Patents

Literature

160results about How to "Guaranteed dense" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite water permeable brick

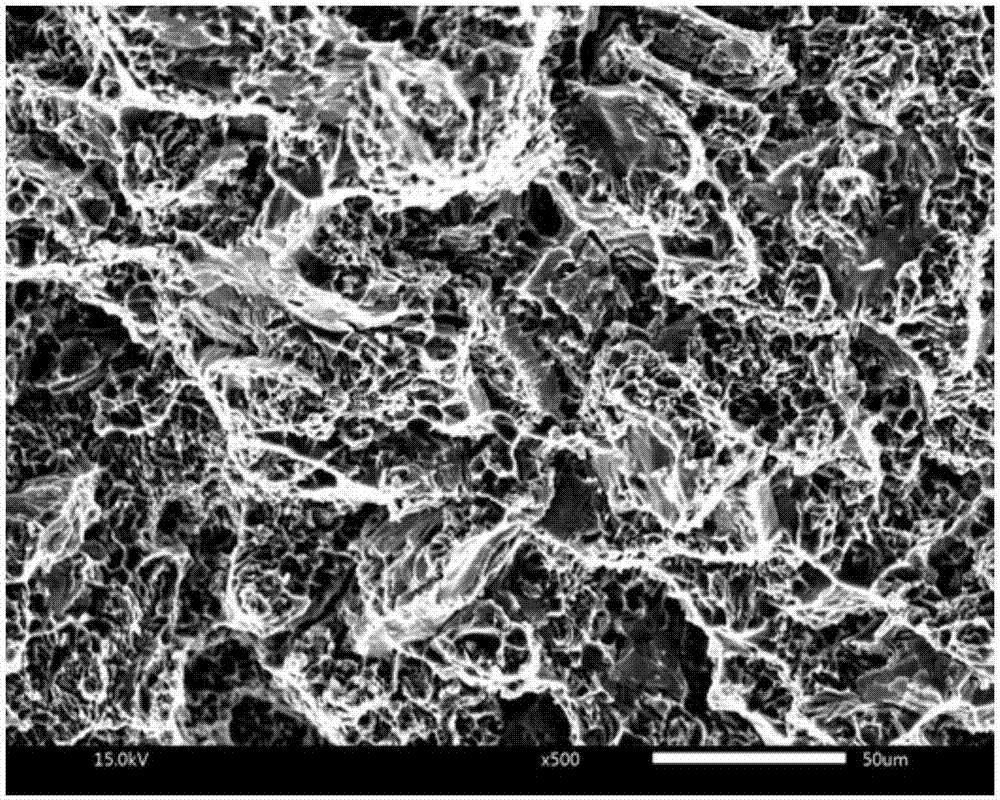

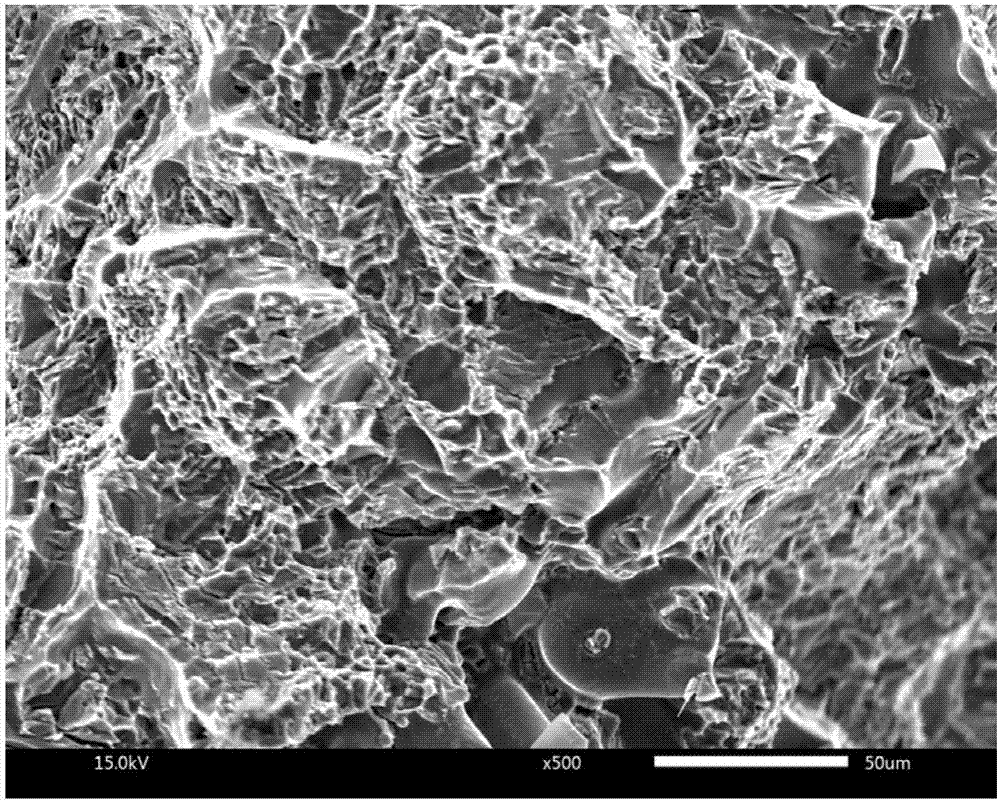

InactiveCN1966861AGood water permeabilityLow costSingle unit pavingsClimate change adaptationBrickAdhesive

A composite water permeable brick comprises water permeable surface and base closely combined together with aggregate and adhesive coating the aggregate, with the adhesive of the said water permeable surface including at least hydrophilicity adhesive. It can keep fine water permeability, with the brick surface fine and close and reduced in cost.

Owner:RENCHSAND ECO ENVIRONMENT PROTECTION SCI & TECH CO LTD

Wax-containing composition for leather and its product surface coating

ActiveCN1611560AGood miscibilityHigh affinityLiquid surface applicatorsCoatingsSolubilityCarbon chain

The invention relates to a kind of waxy combination for surface coating of leather and its products, which is mainly composed with wax, high molecular polymer cream, long carbon-chain fatty alcohol, fatty amide, surface-active agent, and water, but its components doesn't contain organic solvent, water solubility organic alcohol, and mineral oil. Use fatty amide as cosolvent of coating combination system; fatty amide has fine intersolubility with wax, fatty alcohol, high molecular polymer, and other solid constituents; so it can improve stability of coating combination system, can guarantee continuation and compactness of coating film, and also can avoid the disadvantages of containing mineral oil and low molecular water solubility alcohol in the components. When using for surface coating of leather and its products, it has natural gloss, excellent abilities of water-resistant, antidusting, drying proof, and wet proof, and fine frictional property. So it has convenient usage that is safe, and can decline pollution.

Owner:CHINA PETROLEUM & CHEM CORP +1

A high temperature resistant solder nickel zinc soft ferrite material

The invention discloses a nickel and zinc soft magnetic ferrite material and a preparation method thereof. A high-temperature-resistant soldering tin, nickel and zinc soft magnetic ferrite material comprises the following components in parts: 45-50mol percent of Fe2O3, 26-32 mol percent of ZnO, 17-21 mol percent of NiO and 4-8 mol percent of CuO, and also comprises the following components in parts: 0.2-0.5 wt percent of auxiliary material A and 0.1-0.2 wt percent of auxiliary material B, wherein the auxiliary material A is one or two of Bi2O3, SiO2 and Ta2O5, and the auxiliary material B is one or more of TiO2, ViO5 and Nb2O5. The high-temperature-resistant soldering tin, nickel and zinc soft magnetic ferrite material has the characteristics of high frequency, high magnetic conductivity,high Bs and TC (Temperature Curie).

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG +2

Casting method for impeller made of super duplex stainless steel 5A material

ActiveCN107309405AAvoid crack defectsGuaranteed denseFoundry mouldsFurnace typesImpellerVolumetric Mass Density

The invention provides a casting method for an impeller made of a super duplex stainless steel 5A material. The method comprises the steps of preparation of a casting mould and a sand core, specifically, the casting mould and the sand core are prepared in the manner that alkaline phenolic resin is added to crude sand, the casting mould is provided with an impeller cavity for storing the sand core, and a dead head is internally provided with a ceramic foam filter; casting and pouring; and sand shakeout and heat treatment of a heat-filling furnace, and an impeller finished product is obtained. The temperature ranges of precipitation of brittle phases including Eta, Chi and Sigma can be avoided, precipitation of the brittle phases by an impeller casting structure is avoided, crack defects of an impeller casting are overcome fundamentally, density of the casting structure can also be guaranteed, and the yield rate of a casting finished product can be increased to 96% or above; and meanwhile, the casting production cost is greatly lowered as the technological yield is increased, and the heat-filling furnace process is implemented.

Owner:LUOYANG SUNRUI SPECIAL EQUIP

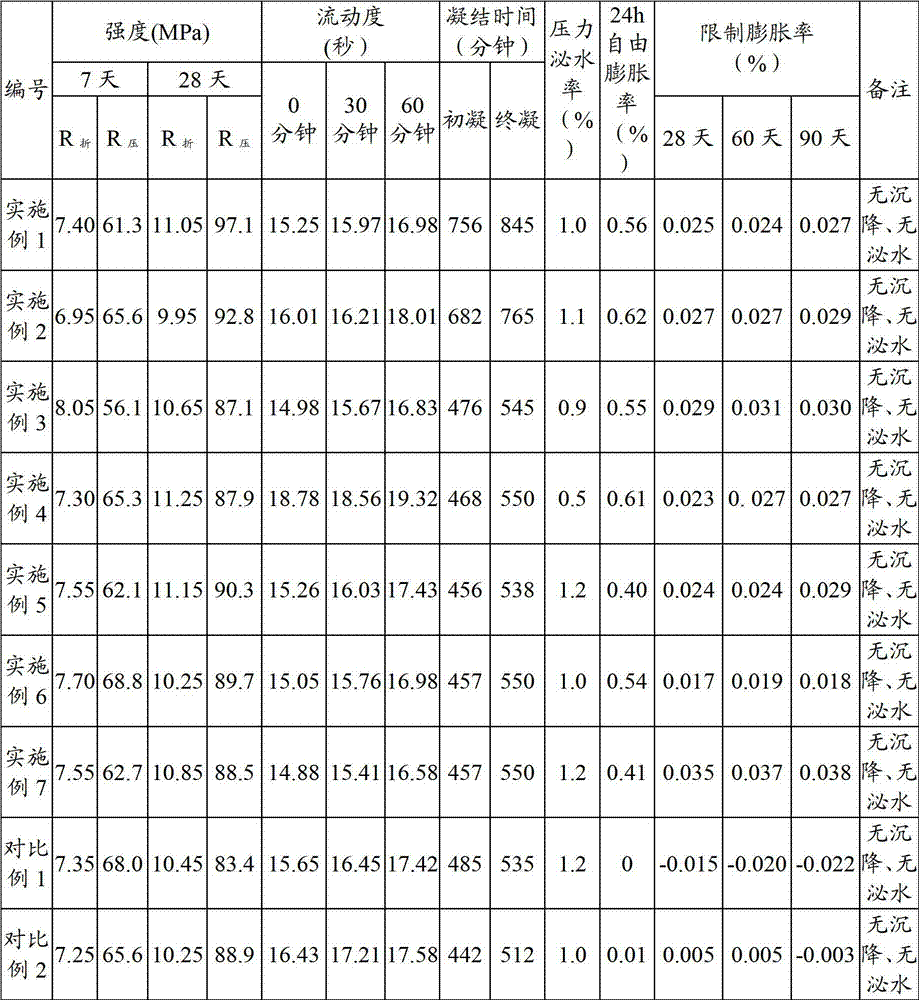

Expanding agent, post-tensioning prestressed concrete porelike grouting agent and grouting material

The invention relates to an expanding agent, a post-tensioning prestressed concrete porelike grouting agent and a grouting material. The expanding agent comprises a nitrogen expanding agent, gypsum and magnesium oxide at a mass ratio of (0.3-0.6):30:(3-15). The post-tensioning prestressed concrete porelike grouting agent comprises the following components in parts by mass: 5-12 parts of water reducing agent, 0.3-0.7 parts of stabilizing agent, 18-60 parts of mineral admixture, 0-15 parts of early strength agent, and 35-50 parts of expanding agent. The invention further provides the post-tensioning prestressed concrete grouting material which comprises portland cement, water and the grouting agent, wherein the mass ratio of the grouting agent to the portland cement is (10-20):(80-90), and a range of the water-binder ratio is 0.26-0.28. In a grouting material slurry hardening process, a continuous and stable expanding effect is generated, so that the grouting material can be tightly bonded with prestressed reinforcements and structural concrete, and the effective transmission of a stress is ensured.

Owner:RES INST OF HIGHWAY MINIST OF TRANSPORT +1

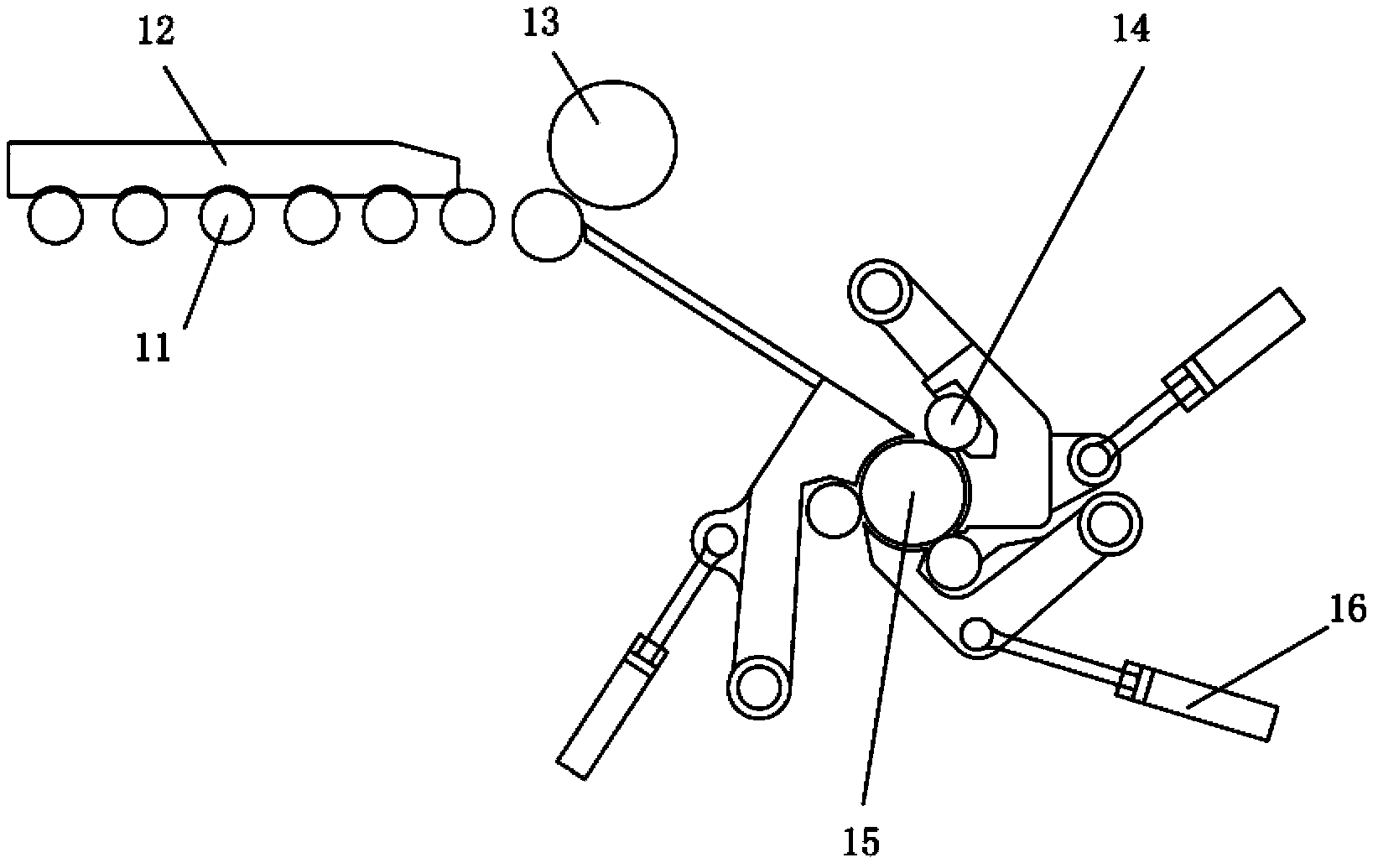

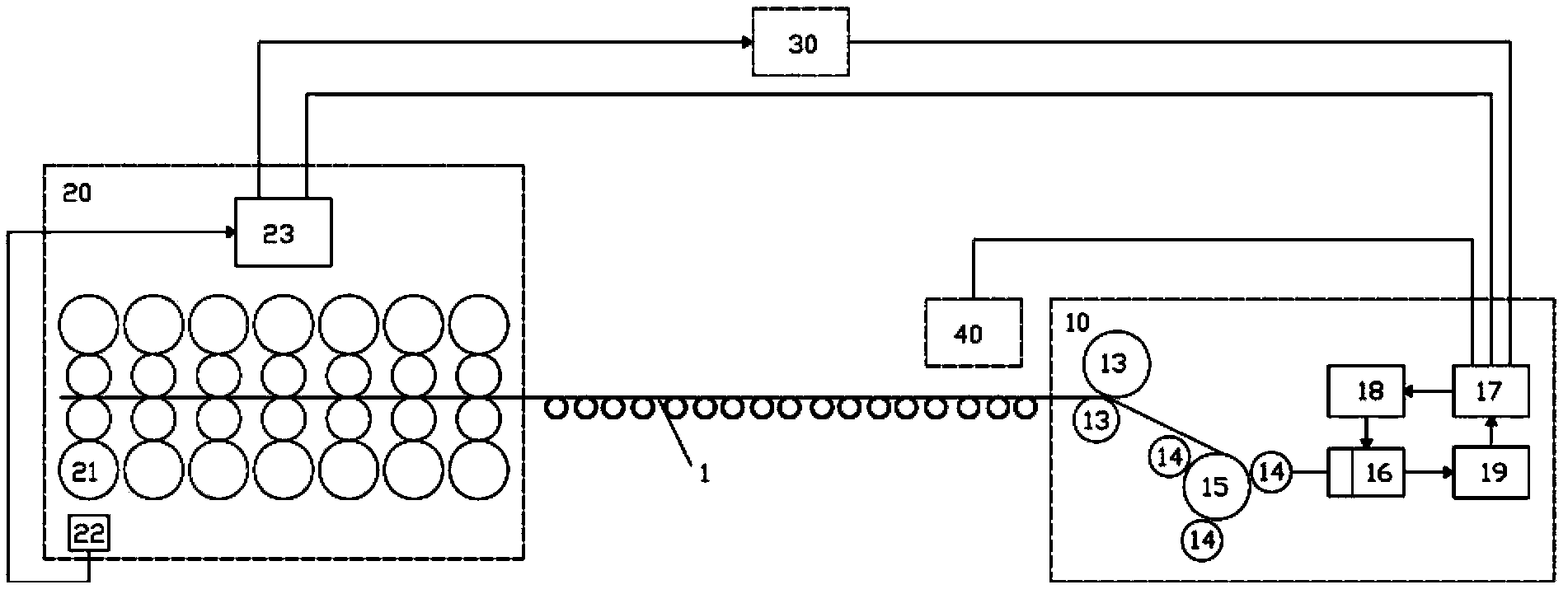

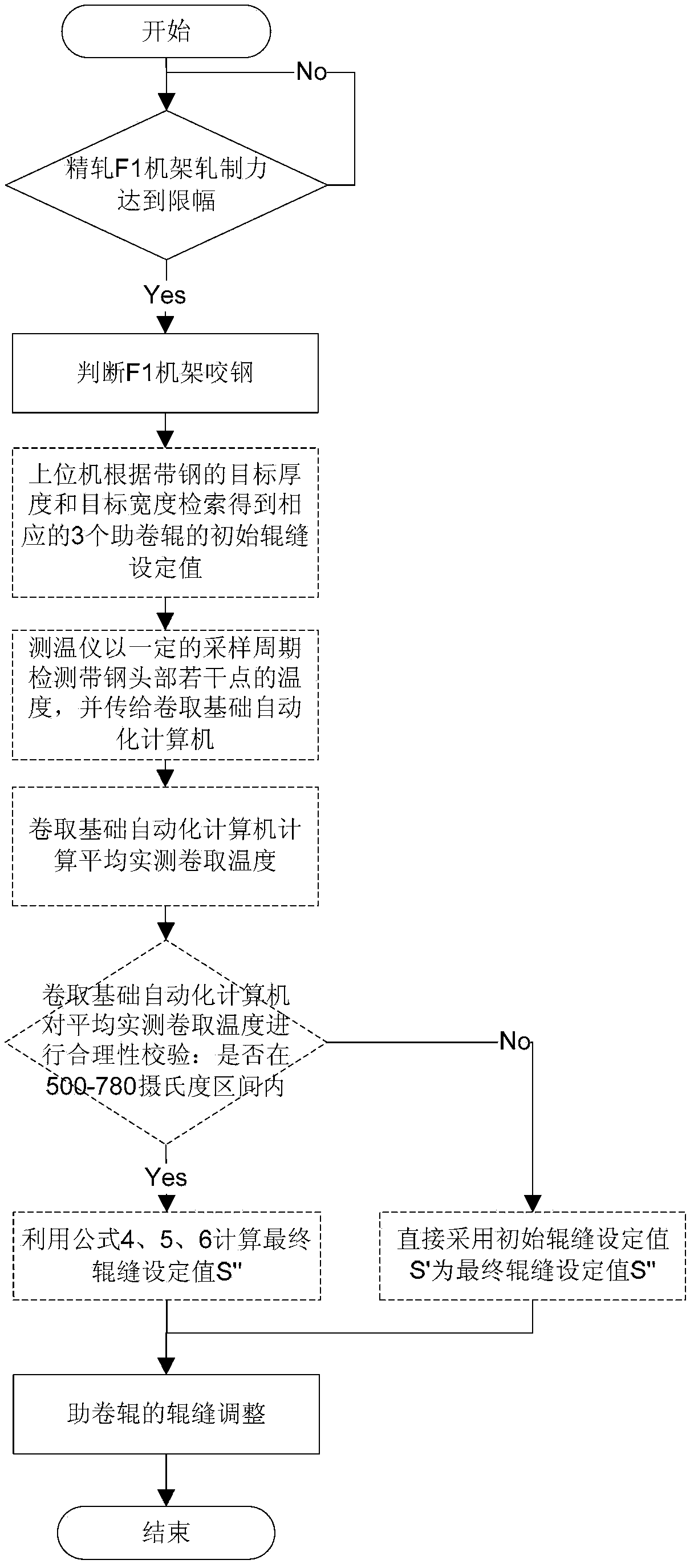

Roll gap setting method of wrapper roller in recoiling machine

Disclosed is a roll gap setting method of a wrapper roller in a recoiling machine. The method belongs to the technical field of control. A temperature measuring instrument is arranged at an inlet of a recoiling machine set. An initial roll gap set value static table is established in a host computer. According to characteristics of strip steel in different specifications, initial roll gap set values of different wrapper rollers are set. When the host computer receives a steel-biting signal, three initial roll gap set values of the wrapper roller are searched in the initial roll gap set value static table of the wrapper roller and then the three initial roll gap set values are downwardly sent to a recoiling basic automatic computer of the recoiling machine. According to an actual recoiling temperature, the recoiling basic automatic computer carries out a corresponding compensative correction to roll gap set values. Influences of factors such as a recoiling temperature, a width of the strip steel and a thickness of the strip steel on tightness degree of a rolling layer of an inner circle of a steel roll can be fully considered. All of the influences of the factors on the tightness degree of the rolling layer of the inner circle of the steel roll can be considered. Inner circles of various steel rolls are ensured to be compact and slipping accident of the recoiling machine can be effectively reduced. In addition, introduction of thick-specification stripe steel can be improved and steel-waste accident is reduced.

Owner:BAOSHAN IRON & STEEL CO LTD

Super high-rise steel pipe column interior concrete pouring construction method

ActiveCN103526929ASimple and safe operationStrong construction applicabilityBuilding material handlingBuilding support scaffoldsSheet steelMaterial consumption

The invention discloses a super high-rise steel pipe column interior concrete pouring construction method. The method mainly comprises the steps of detaching a last section of steel pipe column top sealing hole thin steel plate; hoisting the present section of steel tube column; locating the present section of steel tube column after hoisting a first floor layer steel beam of the present section of steel tube column; arranging a detachable construction steel platform; enabling a sectional connectable serial barrel to extend into the steel pipe column through a locating hole of the construction steel platform; filling same-grade concrete protoplasmic into the steel pipe column; pouring concrete; when the concrete pouring height surpasses the single section serial barrel, detaching one section and continuing concrete pouring construction, and then conducting subsequent pouring; slowing down the speed of concrete discharging and the speed of pouring when a concrete puring face is close to a partition plate in the steel pipe column; pouring the concrete to a certain distance below the top of the steel pipe column and then stopping; adopting a thin steel plate to close the steel pipe column top pouring hole. By the adoption of the construction method, the concrete pouring construction is made to be more convenient, potential safety hazards are eliminated, the construction period is shortened, and manpower and turnover material consumption are reduced.

Owner:ZHEJIANG CONSTR ENG GRP CO LTD

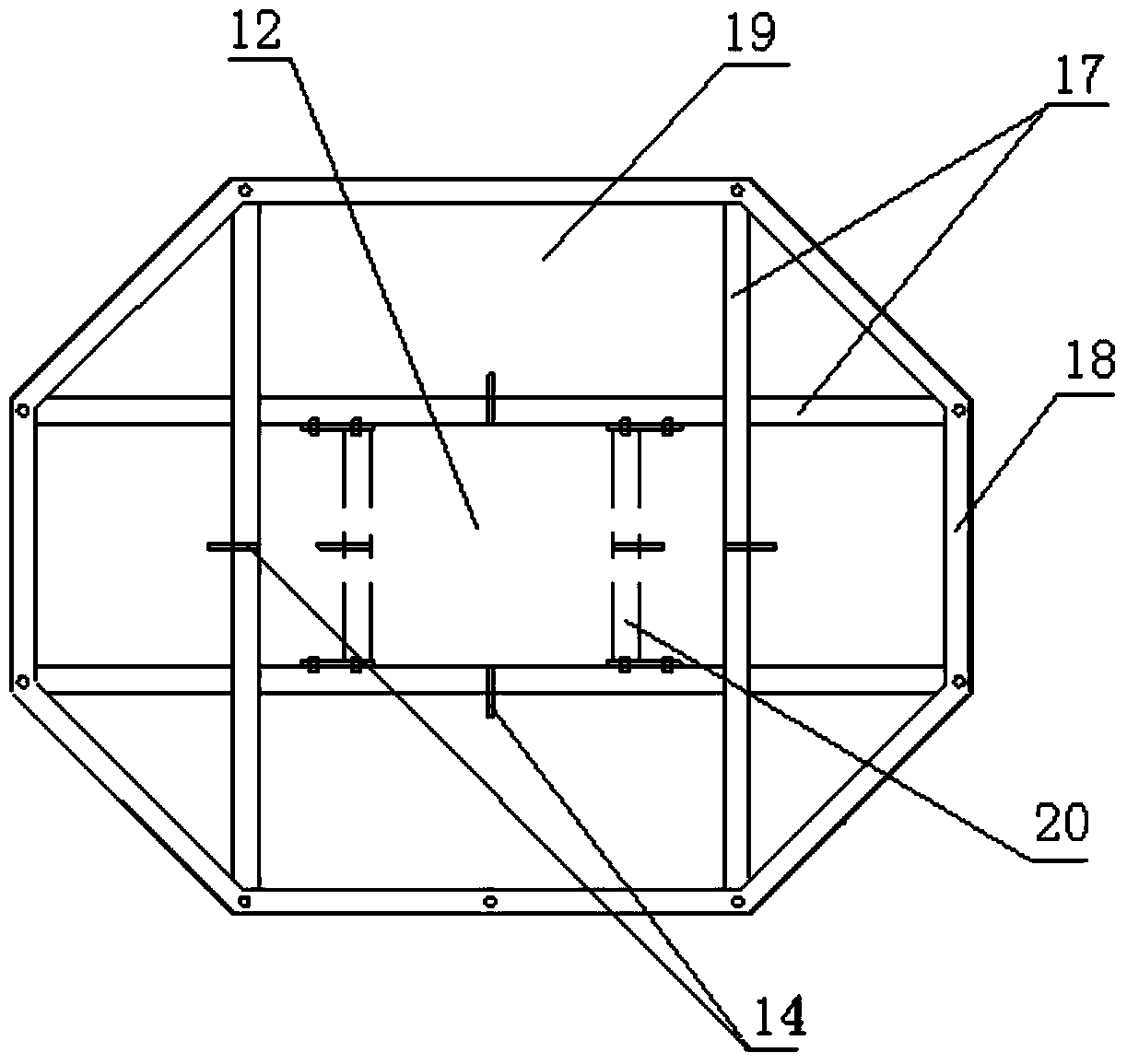

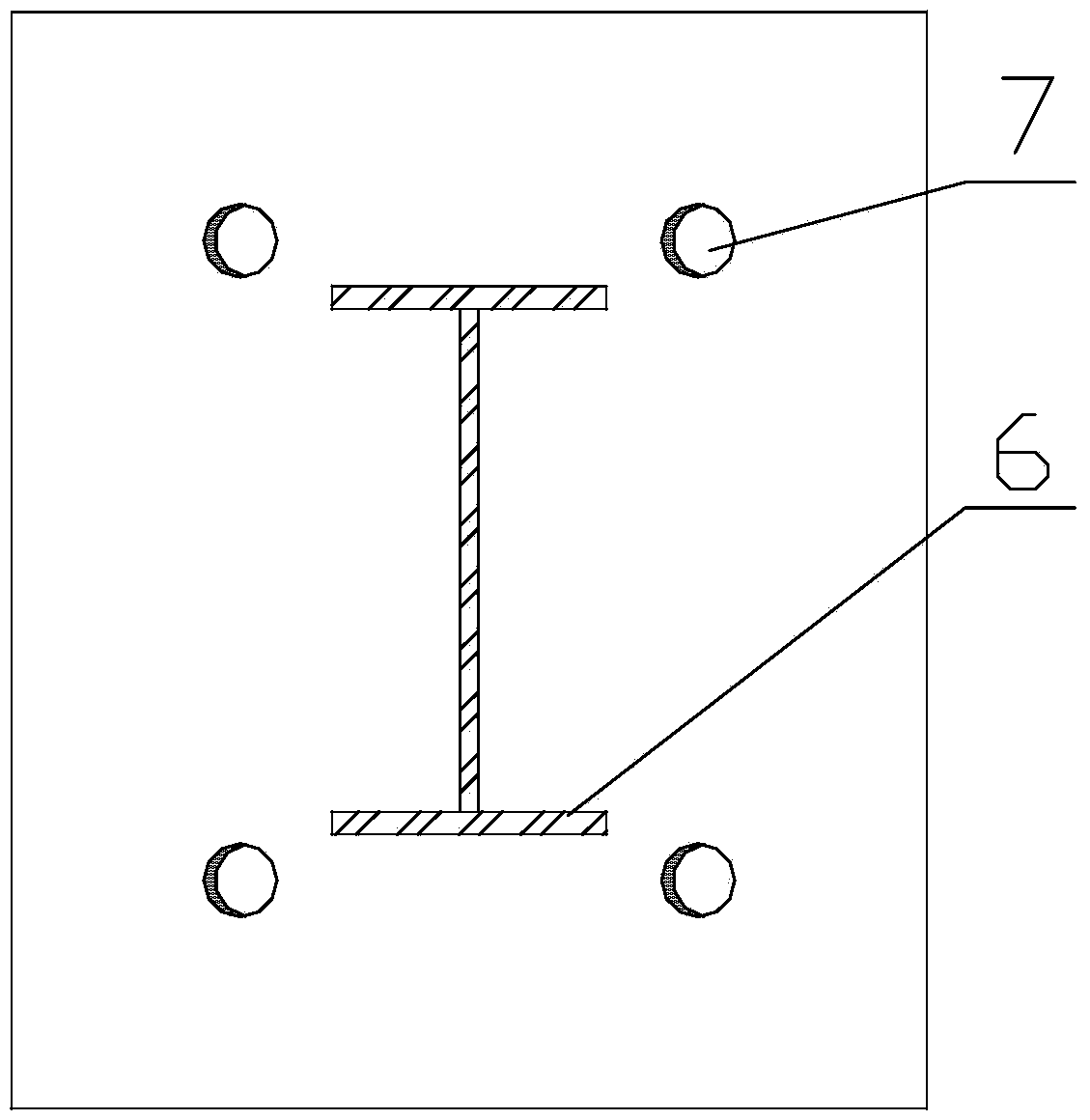

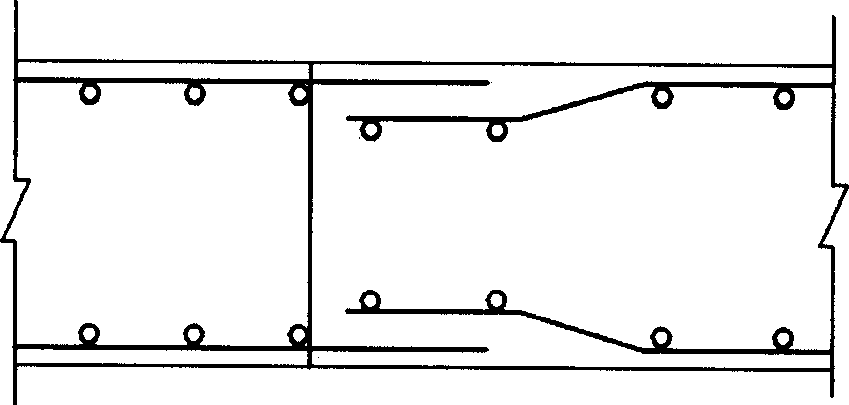

Design method for grouting channel of prefabricated concrete vertical members

PendingCN108625536AGuaranteed denseEasy construction and operationBuilding reinforcementsRebarEngineering

The invention discloses a design method for a grouting channel of prefabricated concrete vertical members. The design method comprises the following steps that the upper-section prefabricated concretevertical member and the lower-section prefabricated concrete vertical member are prefabricated; a first bottom key groove, a second bottom key groove, an L-shaped grouting pipeline and an L-shaped observation pipeline are prefabricated in the upper-section prefabricated concrete vertical member; the first bottom key groove is connected with the L-shaped grouting pipeline, and the second bottom key groove is connected with the L-shaped observation pipeline; steel bar grouting sleeves are arranged on the lower portion of the upper-section prefabricated concrete vertical member and communicate with a horizontal joint of the upper and lower prefabricated members; and a grouting material sequentially enters the second bottom key groove, the horizontal joint of the upper and lower prefabricatedmembers and the first bottom key groove from the L-shaped grouting pipeline, is discharged form slurry outlets of the steel bar grouting sleeves firstly to block the slurry outlets of the steel bar grouting sleeves, and then is discharged from the L-shaped observation pipeline to block the L-shaped observation pipeline and the L-shaped grouting pipeline.

Owner:THE THIRD CONSTR OF CHINA CONSTR EIGHTH ENG BUREAU

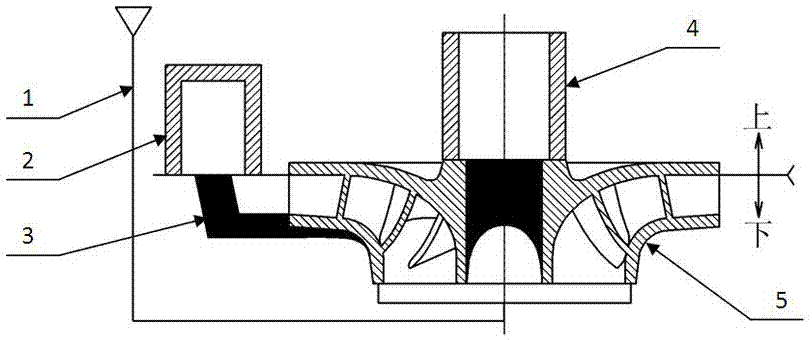

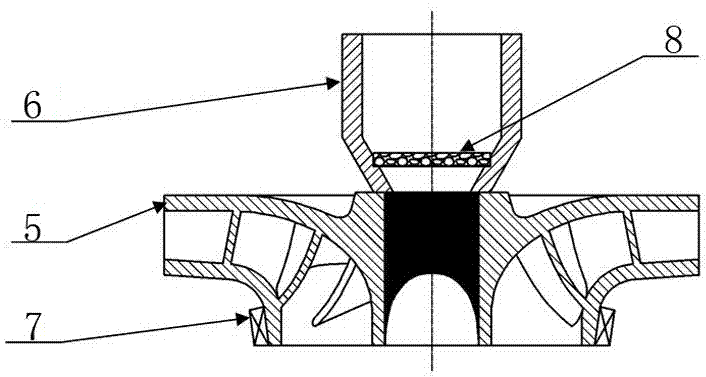

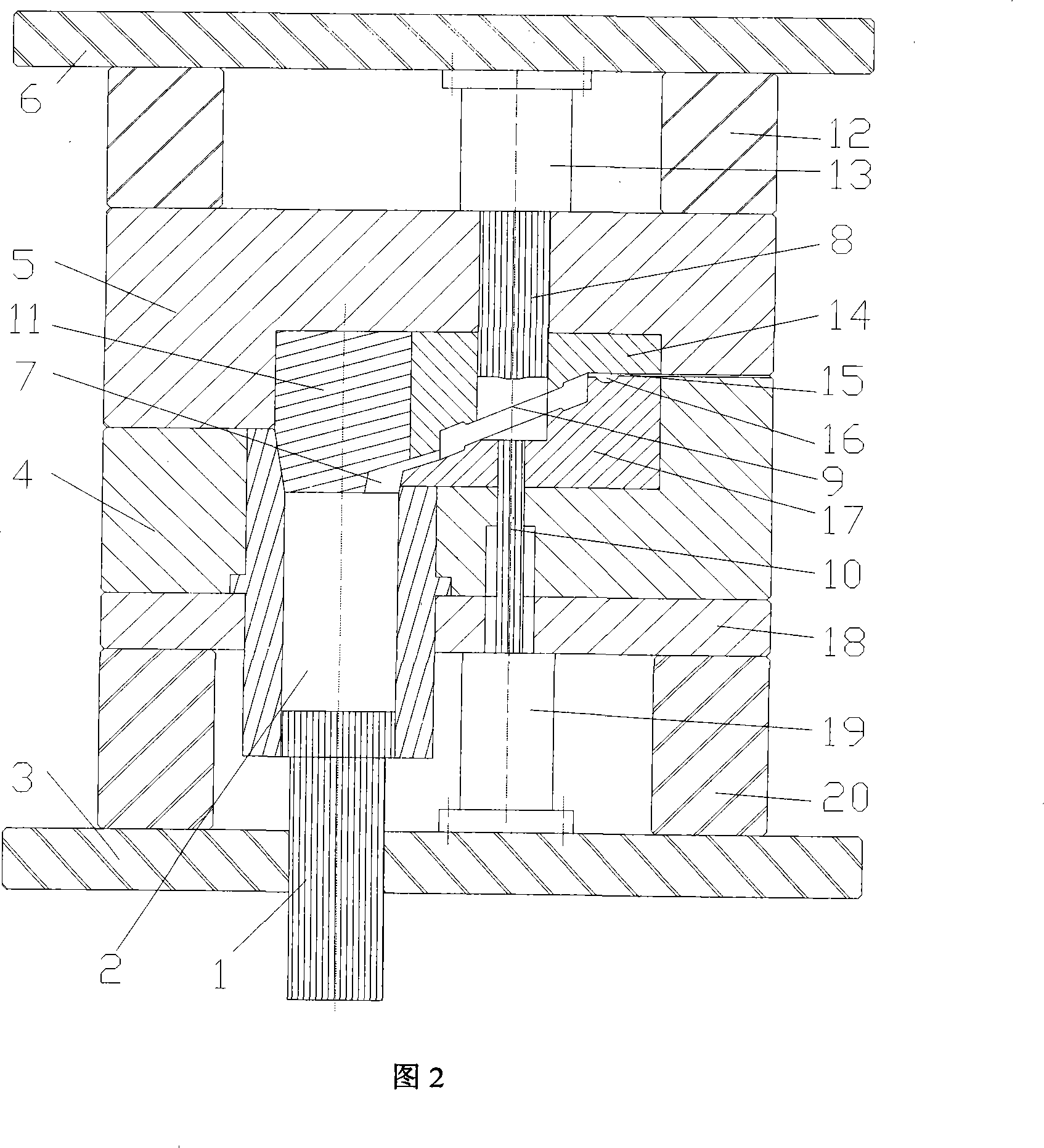

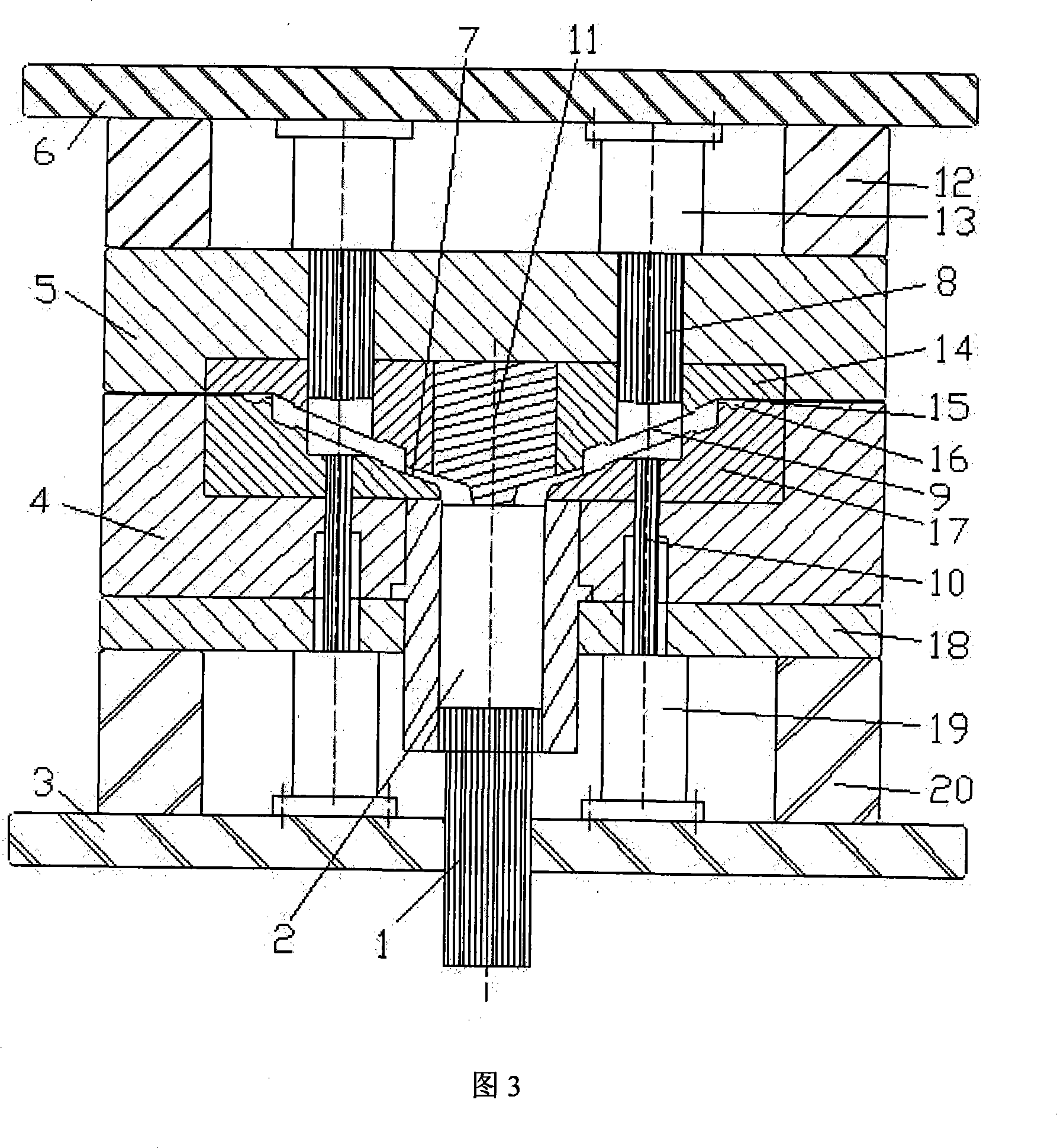

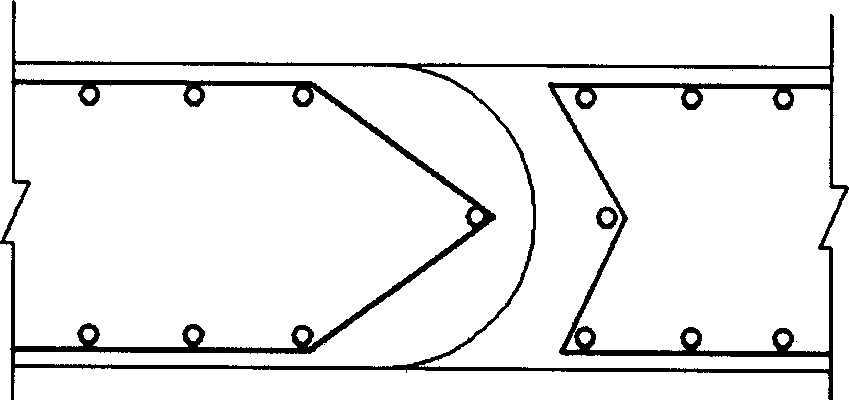

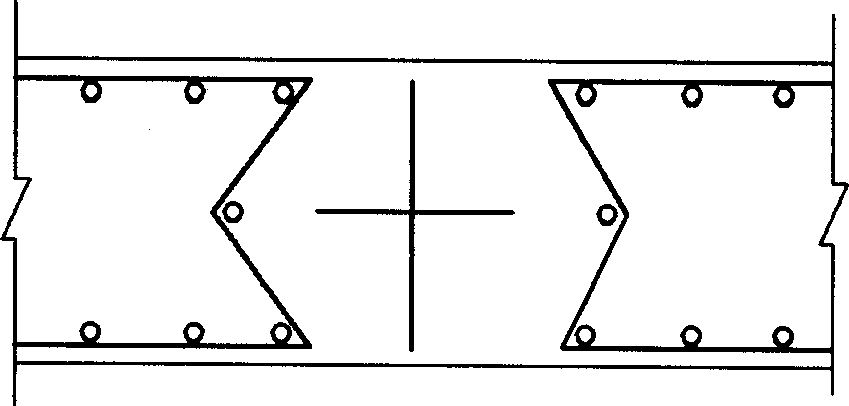

Casting method and mould for car air conditioning compressor slanting plate

The invention provides a method for casting a swashplate of an automobile air-conditioning compressor and a mould thereof. The method comprises the steps: squeezing press is exerted to melt inside a feed room so as to cause the melt to flow into a die cavity stably from the side surface through a pouring channel; when the die cavity is filled with the melt, pressure-keeping press is exerted to the melt from one end vertical to the die cavity, feeding pressure is exerted to the center of the melt from the other end vertical to the die cavity before the melt is completely solidified and the pressure is canceled after maintained for 4-10s; the squeezing press is canceled after the melt at the connection part of a pouring channel and the die cavity is solidified; the pressure-keeping press is canceled after the melt is completely solidified; then a cast is fetched out by opening the die. The mould provided by the invention essentially comprises the sequentially communicated feed room, pouring channel and die cavity; the top and the bottom of the die cavity are respectively provided with a channel inside which a punch used for providing pressure to the top and the bottom of the die cavity is arranged. The aluminum alloy swashplate cast by the invention is compact and has small content of inner impurities, good shaped appearance, fine structure and no bubble in thermal treatment.

Owner:HUAZHONG UNIV OF SCI & TECH

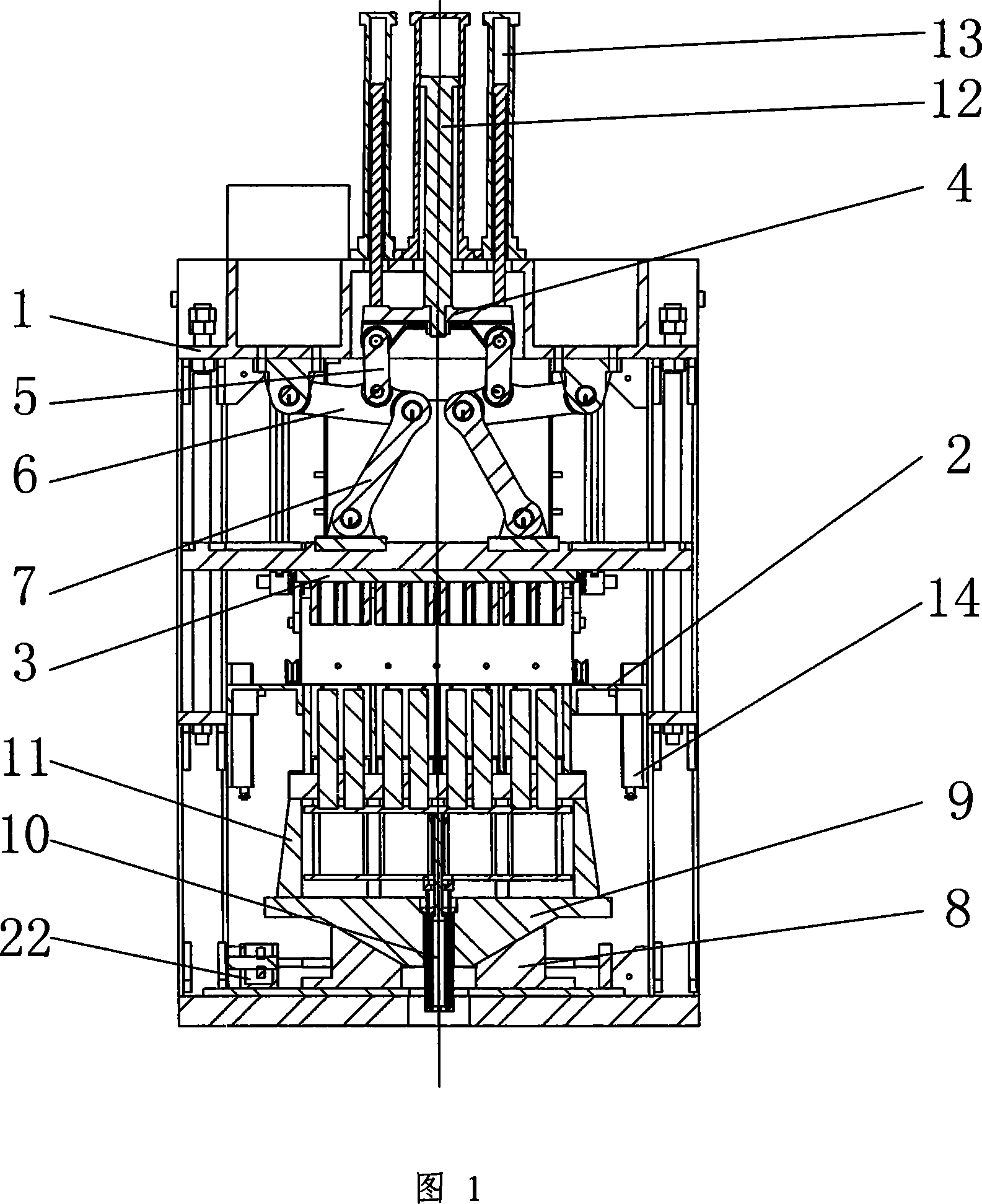

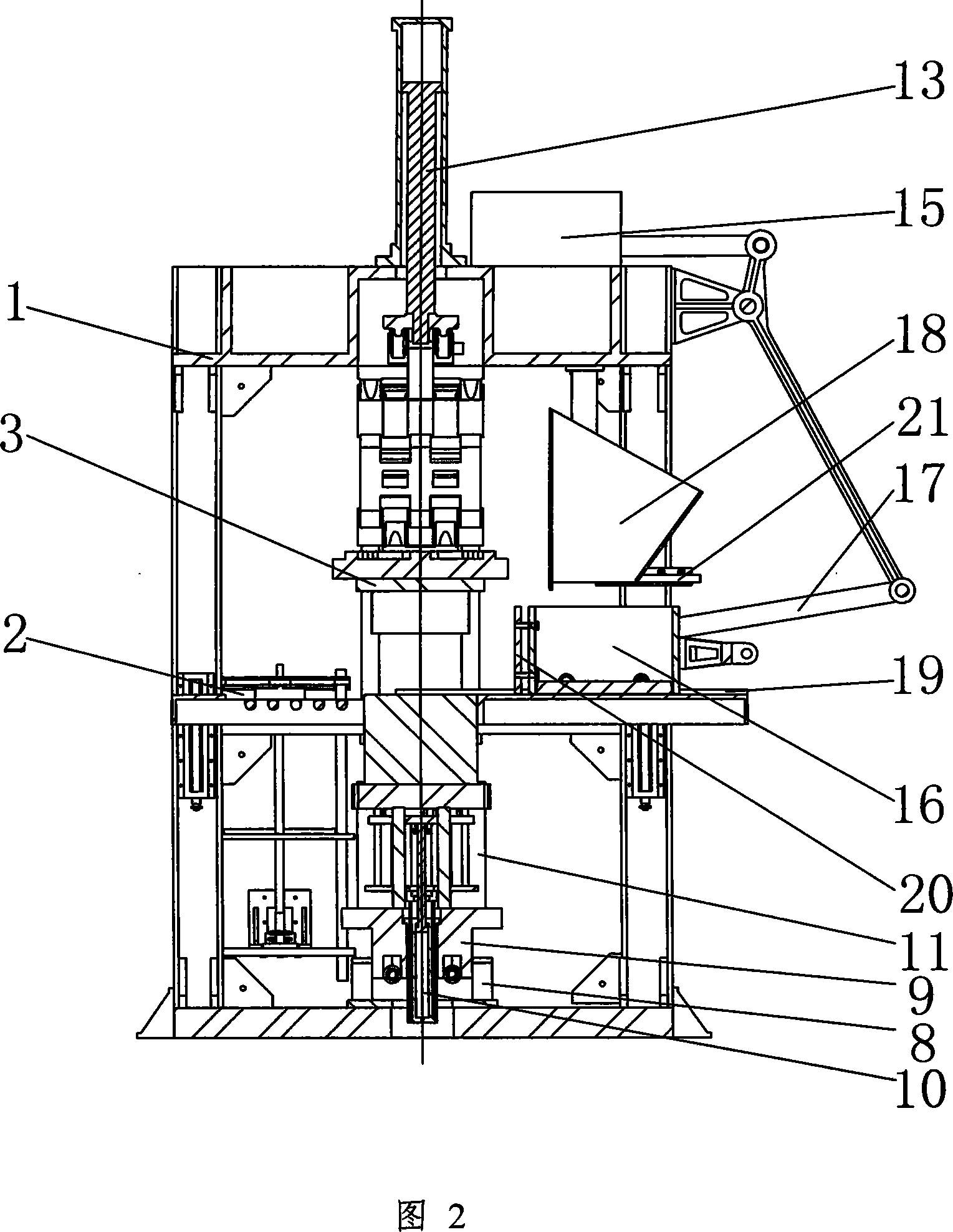

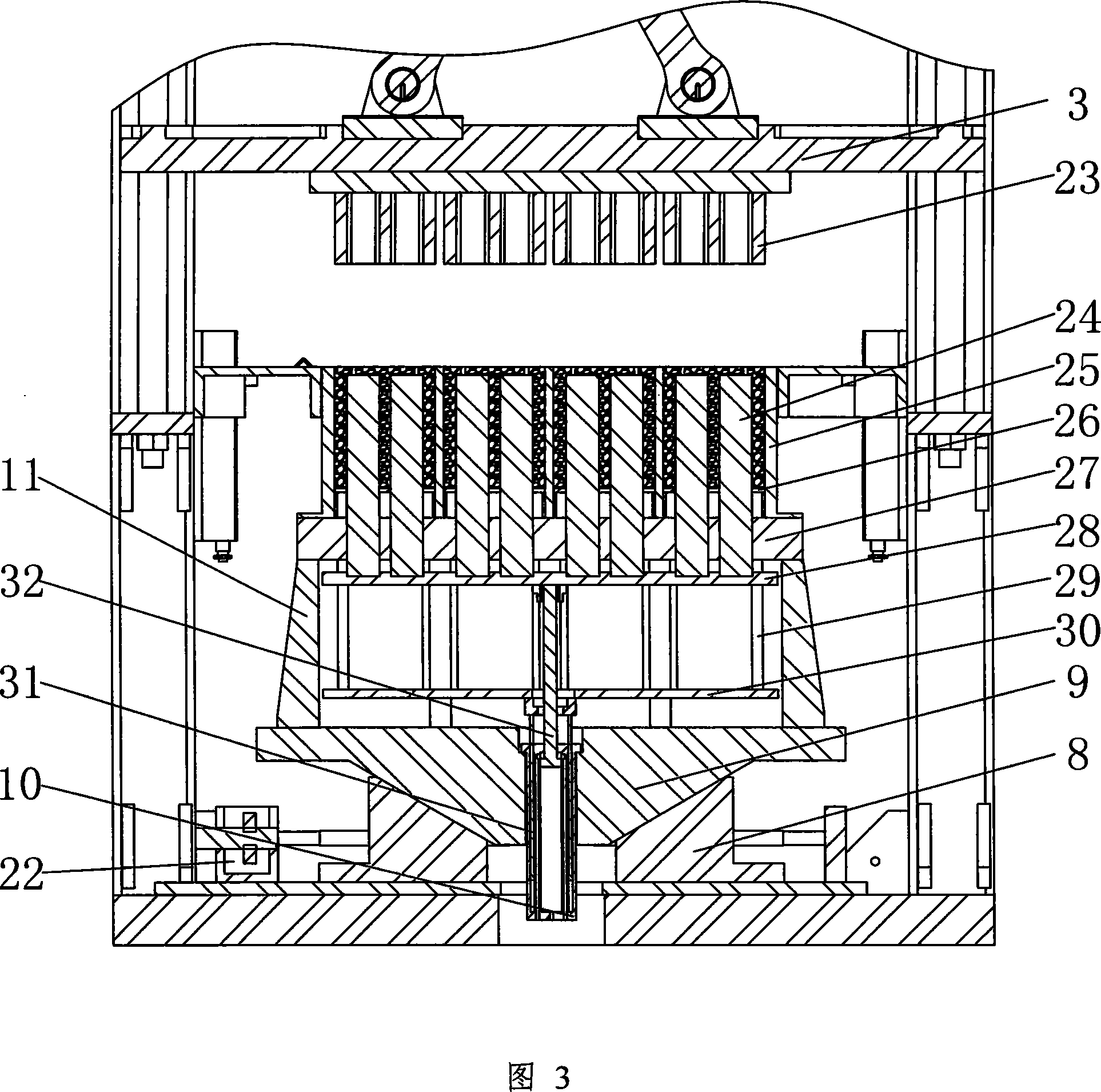

Full-automatic hydraulic without excitation building block shaping machine

InactiveCN101214734AHigh compressive strengthStandard sizePress ramShaping pressHydraulic cylinderEngineering

The invention provides a full automatic hydraulic building block forming machine without shock excitation, which comprises a frame, a workbench, an upper die, a lower die, a mould emptier, a feeding mechanism and a compaction mechanism. The compaction mechanism comprises a hydraulic cylinder, a hydraulic cylinder push frame, a bar chain force increasing and pressurizing mechanism. The hydraulic cylinder arranged on the frame passes through the frame; the lower end of the hydraulic cylinder is provided with the hydraulic cylinder push frame which is fixed. The lower end of the hydraulic cylinder push frame is provided with the bar chain force increasing and pressurizing mechanism. The lower end of the bar chain force increasing pressurizing mechanism is fixed with an upper templet. The invention provides a full automatic hydraulic forming machine of low power and large pressure without shock excitation, noise or a carrier for high strength bearing building blocks and interlocking building blocks.

Owner:陈大庆 +1

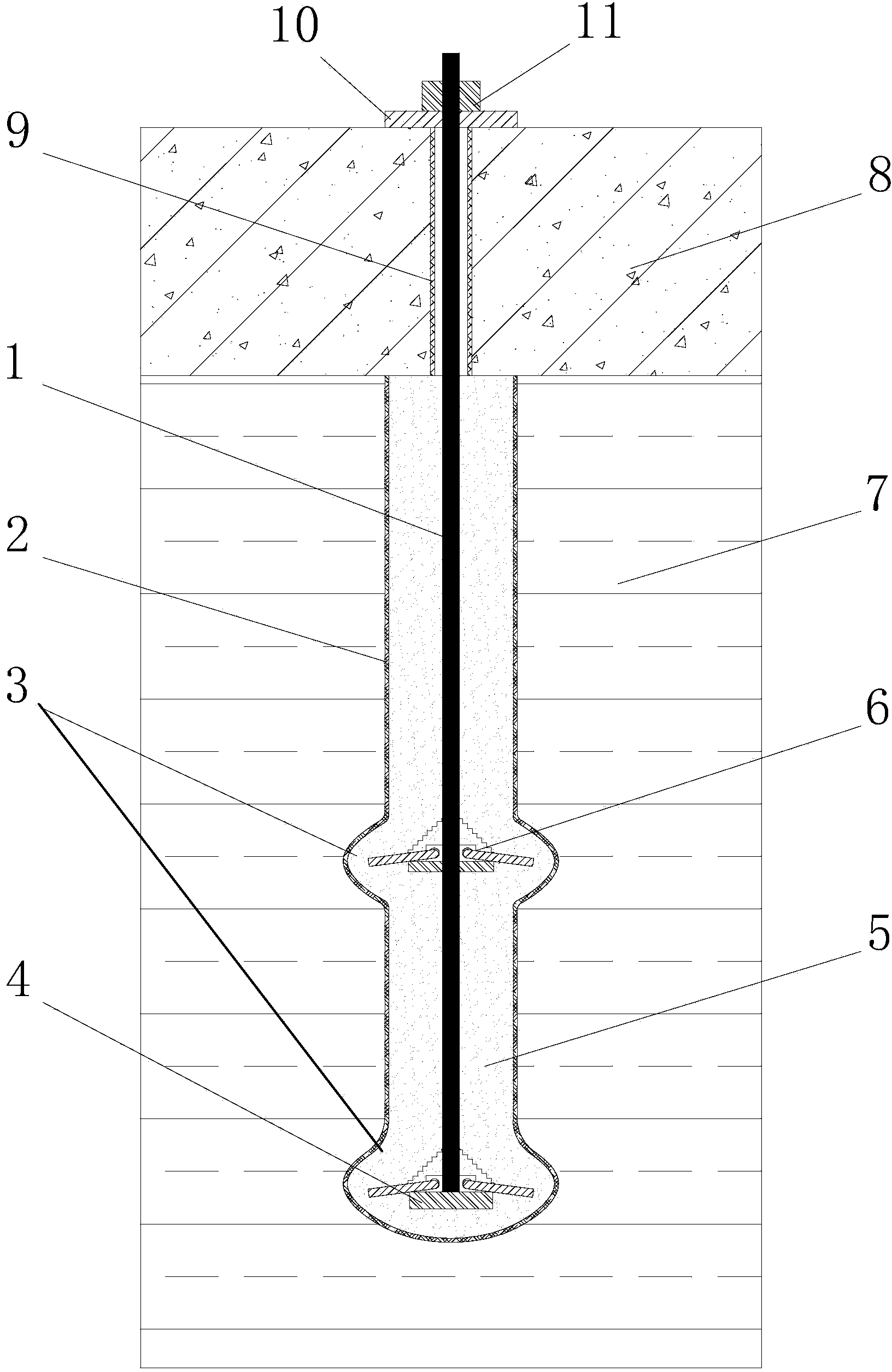

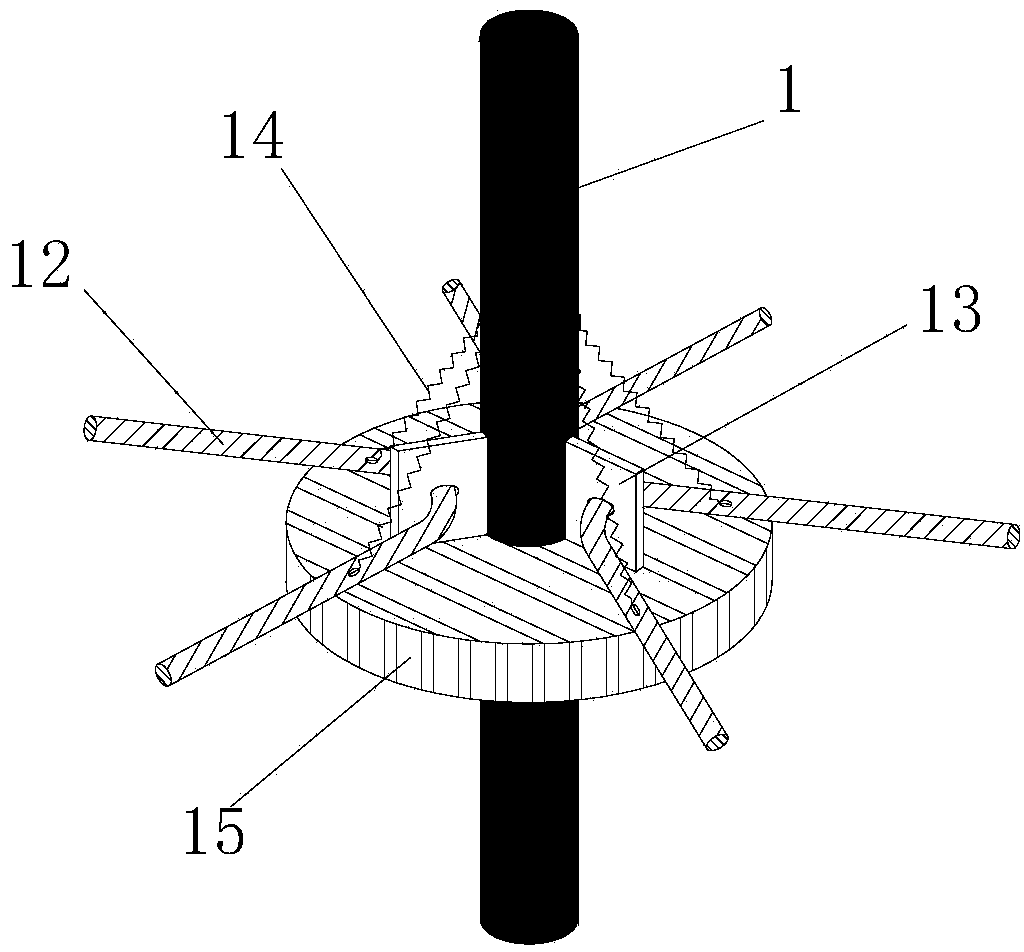

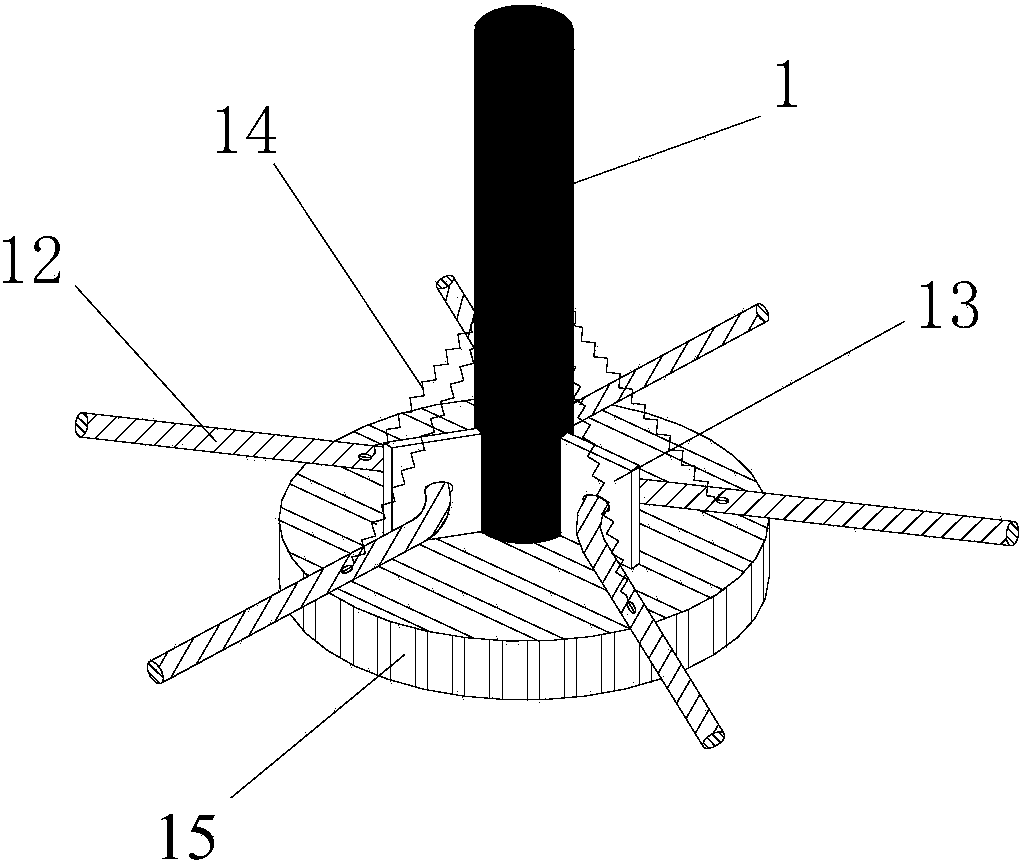

Lead hole implanted anti-floating rock anchor rod with supporting trays and construction method thereof

ActiveCN104234050AHigh bonding strengthImprove molding qualityProtective foundationBulkheads/pilesRebarRock bolt

The invention relates to a lead hole implanted anti-floating rock anchor rod with supporting trays. The lead hole implanted anti-floating rock anchor rod is characterized by mainly consisting of an anchor rod, supporting tray steel bar frameworks, a chassis, a backing plate and an anchor head, wherein an anchoring section of the anchor rod is arranged in a rock stratum pore passage with the supporting trays; the rock stratum pore passage is filled with a steel bar anchoring agent; the steel bar anchoring agent is wrapped with a geotextile bag; a free section of the anchor rod is arranged in a foundation bottom plate, is wrapped with a drivepipe and is isolated from concretes of the bottom plate; the supporting tray steel bar frameworks are fixed to the anchor rod in a manner of corresponding to the heights of the supporting trays in the rock stratum pore passage. The reaming supporting trays are arranged in the rock stratum pore passage, and the expandibility and adhesiveness of the steel bar anchoring agent are utilized, so that the anchoring force in unit length of the anchor rod is improved, the anti-floating capability of the anchor rod can be increased, the length of the anchor rod and the drilling depth of a rock stratum can be relatively shortened, and the lead hole implanted anti-floating rock anchor rod has favorable technical and economical benefits. The invention also discloses a construction method of the anti-floating rock anchor rod.

Owner:德达交通建设发展集团有限公司

Construction method of mass concrete of high-rise building foundations

InactiveCN104264676ASimple technologyImprove construction efficiencyFoundation engineeringMass concreteCasting

The invention discloses a construction method of mass concrete of high-rise building foundations. According to the construction method, continuous construction is adopted for concrete construction, concrete is subject to segmental and layered casting and mechanical vibrating, and the temperature and the casting time are strictly controlled. The construction method is simple in technique, high in site construction efficiency, reliable in quality, short in construction period and low in labor intensity, the quality after construction reaches the design demands, and the thickness of casting layers is strictly controlled. Vibrators are arranged at multiple casting points to ensure density of the concrete. The opening temperature and the molding temperature of the concrete are strictly controlled so that shrinkage and closing of the concrete are effectively ensured. The concrete is vibrated in a fast inserting and slow stirring mode during casting so that holes caused by mixing of air during concrete casting are effectively prevented.

Owner:沈建东

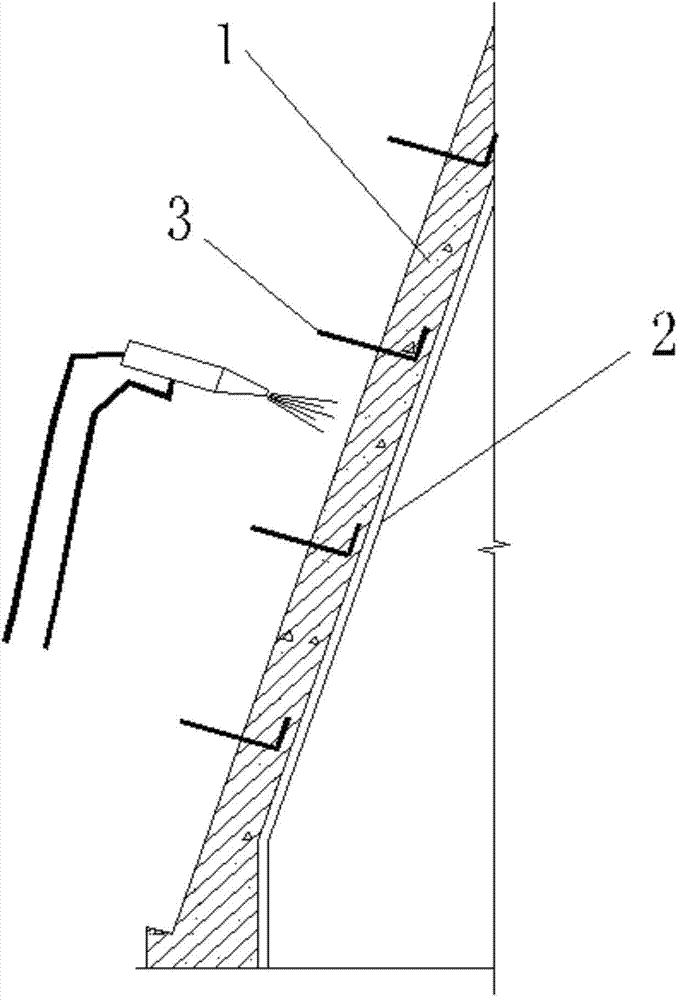

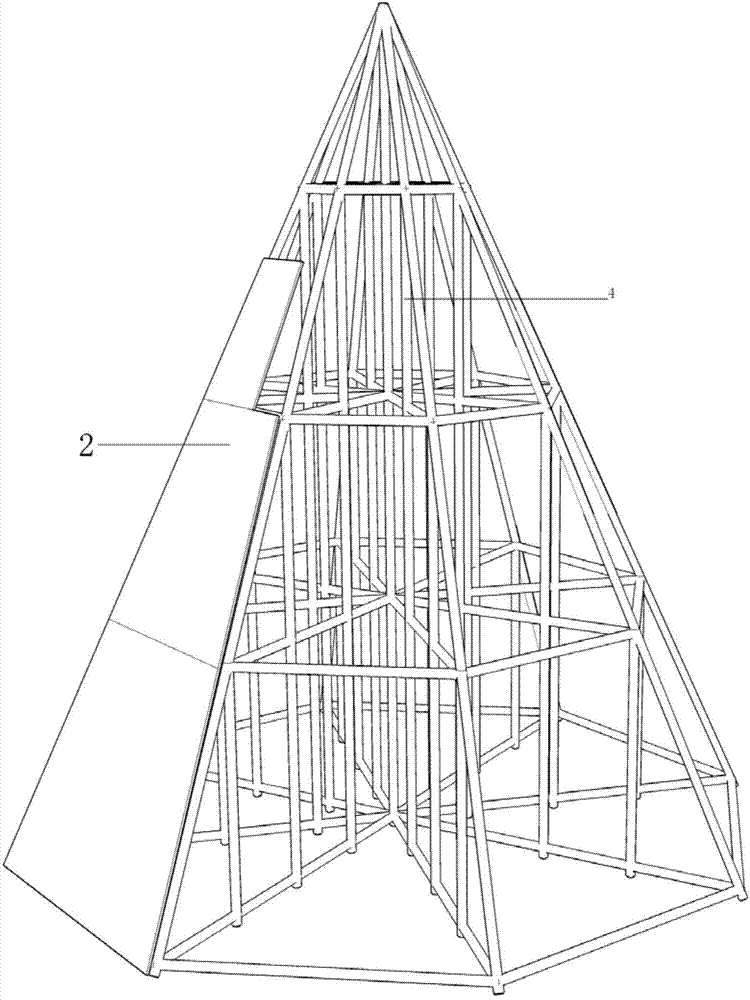

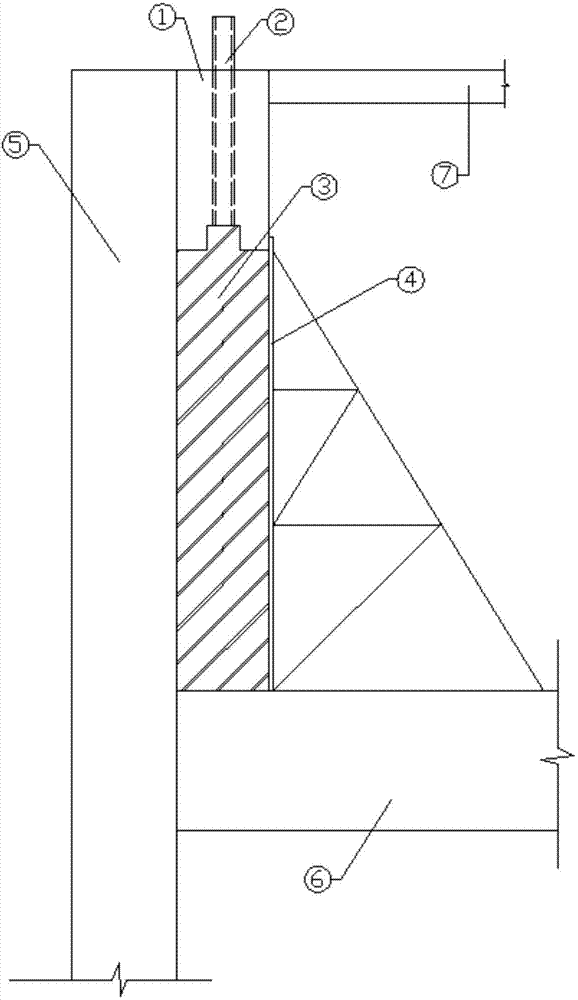

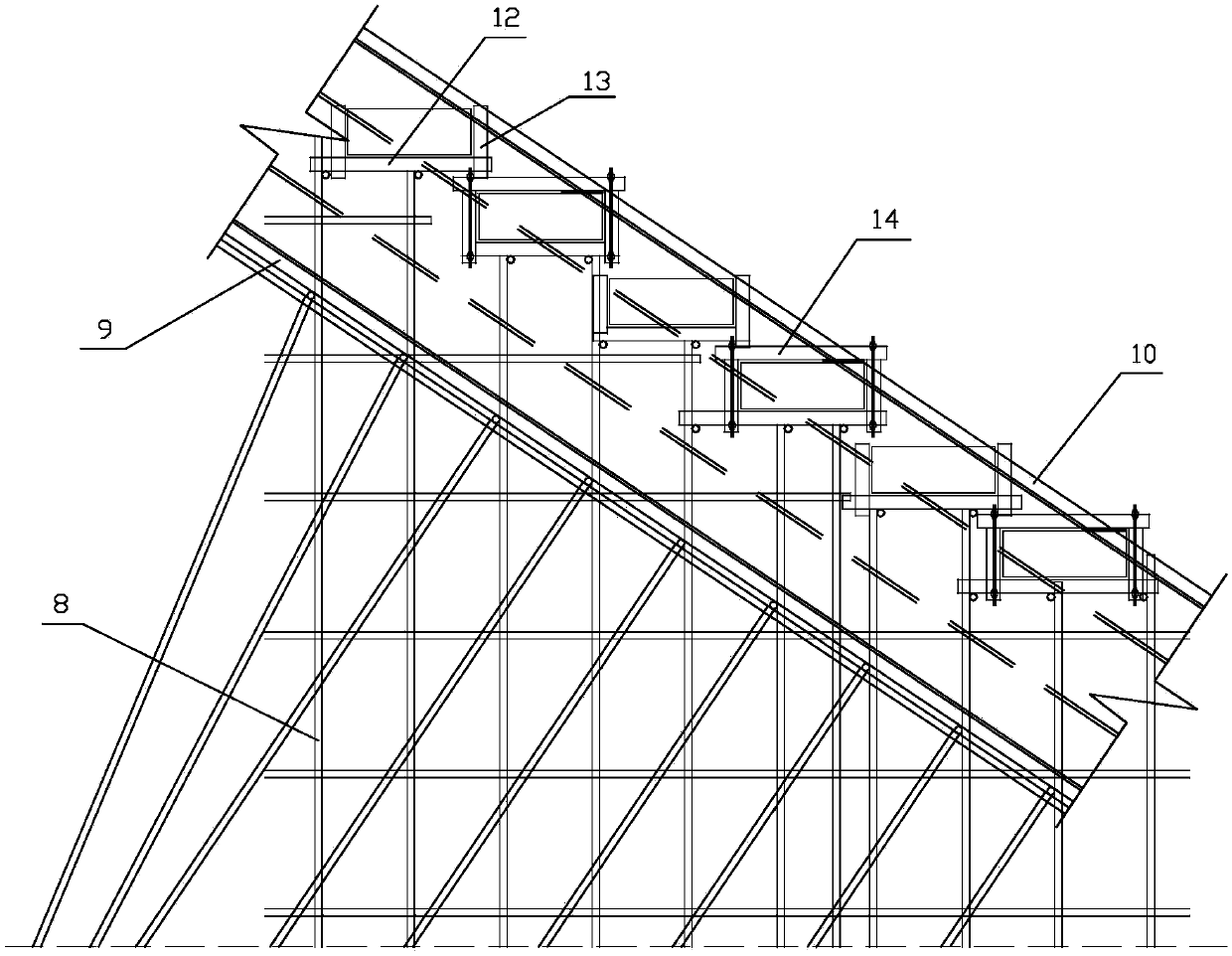

Concrete construction method for big-gradient sloping roof

ActiveCN103615076AShorten the construction periodReduce labor costsRoof covering using sealantsArchitectural engineeringRebar

The invention discloses a concrete construction method for a big-gradient sloping roof. At first, a bottom layer formwork module 2 of the big-gradient sloping roof is installed according to needs, roof panel steel bars are bound according to construction drawings and standard requirements, then sprayed concrete construction is carried out on the big-gradient sloping roof panel 1, the big-gradient sloping roof panel 1 comprises the sloping roof formwork module 2 and pre-buried L-shaped pulling ribs 3, the formwork module 2 is machined in advance to be formed and to be hoisted to a full space bearing frame 4, concrete is continuously sprayed and constructed at one time, construction quality of the concrete can be visually observed, and it is guaranteed that the interior of the concrete is dense; after roof concrete is renovated by means of cement mortar with the same proportion of the roof concrete through cleaning of dross on the surface layer, the concrete is square in appearance size, the exterior of the concrete is flat, and the interior of the concrete is solid.

Owner:CHINA CONSTR 4TH ENG BUREAU 6TH

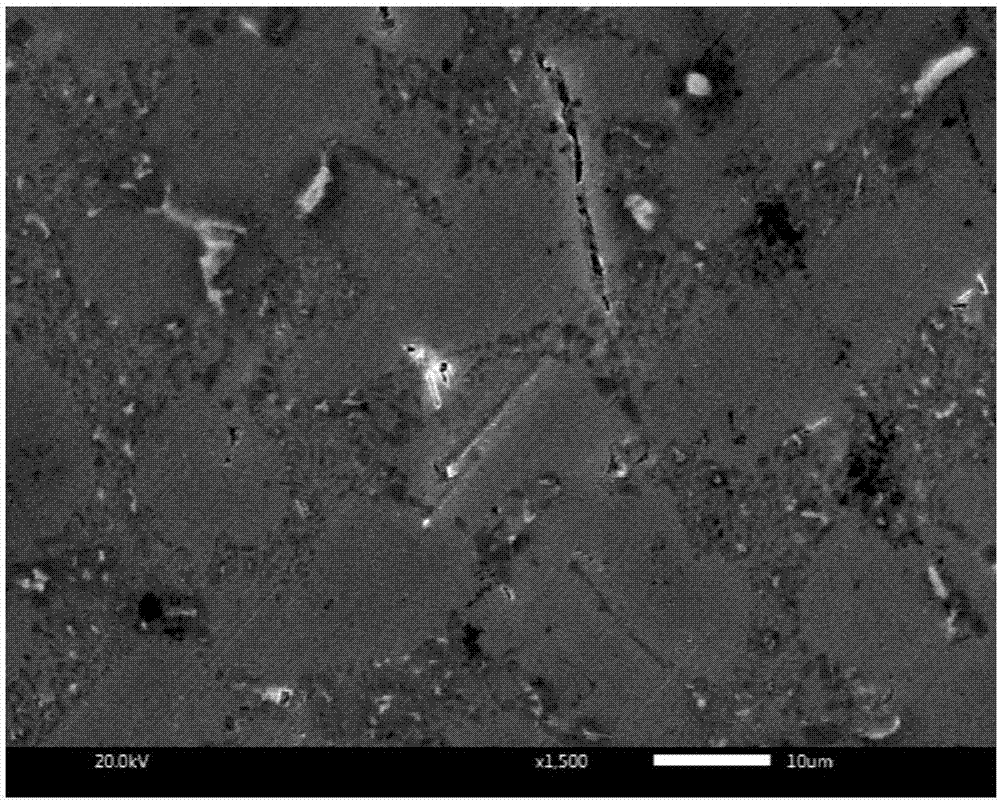

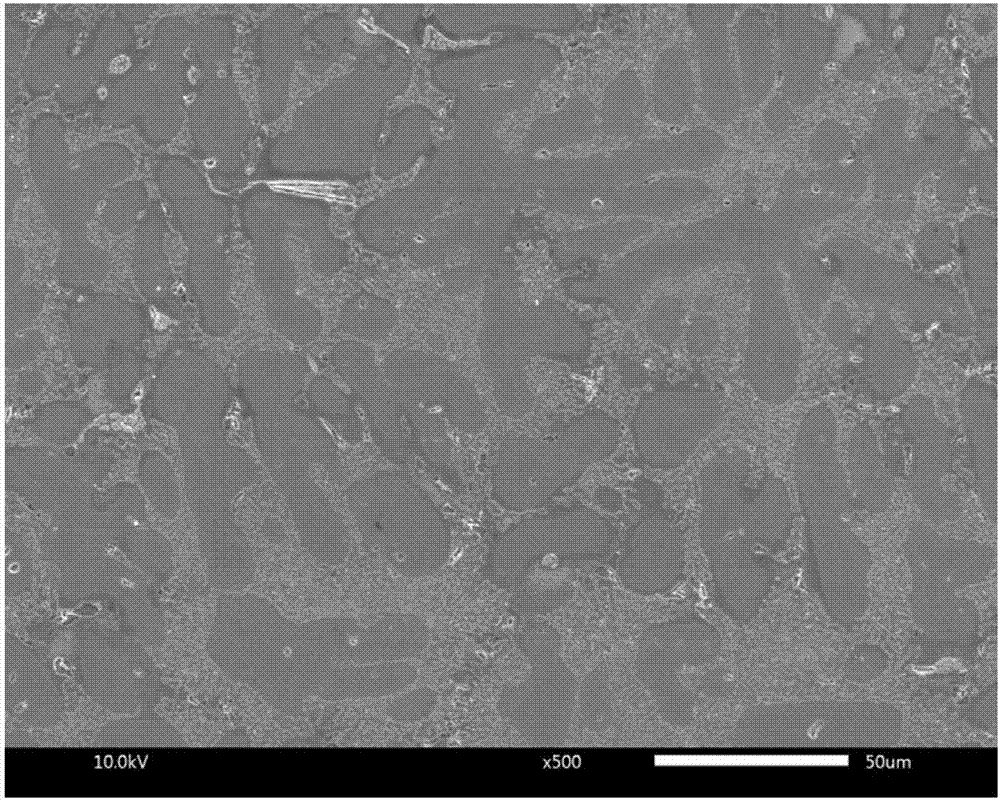

High-hardness corrosion-resistance aluminum-silicon-copper series cast aluminum alloy obtained through zirconium-strontium composite microalloying and magnesium alloying and preparing method

Disclosed is a high-hardness corrosion-resistance Al-Si-Cu series cast aluminum alloy obtained through Zr-Sr composite microalloying and Mg alloying. The high-hardness corrosion-resistance aluminum-copper-silicon cast aluminum alloy of the zirconium strontium composite microalloying and the magnesium alloying is characterized in that the aluminum alloy is mainly composed of aluminum (Al), silicon (Si), cuprum (Cu), magnesium (Mg), zirconium (Zr), strontium (Sr) and ferrum (Fe). A preparing method comprises sequentially the following steps that (1), pure Al and Al-Si intermediate alloy are molten and then are heated to 850 DEG C, and then Al-Cu, Al-Zr and Al-Sr intermediate alloy are added in sequence; and (2), after all intermediate alloys and metals are molten, the temperature is adjusted to 750 DEG C, and pure Mg is added; and after the pure Mg is molten, hexachloroethane is added for refining and degassing until no gas escapes, the melt is deslagged and cast into an ingot after standing and heat preservation for 5-10 min. According to the high-hardness corrosion-resistance aluminum-silicon-copper series cast aluminum alloy obtained through the zirconium-strontium composite microalloying and the magnesium alloying and the preparing method, the casting-state texture of the aluminum alloy is compact, the indoor temperature non-notch impacting tenacity average value is 16.35 J / cm2, the tensile strength is 262.132 MPa, the ductility is 5.645%, and meanwhile, the uniform corrosion rate is 0.321081508 mm / y when the aluminum alloy is soaked for 93 h in 3.5% NaCl water solution under the temperature of 37 DEG C.

Owner:JIANGSU UNIV

Particle diameter selecting pouring procedure of concrete aggregate for thermal insulation wall

InactiveCN101338597ASimple construction processImprove construction efficiencyWallsBuilding material handlingThermal insulationPebble

The present invention discloses a heat preserving wall concrete aggregate grain diameter selecting and pouring method, which comprises the following steps: a, preparing a concrete with separable aggregate grain diameters, wherein, the aggregate grain diameters of the concrete adopt subsection continue preparation, the pebble with grain diameter of 5 to 10 mm is 30 to 35% of the total amount of the pebble, and the pebble with grain diameter of 10 to 30 mm is 65 to 70% of the total amount of the pebble; b, conveying the concrete with separable aggregate grain diameter to a pouring working surface by a set of concrete conveying equipment, separating the concrete by using a concrete aggregate grain diameter selecting and separating device, conveying the concrete with small grain diameter aggregate to a shuttering with small thickness and pouring the concrete to a protection wall, and conveying the concrete with big grain diameter aggregate to a shuttering with large thickness and pouring the concrete to a shear wall, and the two pouring processes are carried out at the same time; c, vibrating the concrete at the two sides to guarantee that the concrete is compact. The invention has convenient construction, easy operation, low cost and excellent pouring effect, is suitable for the construction of the home building and office building in various forms in the town, and has good society and economic benefits.

Owner:ZHENGZHOU NO 1 CONSTR ENG GRP +2

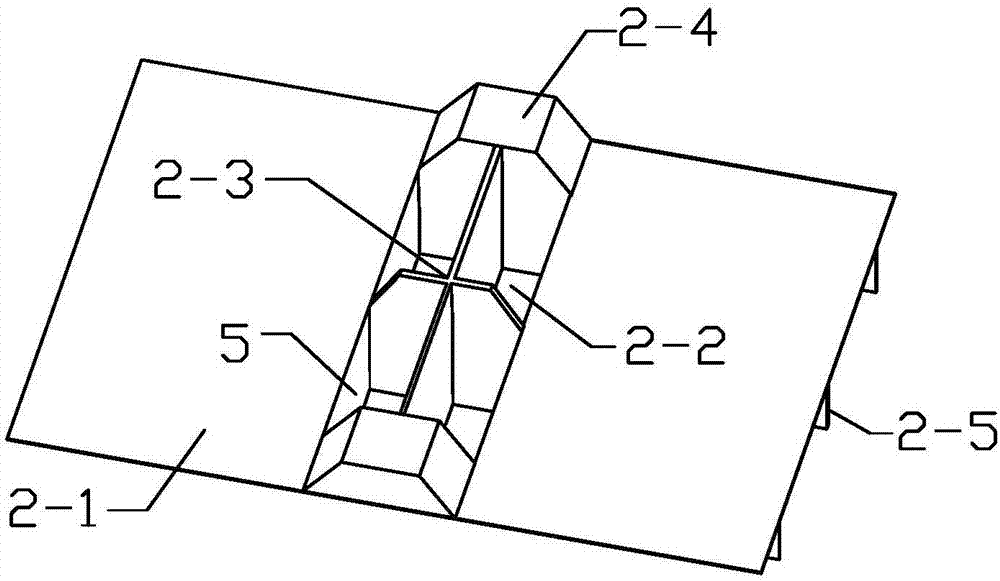

Environment-friendly water permeable brick as well as compression forming mould and preparation method for preparing environment-friendly water permeable brick

InactiveCN107324723AEnsure infiltrationWon't cause stagnant waterPaving gutters/kerbsFeeding arrangmentsPolymer scienceBrick

The invention provides an environment-friendly water permeable brick as well as a compression forming mould and a preparation method for preparing the environment-friendly water permeable brick. The water permeable brick is formed by a water permeable brick surface layer and a water permeable brick base layer, wherein materials of the surface layer mainly comprise sand with the particle size being 10 to 20 mesh and cement; materials of the base layer mainly comprise large gravel with the particle size being 3 to 8mm and cement. The method specifically the steps of adding the materials into two stirring machines respectively, adding other materials of corresponding formulas for evenly stirring, then compressing by a brick compression forming machine, distributing the base layer materials twice and the surface layer materials once in a lower mould hollow part of the compression forming mould, performing shaking compression for 2 to 3s after each time of material distribution, thus preparing a formed green brick, and then performing curing to form the water permeable brick. A dry-press forming process is adopted to prepare the water permeable brick, so that the production cost and the energy consumption are reduced; the prepared water permeable brick has good water permeability, abrasion performance, skid resistance and crushing resistance.

Owner:武汉车都环保再生资源有限公司

Construction method for integrated unilateral formwork of circular lining wall based on inverse method

InactiveCN110552370AImprove molding qualityQuality assuranceArtificial islandsProtective foundationSlurry wallRebar

The invention discloses a construction method for an integrated unilateral formwork of a circular lining wall based on an inverse method. Relays are installed on a steel bar framework of an underground diaphragm wall, after the bottom earthwork of a template is flattened, a concrete cushion layer is leveled and arranged, pull rods are arranged in the lining wall, one end of each pull rod is connected with the corresponding relay, the other end of each pull rod penetrates through the template in a sealing manner and is fixedly connected with a horizontal reinforcement pipe and a vertical reinforcement pipe on the outer side of the template, the horizontal reinforcement pipes on the outer sides of adjacent template sections abut together to form a complete circle of the unilateral formwork,a discharge port is arranged at the top of the template, the upper part of the discharge port is higher than a bottom opening of an upper lining wall, the distance between the discharge port and the wall surface of the upper lining wall can ensure pouring and vibration construction, the excess concrete at the discharge port is chiseled and repaired before initial setting of lining wall concrete. According to the method, the whole circle is poured and formed at a time without vertical construction joints, compactness is guaranteed, no support is required to be erected on the outer side of the template, and Rachel steel bars between the template and the underground diaphragm wall are reduced.

Owner:CHINA FIRST METALLURGICAL GROUP

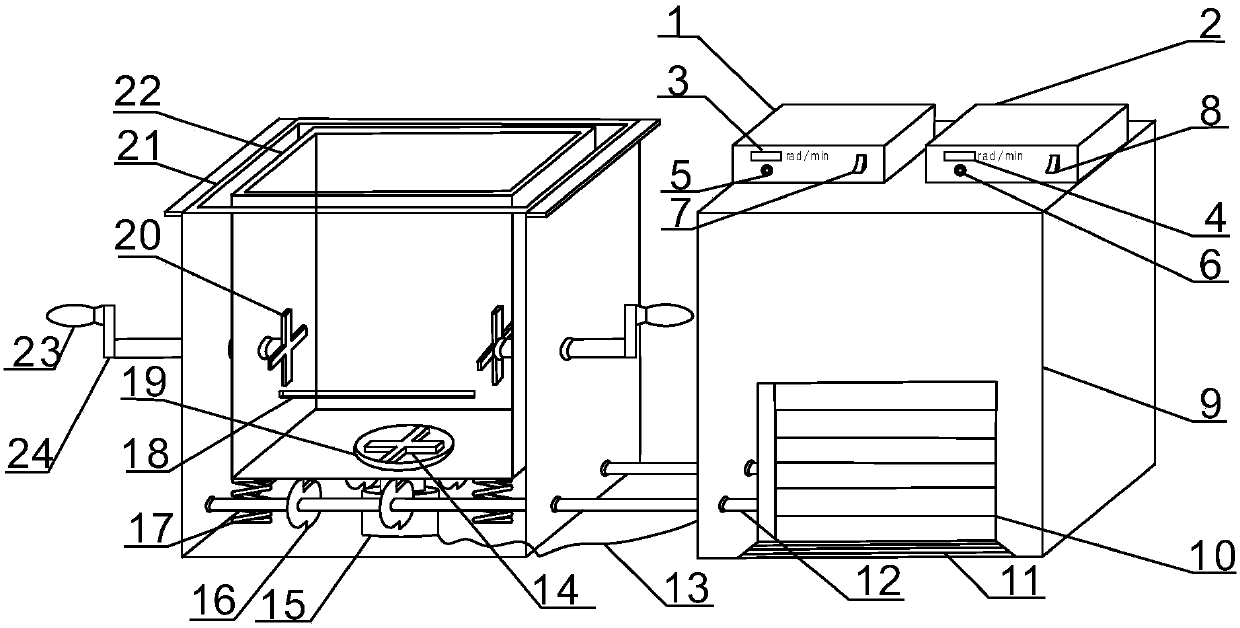

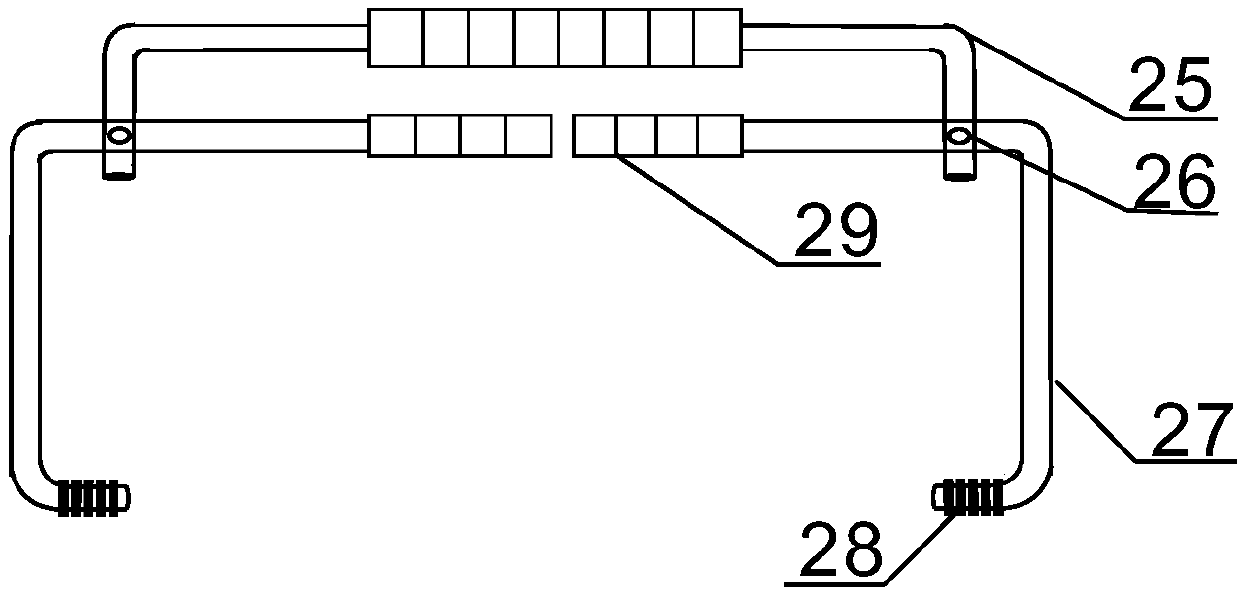

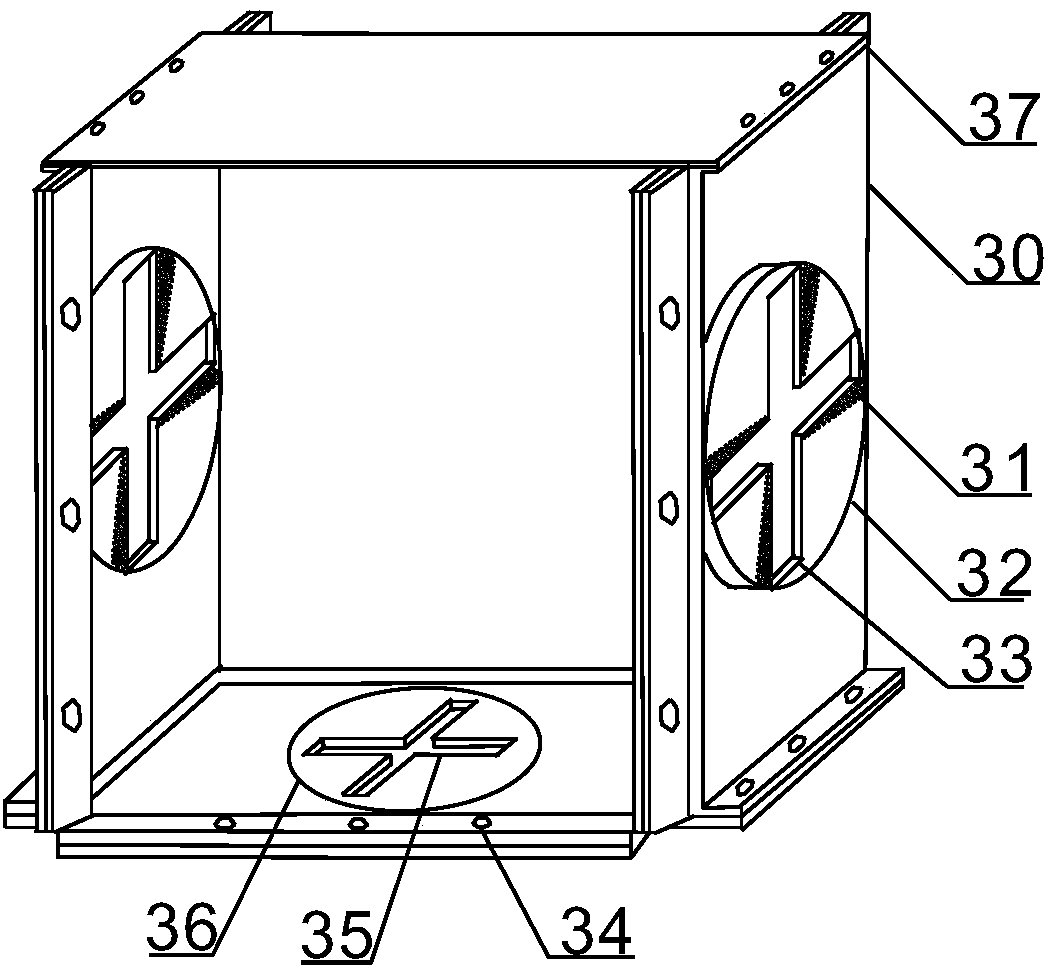

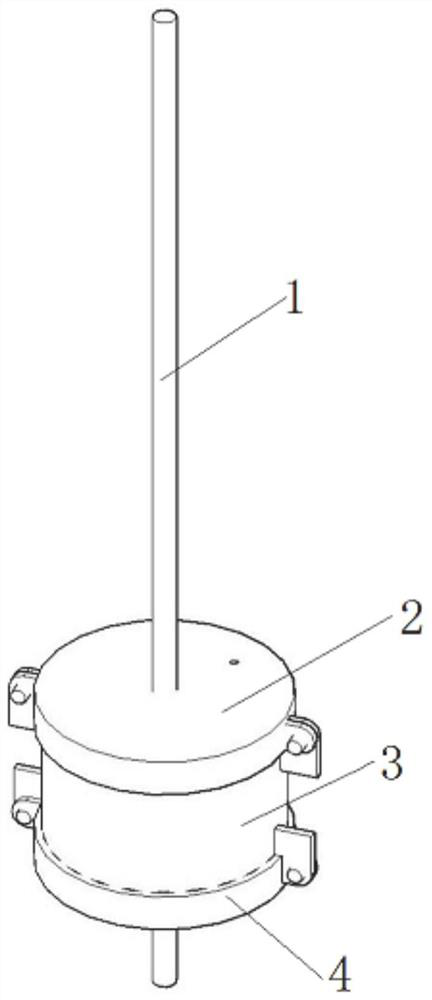

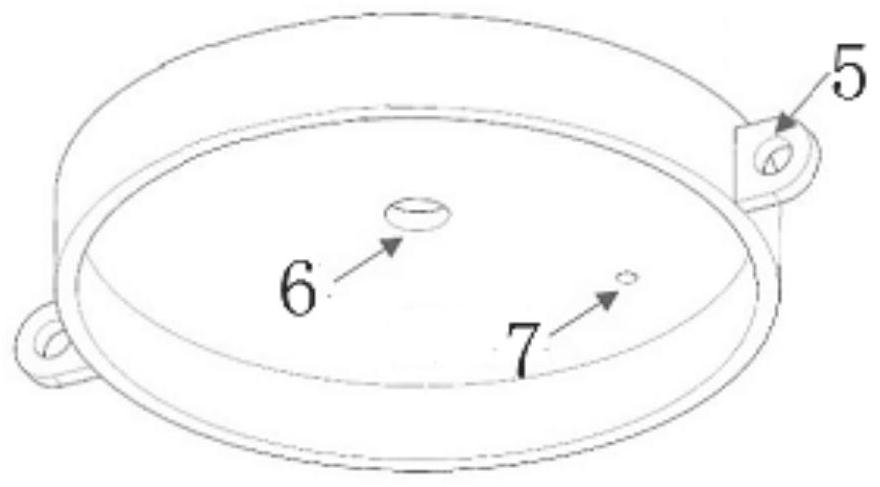

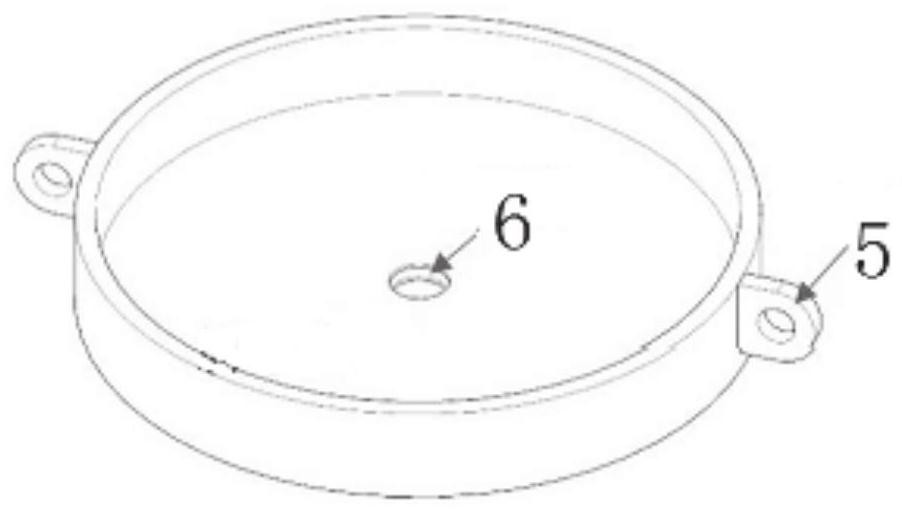

Small concrete compaction and curing slowing device used for experiment and its implementation method

PendingCN107639718AReduce noise pollutionReduce lossCeramic shaping plantsEngineeringExperimental methods

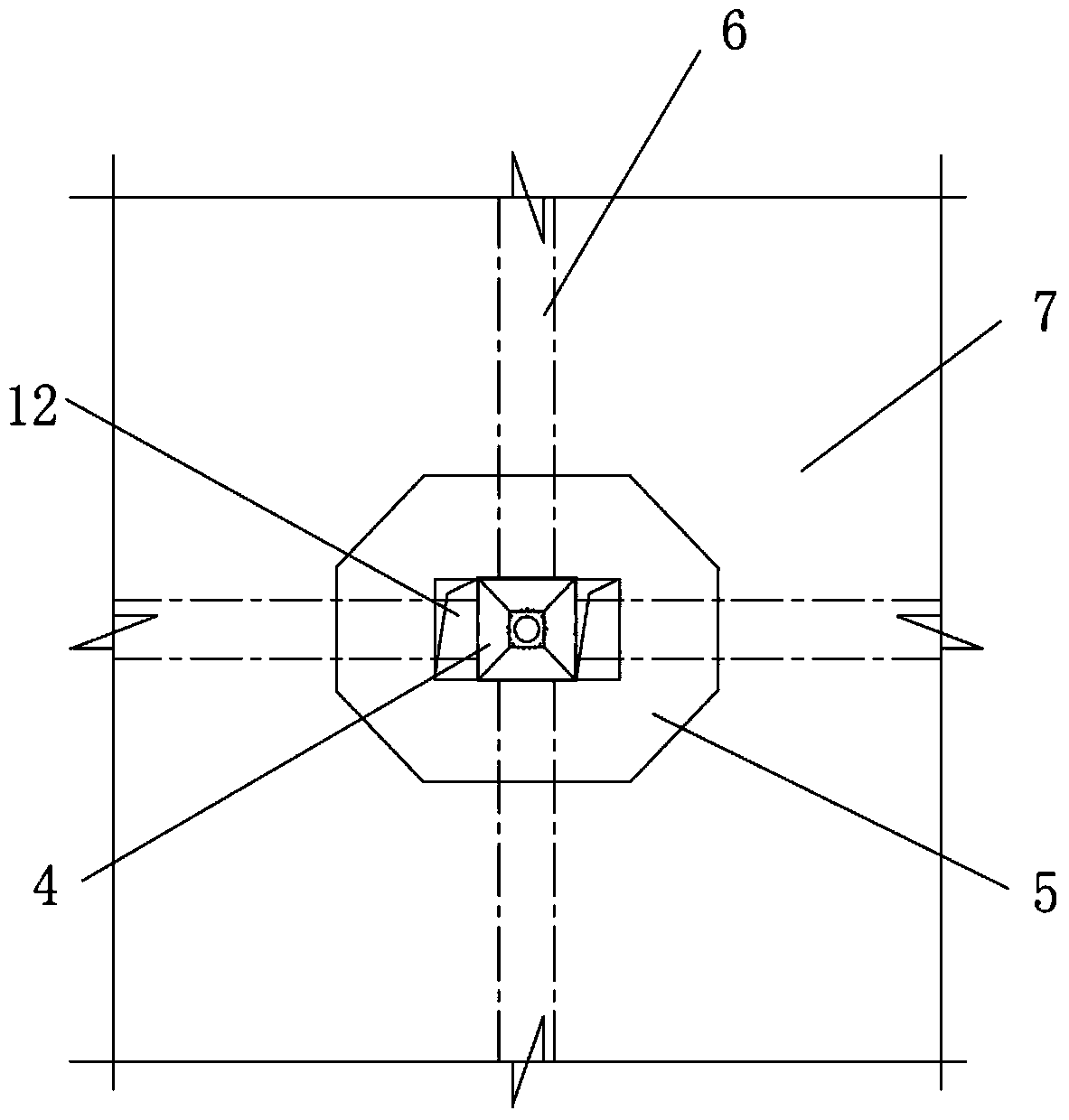

The invention relates to a small concrete compaction and curing slowing device used for an experiment. The device includes a vibration mechanism, a centrifugal mechanism, a curing slowing mechanism, amaterial loading and unloading mechanism and a clamping mechanism; the vibration mechanism is located on the outermost layer of the device, the centrifugal mechanism is located on the middle layer ofthe device, the curing slowing mechanism is located on the secondary inner layer of the device, and the material loading and unloading mechanism is located on the innermost layer of the device. The invention further discloses a concrete compaction and curing slowing method by means of the concrete compaction and curing slowing device. According to the small concrete compaction and curing slowingdevice used for experiment and its implementation method, solid compaction and curing slowing functions are both achieved, there is a big difference between the existing experimental method and corresponding instruments and the small concrete compaction and curing slowing device and its implementation method, the characteristics such as low noise, low loss, low splashing, disassembly, matching, uniform sample discharge and compaction in the compaction process of concrete are taken into consideration, and the device is very high in feasibility and practicability.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

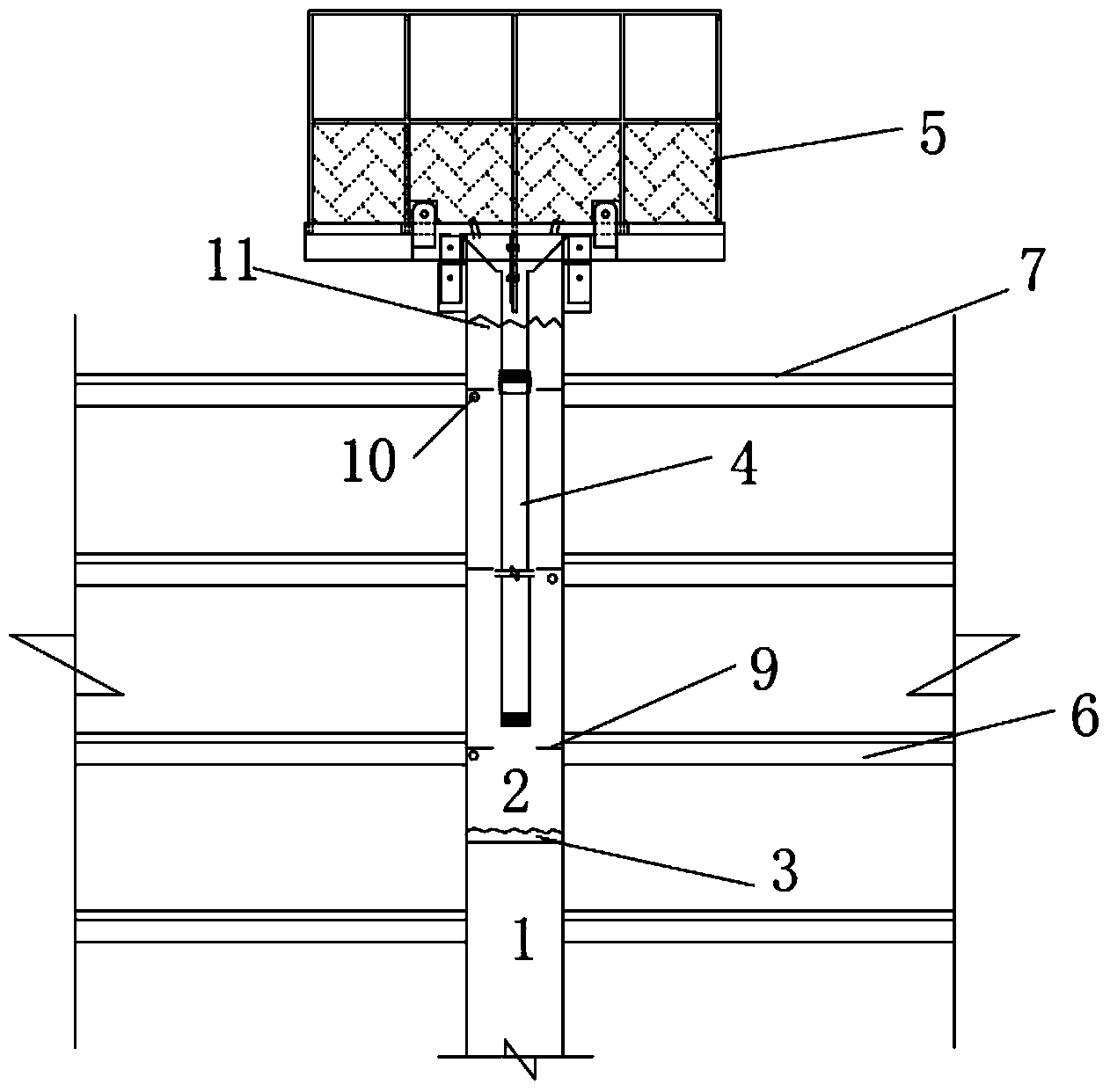

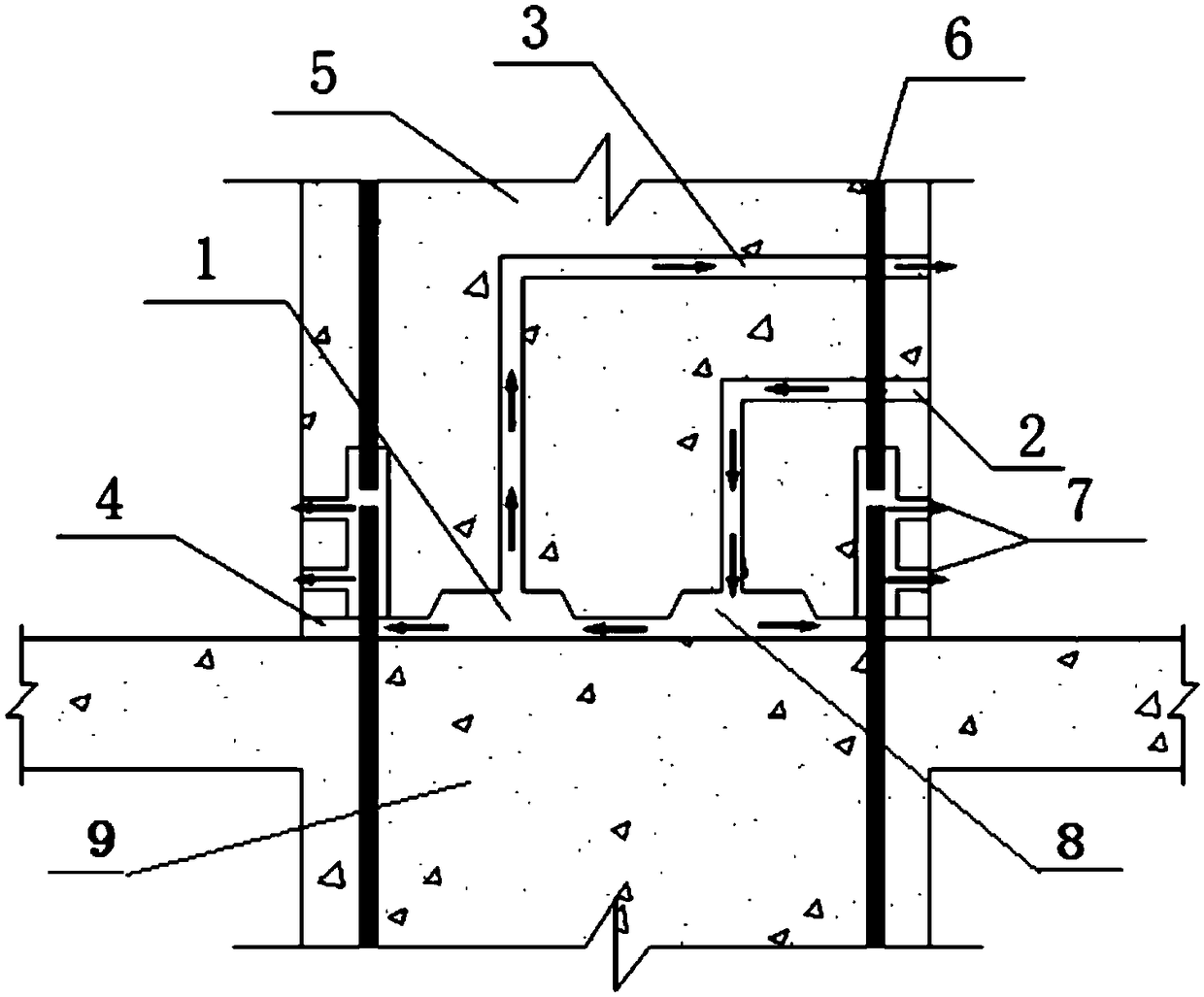

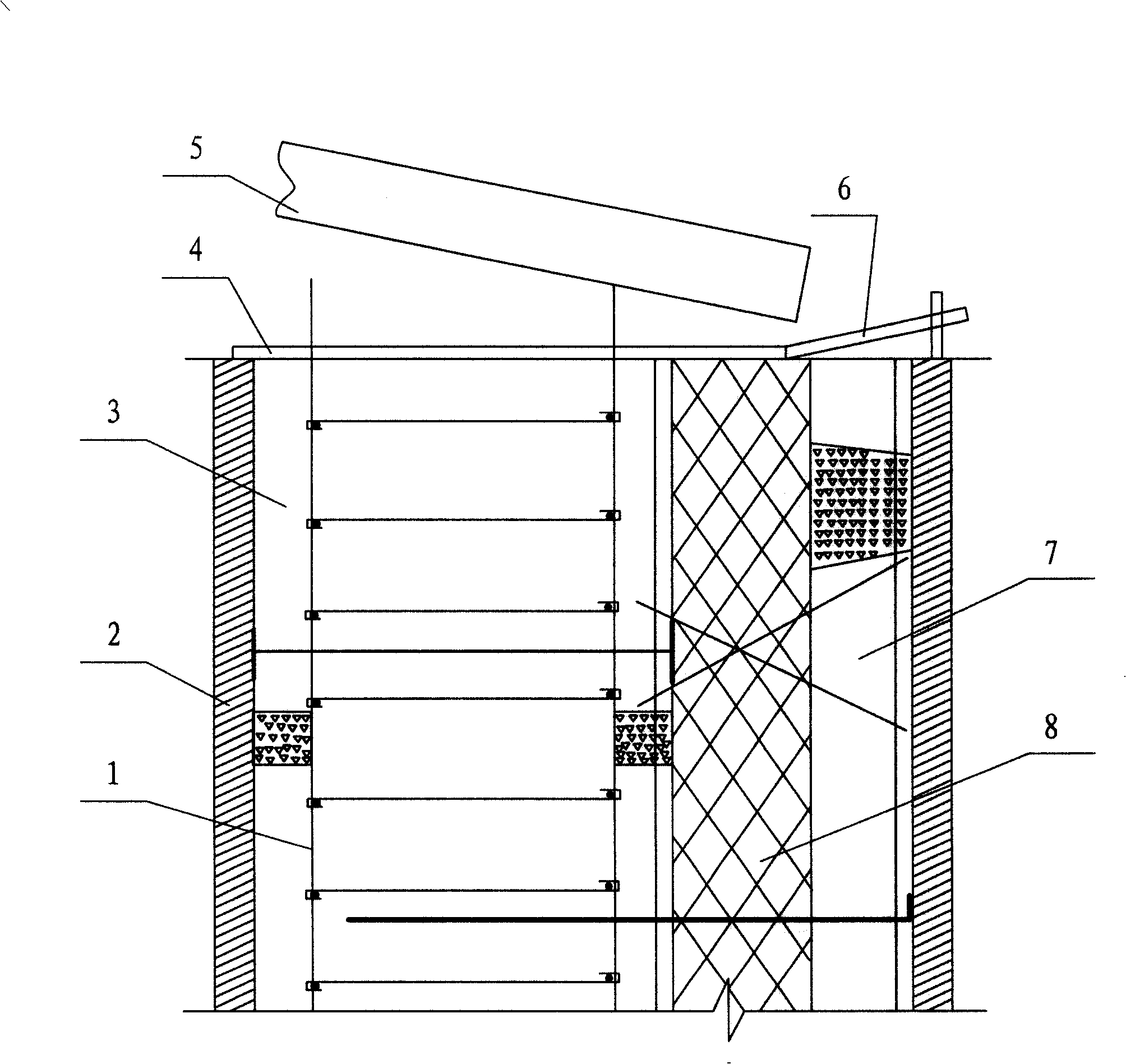

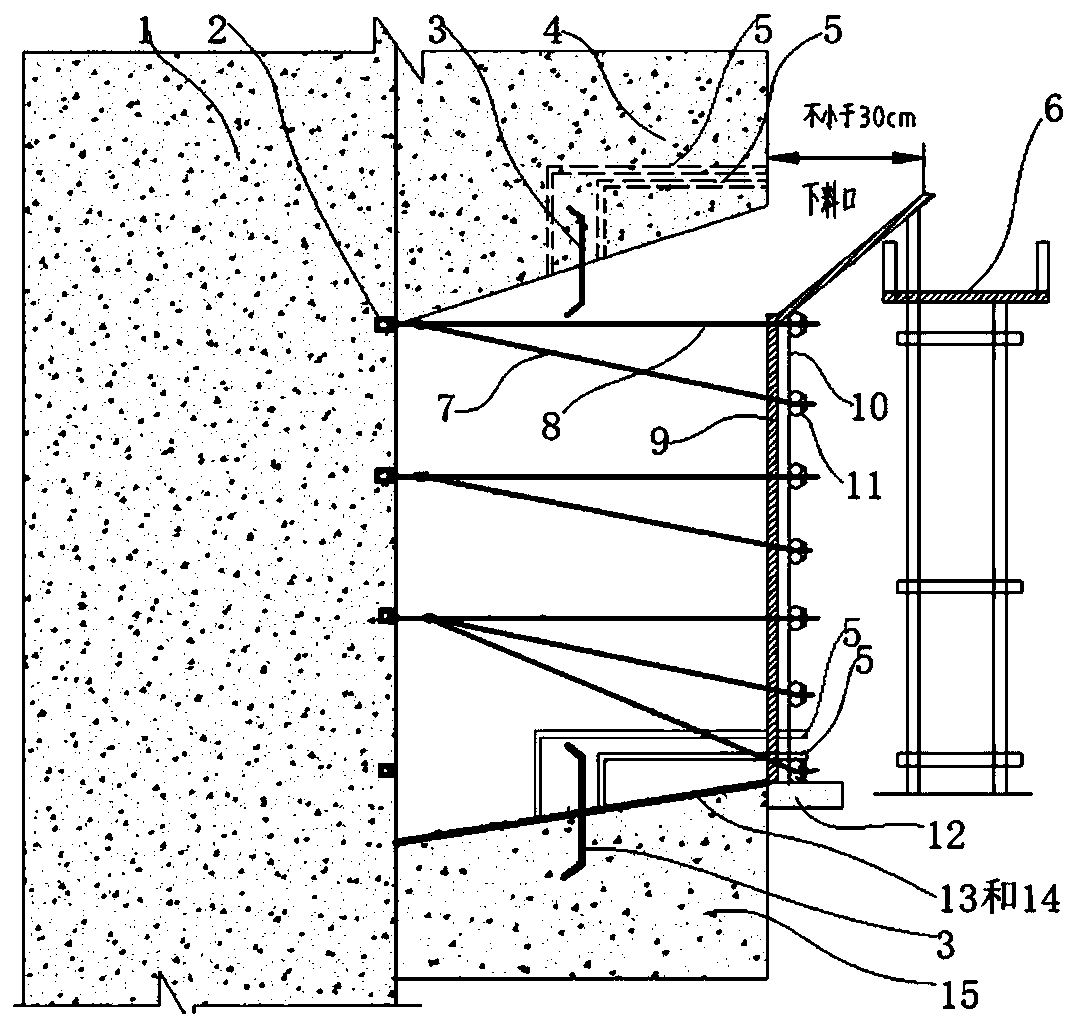

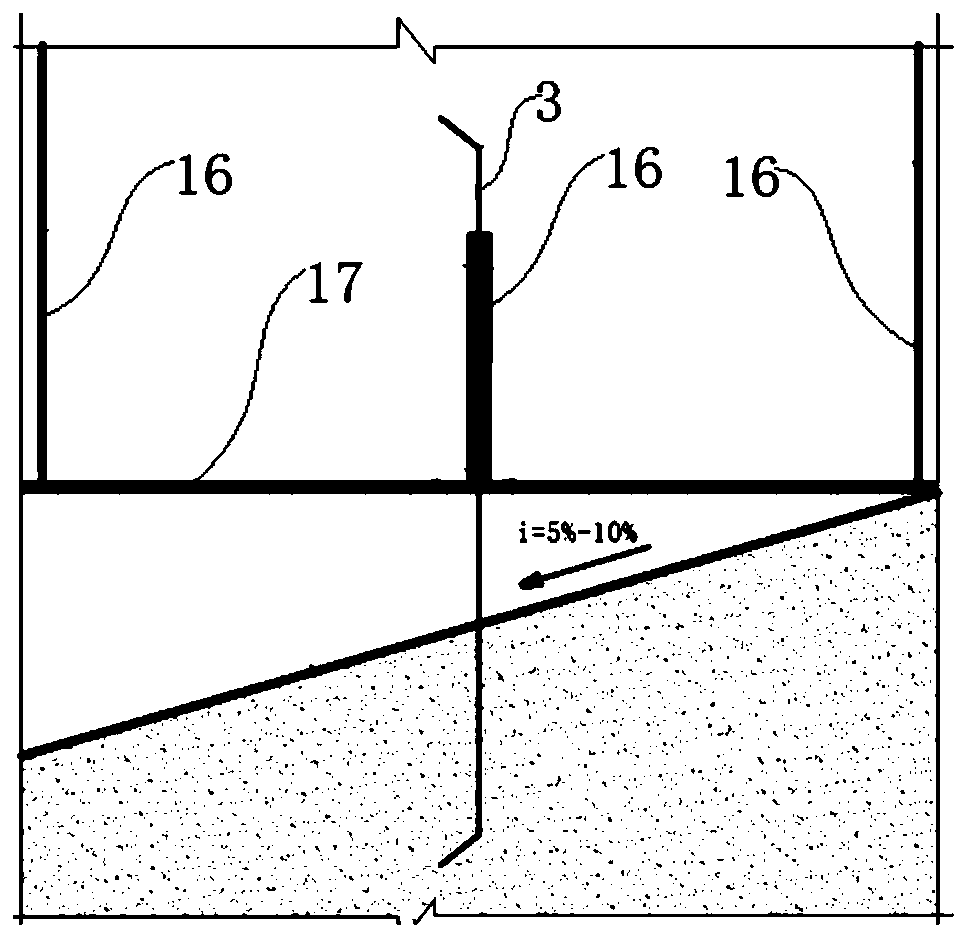

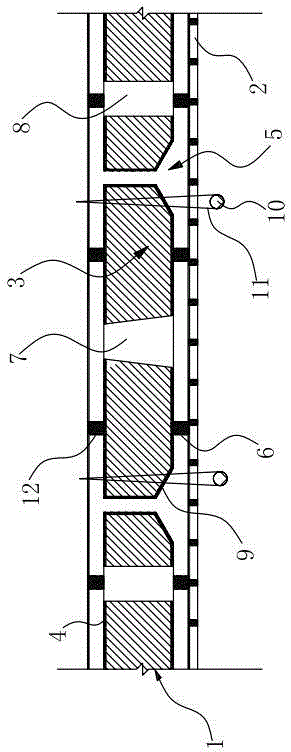

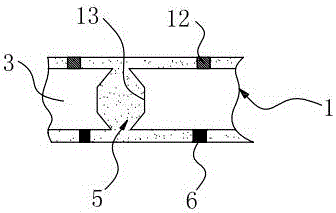

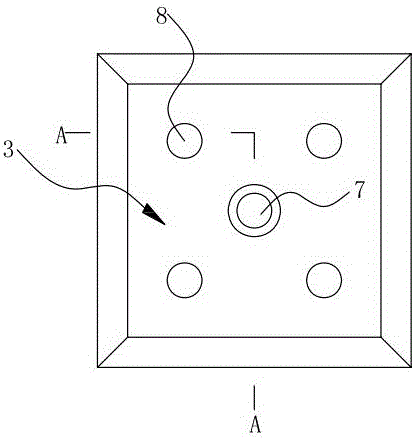

Lining wall concrete placement top-down method based on underground diaphragm wall

ActiveCN103614998ASimple operation processGuaranteed denseExcavationsBulkheads/pilesSlurry wallFloor slab

The invention relates to a lining wall concrete placement top-down method based on an underground diaphragm wall. The lining wall concrete placement top-down method comprises the following steps: (1) the underground diaphragm wall is constructed; (2) a foundation floor slab is constructed; (3) an upper floor slab is constructed; (4) a formwork is erected, an upper layer of lining wall concrete is poured, a steel pipe is pre-buried every 2-3 meters in the upper layer of lining wall concrete, and the lower end of each pre-buried steel pipe is arranged on the top of an inverted groove in the lower portion of an upper lining wall which is formed in a pouring mode; (5) a lower lining wall formwork is erected, wherein the formwork is directly connected with the upper lining wall from the bottom surface of the foundation floor slab and is mounted in a closed mode, pump truck concrete delivery pipes used for pouring a lower layer of lining wall concrete are inserted in the pre-buried steel pipes to conduct pouring continuously, the concrete is compacted by means of vibration, a micro-expanding agent is added into the concrete, and then pouring of the lining wall concrete is completed. The lining wall concrete placement top-down method based on the underground diaphragm wall is simple in operation process, can sufficiently guarantee that the concrete poured in the lining walls later is compact, accelerates construction progress, and improves construction efficiency.

Owner:MCC TIANGONG GROUP

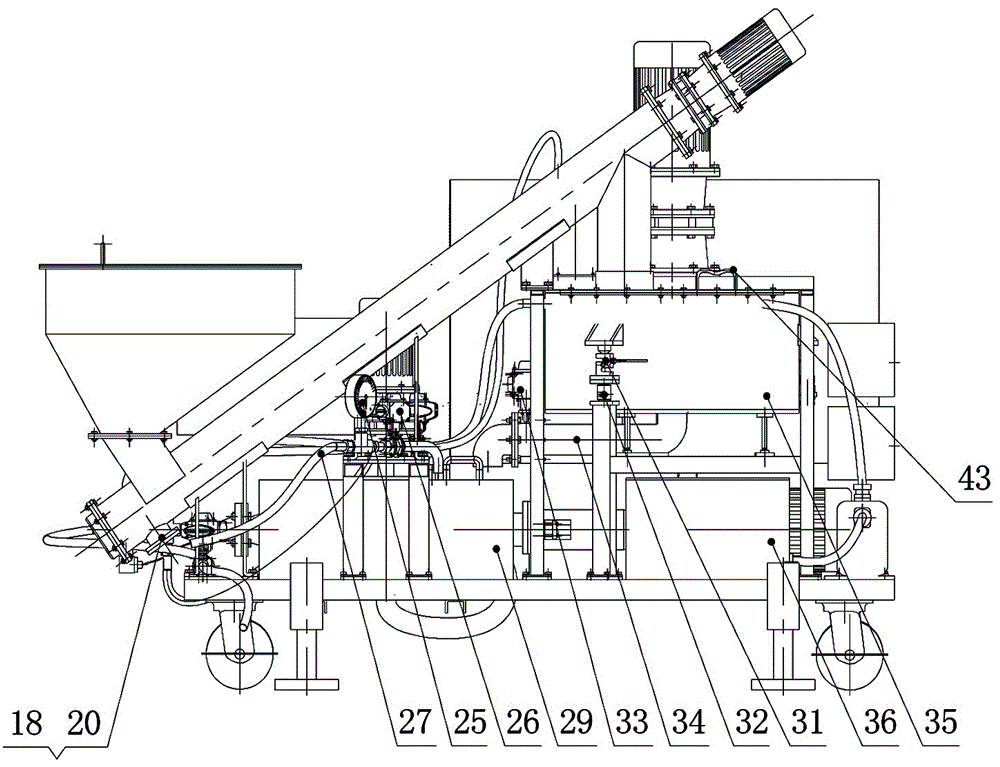

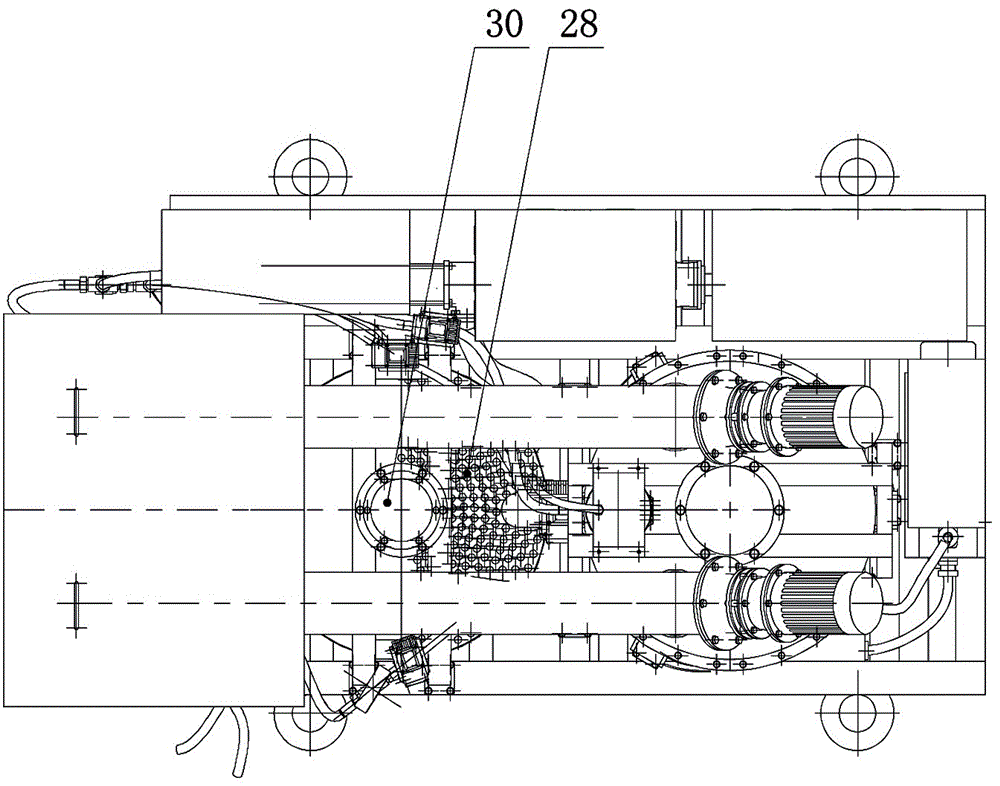

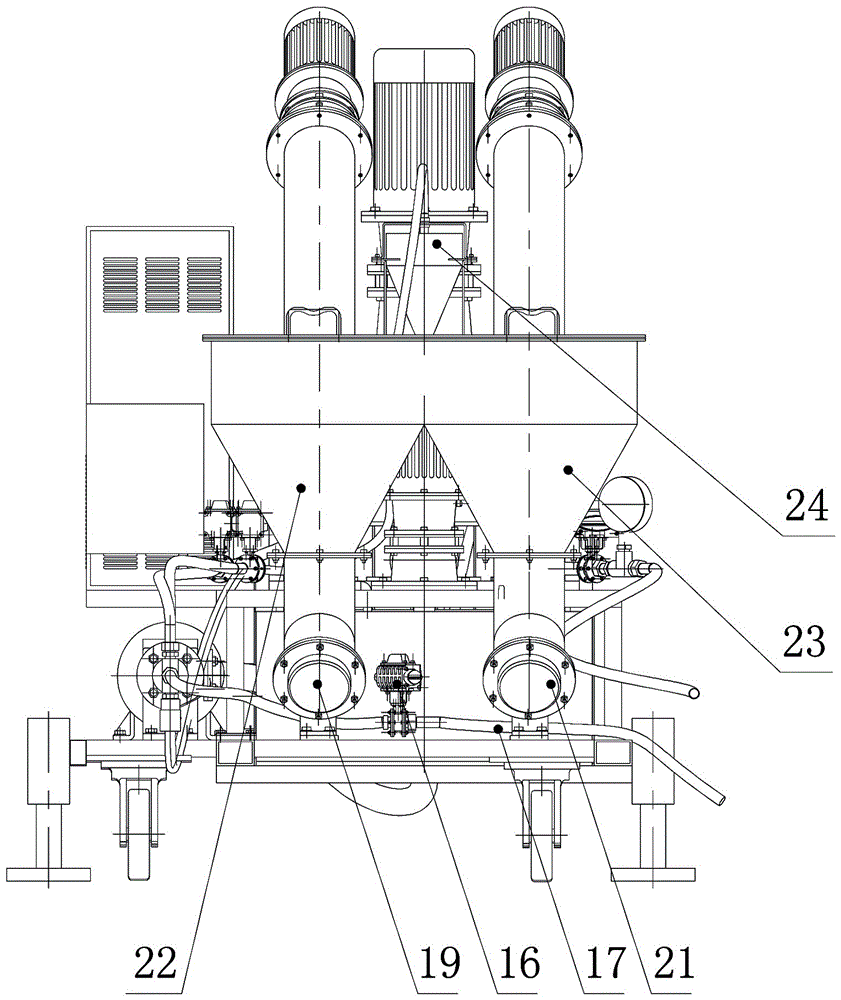

Intelligent large grouting equipment

InactiveCN106638317AControl mix ratioGuaranteed compressive strengthBridge erection/assemblyMicrocomputerFlexural strength

The invention discloses intelligent large grouting equipment, comprising an automatic feeding system, a grout liquidity auto-detection system, a weighing system, a control center system, a high-speed stirring system, a low-speed stirring system, an automatic grouting system, a cleaning system, an automatic water-adding system and a grout circulating loop system; a grouting agent charging tank is connected to the lower portion of a grouting agent feeding pipe, and cleaning outlet II is positioned below the grouting agent feeding pipe; a high-speed stirring barrel is fixed to a triangular frame through a weighing sensor and is measured and controlled via a microcomputer; the large grouting equipment also comprises a backup power system and a cleaning system. The intelligent large grouting equipment has the function of automatically metering raw material in static discharging state, accurate control for grout matching ratio is ensured, and effective guarantee is provided for grout compressive strength, flexural strength and performance indexes; the system can automatically detect the liquidity of grout, an operator needs to carry out irregular detection in non-fixed batches, and unqualified grout is avoided being pressed into a beam duct.

Owner:柳州市邱姆预应力机械有限公司

Induced joint structure for basement joint control and construction method

ActiveCN110552431AReduce constraintsAccurate locationBuilding insulationsSewer pipelinesVertical barBasement

The invention discloses an induced joint structure for basement joint control. A plurality of outer side horizontal bars, a plurality of inner side horizontal bars and a plurality of vertical bars arearranged inside a concrete main body; induced joints are arranged on the inner side of the inner side horizontal bars; the inner side horizontal bars break off on the two sides of the induced joints;the induced joints adopt a semi-arc structure extending vertically; an inwards concave induced joint groove is arranged at the arc midpoint of the semi-arc structure, so that under the action of theinduced joints, shrinkage cracks of the concrete main body occur according to preset traces; the vertical section where the shrinkage cracks exist is vertical to the length direction of the inner sidehorizontal bars; waterstop rings are arranged on the positions of the outer side horizontal bars on the two sides of the induced joints; a plurality of later injection pipes are vertically arranged at the vertical section wherein the induced joints are arranged. According to the invention, the technical problems that irregular cracks are generated, joint positions are uncontrollable in the basement, leakage is likely caused at the later joints and sealing is not easy to carry out, and leaked water cannot be collected, are solved.

Owner:CHINA FIRST METALLURGICAL GROUP

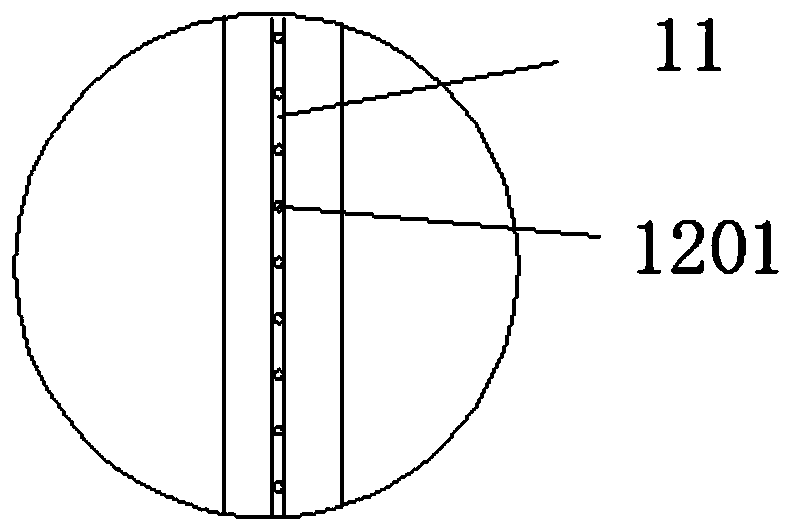

Rib-grouting body interface mechanical property testing system and method

PendingCN111707562ASmall footprintEasy to placeForce measurementMaterial analysis by optical meansStructural engineeringMechanical engineering

Owner:SHANDONG JIANZHU UNIV +2

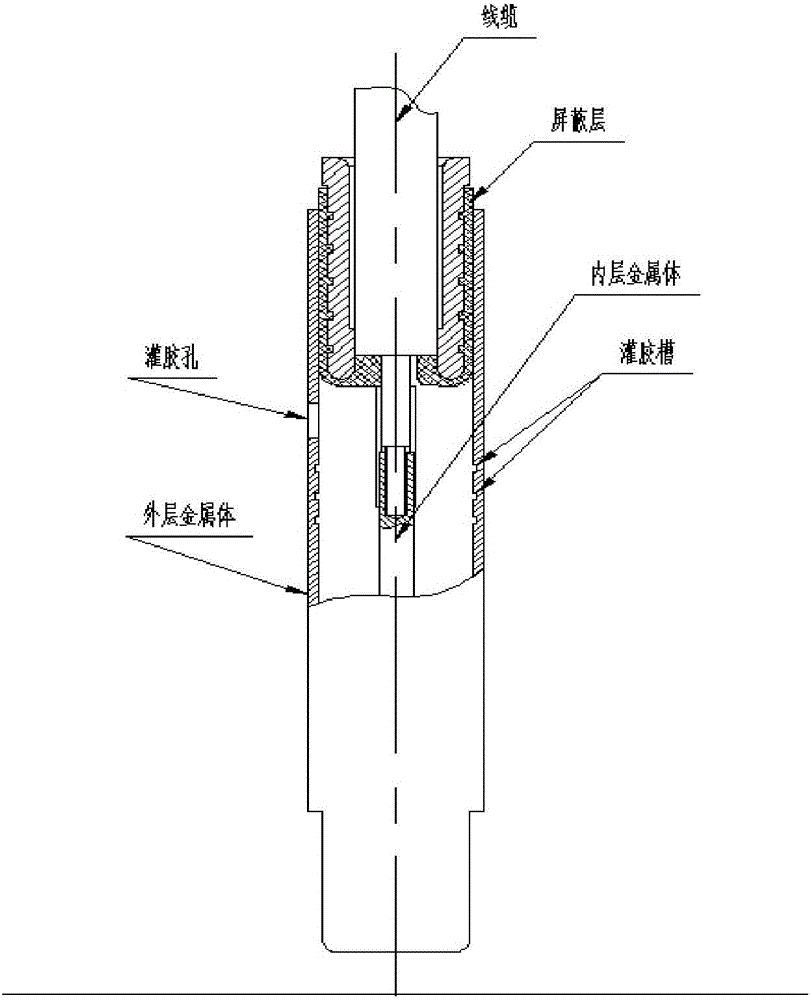

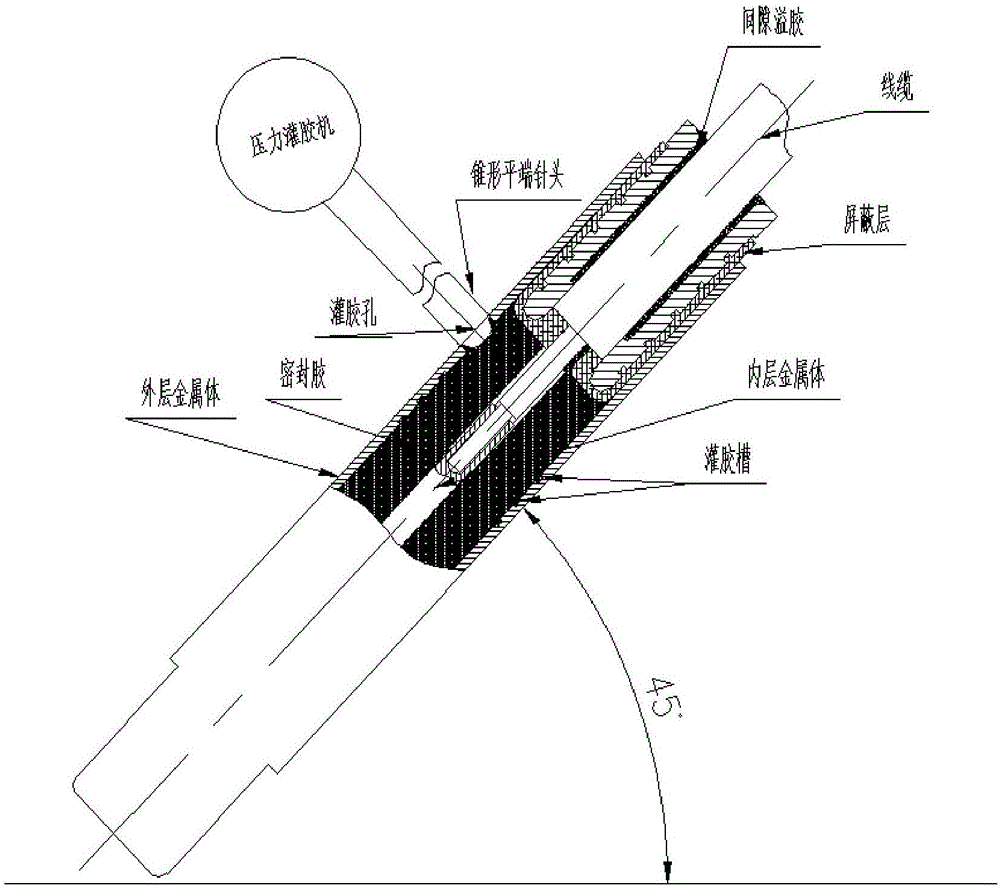

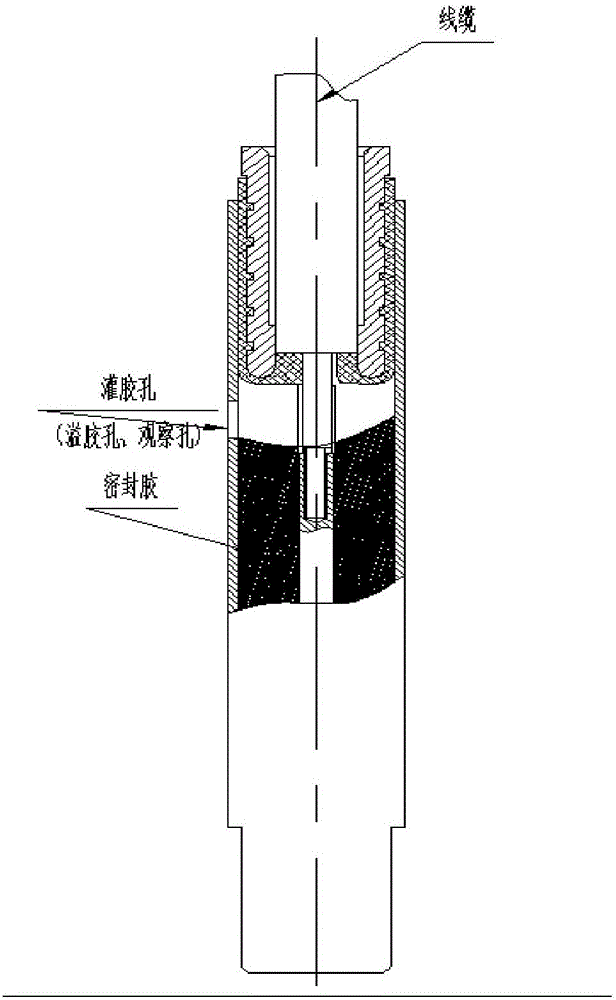

Assembly and encapsulation method of high-frequency elongate contact piece with cable

ActiveCN106785792AReliable pottingSelf-sealingContact member cases/bases manufactureElectrical performanceElectrical connector

The invention relates to an assembly and encapsulation method of a high-frequency elongate contact piece with a cable. The assembly and encapsulation method comprises the following steps of opening an encapsulation hole with a diameter slightly smaller than the maximum diameter of an encapsulation needle head in an outer-layer metal body above a part needed to be encapsulated of an electrical connector by 1-2 millimeters; assembling the cable and the electrical connector to form a high-frequency contact piece which is not sealed; inclining the high-frequency contact piece at an angle of 45 degrees, hermetically connecting the encapsulation needle head and the encapsulation hole of the electrical connector, and performing pressurization and encapsulation until an adhesive liquid overflows out of a tail press part of the high-frequency contact piece; and vertically placing and curing the high-frequency contact piece, wherein a part of adhesive liquid overflows out of the encapsulation hole. The technical operation and method is practical, and reliable encapsulation of the elongate contact piece which is automatically sealed, has high reliable electrical performance and is provided with the cable is achieved.

Owner:杭州航天电子技术有限公司

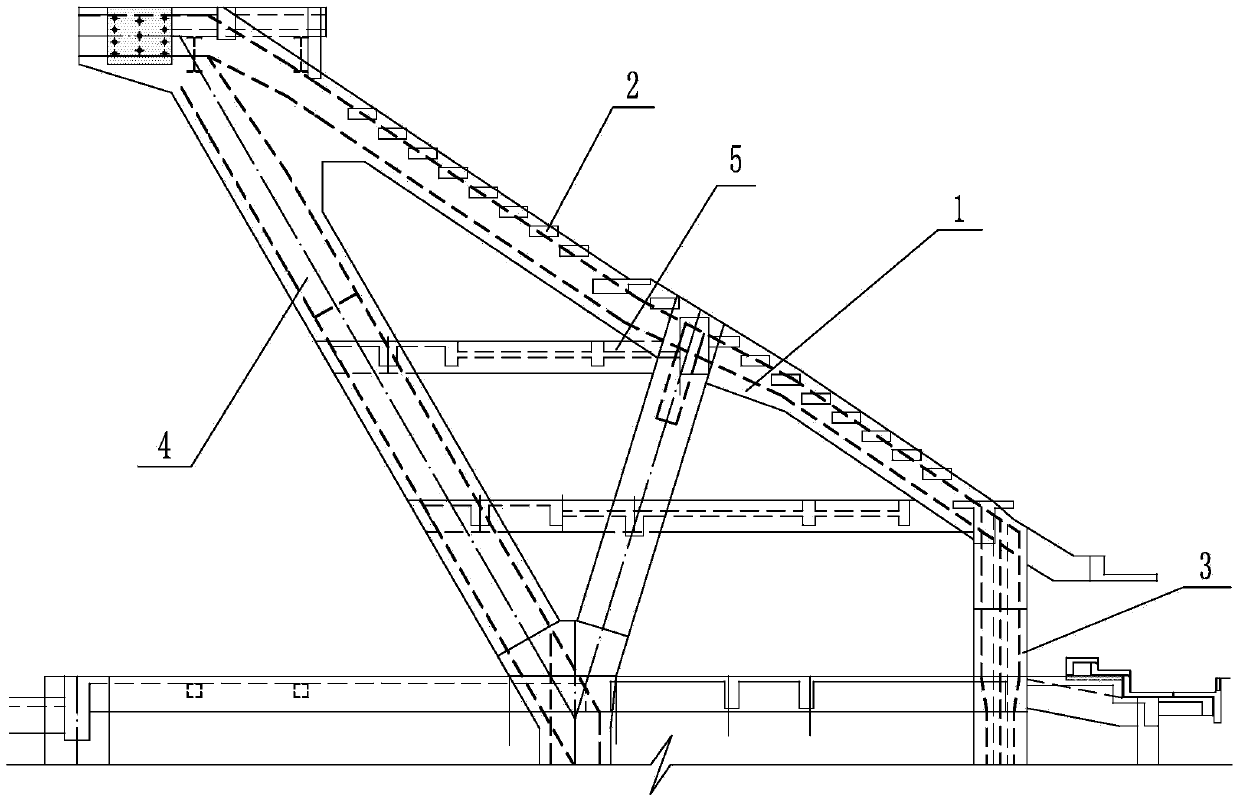

Oblique beam for grandstand of stadium and construction process for oblique beam

ActiveCN104213728AGuaranteed viewing effectSolve the problem of excessive horizontal thrustGrandstandsBuilding constructionsUpper floorPhysics

The invention belongs to the technical field of construction for oblique beams for grandstands of stadiums, and particularly relates to an oblique beam for a grandstand of a stadium and a construction process for the oblique beam. The oblique beam for the grandstand of the stadium is characterized by mainly comprising an oblique beam body; the lower end of the oblique beam body is connected with the upper end of a first-layer column through casting; the middle and the upper end of the oblique beam body are connected with a Y-shaped column through casting; two sides of the oblique beam body and the oblique beam body are provided with lugs through casting; the lugs are higher than the upper surface of the oblique beam body. The oblique beam can ensure the visual effect of upper-layer spectators under the condition of a certain inclination angle.

Owner:ZHEJIANG YIJIAN CONSTR GROUP

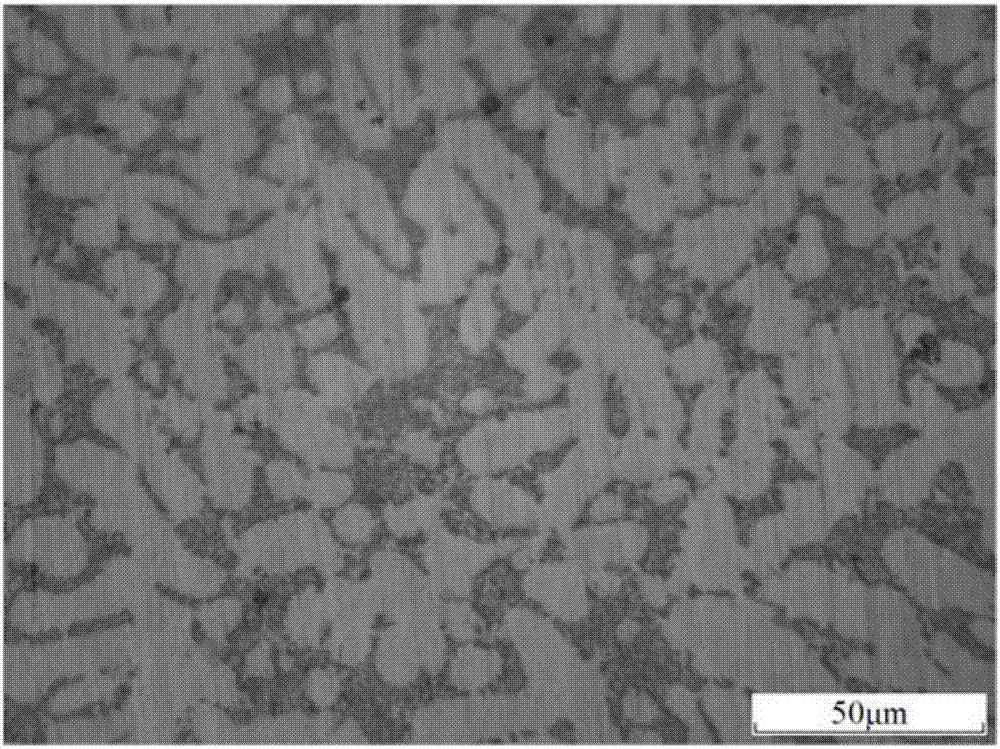

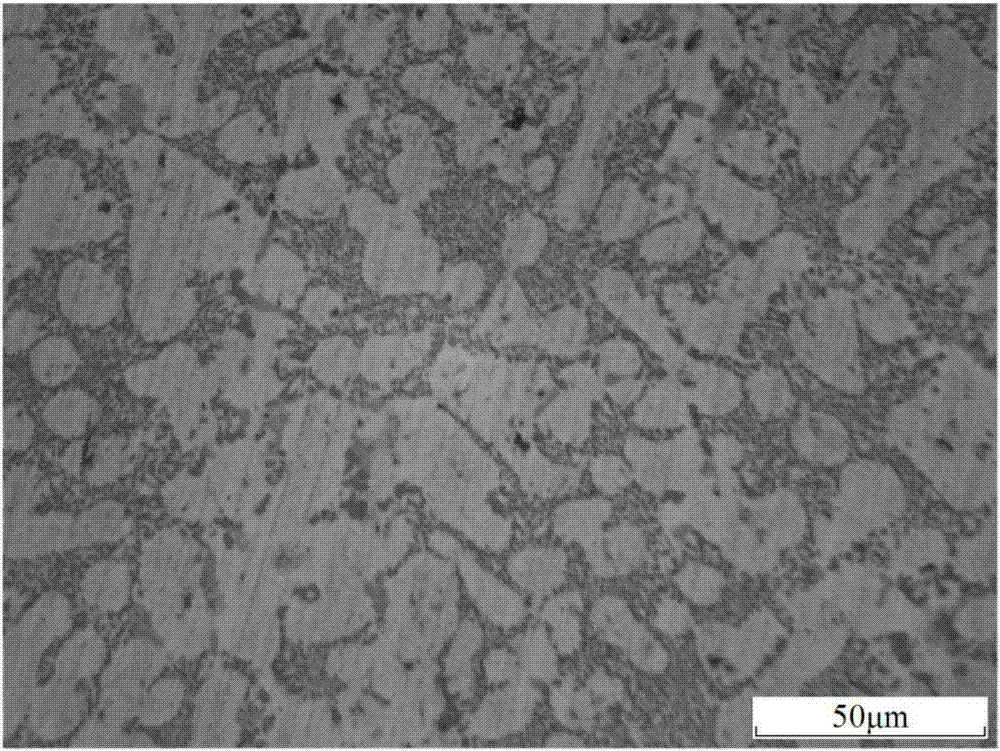

Zr and Sr compound microalloyed and Mn microalloyed high toughness Al-Si-Cu serial cast aluminum alloy and preparation method thereof

A Zr, Sr composite micro-alloyed and Mn-alloyed high-strength Al-Si-Cu cast aluminum alloy and a preparation method thereof, characterized in that the aluminum alloy is mainly composed of aluminum, silicon, copper, manganese, magnesium, Composed of zinc, zirconium, strontium and iron, wherein the mass percentage of silicon (Si) is 8.28-8.41%, the mass percentage of copper is 2.06-2.29%, the mass percentage of manganese is 0.472-0.483%, and the mass percentage of zirconium is 0.187 ~0.192%, the mass percentage of strontium is 0.0334~0.0378%, the mass percentage of iron is 0.142~0.147%, and the balance is aluminum and a small amount of impurity elements. The as-cast structure of the aluminum alloy of the present invention is dense, and the average value of the unnotched impact toughness at room temperature measured by the as-cast alloy is 18.386366 J / cm2, and its tensile strength is 238.85 MPa, elongation is 7.06%, and the temperature is 37 ° C in 3.5% NaCl aqueous solution. The average uniform corrosion rate is 0.324870443 mm / y, which can meet the manufacturing needs of large complex thin-walled high-strength cast aluminum alloy structural parts.

Owner:JIANGSU UNIV

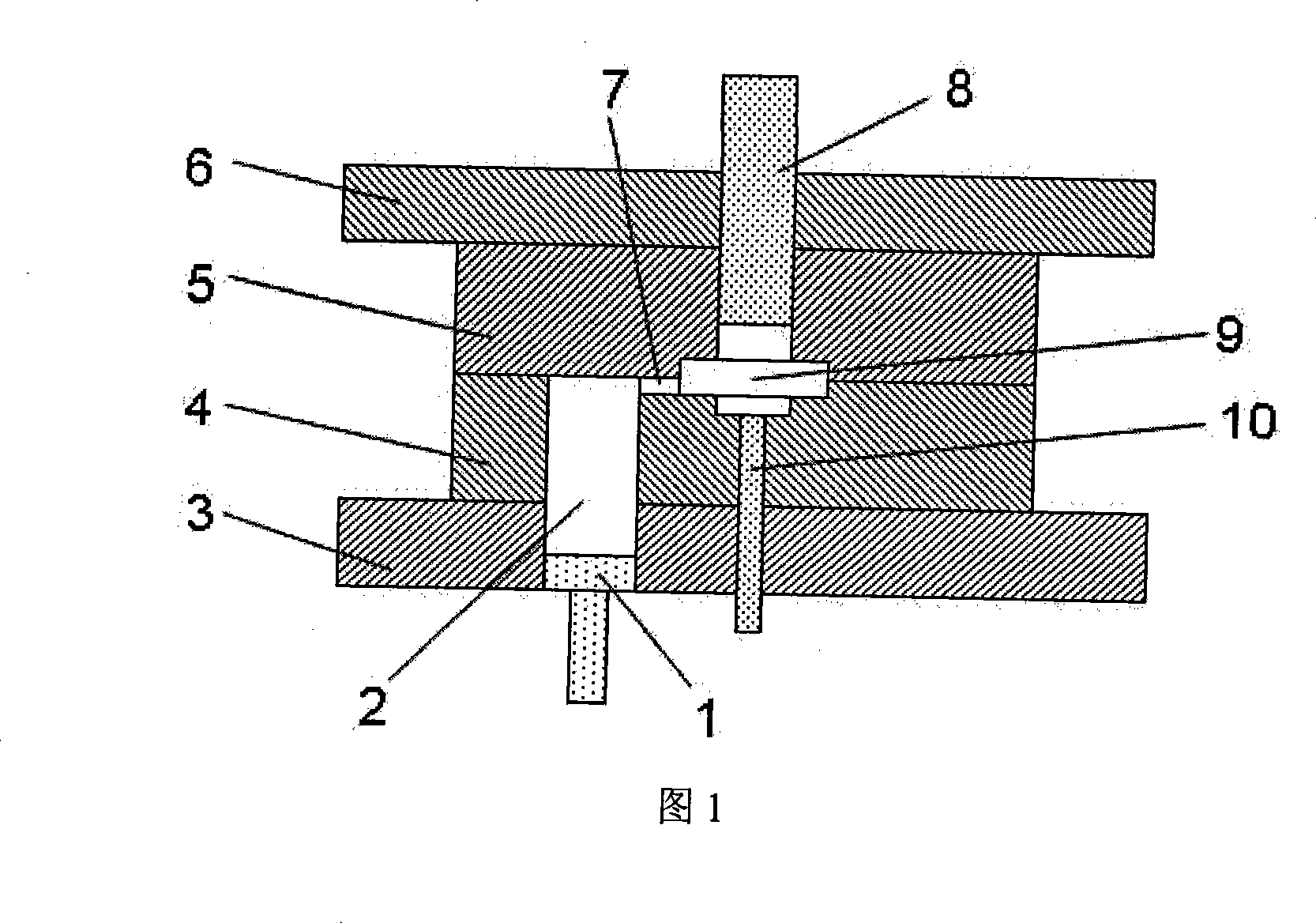

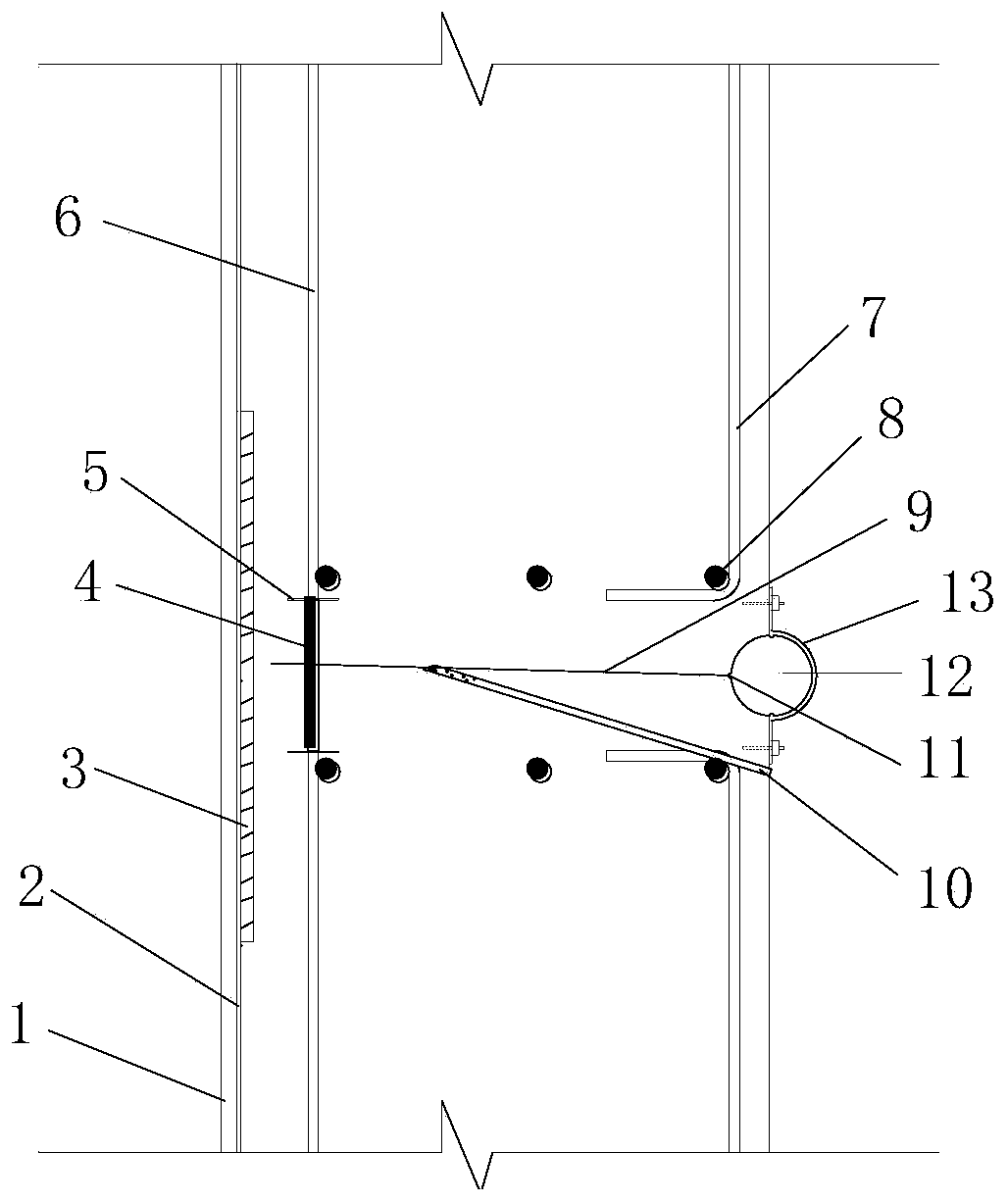

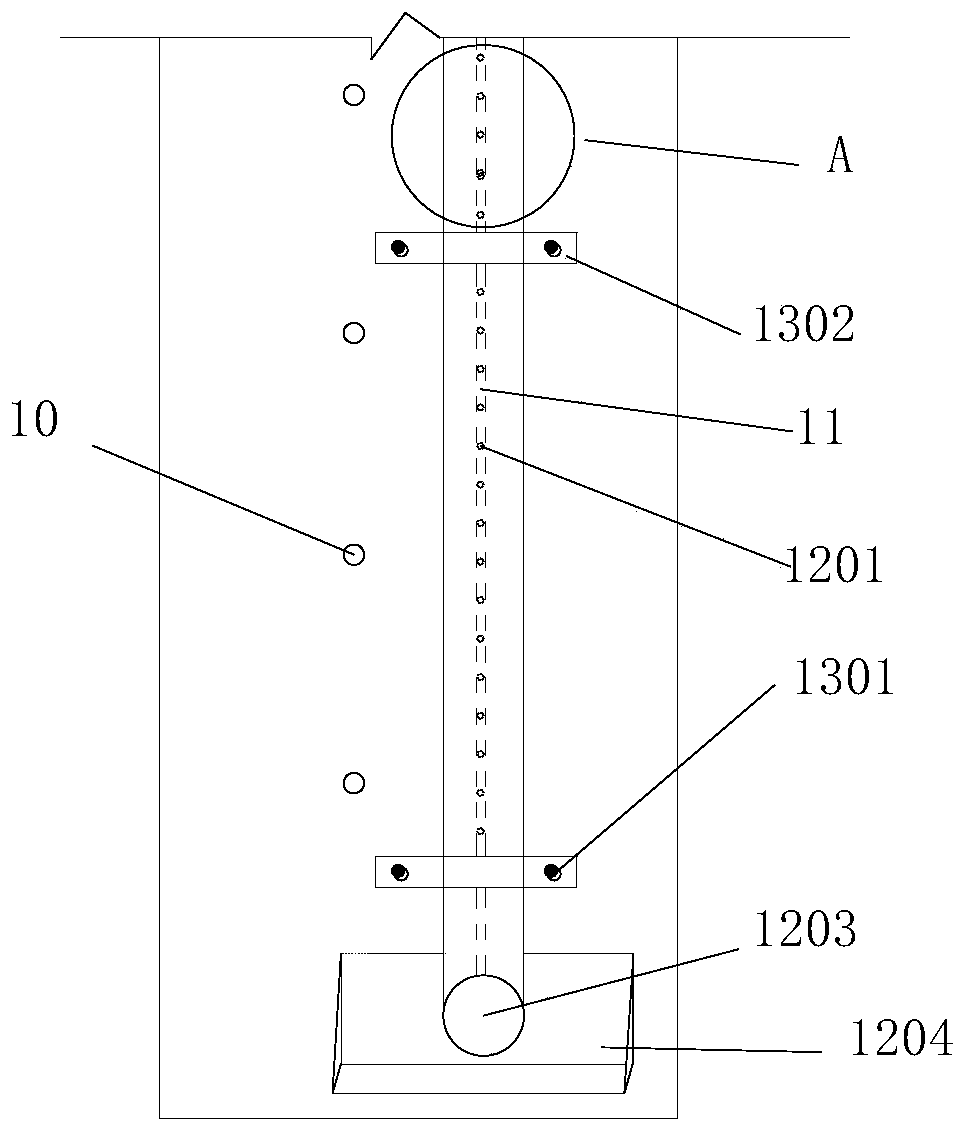

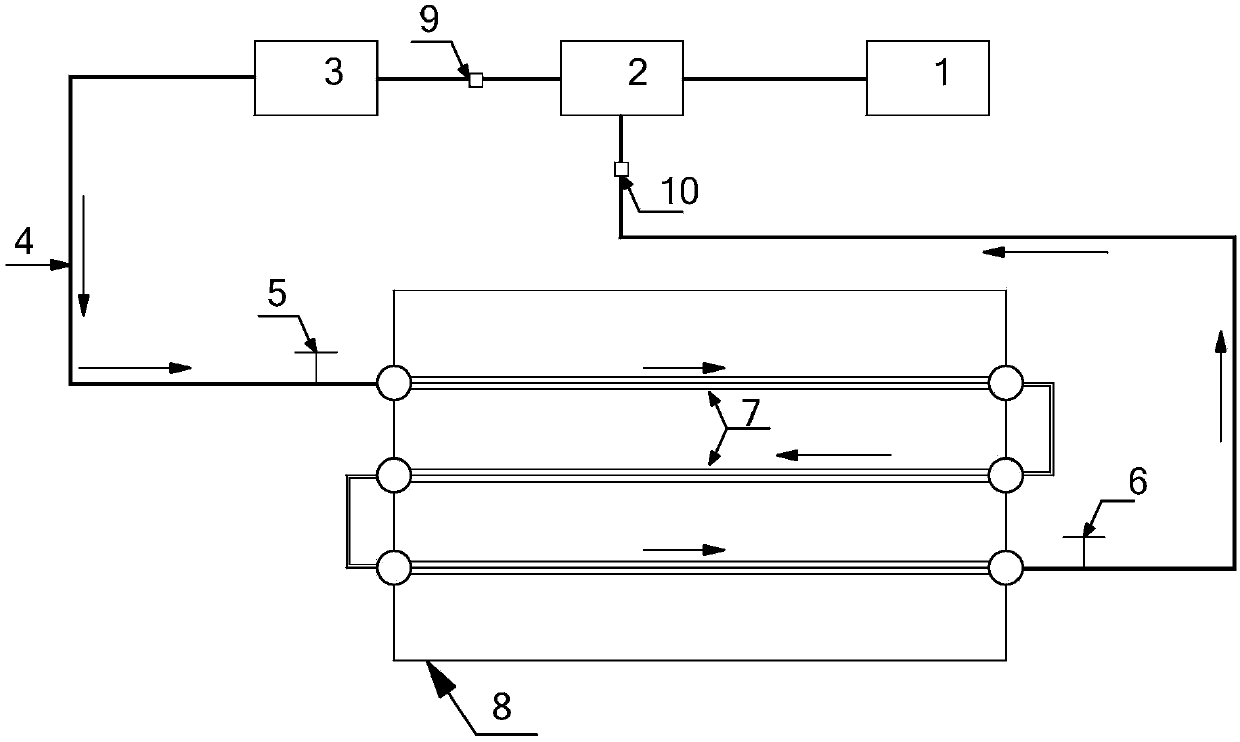

Serial-connection circulating pressure grouting device and pressure grouting method

ActiveCN104196244ATimely detection of blockageGuaranteed denseBuilding material handlingAnchoring boltsEngineeringPressure grouting

The invention discloses a serial-connection circulating pressure grouting device and a pressure grouting method. The device comprises a grout storage barrel, a pressure grouting pump with a pressure gage, a plurality of prestressed pipes, a pressure grouting port valve, a grout outlet valve, an inflow grout thickness detector, an outflow grout thickness detector and pressure grouting pipes. The prestressed corrugated pipes are distributed in a concrete prestressed component in parallel and connected in series to form a prestressed pipe bundle, the grout storage barrel, the pressure grouting pump and the prestressed pipe bundle are sequentially connected in series through the pressure grouting pipes to form a circulating loop, the pressure grouting port valve is arranged on the pressure grouting pipe between the pressure grouting pump and the prestressed pipe bundle, the grout outlet valve is arranged on the pressure grouting pipe between the prestressed pipe bundle and the grout storage barrel, the inflow grout thickness detector is arranged on the pressure grouting pipe between the grout storage barrel and the pressure grouting pump or on the pressure grouting pipe between the pressure grouting pump and the prestressed pipe bundle, the outflow grout thickness detector is arranged on the pressure grouting pipe between the prestressed pipe bundle and the grout storage barrel, compact pressure grouting can be guaranteed through circulating pressure grouting, and grout pipes can be prevented from being blocked.

Owner:SHANGHAI NO 7 CONSTR +1

Concave-convex type wedge joint for underground continuous wall

InactiveCN1715567ALong seepage pathImprove anti-seepage effectArtificial islandsUnderwater structuresSlurry wallEngineering

Owner:上海市特种基础工程设计所 +1

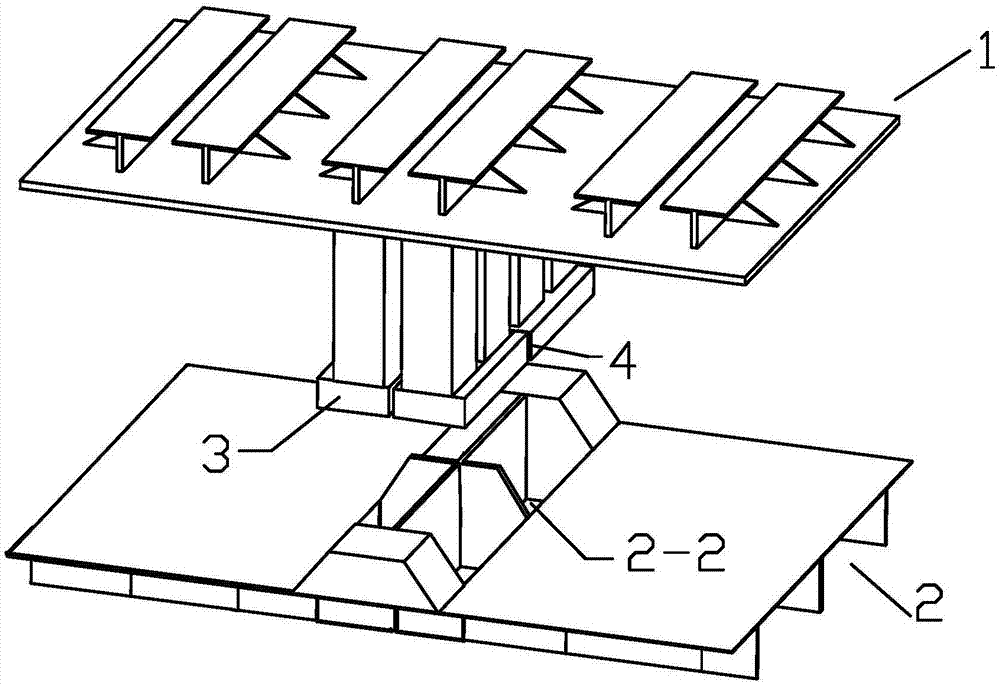

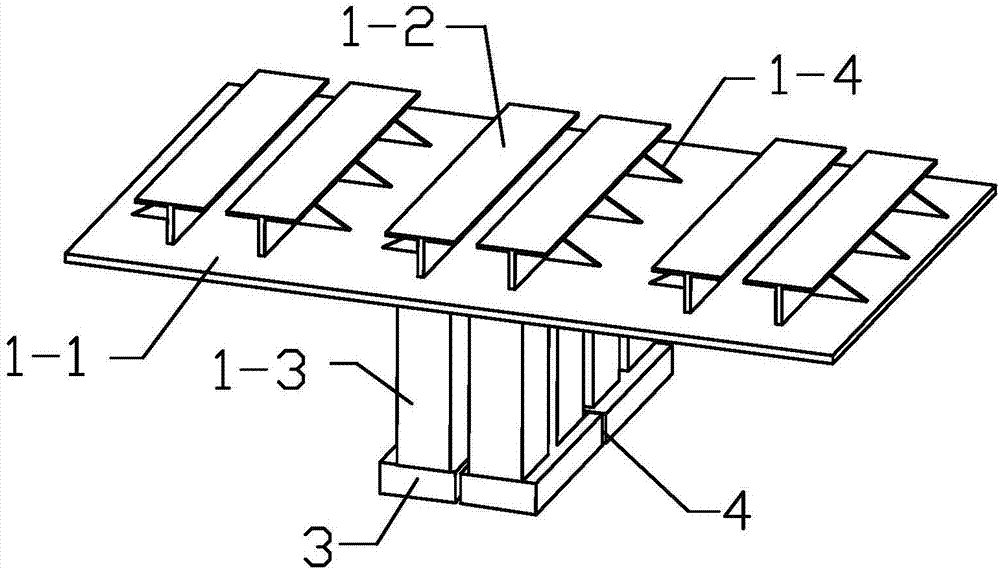

Great-width multi-hole lightweight core formwork and construction method thereof

The invention discloses a great-width multi-hole lightweight core formwork which comprises a lightweight core formwork laid on a to-be-poured concrete hollow floor bottom formwork in advance, wherein pouring areas used for pouring concrete hollow floors are formed between the lightweight core formwork and the bottom formwork and between adjacent lightweight core formworks; a supporting piece used for supporting the lightweight core formwork is arranged between the lightweight core formwork and the bottom formwork; a notch used for enhancing the connection strength of concrete in the pouring areas is formed in the lightweight core formwork; and pouring holes which penetrate through the upper and lower surfaces of the lightweight core formwork and inject concrete into the pouring areas and vibrating holes for performing vibrating compaction on the concrete in the pouring areas are respectively formed in the lightweight core formwork. According to the invention, the problems thin concrete even cavities occur around the central holes of the lightweight core formwork after penetration holes are reserved in the middle of the great-width multi-hole lightweight core formwork and the like are solved, the construction quality is ensured, and the economic benefits are improved.

Owner:QINGDAO NO 1 CONSTR GRP

Method for solving saltpetering problem of water permeable brick

The invention discloses a method for solving the saltpetering problem of a water permeable brick. A specially-made water permeable brick is included, the specially-made water permeable brick comprisesa water permeable surface layer and a water permeable base layer, and the water permeable surface layer and the water permeable base layer are tightly combined into a whole; the water permeable baselayer comprises internal aggregate, and cement, a reinforcing agent and cementing material slurry which are mixed and uniformly coat the surface of the internal aggregate, wherein the internal aggregate, the cement, the reinforcing agent and and the cementing material slurry are mutually bonded; the cementing material slurry in the water-permeable base layer comprises a hydrophilic binder; and thewater-permeable surface layer comprises an external aggregate, and cement, a water repellent, a pigment mixture, an enhancer and cementing material slurry which are mixed and uniformly coat the surface of the external aggregate, and the cementing material slurry comprises a hydrophilic binder, a hydrophilic resin binder and an inorganic binder. The method for solving the saltpetering problem of the water permeable brick achieves the effects of good water permeability, low cost and capability of solving the saltpetering problem of the brick.

Owner:山西大地华基建材科技有限公司

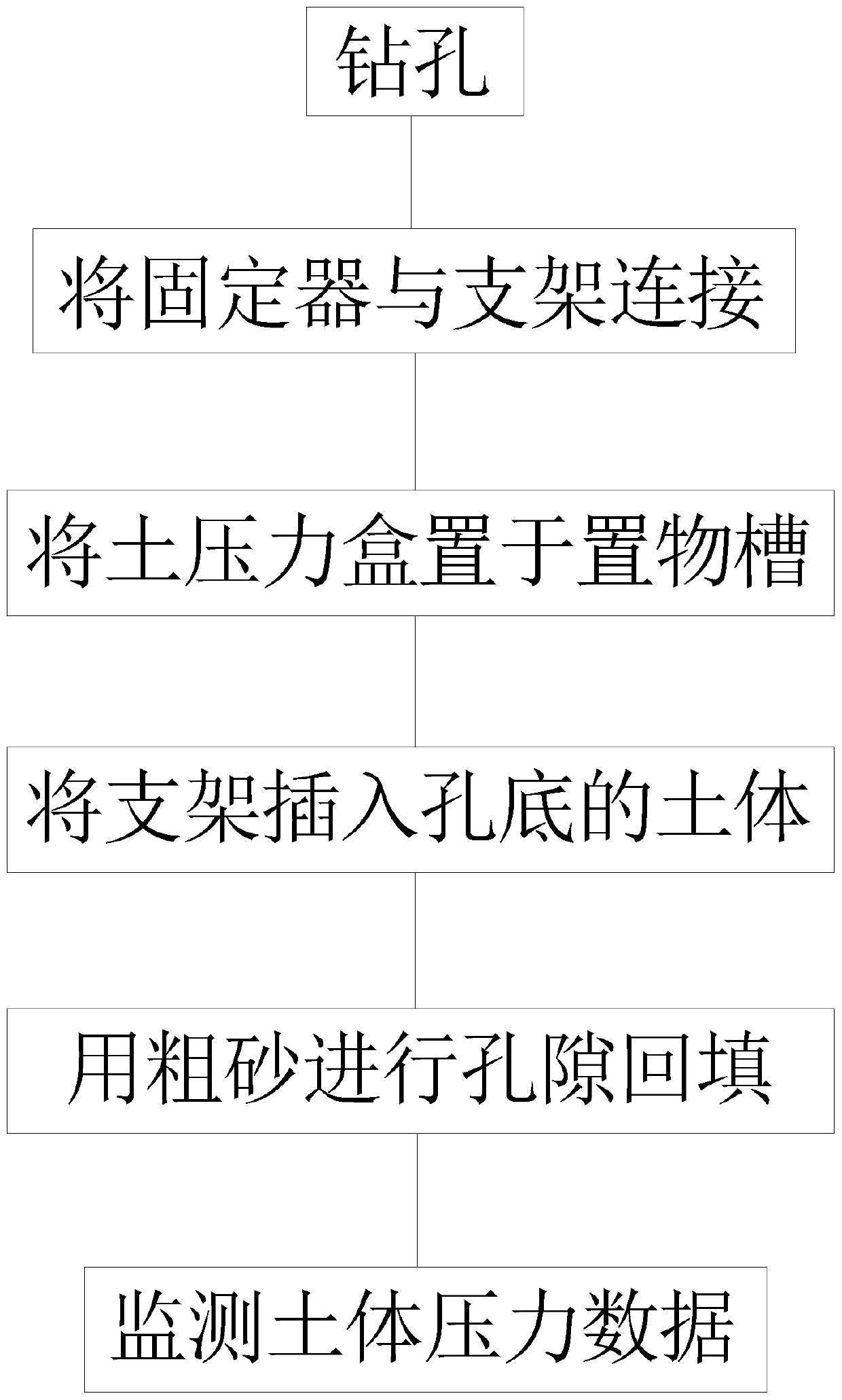

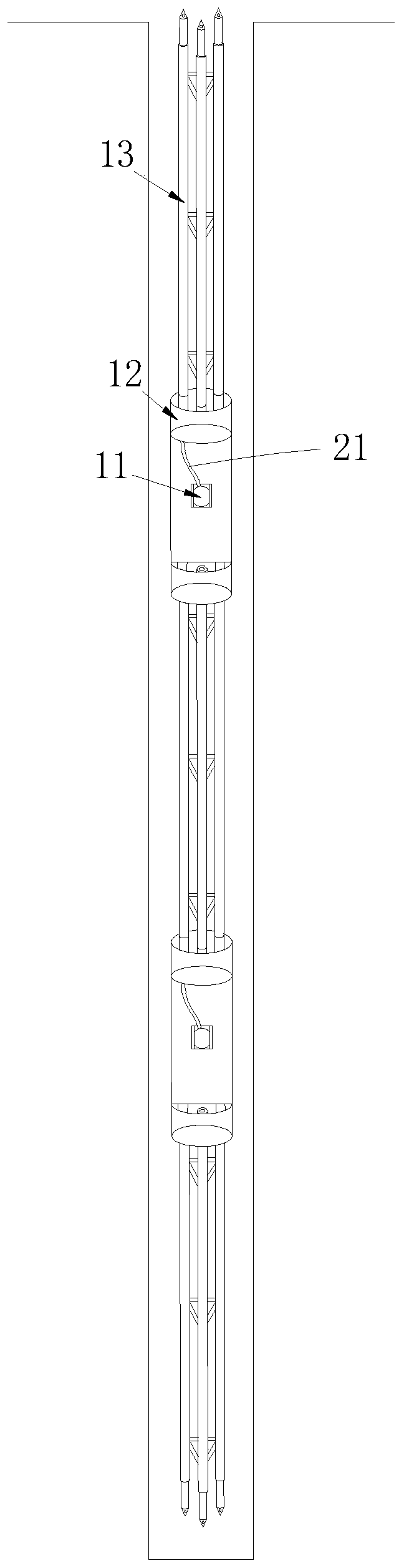

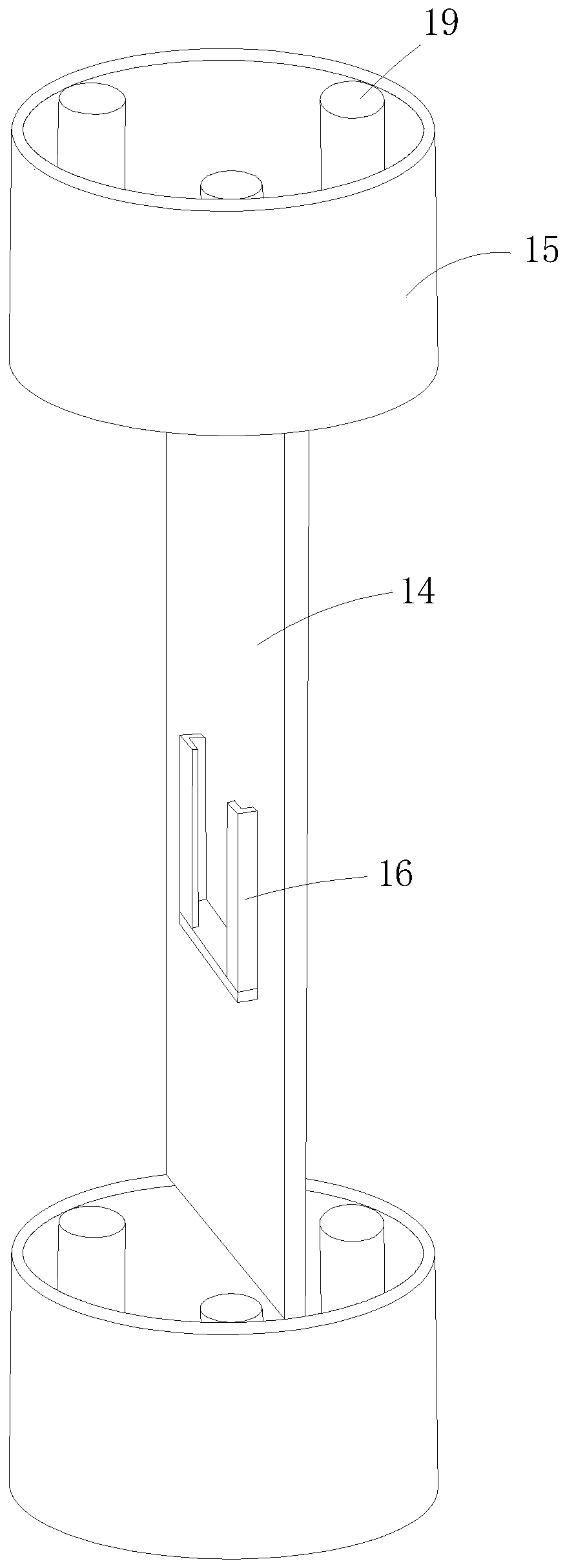

Improved deep soil pressure box mounting method

ActiveCN111021329APrevent rotationImprove installation efficiencyIn situ soil foundationSoil scienceStructural engineering

The invention relates to the technical field of monitoring of soil pressure and discloses an improved deep soil pressure box mounting method. The improved deep soil pressure box mounting method comprises the following specific mounting steps: (1) drilling a hole in a selected buried position until the depth of the hole reaches the required depth; (2) providing a fixing device comprising a fixing plate and two fixing rings which are fixed at two ends of the fixing plate respectively, and connecting the ends of a support frame with the fixing rings; (3) forming a storage groove in the fixing device and placing a soil pressure box in the storage groove; (4) inserting the fixing device and the support frame which are connected with each other into the drilled hole according to the designed depth and direction, and inserting the lower end of the support frame into the soil; (5) backfilling the hole with coarse sand; and (6) monitoring soil pressure data according to the designed requirementafter detecting and calibrating normally. Through the improved deep soil pressure box mounting method, the support frame is used for inserting the fixing device equipped with the soil pressure box into the soil so as to prevent the soil pressure box from rotating, prevent the direction of the soil pressure box from moving, enable the soil pressure box to keep correct orientation all the time andensure the soil pressure monitoring accuracy of the soil pressure box.

Owner:SHENZHEN HONGYEJI GEOTECHNICAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com