Double-twisting strander of external take-up and internal pay-off type

A double-twisting machine and built-in technology, which is used in textiles, papermaking, rope-making auxiliary devices, textile cables, etc., can solve uneven twisting at the bottom of the wheel, unqualified product quality, unstable take-up tension, etc. problems, to achieve the effect of easy observation, ensuring stability, and avoiding unqualified products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

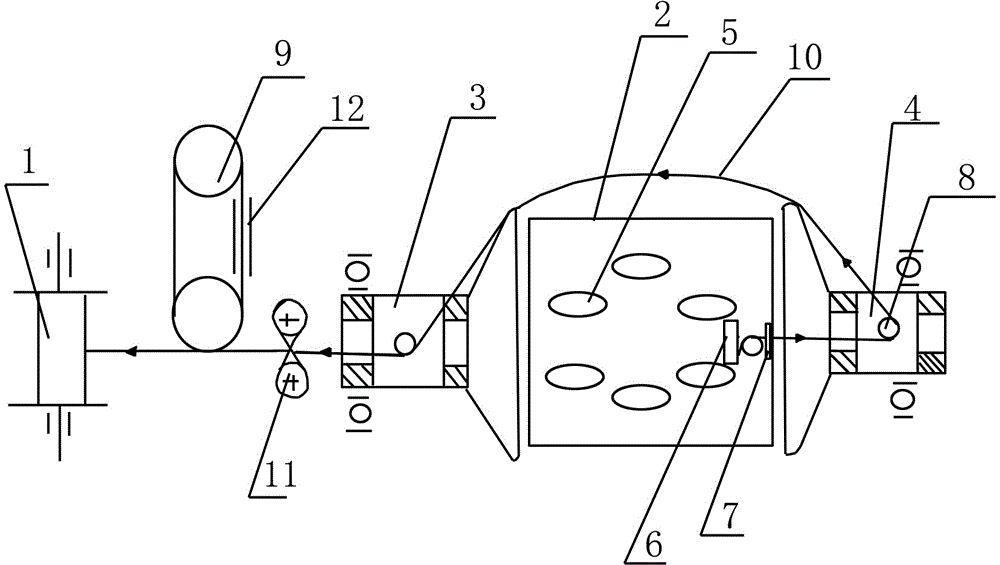

[0008] exist figure 1 Among them, the present invention provides a double-twisting machine with external retraction and internal release, which includes a take-up I-shaped wheel 1, a traction wheel combination 9, a rotating body 2, a left main shaft 3 and a right main shaft 4, and the rotating body 2 The left side and the right side are respectively connected with a left main shaft 3 and a right main shaft 4, and the left main shaft 3 and the right main shaft 4 rotate with the rotating body 2, and a wire-releasing I-shaped wheel combination 5 is arranged in the rotating body 2, and the described wire-releasing The I-shaped wheel combination 5 includes twelve φ172 monofilament I-shaped wheels and one φ200 core wire I-shaped wheel. One side of the line is corresponding to the outlet side of the pay-off I-shaped wheel combination 5, and the other side of the line distribution plate 6 is provided with a crimping die 7, and the crimping die 7 is set as a φ1.28mm crimping die, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com