Patents

Literature

519results about How to "Avoid affecting performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

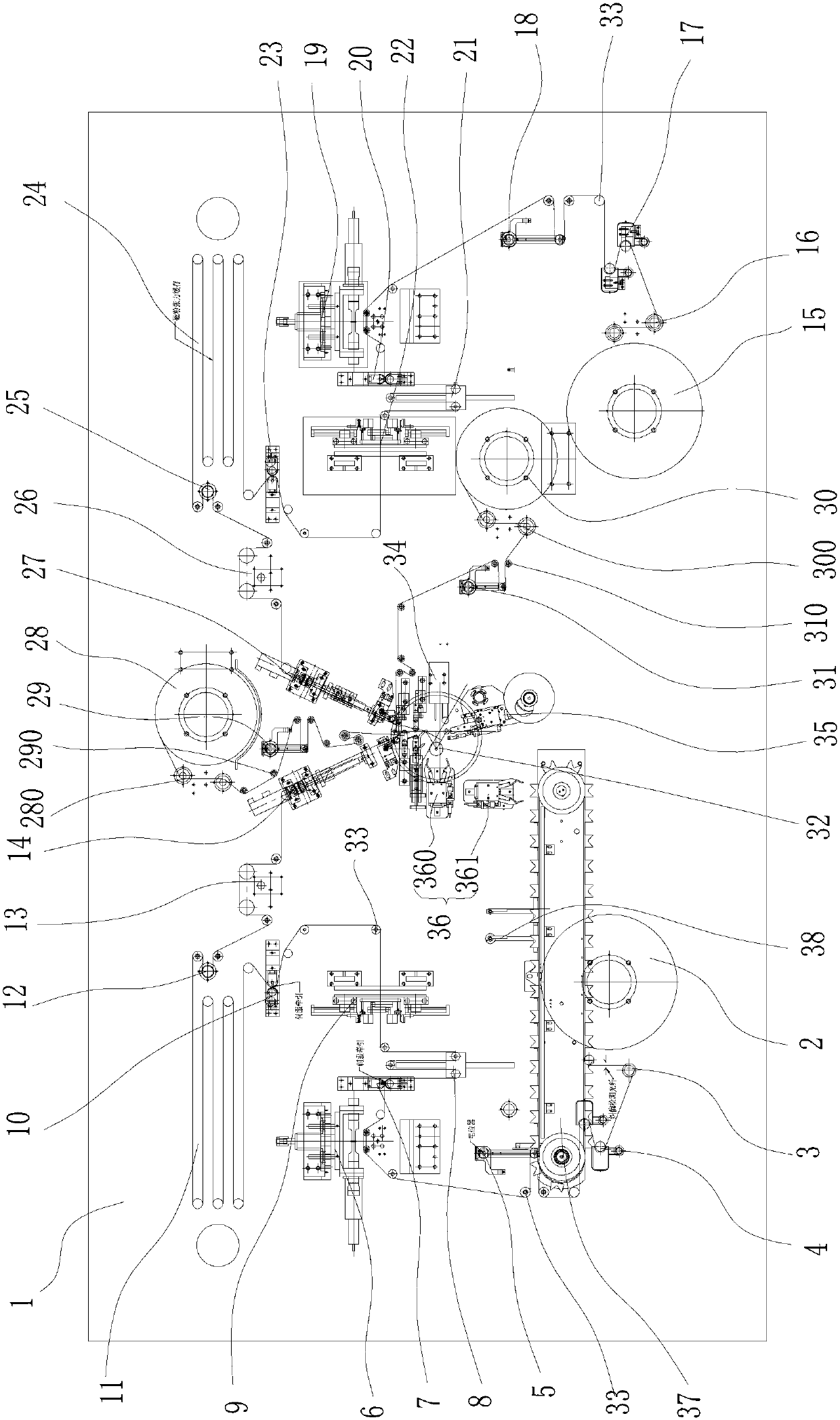

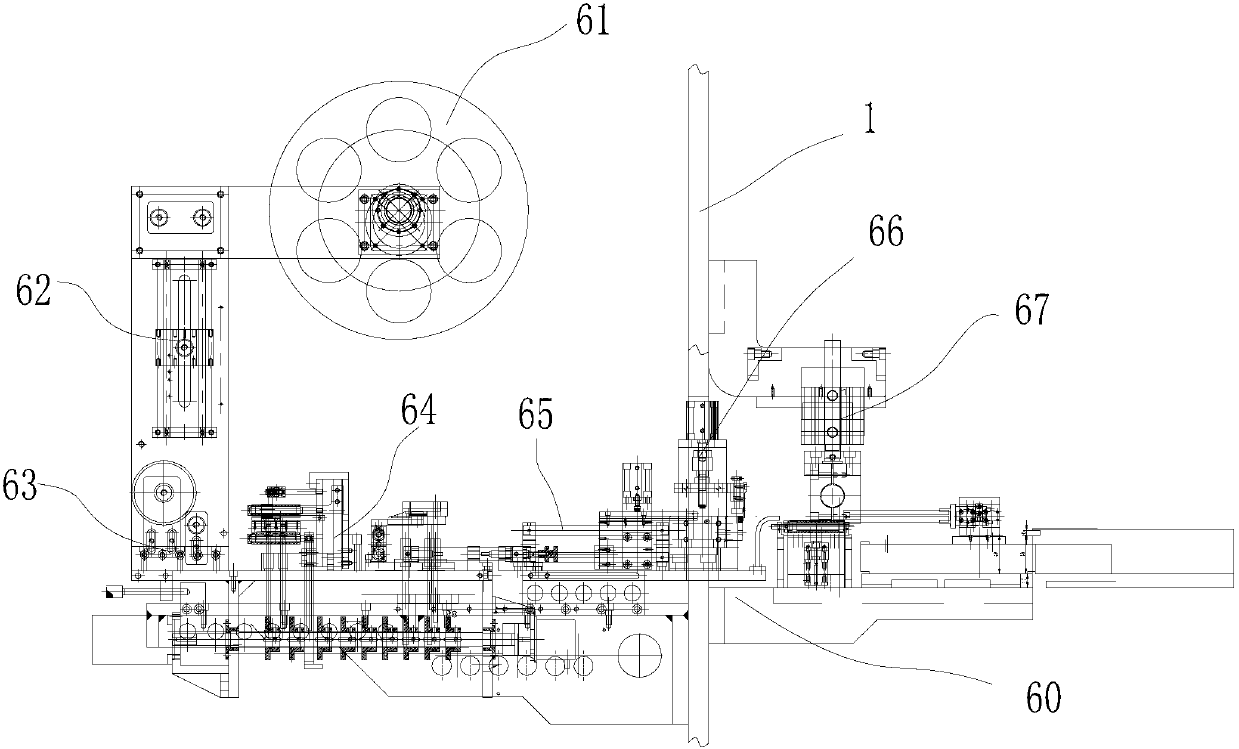

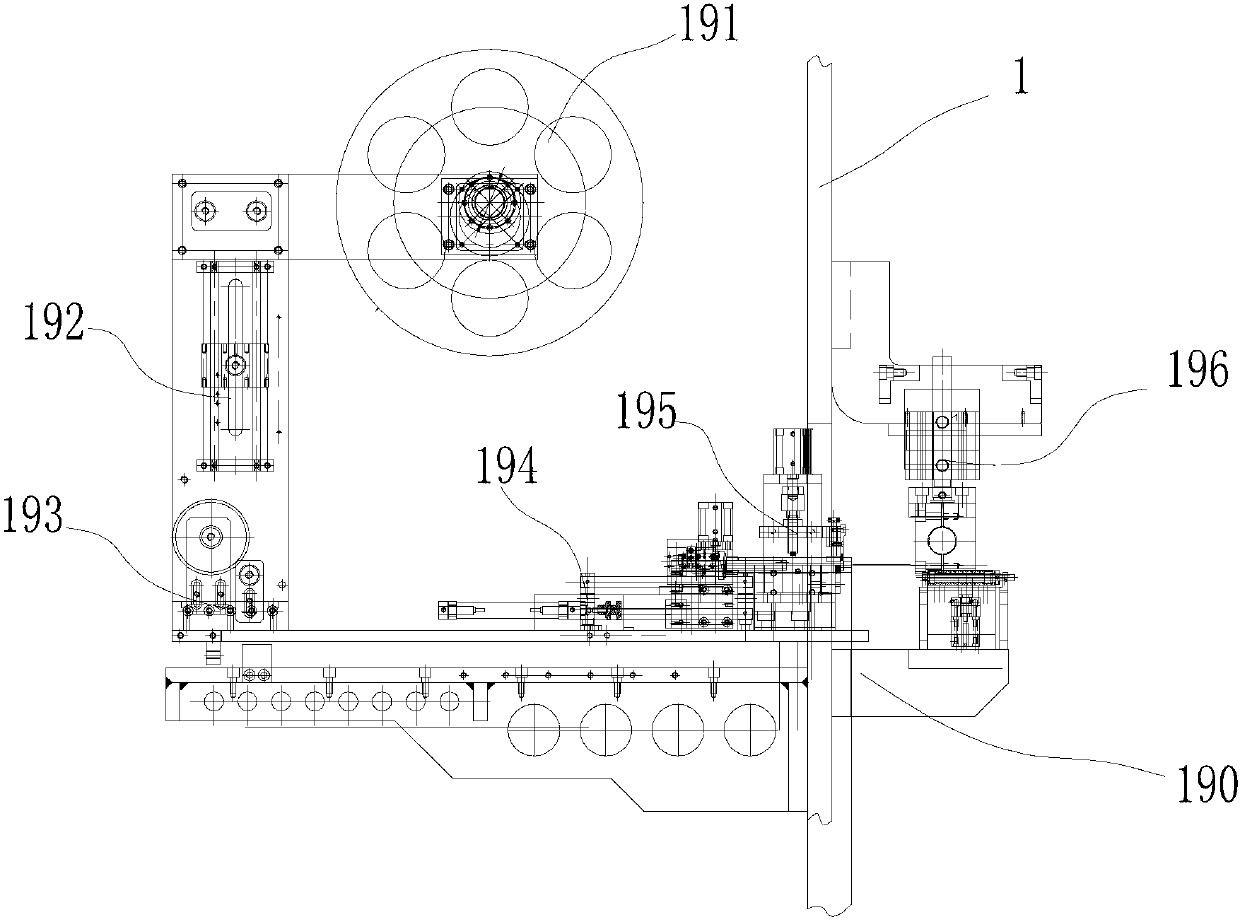

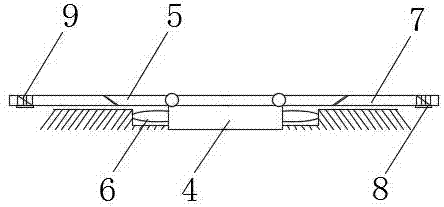

Battery pole piece making and battery cell coiling integrated equipment

ActiveCN102969479AReduce labor intensitySave time at workElectrode manufacturing processesFinal product manufactureControl systemPole piece

The invention discloses battery pole piece making and battery cell coiling integrated equipment, which comprises a rack and a control system. The center of the rack is equipped with a coiling device, which coils a positive pole piece transmitted by a positive pole piece supply device, a negative pole piece transmitted by a negative pole piece supply device, and diaphragms output by a first diaphragm supply device and a second diaphragm supply device into a battery cell according to the order of the positive pole piece, a diaphragm, the negative pole piece and a diaphragm. A secondary unloading manipulator and an unloading conveyor belt mechanism are arranged at left lower side of the coiling device. When the secondary unloading manipulator unloads, hole ironing processing is performed simultaneously, and the mode is convenient and effective. A glue wrapping mechanism of a positive lug welding device on the rack adopts a cam control structure, which has high precision and good stability. A positive lug support of the positive lug welding device passes through the rack of the equipment and is installed at the back side of the rack. A negative lug support of a negative lug welding device passes through the rack of the equipment and is installed at the back side of the rack. Thus, for the whole equipment, the layout of all the devices is more reasonable, and the overall size is decreased effectively.

Owner:ZHUHAI HIGRAND ELECTRONICS TECH

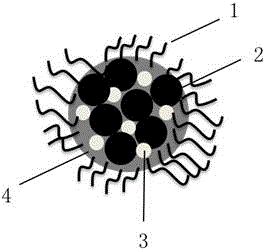

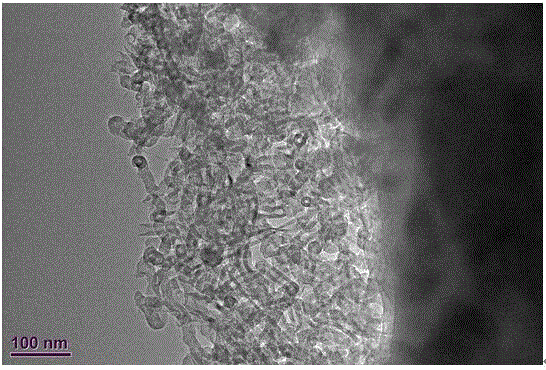

Multifunctional double-layer core-shell structure magnetic nano particle, preparation method and application thereof

InactiveCN101923932ARapid enrichmentRapid separation and purificationInorganic non-active ingredientsInorganic material magnetismMagnetite NanoparticlesSuperparamagnetism

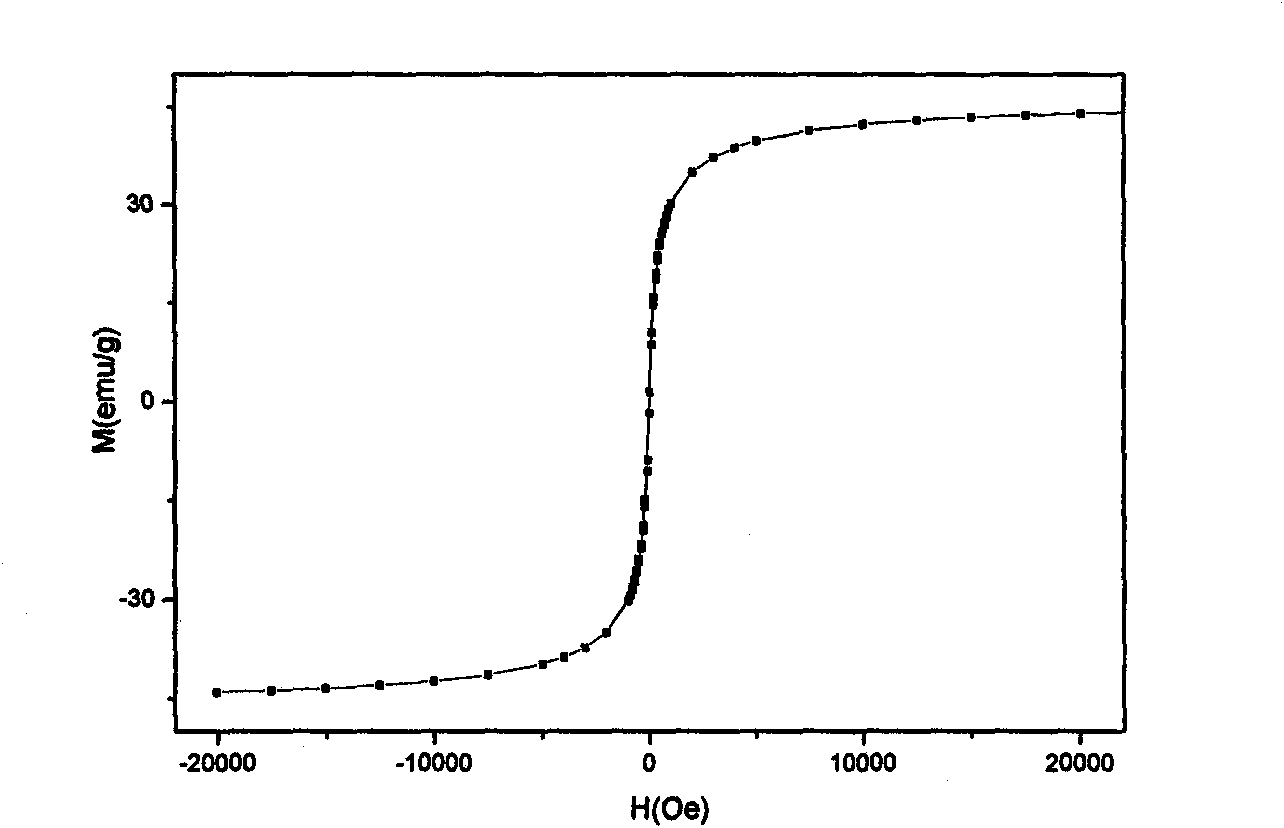

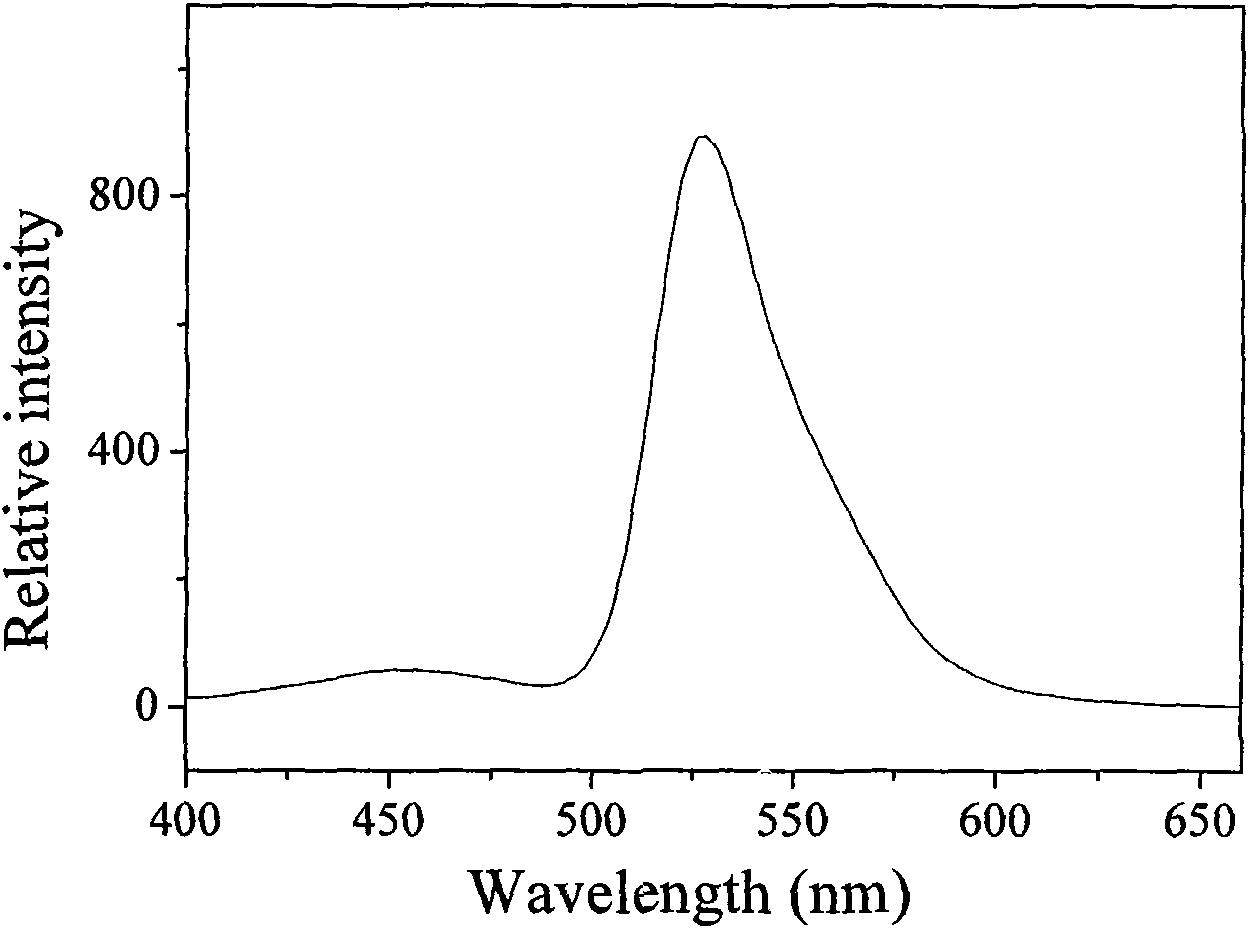

The invention relates to a multifunctional double-layer core-shell structure magnetic nano particle. In the invention, a magnetic nano particle with a particle size of 1-300 nm is used as a core and coated with a double-layer shell consisting of a SiO2 layer with a thickness of 1-200 nm and a hydrolyzed silane coupling agent layer is 1-100 nm thick and comprises one or more multifunctional groups; the particle size and the shell layer thickness can be controlled through regulating the volumes, the weight ratios and the reaction time of the magnetic core, a silicon dioxide precursor, a silane coupling agent and a catalyst in a preparation process; the total particle size of the nano particle can be as small as 5-50 nm and as large as 700-800 nm; the nano particle can have superparamagnetism, paramagnetism and ferromagnetism according to the change of the magnetic core particle size; and one or more bioactive molecules can be connected into the shell layer of the magnetic nano particle or to the surface of the shell layer through a chemical method or a physical method. The invention also provides a preparation method of the multifunctional double-layer core-shell structure magnetic nano particle and application thereof. The particle preparation method has the advantages of simplicity, moderate condition, low cost and easy realization of industrial production. The nano particle can obtain different functions through connecting different bioactive molecules and can be applied to the fields of protein enrichment, biological detection, separation and purification, targeted drug carriers, cell imaging and medical imaging.

Owner:NANJING UNIV

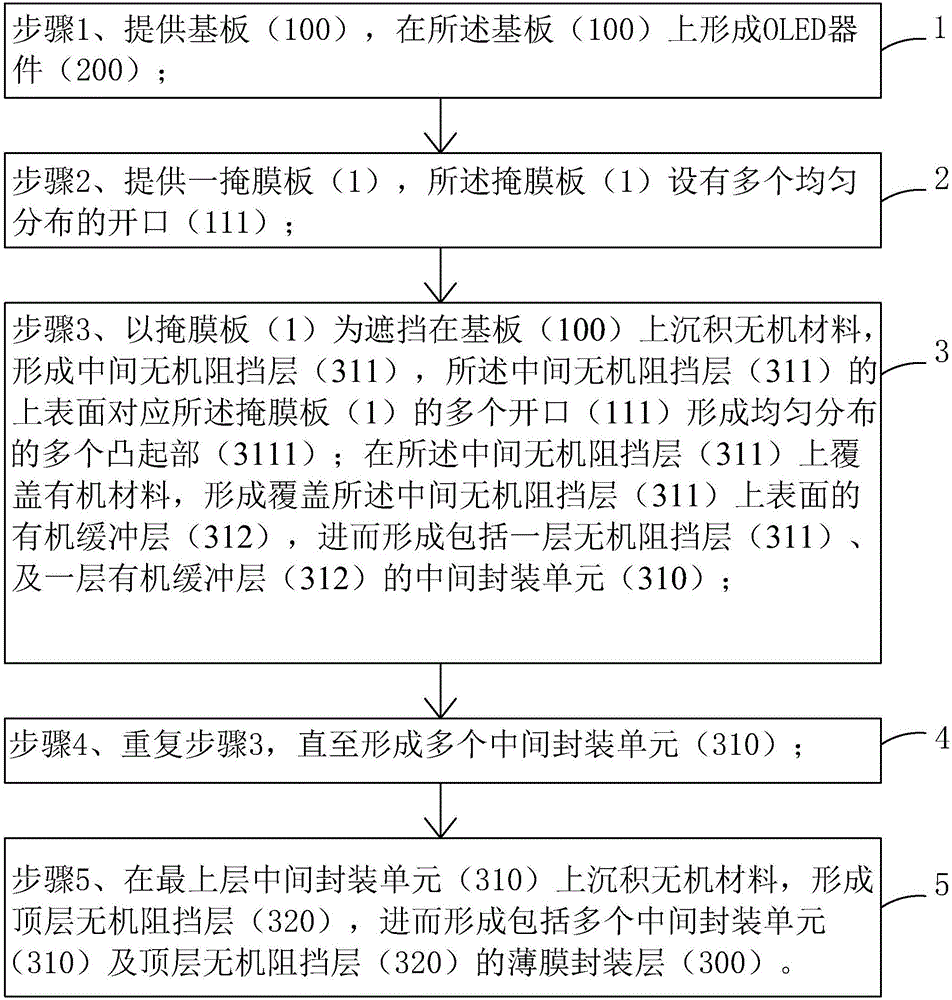

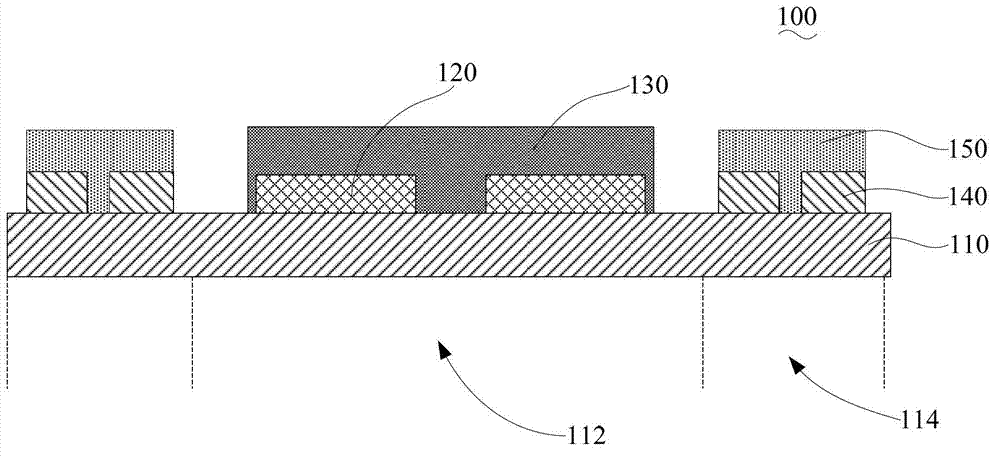

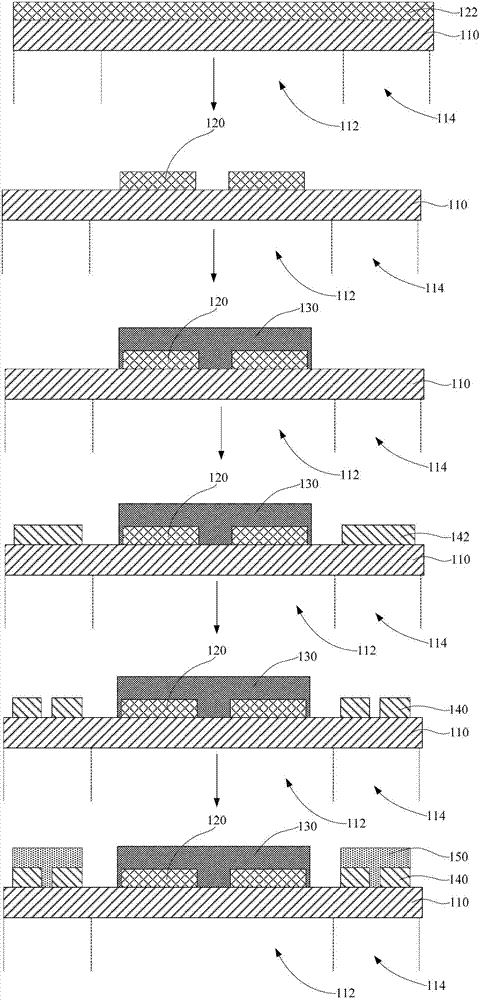

OLED display device and fabrication method thereof

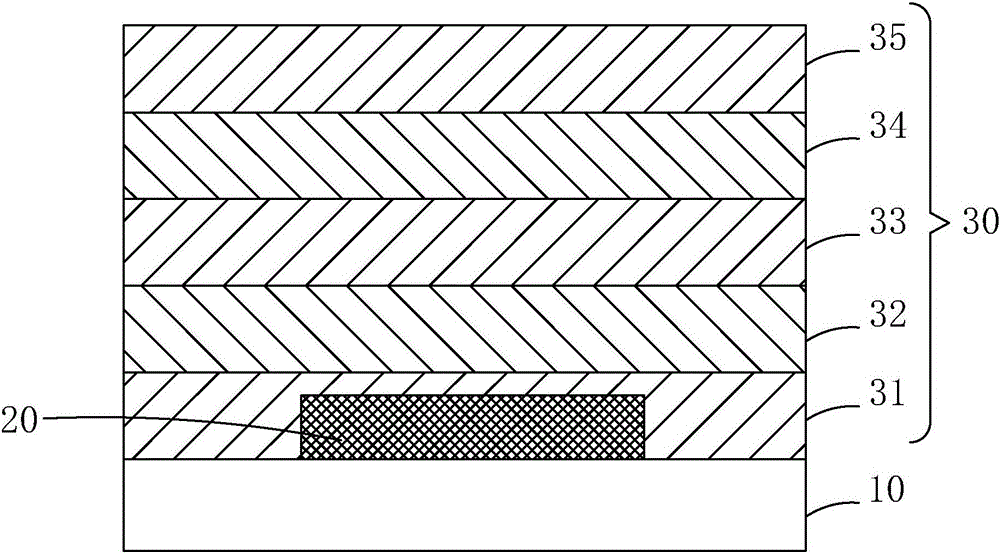

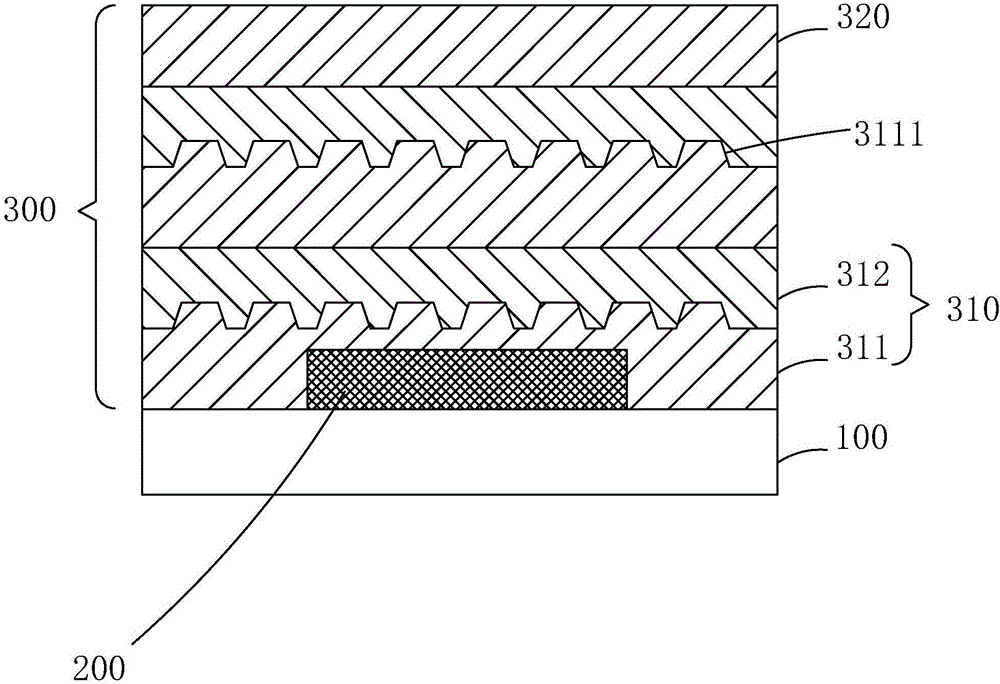

ActiveCN106328826ABlock movementBlock movement, prevent water and oxygen molecules from continuing to invadeSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceOxygen

The invention provides an OLED display device and the fabrication method thereof. The invention uses a mask with multiple openings as the cover to form the middle inorganic blocking layer in the film encapsulation layer, making the upper surface of the middle inorganic blocking layer has many evenly distributed bulges, greatly increasing the contact area between the organic buffer layer covered on the middle inorganic blocking layer and the middle inorganic blocking layer, thus increasing the adhesive force between the middle inorganic blocking layer and the organic buffer layer at the interface and greatly reducing the probability the partition between the inorganic blocking layer and the organic buffer layer. The bulges can prevent water and oxygen molecules from moving on the interface between the middle inorganic blocking layer and the organic buffer layer and prevent water and oxygen molecules from continuing to intrude into the internal part of the OLED display device, which will influence efficiency of the components of OLED.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

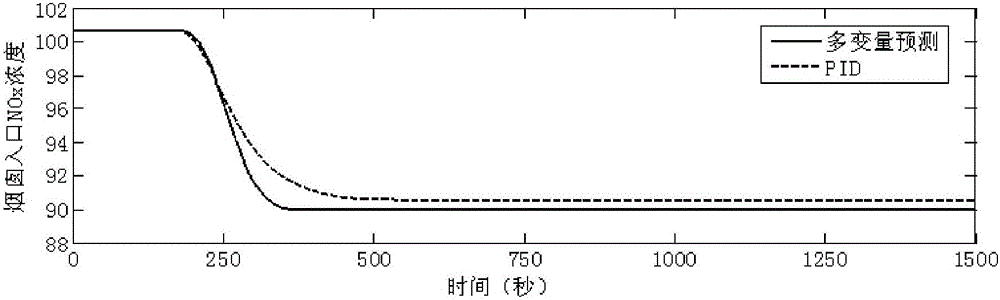

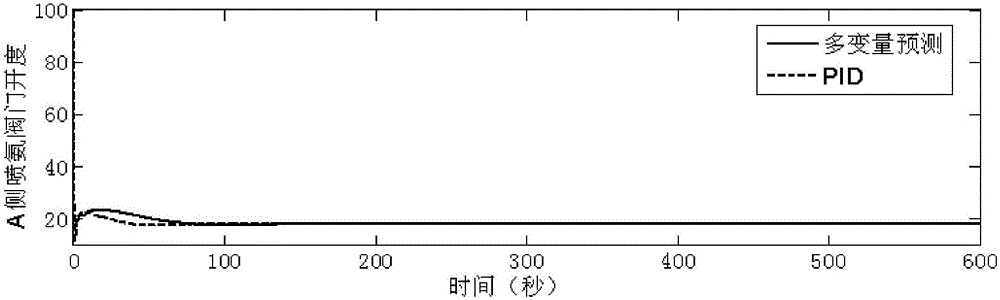

Selective catalytic reduction (SCR) denitration system and method based on constraint predictive control

ActiveCN104607042AQuick responseReduce escape rateDispersed particle separationEscape rateEngineering

The invention discloses a selective catalytic reduction (SCR) denitration system and method based on constraint predictive control. The flow of injected ammonia of the SCR denitration system is controlled by utilizing a predicting-proportioning cascade control policy; the flow of the injected ammonia is regulated by predicting the future change tendency of the concentration of NOx at an outlet of an SCR reactor and regulating the opening degree of an ammonia injection valve in advance; therefore, the defects of large inertia and delay of the SCR denitration system can be greatly overcome, the response speed of ammonia injection amount control to unit load change is increased, and the dynamic regulation quality of the SCR denitration system is improved; under the constraint predictive control, practical constrains, such as upper and lower constrains of valve opening degree, valve operation speed constrain and outlet NOx concentration constrain, are simultaneously considered and are used in parallel, so that the fact that the system performance is influenced due to saturation of execution mechanisms is avoided; based on ensuring the fact that the concentration of the NOx at the outlet reaches a target value, the ammonia injection amount is reduced as much as possible, and the operation cost and the ammonia escape rate are effectively reduced.

Owner:SOUTHEAST UNIV

Spherical silicon-oxygen-carbon negative electrode composite material and preparation method and application thereof

InactiveCN106025219AHigh specific capacityImprove conductivityCell electrodesSecondary cellsSilicon oxygenCarbon nanotube

The invention discloses a spherical silicon-oxygen-carbon negative electrode composite material, which is of a three-layer structure comprising an inner layer, an intermediate layer and an outer layer, wherein the inner layer is an SiOx / graphite substrate; the intermediate layer is an amorphous carbon coating layer; the outer layer is a carbon nanotube coating layer; the mass of the inner layer SiOx / graphite substrate accounts for 80%-90% of total mass of the spherical silicon-oxygen-carbon negative electrode composite material; the mass of the intermediate layer amorphous carbon accounts for 5%-10% of total mass of the spherical silicon-oxygen-carbon negative electrode composite material; and the outer layer carbon nanotube accounts for 5%-10% of total mass of the spherical silicon-oxygen-carbon negative electrode composite material. The grain diameter of the adopted SiOx substrate is smaller than 5 microns; the grain diameter is relatively small; intercalation and deintercalation of active substances are facilitated; higher specific capacity can be obtained; meanwhile, a dispersing agent is added when an SiOx sample is ground; and condition that the SiOx with a relatively small grain diameter is agglomerated in quantity to affect the performance is prevented.

Owner:ZHONGTIAN ENERGY STORAGE TECH

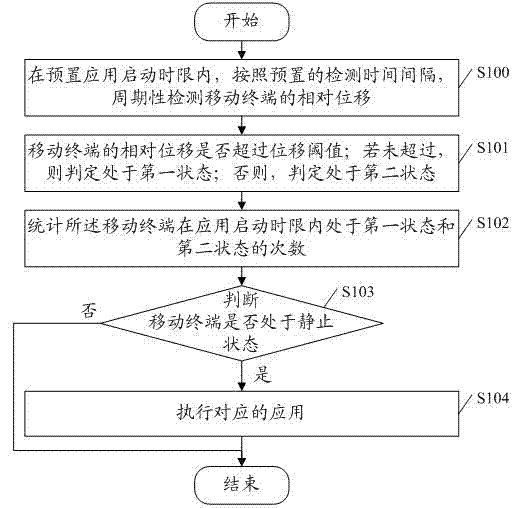

Mobile terminal application control method and device

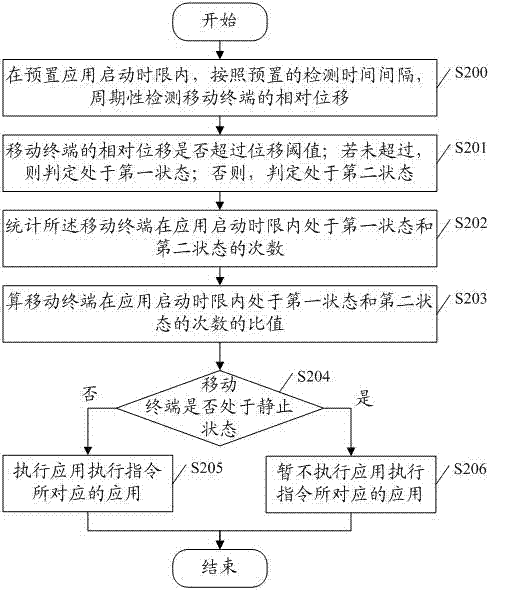

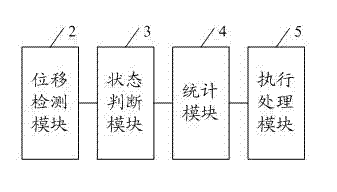

ActiveCN102520858AAffect qualityAvoid affecting the performance of the applicationInput/output processes for data processingRelative displacementTime limit

The embodiment of the invention discloses a mobile terminal application control method and a device. The method comprises the following steps: detecting relative displacement of a mobile terminal according to a preset detection time interval in a preset application startup time limit after receiving an application execution instruction; determining whether the relative displacement of the mobile terminal exceeds a preset displacement threshold; determining that the mobile terminal is in a first state if the relative displacement does not exceed the displacement threshold, otherwise, determining that the mobile terminal is in a second state; counting the times of the mobile terminal in the first state and the second state; determining whether the mobile terminal is in a still state; and executing corresponding application if the mobile terminal is in the still state, otherwise, not executing the corresponding application. The mobile terminal application control method and device provided by the embodiment can detect the stability of the mobile terminal according to application startup time limit of the mobile terminal, and can automatically execute corresponding application when the mobile terminal is in the still state, no need for clicking the mobile terminal by user.

Owner:WONDERSHARE TECH CO LTD

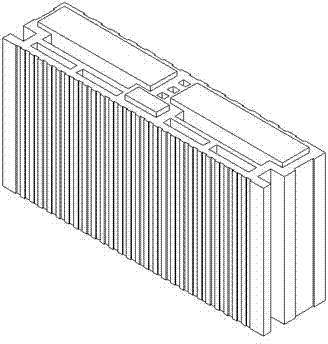

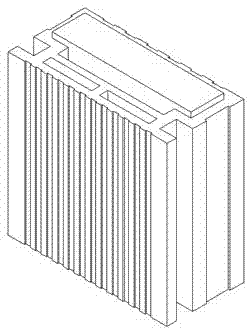

Externally laid masonry composite heat-insulating sintered building block exterior wall heat insulating system

InactiveCN102505763AFast constructionImprove integrityConstruction materialHeat proofingArchitectural engineeringStructural engineering

The invention discloses an externally laid masonry composite heat-insulating sintered building block exterior wall heat insulating system, and relates to the technical field of building wall heat insulating and energy saving technology. The system comprises an exterior wall main body structure, a ring beam gutter, a floor gutter, a heat insulating material, I-type main building blocks, II-type main building blocks and the like, wherein the external laid masonry composite heat insulating sintered building blocks are laid and built outside a building exterior wall structure part; the heat insulating material is placed in the sintered building blocks; and an air space is reserved in the building blocks and outside the heat insulating material, and a protective layer is arranged on the outer side. The externally laid masonry composite heat-insulating sintered building blocks consist of main building blocks, corner matching blocks and hole matching blocks, wherein the main building blocks are divided into the I-type main building blocks and II-type main building blocks in category; and the corner matching blocks are divided into external corner matching blocks and internal corner matching blocks. The system has the advantages of easiness, convenience and practicability in building type construction, high construction speed, excellent wall integrity, superior wind resistance to the conventional sandwich heat insulation, factory production of materials and capability of reducing a complex operation process with high probability of causing the quality problem on site.

Owner:SHENYANG JIANZHU UNIVERSITY

Pressure-sensitive adhesive for wafer grinding and preparation method thereof

InactiveCN103571367AImprove cohesionGood adhesionFilm/foil adhesivesPolyureas/polyurethane adhesivesPlastic materialsCohesive strength

The invention discloses a pressure-sensitive adhesive for wafer grinding and a preparation method thereof. The adhesive comprises a plastic base material, an adhesive layer coated on the base plastic material, and a release film which covers the adhesive layer. The preparation method of the pressure-sensitive adhesive comprises the following steps of: A) preparing a prepolymer; B) preparing an adhesive; C) preparing an adhesive tape. Compared with the prior art, the preparation method has the advantages that the dose and addition way of an initiating agent as well as the polymerizing temperature are controlled to realize the maximum molecular weight as well as high cohesive strength, and the problems of relatively high peeling strength and small shearing strength of the traditional pressure-sensitive adhesive are solved. In addition, a hard monomer added brings the pressure-sensitive adhesive with high shearing strength, and the demand on wafer grinding is met. The pressure-sensitive adhesive for wafer grinding is different from other adhesive tapes for wafer grinding in that a silane coupling agent bringing water resistance is directly polymerized onto a polymer molecular chain, instead of being directly added. Therefore, the migration of micromolecule in storage process is avoided, and the resulting influence to the effect or the resulting residue on a wafer is removed.

Owner:YANTAI DARBOND TECH

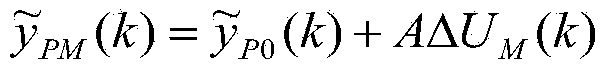

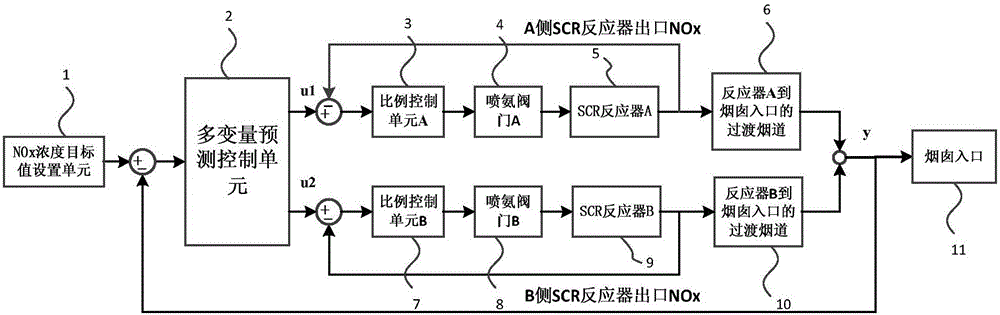

Multi-variable interval constrained estimation-based SCR denitration optimized control system and method

ActiveCN105700576AImprove economyQuick responseControlling mixing ratio of fluids with different temperaturesProportional controlActuator

The invention discloses a multi-variable interval constrained estimation-based SCR denitration optimized control system, which comprises an NOx concentration target value setting unit, a multi-variable predictive control unit, a proportional control unit A, an ammonia spraying valve A, an SCR reactor A, a transition flue between the reactor A to a chimney inlet, a proportional control unit B, an ammonia spraying valve B, an SCR reactor B, a flue between the reactor B and the chimney inlet, and the chimney inlet. The invention also discloses a control method of the above system. According to the technical scheme of the invention, the response speed of the ammonia spraying amount control to the unit load change is increased. Meanwhile, the influence on the performances of the system, caused by the saturation of an actuator, can be avoided. The actuating number of the actuator is reduced, and the service life thereof is prolonged. The economical efficiency of the denitration system is improved.

Owner:SOUTHEAST UNIV

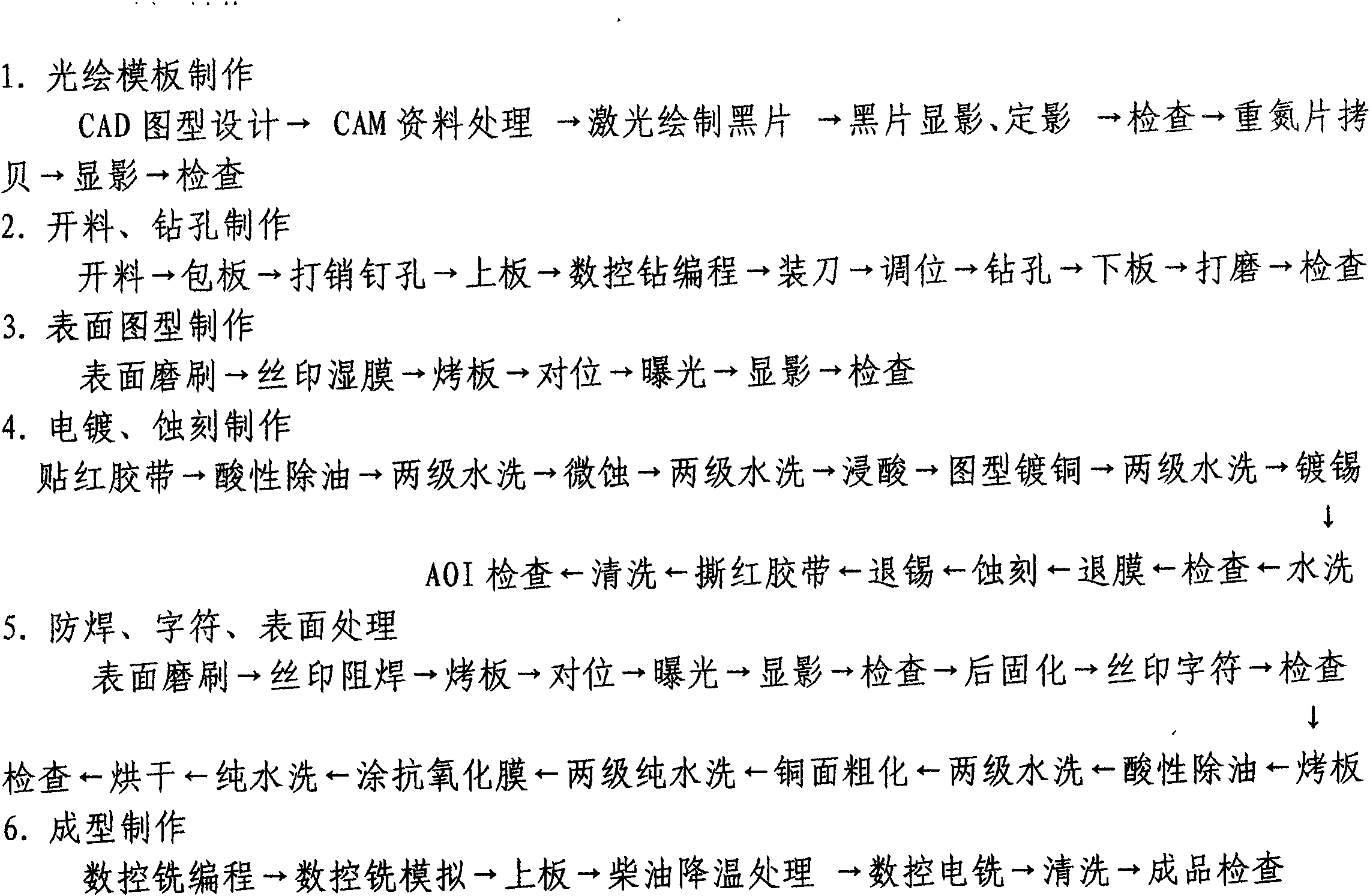

Method for making high-frequency aluminium-based circuit board

ActiveCN102159029AAvoid glitchesImprove performancePrinted circuit manufactureCircuit susbtrate materialsSurface patternElectrical and Electronics engineering

The invention discloses a method for making a high-frequency aluminium-based circuit board. The method comprises the following steps of: 1, making a photo-plotted template; 2, cutting and drilling holes; 3, making surface patterns; 4, electroplating and etching; 5, carrying out welding preventing and character and surface weldable processing; and 6, molding to make the high-frequency aluminium-based circuit board. The making accuracy of the method is high, the product quality and the work efficiency are effectively improved, and the performance of the made high-frequency aluminium-based circuit board is stable.

Owner:TAIZHOU JINDING ELECTRONICS

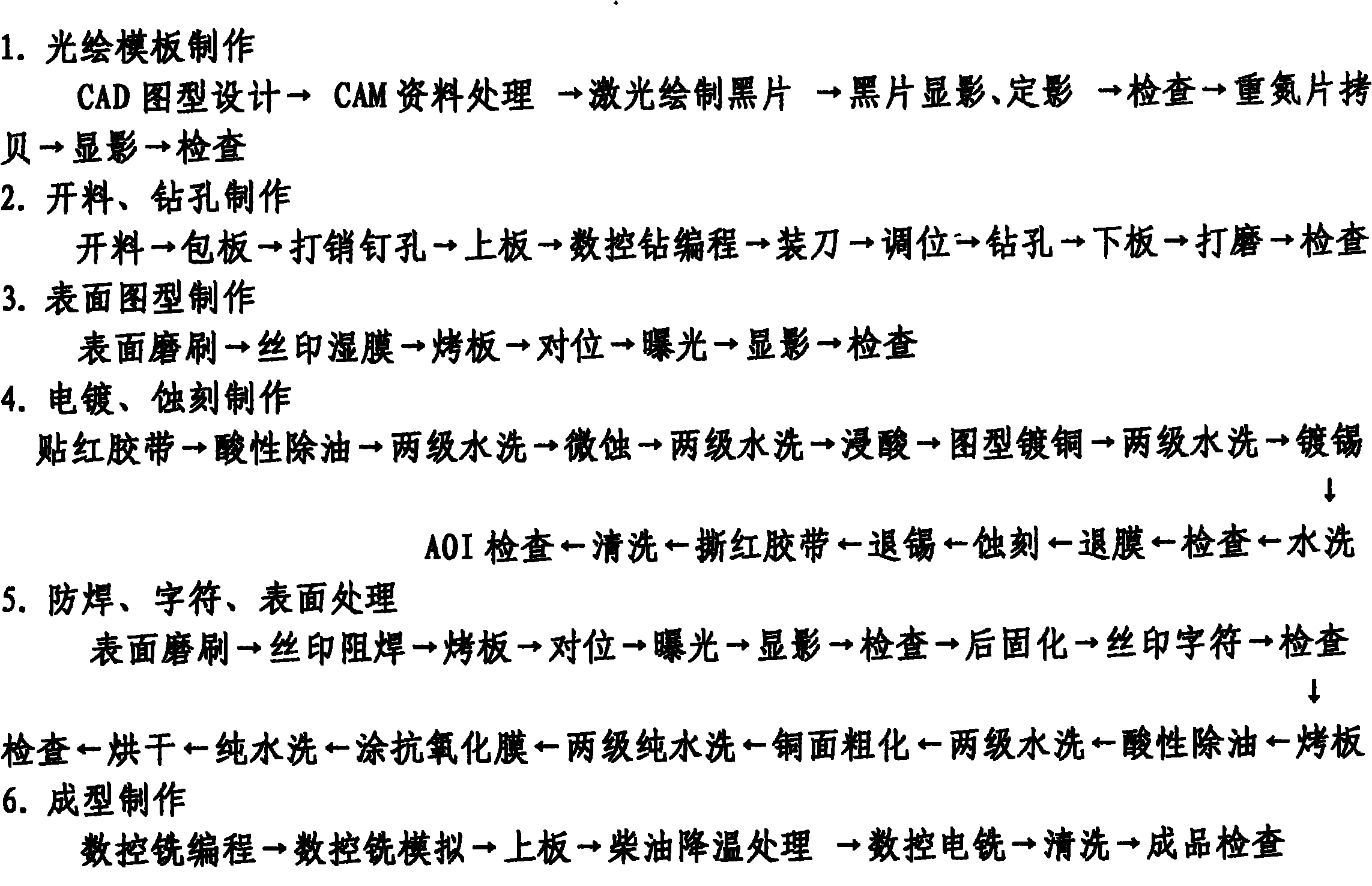

Melting sealing cap-sealing process-based chip vacuum eutectic welding method

InactiveCN102157405AAvoid secondary melting problemsEffective controlSolid-state devicesSemiconductor/solid-state device manufacturingAlloyDie bonding

The invention discloses a melting sealing cap-sealing process-based chip vacuum eutectic welding method. The technical difficult problems that the conventional vacuum eutectic welding cannot adopt a melting sealing cap-sealing process are solved by performing gold-plating, slicing, vacuum eutectic welding, lead wire bonding, gold-stannum alloy melting-sealing cap-sealing and the like on a ceramic shell and a wafer. In the method, the welding temperature is 340 DEG C and the heat insulation time is 6 minutes; the time and the temperature are both higher than those of conventional welding conditions so that a welding flux is permeated into the chip loading surface of the ceramic shell and the chip surface to change the components of Au / Sn in the welding flux; therefore, the problem of secondary melting in a chip welding area when performing the melting-sealing cap-sealing is avoided. In the method, vacuumizing is performed after melting the welding flux, most of air bubbles formed when welding the chip are vacuumized so as to effectively reduce the cavity formation probability of the welding area; therefore, welding cavities are controlled effectively. The chip bonding method adopted by the invention is on the basis of the melting-sealing cap-sealing process, contributes to batch production of the overall packaging production and improves the consistency level of products.

Owner:BEIJING MXTRONICS CORP +1

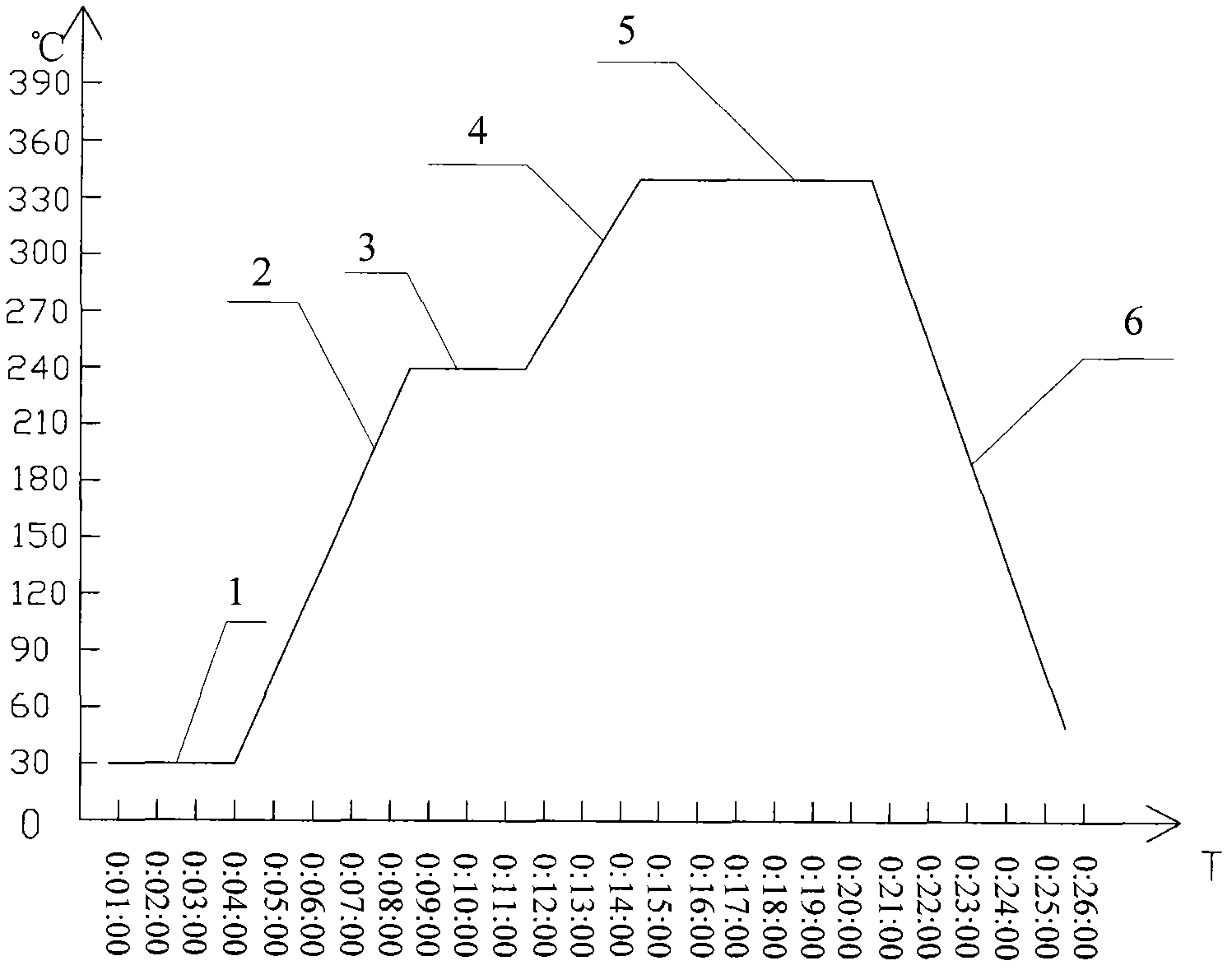

Laser strengthening process of piercing point

InactiveCN102732878AHigh surface hardnessImprove surface wear resistanceMetallic material coating processesPiercing pointHigh intensity

The invention relates to a laser strengthening process of a piercing point. The laser strengthening process comprises the following steps of: smelting a transition alloy layer on the surface of a substrate of the piercing point; smelting a high-strength alloy layer on the transition alloy layer by laser, wherein alloy powder used by the transition alloy layer is an nickel-based alloy; and the alloy powder used by the high-strength alloy layer is a cobalt-based alloy. In the process, the hardness of the transition alloy layer is lower than that of the high-strength alloy layer, has the transition effect on the high-hardness and high-abrasion-resistance high-strength alloy layer, and can better remit an overlaying stress, so that a residual overlaying stress does not cause great influences on tissues of a laser smelting layer even if the point is not pre-heated and not annealed, so that the phenomenon that the performance of the smelting layer is influenced by annealing can be effectively avoided and the surface hardness and the abrasion resistance of the piercing point are greatly improved; and meanwhile, the pre-heating and annealing processes are saved and the production efficiency is improved.

Owner:佛山市顺德区新特瓦钢型材有限公司

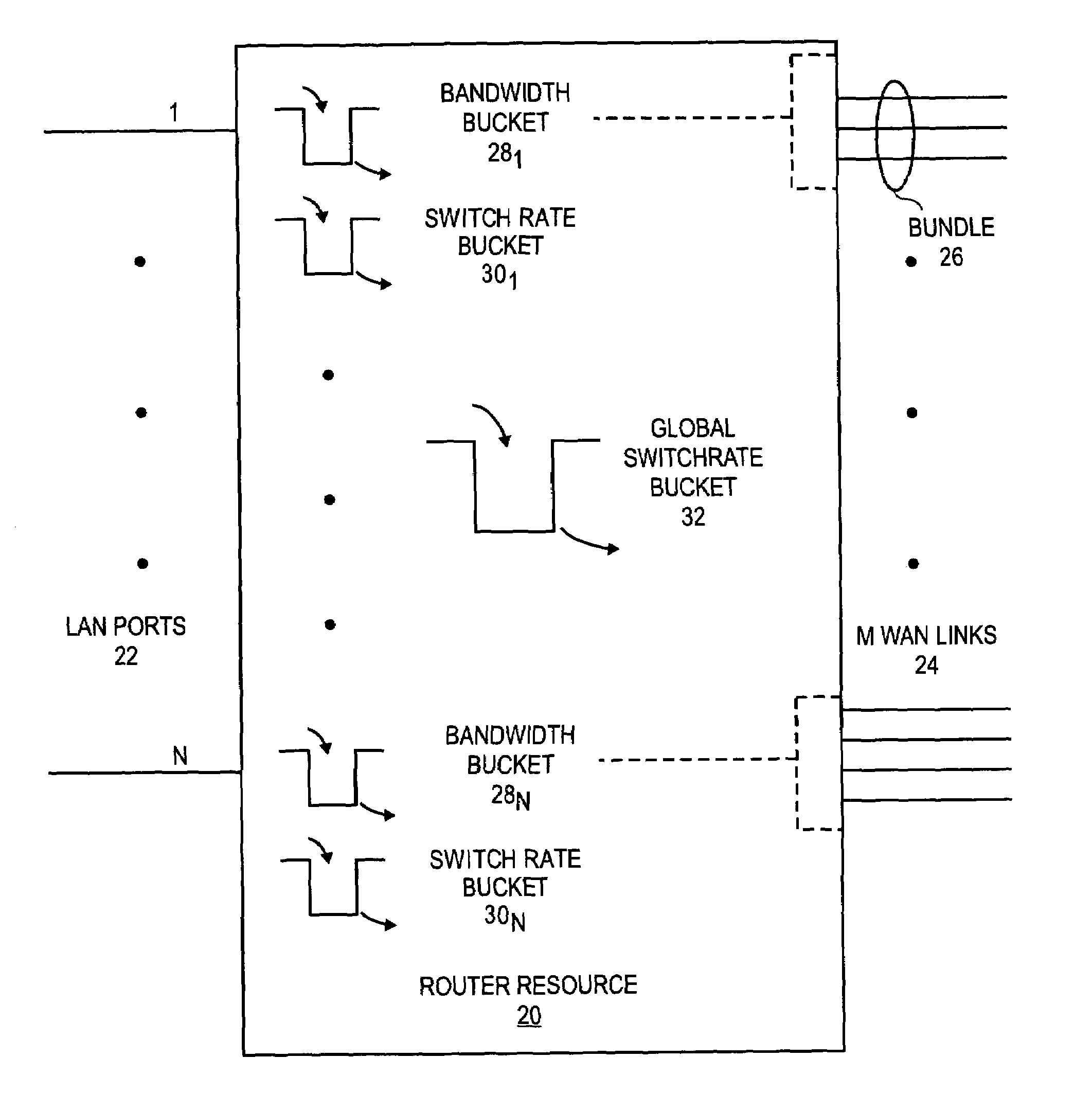

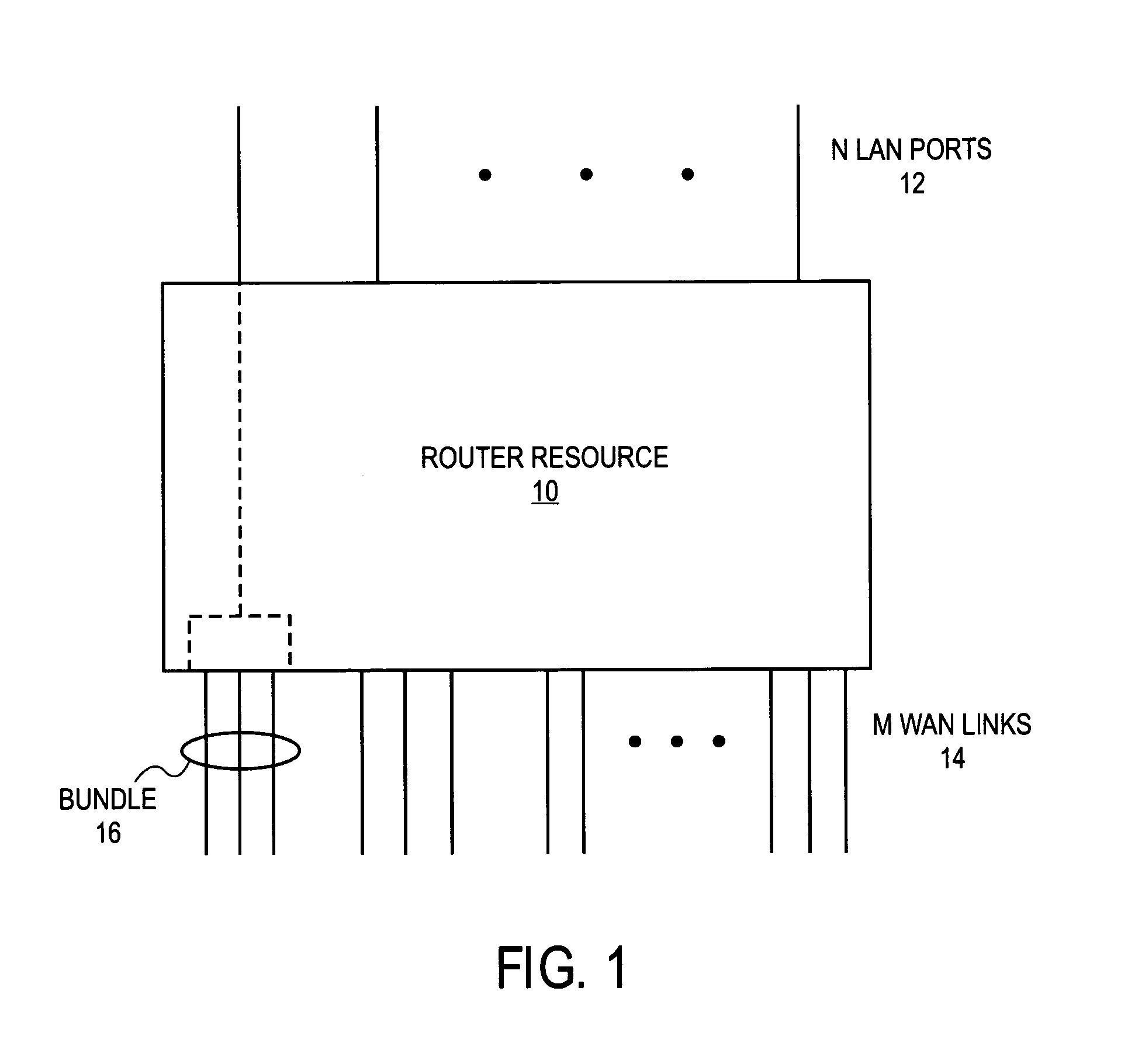

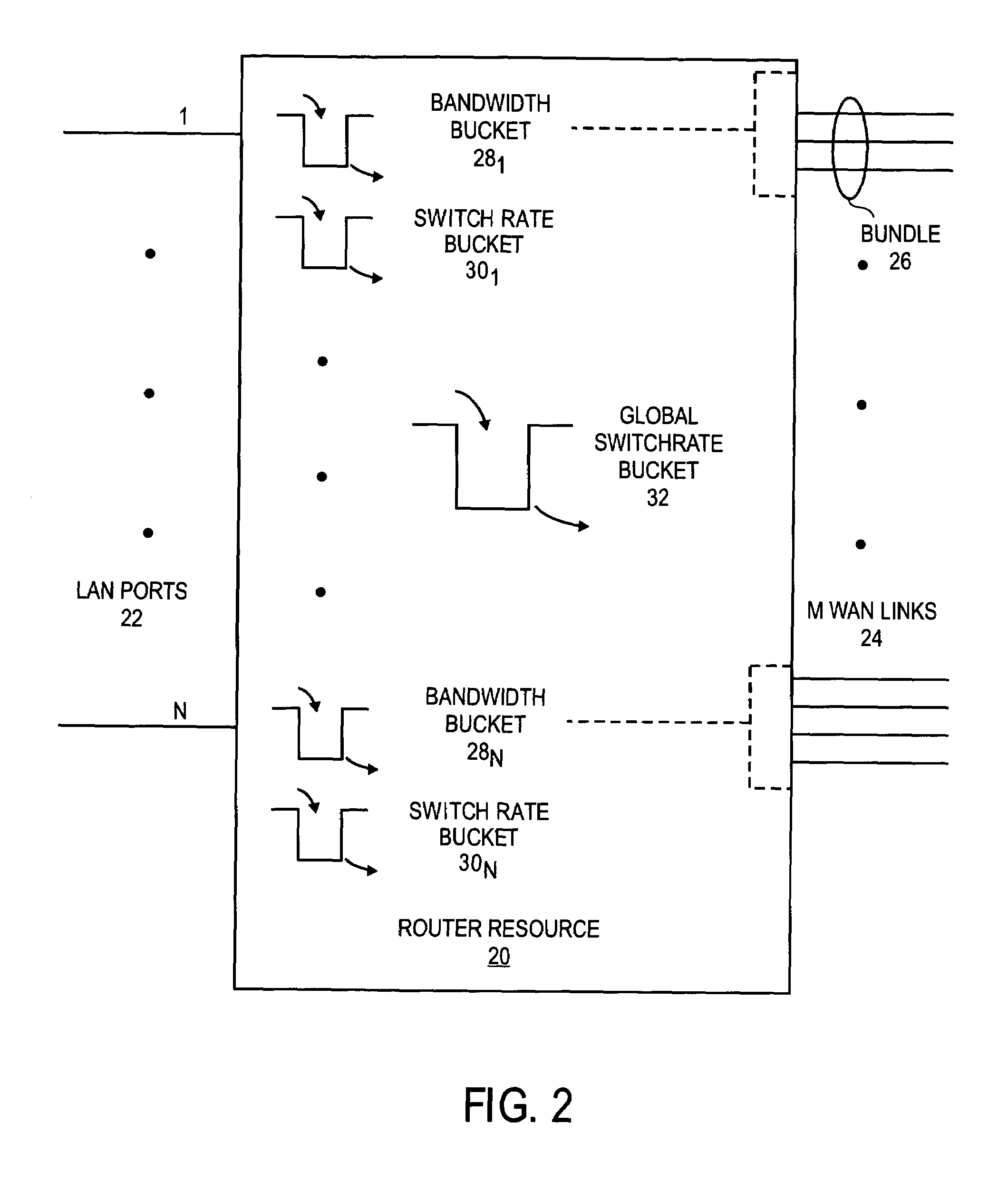

Fair multiplexing scheme for multiple input port router

InactiveUS7016301B1Avoid affecting performanceError preventionTransmission systemsTraffic volumeTraffic capacity

The present scheme provides a mechanism for preventing traffic on one ore more LAN ports from dramatically affecting performance on other LAN ports of a router resource. In one embodiment, the utilization of a router resource at the interface between a first number of local area network ports and a second number of wide area network links by each LAN port is controlled according to the bandwidth availability of corresponding bundles of the WAN links assigned to each of the LAN ports and a switching capacity of the router resource. In this scheme, individual ones of the LAN ports may be permitted to exceed their fair share of the switching capacity of the router resource, but only if a current switching load due to the traffic from all of the LAN ports is less than the maximum switching capacity for the router resource as a whole. If the current switching load due to traffic from all of the LAN ports is equal to the maximum switching capacity of the router resource, however, those of the LAN ports that are attempting to utilize more than their fair share of the bandwidth availability or the switching capacity may be throttled back. Such throttling back may include dropping packets inbound on those LAN ports that are attempting to utilize more than their fair share of the resources, preferably at the entry point to the router resource.

Owner:CISCO TECH INC

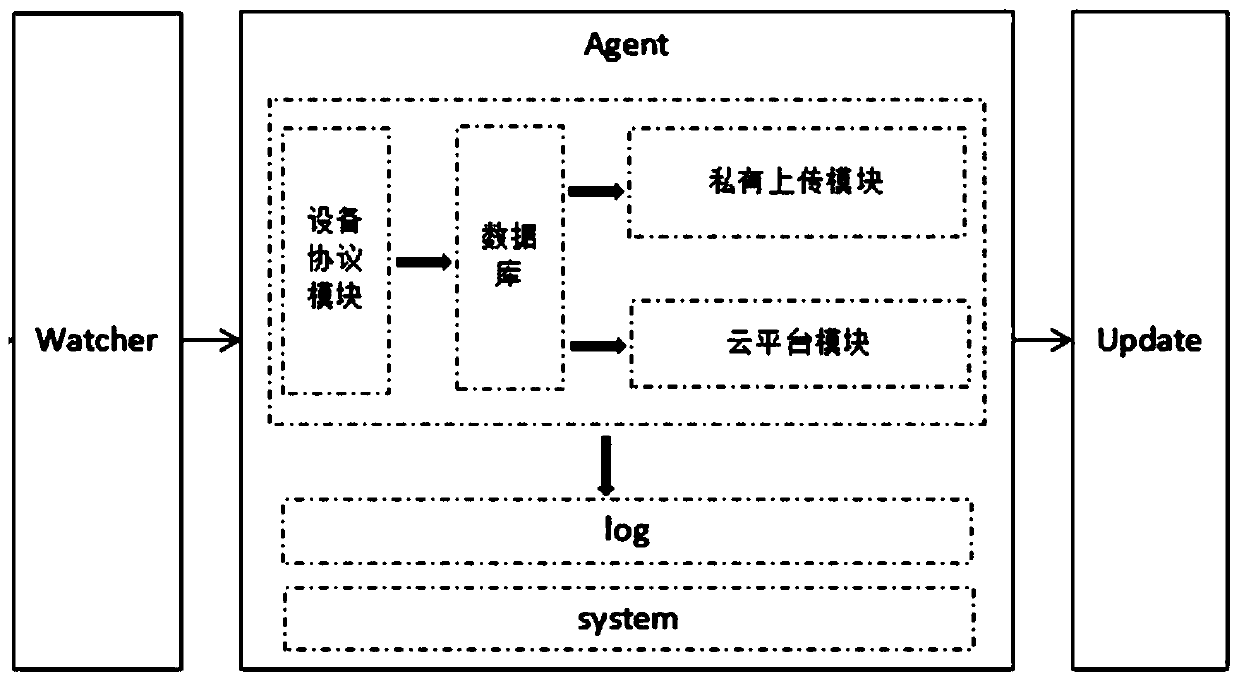

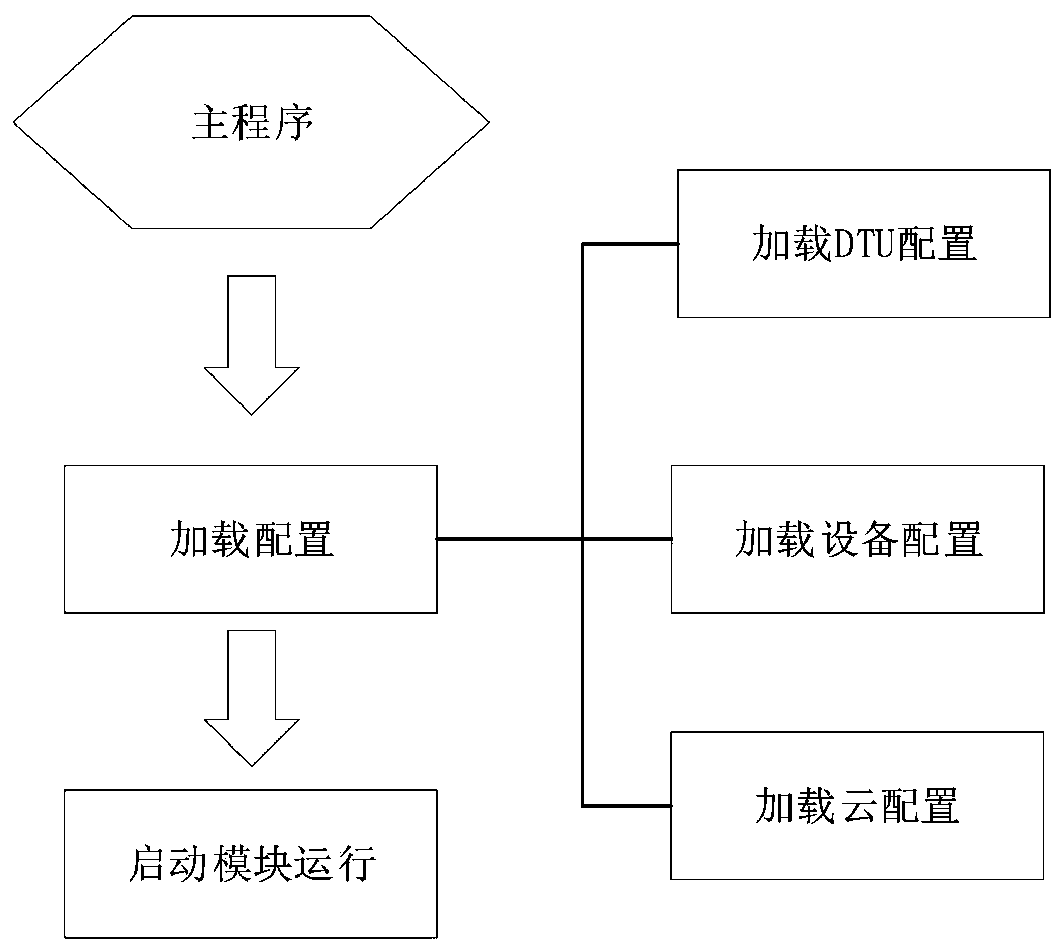

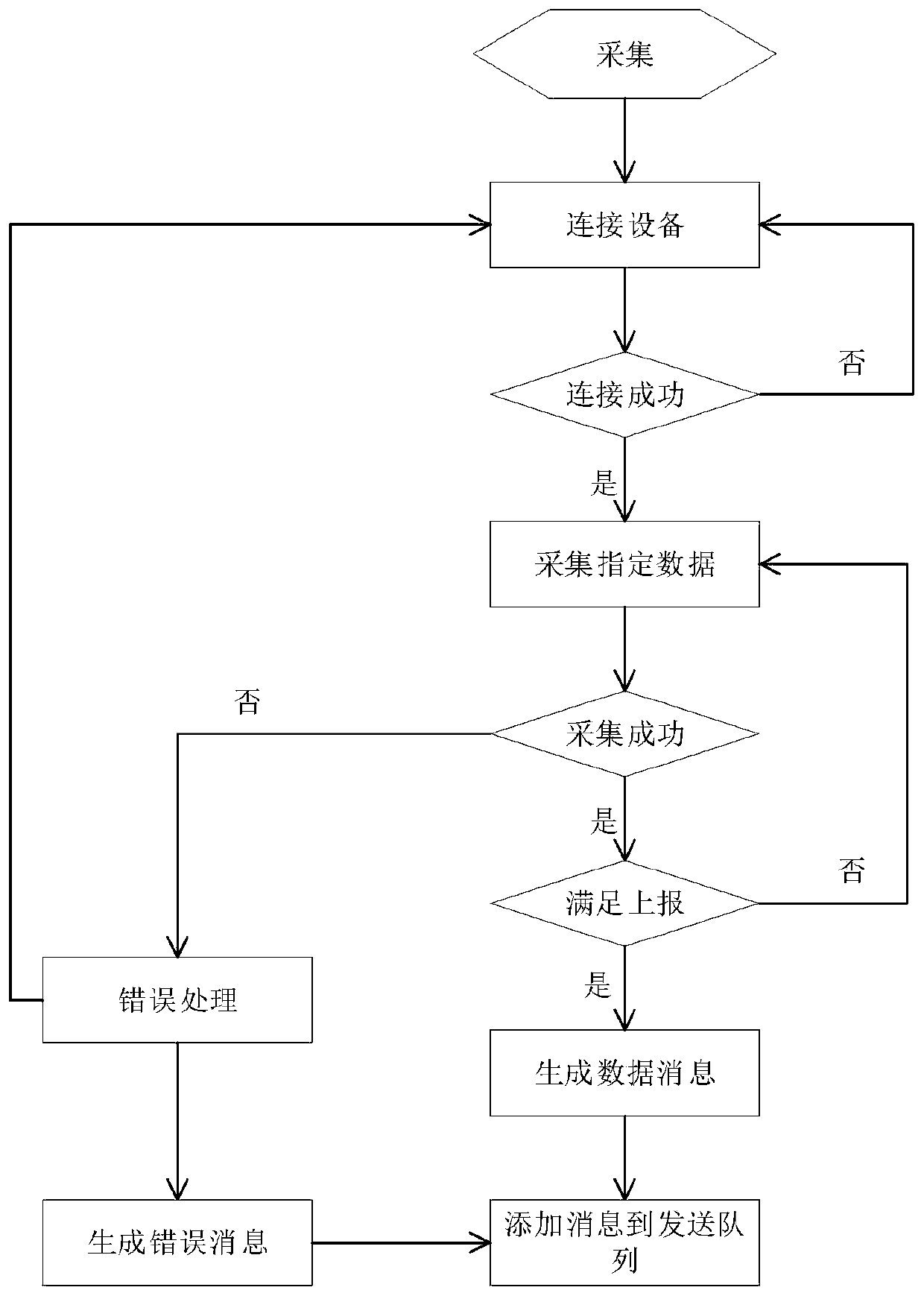

Internet of things equipment information acquisition method, system and device

InactiveCN111416821AAvoid affecting performanceImprove response speedTransmissionMessage queueSoftware engineering

The invention provides an Internet of Things equipment information acquisition method, system and device. The system comprises a host process, wherein host process is used for loading a terminal configuration file, acquiring data, analyzing the data and uploading the data; the host process comprises an equipment protocol module; the equipment protocol module is used for acquiring the data of the Internet of Things equipment; the database is used for caching the data acquired by the equipment protocol module and storing a message queue; the cloud platform module is used for being connected withan Internet of Things cloud platform, obtaining the message queue from the database, reporting the message queue to the Internet of Things cloud platform and receiving an instruction issued by the Internet of Things cloud platform; the equipment protocol module is linked to an equipment protocol library, and the cloud platform module is linked to a cloud platform protocol library, and therefore the equipment protocol module and the cloud platform protocol module can extend a new protocol. The Internet of Things equipment information acquisition system is high in response speed and timelinessand good in expandability and configurability.

Owner:杭州物源科技有限公司

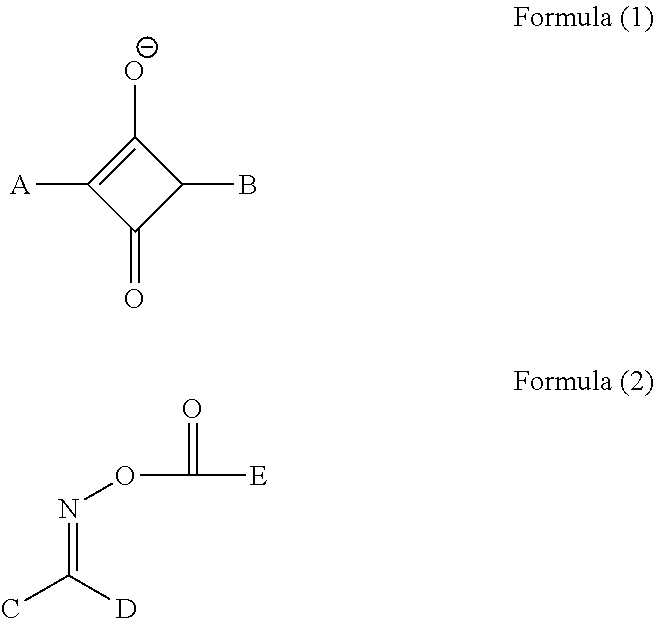

Colored photosensitive composition, color filter and process for producing same, and liquid-crystal display device

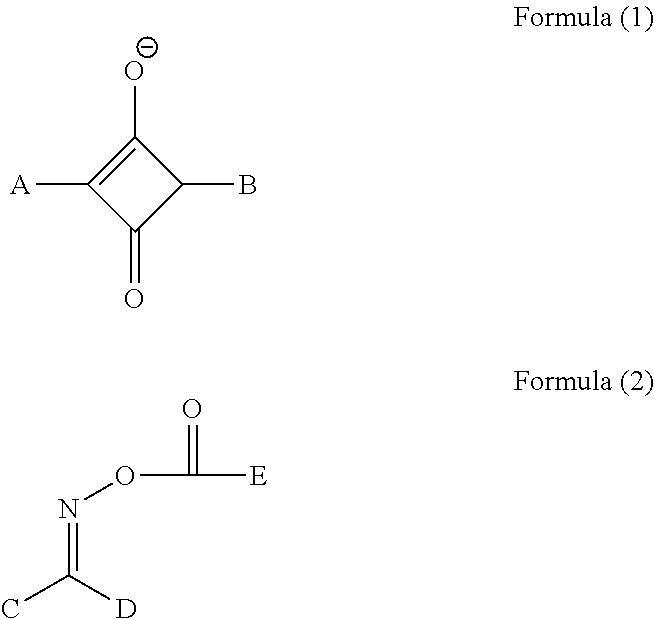

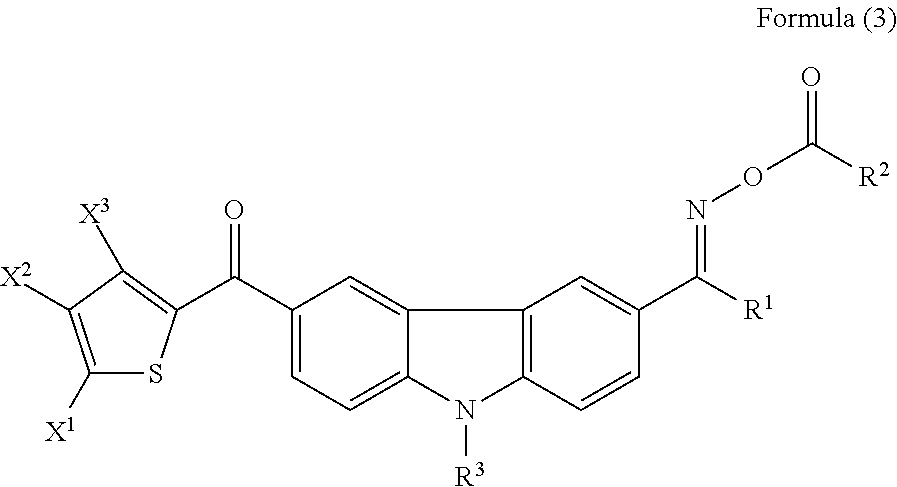

ActiveUS20140198285A1Good hueIncrease contrastPhotomechanical apparatusOriginals for photomechanical treatmentHydrogen atomThiol

A colored photosensitive composition includes: (A) a dye represented by the following Formula (1); (B) a multifunctional thiol compound; (C) a photopolymerization initiator represented by the following Formula (2); and (D) a polymerizable compound. In Formula (1), each of A and B independently represents an organic group containing an aromatic ring or an organic group containing a heterocyclic ring. In Formula (2), each of C, D, and E independently represents a hydrogen atom or an organic group.

Owner:FUJIFILM CORP

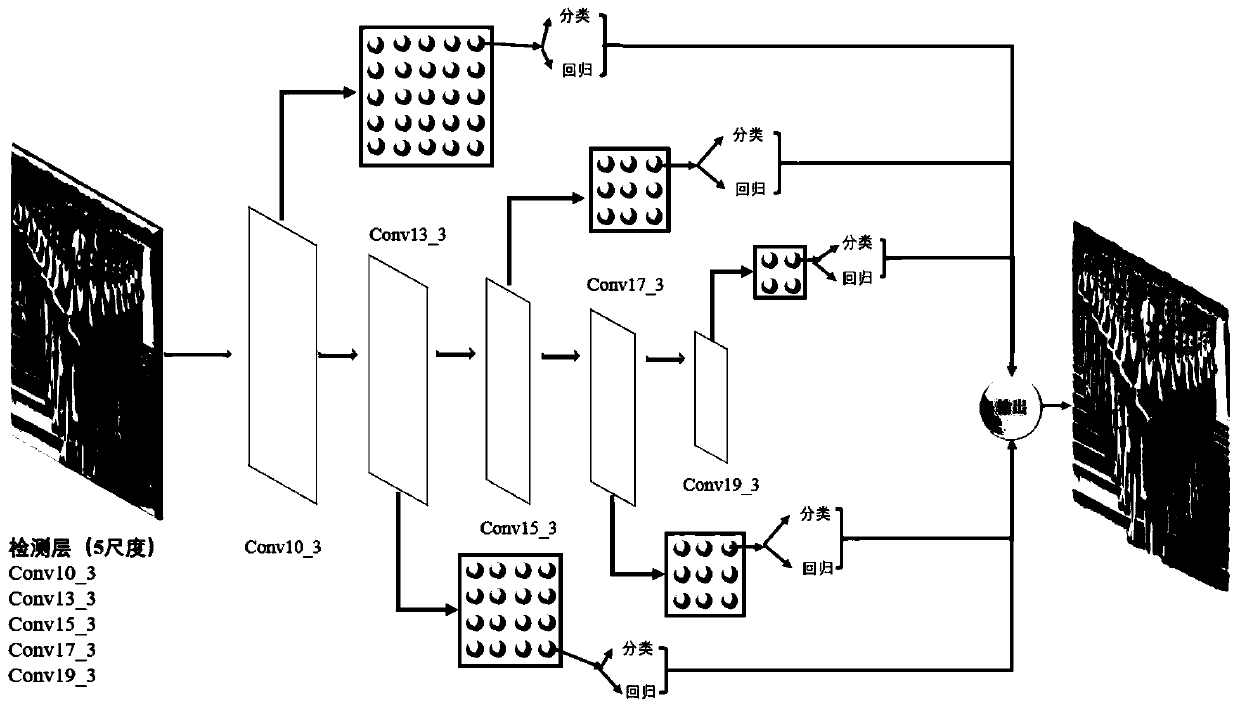

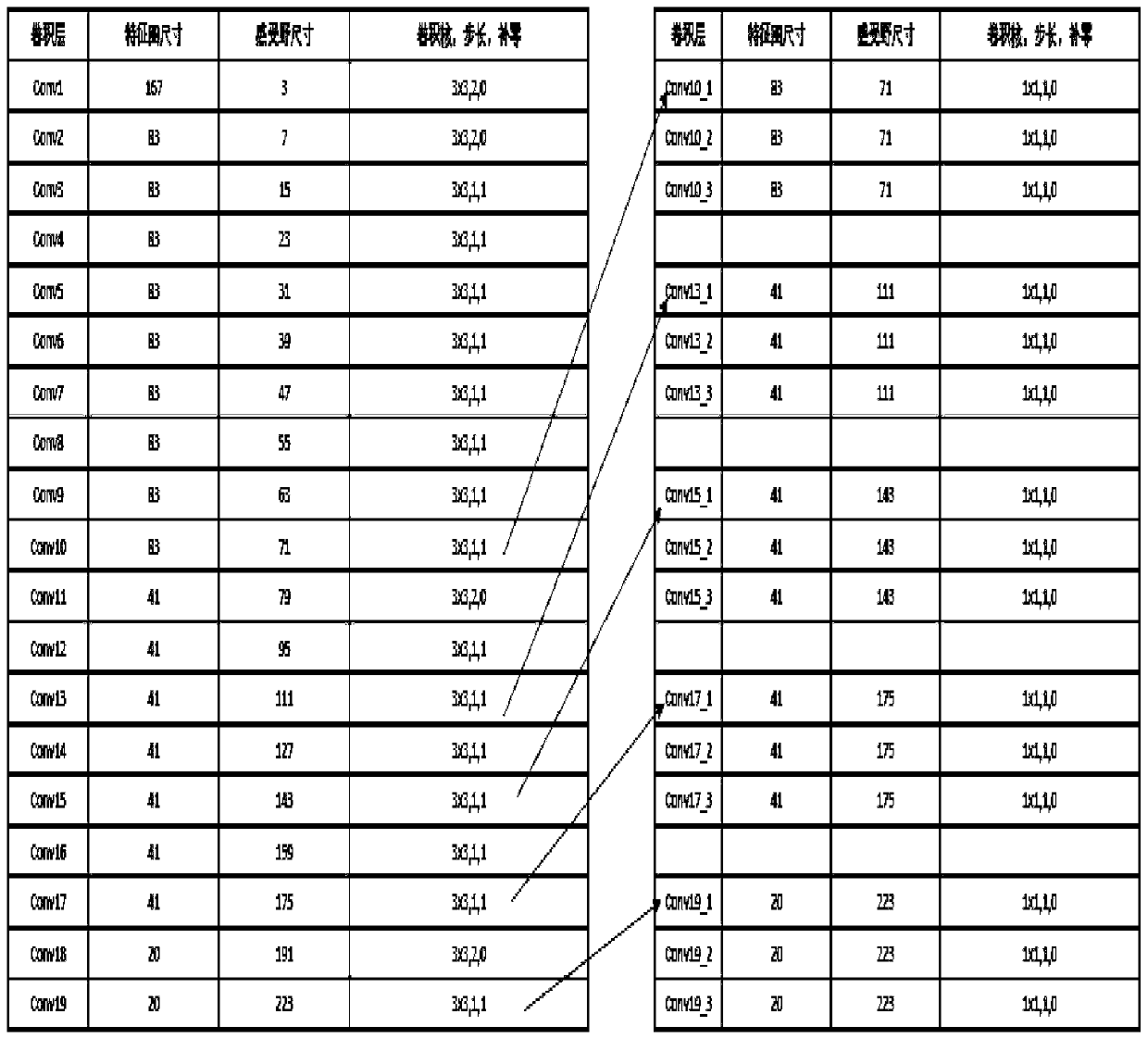

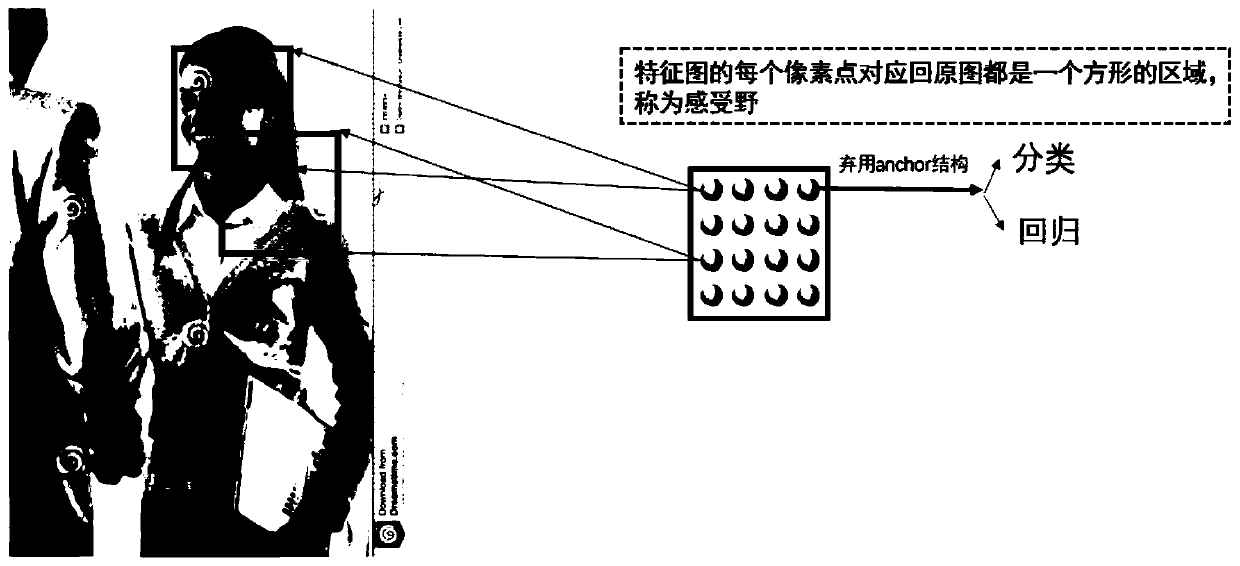

A real-time detection method for a single-stage multi-scale specific target based on an effective receptive field

ActiveCN109741318AReduce complexityAvoid affecting performanceImage analysisCharacter and pattern recognitionSingle stageComputer vision

The invention provides a real-time detection method for a single-stage multi-scale specific target based on an effective receptive field. The method comprises the following steps: firstly, extractinga corresponding feature layer from a multi-scale architecture of an SSD, and selecting a scale according to a pixel range covered by a receptive field; secondly, an anchor structure in a traditional method is removed, fewer feature layers are adopted, and classification and regression are directly carried out on corresponding receptive field frames of the feature map by utilizing the characteristics of a natural receptive field; Finally, an RF (receptive field) sampling frame ash placement learning strategy is adopted, and redundant parameters are prevented from being learned. According to themethod, the complexity of a traditional algorithm based on an anchor sampling frame is greatly reduced, the detection efficiency is improved, the real-time effect can be achieved, and the method hasvery high use value under the application background with very large data volume.

Owner:BEIJING UNIV OF TECH

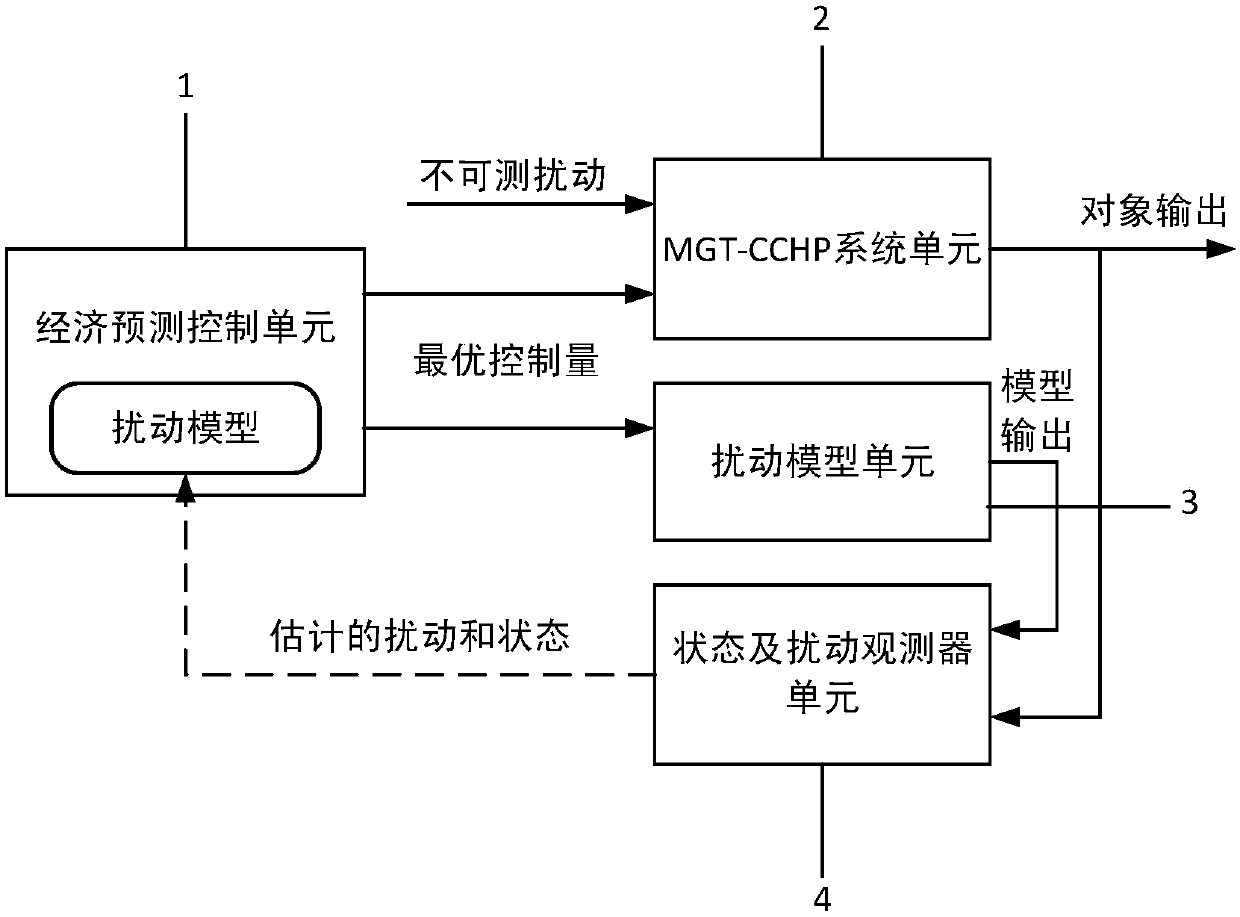

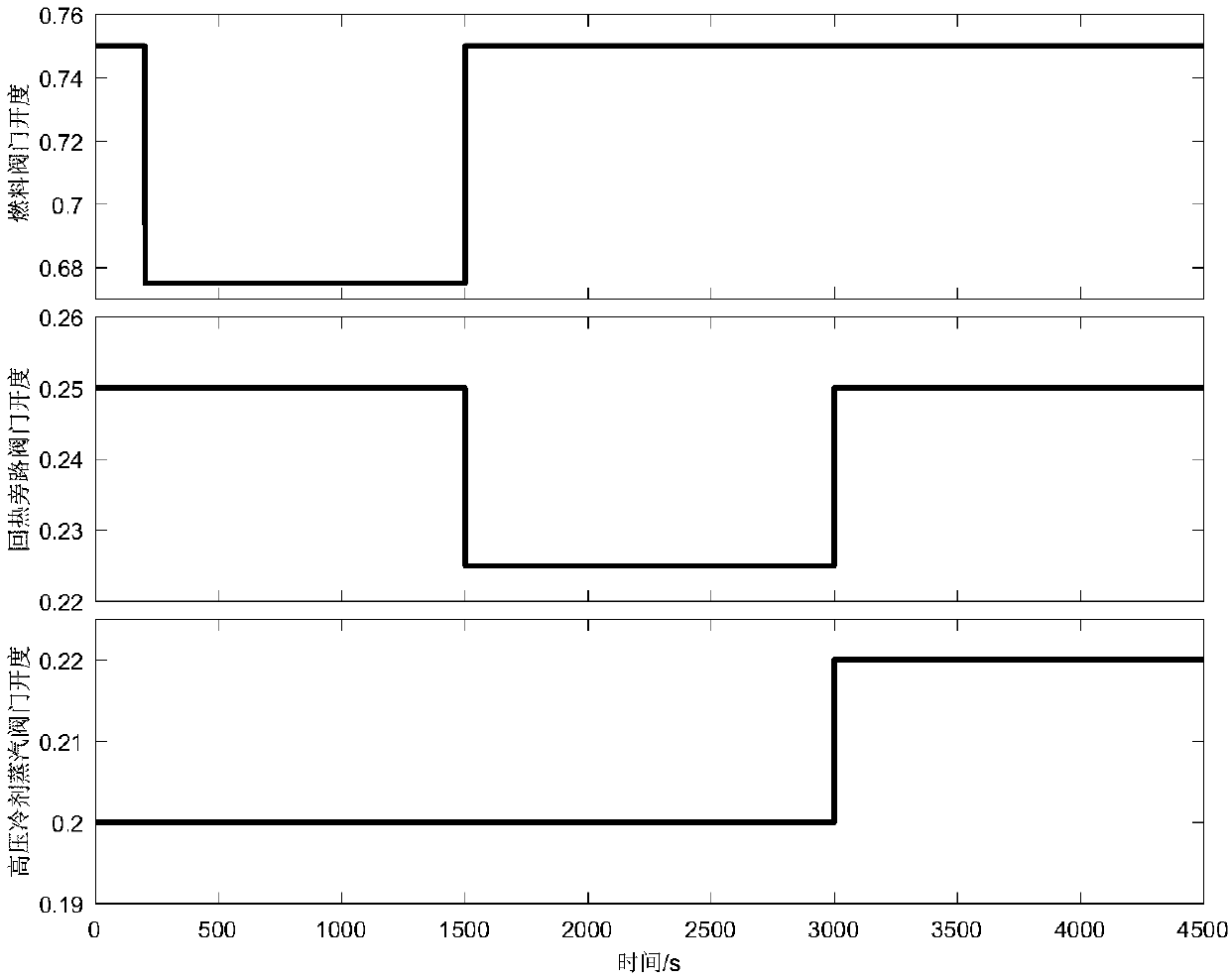

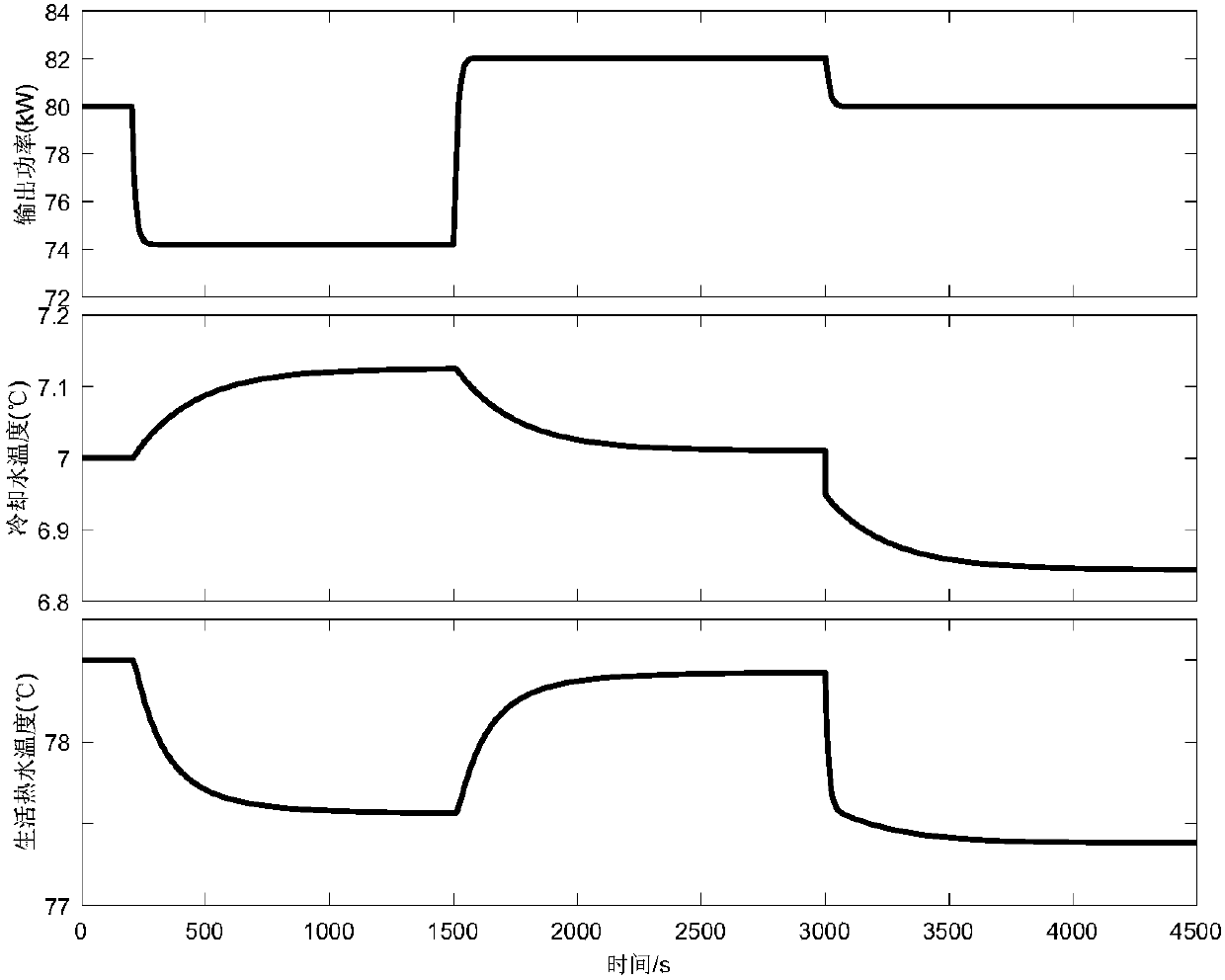

MGT-CCHP control system based on economic forecast control

ActiveCN107703745AGuaranteed economyAvoid affecting performanceAdaptive controlWeight coefficientOptimal control

The invention discloses an MGT-CCHP control system based on economic forecast control. The MGT-CCHP control system comprises an economic forecast control unit, an MGT-CCHP system unit, a disturbance model unit and a state and disturbance observer unit. By introducing a disturbance model into an object model, the MGT-CCHP control system integrates the immeasurable disturbance of the system and model mismatch information into one disturbance quantity, an original state space model is amplified, then all the state quantities are estimated by a Kalman filter and used for the calculation in an economic forecast controller, so that the influence of the disturbance on the optimization of an optimal control quantity by the economic forecast controller is removed and the anti-interference performance of the system is improved. Weight coefficients of different objective functions in the economic forecast controller can be adjusted to allow the MGT-CCHP system to switch rapidly under different operating modes to meet the complex and changeable load requirements. At the same time, the actual constraints such as upper and lower valve opening limits and the rate limit are taken into account to avoid the influence on the system performance saturation due to the saturation of an actuator.

Owner:SOUTHEAST UNIV

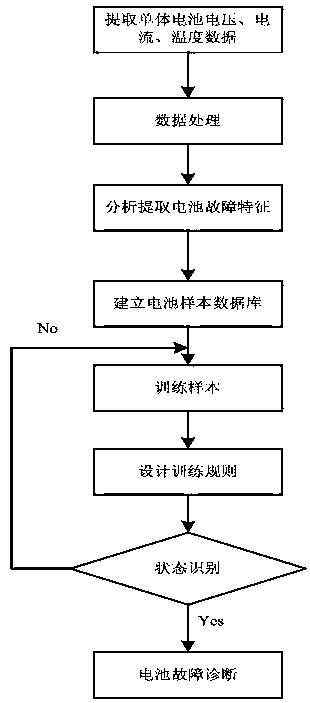

Hybrid energy-storage battery pack fault diagnosis method

InactiveCN109061495ATimely resectionAvoid affecting performanceElectrical testingFeature vectorDiagnosis methods

The invention relates to a hybrid energy-storage battery pack fault diagnosis method, and especially a hybrid energy-storage battery pack fault diagnosis method. The method comprises the following steps: extracting voltage, current, temperature and like information signal data of a monomer battery, and removing noise of the collected signal information data through a filter algorithm to acquire anoriginal sample with fault information, analyzing to extract a feature vector of a battery status from the original information, and regarding the feature vector as an input signal of an improved neural network classifier algorithm; and meanwhile, establishing a battery data training rule with feature vectors and fault types in one-to-one correspondence, wherein the battery data training rule isused for training and testing, wherein a diagnosis method with the diagnosis precision meeting a requirement after testing is used for performing fault positioning on a battery module in the actual operation. The diagnosis method disclosed by the invention has the advantage that the diagnosis method is fast in speed and high in efficiency, the fault battery detection accuracy rate can be improved,and the fault battery can be timely removed.

Owner:POWERCHINA FUJIAN ELECTRIC POWER SURVEY & DESIGN INST CO LTD

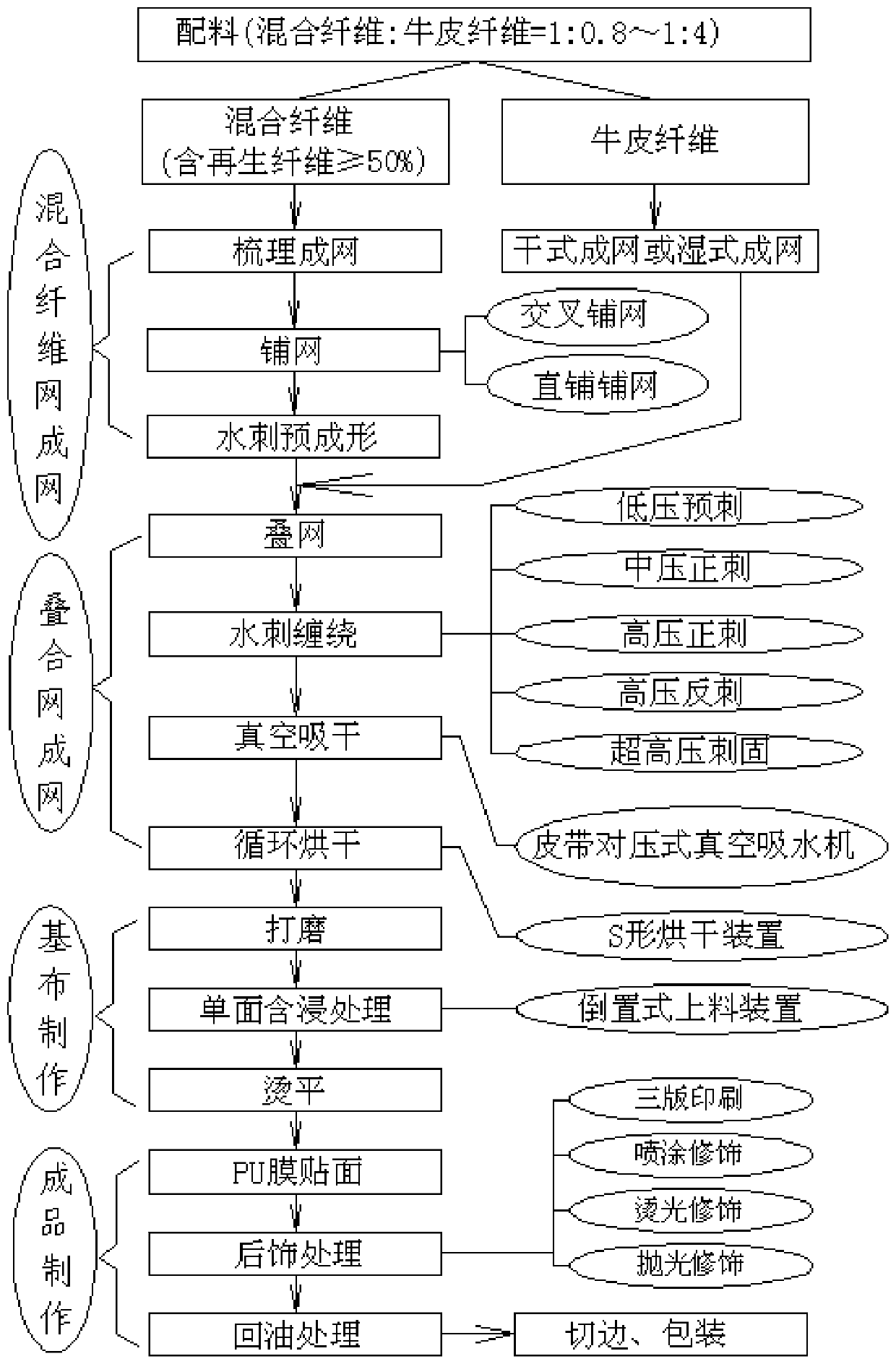

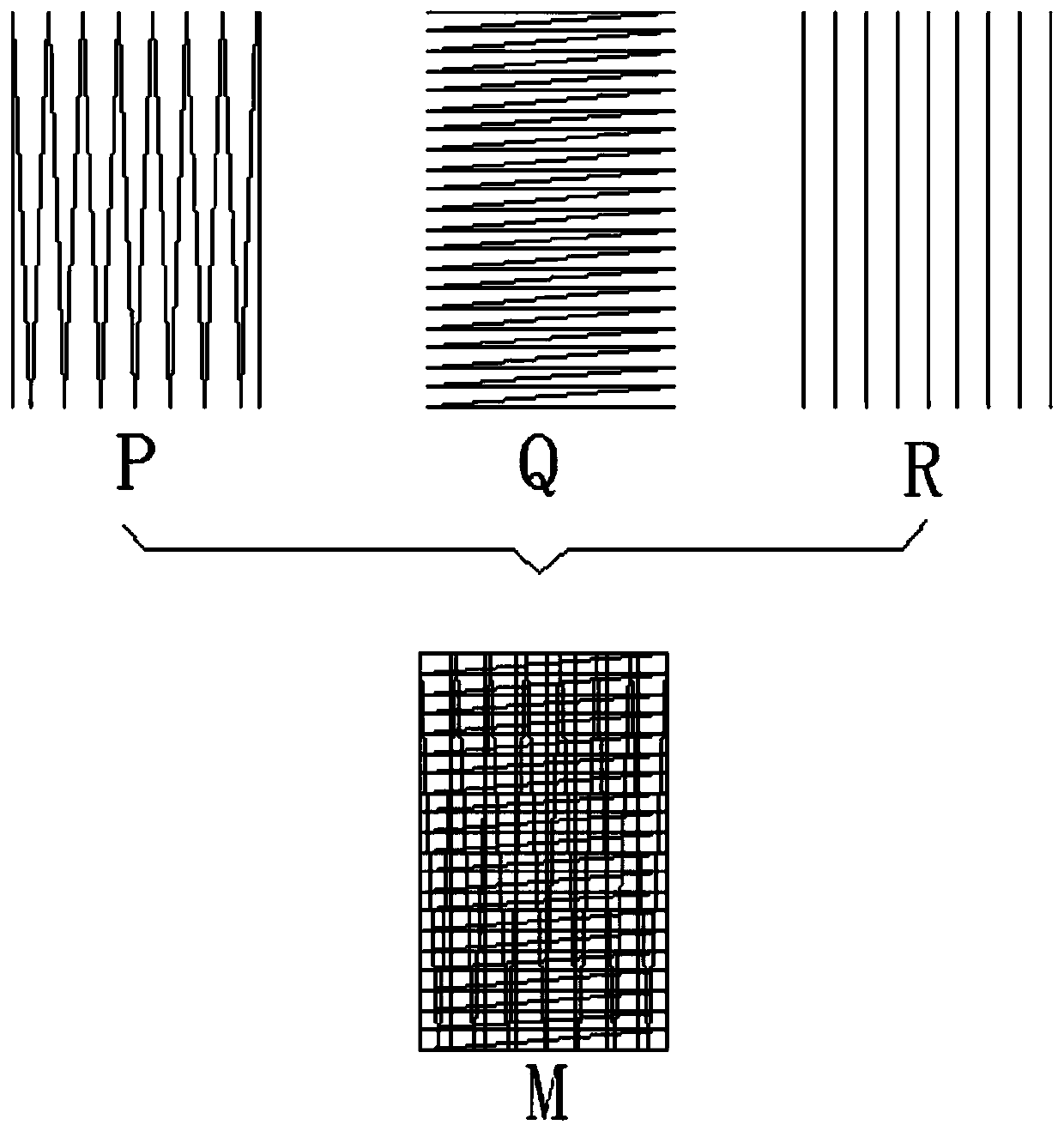

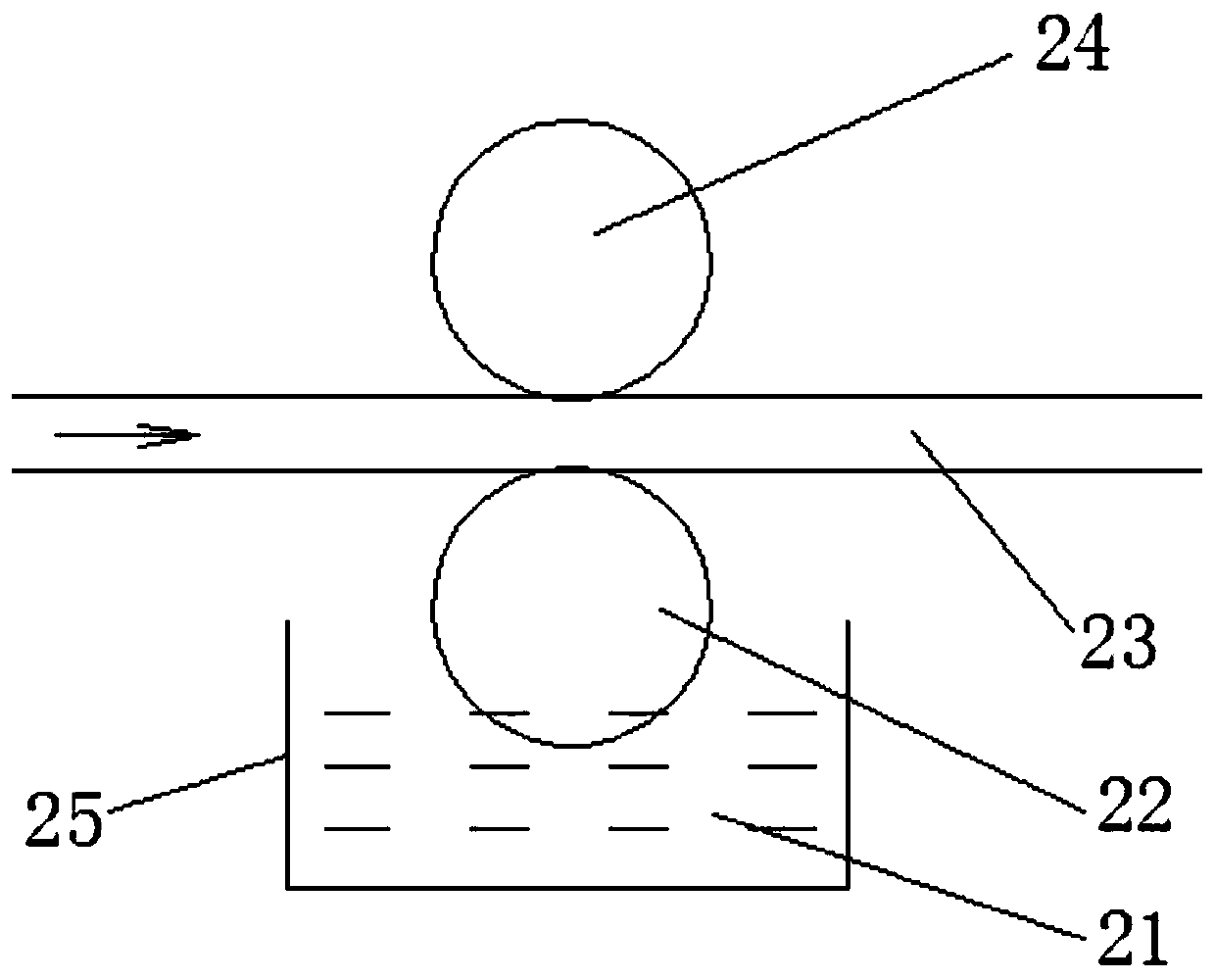

Preparation process of spunlace winding type cyclic cow leather

ActiveCN110331516AImprove physical performanceIncreased durabilityLamination ancillary operationsDrying solid materials without heatWater basedFiber

The invention relates to the technical field of leather manufacturing and discloses a preparation process of spunlace winding type cyclic cow leather. The preparation process comprises a matching process, a cow leather fiber web forming process as well as a mixed fiber web forming process, a stacked web forming process, a base cloth production process and a finished cow leather product productionprocess which are set sequentially according to the preparation process; the base cloth production process comprises a polishing process, a single-sided impregnation process and an ironing process which are set sequentially to produce a stacked web into base cloth; the single-sided impregnation process includes performing single side coating treatment with a water-based PU material or an oil-basedPU material as a coating on a single side of the base cloth by adopting an inverted feeding device so as to form a single-sided permeation impregnation layer of the base cloth. The physical performance and hand feel of the cow leather product are improved, the sense of genuine leather is enhanced, and meanwhile, energy consumption in the production process is reduced.

Owner:JIANGYIN JUNHUA TEXTILE TECH

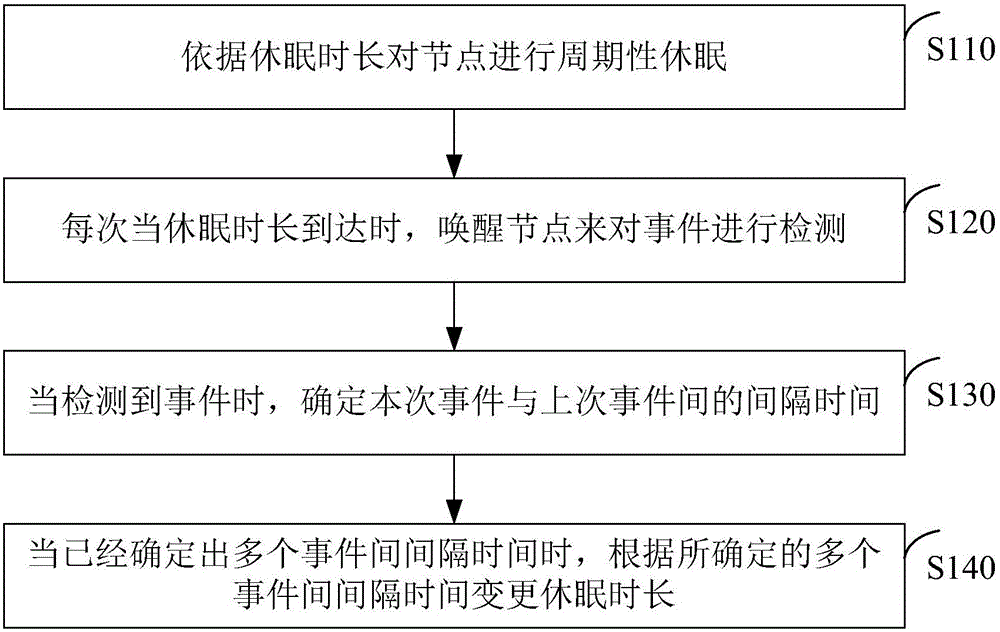

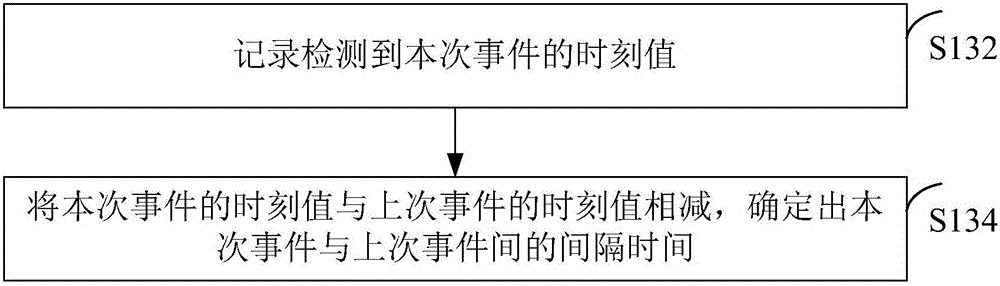

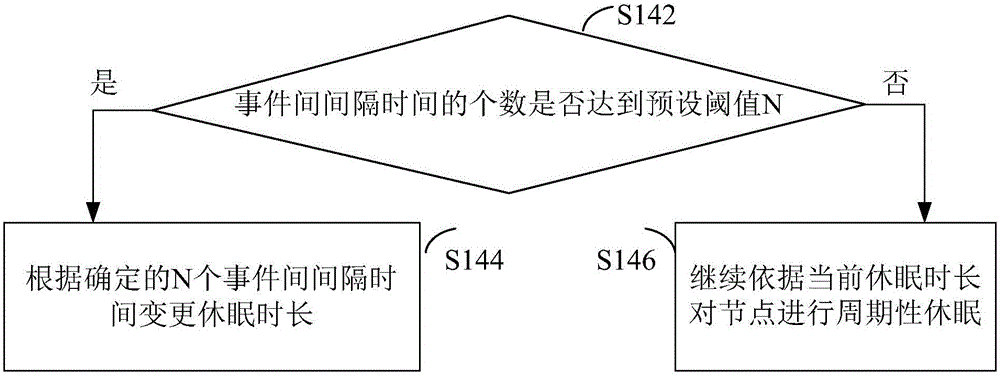

Method and device for periodically awaking node

InactiveCN105873200AExtend working lifeAvoid affecting performancePower managementNetwork topologiesWork performanceLife time

The invention relates to the technical field of electronic equipment and discloses a method and a device for periodically awaking a node. The method comprises steps as follows: periodical dormancy is performed on the node according to dormancy duration; the node is awakened to detect events every time dormancy time arrives; a time interval between the event and the last event is determined when the events are detected; the dormancy duration is changed according to the determined time intervals between multiple events when the time intervals between multiple events are determined. With the adoption of the method, the dormancy duration can be automatically adjusted according to changes of the time intervals of the events, accordingly, the working performance of the node is improved, and the service life of the node can be prolonged.

Owner:MIDEA GRP CO LTD

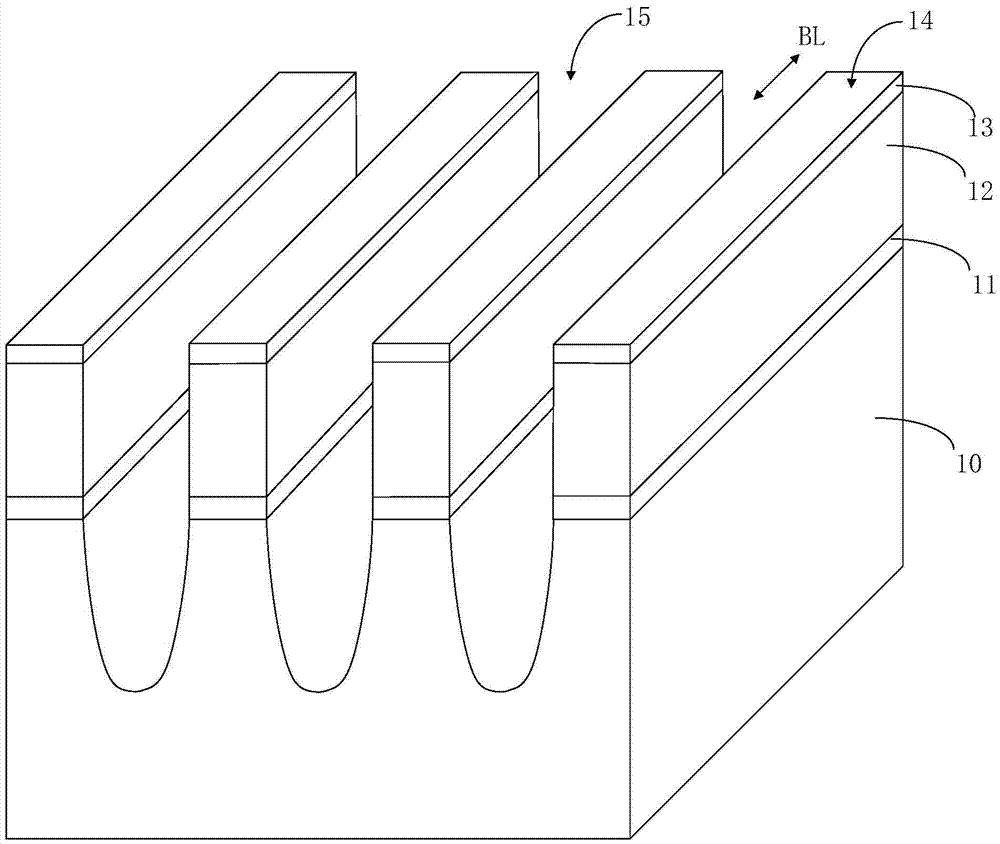

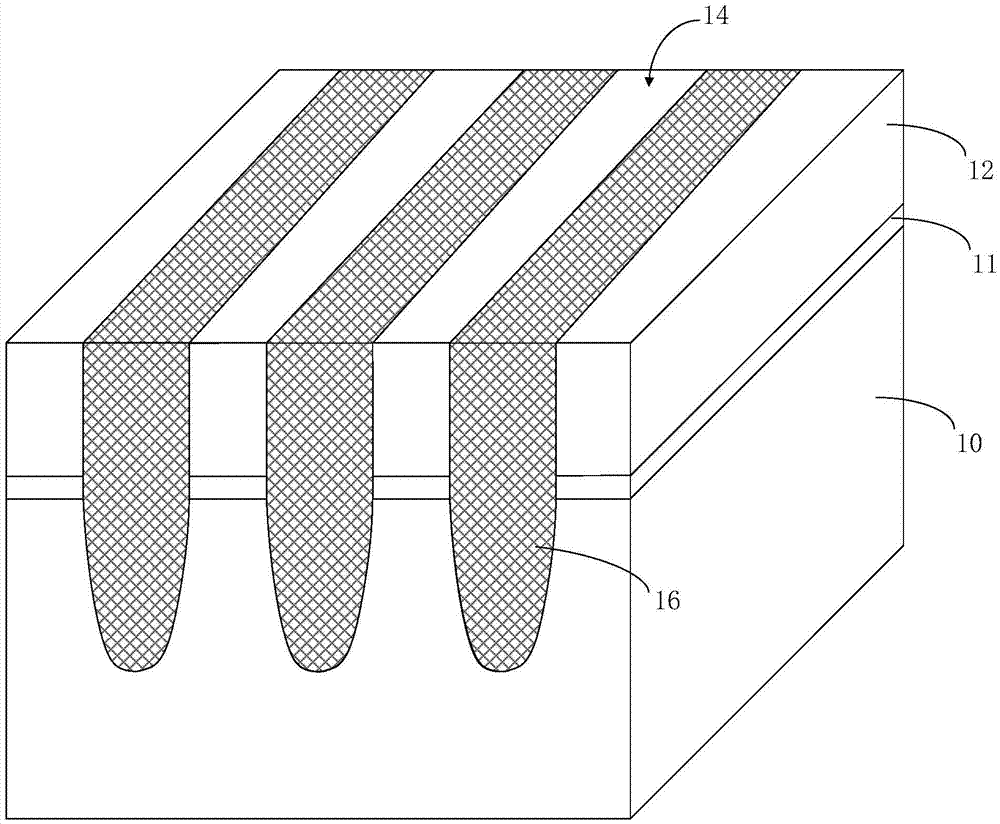

Flash memory and manufacturing method therefor

ActiveCN106952919AAvoid mutual interferenceReduce parasitic capacitanceSolid-state devicesSemiconductor/solid-state device manufacturingBit lineParasitic capacitance

The invention discloses a flash memory and a manufacturing method therefor. A filling process with relatively poor filling performance is adopted in filling gate stacking structures of adjacent memory transistors so as to form air gaps in a semiconductor substrate between bit lines in each column, and between floating gate stacking structures in each column below word lines. The dielectric constant of the air gaps is less than that of a silicon dioxide dielectric layer, so that parasitic capacitance generated in the processes of reading, writing and erasing can be lowered, and mutual interference between adjacent memory transistors can be avoided.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

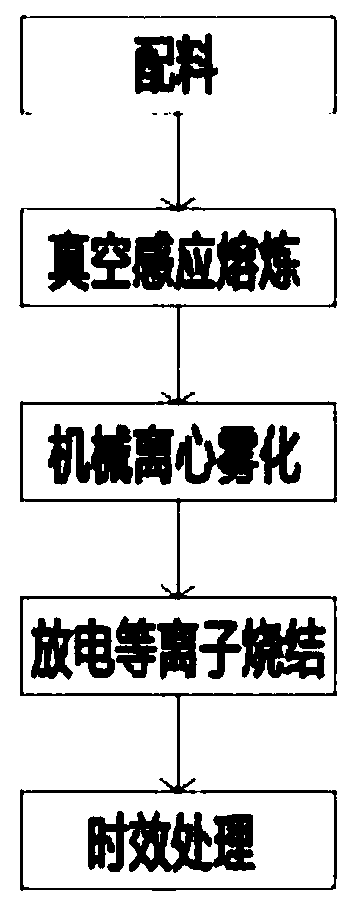

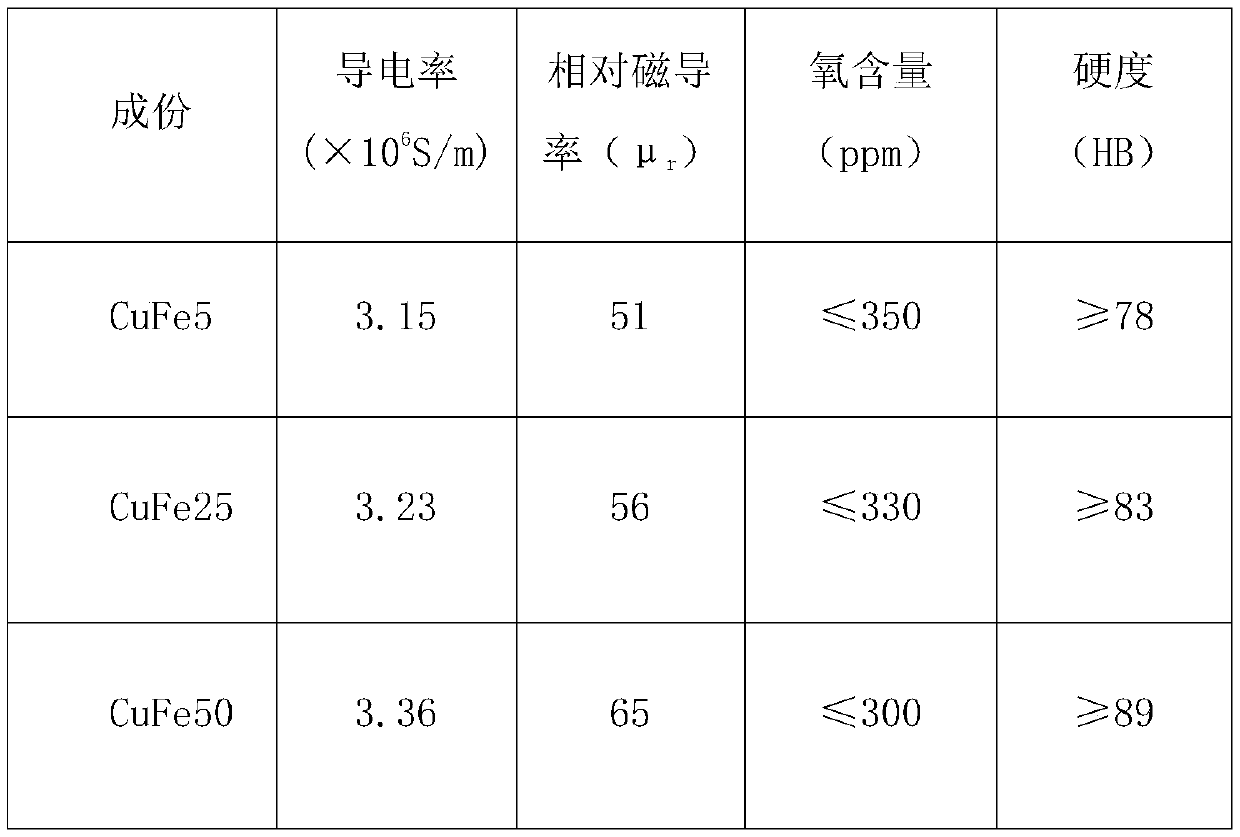

Method of copper and iron alloy materials for novel motor rotors

ActiveCN110484762AIncrease cooling rateOvercoming the problem of prone to macro segregationMagnetic/electric field screeningElectromagnetic shieldingSolid solubility

The invention discloses a method of copper and iron alloy materials for novel motor rotors, and belongs to the technical field of nonferrous metal material manufacturing. The method mainly comprises the steps of (1) burdening, (2) vacuum induction smelting, (3) mechanical centrifugal atomization, (4) discharge plasma sintering and (5) aging. Cu and Fe raw materials with higher purity are selected,fed silver is excellent in electric conductivity, and meanwhile, iron, silicon and copper are lower in solid solubility, so that the influence on electricity and heat conductivity of copper rods is lower, the solid solubility cannot be changed along with the temperature change, and alloys formed by Cu and Fe achieve higher electric conductivity; and through the mechanical centrifugal atomizationmode, Cu-Fe alloys are atomized as drops, and the drops are quickly condensed through low-temperature and high-purity argon, so that the cooling speed of the alloy drops can be accelerated, the macroscopic segregation of the alloys is overcome, and the electromagnetic shielding performance of the alloys is further improved.

Owner:SHAANXI SIRUI ADVANCED MATERIALS CO LTD

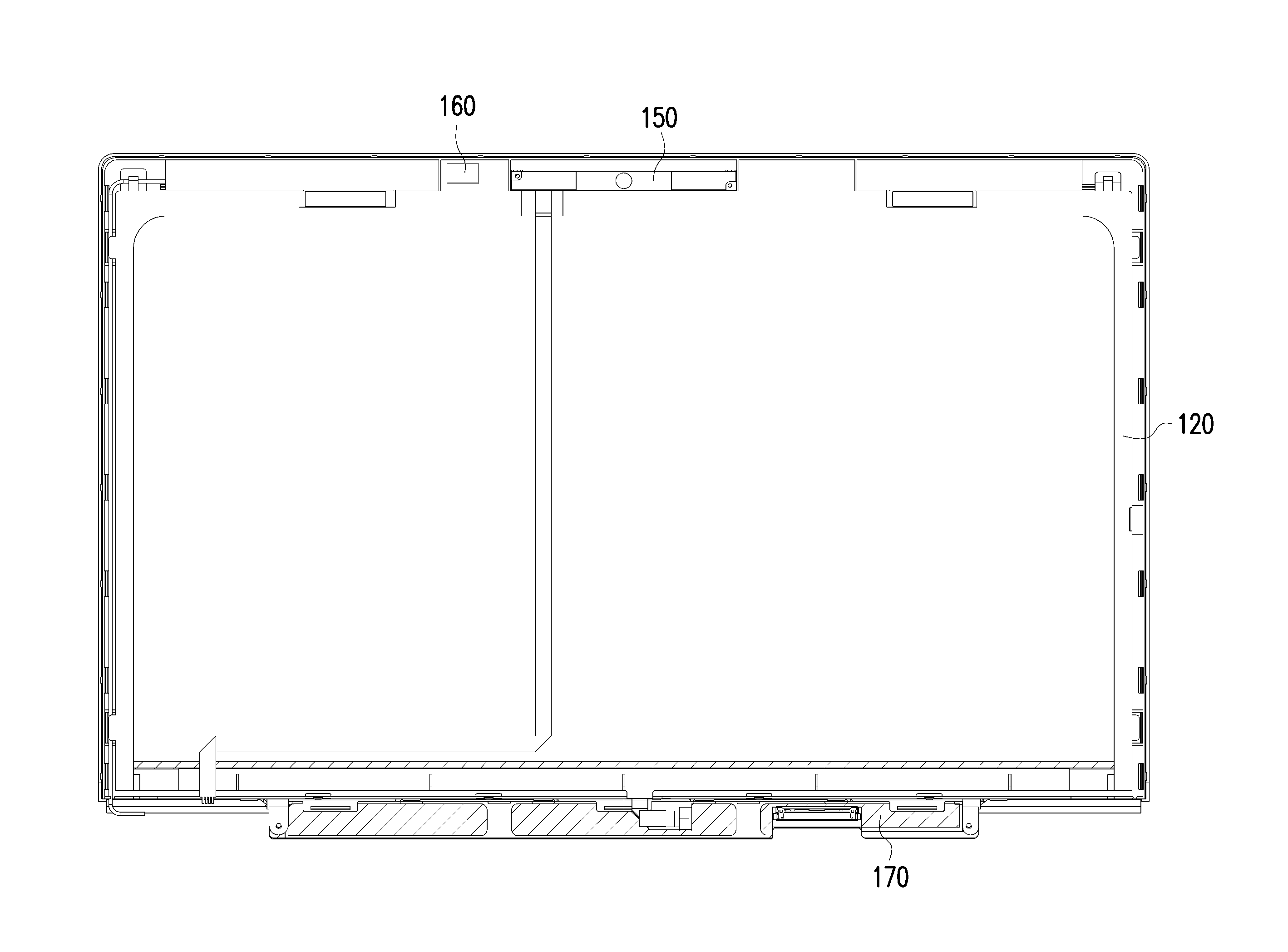

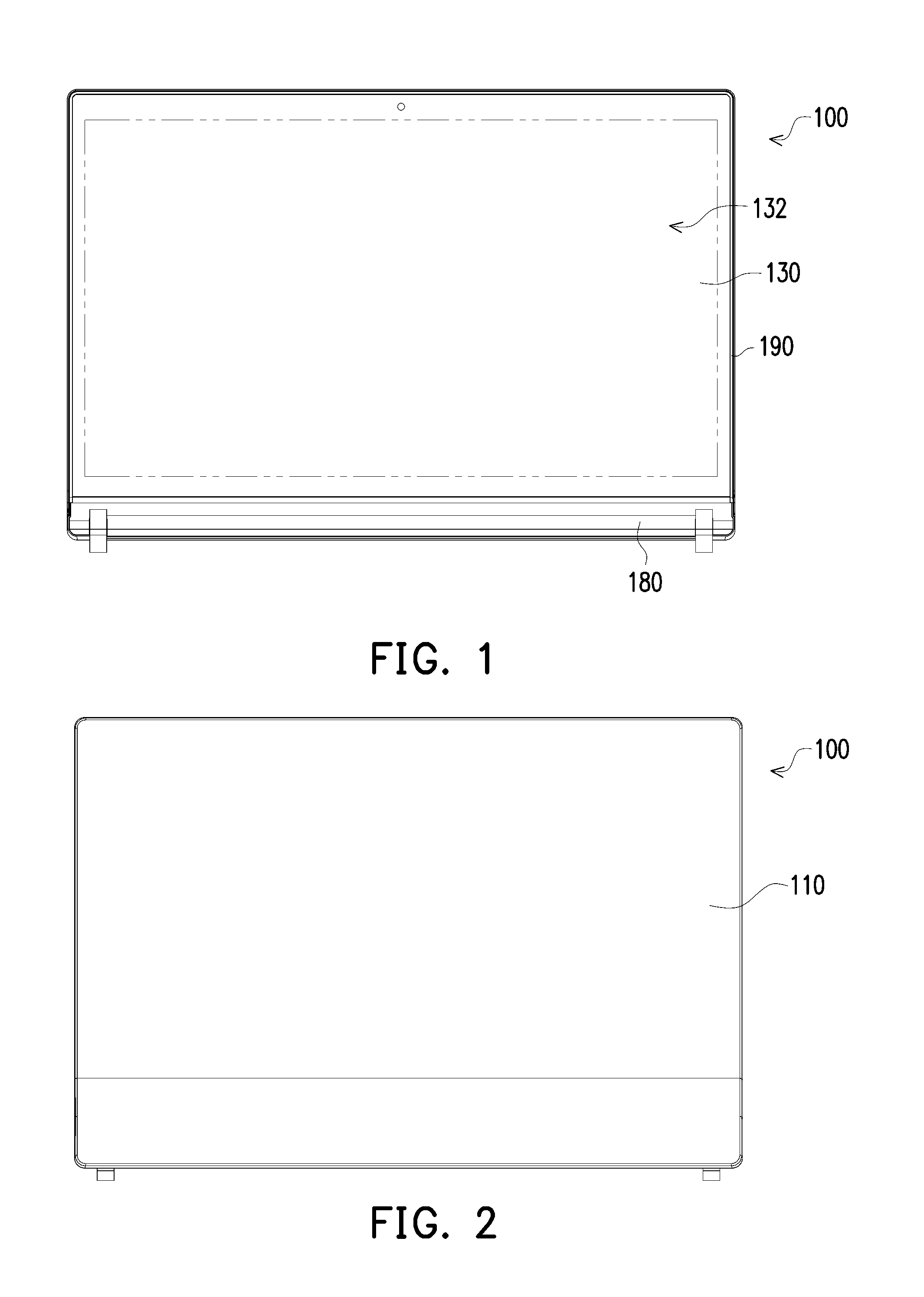

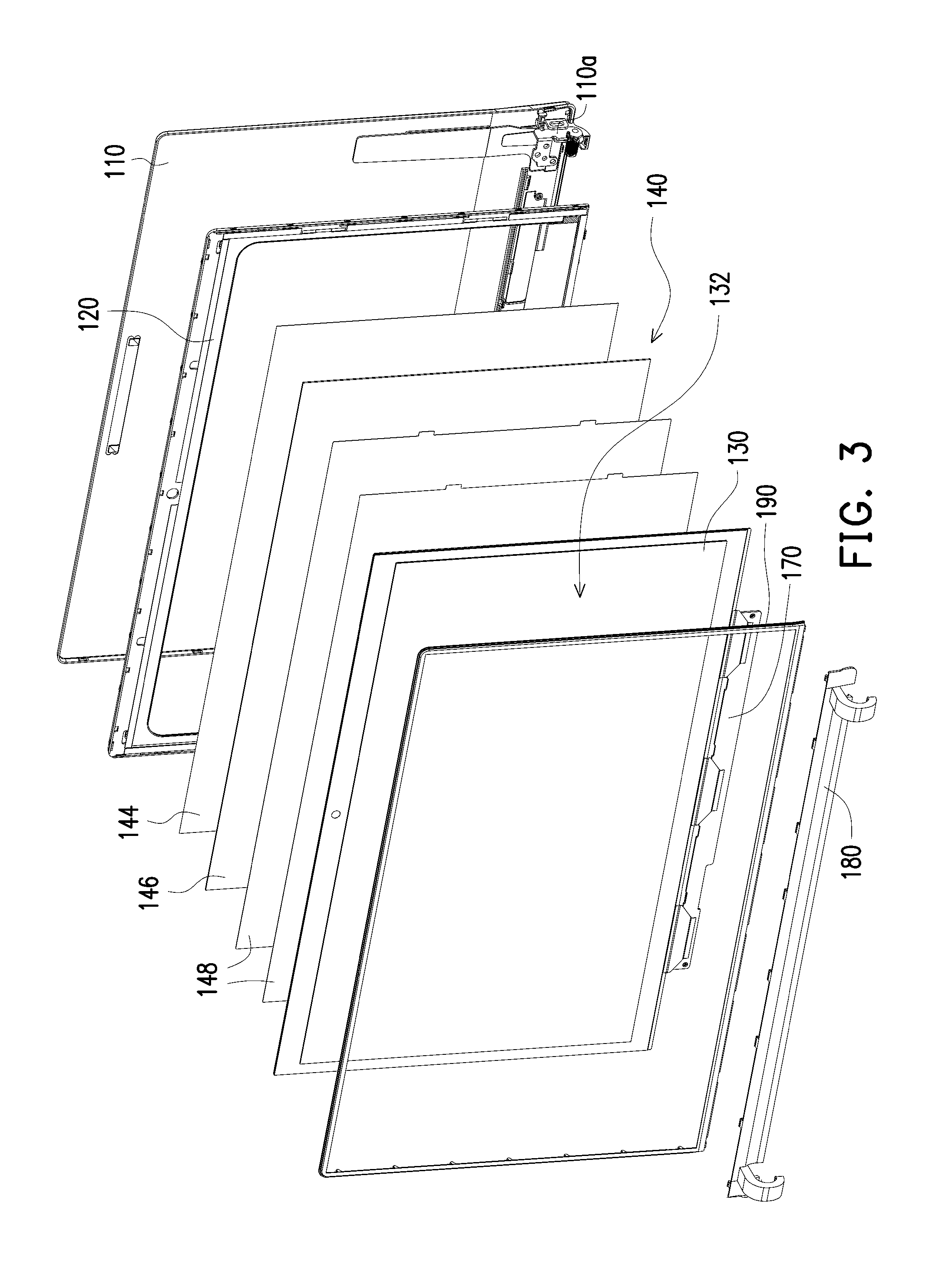

Display module

InactiveUS20110317401A1Avoid light leakageAvoid affecting performanceCasings/cabinets/drawers detailsDetails for portable computersComputer moduleEngineering

A display module including an electronic component and a panel module is provided. The electronic component is installed inside the display module. The panel module includes a first side and a second side, and the first side includes a glass module having an electro-conductive material and a display region, wherein the glass module includes an electronic component projection area and the electronic component projection area does not contain the electro-conductive material to prevent affecting the performance of the electronic component. The electronic component projection area is an area where the electronic component is projected on the panel module along a normal direction of the display region. According to a design requirement of the product, the electronic component may be fixed to a frame combined with the panel module or located in the glass module.

Owner:COMPAL ELECTRONICS INC

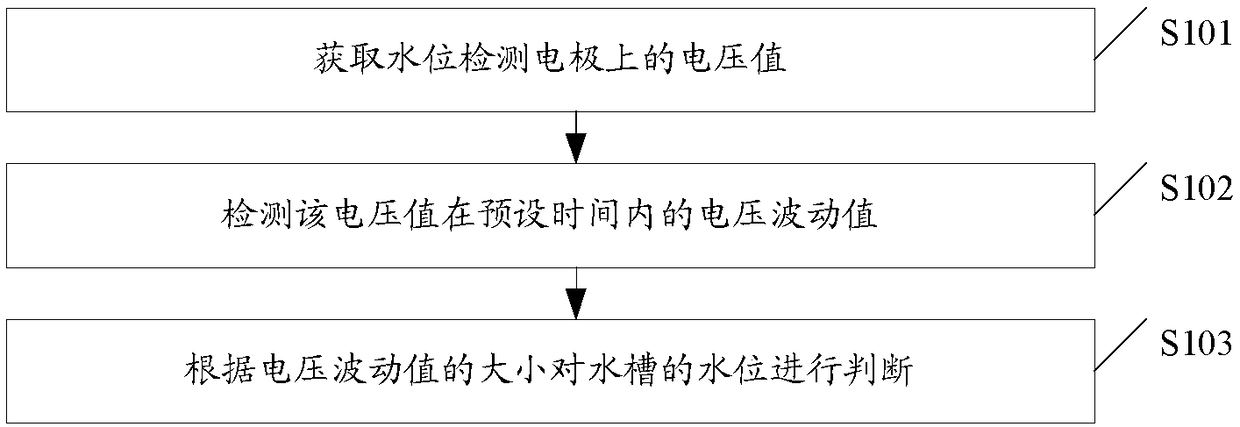

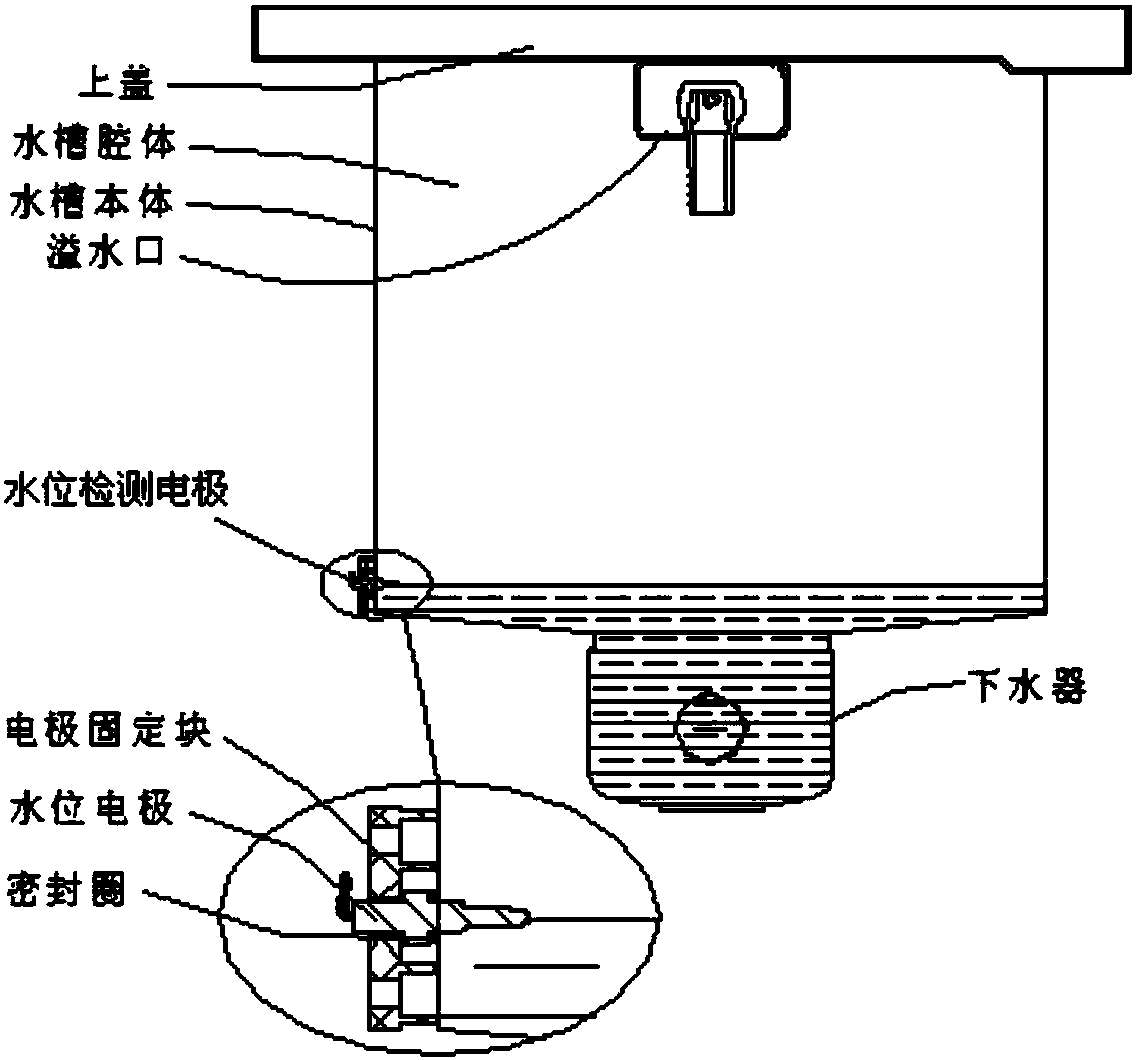

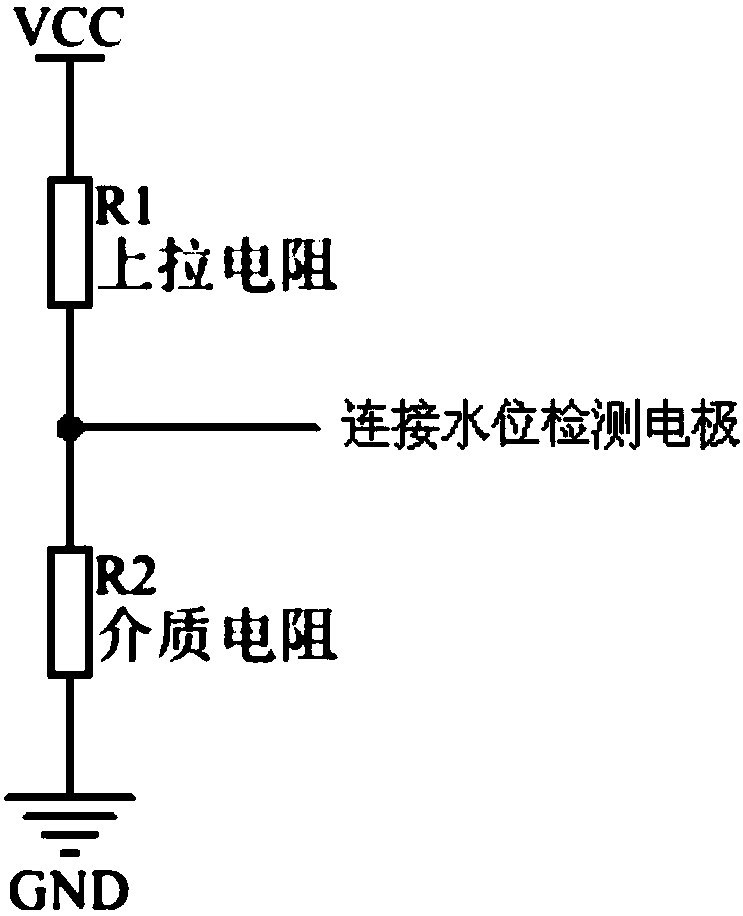

Method and device for water level detection of water tank

ActiveCN108931283AAvoid affecting performanceImprove experienceLevel indicators by physical variable measurementWater qualityEngineering

Embodiments of the invention disclose a method for water level detection of a water tank. The method comprises: acquiring a voltage value on a water level detection electrode; detecting a voltage fluctuation value of the voltage value within a preset time; and determining water level of the water tank according to the voltage fluctuation value. An embodiment of the invention disclose a device forwater level detection of a water tank. Through embodiment scheme of the invention, water level of the water tank can be directly and accurately detected without being influenced by water quality.

Owner:JOYOUNG CO LTD

Touch input sheet and production method thereof

ActiveCN103399664AAvoid disconnectionImprove adhesionInput/output processes for data processingSilver pasteTransparent conducting film

The invention relates to a touch input sheet comprising a transparent substrate, a transparent conductive film, a protective film, photosensitive sliver paste threads and an insulation film. The protective film is arranged on the transparent conductive film of the touch input sheet, so that conductive patterns in a visible area can be protected from scratch during the production process of the photosensitive sliver paste threads, or photosensitive sliver powder is prevented from remaining in the visible area to influence the properties of products. The photosensitive silver paste threads are covered with one insulation film, so that the photosensitive silver paste threads can be better adhered to the transparent substrate by edge area and disconnection or short circuit of the photosensitive sliver paste threads is prevented in the subsequent production process. Therefore, the produced touch input sheet allows for a narrow frame of a touch product, product yield can be increased greatly, and mass production of the process is realized. In addition, the invention relates to a production method of the touch input sheet.

Owner:ANHUI JINGZHUO OPTICAL DISPLAY TECH CO LTD

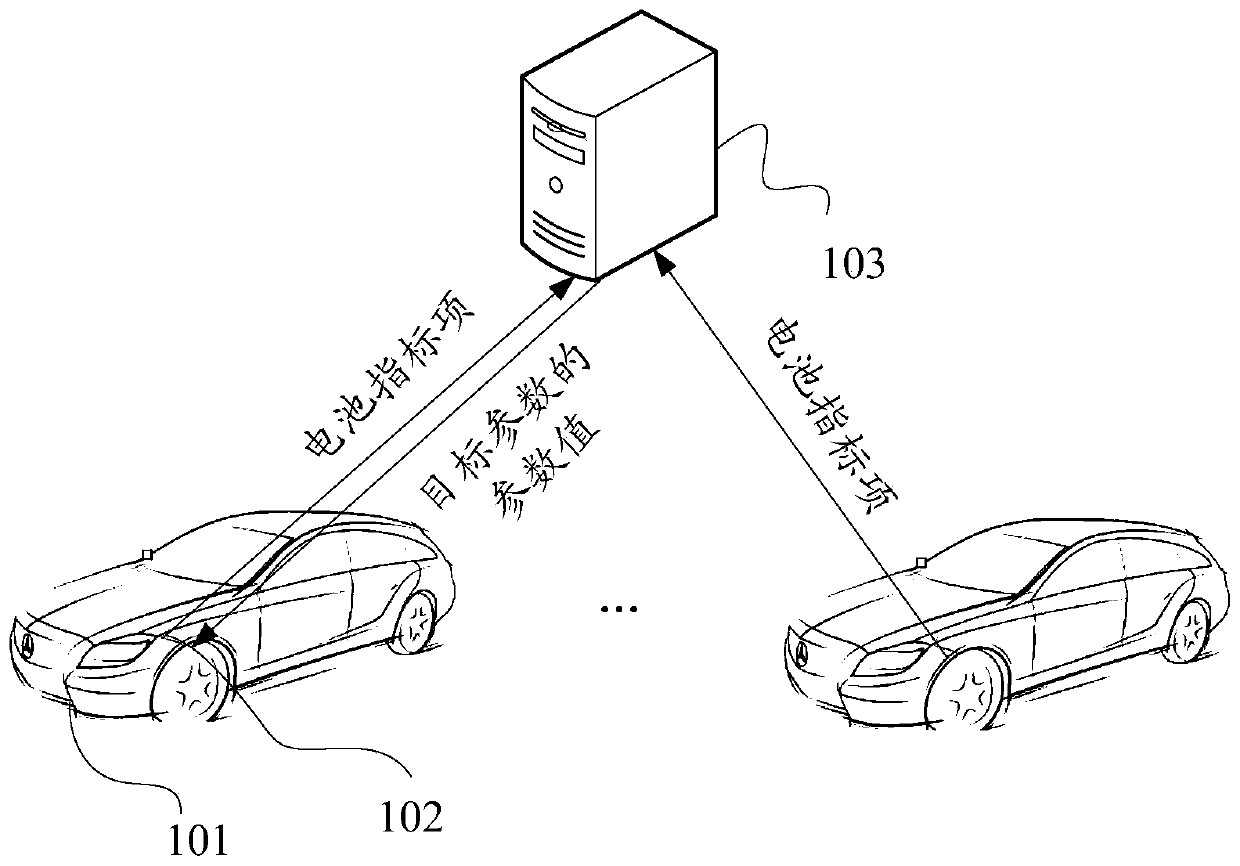

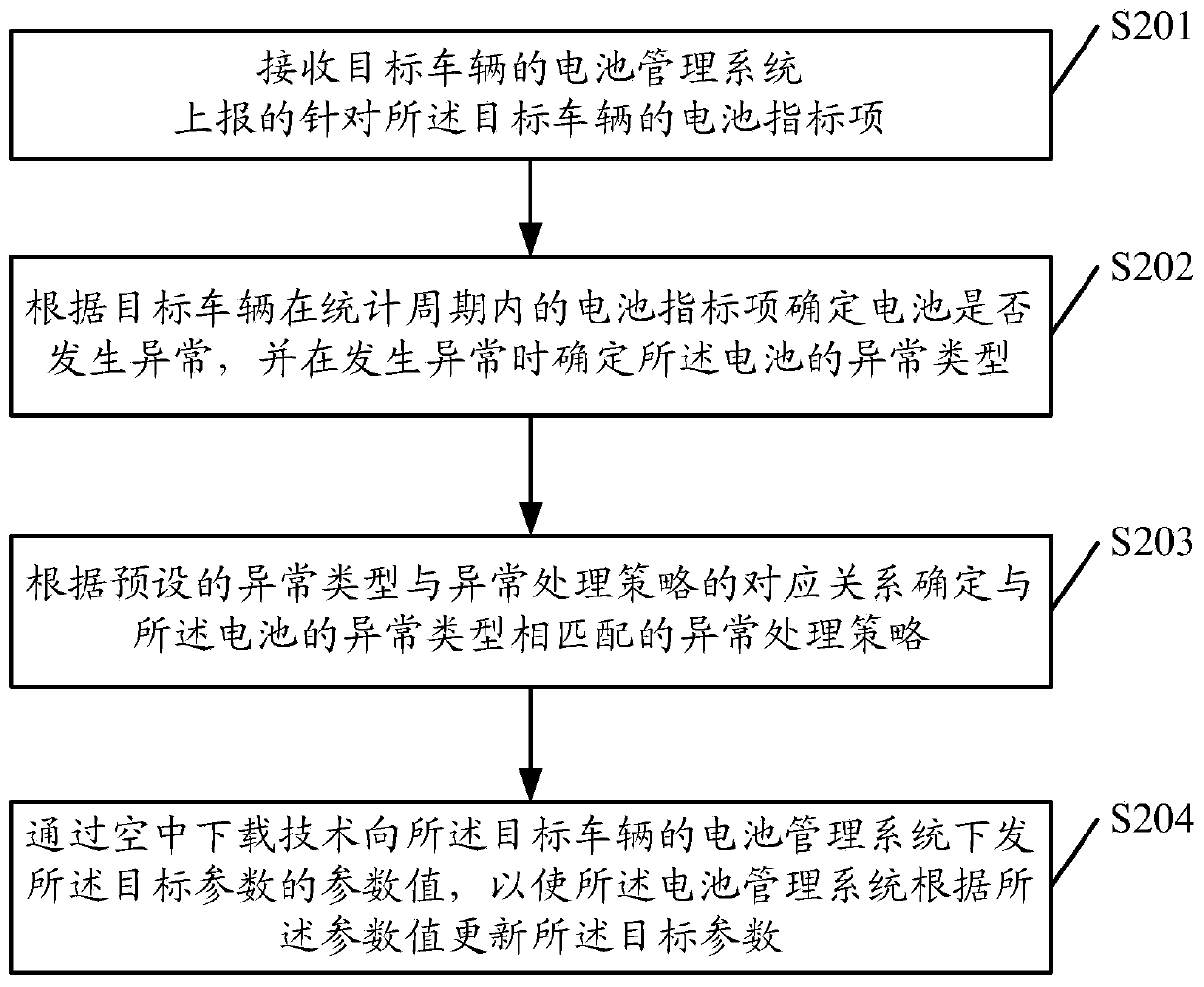

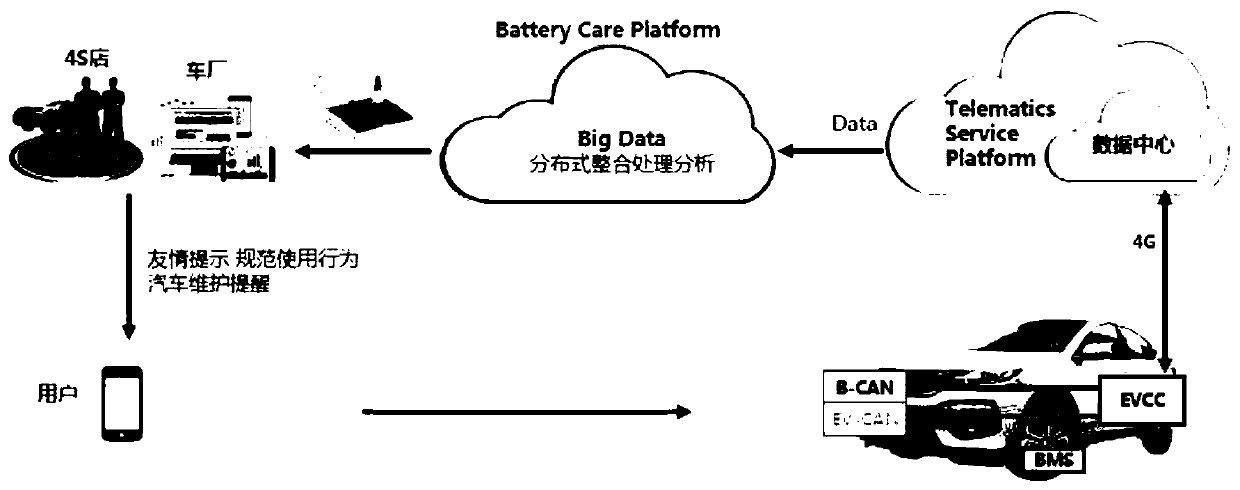

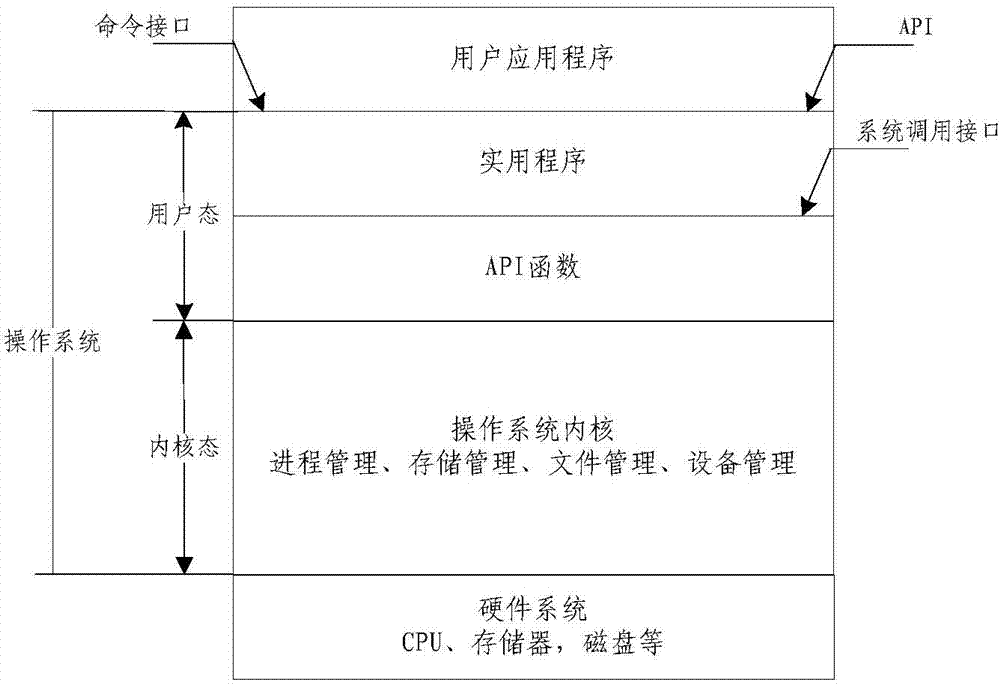

Exception handling method, device, equipment and medium

ActiveCN110712560AAvoid affecting performanceAvoid affecting lifeCells structural combinationVehicular energy storageComputer scienceBattery cell

The invention discloses an exception handling method which comprises the steps of receiving a battery index item aiming at a target vehicle reported by a battery management system of the target vehicle; determining whether the exception of a battery occurs or not according to the battery index item of the target vehicle in a statistics period, and determining an exception type of the battery whenthe exception occurs; determining an exception handling strategy matched with the exception type of the battery according to a preset corresponding relation of exception types and exception handling strategies, wherein the exception handling strategy comprises updating a target parameter of the battery; and issuing a parameter value of the target parameter to the battery management system of the target vehicle through an over-the-air download technology, and updating the target parameter through the battery management system according to the parameter value.

Owner:NEUSOFT REACH AUTOMOBILE TECH (SHENYANG) CO LTD

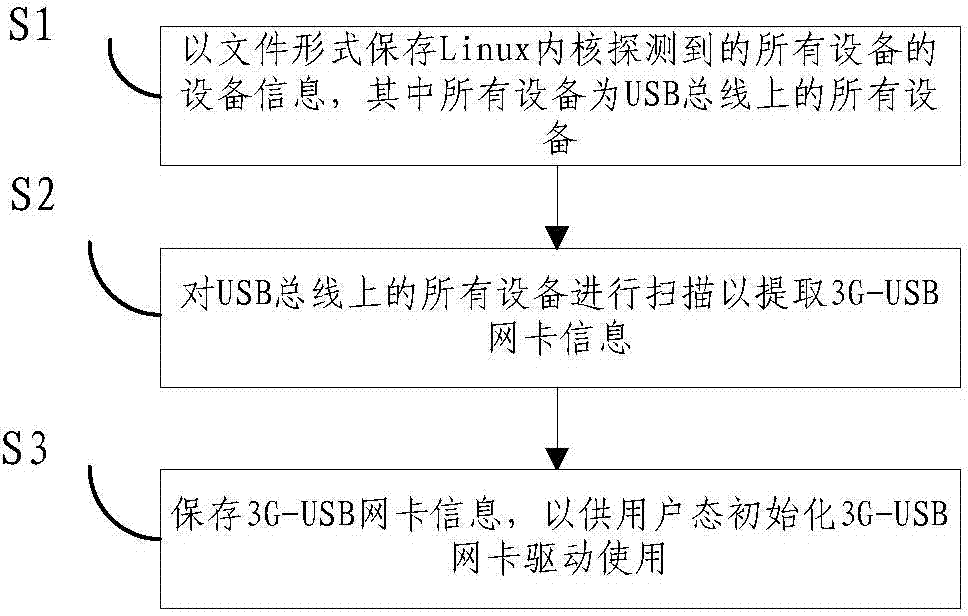

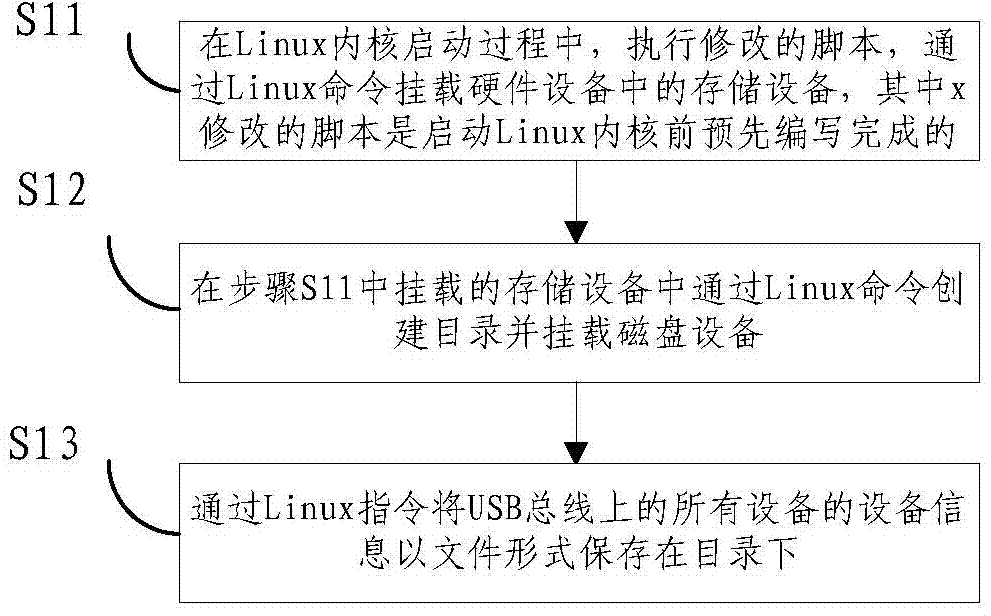

Automatic user-mode 3G-USB network interface card detecting method based on Linux kernel

InactiveCN103777978AImprove reliabilityAvoid affecting performanceProgram loading/initiatingOperational systemLinux kernel

The invention relates to an automatic user-mode 3G-USB network interface card detecting method based on a Linux kernel. According to the method, equipment information, detected by the Linux kernel, of all equipment is saved in a file mode, wherein all the equipment is equipment on a USB; scanning is performed on all the equipment on the BUS so as to extract 3G-USB network interface card information; the 3G-USB network card information is saved so as to drive 3G-USB user-mode initialization. According to the method, due to the facts that the equipment information, detected by the kernel, of all the equipment on the BUS is saved in the file mode, saved files are opened when a user-mode driver is loaded and the 3G-USB network card information is extracted from the files, the possibility is provided for automatic user-mode 3G-USB network card detecting and automatic 3G-USB network card information obtaining, and only a small amount of modification needs to be conducted on the kernel so that the situation that equipment performance is influenced due to the fact that the kernel is modified many times can be avoided. The method is simple and easy to implement, and improves the reliability of an operation system.

Owner:OPZOON TECH

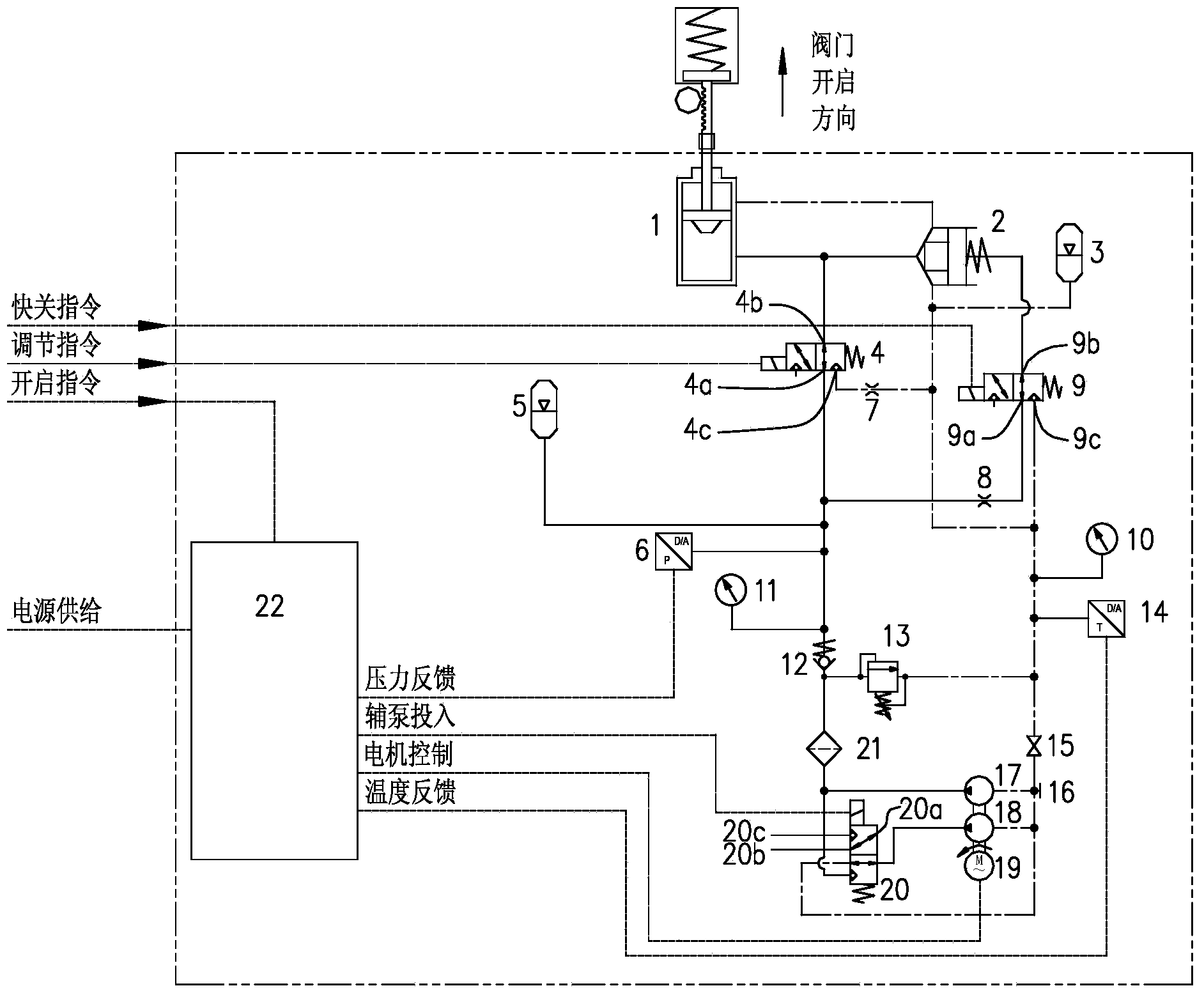

Hydraulic actuator

ActiveCN103644155AReduce complexityReduce the difficulty of equipment investment and operation managementServomotorsFluid-pressure actuator componentsFuel tankCheck valve

The invention provides a hydraulic actuator. The hydraulic actuator comprises an oil cylinder, a main oil pump, a motor for driving the main oil pump, a high-pressure energy accumulator, an oil-return energy accumulator and a controller, wherein a piston rod of the oil cylinder is connected with an actuation component, and the oil cylinder comprises an oil control cavity and an oil return cavity; an oil outlet of the main oil pump is connected with a liquid inlet of a check valve, a liquid outlet of the check valve is connected with a liquid inlet of a first two-position three-way valve through an oil inlet pipeline, a liquid outlet of the first two-position three-way valve is connected with the oil control cavity, and a liquid return port of the first two-position three-way valve is connected with the oil return cavity; an oil inlet of the main oil pump is connected with the oil return cavity through an oil return pipeline, and an oil suction port and a stop valve are sequentially arranged on the oil return pipeline from the main oil pump to the oil return cavity; a fast valve is connected between the oil control cavity and the oil return cavity; the high-pressure energy accumulator is connected with the oil inlet pipeline, and the oil-return energy accumulator is connected with the oil return pipeline between the stop valve and the oil return cavity; and the motor is connected with the controller. According to the hydraulic actuator, an oil tank is not required to be configured, complicated equipment configurations of hydraulic actuators in the prior art are reduced, and the hydraulic actuator is low in investment and convenient to operate and manage.

Owner:SHANGHAI ELECTRIC POWER GENERATION EQUIPMENT CO LTD +1

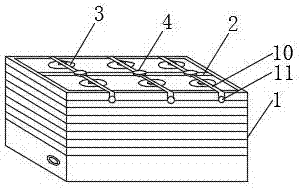

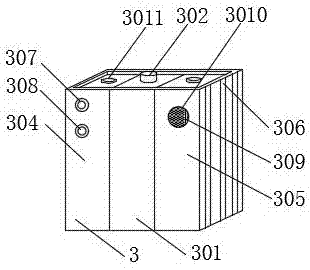

Lithium ion battery pack structure

PendingCN107516720AImprove isolationEasy to transportSmall-sized cells cases/jacketsBattery isolationEngineeringWater pipe

The invention discloses a lithium ion battery pack structure. The lithium ion battery pack structure comprises a battery pack body, a second air outlet pipe and a round air pipe, wherein a partition board is arranged in the middle in the battery pack body, a flexible package tank is arranged outside the battery pack body, and a first heat dissipation aluminum plate is arranged on the top end of the flexible package tank. The lithium ion battery pack structure specifically has an automatic protection function to lithium ions after the power is off, a certain air leakage protection function and a certain warning effect and is simple and convenient, and meanwhile, the specific fault type can be conveniently known, so that the situation that the performance of other lithium ion batteries is influenced due the continuous heat dissipation of a faulted lithium ion battery can be prevented, and furthermore, the security coefficient of the battery pack can be increased; and meanwhile, the lithium ion battery pack structure has a temperature warning effect, so that the overheated battery pack can be conveniently cooled, can be continuously cooled by virtue of heat dissipation aluminum plates, can be further cooled by virtue of a flexible water pipe and can be rapidly cooled by virtue of a draught fan.

Owner:刘一锋

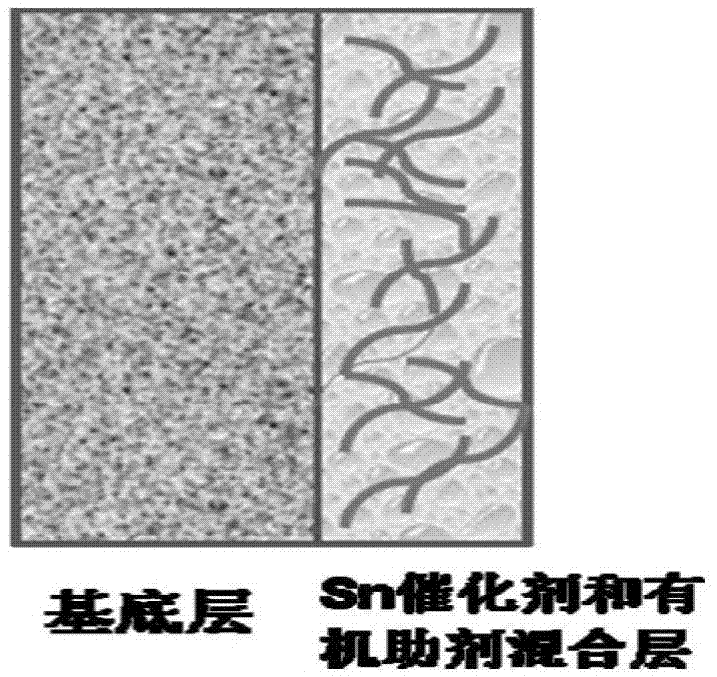

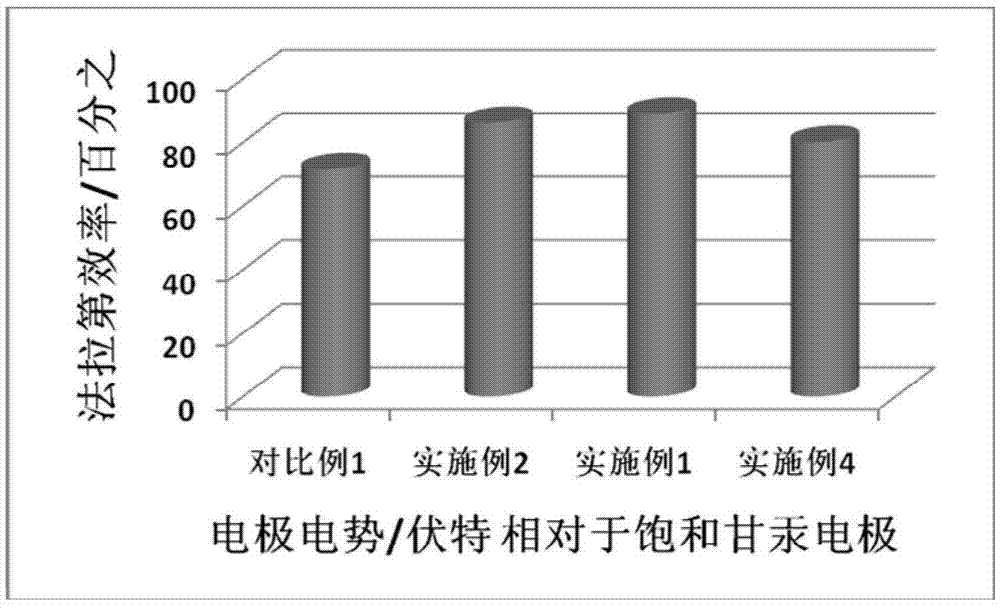

Gas diffusion electrode used for electrochemical reduction of carbon dioxide and preparation method and application of gas diffusion electrode

ActiveCN106876722AAvoid affecting performanceIncreased reaction current densityCell electrodesChemical reactionElectrochemical reduction of carbon dioxide

The invention relates to a gas diffusion electrode used for electrochemical reduction of carbon dioxide and a preparation method and an application of the gas diffusion electrode. The electrode comprises a base layer, and a Sn catalyst and an organic accessory ingredient mixing layer attached on the base layer; the molar ratio of the Sn catalyst to the organic accessory ingredient is 100:1 to 30:1; and the loading amount of the Sn catalyst in the electrode is 0.1-5mg / cm<-2>. In the electrochemical reduction of carbon dioxide, the base layer plays the effects of a supporting body, electric conduction, and forming liquid and gas transmission channels; the Sn catalyst catalyzes reduction of carbon dioxide while the organic accessory ingredient can stabilize an intermediate reactant CO<2>.-, so that the concentration of CO<2> is improved, overpotential in electrochemical reduction of carbon dioxide is lowered, and current density and efficiency are improved; and in addition, the accessory ingredient in the electrode also anchors the Sn catalyst on the surface of the carbon base, so that the electrode has quite high stability.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com