Externally laid masonry composite heat-insulating sintered building block exterior wall heat insulating system

A composite thermal insulation and external wall thermal insulation technology, which is applied in the direction of thermal insulation, building materials, building components, etc., to achieve the effects of ensuring life expectancy, facilitating fire prevention, and facilitating quality control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in detail below with reference to the accompanying drawings.

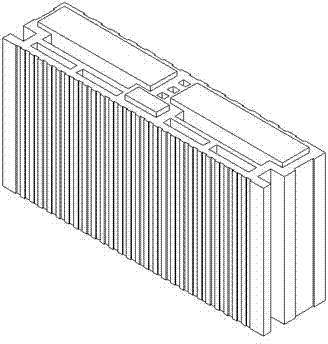

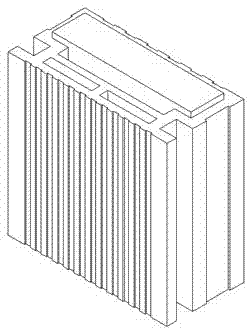

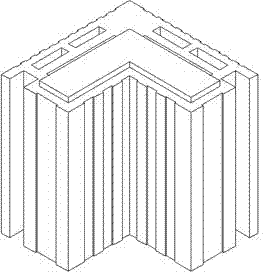

[0047] The external wall thermal insulation system of the externally attached masonry type composite thermal insulation sintered block is composed of the main block, the corner matching block and the hole matching block. Its main block type is divided into type I main block 5 and type II main block 6 . The corner matching block is divided into male corner matching block 7 and female corner matching block 8. Hole matching block 9 has only a kind of form, is used for wall body modulus coordination.

[0048] For the external wall insulation system of externally attached masonry type composite thermal insulation sintered blocks as mentioned above, the main block of type I is used as the main block during masonry. Regularly, the upper and lower skin blocks should be hole-to-hole, rib to rib, the insulation materials should be aligned up and down, close to each other, tigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com