[0003] The first type of

pressure grouting in the connecting cavity is difficult to overcome the

grout leakage problem during grouting. The connecting cavity is a closed structure and

pressure grouting must be used. If the seal around the horizontal joint is not tight or the sealing material is insufficient in

pressure resistance, the problem of

grout leakage will occur. Once connected

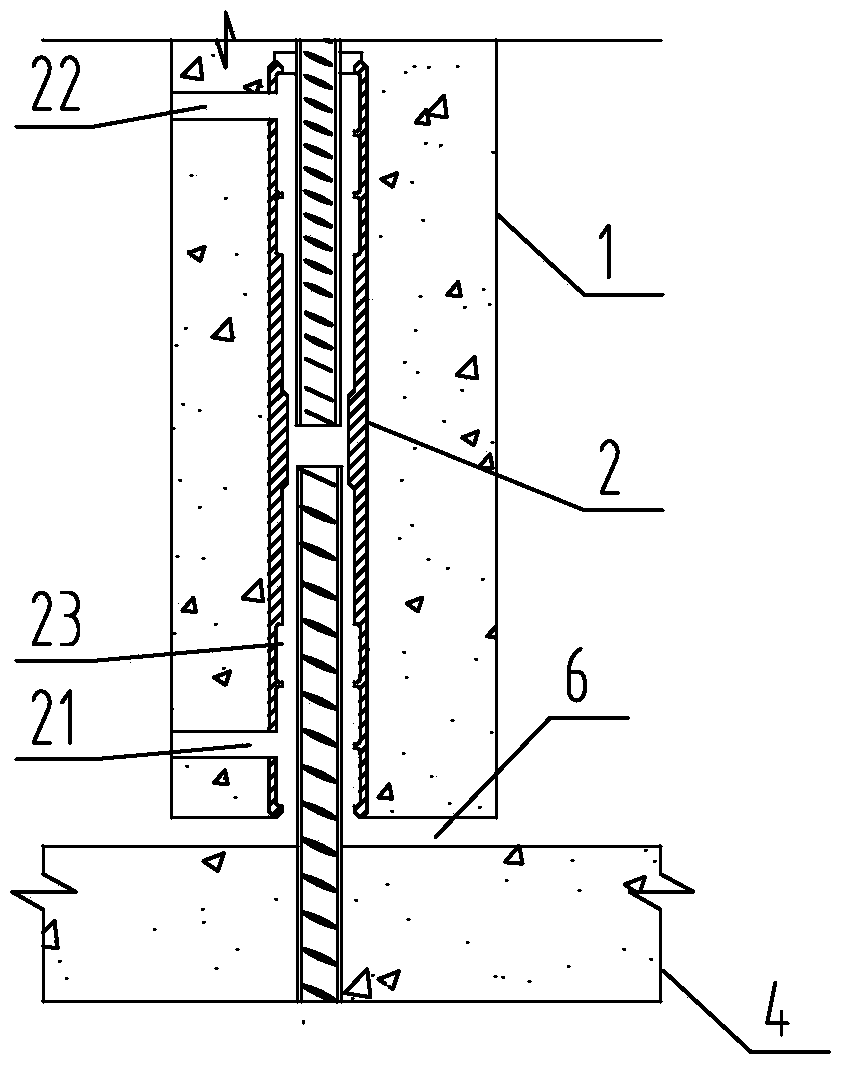

Grout leakage in the cavity directly affects the filling degree of the grouting material in the steel grouting joint, and affects the quality of the steel grouting connection of the prefabricated component. The main reasons are: 1. Assembled concrete

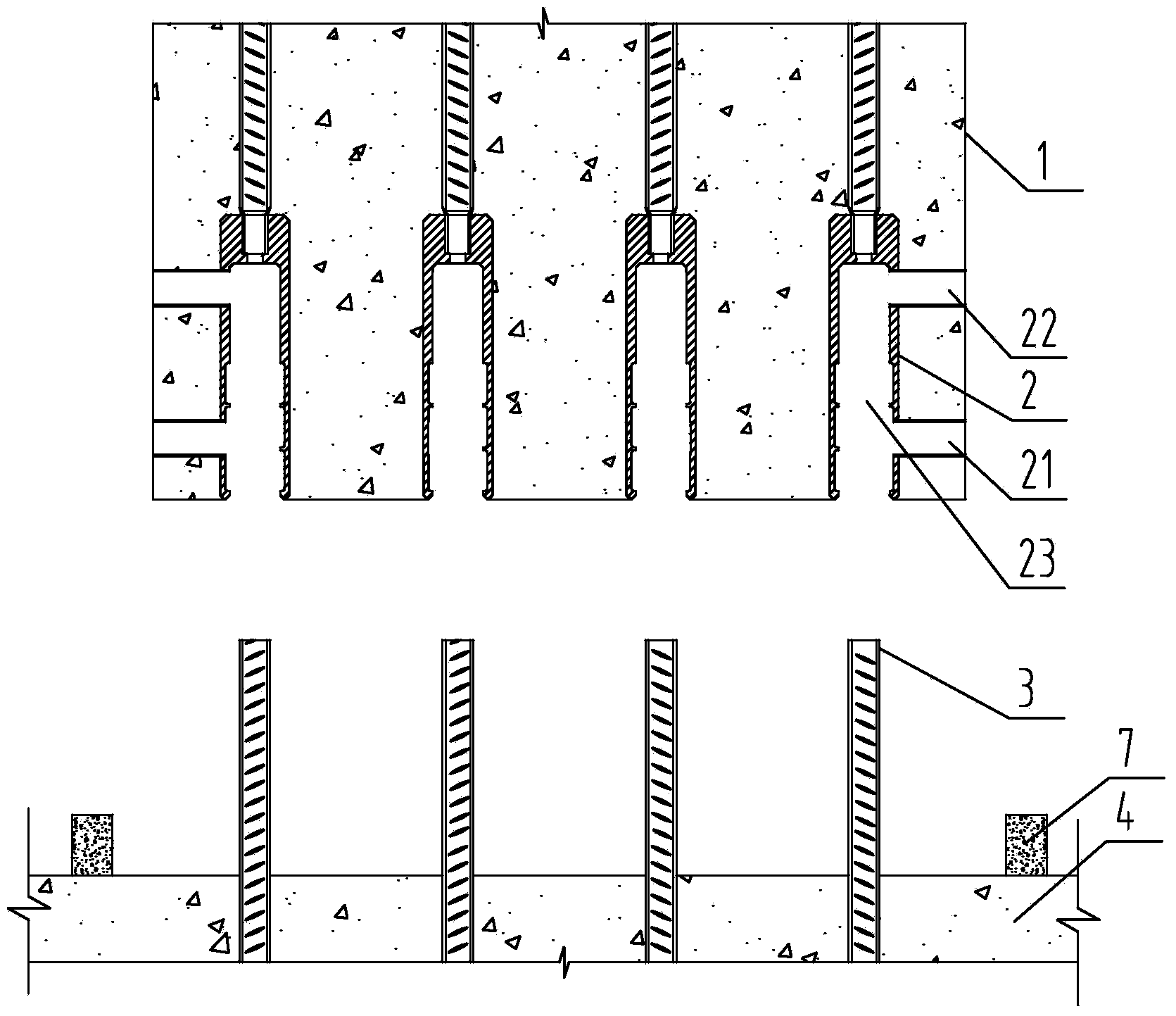

shear wall structure, the lower component connected by the prefabricated

shear wall component For the cast-in-place concrete slab, the high points on the surface of the cast-in-place concrete slab are difficult to be on the same level, so the prefabricated

shear wall components are installed on this surface, and after the bottom surface is adjusted to the level, the upper surface of the cast-in-place slab and the prefabricated shear wall The height of the gap between the lower end faces of the force wall components is inconsistent. Therefore, when the horizontal seam is sealed with elastic rubber strips, PE rods or

sponge strips, the lower end face of the prefabricated shear wall above will press it against the concrete surface below. When the frictional force on the surface of the concrete structure is sealed, when the grouting material is poured into the steel grouting connection device, and the grouting pressure reaches a high level, the grouting material will push the above-mentioned sealing material and the place where the frictional force of the concrete surface is small and leak out. , resulting in quality problems of steel grouting connections and potential safety hazards

After the

grout leakage problem was found, grouting and other treatment measures had to be taken, but the work efficiency was very low, which affected the construction progress of the structure; when the horizontal joints were sealed with special

cement base

slurry, although the sealing effect and reliability It has been greatly improved, but it takes a long time to wait for the sealing material to harden and reach the working strength, so it also has a great

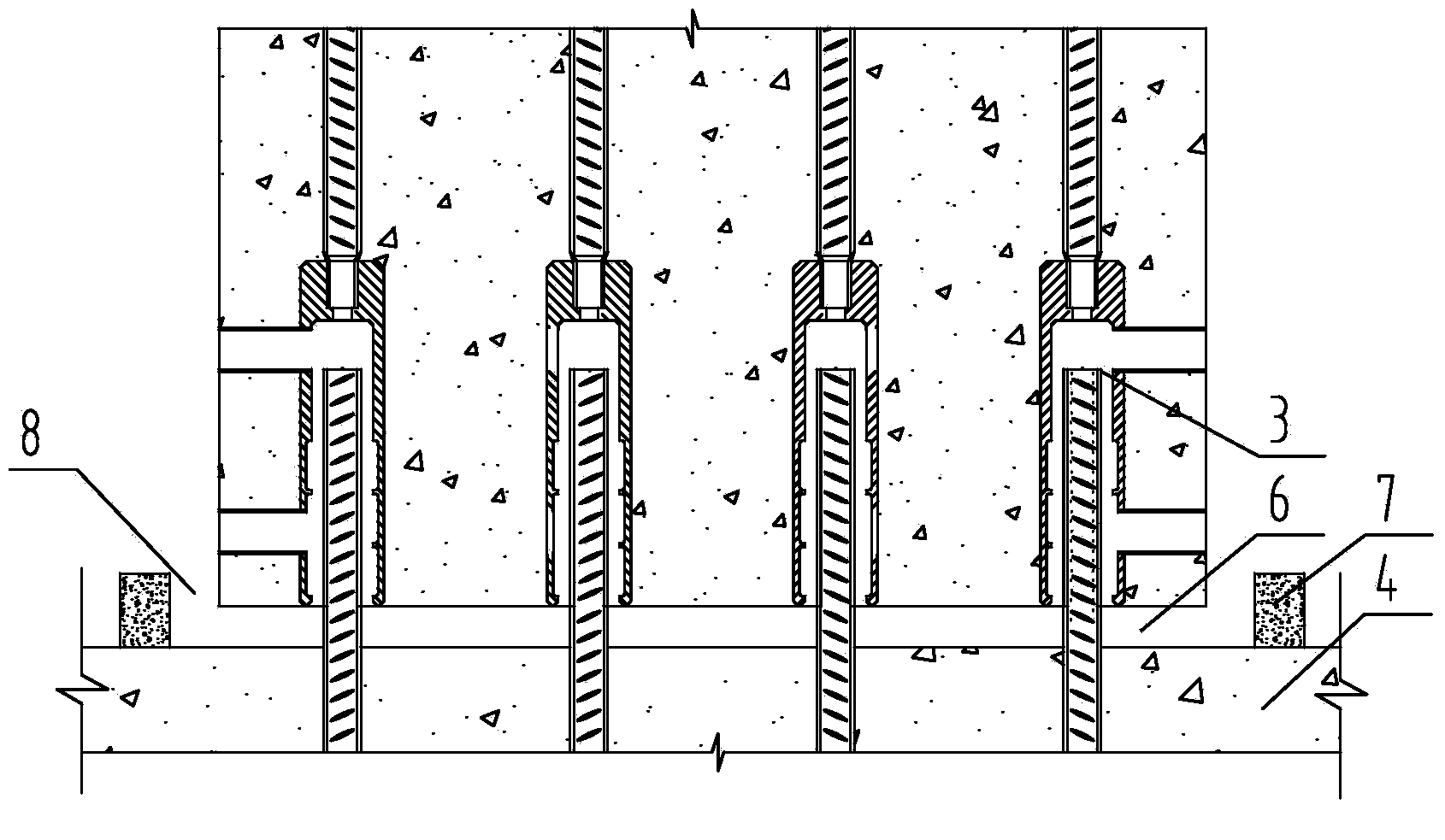

impact on the construction speed of structure installation; The gap between the upper surface of the poured concrete and the lower surface of the prefabricated column is the same as that of the prefabricated shear wall structure. The gap height of the horizontal joints is uneven. When the cross-sectional size of the structural column does not exceed 100cm×100cm, the horizontal joint grouting connection cavity is usually not divided. However, the area of the connected grouting cavity at the bottom is mostly larger than the maximum area allowed by the connected grouting cavity of the shear wall, and the grouting pressure is high. Once the grouting material breaks through any part of the surrounding sealing zone If the grouting of the prefabricated column fails, the sealed seat grout must be opened, all the grouting material filled in must be washed out, and then re-sealed and grouted, which greatly affects the construction efficiency; for larger prefabricated structural columns, separate Multiple grouting interconnected cavities are made in the warehouse method, which also has high requirements for horizontal sealing and separate warehouses, and the

workload is large and the construction cost is high.

In short, although the grouting construction of the Unicom cavity can be grouted to connect multiple connecting devices at one time, it has high requirements for sealing materials and sealing methods. It is also a severe test for the management and personnel quality of construction in my country. It not only affects the overall construction efficiency, but also the difficult-to-

handle grout leakage connection structure will cause quality problems

[0004] The second type of seat grouting method has problems of low work efficiency and the gap at the bottom of the component: 1. Work efficiency problems, because the seat grout method is to

pile up plastic dry and hard seat

slurry or pour fluid seat

slurry, and then install For prefabricated components, the dry and hard seat slurry should remain plastic before the component is installed, and the fluid seat slurry should remain flowable and cannot be solidified or hardened. Therefore, the construction of the seat slurry must cooperate well with the hoisting work of the prefabricated component, that is, mixing and The grouting construction must be carried out in conjunction with the hoisting time of the components. The grouting construction is restricted by the lifting of the components, and the work efficiency is low, which does not meet the characteristics of fast construction and high work efficiency of modern prefabricated structures; It is extremely difficult to keep the bottom surface of the component parallel to the horizontal plane and sit on the seat slurry. Therefore, for the dry hard seat slurry, after the component sits on the seat slurry, adjust the prefabricated component to make the bottom surface parallel to the horizontal plane, while The dry hard seat slurry cannot flow. Once such an adjustment is made, there will inevitably be a gap between the lower surface of the component and the upper surface of the shaped seat slurry; for the fluid seat slurry, when the component falls to the surface of the seat slurry, the falling speed is faster The air in the chiseling at the bottom of the component or the hollow on the exposed surface cannot be fully discharged, so that local pockets of air may appear on the bottom surface. If the falling speed of the component is carefully controlled when it contacts the seat slurry, the installation speed of the component will inevitably be affected. Therefore, the seat slurry grouting construction with low work efficiency, and there is a quality risk of gaps or pockets between the bottom of the component and the seat grout layer

Login to View More

Login to View More  Login to View More

Login to View More