Tab short-circuit-proof method of soft package lithium battery

A lithium battery and flexible packaging technology, which is applied in the field of anti-short circuit of the electrodes of the flexible packaging lithium battery, can solve the problems of battery failure, weak battery reliability, safety accidents, etc. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

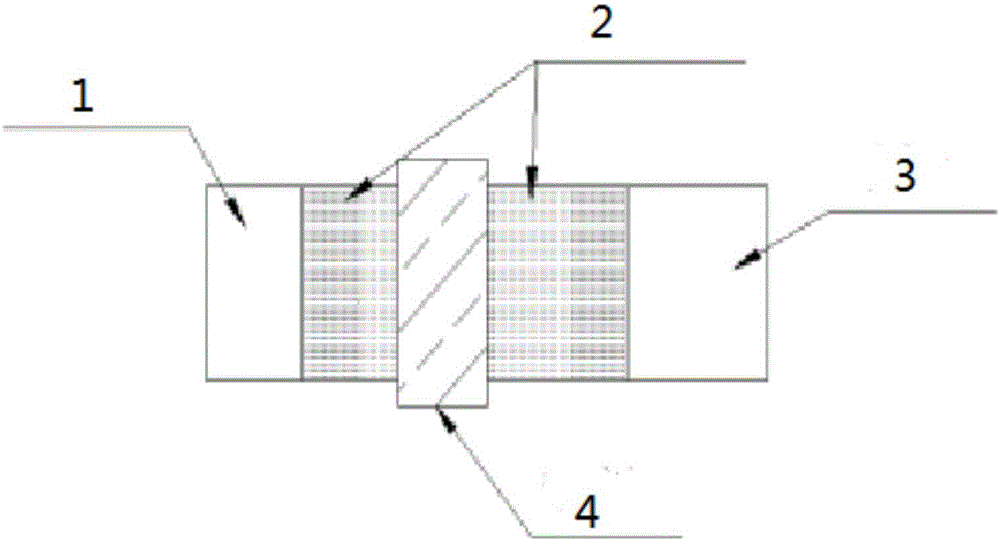

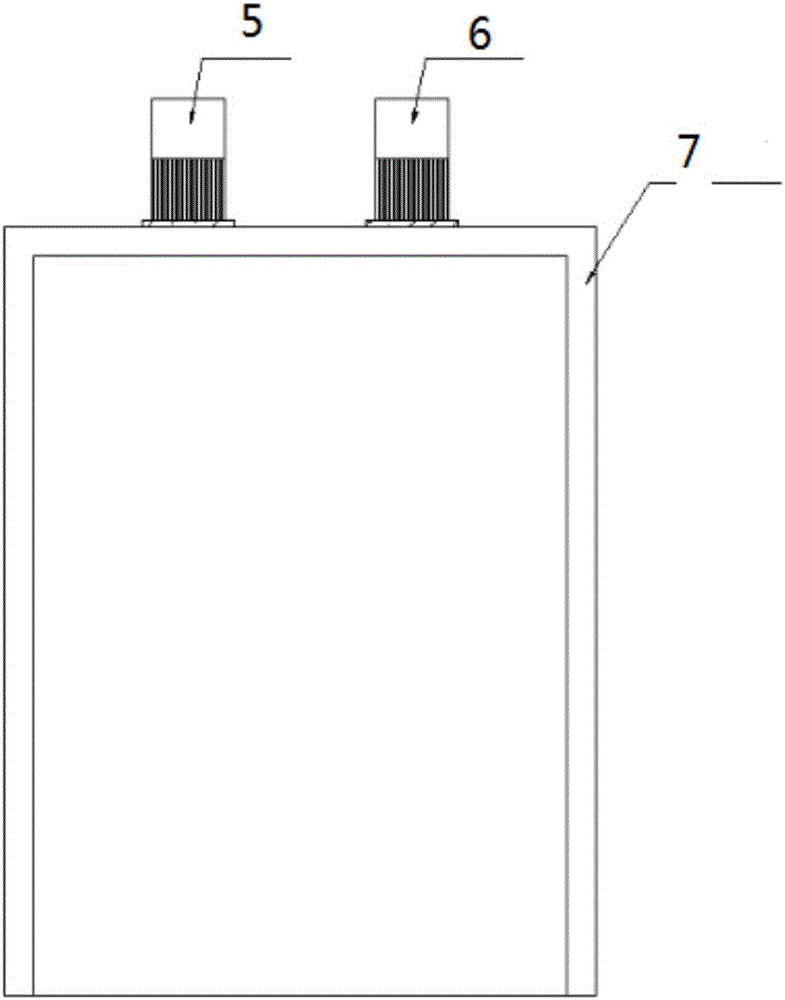

[0029] see figure 1 and figure 2 , a method for preventing short-circuiting of tabs of a soft-packaged lithium battery, comprising:

[0030] Step 1. Positive pole ear treatment:

[0031] The material of the positive pole lug matrix is aluminum, which has a flat structure with a thickness of 0.1 mm to 1 mm.

[0032] The ear glue used can be black glue, white glue or yellow glue.

[0033] The specific manufacturing steps are as follows:

[0034] ⑴Using methods such as natural color anodizing, black anodizing or micro-arc oxidation to form an insulating layer on the surface of the positive electrode lug substrate, the thickness is not less than 10 microns, and the surface insulation resistance measured by a 500V insulation resistance mete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com