product manufactureEngineeringMechanical engineering

The invention provides an automatic seal ring loading system for a lead-acid battery after cover closure. The automatic seal ring loading system comprises a conveying mechanism, a material pile arranged at an input end of the conveying mechanism, a feeding device located on the rear side of the material pile, a detection and correction device located on the rear side of the feeding device as wellas a seal ring loading device located on the rear side of the detection and correction device. Perpendicularity of a pole of the lead-acid battery is corrected by the detection and correction device,then the seal ring is loaded to the pole by the seal ring loading device, the seal ring is rotationally pressed by a pressing mechanism in a loading process, the technical problem of low seal ring loading precision for the pole of the lead-acid battery is solved, sealing performance of the seal ring is improved, seal ring loading speed is increased, and poor sealing effect caused by twist in the seal ring loading process is prevented.

Owner:浙江金麦特自动化系统有限公司

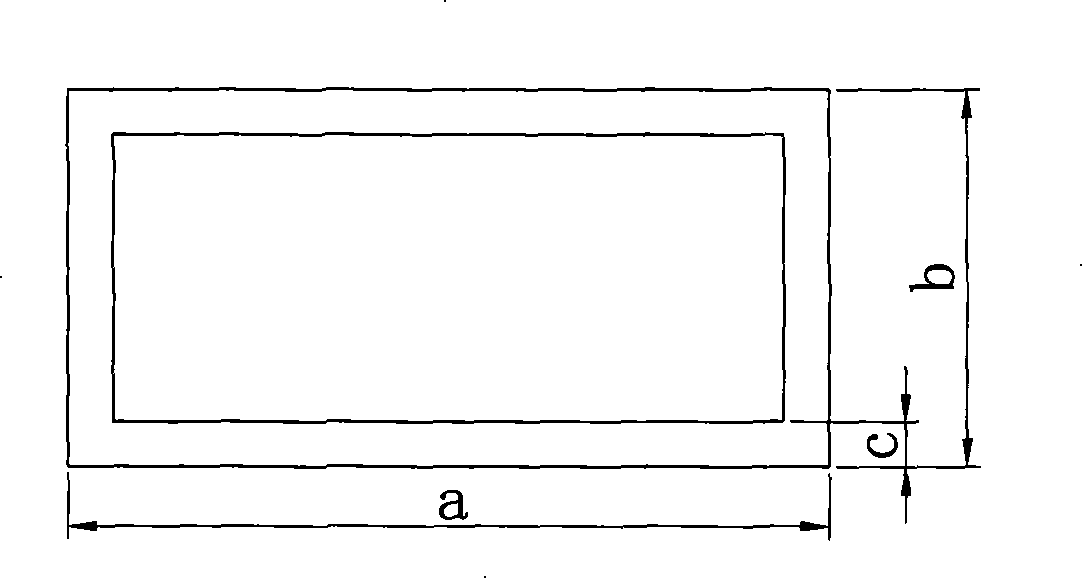

Method for processing austenite seamless stainless steel rectangular water pipe used for turbine generator

ActiveCN101245879AReduced intermediate annealingReduce cleaning effectRigid pipesRare-earth elementLanthanum

The invention relates to a processing method of an austenitic seamless stainless steel rectangle water pipe used for a turbo-generator, which sequentially has the processing steps of hot rolling round bar, continuous extruding round pipe, drawing an elliptic pipe with a non-core bar, drawing a rectangle pipe with a short core bar, and carrying out solution treatment and annealing to obtain the finished product. According to the mass percentage, the stainless steel which is adopted by the water pipe contains carbon less than or equal to 0.030%, silicon less than or equal to 1.0%, manganese less than or equal to 2.0%, sulphur less than or equal to 0.030 %, phosphorus less than or equal to 0.035%, chromium ranging from 18.00% to 20.00%, Ni ranging from 9.0% to 13.0%, rare earth element Re ranging from 0.002% to 0.008%, silver ranging from 0.001% to 0.005%, and iron and other impurities with the residual quantity; wherein, the rare earth element is a compound which consists of 40% to 45% of Ce, 40% to 45% of lanthanum and Yt with residual quantity according to the mass percentage. The processed water pipe has good toughness, strong corrosion resistance and low magnetic permeability, and is an ideal material used for the motor stator water pipes of 1000MW-class turbo-generators.

Owner:TAIXING SHENGDA COPPER IND CO LTD

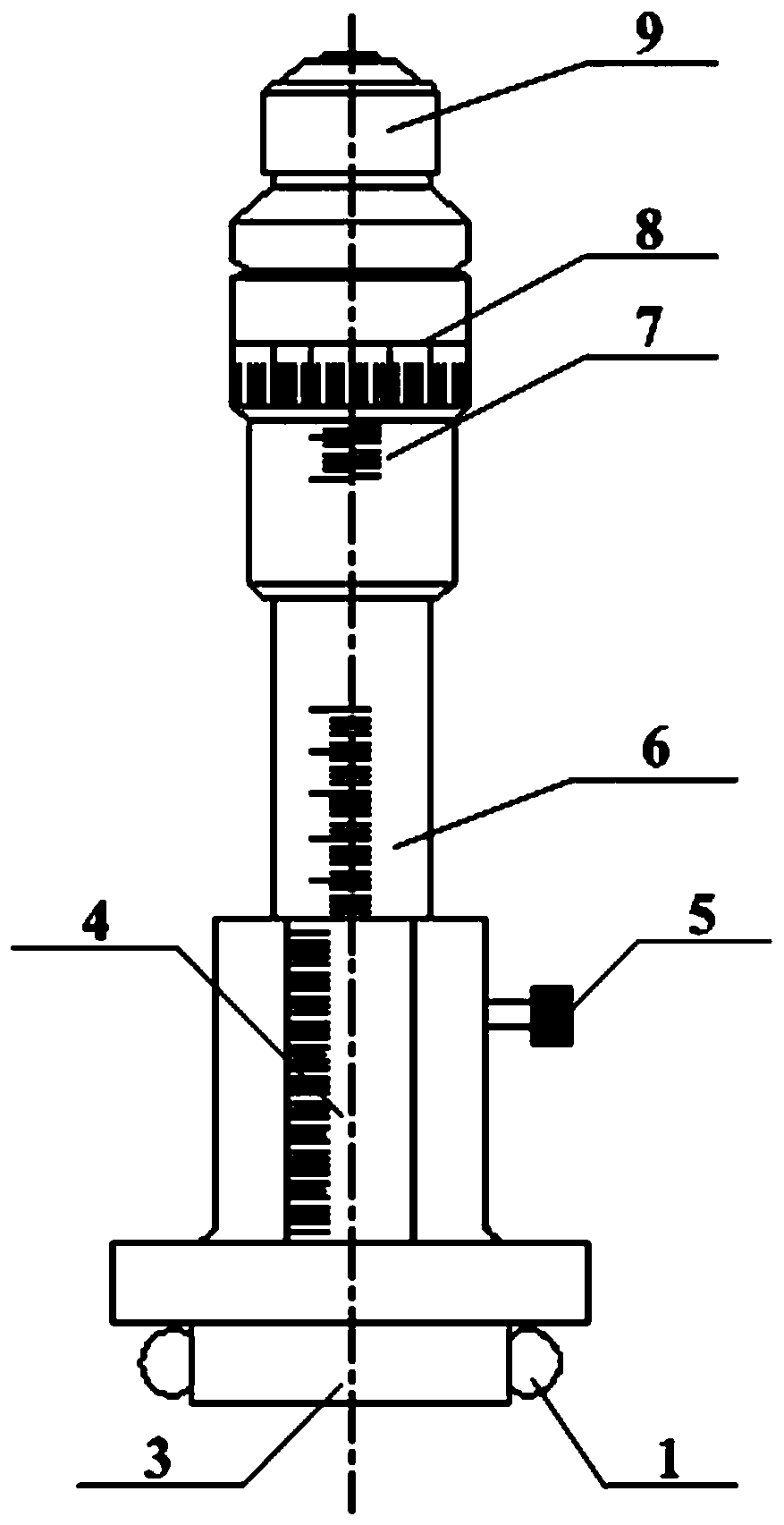

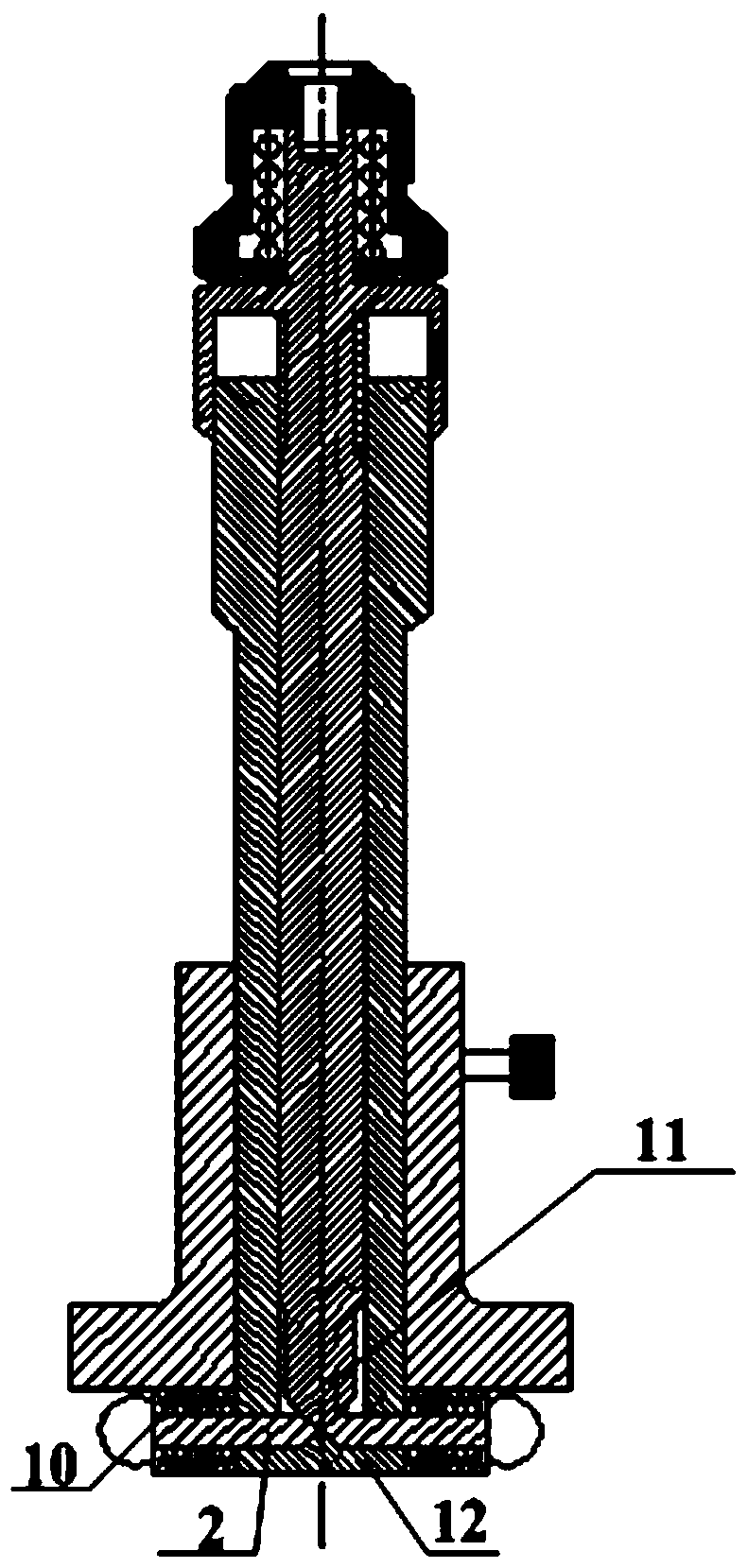

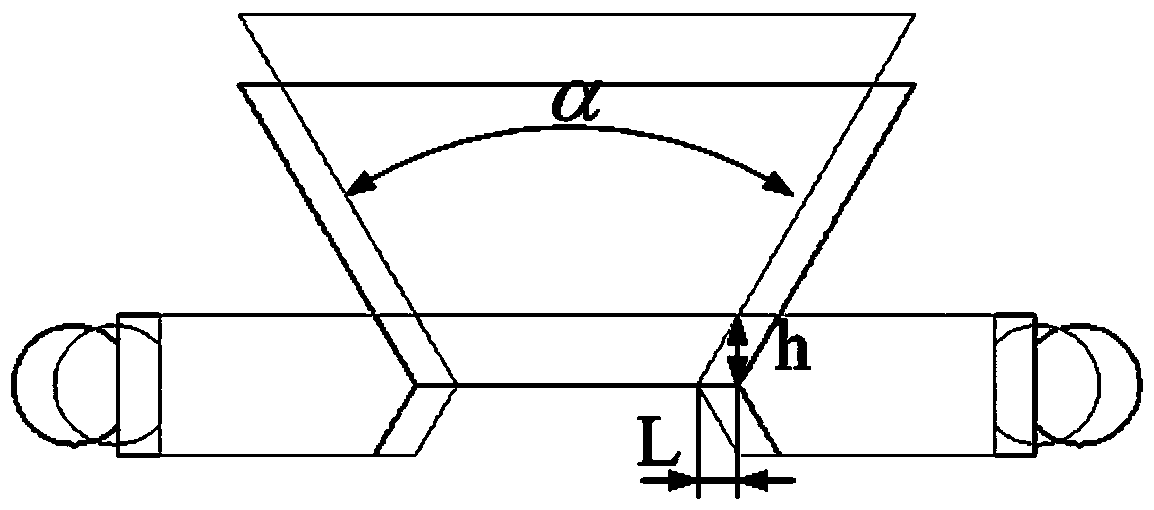

Conicity measuring device and method of inner taper hole

PendingCN108151625AQuick measurementAccurate measurementAngles/taper measurementsMeasurement deviceMicrometer

The invention relates to a conicity measuring device and method of an inner taper hole. A pedestal is arranged in the bottom end of a measuring sleeve, and a scale sleeve is arranged in the top end ofthe measuring sleeve; the top end of the scale sleeve is provided with a microdrum and a ratchet sleeve successively; the measuring sleeve is internally provided with a micrometer screw with a taperhead, and the top end of the micrometer screw with the taper head is connected with the ratchet sleeve and integrated with the microdrum; and the pedestal is internally provided with a guide slot, theguide slot is internally provided with measuring claws, the outer ends of the measuring claws are connected with bulbs respectively, and the taper head of the micrometer screw makes contact with thetwo measuring claws. The device and method are mainly used to measure the conicity of the inner taper hole of the sleeve, the measuring device can carry out rapid and accurate measurement in a production site and provides convenience for adjustment of a machine tool, the conicity can be measured at any time, and unqualified products due to out-of-tolerance of the conicity dimension are avoided.

Owner:SHENYANG AEROSPACE XINGUANG GRP

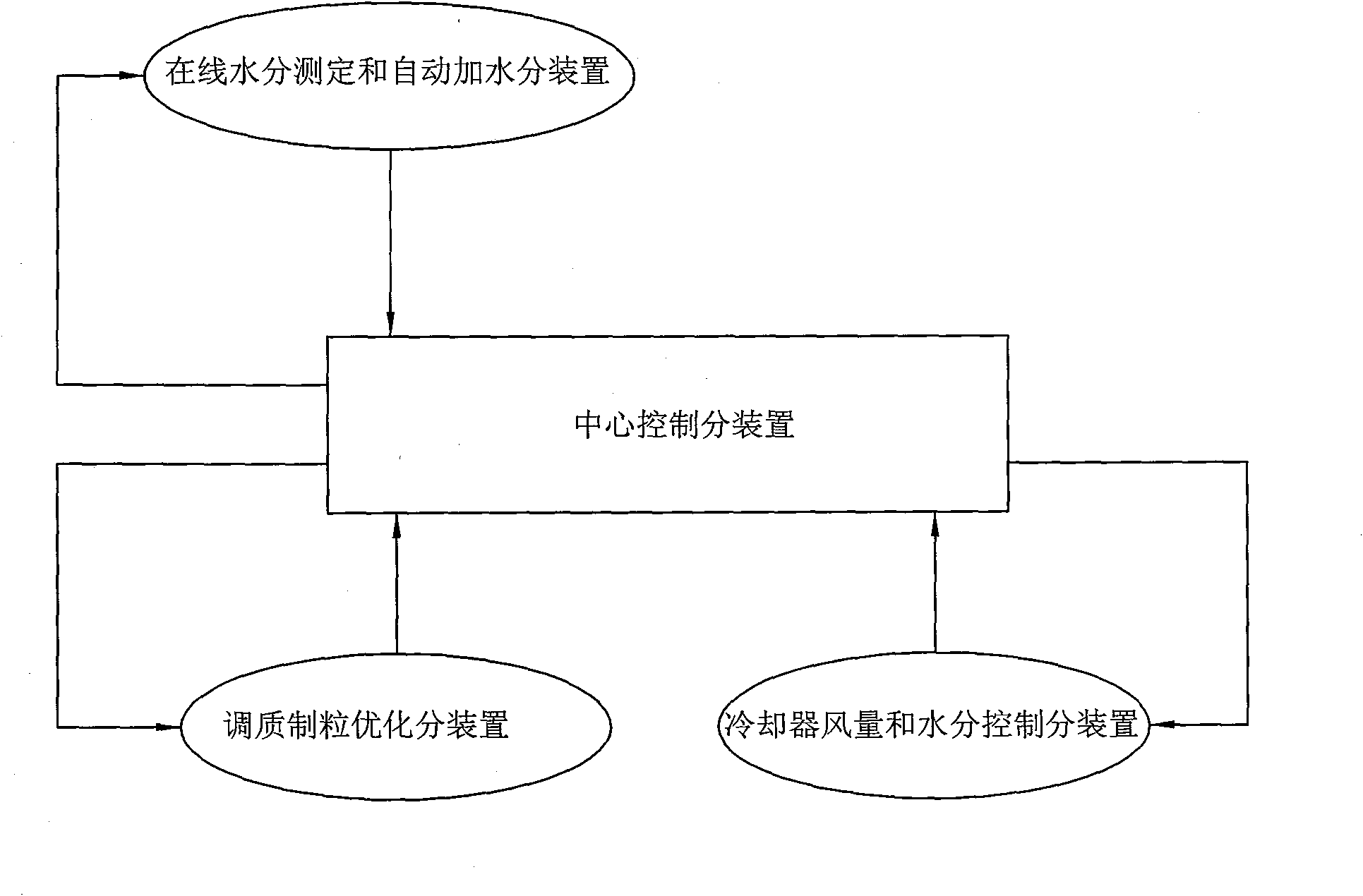

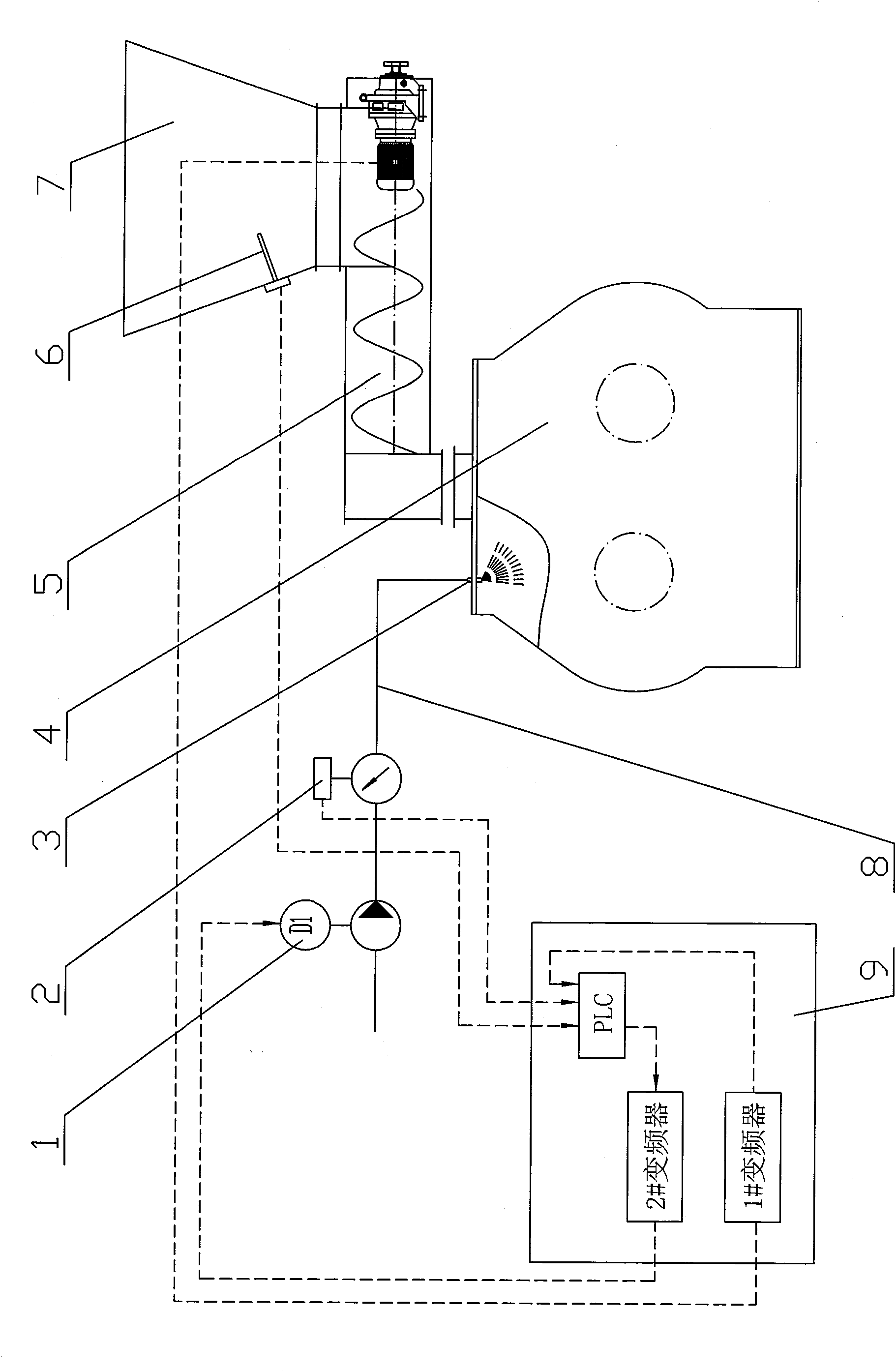

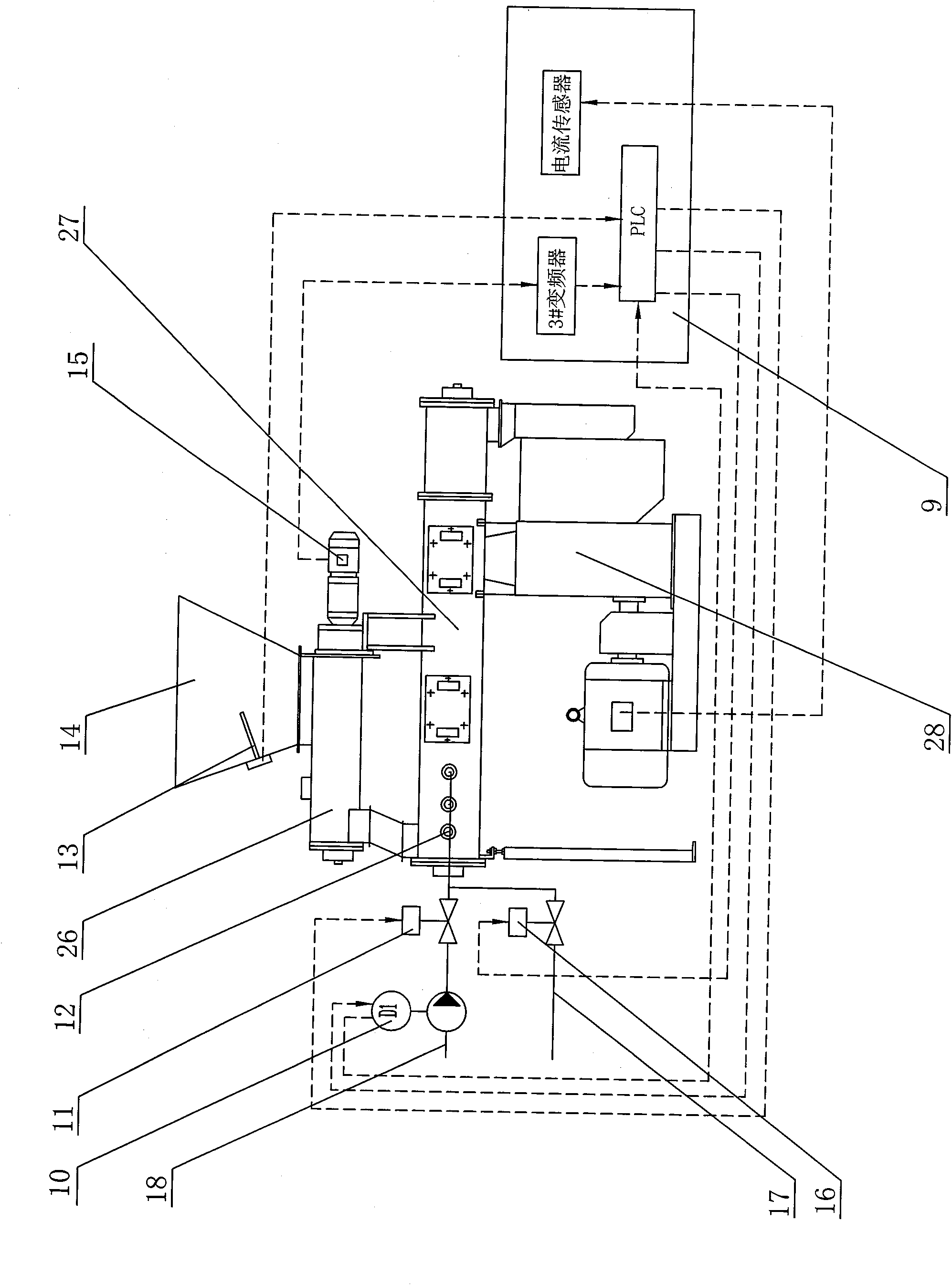

On-line water detection and pellet-fodder optimization device

ActiveCN101782564AAvoid failing moisture content indicatorsEnsure consistencyFeeding-stuffTotal factory controlAir volumeEngineering

The invention discloses an on-line water detection and pellet-fodder optimization device which comprises a powdery material buffer storehouse, a screw feeder, a granulator, a conditioner and a cooler, and is characterized in that the whole set of granulating equipment comprises an on-line water determination and automatic water feeding device, a conditioning, granulating and optimizing separated device, a cooler air volume and water control separated device and a central control separated device; and the central control separated device is respectively connected with the on-line water determination and automatic water feeding device, the conditioning, granulating and optimizing separated device, and the cooler air volume and water control separated device. The on-line water detection and pellet-fodder optimization device has the advantages of timely and precise control and convenient use operation, prevents the problem that the water content index of a large amount of finished productmaterial is unqualified because the water control is not timely, can keep the consistency of water in finished fodder and improve the fodder quality, saves time and labor, and improves the working efficiency and reduces the energy consumption; and in addition, the device prolongs the service life of a granulator circular mold through the on-line precise control of water when in fodder processing.

Owner:JIANGSU GUOLIANG STORAGE ENG CO LTD

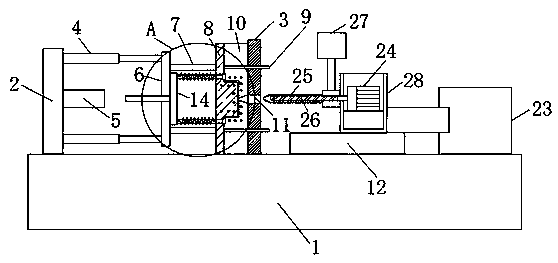

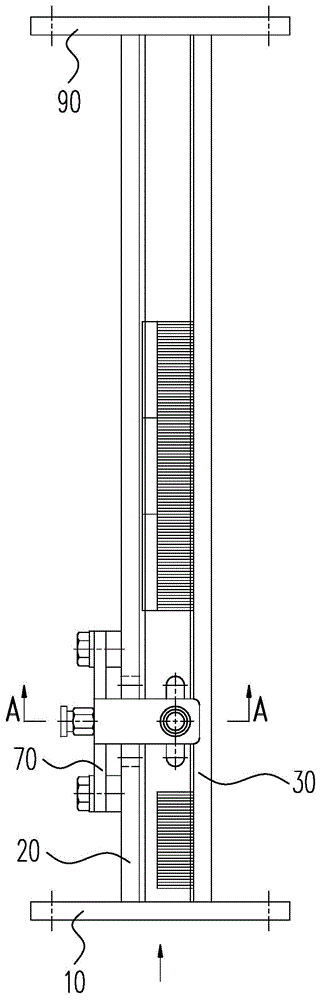

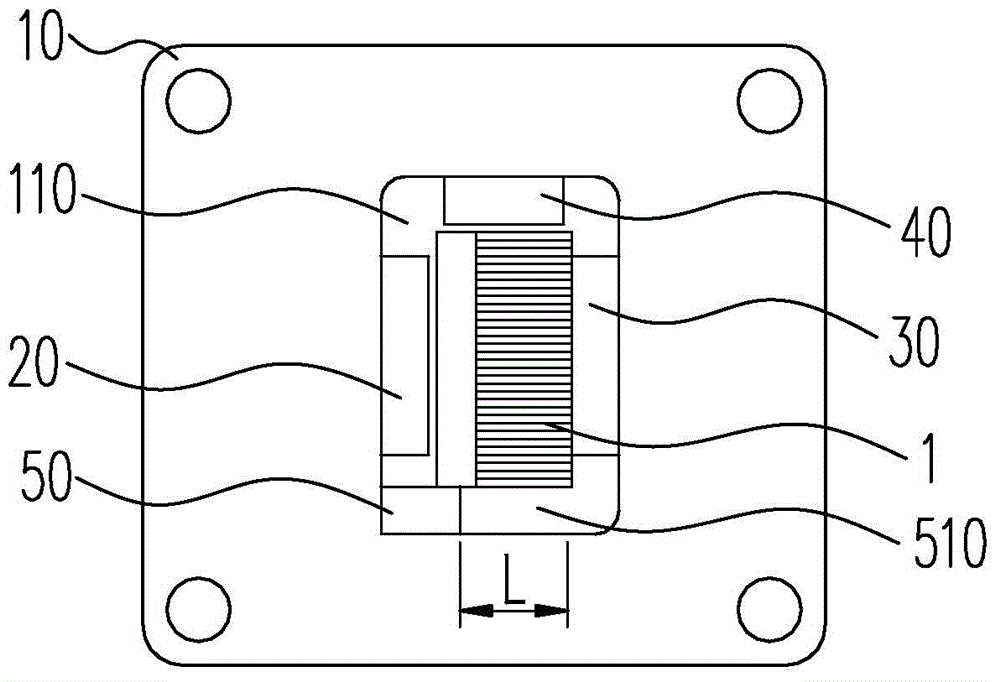

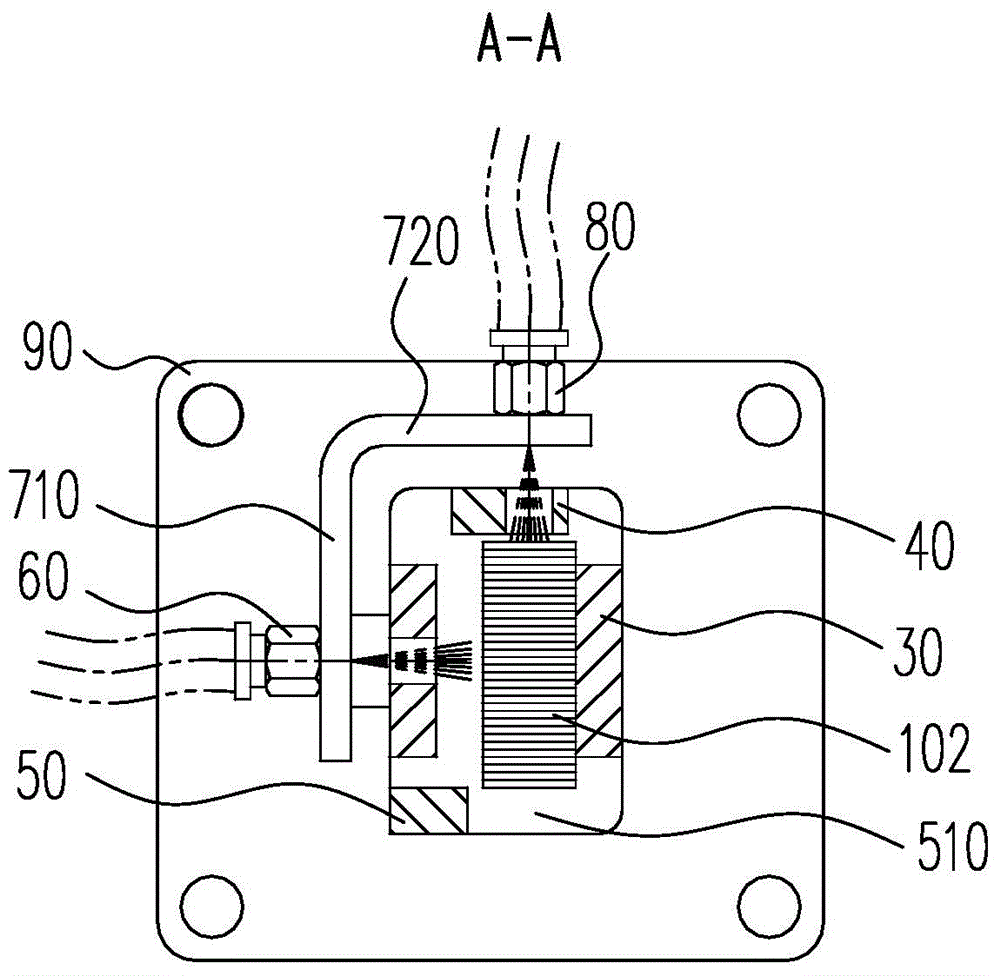

Self-aligning sintering clamp and method for semiconductor laser chip

ActiveCN105896307ASimple structureLow costLaser detailsSemiconductor lasersSemiconductor chipEngineering

The invention relates to a self-aligning sintering clamp and method for a semiconductor laser chip. The clamp comprises a pedestal, a guide rail support, and a press block. The pedestal is provided with a positioning card slot matched with a heat sink. Two sides of the press block are provided with symmetric positioning racks. The guide rail support is vertically disposed on the pedestal, and is provided with symmetric suspension arms. The interior of each suspension arm is provided with a positioning guide rail. The positioning racks of the press block can be sleeved by the positioning guide rails, and move up and down in the positioning guide rails. The bottom end of the press block is provided with a press column. When the press block moves downwards, the press column compresses a chip on the heat sink. The invention also provides the method for sintering the semiconductor laser chip through the above clamp. The clamp is simple in structure, is low in cost, can achieve the self-aligning, and is convenient for operation and observation. The method can achieve the quick batch sintering of the semiconductor laser chips and heat sinks, and remarkably improves the sintering yield of the clamp.

Owner:Shandong Huaguang Optoelectronics Co. Ltd.

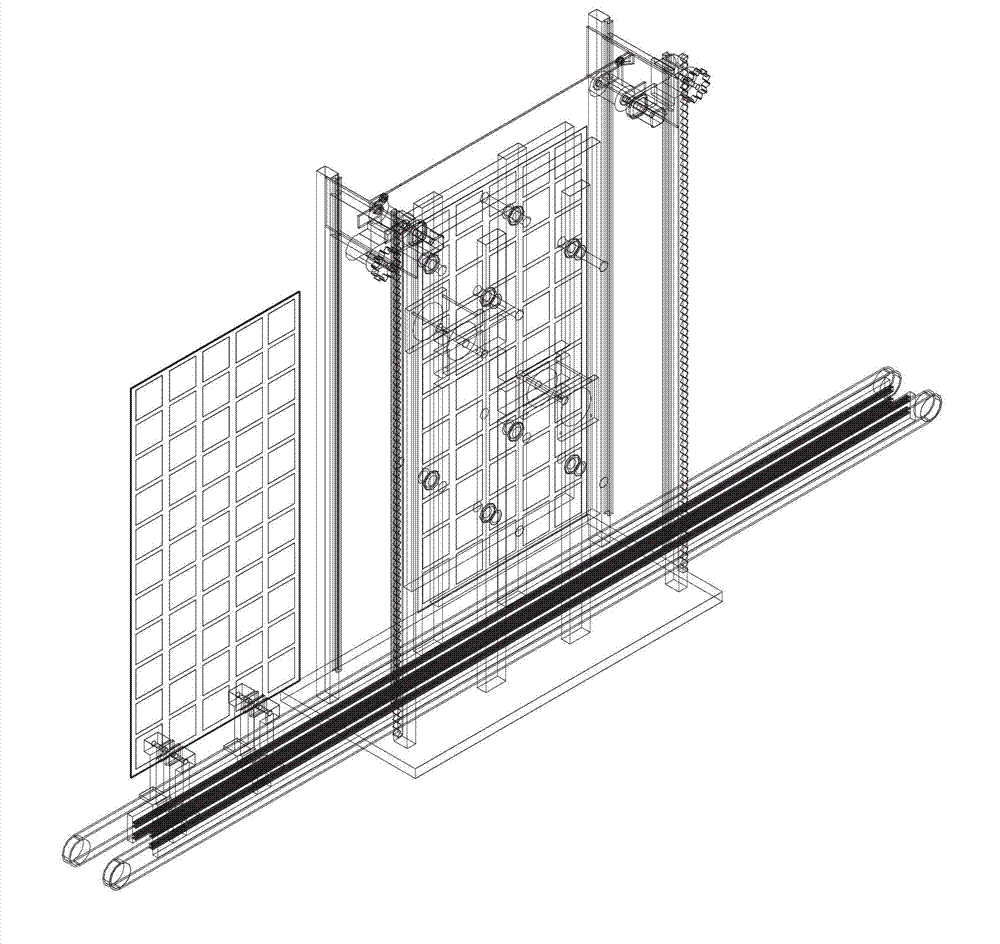

Stripping method applied to full-glass solar cell panel and stripping machine thereof

ActiveCN102856439AAvoid unqualifiedAvoid damageFinal product manufactureSemiconductor devicesPulp and paper industrySolar cell

The invention discloses a stripping machine which comprises two parallel brackets and a liftable cutting mechanism arranged between the brackets, wherein the cutting mechanism comprises two cutting roller wheels which are respectively arranged at the positions corresponding to the two brackets, gold steel wires wound between the two cutting roller wheels to form cutting lines, and two first driving parts for driving the two cutting roller wheels. On the basis, the invention also discloses a stripping method applied to a full-glass solar cell panel. According to the invention, the line cutting mode is adopted; the accuracy is high; the stripping machine stably works; the stripping machine and the stripping method are simple and convenient to operate; the full-glass solar cell panel can be cut apart from the middle to implement the separation of back glass; and the repair of defective full-glass solar cell panels becomes possible, so that the problem that the full-glass solar cell panel cannot be repaired is solved, and thus, the production cost is reduced to a great extent and the gap of no repair equipment for the full-glass solar cell panel is filled. Meanwhile, the resource waste and the environment pollution which are caused by direct abandon of the defective products are also reduced.

Owner:TIANJIN YINGLI NEW ENERGY RESOURCES

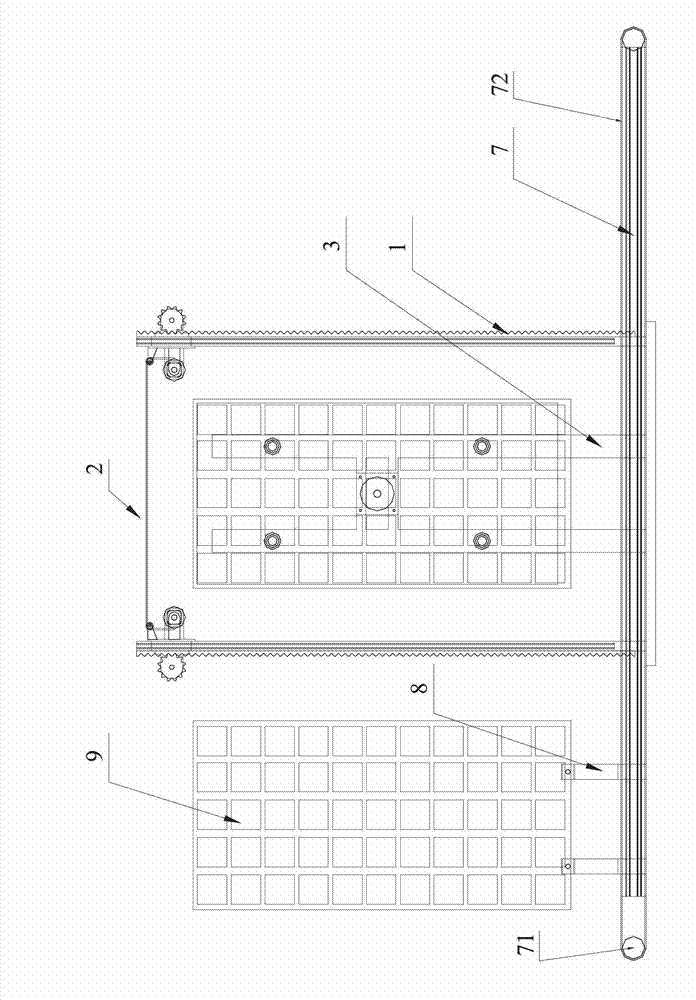

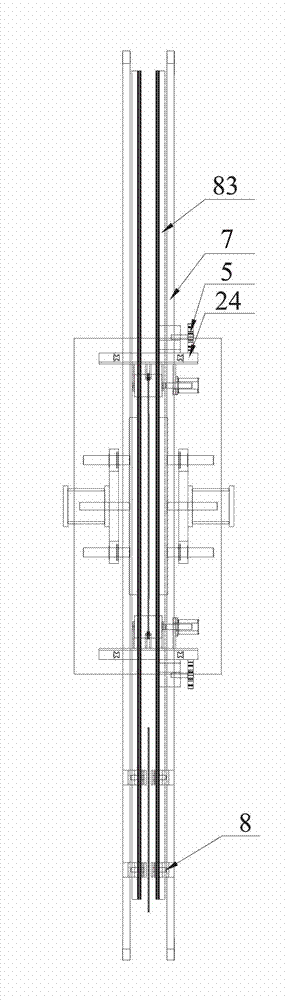

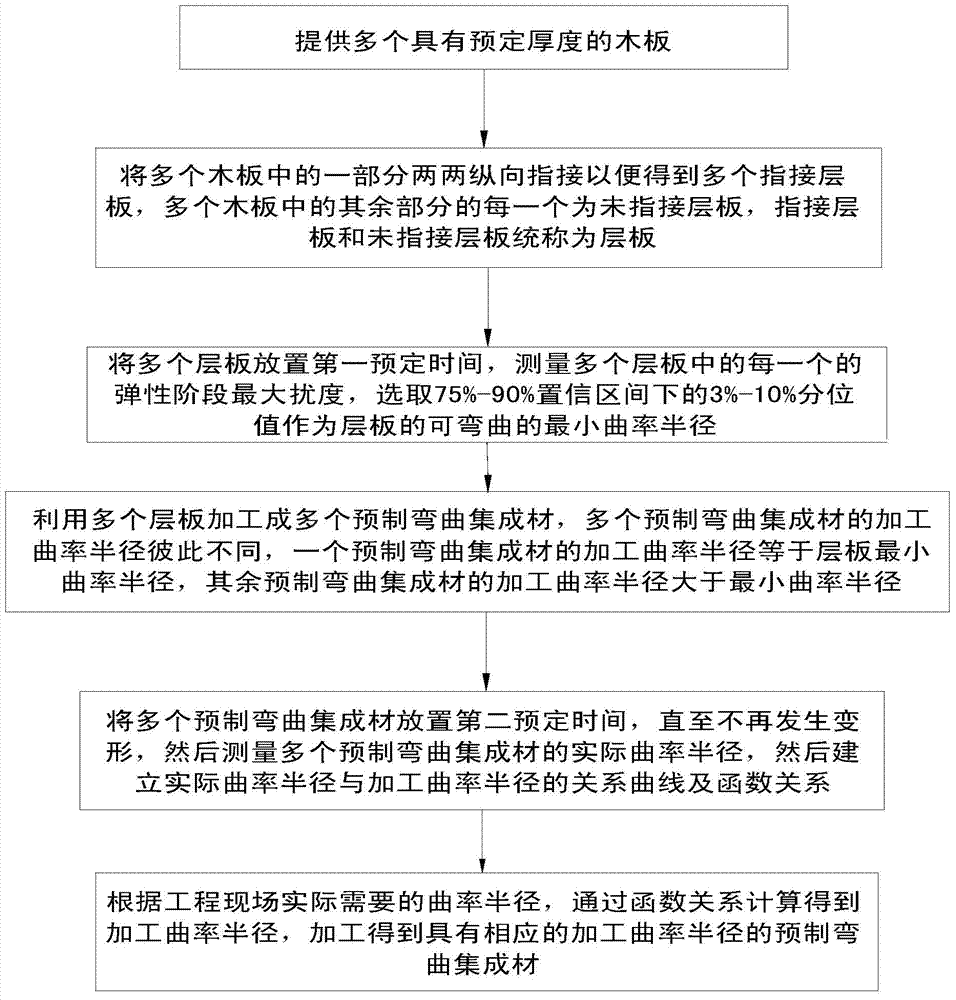

Manufacturing method of prefabricated bending integrated materials

ActiveCN104493918ASimple manufacturing methodEasy to implementWood veneer joiningWood stock bendingFinger jointManufacturing engineering

The invention discloses a manufacturing method of prefabricated bending integrated materials. The manufacturing method of the prefabricated bending integrated materials comprises the following steps that a plurality of wood plates with the preset thickness are provided; a part of wood plates in the plurality of wood plates are in longitudinal finger joint in pairs; the elastic stage maximum interference degree of a plurality of layer plates is measured, and in addition, the bendable minimum curvature radius of each layer plate is calculated; the plurality of layer plates are used for being processed into the prefabricated bending integrated materials with different curvature radii; the prefabricated bending integrated materials are placed until the prefabricated bending integrated materials cannot deform, then, the actual curvature radii of the prefabricated bending integrated materials are measured, and next, the relationship curve and the function relationship of the actual curvature radius and the processing curvature radius are established; according to the actually required curvature radius, the processing curvature radius is obtained through the calculation via the function relationship, and the prefabricated bending integrated materials with the corresponding processing curvature radius can be obtained through processing. The manufacturing method of the prefabricated bending integrated materials is simple and feasible, and the implementation is convenient.

Owner:BEIJING FORESTRY UNIVERSITY

Semiconductor device and its grid and metal line forming method

InactiveCN101312127AGuaranteed electrical performanceGuaranteed process impactTransistorSolid-state devicesEngineeringSemiconductor

The invention relates to a semiconductor device and gate and metal line forming method thereof and discloses a gate forming method of the semiconductor device having a gate bonding pad or a virtual gate pattern for protecting the gate pattern and the metal line forming method providing power supply to the semiconductor device and transmitting signals and the semiconductor device including a quadruple couple receiver input and output buffer. The semiconductor device disclosed forms the gate on an active region and is composed of a gate line and a gate bonding pad extending in a length direction. The bonding pad is in exterior side of the active region and is connected with the gate lien extending in a length direction and is aligned with an extension lien of a side edge of the gate line in the length direction. The gate can be used for a virtual gate or an accessorial pattern. Moreover, the semiconductor device disclosed includes a first metal line pattern composed of a plurality of units and providing different power supplies on blocks, a second metal line pattern transmitting signals to the unit between the first metal line patterns and a metal line of the virtual metal line pattern formed by image that is divided into above two patterns in the length direction between the first metal line patterns in a region where the second metal line pattern is not formed.

Owner:SK HYNIX INC

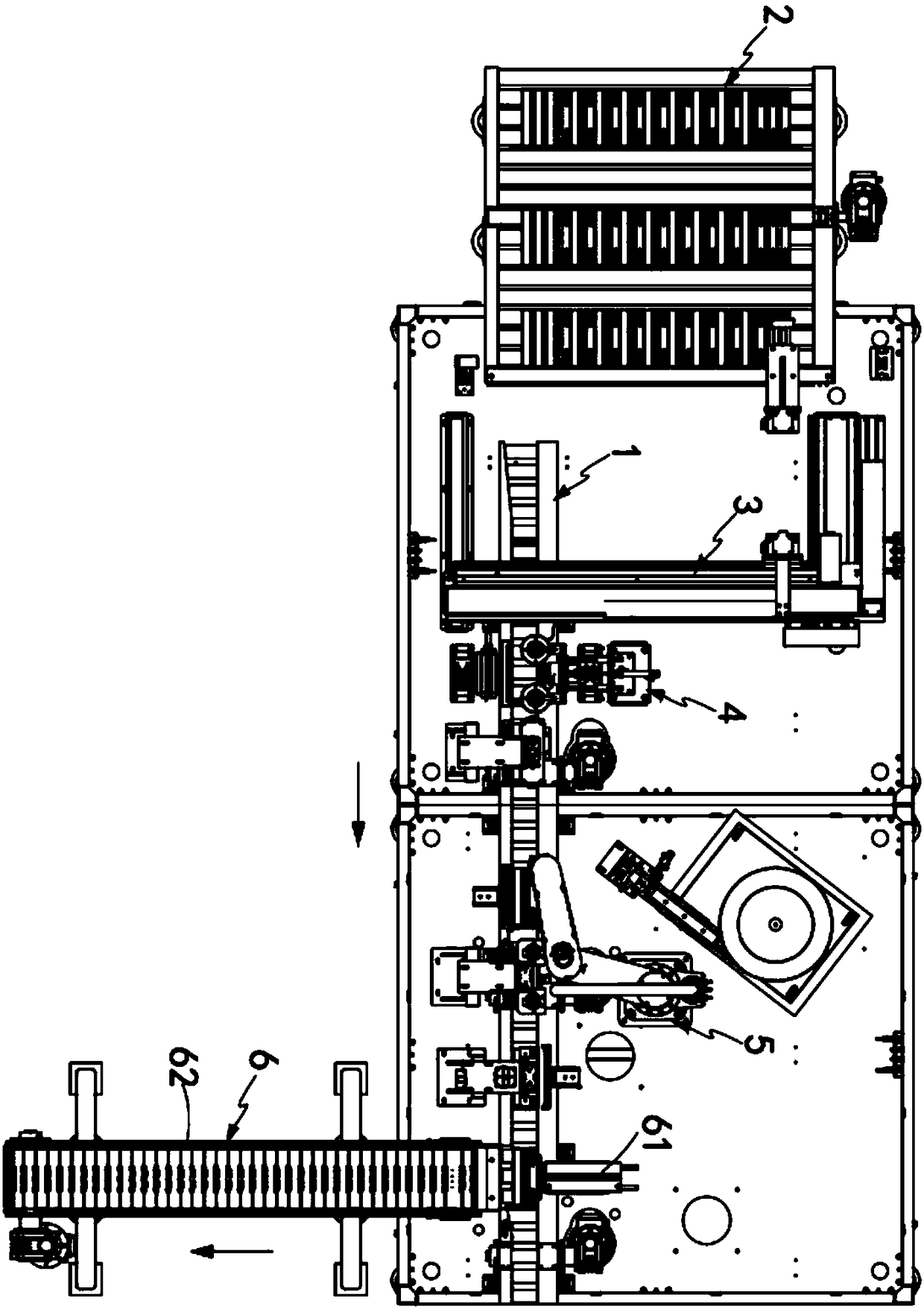

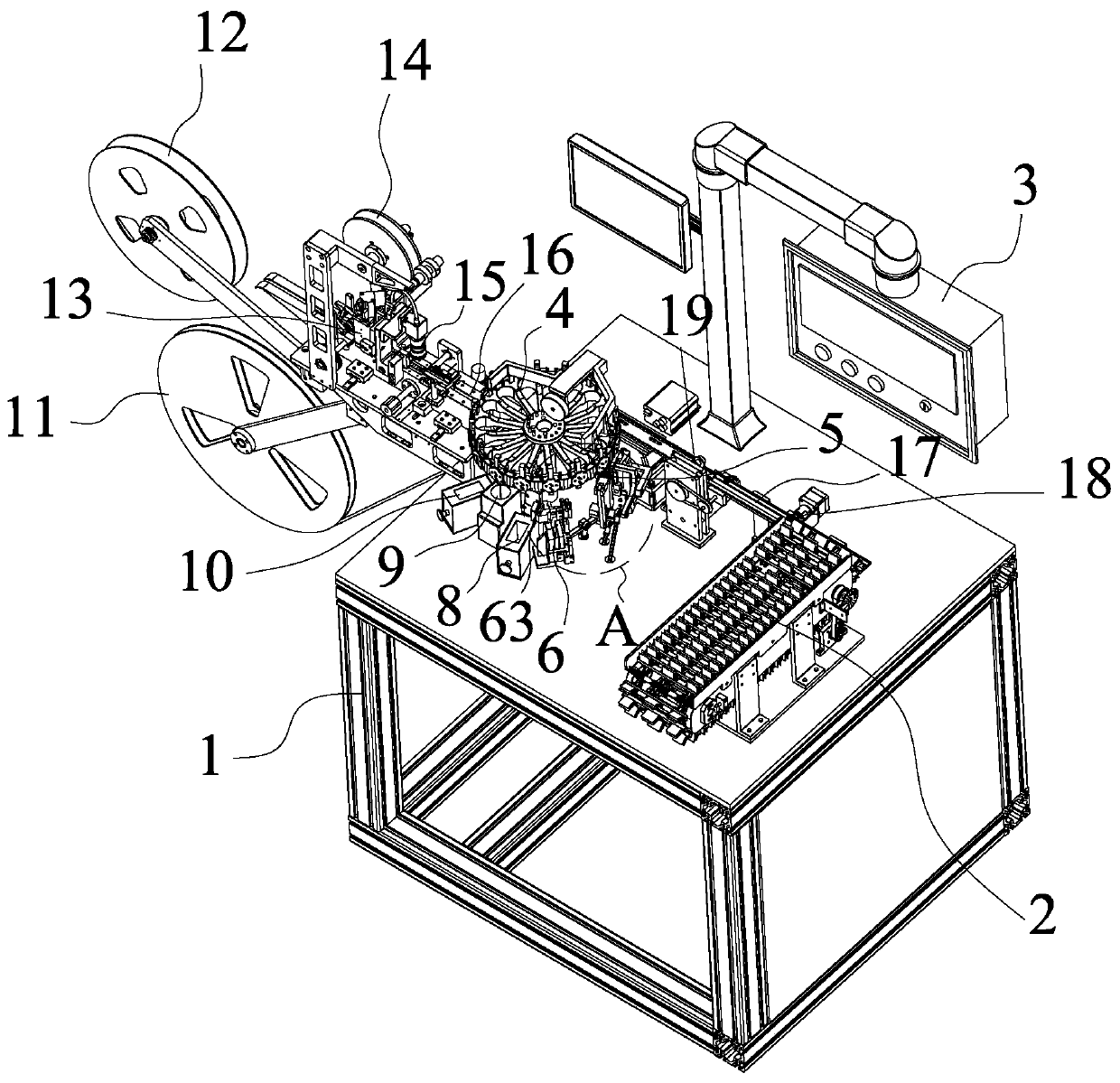

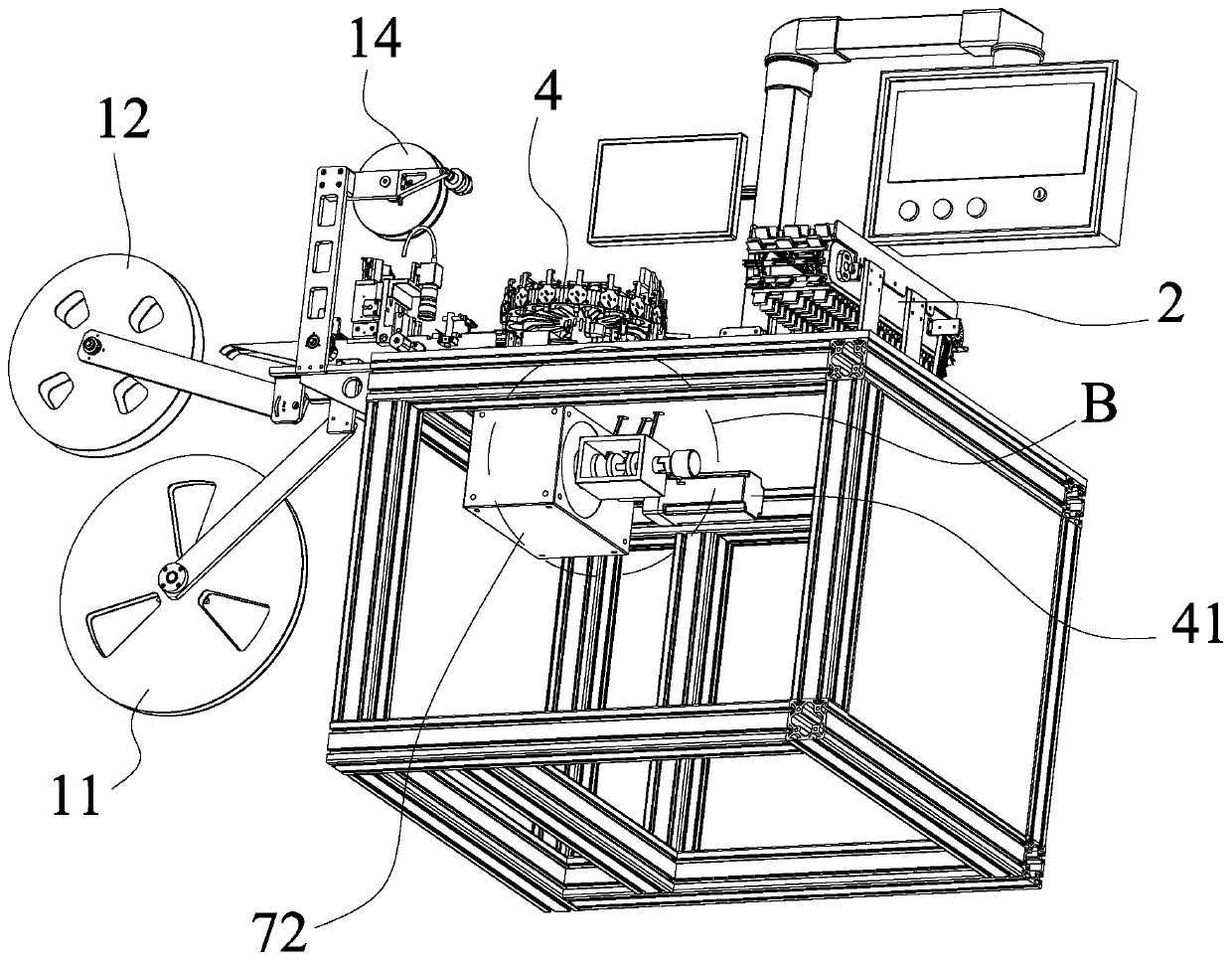

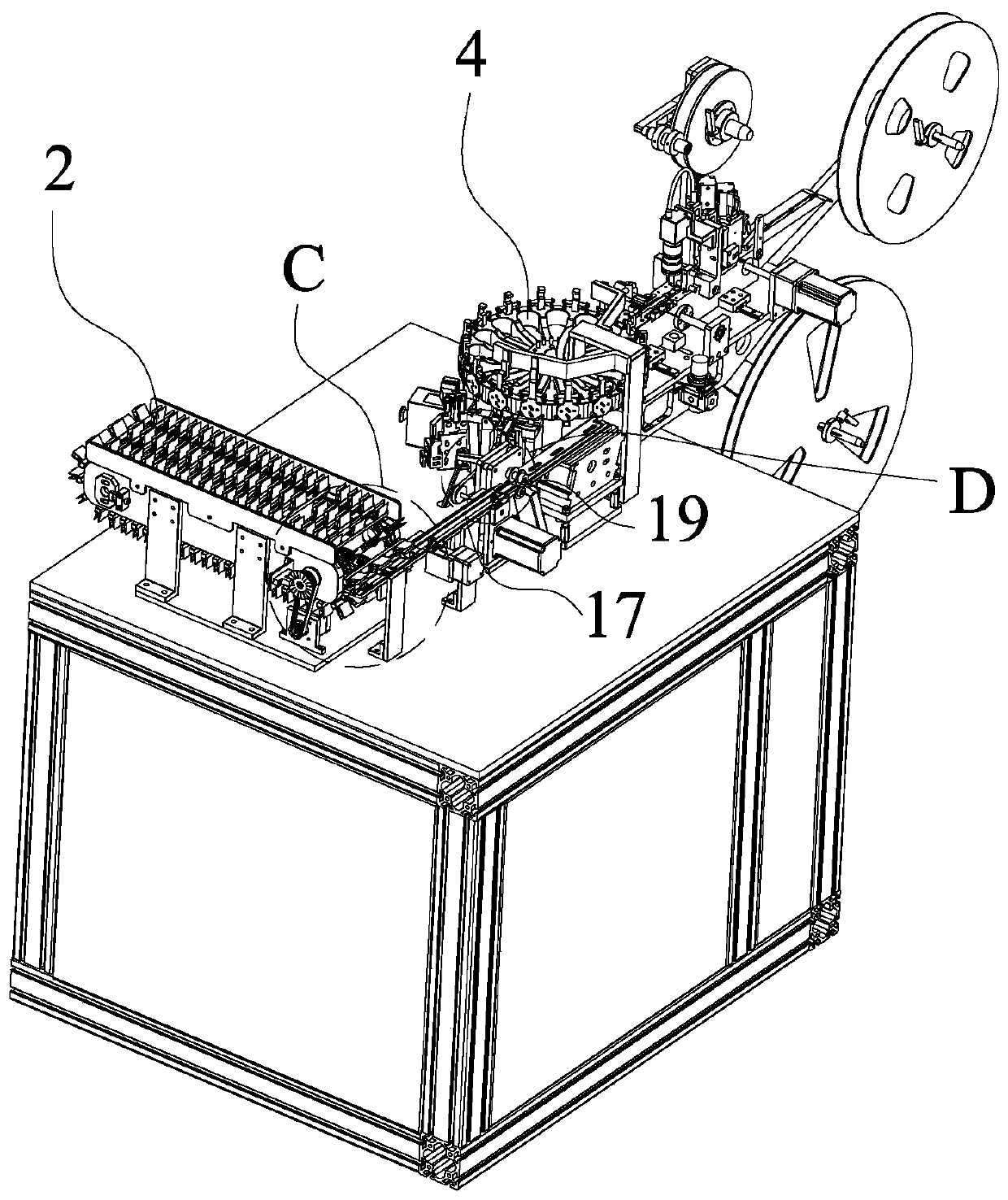

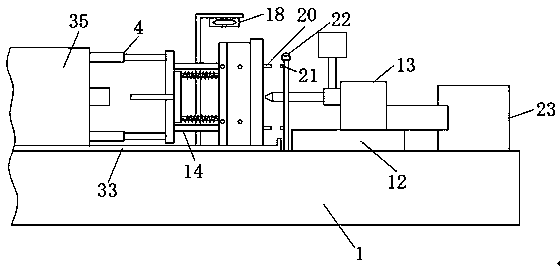

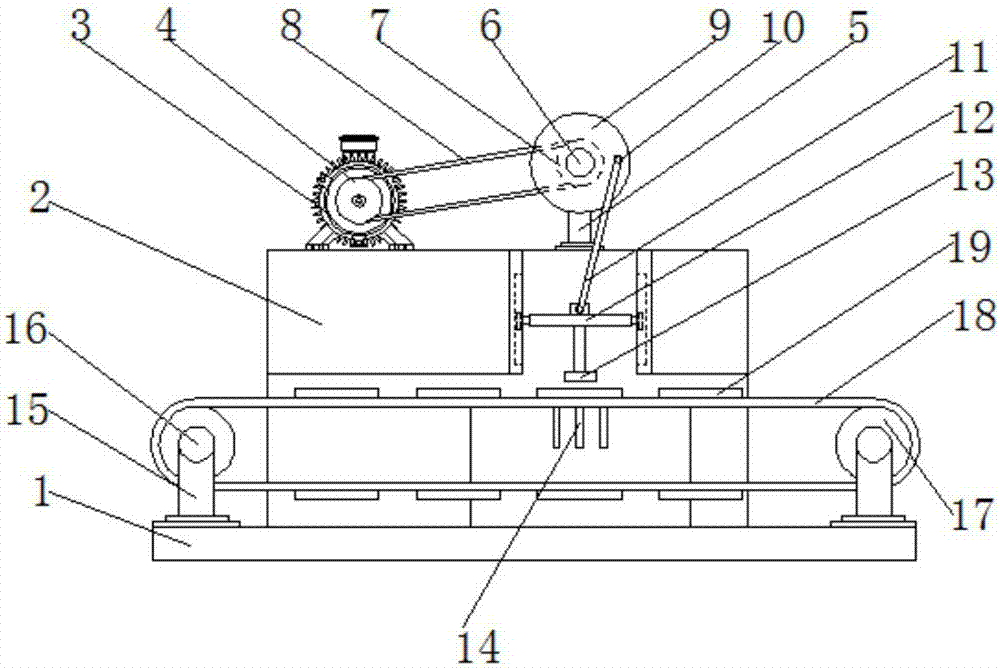

Chip component slitting, molding detection and braiding linkage integrated machine

The invention discloses a chip component slitting, molding detection and braiding linkage integrated machine. The chip component slitting, molding detection and braiding linkage integrated machine comprises a rack. A feeding channel is mounted on the rack. A feeding mechanism, a clamping and conveying mechanism, a slitting mechanism and a rotary disk mechanism are arranged on the feeding channel in sequence. A first wire bending mechanism, a second wire bending mechanism, an electric detection mechanism, a first defective product discharge tank, a CCD contour detection mechanism, a second defective product discharge tank and a discharging and braiding mechanism are arranged on the periphery of the rotary disk mechanism in sequence. A molding driving mechanism is mounted on the lower side of the rack. The molding driving mechanism drives the first wire bending mechanism and the second wire bending mechanism. The first wire bending mechanism and the second wire bending mechanism are matched with the rotary disk mechanism to operate. The discharging and braiding mechanism comprises a braiding channel. A braid charging position, a CCD braid charging detection mechanism, a braid covering mechanism and a braid carrying reel are arranged along the braiding channel in sequence. The chip component slitting, molding detection and braiding linkage integrated machine realizes slitting, molding detection and packaging full-automatic of chip components, improves the braiding efficiency and saves the braiding cost.

Owner:广东南方宏明电子科技股份有限公司

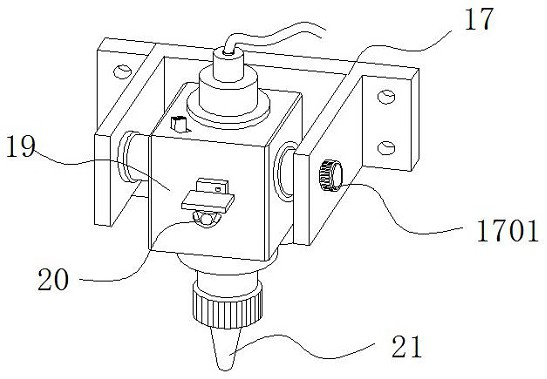

LED lamp belt automated assembling equipment with groove glue injection height detection

InactiveCN111974623AAvoid wastingEasy to useLiquid surface applicatorsMaterial gluingStructural engineeringWorkbench

The invention discloses LED lamp belt automated assembling equipment with groove glue injection height detection. The equipment particularly comprises a base, a workbench, a laser displacement sensorand a U-shaped half sleeve, wherein a frame body is installed on one side of the top of the base, a vacuum pump is installed at the middle position of the top of the frame body, electromagnetic sliderails are arranged at both ends of the top of the frame body, sliding blocks are installed inside the electromagnetic slide rails, hydraulic telescopic rods are fixed to the bottom ends of the slidingblocks, and vacuum suction cups are arranged at the bottom ends of the hydraulic telescopic rods. According to the LED lamp belt automated assembling equipment with groove glue injection height detection, through the arrangement of the laser displacement sensor and an alarm, the laser displacement sensor can detect the glue injection groove depth of the U-shaped half sleeve, if the glue injectiongroove depth is detected as unqualified, a control panel can control the alarm to send an alarm to remind staff to take away a bad U-shaped half sleeve, and unqualified assembled LED lamp belts are avoided.

Owner:广州市金点子机电科技发展有限公司

Adhesive sheet for semiconductor device manufacture, semiconductor device using it and manufacturing method

ActiveCN1622279ANo residuePrevent disqualificationFilm/foil adhesivesSolid-state devicesHeat resistanceEngineering

A laminate having a heat-resistant base material and an adhesive layer, releasably bonded to a lead frame or a wiring substrate in which the adhesive layer contains a thermoplastic resin component (b) and a re-peelable additional component (c) The adhesive sheet for semiconductor device manufacturing, when used in the manufacture of semiconductor devices such as QFN, maintains good wire solderability, molding burr characteristics, and prevents adhesive transfer, thereby preventing semiconductor device failure.

Owner:TOMOEGAWA PAPER CO LTD

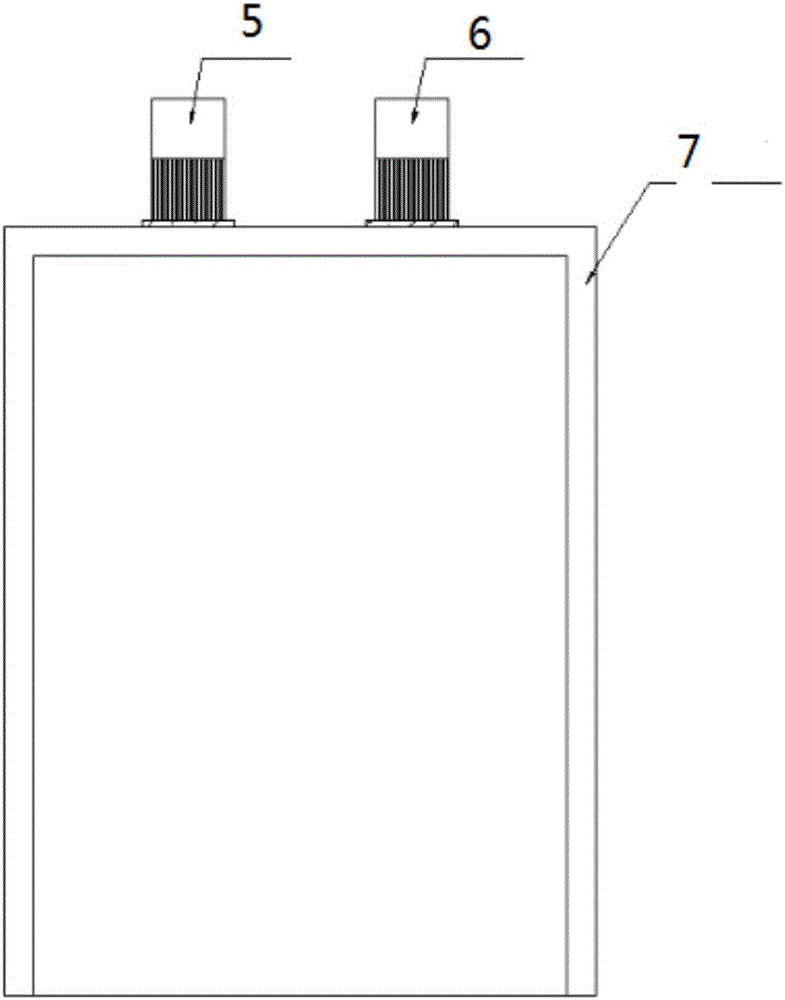

Transfer device used for lithium ion battery machining

InactiveCN111924332AAvoid unqualifiedPlay a protective effectContainers to prevent mechanical damageInternal fittingsEngineeringLithium-ion battery

The invention discloses a transfer device used for lithium ion battery machining, and belongs to the technical field of lithium ion battery machining. The transfer device used for lithium ion batterymachining comprises a base, a first box body and a second box body. The first box body and the second box body are both fixedly connected to the base. The second box body is located above the first box body. The bottom of the base is connected with walking wheels. A containing cavity is formed in the second box body. Two first clamping plates are connected in the containing cavity. Second clampingplates are elastically connected to the two first clamping plates. The bottom of the containing cavity is elastically connected with a bottom plate. A first gas bag is connected to each second clamping plate. Second gas bags are connected between the bottom plate and the containing cavity. A clamping device further comprises an inflation mechanism used for conducting inflation on the first gas bags and the second gas bags. The power end of the inflation mechanism is connected with the walking wheels. The clamping device further comprises a drive part. When the transfer device moves, the inflation mechanism can be driven by the walking wheels to conduct inflation on the first gas bags and the second gas bags, and therefore the function of protecting workpieces is achieved.

Owner:吕静瑶

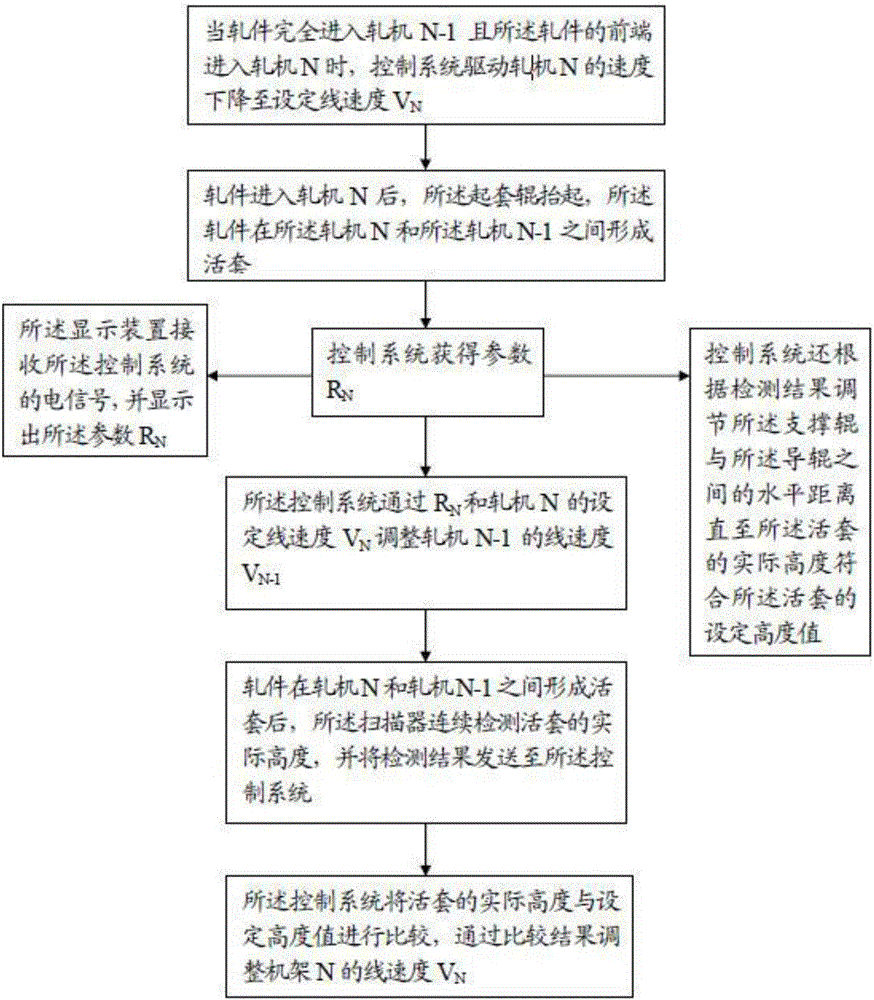

Control method for loop height

ActiveCN106734235AAvoid unqualifiedAvoid piles of steelRoll mill control devicesMetal rolling arrangementsControl systemRolling mill

The invention discloses a control method for the loop height. Before a rolled piece enters a rolling mill N-1 and the front end of the rolled piece enters a rolling mill N, the speed of the rolling mill N is decreased to a set linear speed VN. After the rolled piece is bitten into the rolling mill N, a loop rising roll is lifted, a loop is formed by the rolled piece between the rolling mill N and the rolling mill N-1. A parameter RN is obtained by a control system through the rolled piece sectional area FN of the rolling mill N and the rolled piece sectional area FN-1 of the rolling mill N-1. The control system regulates the linear speed VN-1 of the rolling mill N-1 through the RN and the set linear speed VN of the rolling mill N. The control method for the loop height has the beneficial effects of being high in percent of pass and easy to control.

Owner:SICHUAN DESHENG GRP VANADIUM & TITANIUM CO LTD

Printed matter cutting device

InactiveCN109159188AAdjustable sizeImprove cutting efficiencyMetal working apparatusSurface mountingPulp and paper industry

The invention discloses a printed matter cutting device, and belongs to printed matter cutting equipment. The printed matter cutting device comprises a fixed base and a movable base, the upper surfaceof the fixed base is provided with a stand column, the stand column is provided with a vertical slide rail, a vertical sliding block matched with the vertical sliding rail is arranged on the movablebase, a horizontal sliding rail is arranged on the lower surface of the movable base, a plurality of working tables are arranged on the horizontal sliding rails, a cutting knife and a paper fixing device are arranged on the surface of the working tables, the paper fixing device comprises a telescopic rod fixedly arranged on the surface of the working table, the telescopic rod is a sleeve type telescopic rod, the telescopic rod is sleeved with a reset spring, and the lower end of the telescopic rod is provided with an idler wheel; the working tables are provided with a first locking screw, andthe movable base is provided with a lifting device. According to the printed matter cutting device, the position error of the printed matter in the cutting process can be kept, and can also be adaptedto cutting of printed matters of various sizes and specifications, so that the cutting efficiency is improved.

Owner:安徽瀚洋纸品印刷有限公司

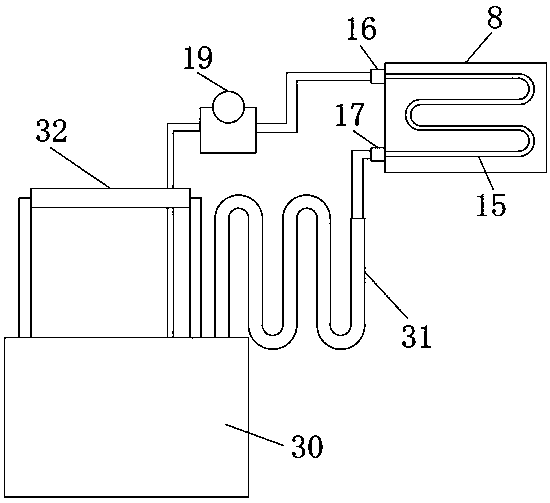

Plastic injection molding machine with cooling mechanism

PendingCN109940830ASpeed up circulationImprove cooling efficiencyHydraulic cylinderPlastic injection molding

The invention discloses a plastic injection molding machine with a cooling mechanism. The plastic injection molding machine with the cooling mechanism comprises an operation platform. A first baffle and a second baffle are fixedly installed on the operation platform. The side portion of the first baffle is fixedly provided with a first hydraulic cylinder and a limiting column. One end of the firsthydraulic cylinder is fixedly connected with a supporting plate. The side portion of the supporting plate is fixedly connected with a connection rod. One end of the connection rod is fixedly connected with a moving mold. One side of the moving film is fixedly connected with a guide mechanism. One side of the second baffle is fixedly provided with a fixed mold matched with the moving mold. An injection molding hole is formed in one side of the second baffle. The operation platform is provided with an injection molding mechanism in a sliding manner through a sliding platform. The injection molding hole communicates with an injection molding opening of the injection molding mechanism. The plastic injection molding machine with the cooling mechanism can improve the cooling efficiency, cool cooling water and guarantees cooling efficiency, the moving mold is located and monitored, and the situation that the moving mold shifts, so that unqualified products are caused is avoided.

Owner:新沂天晟新材料有限公司

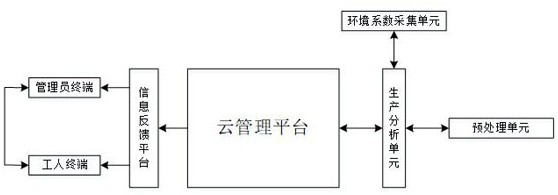

Coating processing production line supervision and feedback system based on Internet

ActiveCN113298450ARelieve production pressureIncrease productivityMeasurement devicesResourcesProduction lineInformation transmission

The invention discloses a paint processing production line supervision and feedback system based on the Internet, and relates to the technical field of production line supervision and feedback. The technical problem that in the prior art, the production pressure is increased due to the fact that paint orders cannot be preprocessed is solved, the paint orders are analyzed through the preprocessing unit, the paint orders which are not produced are sorted, the orders are divided into loose orders and tension orders, the production pressure is effectively relieved, the production efficiency is improved, the unproduced paint orders are sorted according to the time values, the reliability of order production completion is improved, meanwhile, the situation that the orders cannot be completed due to improper order allocation is effectively prevented, information feedback is conducted on administrators and workers after information feedback signals and corresponding procedures are received through the information feedback platform, The information transmission time can be shortened by establishing an information feedback channel, meanwhile, the communication efficiency is improved by direct information communication between the administrator and the worker, and the production problem can be solved easily.

Owner:滨州市鸿海涂料有限公司

Machining process for strain-hardening seal head

InactiveCN104384833AGuaranteed uniformityGuaranteed appearance size requirementsPressure vesselsEngineeringUltimate tensile strength

The invention relates to a machining process for a strain-hardening seal head. The machining process comprises the following steps: making welding process assessment; selecting and using a steel plate; cutting a wafer; molding the seal head; chamfering; pickling; polishing. According to the machining process, a high-quality steel plate material is selected and used, and the strength of the steel plate is controlled so as to ensure the performance and the molding quality of a welding joint of the seal head; the performance of the welding joint is ensured by pre-stretching (through 9 percent deformation) a welding test plate before the seal head is made; the requirement on the appearance size of the seal head is met by adopting an accurate mold.

Owner:CHANGZHOU KUANGDA WEIDE MACHINERY

Double-twisting strander of external take-up and internal pay-off type

InactiveCN104594088AGuaranteed stabilityAvoid affecting the phenomenon of uneven twisting at the bottom of the wheelRope making machinesEngineering

Owner:JIANGSU XINGDA STEEL TYPE CORD

Tab short-circuit-proof method of soft package lithium battery

InactiveCN106159344AWill not cause a short circuitAvoid unqualifiedFinal product manufactureSmall-sized cells cases/jacketsElectrical resistance and conductanceMicro arc oxidation

The invention discloses a tab short-circuit-proof method of a soft package lithium battery. The tab short-circuit-proof method comprises the following steps: step 101, carrying out positive electrode tab treatment: selecting tab glue, wherein the tab glue is one of black glue, white glue or yellow glue; firstly, forming an insulating layer on the surface of a positive electrode tab base body by utilizing a natural color anodic oxidization, black anodic oxidization or micro-arc oxidization method, wherein the thickness of the insulating layer is no smaller than 10 microns; measuring surface insulating resistance by a 500V insulating resistance meter, wherein the surface insulating resistance needs to be more than 200 megohms; then casting the tab glue on the positive electrode tab base body in a curtain coating way; cutting a positive electrode tab to a required size; finally, carrying out oxidation layer removal treatment on two ends of the tab by utilizing a chemical method; step 102, assembling a single battery: specifically, firstly, welding the tab; then packaging the battery; vacuumizing and sealing, and standing for more than 24h; observing whether leakage exists or not; cutting apart a single battery side plate, injecting liquid, aging and standing; finally, vacuumizing and carrying out secondary package on the single battery in a final state.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

Surface marking device for processing mechanical parts

InactiveCN107262554AGuaranteed depthTo achieve the purpose of markingMetal working apparatusMechanical componentsMachine parts

The invention discloses a surface marking device for processing mechanical parts, which comprises a bottom plate, the top of the bottom plate is fixedly connected with a fixed table, and the top of the fixed table is fixedly connected with a motor, and the surface of the output shaft of the motor is sleeved with a The first pulley, the top of the fixed table is fixedly connected with the first support rod, the top of the first support rod is rotatably connected with the first rotating rod, and the surface of the first rotating rod close to the motor end is provided with the second pulley, and the second pulley The surface is connected to the first pulley through a belt, and a turntable is sheathed on the surface of the first rotating rod away from the motor. The invention belongs to the technical field of marking equipment. The surface marking device for processing mechanical parts ensures the marking depth of the marking plate on the mechanical parts, avoids unqualified products caused by insufficient depth reaching the standard, and reduces the need for The processing cycle of mechanical parts improves the efficiency of overall processing of products.

Owner:CHENZHOU JINTONG INFORMATION TECH CO LTD

Bottle cap screening device and method

The invention discloses a bottle cap screening device and method. The bottle cap screening device comprises a connecting plate, a first guard plate, a second guard plate, an upper guard plate and a lower guard plate, wherein a bottle cap inlet is formed in the connecting plate; the first ends of the first guard plate and the second guard plate are oppositely arranged on the left side and the right side of the bottle cap inlet; the first end of the upper guard plate is arranged on the upper side of the bottle cap inlet; the first end of the lower guard plate is arranged on the lower side of the bottle cap inlet and is arranged near the first guard plate; a space formed by the first guard plate, the second guard plate, the upper guard plate and the lower guard plate is a screening passage; a screening opening is formed between the lower guard plate and the second guard plate; the width of the screening opening is smaller than the thickness of a bottle cap with an anti-theft ring, and is greater than or equal to the thickness of the bottle cap which loses the anti-theft ring; a side blowing gas nozzle which blows towards the second guard plate is arranged on the first guard plate. The bottle cap screening device and method can quickly and accurately screen the bottle cap which loses the anti-theft ring, so that the situation that unqualified products appear is avoided.

Owner:GUANGZHOU TECH LONG PACKAGING MACHINERY CO LTD

Thin film transistor, thin film transistor array and repairing method thereof

ActiveUS7408198B2Avoid unqualifiedSolid-state devicesNon-linear opticsParasitic capacitanceEngineering

A thin film transistor (TFT) including a gate, a semiconductor layer, a source and a drain is provided. The gate has a control part, a connection part and a capacitance compensation part. The connection part is disposed between the control part and the capacitance compensation part for joining the two parts together. The semiconductor layer is disposed over the gate, the source and the drain are disposed on the semiconductor layer. An end of the drain overlaps the control part of the gate with a first region for composing a first parasitic capacitance; while another end of the drain overlaps the capacitance compensation part of the gate with a second region for composing a second parasitic capacitance. In a TFT array with the TFT, the sum of the first parasitic capacitance and the second parasitic capacitance is a constant.

Owner:NYTELL SOFTWARE LLC

Bilobalide injection and preparation method thereof

InactiveCN102626383ASolve solubilityAvoid safety hazardsOrganic active ingredientsNervous disorderBilobalidesBULK ACTIVE INGREDIENT

The invention relates to a preparation method for a preparation of Chinese medicine, particularly relates to a bilobalide injection and a preparation method thereof and belongs to the field of medicine. The technical problem is solved by the invention by providing the bilobalide injection. The bilobalide injection has the advantages of clear components and fixed proportion; the bilobalide injection with high purity, clear component and fixed proportion is taken as an active ingredient; the content of the effective component is above 95%; and the bilobalide injection contains the following components.

Owner:CHENGDU BAIYU PHARMA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com