Patents

Literature

48results about How to "Prevent ubiquinol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Exterior wall color surface decoration mortar and preparation method thereof

The invention relates to a building material, and in particular relates to an exterior wall color surface decoration mortar and a preparation method thereof. The exterior wall color surface decoration mortar comprises the following raw materials by weight: 20%-30% of white cement, 50%-60% of quartz sand, 0.1%-0.5% of chopped fiber, 10%-20% of heavy calcium carbonate, 0.2%-1% of latex powder, 0.3%-0.5% of cellulose ether, 1%-5% of an inorganic pigment, 0.2%-0.4% of a water repellent, 5%-10% of coal powder ash, 0.1%-0.15% of a defoaming agent, 1%-3% of metakaolin, 0.2%-0.5% of a thixotropic lubricant and 1%-2% of a water reducing agent. The exterior wall color surface decoration mortar has the advantages of crack resistance, weather resistance, good ultraviolet resistance, permanent and uniform color, good whiskering resistance, and the like, can be well combined with various inorganic base layer materials, is good in coating density, and can be widely used in the building fields such as exterior wall decoration and the like.

Owner:KUNSHAN JIANGUO CONCRETE PROD CO LTD

Method for retreading old porcelain brick wall by paint

InactiveCN101586401AAvoid crackingImprove water resistanceCovering/liningsBuilding repairsGlass fiberBrick

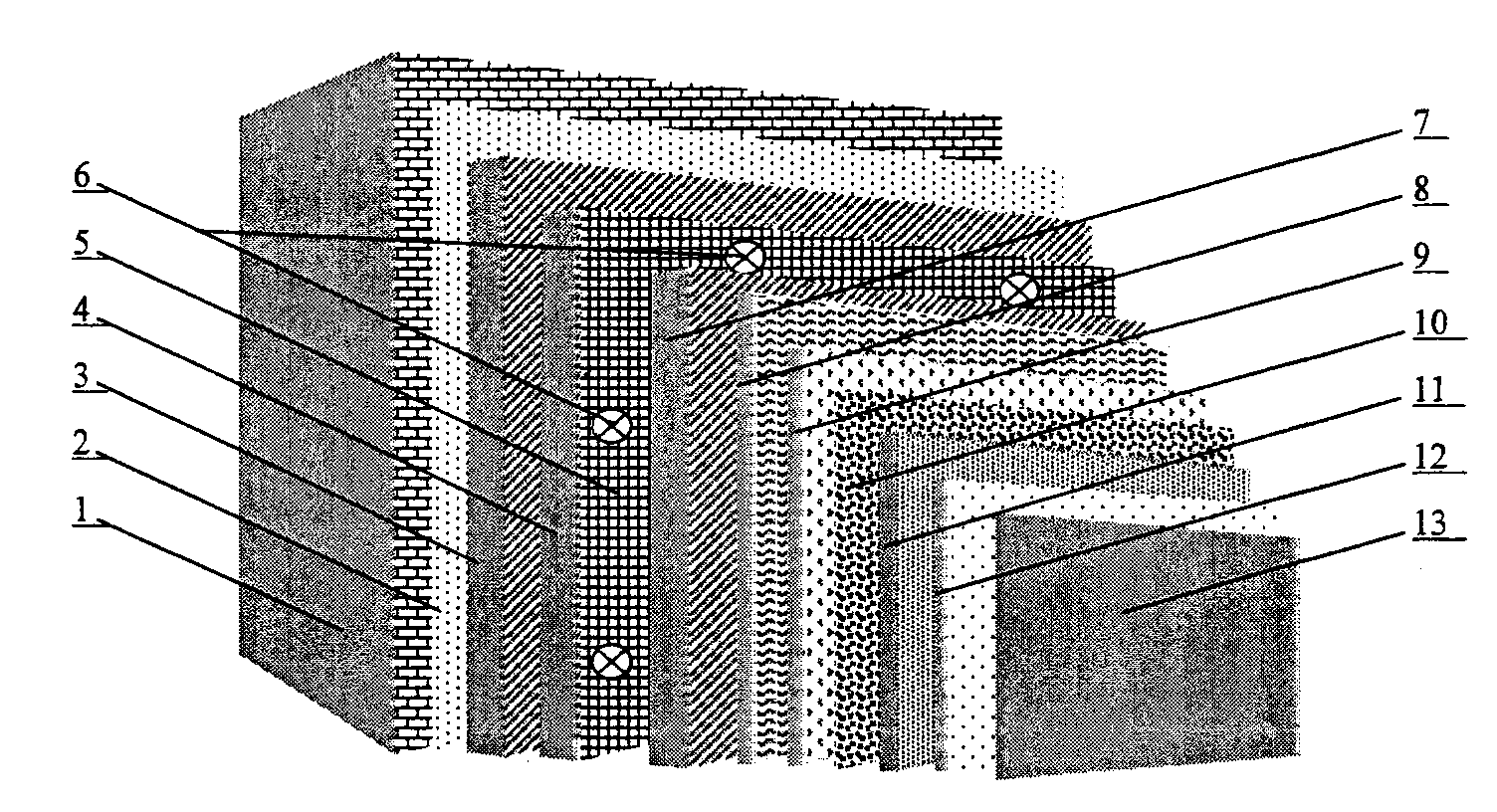

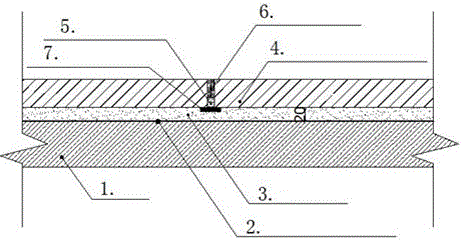

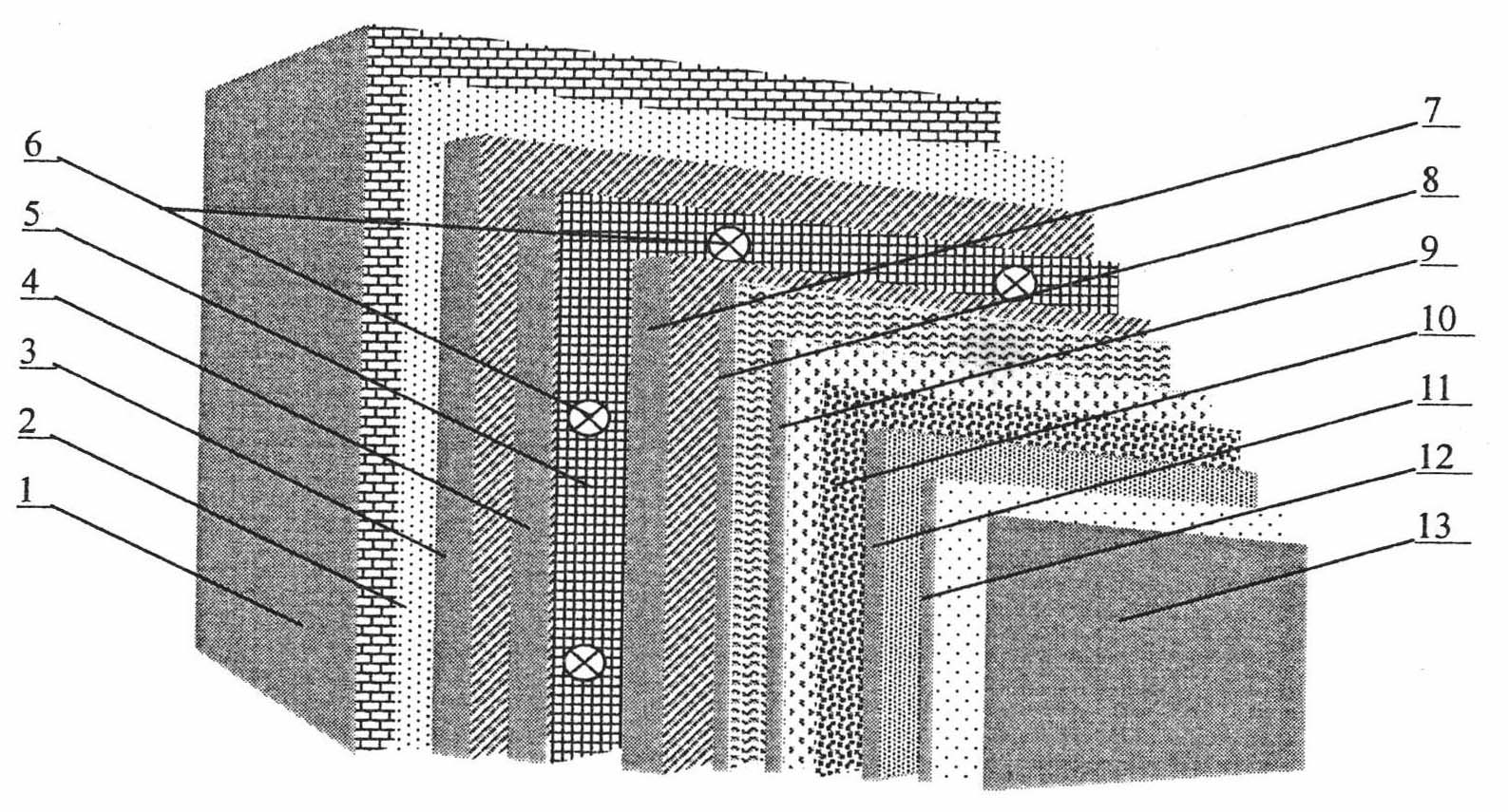

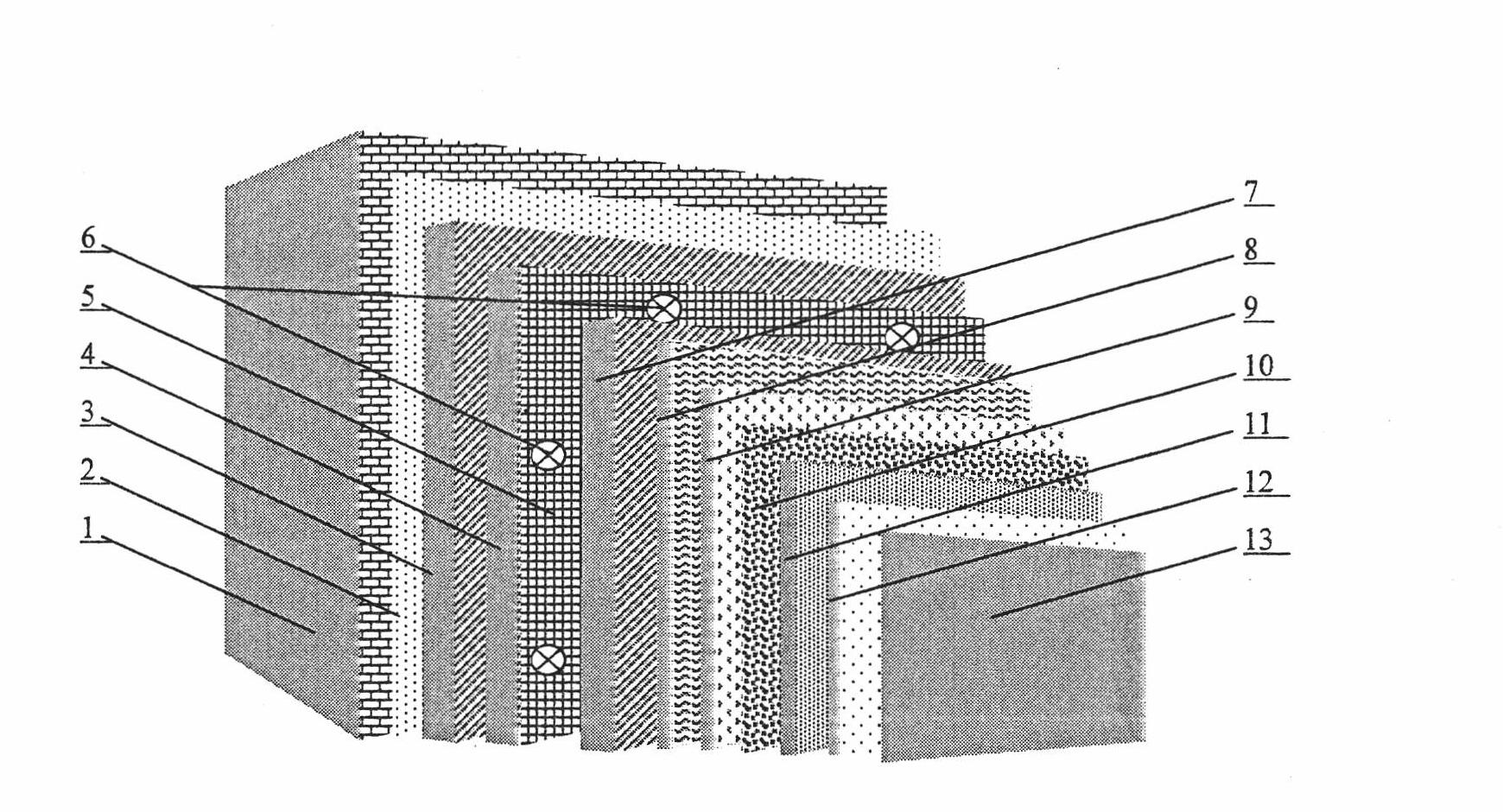

The invention relates to a method for retreading the old porcelain brick wall by the paint, a retreading decorative layer composed of a interface binder layer (2), a first polymer cracking-resistant putty layer (3), a second polymer cracking-resistant putty layer (4), a glass fiber girding cloth (5), a third polymer cracking-resistant putty layer (7), a double-component flexible putty layer (9), a smooth surface putty layer (9), a seal coat layer (10), a middle coating layer (11), a flexible silicone-acrylate latex paint layer (12) and a fluoric-carbon coating varnish layer (13) is formed on the old wall surface porcelain brick of the old wall (1), an anchor nail (6) passes through the glass fiber gridding cloth (5), the second polymer cracking-resistant putty layer (4) and the first polymer cracking-resistant putty layer (3) and is embedded in the old wall (1) for the mechanical reinforcement, all layers above are dried and solidified and are integrated with the old wall (1) firmly to complete the retread of the old wall surface. The construction cost and the labor strength are low, the old porcelain brick on the wall surface can not fall off, the decorative is high.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Anti-efflorescence joint sealing mortar

The invention relates to an anti-efflorescence joint sealing mortar. The motor comprises, by weight, 210-250 parts of ordinary Portland cement, 25-35 parts of high alumina cement, 440-540 parts of sand, 40-60 parts of silica fume, 180-220 parts of coal ash, 3-8 parts of bentonite, 2-4 parts of redispersable latex powder, 1-1.5 parts of cellulose ether, 2-3 parts of a wood fiber, 0.2-0.6 parts of citric acid, and 3-5 parts of a stearate. The anti-efflorescence joint sealing mortar provided in the invention allows the ordinary Portland cement and the high alumina cement to be mixed according to a ratio of 6:1-10:1 through a compound technology, so factors causing the mortar efflorescence are fundamentally eliminated, the compactness of the mortar is improved, the mortar aperture number is reduced, and no efflorescence phenomenon appearance in the use process of the mortar is guaranteed.

Owner:奥捷科技股份有限公司

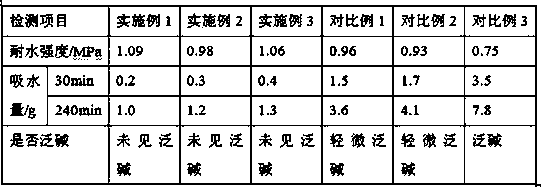

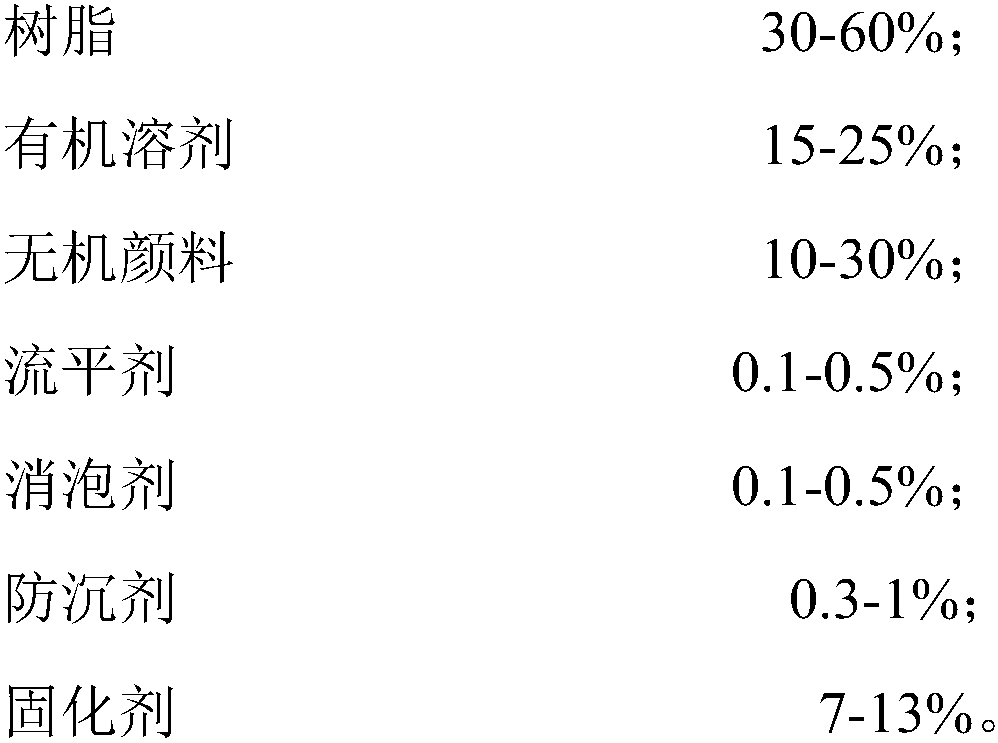

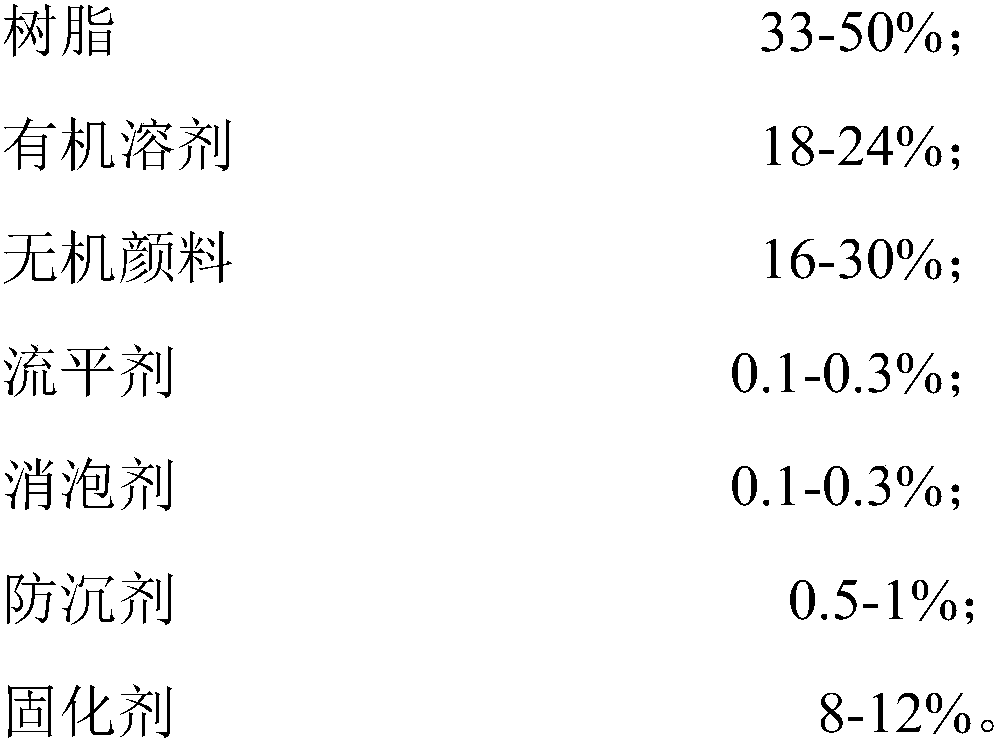

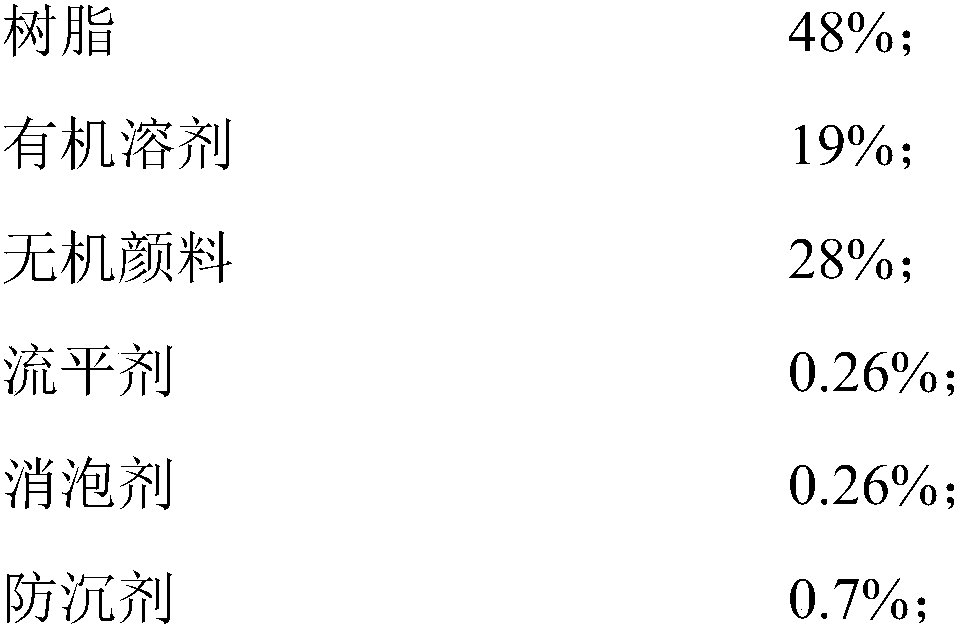

Permeable concrete pavement protection agent and preparation method thereof

ActiveCN106010186ASolve weather resistancePrevent ubiquinolPolyurea/polyurethane coatingsRoad surfaceBond properties

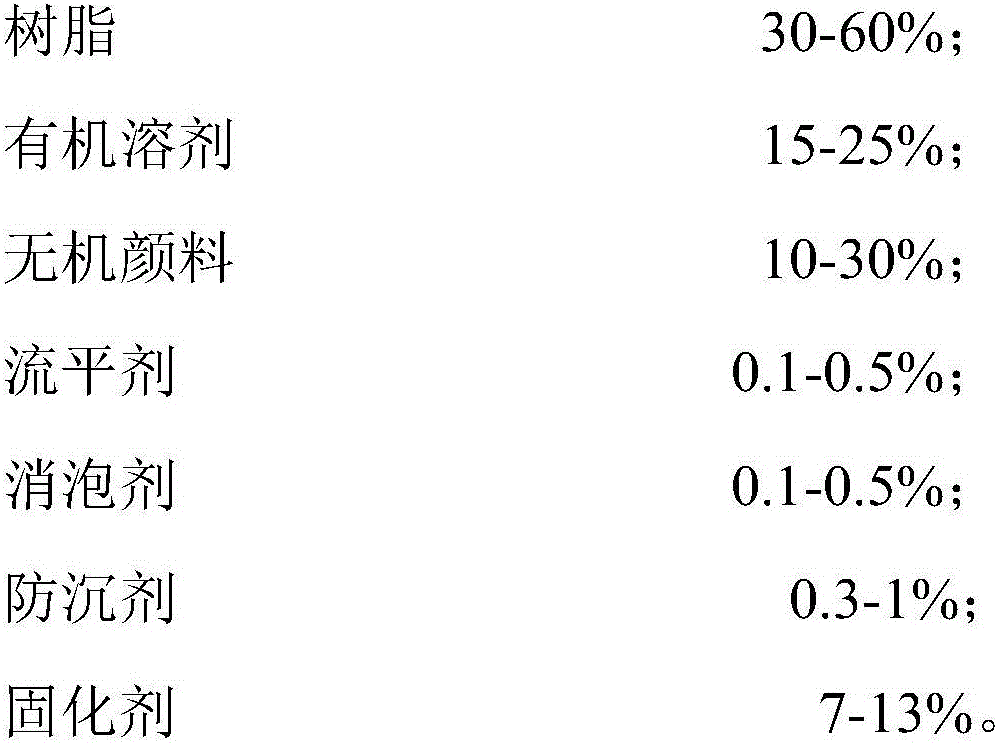

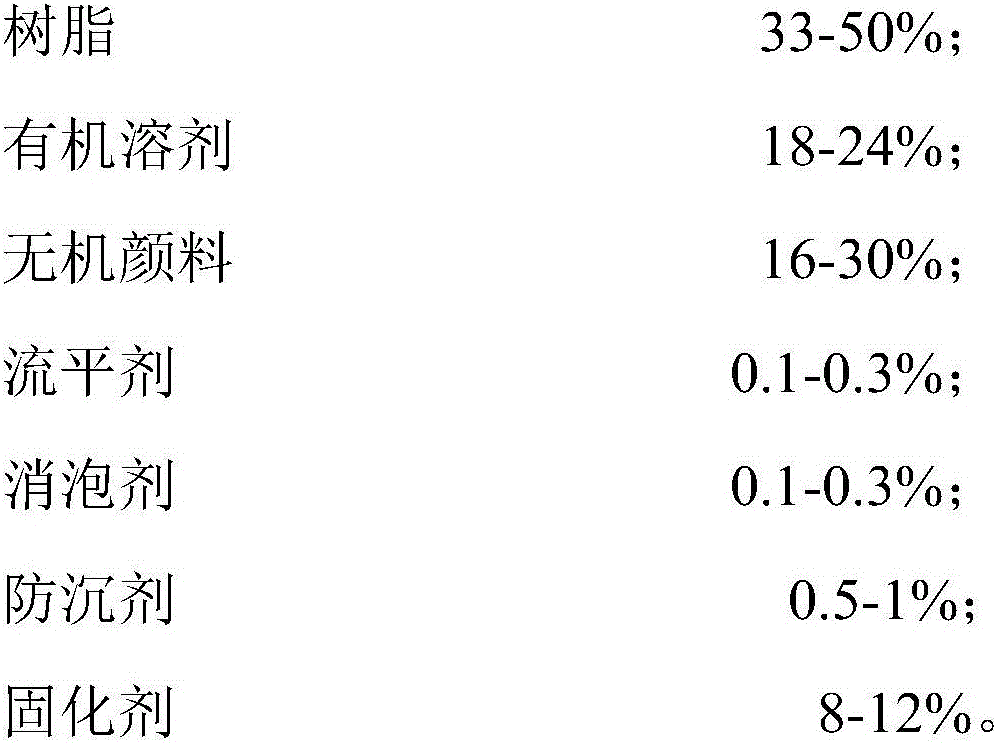

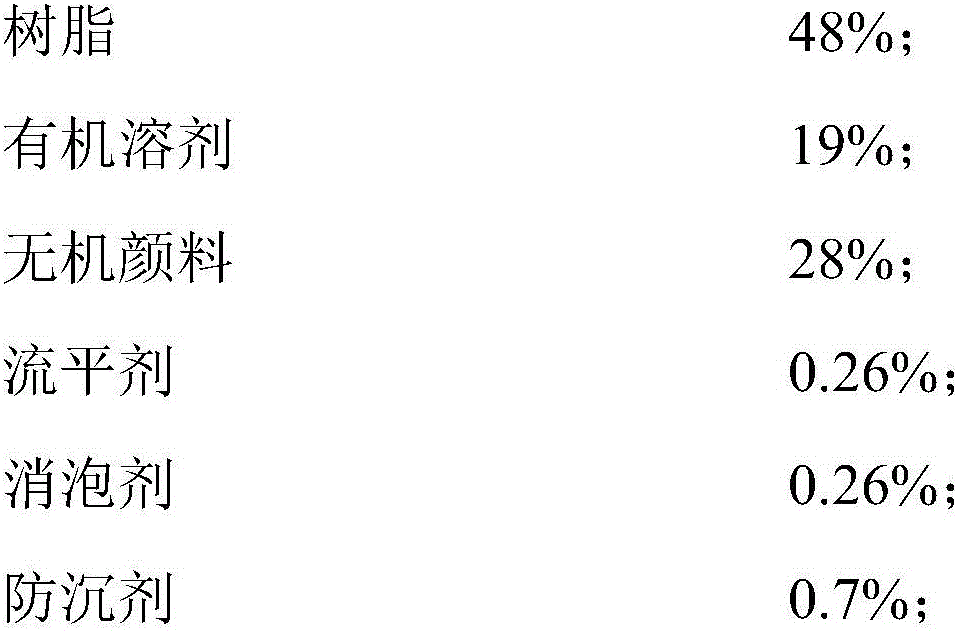

The invention provides a permeable concrete pavement protection agent and a preparation method thereof. The permeable concrete pavement protection agent contains the following components (shown in the description), can improve the bonding properties of pavement aggregates, can improve the water permeable performance of a pavement and effectively prevent concrete whiskering, can make a pavement color more uniform, brighter and more durable, and meanwhile can also slow down the carbonization and aging speed of permeable pavement concrete and improve the usage durability of ecological pavements.

Owner:上海砼仁环保技术发展有限公司

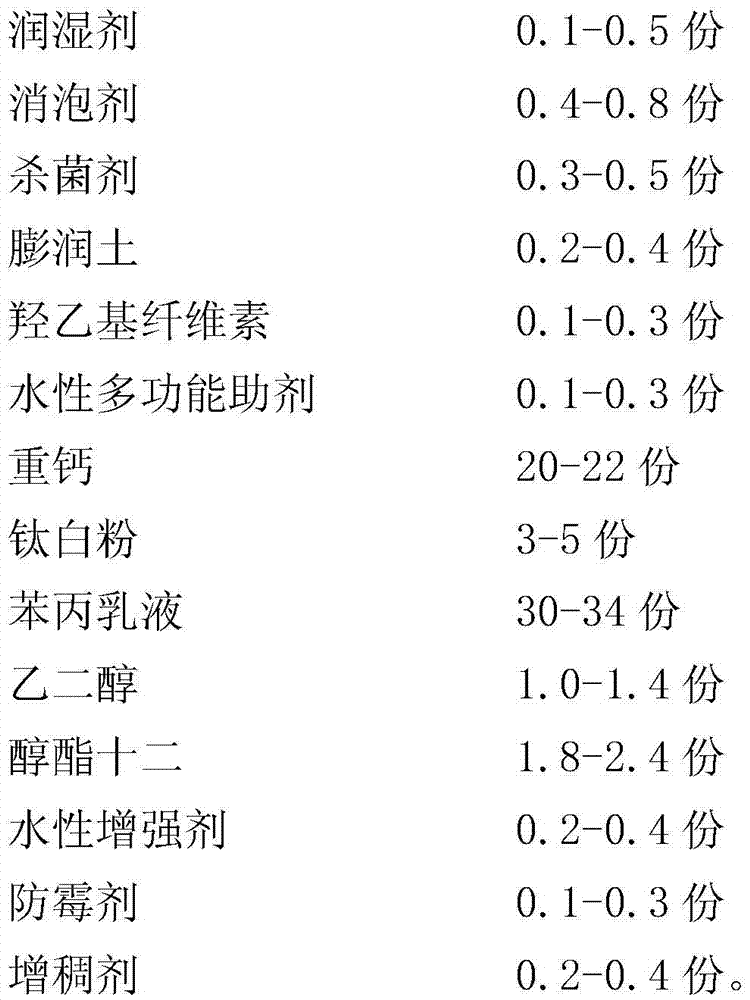

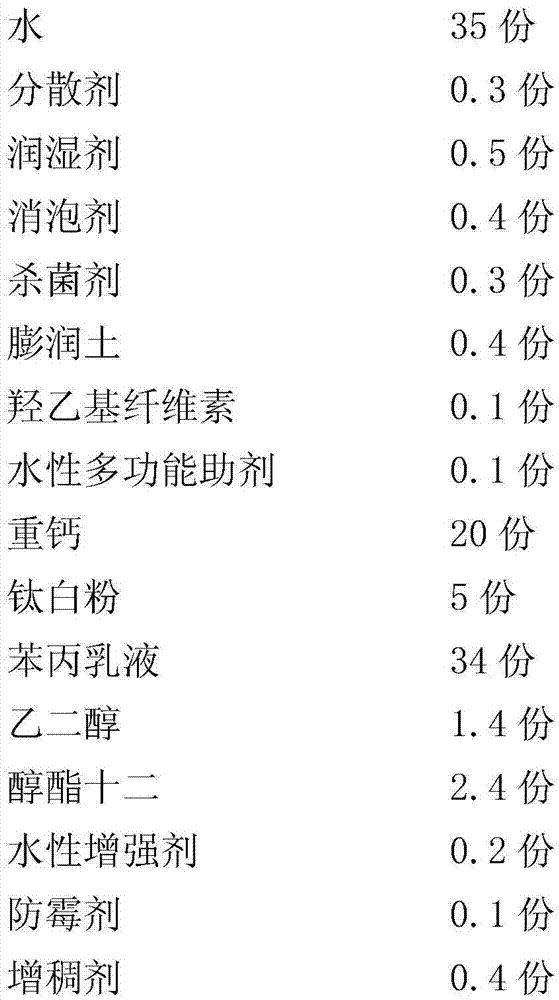

Dilution-free alkali-resistant seal primer for external wall and preparation method thereof

InactiveCN105440819AGood water permeabilityExcellent resistance to salting outCoatingsWater basedEngineering

The invention relates to a dilution-free alkali-resistant seal primer for an external wall. The dilution-free alkali-resistant seal primer for the external wall is prepared from water, a dispersing agent, a wetting agent, an anti-foaming agent, a sterilizing agent, bentonite, hydroxyethyl cellulose, water-based multi-function additives, triple superphosphate, titanium dioxide, styrene-acrylic emulsion, ethylene glycol, 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate, a water-based enhancer, mildew preventive and thickener. The dilution-free alkali-resistant seal primer for the external wall is excellent in water permeability, alkali resistance, salting-out resistance, adhesive force and storage stability, the water permeable rate can reach 0.1 ml, the adhesive force is level 0, saltpetering can be resisted for 72 h without abnormities, and salting-out can be resisted for 144 h without abnormities. In addition, the dilution-free alkali-resistant seal primer for the external wall is low in viscosity, the viscosity for construction can be achieved, using can be achieved after a tank for containing the seal primer is opened, the processes are reduced, construction is convenient and rapid, the quality of the product is further guaranteed, and construction is controllable.

Owner:SKSHU PAINT

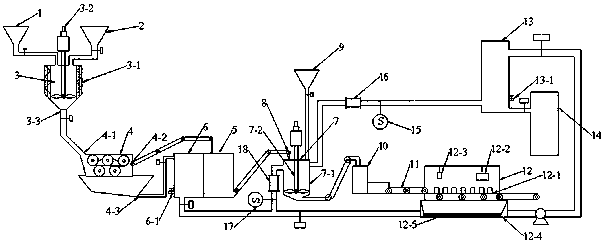

Process for recycling red mud dealkalization waste liquid and support equipment of process

PendingCN108751641ARealize resource utilizationReduce manufacturing costSludge treatmentSolid waste managementBrickEvaporation

The invention discloses a process for recycling red mud dealkalization waste liquid and support equipment of the process. The process concretely comprises the following steps: (1) adding a dealkalization agent and water to carry out dealkalization treatment on red mud, and then performing solid-liquid separation, wherein a separated liquid phase is dealkalization waste liquid, and a separated solid phase is dealkalization red mud; (2) sending the dealkalization red mud into a baking-free brick preparation process to prepare an adobe, carrying out evaporation and concentration on the dealkalization waste liquid, and maintaining the adobe by utilizing steam generated by evaporation and concentration of the dealkalization waste liquid. The support equipment comprises a dealkalization device,a filter press, a dealkalization red mud storage device, a dealkalization waste liquid storage device, a brick making stirrer, a brick making device, a concentration waste liquid temporary storage device, a concentration waste liquid collection device and a maintenance shed, by mutual synergism among various devices, the processes for preparing the baking-free brick through dealkalizing red mud and recycling the dealkalization waste liquid are completed, the cyclic utilization of the dealkalization waste liquid is realized, the resources are saved, and the environment is protected.

Owner:河南建筑材料研究设计院有限责任公司

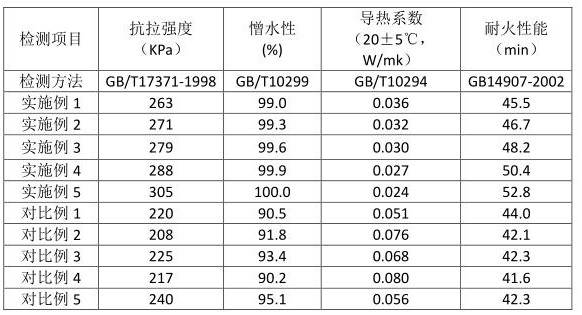

Building energy-saving thermal insulation material and preparation method thereof

The invention discloses a building energy-saving thermal insulation material, which is characterized being prepared from the following raw materials by weight: 15-25 parts of cement, 15-20 parts of blast furnace water granulated slag, 35-40 parts of volcanic ash, 5-8 parts of surface function modified porous hollow aluminum oxide nanofibers, 2-4 parts of rare earth fluoride hollow nano ions, 3-6 parts of Lambda-cyhalothric acid modified aminated beta-cyclodextrin and 1-3 parts of a coupling agent. The invention also discloses a preparation method of the building energy-saving thermal insulation material. The building energy-saving thermal insulation material disclosed by the invention is excellent in comprehensive performance, strong in thermal insulation property, good in aging resistance, weather resistance and flame retardance, excellent in performance stability and mechanical property, green and environment-friendly in use, high in durability, weather resistance, corrosion resistance, freeze thawing resistance and reliability, and wide in application range.

Owner:康亚男

Wall decoration inorganic finishing material

The invention discloses a wall decoration inorganic finishing material. The wall decoration inorganic finishing material comprises silicate cement, high-aluminum cement, re-dispersible emulsion powder, an additive, quartz sand, bentonite, wollastonite and cellulose ether, wherein the additive is a mixed preparation of an organic silicon water repellent, an air entraining agent, a defoaming agent, wood fibers and starch ether. The product is breathable, flame-retardant, safe, environment-friendly and high in plasticity.

Owner:SHANDONG FENGYU ENERGY SAVING MATERIAL MFG

Landscape stone veneer saltpetering-preventing process construction method

The invention discloses a landscape stone veneer saltpetering-preventing process construction method. The method is characterized by comprising the following steps that 1, basic layer construction achieves internal solidness and external smoothness, basic layer face elevation construction is in place, smoothness and precision are achieved, only a bonding layer of 2 cm is left, dry and hard cement mortar is prevented from being used, a low-alkaline dedicated bonder is selected, and the bonding layer porosity is reduced; 2, stone is subjected to six-face protection, on the one hand, a protection agent can permeate into the stone to block stone holes, on the other hand, a face layer is subjected to certain water separation protection, and thus a permeating channel of the stone can be closed. The landscape stone facing saltpetering-preventing process construction method has the advantages that compared with the prior art, according to the technical scheme, the water content in a basic layer is reduced, and water in the basic layer is prevented from flowing out. Alkaliferous matter in a bonding layer material is reduced, the thickness of the bonding layer is reduced, and auxiliary materials are saved. The permeating channel of water is effectively closed, saltpetering of the veneer stone is avoided, and the effect of a landscape stone veneer is improved.

Owner:SUZHOU GARDEN DEV

Scratch-proof heat-insulating and decorating integrated board

InactiveCN105507528AImprove scratch resistanceImprove wear resistanceCovering/liningsHeat proofingEngineeringFluorocarbon

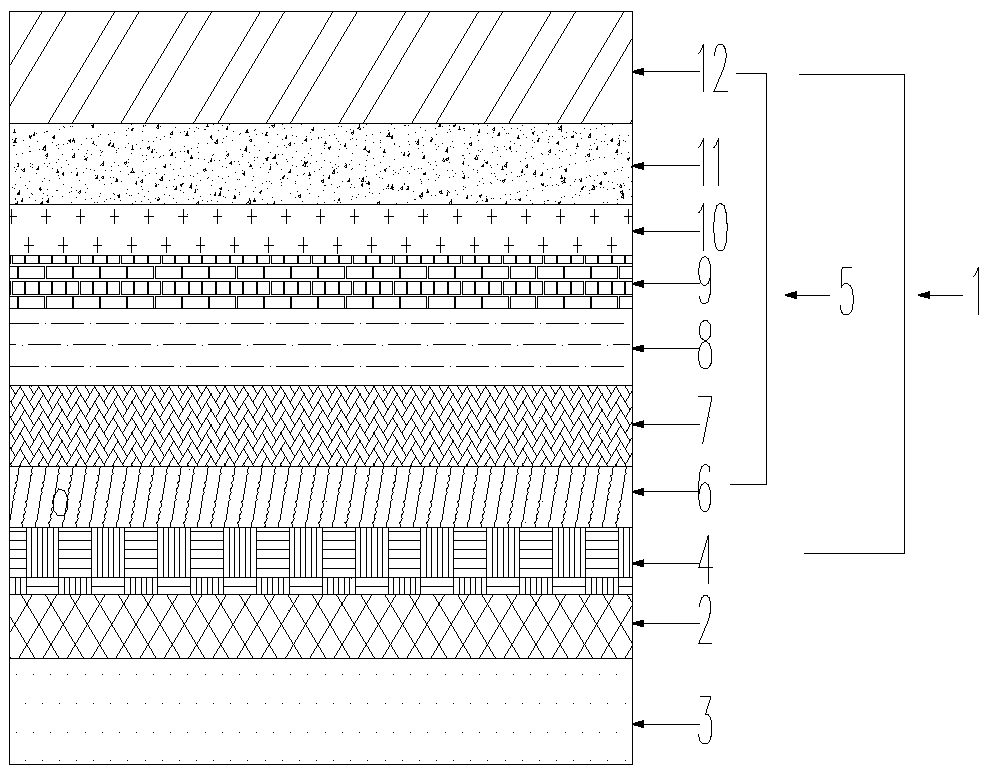

The invention relates to a heat-insulating and decorating integrated board, in particular to a scratch-proof heat-insulating and decorating integrated board and belongs to the technical field of building materials. The scratch-proof heat-insulating and decorating integrated board comprises a veneer, an adhesive layer and a heat-insulating layer, the veneer comprises a face board and a veneer layer, the veneer and the heat-insulating layer are formed by pressing by a cold press through the adhesive layer, the veneer layer comprises a closed primer layer, a UV putty layer, a UV primer layer, a fluorocarbon primer layer, a finish layer, a protecting film A and a protecting film B which are sequentially coated from inside to outside, the protecting film A is formed by sprinkle-coating photocured waterborne polyurethane nano composite emulsion through drying and curing, and the protecting film B is a PVC film. The surface of the heat-insulating and decorating integrated board is scratch-proof, wear resistance is improved greatly, waterproofness is high, breathability is high, and service life is long.

Owner:WUXI JIEYANG ENERGY SAVING TECH

Neutral environment-friendly putty powder and preparation method thereof

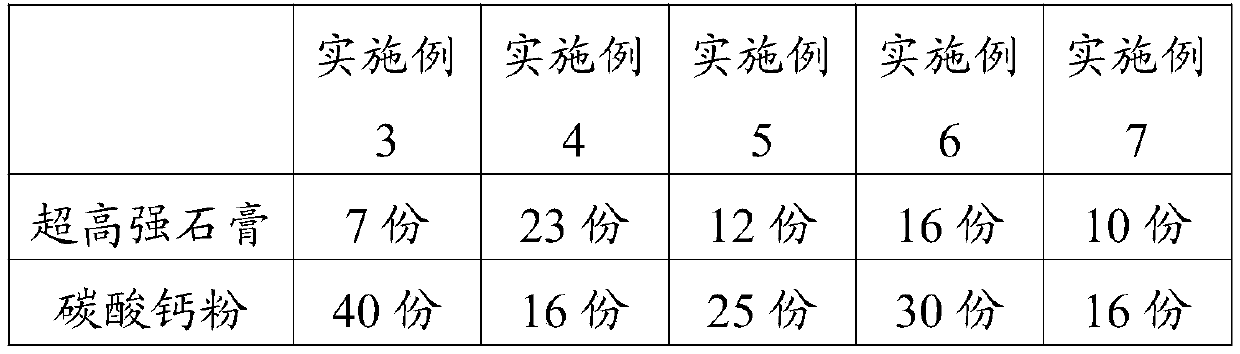

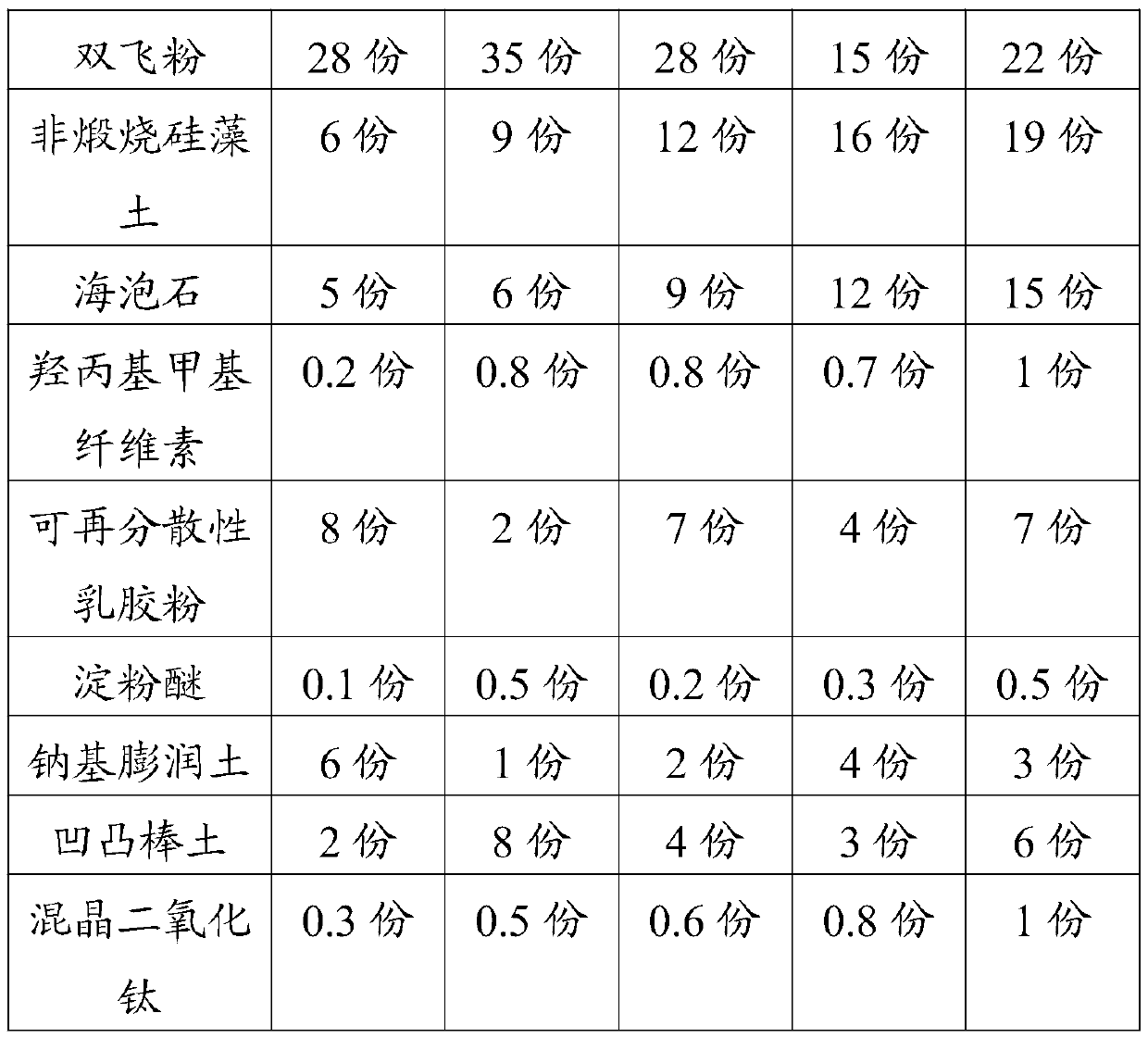

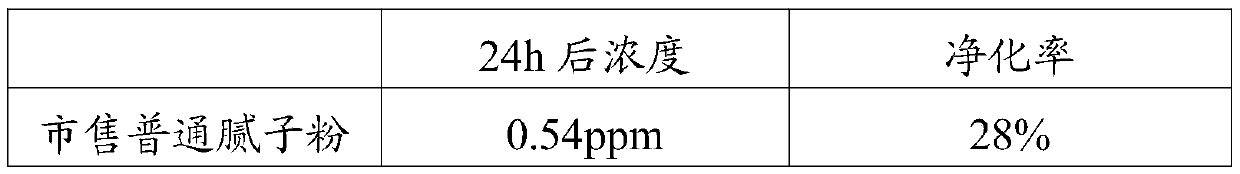

InactiveCN110204944AImprove adsorption capacityLarge aperture rangeFilling pastesSodium BentoniteLiving environment

The invention discloses a neutral environment-friendly putty powder which has the air purification property and is free of coating brushing and smooth in appearance. The putty powder is prepared from,by weight, 7-23 parts of ultra-high-strength gypsum, 16-40 parts of calcium carbonate powder, 15-35 parts of calcium carbonate, 6-19 parts of non-calcined kieselguhr, 0.2-1 part of hydroxypropyl methyl cellulose, 2-8 parts of redispersible latex powder, 0.1-0.5 part of starch ether, 1-6 parts of sodium bentonite, 5-15 parts of sepiolite, 2-8 parts of attapulgite and 0.1-1 part of mixed crystal titanium dioxide. Accordingly, the putty powder has the properties of good safety, environmental protection, water resistance, respiratory hygroscopicity, formaldehyde and harmful gas elimination and the like, and has good capacity of improving the quality of the living environment; meanwhile, the surface of the putty powder is smooth, firm and white, other coating or wallpaper can be omitted, and the effects of protecting the environment and reducing the cost can be achieved.

Owner:长沙标朗住工科技有限公司

Method for solving saltpetering problem of water permeable brick

The invention discloses a method for solving the saltpetering problem of a water permeable brick. A specially-made water permeable brick is included, the specially-made water permeable brick comprisesa water permeable surface layer and a water permeable base layer, and the water permeable surface layer and the water permeable base layer are tightly combined into a whole; the water permeable baselayer comprises internal aggregate, and cement, a reinforcing agent and cementing material slurry which are mixed and uniformly coat the surface of the internal aggregate, wherein the internal aggregate, the cement, the reinforcing agent and and the cementing material slurry are mutually bonded; the cementing material slurry in the water-permeable base layer comprises a hydrophilic binder; and thewater-permeable surface layer comprises an external aggregate, and cement, a water repellent, a pigment mixture, an enhancer and cementing material slurry which are mixed and uniformly coat the surface of the external aggregate, and the cementing material slurry comprises a hydrophilic binder, a hydrophilic resin binder and an inorganic binder. The method for solving the saltpetering problem of the water permeable brick achieves the effects of good water permeability, low cost and capability of solving the saltpetering problem of the brick.

Owner:山西大地华基建材科技有限公司

Saltpetering prevention method for stone paving

The invention discloses a saltpetering prevention method for stone paving, and relates to the technical field of stone paving. The method includes the following steps that stones are cleaned, air-dried or oven-dried; the ground on which the stones needs to be paved is subjected to leveling through a stay wire; the back surfaces of the stones are uniformly coated with white cement with the same labels but low in calcium silicate content, and a bonding layer is formed; the stones are paved according to the design, and then a wooden hammer is used for knocking and compaction of the stones; afterthe stones are paved, the splicing gaps among the stones are cleaned, and melted paraffin is used for filling the gaps among the stones; the surfaces of the stones are coated with a waterproof agent.Through the disclosed stone paving steps and method and the composition of white cement, the saltpetering phenomenon on the surfaces of the stones is effectively reduced, the aesthetic feeling of thestones is increased and disturbance from people is reduced.

Owner:天地间博展科技有限公司

Saltpetering resisting technology for landscape stone decorative finish

The invention discloses a saltpetering resisting technology for a landscape stone decorative finish. The saltpetering resisting technology includes the following steps of (1) conducting treatment on a structural layer, specifically, the structural layer comprises a concrete structure and a brick-wall structure, the concrete structure is formed by adding a calcium hydroxide consumption agent in concrete, and the brick humidity is controlled to 60%-90% in the brick pouring process of the brick wall structure; (2) conducting waterproof treatment after the structural layer dried out; (3) conducting six-face protection treatment on decorative finish stones, specifically, a protective agent permeates in the decorative finish stones to block pores of the decorative finish stones, and conduct watertight protection on the face layers of the decorative finish stones; (4) mounting the decorative finish stones; and (5) sealing permeating channels among decorative finish stones, cleaning mortar in edge joints of the stones after completing mounting of shoving of coping decorative finish stones, using a joint mixture material with good impermeability to seal all of gaps, and conducting strict glue sealing on the inner portions and the outer positions of the edge joints of the stones before conducting grouting on side stones, and accordingly the landscape stone decorative finish can be prevented from saltpetering.

Owner:浙江易道景观工程有限公司

Water-based exterior wall putty powder

InactiveCN102964895AImprove adhesionImprove crack resistanceFilling pastesWater basedCrack resistance

The invention relates to a water-based exterior wall putty powder which comprises the following components by weight percent: 20-35% of cement, 20-25% of silicone acrylic emulsion, 20-25% of talcum powder, 15-20% of powdered calcium carbonate, 0.2-0.4% of methyl cellulose, 0.5-1% of ethylene glycol and 0.3-0.5% of polycarboxylic acid ammonium salt, wherein the calcium carbonate has the particle size diameter of 0.05-0.2mm, and the weight percent of methyl cellulose is 0.3%. The water-based exterior wall putty powder adopts the silicone acrylic emulsion with high permeability and good water resistance, so that the water resistance, the adhesive force and the crack resistance of putty can be improved; therefore, the phenomena of whiskering, discoloration and dropping of an exterior wall can be prevented, a cement wall body and a concrete wall surface are prevented from cracking, the service life of a building is prolonged, and the whole attractiveness of the building can be better improved.

Owner:QINGDAO BAOLIKANG NEW MATERIALS

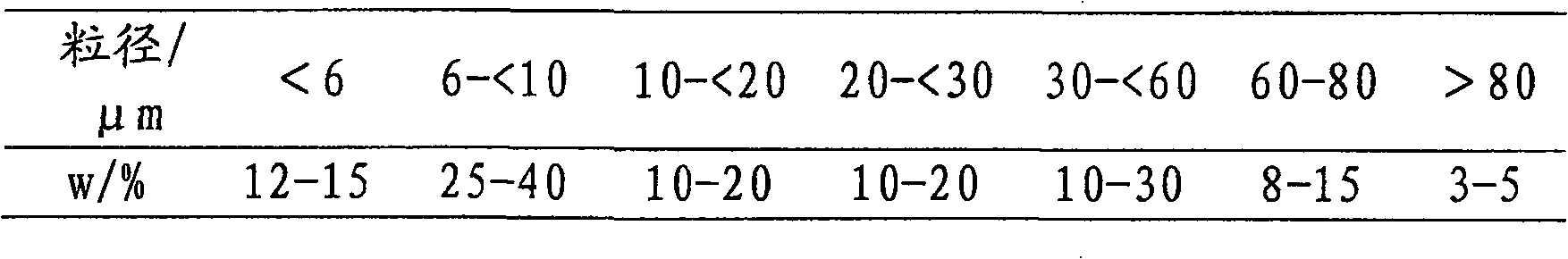

Real stone lacquer and preparation method and construction method thereof

The invention belongs to the technical field of building materials, and particularly relates to real stone lacquer and a preparation method and a construction method thereof. The real stone lacquer isprepared from sealing priming lacquer, middle layer lacquer and finish lacquer, wherein the sealing priming lacquer is prepared from the following raw materials in parts by weight: 30 to 36 parts ofalkali resistant emulsion, 8 to 12 parts of silicon sol, 0.8 to 1.2 parts of texanol, 0.8 to 1.2 parts of ammonium hydroxide and 50 to 60 parts of deionized water; the middle layer lacquer is preparedfrom the following raw materials in parts by weight: 180 to 220 parts of emulsion, 600 to 800 parts of natural color sand, 8 to 12 parts of texanol, 1 to 2 parts of ammonium hydroxide, 12 to 18 partsof thickening agents, 1 to 3 parts of antifoaming agents, 1 to 3 parts of sterilizing agents and 60 to 80 parts of deionized water; the finish lacquer is prepared from the following raw materials inparts by weight: 600 to 800 parts of emulsion, 200 to 400 parts of deionized water, 2 to 4 parts of antifoaming agents and 1 to 2 parts of ammonium hydroxide. The real stone lacquer has the advantagesthat the performance of water-resistance, salt-resistance and alkali-resistance is high; the reasonable color sand particle size grading is used, so that the sand falling phenomenon is obviously reduced; in addition, the preparation and construction methods are simple and are suitable for large-scale popularization and use.

Owner:合肥永泰新型建材有限公司

Preparation method for asphalt alkali-preventing water-resisting agent and construction method for applying same in prevention of efflorescence of stone

The invention relates to a preparation method for an asphalt alkali-preventing water-resisting agent and a construction method for applying the same in prevention of efflorescence of stone. Measures are taken to prevent efflorescence. The preparation method for the asphalt alkali-preventing water-resisting agent is characterized by comprising the following operation steps: 1) weighing and boiling of asphalt; and 2) preparation of the asphalt alkali-preventing water-resisting agent. With the construction method provided by the invention, efflorescence of a natural stone wall surface laid in wet conditions can be effectively prevented, occurrence of efflorescence can be completely avoided as long as links like designing, material selection and construction are strictly checked and scientific control is controlled out, and the ancient building material--natural stone is allowed to play an amazing role in modern buildings.

Owner:杭州爱立特生态环境科技股份有限公司

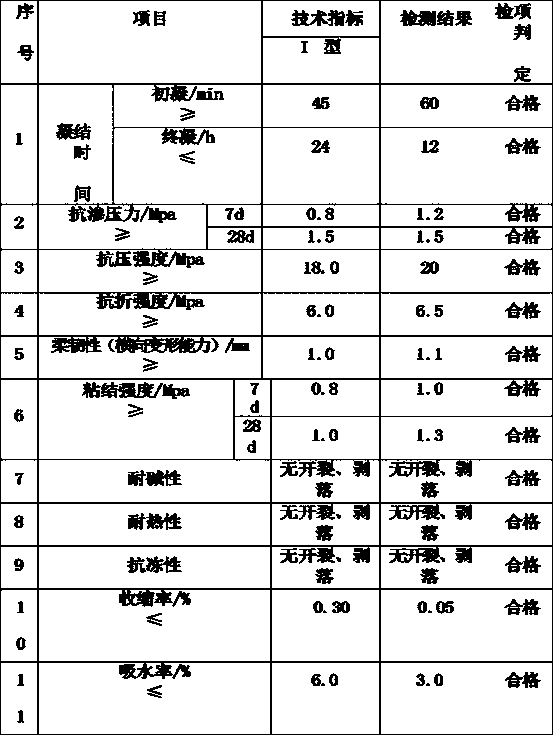

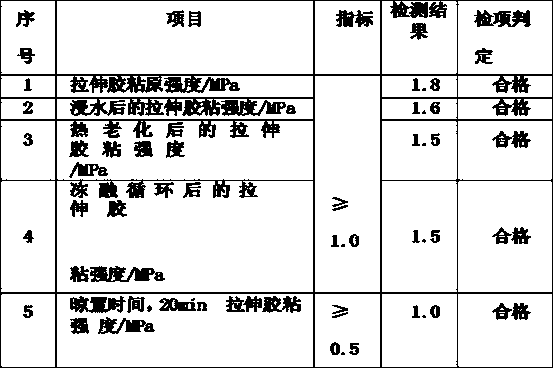

Novel construction scheme of garden waterscape building

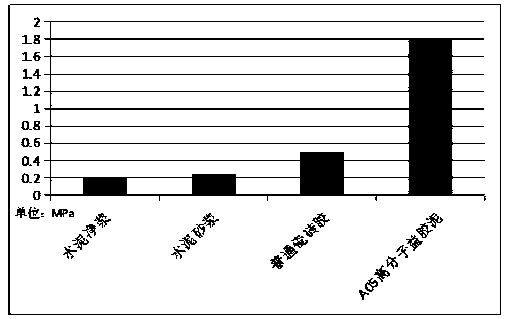

InactiveCN109914175ASolve the ubiquitous problemNot ubiquinolinSingle unit pavingsTemporary pavingsPolymer modifiedBrick

The invention relates to a novel construction scheme of a garden waterscape building. The novel construction scheme of the garden waterscape building comprises the following operation steps: base surface pouring, base surface treatment, brick material paving and pasting and brick joint treatment, wherein the top layer during the base surface pouring is cement mortar; a waterproof layer needs to bescraped on the mortar base surface in batch for overall covering and sealing during the base surface treatment; a polymer modified cement-based binder is used for brick material paving and pasting; and waterproof and weather-resistant joint filling materials with efflorescence inhibition are selected for brick joint treatment. The novel construction scheme of the garden waterscape building can effectively solve problems of efflorescence, hollowing and falling of decorative stone materials of the garden waterscape often exposed in practice; and the novel construction scheme can effectively solve common problems of efflorescence, hollowing and falling of decorative bricks and the like of the garden waterscape building by performing waterproofing and impermeability treatment on the base surface with 'K66 polymer cement waterproof mortar' of Lejiang Brand and pasting the decorative bricks with 'A05 polymer plaster' of Lejiang Brand.

Owner:GUANGZHOU LEJIANG BUILDING MATERIALS CO LTD

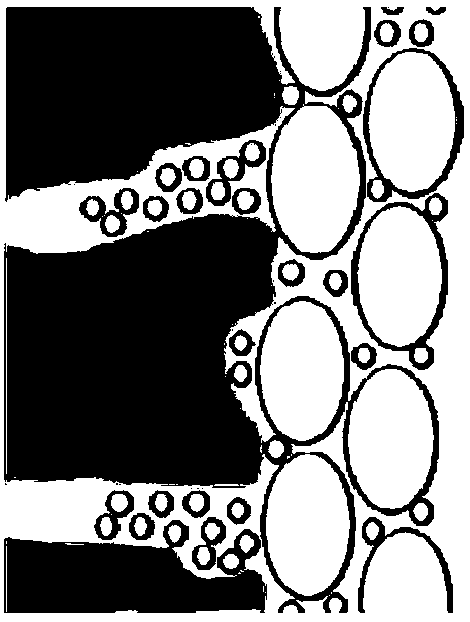

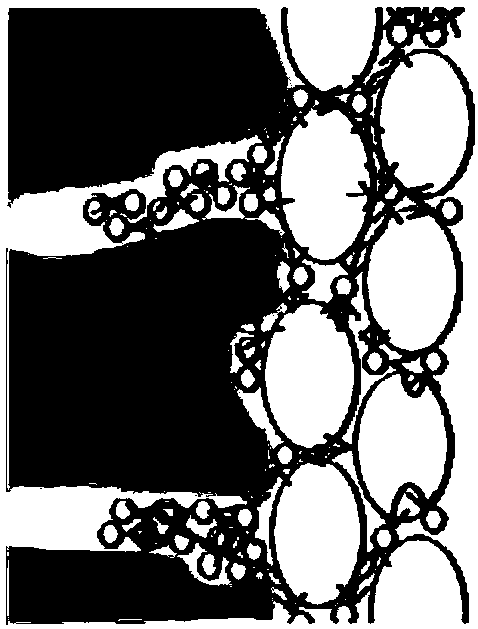

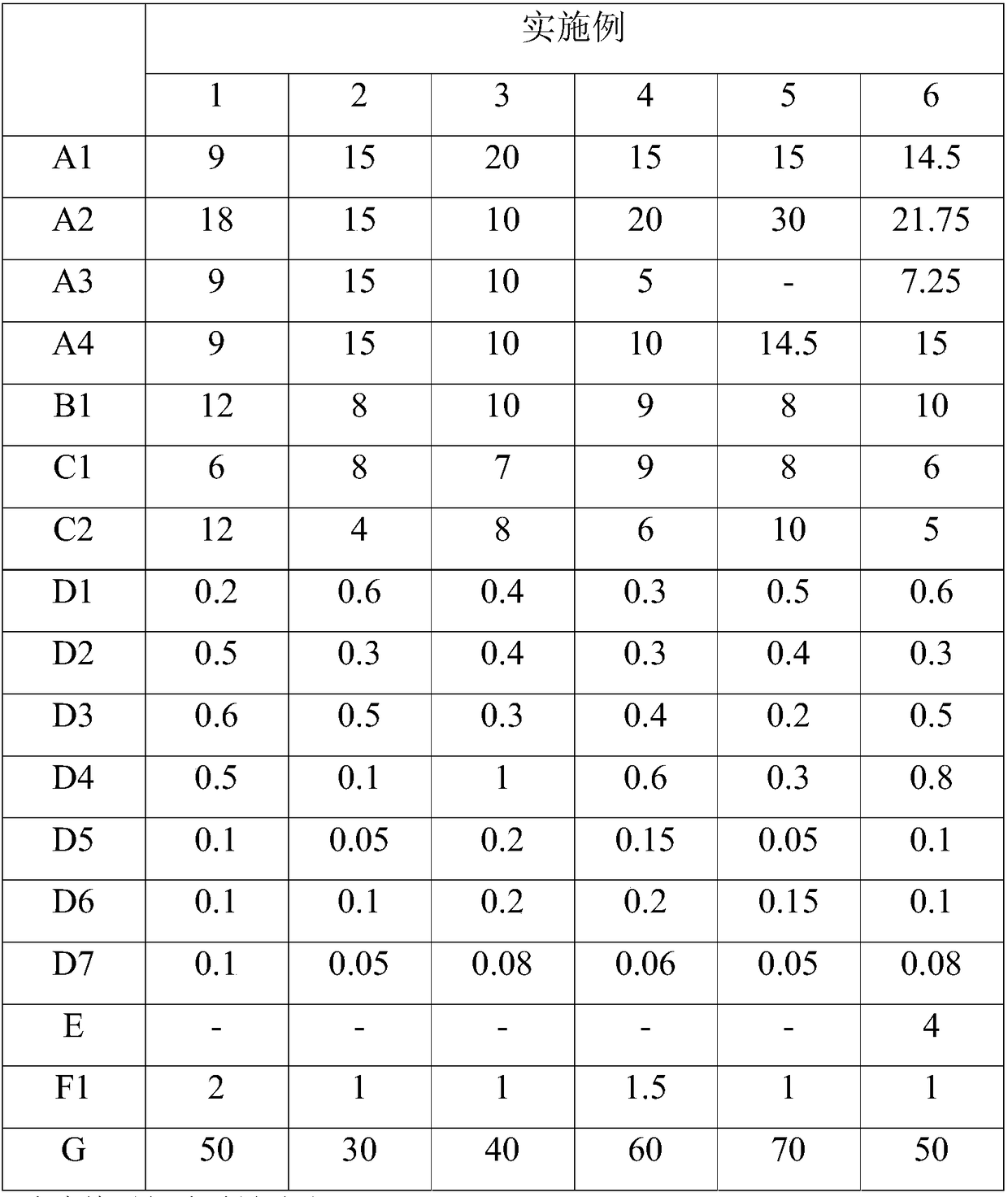

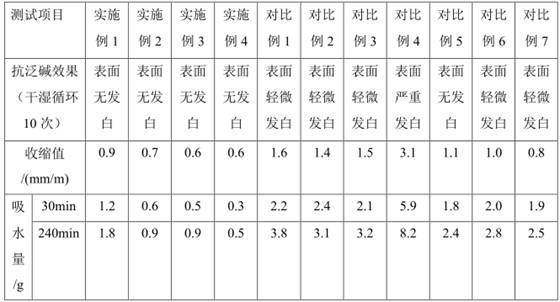

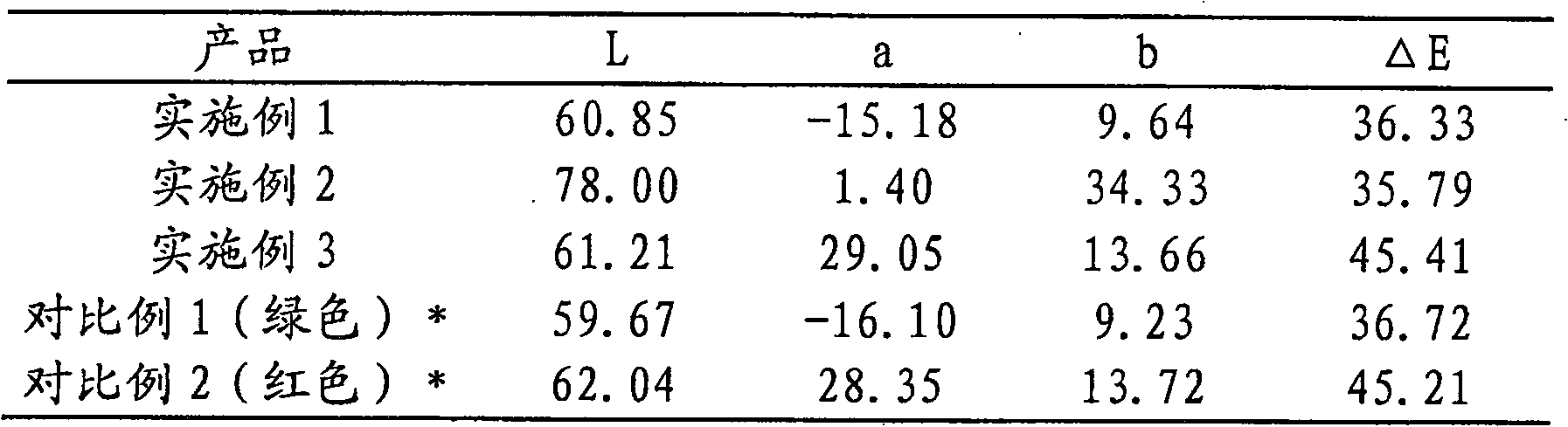

Concrete primer, preparation method of concrete primer and concrete structure body

The invention discloses concrete primer, a preparation method of the concrete primer and a concrete structure body, and relates to the technical field of concrete paint. The concrete primer is prepared from membrane forming substances (A), cellulose (B), fillers (C) and auxiliary agents (D), wherein the membrane forming substances (A) are prepared from styrene-acrylate copolymer emulsion (A1) withthe particle diameter distributed 0.06mu m or less, styrene-acrylate copolymer emulsion (A2) with the particle diameter distributed between 0.4 and 1 mu m, optional styrene-acrylate copolymer emulsion (A3) with the particle diameter distributed between 0.08 and 0.2 mu m and self-crossing acrylic emulsion (A4) with the particle diameter distributed 0.06 mu m or less, wherein the weight ratio of A1to A2 to A4 is (1 to 2):(1 to 3):1. The primer has good salt and alkali dialysis resistant performance, adhesive force, alkali resistance, water resistance and air permeability; the problems of gradual corrosion, pulverization and the like on concrete due to salt lixiviation and alkali lixiviation at the surface of a concrete building are relieved.

Owner:XINJIANG TUNHE PAINTING

A kind of efflorescence-resistant color caulking mortar for prefabricated exterior wall panels integrated with structural decoration and thermal insulation

The invention discloses an anti-pan-alkaline colored joint-filling mortar used for an assembled exterior wall board integrated with structural decoration and heat preservation. The mortar includes white cement, redispersible latex powder, silica fume powder, superplasticizer, anti-efflorescence agent, silicate and other components, which utilizes the bonding and filling functions of redispersible latex powder, silica fume powder The filling effect on the pores of cement particles, the water-reducing mechanism of superplasticizers, the hydrophobic and alkali-inhibiting effects of anti-efflorescence agents, and the ability of silicates to form gels with calcium ions in cement to fill pore channels and enhance the compactness of mortar , to reduce calcium ion precipitation on the surface of the mortar to achieve the purpose of synergistically preventing mortar efflorescence. The mortar can be prefabricated synchronously with the assembled exterior wall panels. It has excellent anti-efflorescence performance, good hydrophobicity, strong adhesion, and beautiful colors. , Simple construction, environmental protection, etc., make the overall color of the prefabricated exterior wall tiles stable, the decorative effect is durable, and can withstand wind and rain without pan-alkali or discoloration.

Owner:湖南固特邦土木科技发展有限公司

Waterproof grout for tiles

The invention discloses a waterproof grout for tiles, and belongs to the field of building materials. Reed leaves are subjected to crushing, refining, alkaline leaching and acid leaching treatment, added diatomite and sodium citrate provide adsorption and chelation effects to form a chelate together with calcium ions generated in the cement hydration process, and a soluble salt is effectively restrained from migrating to the surface, so the saltpetering phenomenon of a traditional grout is prevented; and a micro-block polymer with a surface active structure is prepared from polyether polyol, diphenylmethane diisocyanate and the like, and micelles formed around capillary pores disperse stress, so that migration of chloride ions, carbonate ions and the like in the capillary pores is effectively prevented, the chloride ion permeability resistance of the grout is remarkably improved, and the waterproof property is improved. The problems of poor waterproof property and high saltpetering tendency of existing common grouts are solved.

Owner:曾军

A kind of permeable concrete pavement protective agent and preparation method thereof

ActiveCN106010186BPrevent ubiquinolGood water permeabilityPolyurea/polyurethane coatingsCarbonizationRoad surface

The invention provides a permeable concrete pavement protection agent and a preparation method thereof. The permeable concrete pavement protection agent contains the following components (shown in the description), can improve the bonding properties of pavement aggregates, can improve the water permeable performance of a pavement and effectively prevent concrete whiskering, can make a pavement color more uniform, brighter and more durable, and meanwhile can also slow down the carbonization and aging speed of permeable pavement concrete and improve the usage durability of ecological pavements.

Owner:上海砼仁环保技术发展有限公司

A kind of preparation method of concrete curing agent

The invention discloses a method for preparing a concrete curing agent, and belongs to the field of curing agents. The method includes taking tetrabutyl titanate, aminophenyl trialkoxyl silane, anhydrous ethanol and citric acid solution, mixing uniformly, adding additive, stirring, cooling and collecting a product at 60-80 DEG C, performing ultrasonic processing and centrifugation on the product,collecting precipitate, drying the precipitate, smashing and sieving the precipitate, collecting sieved particles for ball milling, and collecting a ball milling product; and taking acetone, toluene,the ball milling product, hydroxyl terminated polymethyl silicone oil, acrylic acid, phenol, ammonium persulfate and catalyst for mixing, discharging, filtration and drying and the like to obtain theconcrete curing agent.

Owner:广州德雄交通科技有限公司

Method for retreading old porcelain brick wall by paint

InactiveCN101586401BGuaranteed bonding strengthWon't fallCovering/liningsBuilding repairsGlass fiberBrick

The invention relates to a method for retreading the old porcelain brick wall by the paint, a retreading decorative layer composed of a interface binder layer (2), a first polymer cracking-resistant putty layer (3), a second polymer cracking-resistant putty layer (4), a glass fiber girding cloth (5), a third polymer cracking-resistant putty layer (7), a double-component flexible putty layer (9), asmooth surface putty layer (9), a seal coat layer (10), a middle coating layer (11), a flexible silicone-acrylate latex paint layer (12) and a fluoric-carbon coating varnish layer (13) is formed on the old wall surface porcelain brick of the old wall (1), an anchor nail (6) passes through the glass fiber gridding cloth (5), the second polymer cracking-resistant putty layer (4) and the first polymer cracking-resistant putty layer (3) and is embedded in the old wall (1) for the mechanical reinforcement, all layers above are dried and solidified and are integrated with the old wall (1) firmly tocomplete the retread of the old wall surface. The construction cost and the labor strength are low, the old porcelain brick on the wall surface can not fall off, the decorative is high.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Saltpetering-resistant ceramic tile adhesive and preparation method thereof

ActiveCN113880513AHigh late activityImprove performance indicatorsSolid waste managementSodium bicarbonateCellulose

The invention discloses an saltpetering-resistant ceramic tile adhesive which is prepared from aggregate and powder. The powder comprises cement, mineral powder, active silicon dioxide, cellulose ether, latex powder, a water reducing agent, sodium bicarbonate and the like. The invention also provides a preparation method of the ceramic tile adhesive. According to the saltpetering-resistant ceramic tile adhesive disclosed by the invention, different saltpetering-resistant substances are reserved to play a long-timesaltpetering-resistant role through the use change characteristics of the ceramic tile adhesive, various means and different saltpetering-resistant mechanisms. The saltpetering-resistant ceramic tile adhesive can inhibit the saltpetering degree value of the ceramic tile adhesive, the surface is not obviously whitened after multiple times of soaking circulation, the long-time attractive appearance of the surface is effectively ensured, and the saltpetering-resistant ceramic tile adhesive formula improves various performance index values while effectively inhibiting the saltpetering of the ceramic tile adhesive, and has a good application prospect.

Owner:CHINA RESOURCES CEMENT TECH RES DEV

Putty for external wall

The present invention discloses a putty for external wall. Its composition includes (wt%) 10-13% of soft water, 0.2-0.3% of methyl cellulose, 0.1-0.2% of lithium mineral thickening agent, 0.3-0.5% of polycarboxyamine salt, 10-15% of silicon acrylic latex, 0.3-0.5% of wax emulsion, 0.1-0.2% of high-viscosity modifying agent, 0.5-1% of glycol, 0.5-0.7% of 12C ester alcohol, 1-5% of zinc stearate, 0.1-0.3% of defoaming agent, 30-40% of coarse whiting with 200 meshes and 25-35% of talcum powder with 400 meshes.

Owner:JIANGMEN YAGUO BUILDING COATING

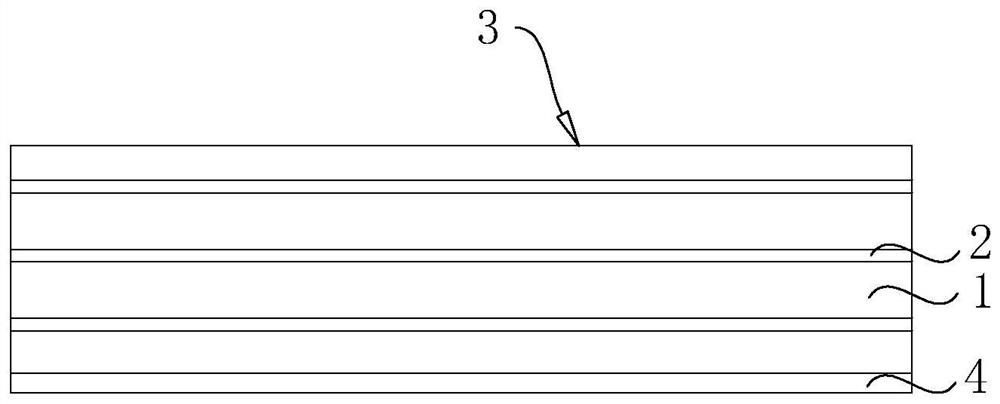

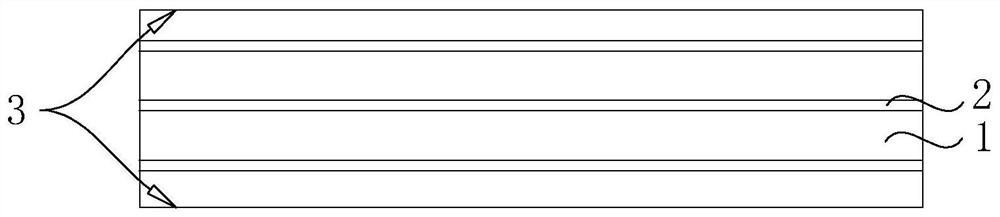

A kind of ultra-thin flexible cement decorative board and preparation method thereof

ActiveCN113024223BGood adhesivenessImprove flexural toughnessSolid waste managementFiberPolymer science

The application relates to the technical field of building materials, and specifically discloses an ultra-thin flexible cement decorative board and a preparation method thereof. An ultra-thin flexible cement decorative board, including a board body and several non-alkali grid cloths, the upper surface of the board body is textured and colored, a single piece of the non-alkali mesh cloth is horizontally embedded in the board body, and several of the Alkali-free grid cloth is distributed along the height direction of the board body; the board body includes the following raw materials in parts by weight: 5-10 parts of cement; 10-20 parts of fine sand; 0.1-0.3 parts of short fibers; 0.2-0.5 parts of filler 10-20 parts of magnesium oxide; 1-5 parts of magnesium chloride; 4.5-22.5 parts of polyvinyl alcohol; 5-10 parts of fly ash; 0.1-0.5 parts of water reducing agent. The ultra-thin flexible cement decorative board of the present application has the advantages of good flexibility and good waterproof effect.

Owner:漳州市贝丘工艺品有限公司

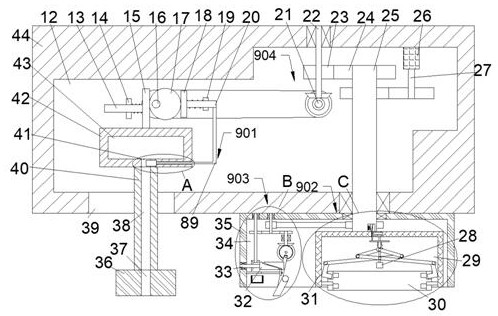

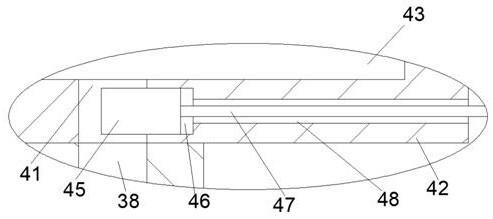

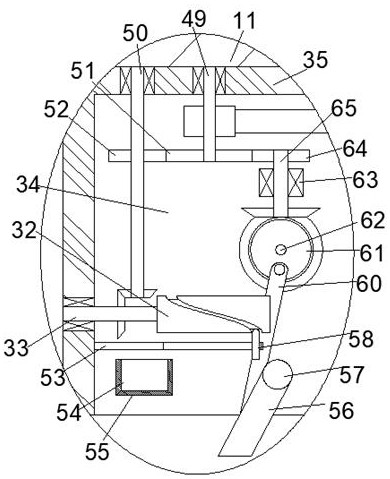

Automatic and uniform stone polishing and glazing device

ActiveCN111941183APrevent ubiquinolImprove work efficiencyGrinding wheel securing apparatusGrinding carriagesPolishingStructural engineering

The invention discloses an automatic and uniform stone polishing and glazing device. The automatic and uniform stone polishing and glazing device comprises a working box, and a working cavity is formed in the working box. A glazing material is smeared on the surface of stone to be subjected to glazing through a smearing device, a redundant part after beingsmeared is scraped off through a scrapingdevice and the stone is then fed into a treatment box, then a used polishing sponge material is turned over through the polishing device when the device does not operate, the surface of the stone is uniformly polished when the device operates, power is further transmitted to operation of the whole device through a power device, the surface of the stone is subjected to glazing treatment without being dried in the same time, the glazing material permeates into the stone, stone saltpetering caused by possible improper treatment in the earlier stage is further prevented while the surface of the stone is polished, the attractive degree is improved, and the working efficiency of workers is also improved.

Owner:聊城市敏锐信息科技有限公司

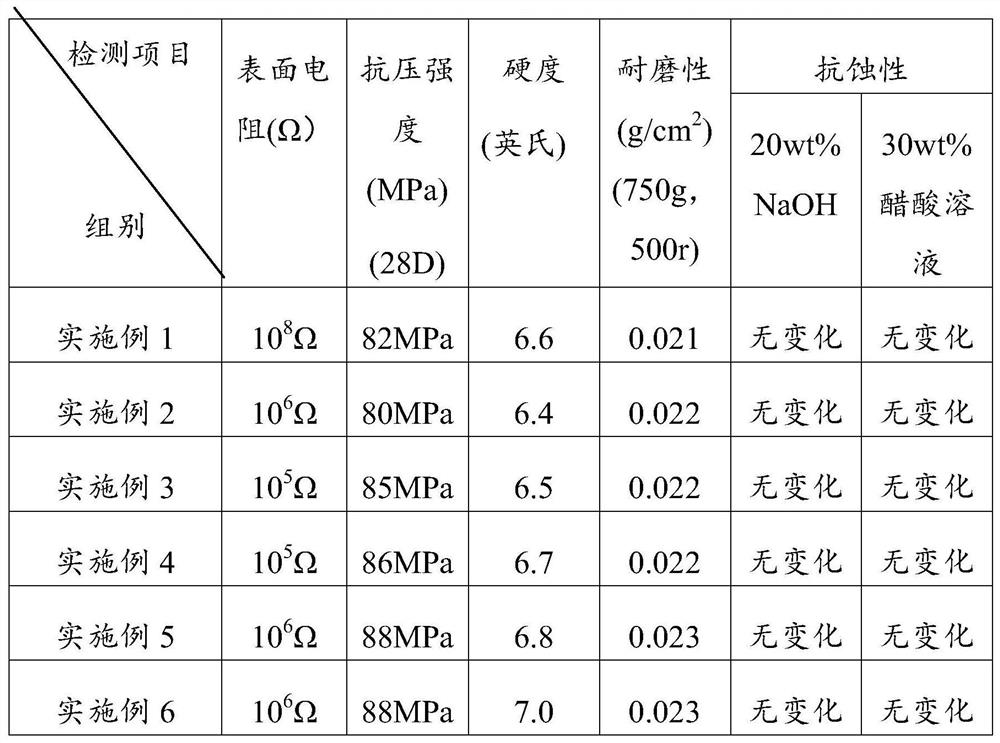

An antistatic non-flammable ground material and its preparation method

The invention provides an anti-static non-flammable ground material. The material is based on dolomite and cement, and modified metal conductive pearl powder is added. The metal conductive pearl powder is well compatible with dolomite and cement, and then added The water reducing agent improves the slump retention performance of the ground, and the anti-alkali agent is added to prevent the efflorescence of the ground. The anti-static non-flammable floor material provided by the invention has the properties of non-flammable, non-deflagration, wear-resistant, acid and alkali resistance, and the surface resistance value is 10 5 -10 8 Ω, excellent electrical conductivity, and increases the richness of the color of the ground material, which is rich in color and elegant in appearance. The preparation method of the antistatic non-flammable ground material provided by the invention is simple, the construction method is convenient and easy to operate, the antistatic non-flammable ground material can form a uniform conductive layer on the ground, the conductive performance is long-lasting and efficient, acid and alkali resistant, impact resistant, and not empty Drum, wear-resistant and pressure-resistant.

Owner:安徽省安达节能科技有限公司

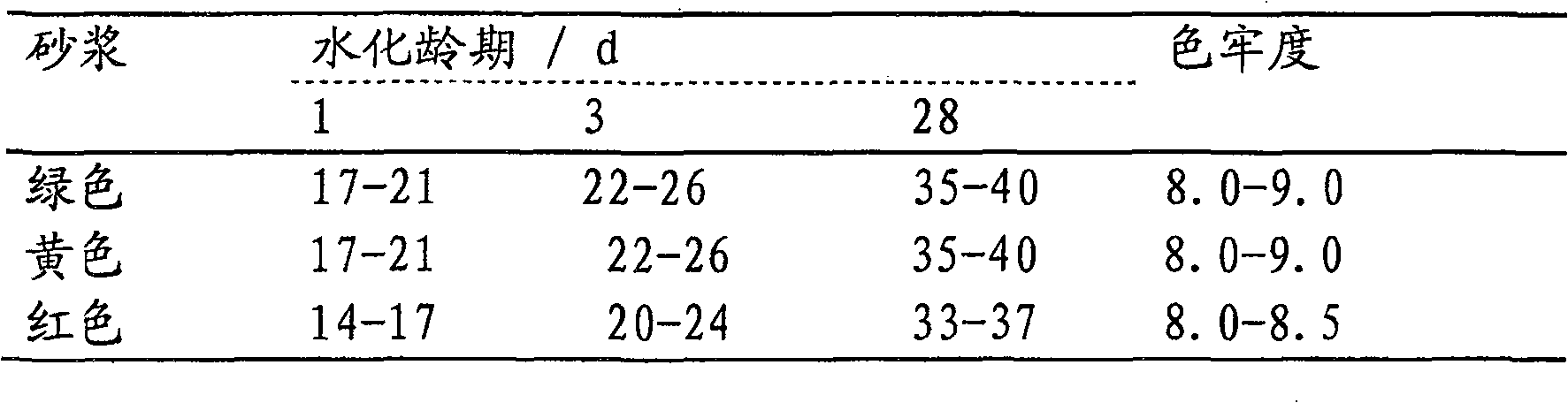

Hydraulicity modulation aluminophosphate color cement

The invention discloses a hydraulic modulation aluminophosphate colored cement, the content of each component in weight percent is: aluminophosphate cement, 85.0-92.0; activated siliceous mineral, 5.0-8.0; water repellent, 0.8-2.0; inorganic pigments, 1.0-8.0. The main component of the present invention is low-alkaline aluminophosphate cement, the hydration product of its hardened slurry does not contain Ca(OH)2, and the structure of the hydration product on the surface of the slurry can solid dissolve various anions, cations or ion groups , such as: Na+, CO32- and SO42-, etc., can inhibit efflorescence; its hardened slurry has good color and high color fastness, greater than 8.0, and improves the strength and durability of cement concrete. This improvement in performance is superior to other existing hydraulic color gelling materials at home and abroad.

Owner:SHENZHEN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com