Transfer device used for lithium ion battery machining

A lithium-ion battery and transfer device technology, which is used in transportation and packaging, containers to prevent mechanical damage, containers, etc., can solve problems such as misalignment, lack of lithium-ion battery protection, impact, etc., and achieve the effect of reducing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

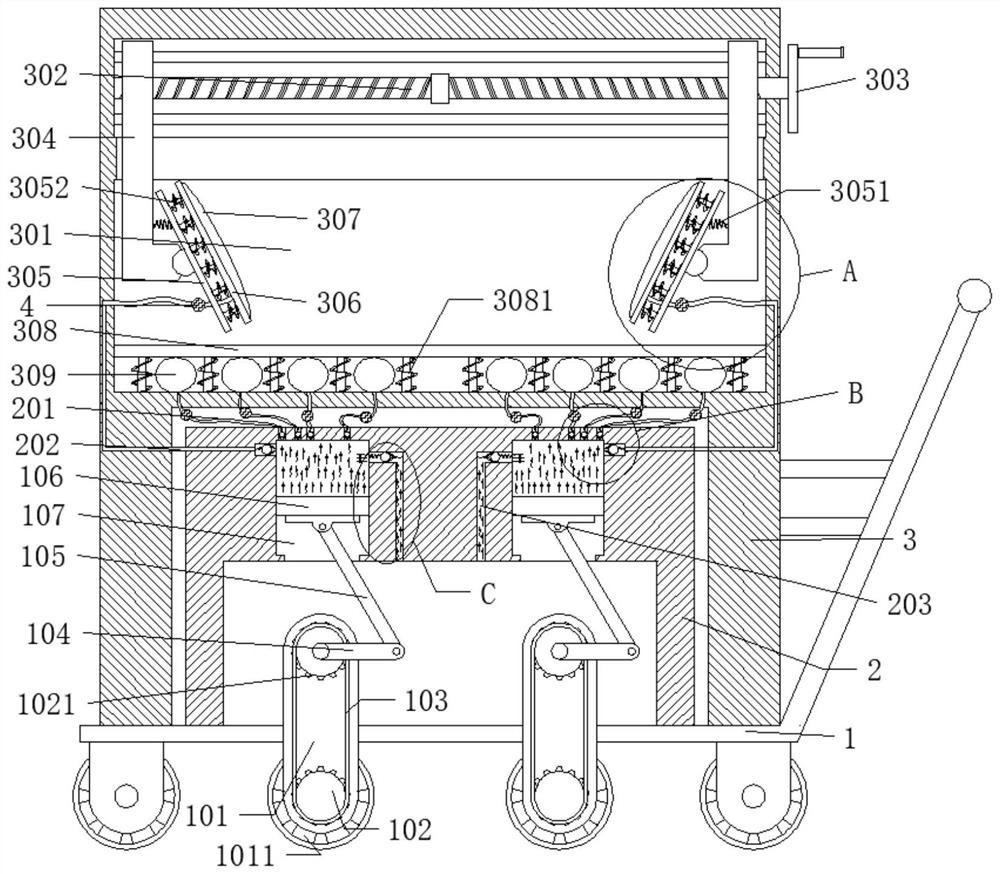

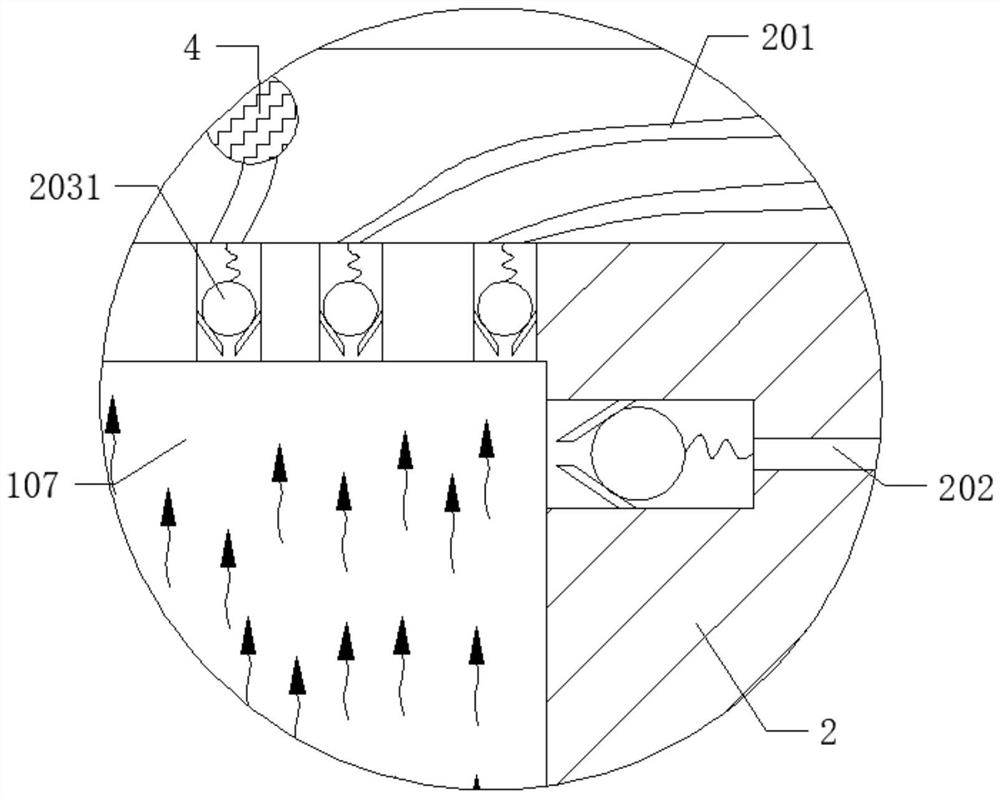

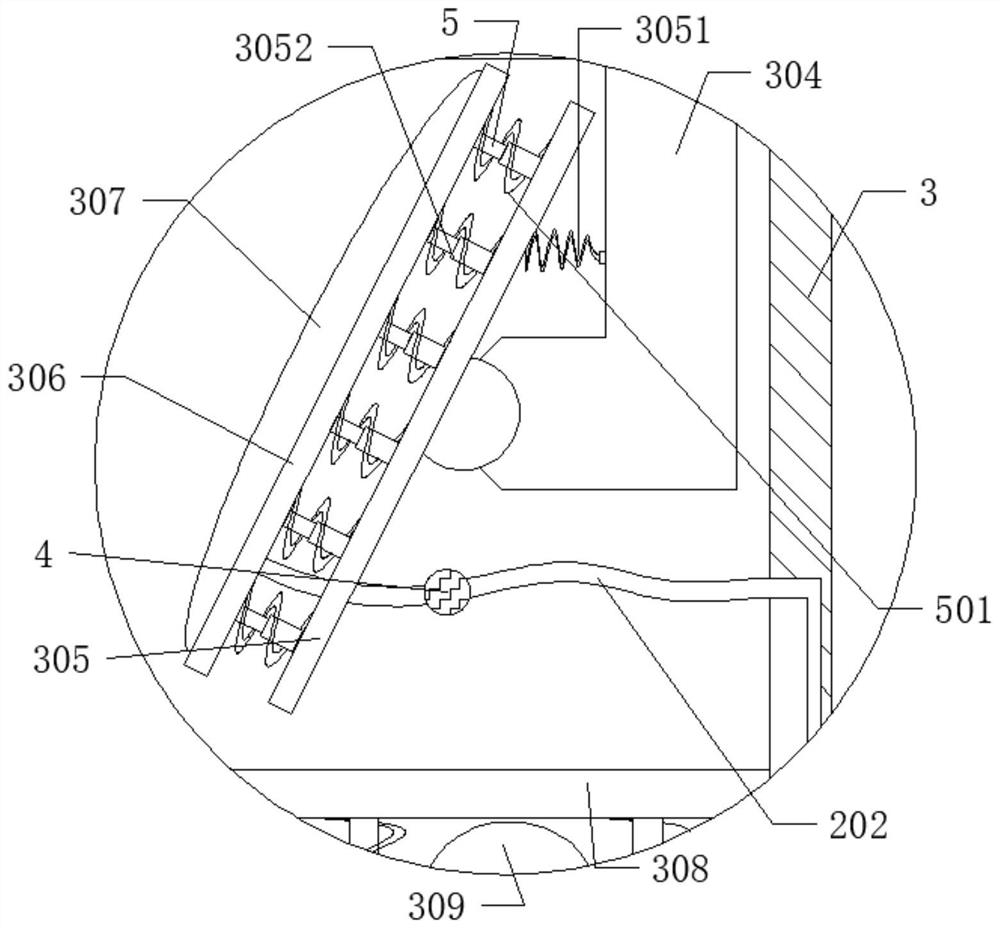

[0025] refer to Figure 1-4 , a lithium-ion battery processing transfer device, including a base 1, a first box 2 and a second box 3, the first box 2 and the second box 3 are fixedly connected to the base 1, the second box 3 is located above the first box body 2, and the bottom of the base 1 is connected with a walking wheel 1011;: the second box body 3 is provided with a placement cavity 301, and the placement cavity 301 is connected with two first pallets 305, two first The clamping plate 305 is elastically connected with a second clamping plate 306; the bottom of the placement chamber 301 is elastically connected with a bottom plate 308; the second clamping plate 306 is connected with a first air bag 307, and a second air bag 309 is connected between the bottom plate 308 and the placement cavity 301 The clamping device also includes an inflation mechanism for inflating the first air bag 307 and the second air bag 309, and the power end of the inflation mechanism is connecte...

Embodiment 2

[0027] refer to Figure 1-4 , a lithium-ion battery processing transfer device, including a base 1, a first box 2 and a second box 3, the first box 2 and the second box 3 are fixedly connected to the base 1, the second box 3 is located above the first box body 2, and the bottom of the base 1 is connected with a walking wheel 1011;: the second box body 3 is provided with a placement cavity 301, and the placement cavity 301 is connected with two first pallets 305, two first The clamping plate 305 is elastically connected with a second clamping plate 306; the bottom of the placement chamber 301 is elastically connected with a bottom plate 308; the second clamping plate 306 is connected with a first air bag 307, and a second air bag 309 is connected between the bottom plate 308 and the placement cavity 301 The clamping device also includes an inflation mechanism for inflating the first air bag 307 and the second air bag 309, and the power end of the inflation mechanism is connecte...

Embodiment 3

[0032] refer to Figure 1-3 In this implementation, an overflow valve 4 is connected to the first sealed pipeline 202 and the second sealed pipeline 201. During the continuous movement of the piston 106, when the first airbag 307 and the second airbag 309 are full, the Discharge, overflow valve 4 is prior art, does not do too many details here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com