Patents

Literature

50results about How to "Solve the ubiquitous problem" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

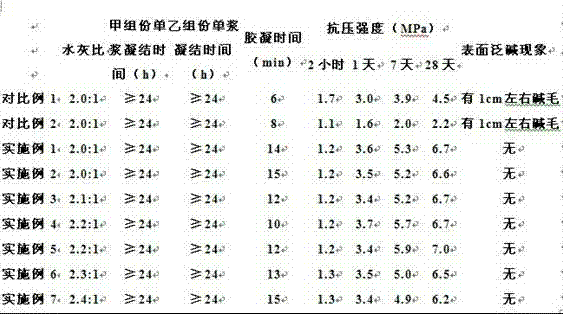

High-moisture filling material and preparation method thereof

The invention discloses a high-moisture filling material and a preparation method thereof. The high-moisture filling material comprises a composition A and a composition B, wherein the composition A comprises 52.4 to 95 by weight percent of sulfo-aluminate cement clinkers, 2.7 to 39 by weight percent of aluminate cement clinkers, 0.3 to 2 by weight percent of setting retarder, and 1.5 to 8 by weight percent of suspending agent; the composition B comprises the following ingredients: 40 to 80 by weight percent of anhydrite, 10 to 30 by weight percent of lime, and 10 to 36 by weight percent of compound additives. The high-moisture filling material has the advantages of easily-available raw materials, low price, good stability, high long-term strength and no risk of surface efforescence.

Owner:CCTEG CHINA COAL RES INST

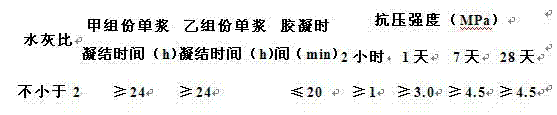

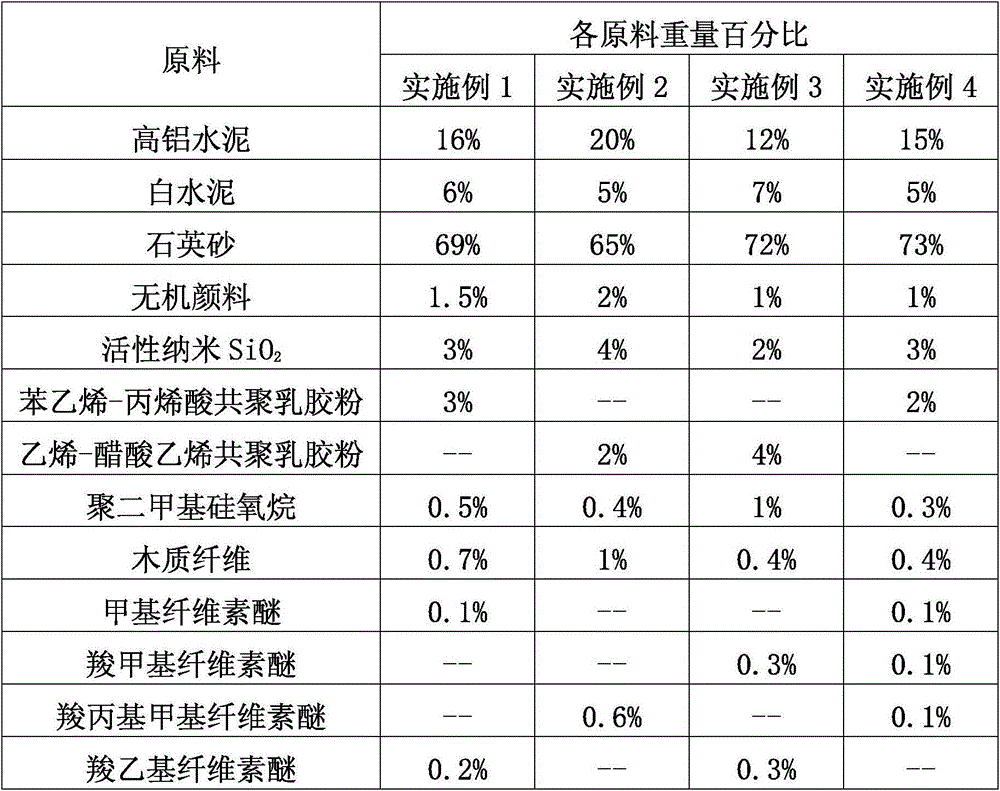

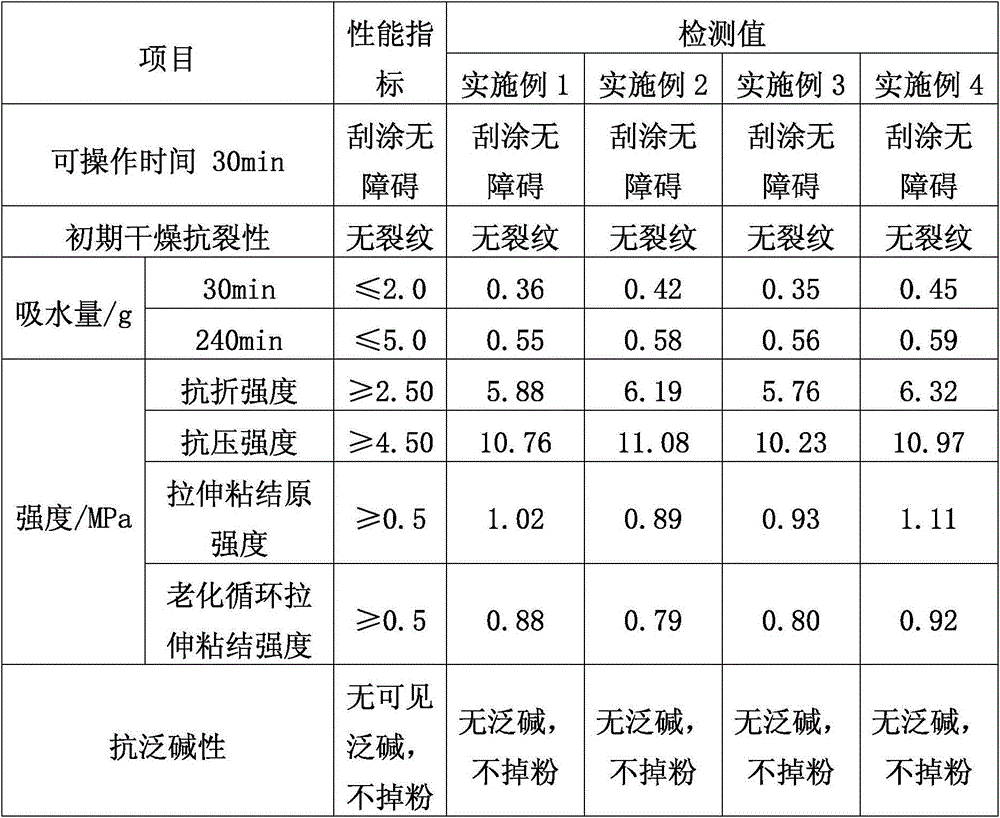

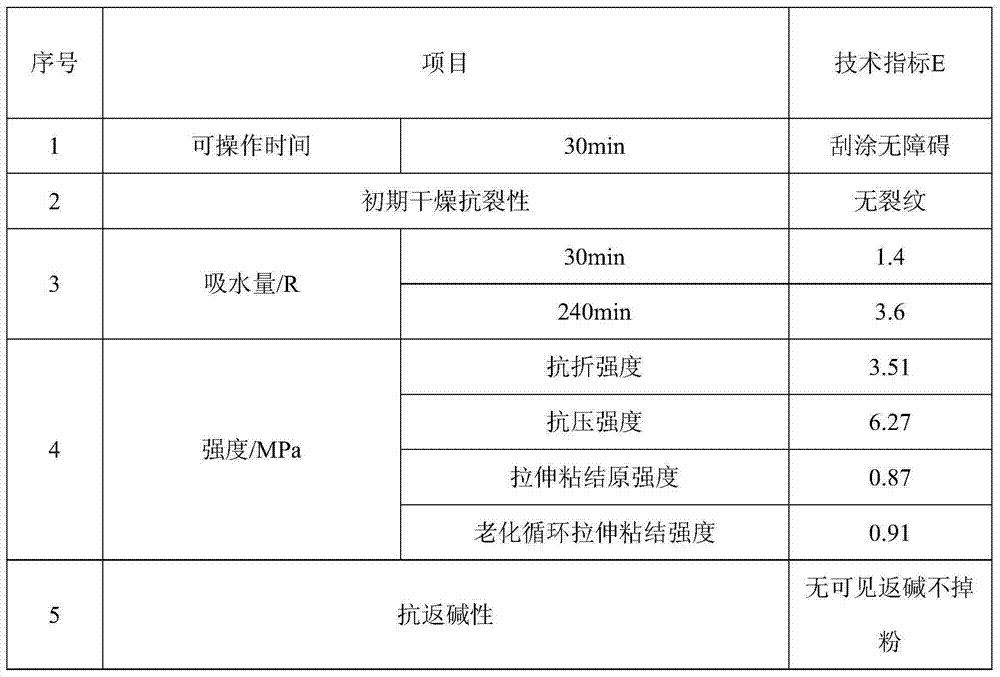

Efforescence resistant colored wall finishing mortar

The invention discloses efforescence resistant colored wall finishing mortar, which is prepared from the following raw materials in percentage by weight: 12%-20% of high-alumina cement, 5%-10% of white cement, 65%-75% of quartz sand, 0.1%-3% of inorganic pigment, 2%-4% of active nanometer SiO2, 2%-4% of redispersible powder, 0.1%-1% of a defoamer, 0.1%-1% of a wood fiber and 0.1%-0.6% of cellulose ether. By adopting a binary gelled material taking the high-alumina cement as a main material and the white cement as an auxiliary material, and matching with the active nanometer SiO2 and the redispersible powder as additives, the strength of the finishing mortar is ensured, the problem of efforescence of the finishing mortar can be effectively solved, the overall decorative effect of the finishing mortar is greatly improved, and the late wall maintenance cost is reduced.

Owner:李开成

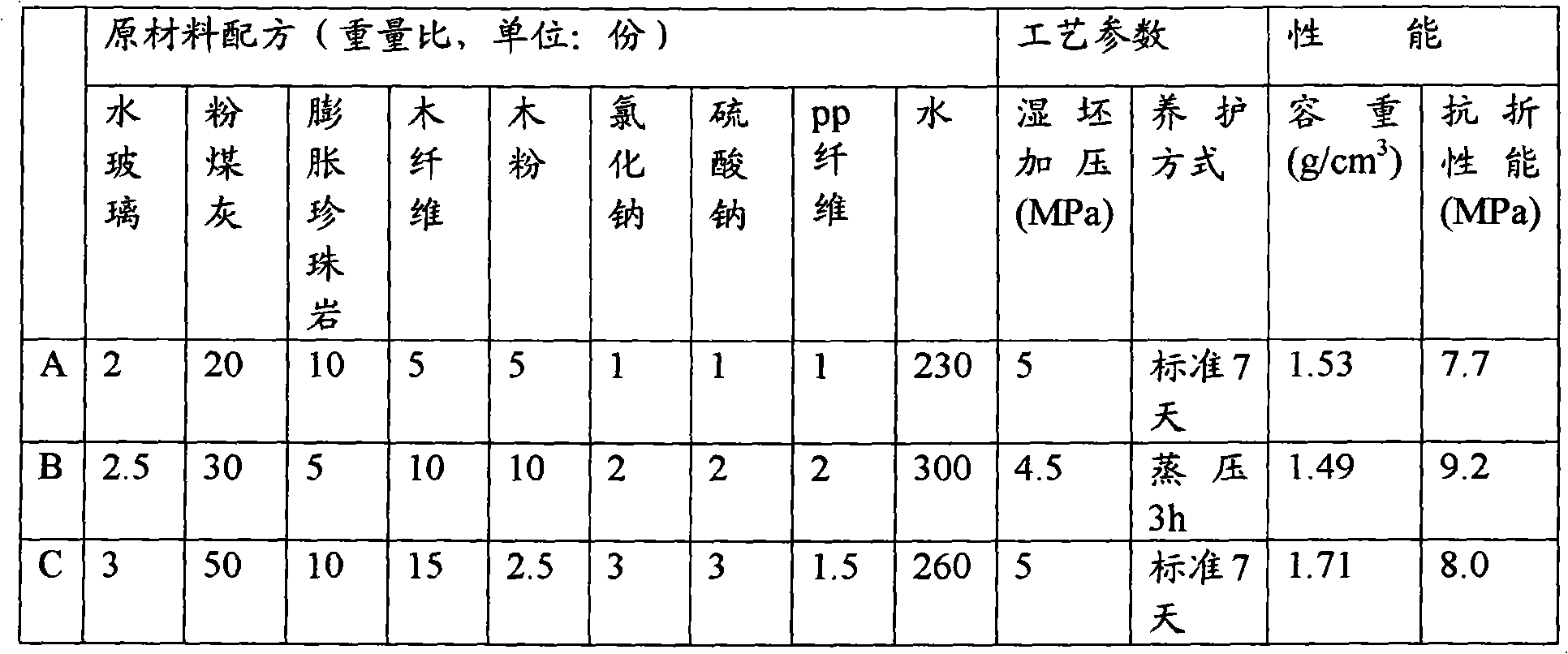

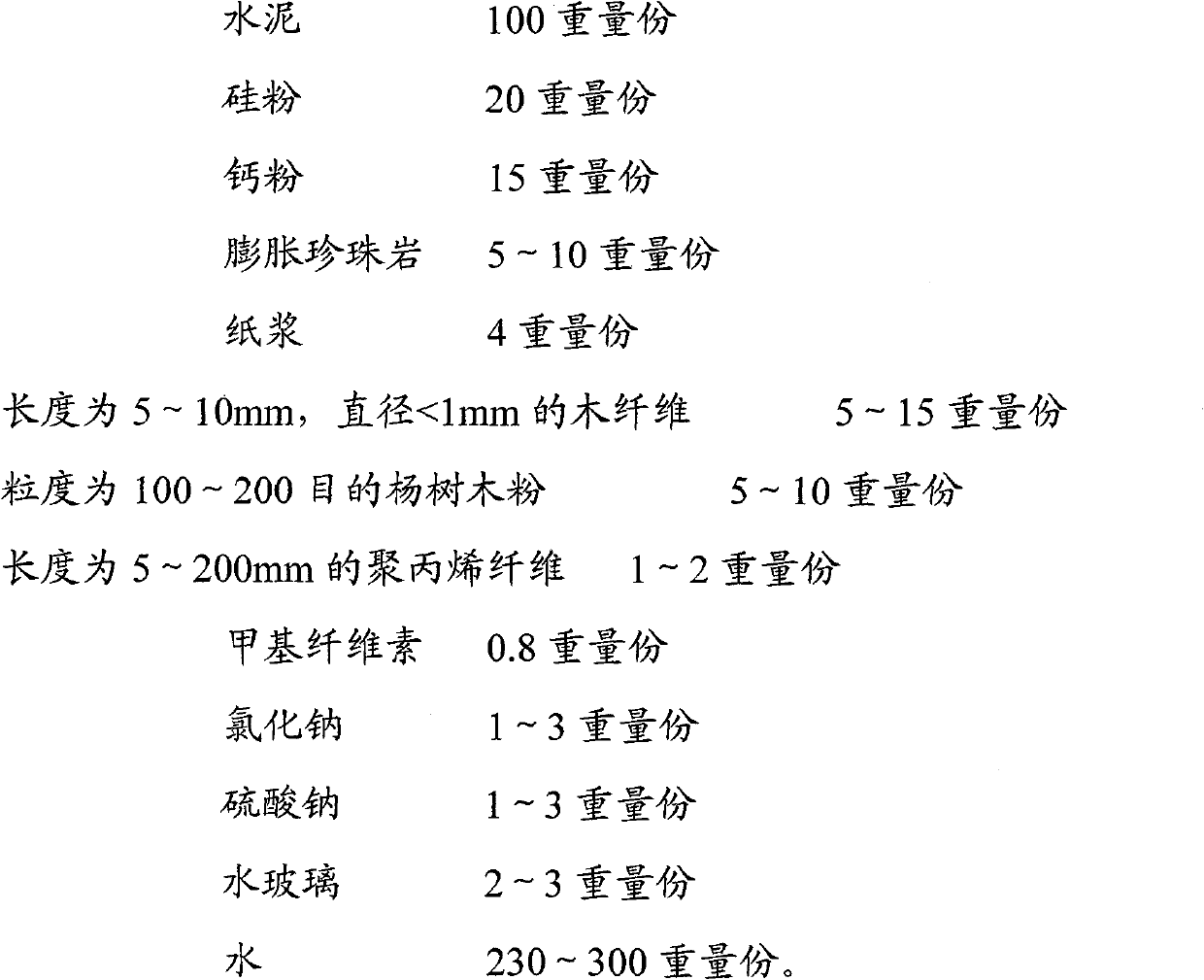

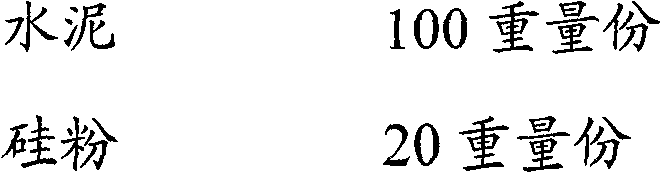

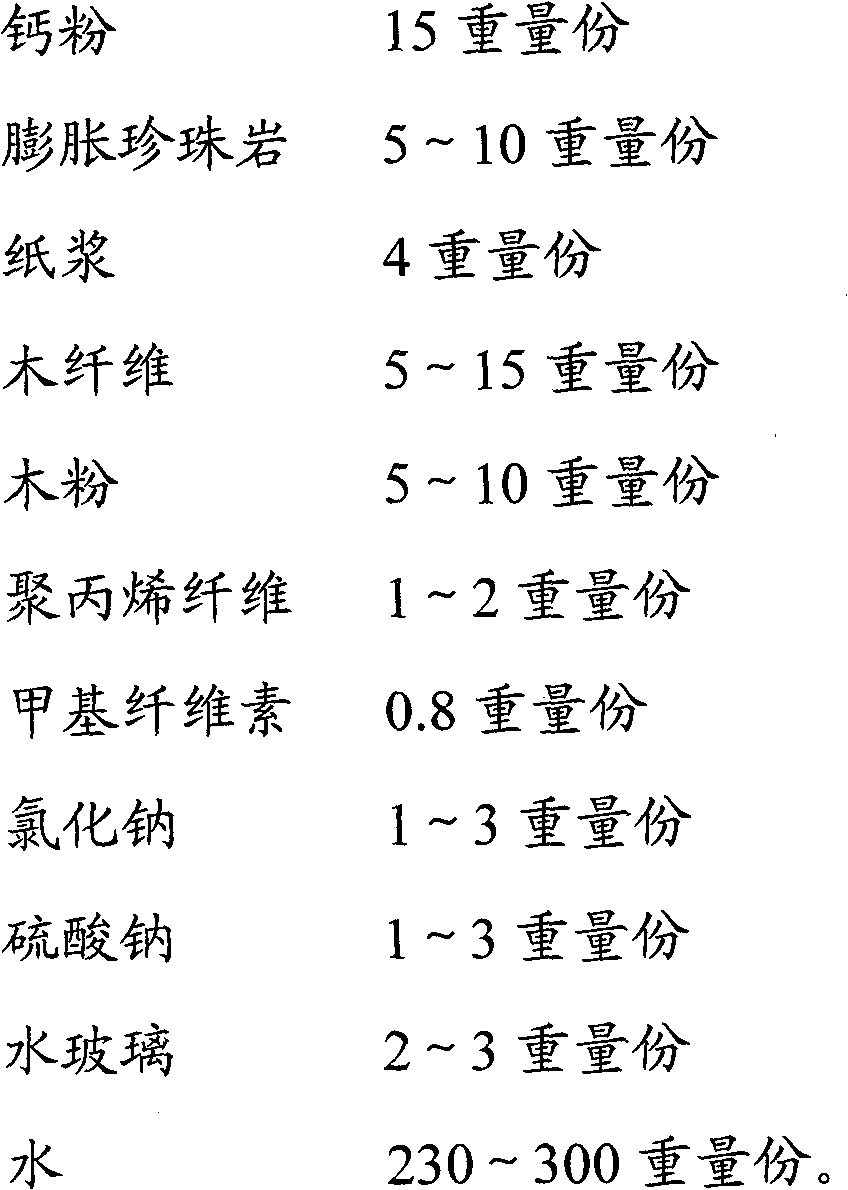

Light-weight fiber reinforced cement board and manufacturing method thereof

ActiveCN101781106AHigh tensile strengthHigh impact strengthSolid waste managementCement boardMethyl cellulose

The invention provides a light-weight fiber reinforced cement board. The light-weight fiber reinforced cement board comprises 100 parts of cement, 20 parts of silicon powder, 15 parts of calcium powder, 5 to 10 parts of expanded perlite, 4 parts of paper pulp, 5 to 15 parts of wood fibers, 5 to 10 parts of wood powder, 1 to 2 parts of polypropylene fibers, 0.8 part of methyl cellulose, 1 to 3 parts of sodium chloride, 1 to 3 parts of sodium sulphate, 2 to 3 parts of sodium silicate, and 230 to 300 parts of water. The invention also discloses a method for manufacturing the light-weight fiber reinforced cement board, which comprises the following steps of: 1, weighing each component according to formula; 2, placing the weighed dry materials into a mixer for uniformly mixing; 3, preparing wet materials, placing the mixed materials obtained by the step 2 into a kneader, adding water and the wet materials into the mixed materials, and kneading the mixture; and 4, placing the kneaded slurryinto a mold, performing compression moulding by using a plate fluidizing machine, and then demolding. The manufacturing method greatly improves the tensile strength, the impact strength, the water-retaining property, and the extrusion property of the materials.

Owner:BEIJING NEW BUILDING MATERIALS PLC

Self-anchored thermal insulation decorative assembly type wallboard and counter-attack preparation process thereof

InactiveCN108086579AAdvantages of anti-hitting preparation processOvercome the weak point of installationConstruction materialLamination ancillary operationsThermal insulationEngineering

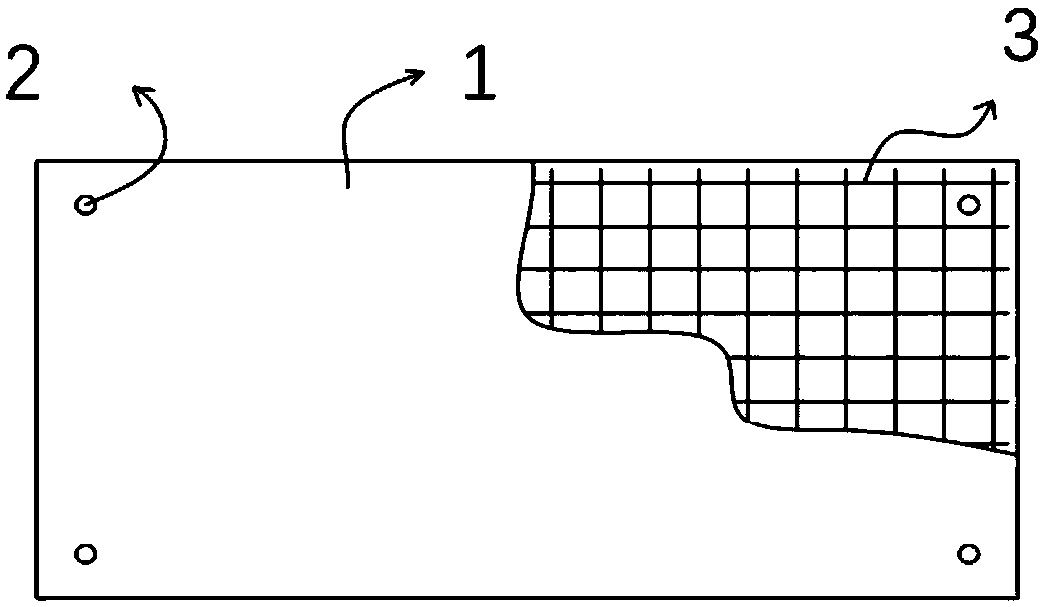

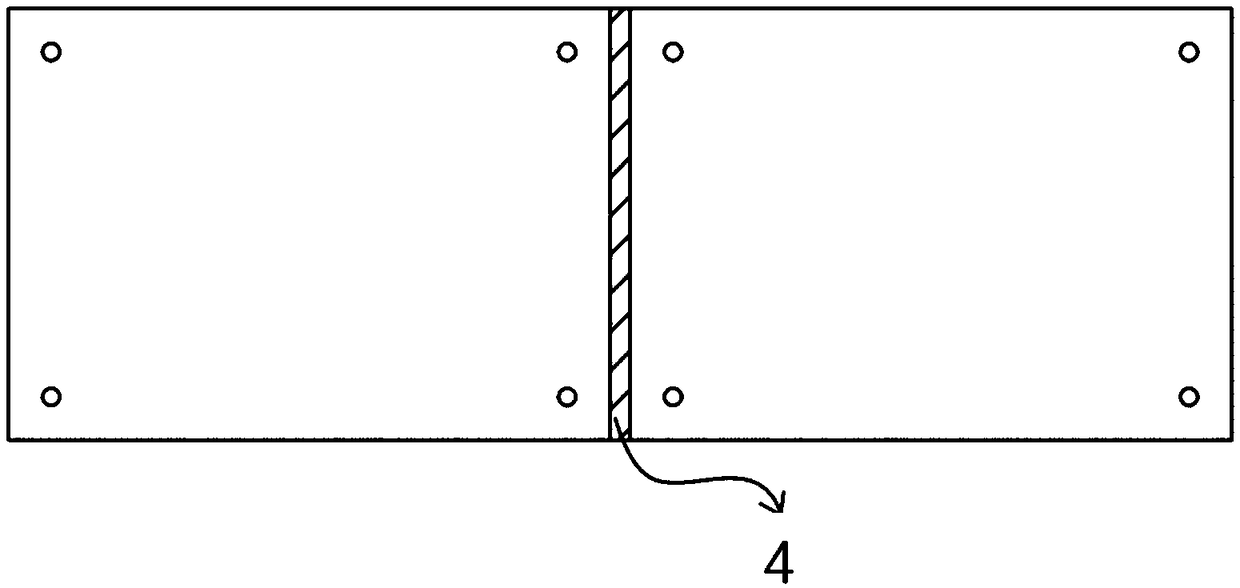

The invention discloses a self-anchored thermal insulation decorative assembly type wallboard and a counter-attack preparation process thereof. The thermal insulation decorative assembly type wallboard sequentially comprises a concrete structure layer, a thermal insulation layer and a veneer layer from inside to outside, wherein the veneer layer is formed by hard thin plates, and an inner anchoring part is embedded in the back of each hard thin plate; an outer anchoring part is inserted in each inner anchoring part. The preparation process of the assembly type wallboard comprises the followingsteps: prefabricating each thermal insulation decorative integrated board with the embedded inner anchoring part veneer layer in the back, and fixing a formwork; reversely spreading the thermal insulation decorative integrated boards on a steel formwork platform one by one; installing one outer anchoring part on each inner anchoring part of each thermal insulation decorative integrated board; filling with slab joints; placing prefabricated steel bar grids or cages; pouring concrete and vibrating; maintaining; removing the formwork. The obtained self-anchored thermal insulation decorative assembly type wallboard and the counter-attack preparation process have the advantages of simple manufacturing steps, short construction period, fire safety, energy-saving and thermal insulation, and lowcost of natural granite sheet veneer.

Owner:中建科技成都有限公司 +1

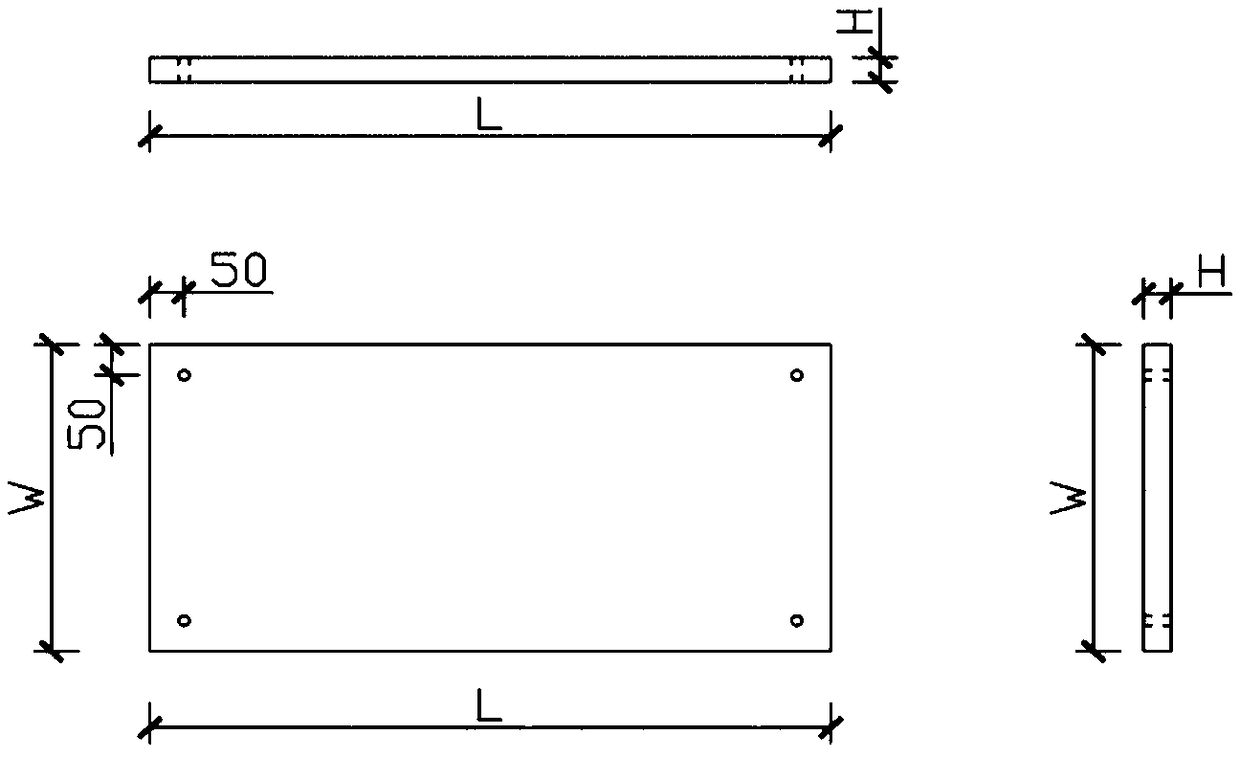

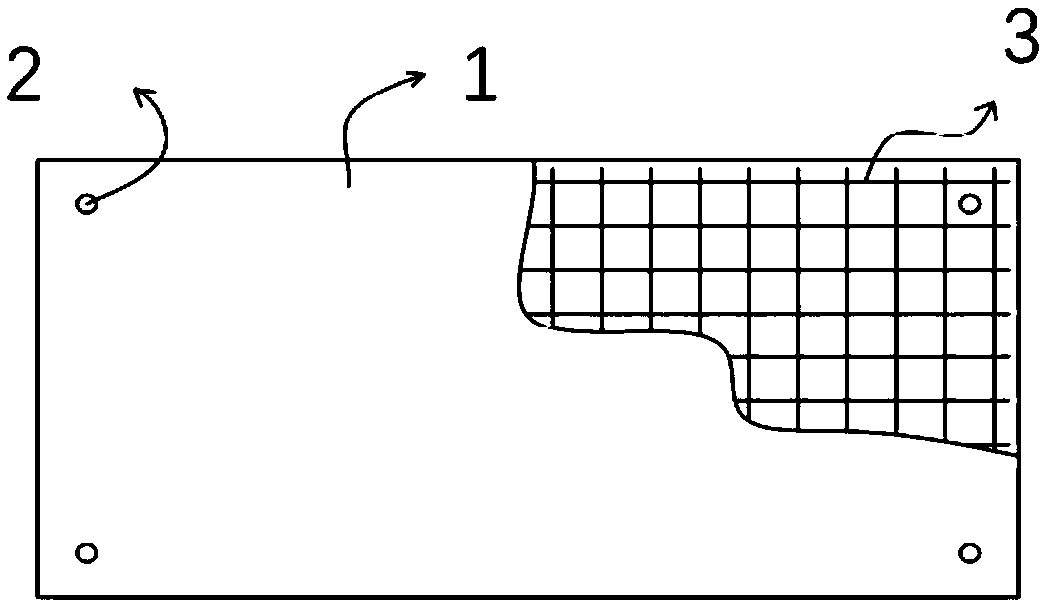

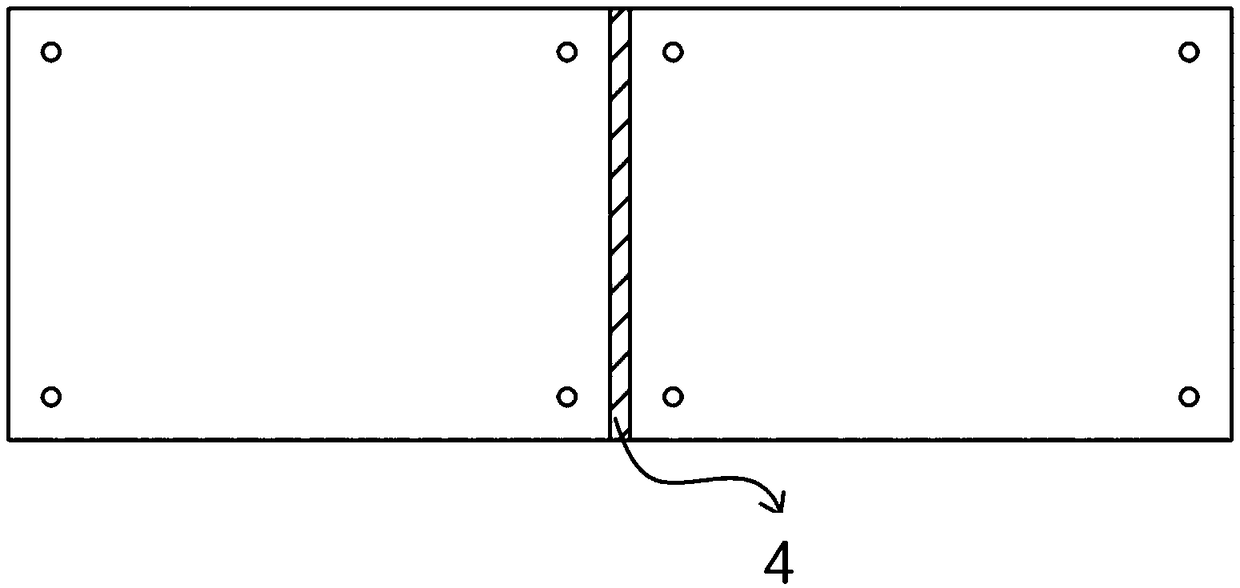

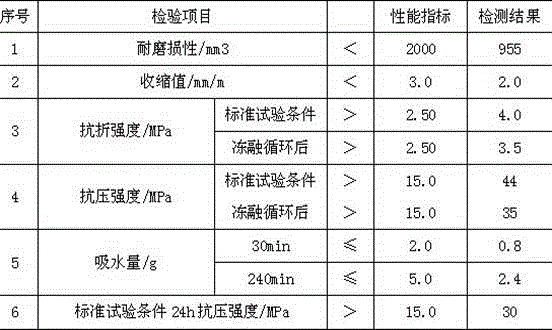

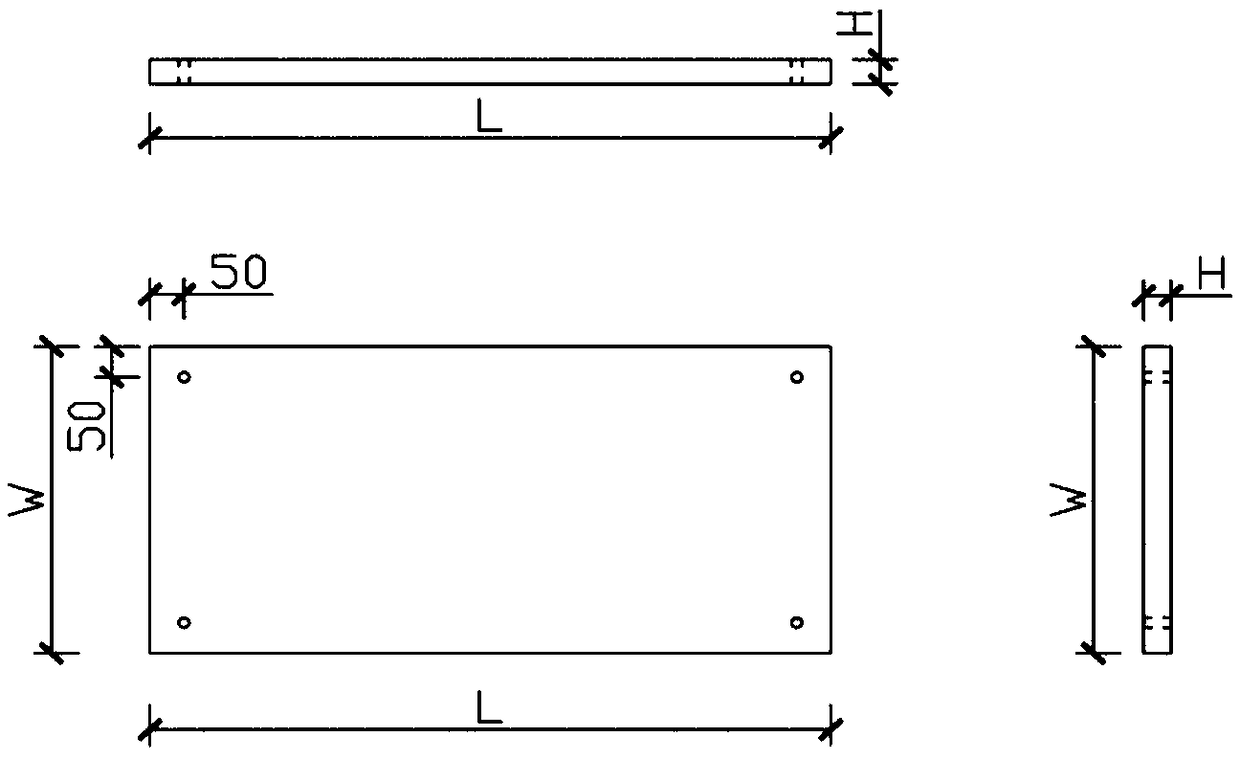

Ultra-high-flexibility concrete inorganic decorative board having pattern-contained surface and preparation method thereof

PendingCN109138310AImprove toughnessSmall shrinkageCovering/liningsCeramic shaping apparatusFlexural strengthCompressive strength

The invention, which relates to the technical field of building decoration materials, discloses an ultra-high-flexibility concrete inorganic decorative board having a pattern-contained surface. The ultra-high-flexibility concrete inorganic decorative board is made of ultra-high-flexibility concrete reinforcement bars by means of prefabrication, wherein the ultra-high-flexibility concrete reinforcement bars have the compressive strength greater than 100 MPa and the bending strength greater than 16 MPa. A decoration pattern is formed on the upper surface of the decorative board; and communicatedmounting bolt holes are formed in the four corners of the decorative board. The reinforcement bars are criss-cross webs; and the adjacent decorative boards are connected by using structural sealants.According to the invention, the inorganic decorative board that is prepared by using ultra-high-flexibility concrete based on vacuum defoaming has characteristics of high flexibility, diversified decorative effects, compact structure without pores, short mold turnover period, relatively low price, good fire-resistant performance, good staining-resistant and waterproof properties, and high durability and is suitable for development and application of green energy-saving decorative materials.

Owner:黄贺明

Inorganic mineral sand putty with decoration performance

ActiveCN104804504AWith mechanical bite forceGood construction stabilityFilling pastesAdditive ingredientMaterials science

The invention provides inorganic mineral sand putty, which consists of the following ingredients in parts by weight: 15 to 40 parts of silicate cement and 1 to 20 parts of attapulgite. In another scheme, the inorganic mineral sand putty comprises the following ingredients in parts by weight: 15 to 40 parts of silicate cement, 1 to 20 parts of attapulgite and 0 to 345 parts of padding. The inorganic mineral sand putty provided by the invention has the advantages that the decoration performance is realized, in addition, the construction performance is good, the construction procedures can be greatly simplified, the construction efficiency is improved, and the construction cost is reduced.

Owner:GUANGZHOU SHENGJING ENVIRONMENTAL BUILDING MATERIALS CO LTD

Quick-drying caulking agent with stain-resistant function

The invention discloses a quick-drying caulking agent with stain-resistant function,belongs to the field of caulking agent.The caulking agent is formulated by the following component by weight: 5-20 parts of white portland cement,15-30 parts of aluminate cement,4-10 parts of hemihydrategypsum, 0-2 parts of anhydrite, 0-5 parts of calcium powder, 40-50 parts of quartzsand, 0.5-1 parts of shrinkage reducing agent,0.5-2 parts of water repellent,0.5-3 parts of antifoam agent, 0.5-2 parts of cellulose ether. The invention acceleratesthe condensation of the caulking agent by using of aluminate cement semi-water gypsum ternary quick-drying system,and prevents the leakage of soluble salts to a certain extent, avoids the problem of saltpetering for materials from the source; and the construction period is greatly shorted, the labor costs is reduced;and at the same a dense material layer is formed,the compactness of the material is increased in combined with the role of hydrophobic agent and rubber powder, the invention improves the problems of loosen and porous and not stain-resistant of ordinary cement-based material, the stain-resistant performance of the caulking agent is greatly improved.

Owner:西卡(上海)管理有限公司

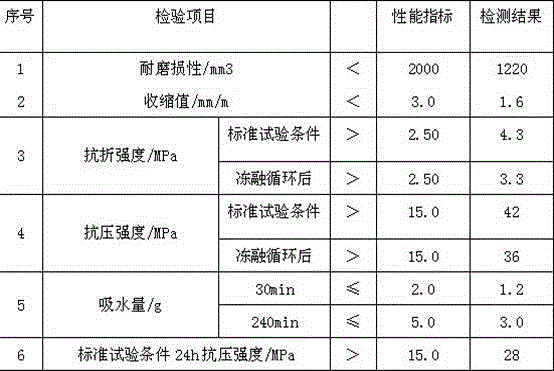

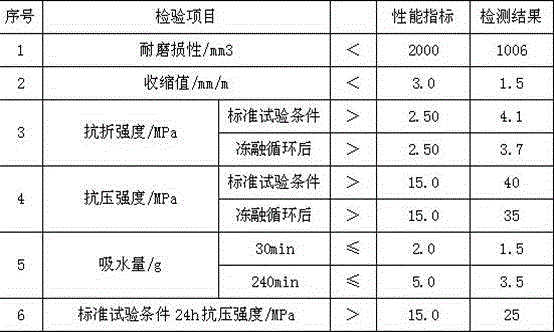

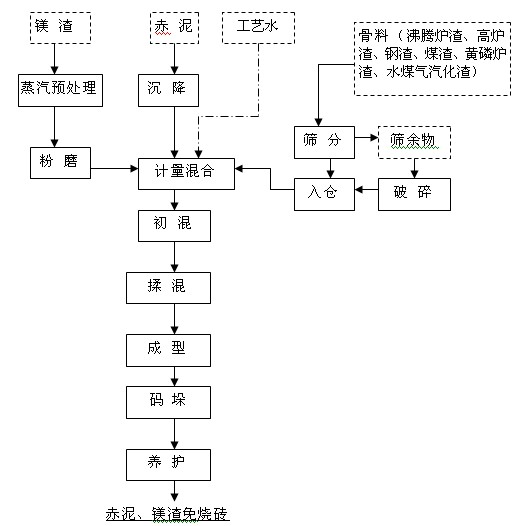

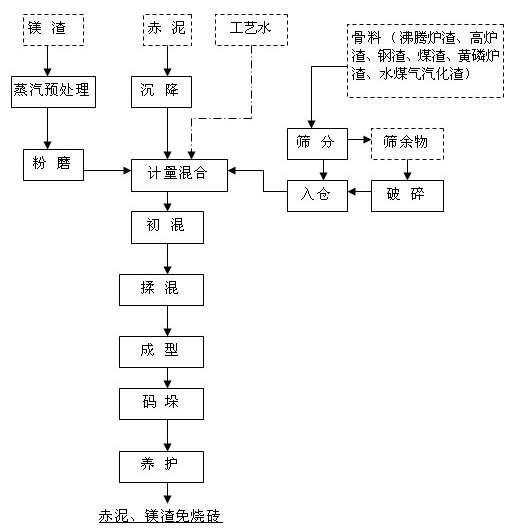

Method for producing braking-free brick from red mud and magnesium slag used as main materials by press shaping

The invention relates to a method for producing a braking-free brick from red mud and magnesium slag used as main materials by press shaping, belonging to the technical fields of resource comprehensive utilization and novel building materials. The method comprises the following steps: based on red mud and magnesium slag used as main raw materials and other industrial waste slag used as aggregate,mixing pretreated magnesium slag, aggregate and red mud according to a proper ratio to obtain a mixed material, adding water to the mixed material until the total water content of the mixed material reaches the requirement, mixing, carrying out static pressure shaping, stacking, curing with steam and carrying out other brick manufacturing processes to obtain the braking-free brick, wherein the mass ratio of red mud to magnesium slag to aggregate is (45-50):(35-40):(10-15), and the ratio of the mixed material to water is 100:(28-32). The method has the advantages that: 100% raw materials are industrial wastes, red mud can be used after simple sedimentation, no any valuable industrial raw materials are added in production processes, the curing mechanism is identical to the mechanism of building fly ash into blocks, the production process is simple, and the energy consumption is low; and the product has the characteristics of high strength, high carbonization coefficient, high softening coefficient, low water absorption rate, alternate moist and heat resistance, good frost resistance, no efflorescence and the like.

Owner:KUNMING UNIV OF SCI & TECH

Super-high-toughness concrete decorative plate and preparation method thereof

PendingCN109184117AReduce toughnessSmall electric fluxCovering/liningsFlooringFiberFlexural strength

A super-high-toughness concrete decorative plate is characterized in that the decorative plate is prefabricated by using super-high-toughness concrete with compressive strength greater than 100MPa andflexural strength greater than 16MPa and reinforcing bars; run-through installation bolt holes are arranged in the four corners of the decorative plate; adjacent decorative plates are connected by structural sealant; the reinforcing ribs are a crisscross fiber mesh and the surfaces of the reinforcing ribs are dip-coated with reinforcing resin; the reinforcing ribs are located in the interlayer ofthe decorative plate; and both the upper and lower surfaces of the reinforcing ribs are covered with a layer of concrete material. The decorative plate prepared by vacuum defoaming from super-high-toughness concrete in the technical scheme of the invention has the characteristics of good toughness, low brittleness, bright color, good pollution resistance and waterproofing performance, relativelylow price, no radiation, good fire resistance and strong durability, and is suitable for the development and application of green energy-saving decorative materials.

Owner:GUANGDONG GAITEQI NEW MATERIAL TECH CO LTD

A non-fired brick with red mud and magnesium slag as the main materials

The invention relates to a baking-free brick based on red mud and magnesium slag as main materials and belongs to the technical fields of novel building materials and comprehensive utilization of resources. The baking-free brick consists of red mud and aggregate, wherein the mass ratio of red mud to magnesium slag to aggregate is (45-50):(35-40):(10-15); the ratio of mixture to water is 100:(28-32); the aggregate is one or any mixture of more of industrial solid wastes such as boiled furnace slag, blast furnace slag, steel slag, coal slag, yellow phosphorus furnace slag, water gas gasifying slag and the like which are subjected to quick cooling at high temperature; and the content of SiO2 and Al2O3 in the aggregate is less than 65%. According to the invention, the baking-free brick is obtained by brick-manufacturing processes such as raw material pretreatment, mixing, static pressure formation, palletizing, steam curing and the like. According to the invention, the production process is simple, the energy consumption is low, and the product has the characteristics of high strength, high carbonization coefficient, high softening coefficient, low water absorption, damp and hot alternation resistance, good freezing resistance, no crystalline bloom and the like.

Owner:KUNMING UNIV OF SCI & TECH

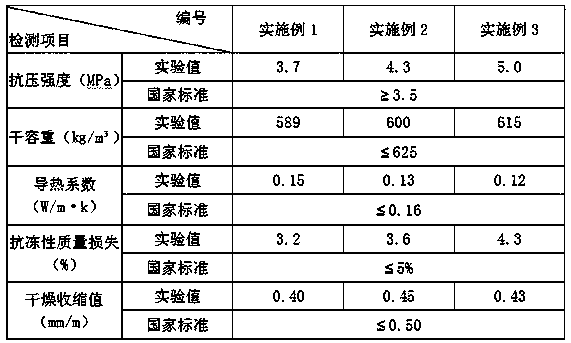

Red mud geopolymer foam building block and preparation method thereof

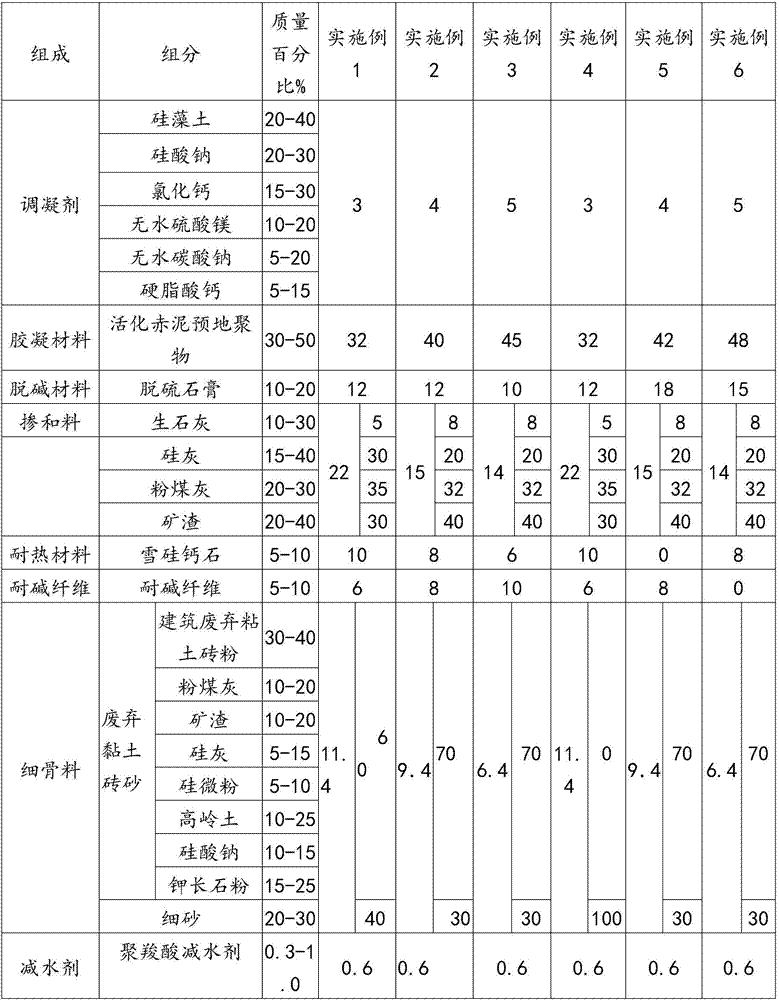

InactiveCN107572920ASolve the ubiquitous problemImprove thermal insulation performanceCement productionCeramicwareFiberThermal insulation

The invention provides a red mud geopolymer foam building block and a preparation method thereof. The red mud geopolymer foam building block is prepared from the following components in percentage bymass: 30-50% of activated red mud pre-geopolymer, 6-15% of fine aggregate, 10-20% of desulfurized gypsum, 10-25% of admixture, 2-8% of thickening time control agent, 5-10% of tobermorite, 5-8% of alkali-proof fiber and 3-5% of hydrogen peroxide. By adopting the technical scheme of the invention, the problem of efflorescence of a red mud lightweight wall building block is solved; meanwhile, by adding the tobermorite with excellent thermal insulation property, the thermal insulation property of the red mud and foam building blocks is remarkably enhanced.

Owner:南宁恒慕科技有限责任公司 +1

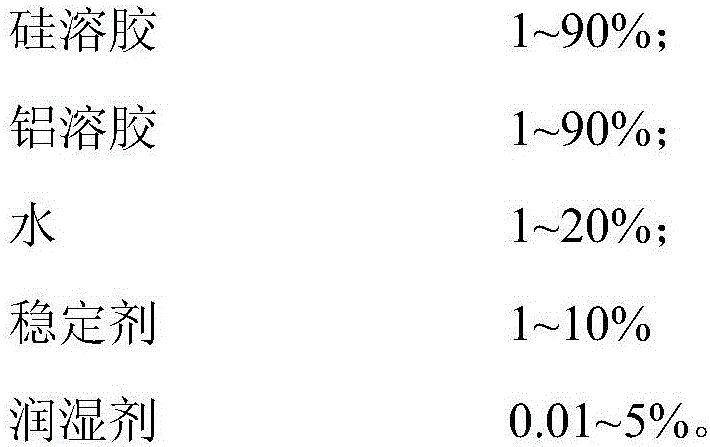

Cement hardening agent and preparing method thereof

The invention relates to a cement hardening agent and a preparing method thereof. The hardening agent is prepared from 1-90% of silica sol, 1-90% of alumina sol, 1-20% of water, 1-10% of a stabilizing agent and 0.01-5% of a wetting agent, wherein the mass of the hardening agent is considered as 100%. Silica sol and alumina sol are adopted as main components, and hardness and abrasion resistance of cement can be improved substantially. Meanwhile, the preparing method is simple and convenient, which is beneficial for reducing industrial production cost. Paint can be prepared by stirring and dispersing the raw materials through the preparing method, the preparing technology is simple, easy to implement, convenient to operate and beneficial for large-scale industrial production and reduces industrial production cost, and the cement hardening agent is particularly suitable for heavy load bearing cement-based terraces of an industrial factory building, a parking lot and the like and has broad application prospects.

Owner:HANGZHOU GELING NEW MATERIAL TECH

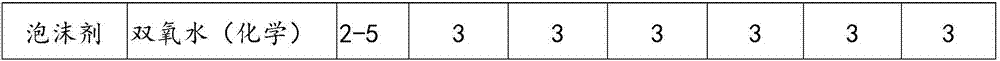

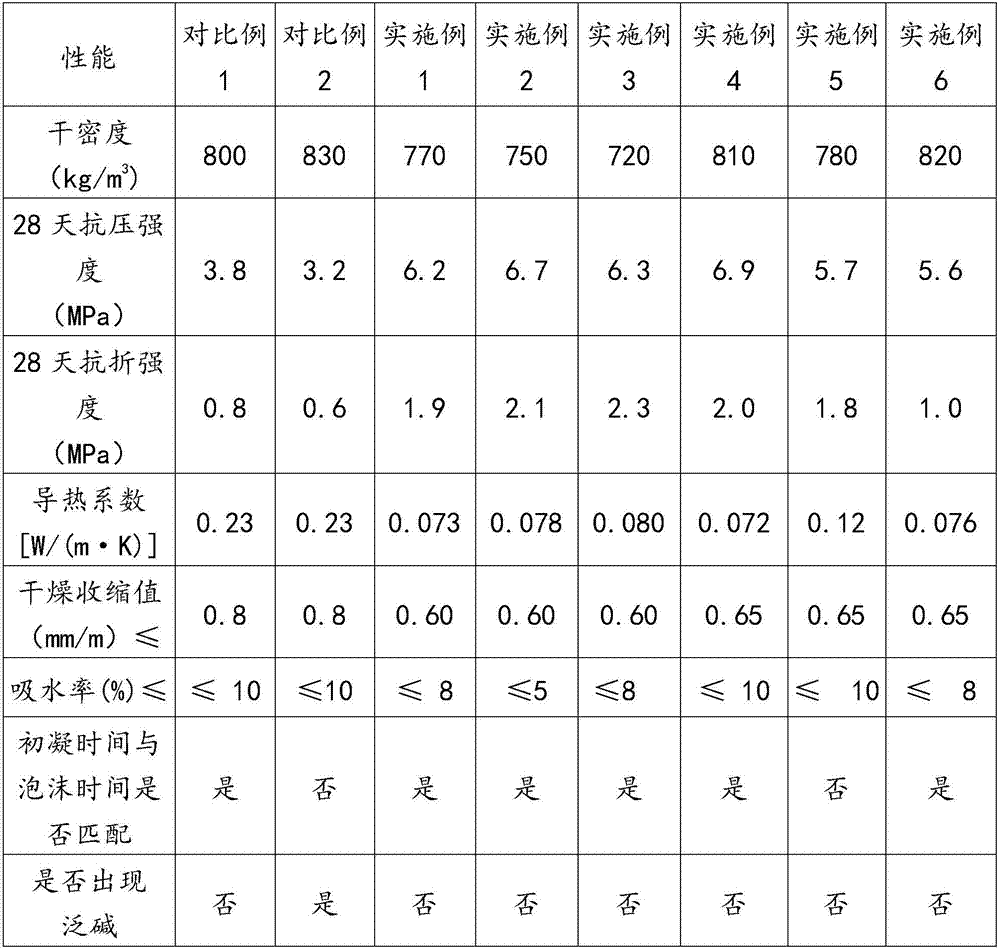

Red mud and aluminum ash based steam-curing-free aerated concrete and preparation method thereof

InactiveCN109534761ASolve the ubiquitous problemSolving the ubiquitous problemCeramicwareHydrogenRed mud

The invention provides a red mud and aluminum ash based steam-curing-free aerated concrete and a preparation method thereof. The aerated concrete is prepared through the following steps: adding a proper amount of water into a powder material, carrying out blending at a normal temperature so as to prepare a slurry, and carrying out aging and foaming. According to the invention, the mass of water accounts for 30 to 50% of the mass of the powder material; the mass of a water reducing agent accounts for 0.5 to 1% of the mass of the powder material; and the powder material comprises the following components by mass: 20 to 30% of a calcium cementing material, 15 to 30% of aluminum ash and 40 to 65% of red mud. According to a technical scheme of the invention, the red mud is utilized to react with the calcium cementing material at a normal temperature to establish mechanical strength; elemental aluminum in the aluminum ash is utilized to react with strong alkali in the red mud to generate hydrogen gas for foaming expansion; and the elemental aluminum in the aluminum ash eliminates the strong alkali in the red mud. Thus, the problem of efflorescence of a red mud building material product is solved, and highly-efficient utilization of the elemental aluminum in the aluminum ash is realized. Meanwhile, through proper increase of the calculation amount of the aluminum ash, the rate of foaming and the viscosity of the slurry are balanced, and the problem of difficult foaming due to viscousness of a red mud fresh slurry is solved.

Owner:CHINA UNIV OF MINING & TECH

Architectural decoration mortar and application thereof

InactiveCN106587883AAvoid generatingWith coloring decoration beautification effectFiberMaterials science

The invention relates to architectural decoration mortar and an application thereof. The architectural decoration mortar contains the ingredients in parts by weight: 24-28 parts of silicate cement, 40-65 parts of high-alumina cement, 7-15 parts of plaster, 200-240 parts of quartz sand with the particle size of 40 to 70 meshes, 440-475 parts of quartz sand with the particle size of 70 to 140 meshes, 0.5-2.2 parts of wood fibers and 5-33 parts of metal alloy pigment. According to the architectural decoration mortar, the silicate cement, the high-alumina cement and the plaster serve as a gelatinization system, the silicate cement and the high-alumina cement can rapidly produce ettringite with the plaster in case of encountering water, the ettringite wraps the surface of cement clinker so as to form a protective film, thus, the production and further hydration of calcium hydroxide are avoided, then, the production of alkalis is reduced, and the problem of efforescence is solved. The high-alumina cement and the silicate cement jointly produce gehlenite hydrate during hydration; and by adopting the quartz sand of size distribution and the wood fibers, the mechanical strength and durability of the architectural decoration mortar are further guaranteed. The architectural decoration mortar can reflect 10% to 20% of infrared radiation in sunlight, thereby playing roles in insulating heat and saving energy.

Owner:CHINA MINGSHENG DRAWIN TECH INVESTMENT CO LTD

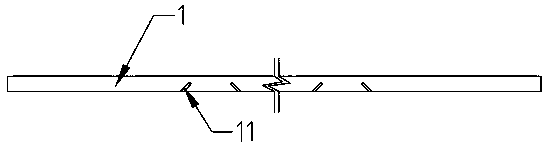

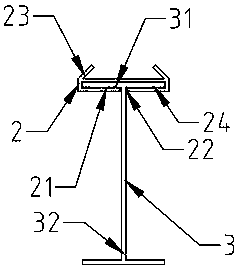

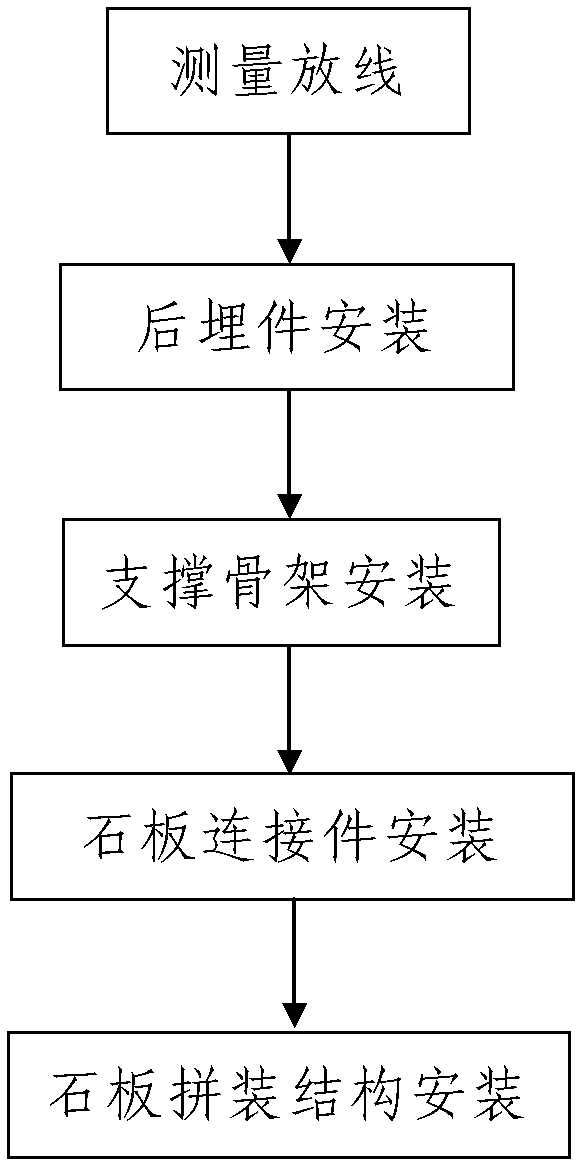

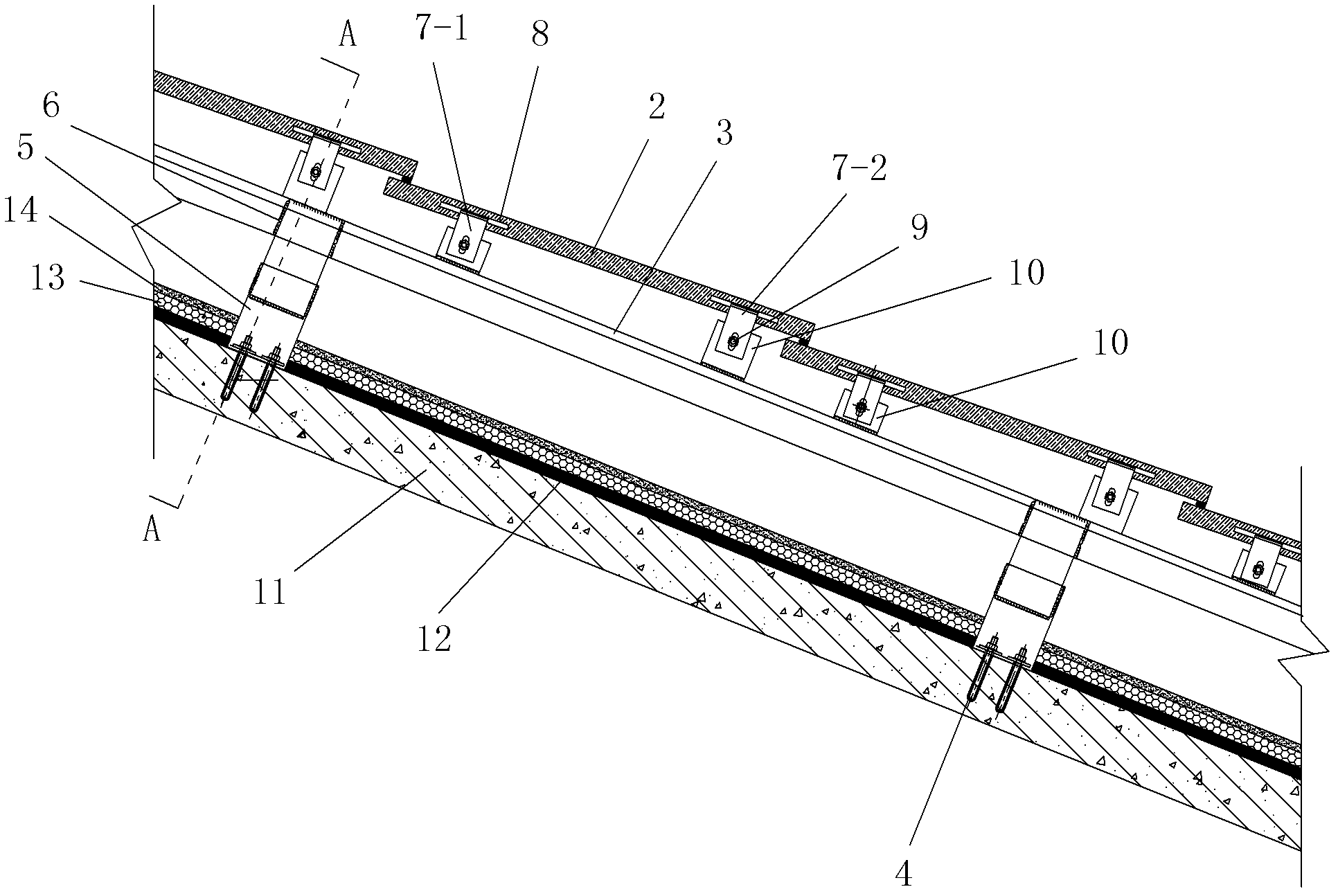

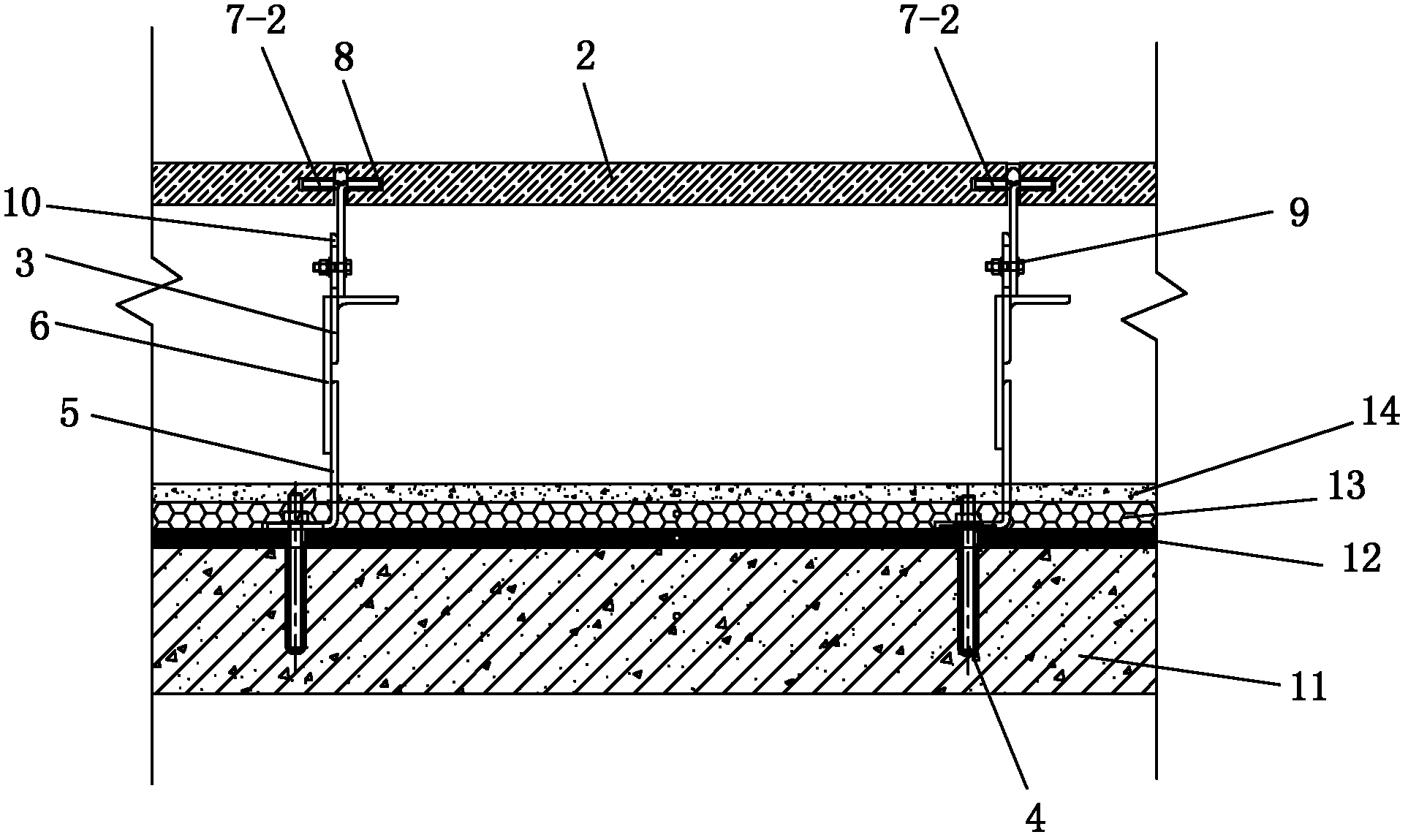

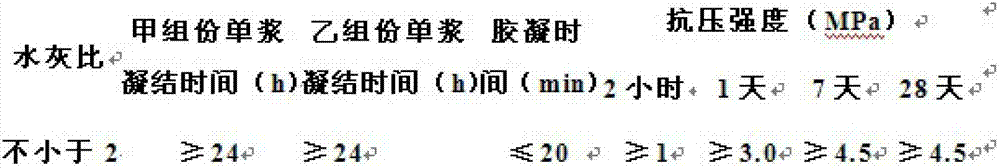

Construction method of overhead stone plate of slope roof

InactiveCN102561710ASimple stepsEasy to operateBuilding roofsBuilding material handlingAssembly structureBuilding construction

The invention discloses a construction method of an overhead stone plate of a slope roof. The overhead stone plate is arranged on the constructed slope roof and comprises a supporting framework and a plurality of stone plate assembly structures, wherein the supporting framework consists of multiple rows of supports, the stone plate assembly structures are mounted on the supporting framework from bottom to top, a plurality of rectangular stone plates which are arranged on the same plane are continuously assembled from left to right to form each stone plate assembly structure, the lap joint length between each two vertically adjacent stone plate assembly structures is not smaller than 30mm, and a plurality of groups of stone plate connectors which support the stone plate assembly structures are disposed on the supports from top to bottom. The construction process of the overhead stone plate comprises steps of 1, measuring and paying off a line; 2, mounting the supporting framework; and 3, mounting the stone plate assembly structures. The construction method is simple in step, convenient in implementation, easy to guarantee construction quality, high in construction efficiency and fine in construction effect, and can resolve problems that an existing construction method of a stone plate of a slope roof is complex in process, low in work efficiency, high in invested cost and difficult to guarantee construction quality, and the like.

Owner:SCEGC NO 6 CONSTR ENG GRP CO LTD

High-moisture filling material and preparation method thereof

The invention discloses a high-moisture filling material and a preparation method thereof. The high-moisture filling material comprises a composition A and a composition B, wherein the composition A comprises 52.4 to 95 by weight percent of sulfo-aluminate cement clinkers, 2.7 to 39 by weight percent of aluminate cement clinkers, 0.3 to 2 by weight percent of setting retarder, and 1.5 to 8 by weight percent of suspending agent; the composition B comprises the following ingredients: 40 to 80 by weight percent of anhydrite, 10 to 30 by weight percent of lime, and 10 to 36 by weight percent of compound additives. The high-moisture filling material has the advantages of easily-available raw materials, low price, good stability, high long-term strength and no risk of surface efforescence.

Owner:CCTEG CHINA COAL RES INST

Sand planting and wet combining process for vetrified tiles

InactiveCN105822030AReduce repair costsSolve the problem of efflorescence and hollowingCovering/liningsBuilding material handlingAgricultural engineeringBiology

The invention relates to a sand planting and wet combining process for vetrified tiles. Sand planting is performed on the back of the vetrified tiles to achieve a roughening effect. The tiles are connected with cement, have adhesive force and are constructed according to the previous wet combining mode. The process comprises the following specific steps of: (1) preparing materials; (2) cleaning and drying the back of the tiles; (3) performing glue preparation; (4) pouring the glue; (5) paving sand; (6) paving after curing; and (7) watering and maintaining. The process disclosed by the invention has the advantages that (1) the strength and anti-permeability can be enhanced; (2) the repair cost is reduced; and (3) problems of alkali whiskering and hollowing are solved, and the rigidity of the wall and the shock strength of the wall space are improved.

Owner:曹颖

Test method used for detecting concrete product efflorescence degree

InactiveCN108918576ASolve the ubiquitous problemHigh strengthMaterial thermal analysisBrickAbsorption saturation

The invention relates to a test method used for detecting concrete product efflorescence degree. The test method comprises following steps: 1, test piece preparation is carried out, wherein moulded test pieces are separated in groups, the 1th group is taken as a reference group, and no efflorescence inhibitor is added into the 1th group, and different efflorescence inhibitors are added into the 2th to the Nth groups based on the mass ratio of the efflorescence inhibitors to cement; 2, 7 days of natural curing is carried out; 3, the above test pieces are immersed in a sodium chloride solution with a concentration of 1% for water absorption saturation; 4, high low temperature circulation is adopted for efflorescence test, and efflorescence situations are recoded; 5, the ideal efflorescence inhibitor is determined based on ideal efflorescence situations on the test piece surfaces after 5 to 7 circulations of step 4; and 6, verify test is carried out. The test method can be used for effective examination of pavior brick efflorescence effectively, the reasonable efflorescence inhibitor is selected, the strength and the compactness of the pavior bricks and road edge stones are improved,and it is beneficial for improvement of product quality.

Owner:爱尔建材(天津)有限公司

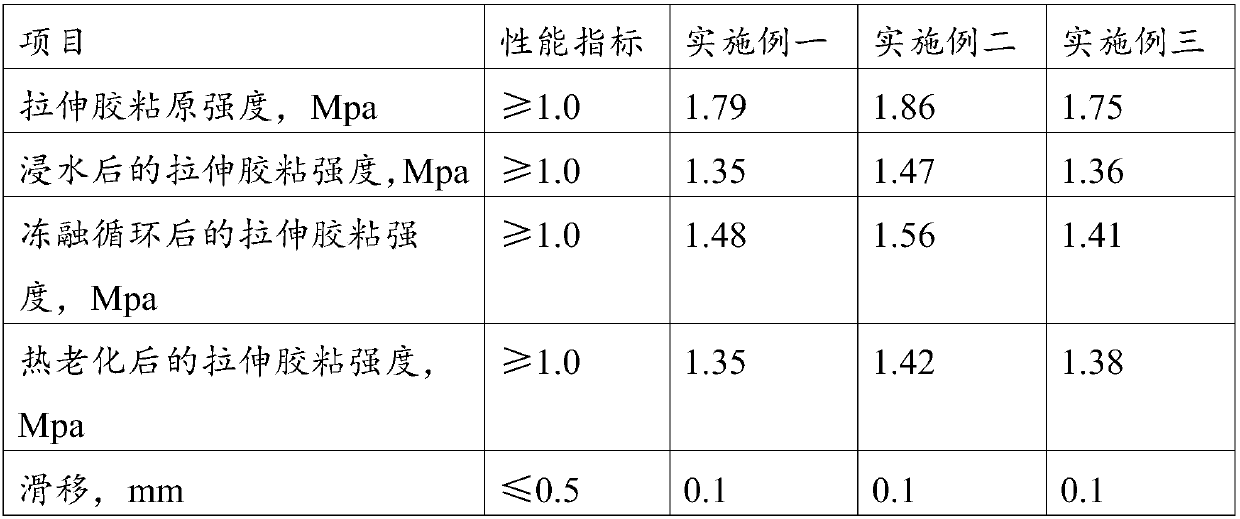

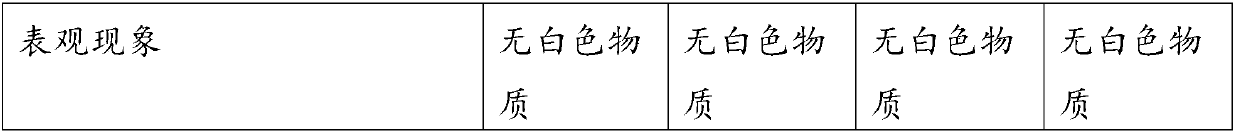

Adhesive for tiles and preparation method of adhesive

The invention relates to the technical field of building materials, in particular to an adhesive for tiles and a preparation method of the adhesive. The adhesive comprises, by weight, 25-38 parts of Yellow River sediments, 20-35 parts of dry fine sand, 10-25 parts of sludge, 12-20 parts of cement, 2-10 parts of rosin saponified products, 1-5 parts of water-soluble silicate, 1-5 parts of re-dispersible latex powder and 0.2-2 parts of micro-expansion agents. The adhesive for the tiles has high bonding strength, water resistance, corrosion resistance and thermal aging resistance (70 DEC C), and can withstand tests in which wet and dry conditions alternate or freezing and thawing conditions alternate, completely solving the problems of whiskering, hollowing and peeling of the tiles.

Owner:陈谓清

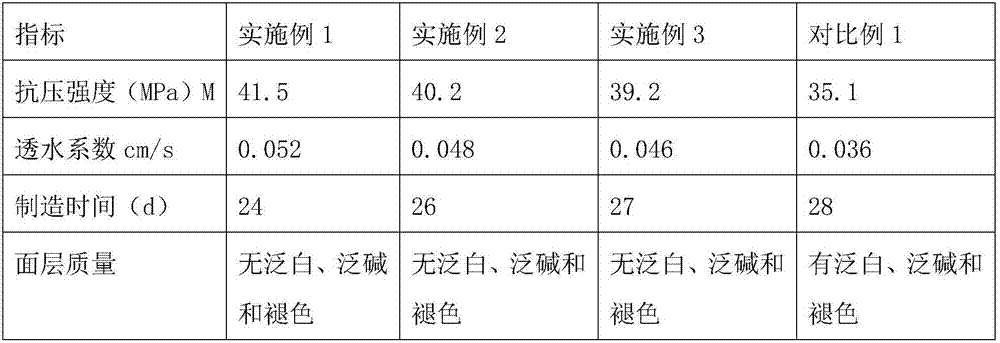

Color steel slag road pavement brick and preparation method thereof

InactiveCN107117880ASolve the problem that waste cannot be reusedGood water permeabilityBrickRed mud

The invention provides a color steel slag road pavement brick and a preparation method thereof, and relates to the technical field of production of road pavement bricks. The color steel slag road pavement brick comprises a surface layer and a bottom layer, wherein the surface layer is prepared from the following raw materials in parts by weight: 17 to 25 parts of cement, 25 to 30 parts of steel slag molding sand, 18 to 20 parts of quartz sand, 5 to 10 parts of crushed stone, 3 to 6 parts of volcanic ash, 3 to 5 parts of zeolite, 3 to 6 parts of red mud, 4 to 6 parts of mixture, 0.2 to 0.4 part of quick setting agent, 1.3 to 2.3 parts of early strength agent, 0.5 to 1.5 parts of alkaline efforescence-resistant agent, 0.3 to 0.5 part of pigment powder, 1.2 to 1.6 parts of water reducing agent and 1 to 3 parts of water; the bottom layer is prepared from the following raw materials in parts by weight: 16 to 25 parts of cement, 22 to 28 parts of steel slag molding sand, 19 to 25 parts of crushed stone, and 2 to 3 parts of water. The preparation method comprises the following steps of weighing the raw materials, manufacturing the surface layer, manufacturing the bottom layer, forming, demolding, stacking and curing. The color steel slag road pavement brick and the preparation method can solve the problems of failure to reutilize the wastes, poor water permeability, low compressive strength, long manufacturing time, whitening, alkaline efforescence discoloring of the surface layer, and the like.

Owner:合肥慧林建材有限公司

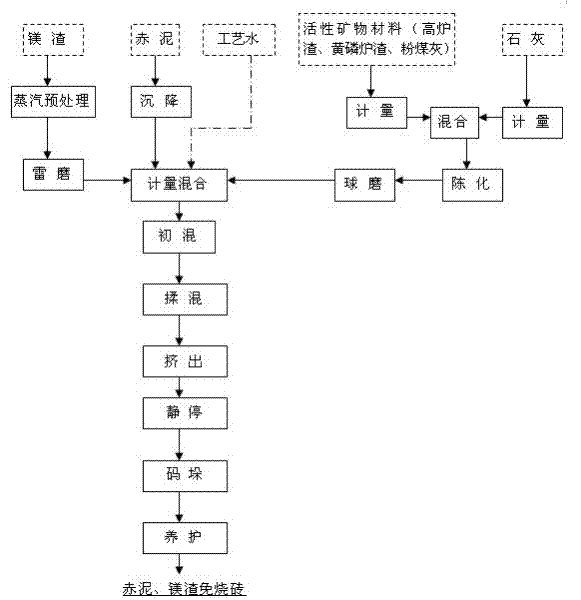

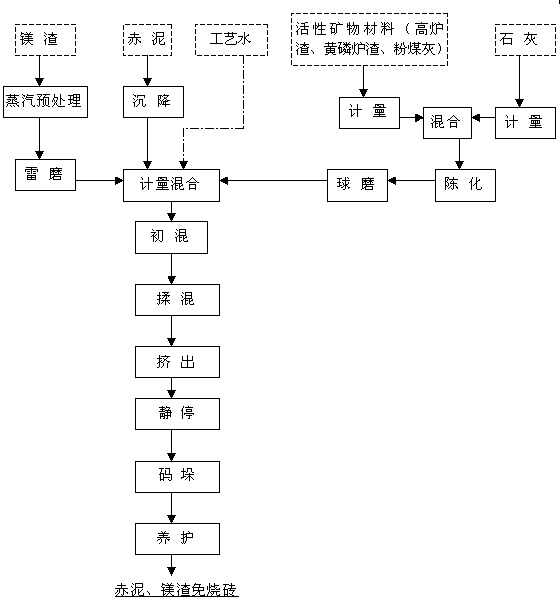

Method for producing baking-free brick mainly from red mud and magnesium slag by extrusion molding

The invention relates to a method for producing a baking-free brick mainly from red mud and magnesium slag by extrusion molding and belongs to the technical fields of comprehensive utilization of solid waste resources and novel building materials. The baking-free brick is produced by the processes of raw material pretreatment, grinding, metering, stirring and primary mixing, forced mixing, extruding, cutting, steam curing and the like. According to the mass ratio of red mud to magnesium slag to active mineral materials (blast furnace slag, yellow phosphorus furnace slag and fly ash) to lime is (45-50): (35-40): (10-15): (2-5); the mass ratio of a batch mixture to water is 100: (32-35); and the active mineral materials can be individually used and can also be mixed and collocated for use. In the batch mixture of the invention, the moisture of red mud can be up to more than 65%; production of a blank can be carried out by using a traditional vacuum extruder, and operation is simple; the product is easy to build, blank hardening speed is high, static curing time is short, occupied field is less, and energy consumption is low; and the product has the advantages of high strength, high carbonization coefficient, high softening coefficient, low water absorption, good damp and hot alternation resistance and frost resisting capacities and no saltpetering.

Owner:KUNMING UNIV OF SCI & TECH

Preparation method of waterproof agent

The invention discloses a preparation method of a waterproof agent, and belongs to the technical field of building waterproofing. A soap-free emulsion method is adopted in the process of preparing anacrylic emulsion; the water resistance and the cohesiveness of the waterproof agent are improved; corn starch reacts with epichlorohydrin, and grafted with acrylic acid, a graft with a network structure is obtained; coconut oil reacts with ethylene glycol butyl ether under an alkaline condition to obtain fatty acid salt; the plugging waterproof performance and the durability of the waterproof agent are improved; sodium silicate in the waterproof agent reacts with calcium ions in cement paste to generate a hydrated calcium silicate C-S-H colloidal core, C-S-H gel can be formed by the hydrated calcium silicate C-S-H colloidal core and calcium hydroxide in cement, and whiskering problem of the waterproof agent is avoided; sodium silicate is dissolved in water to form a colloidal sodium silicate aqueous solution, the particle size of the colloidal sodium silicate aqueous solution is smaller than that of cement particles, concrete micropores and gaps formed by hydration of the cement particles can be filled with particles of the colloidal sodium silicate aqueous solution, the microstructure of plastic slurry and set cement is improved, and the permeability of concrete to water is reduced.

Owner:广州国色生物科技有限公司

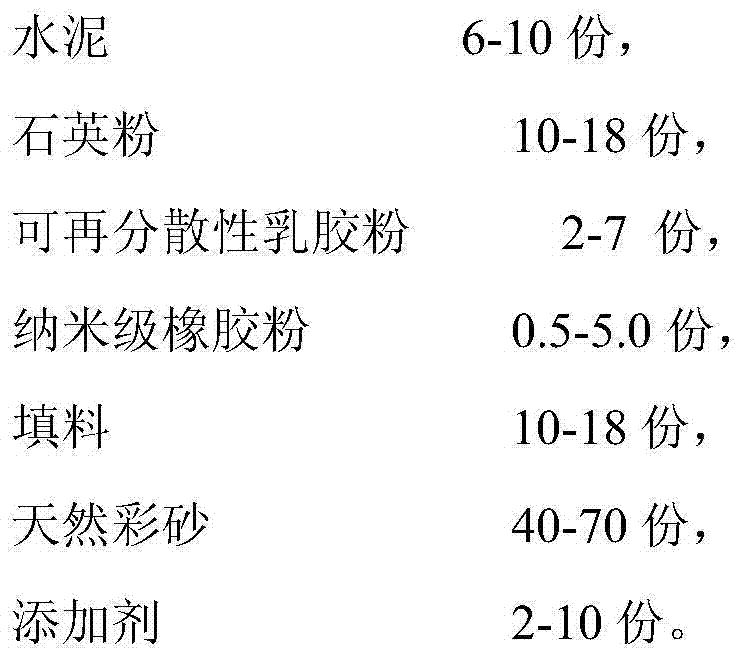

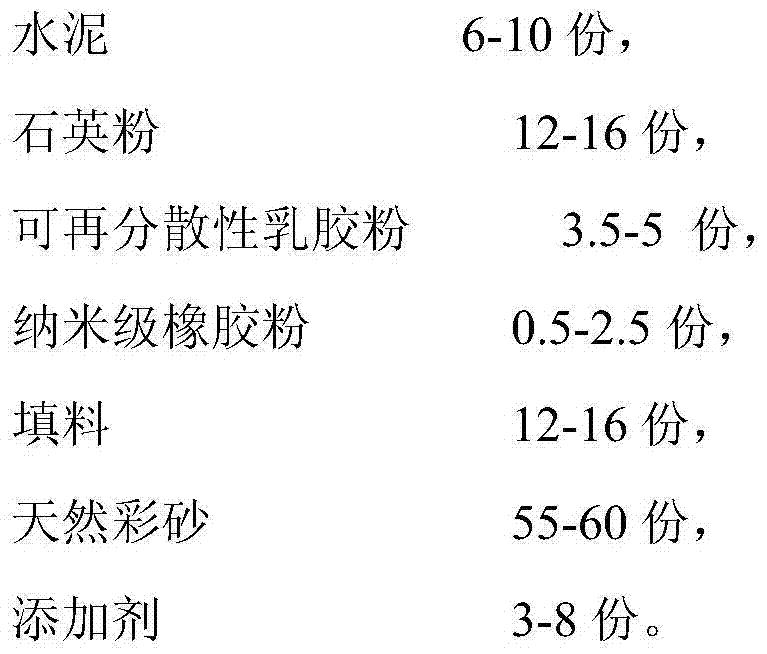

Veneer mortar for whiskering-resistant outer walls

The invention provides a veneer mortar for whiskering-resistant outer walls, into which nano rubber powder is introduced. The rubber powder can retard the cement component from moving toward the coating surface, thereby well solving the problem of whiskering. In one typical embodiment, the veneer mortar is mainly composed of cement, quartz powder, redispersible latex powder, nano rubber powder, filler, natural sand and additives, and a reinforcer is preferably introduced.

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD

Method for producing baking-free brick mainly from red mud and magnesium slag by extrusion molding

The invention relates to a method for producing burn-free bricks by utilizing red mud and magnesium slag, and belongs to the technical field of comprehensive utilization of solid waste resources and new building materials. Unburned bricks are produced by raw material pretreatment, grinding, metering, initial mixing, forced mixing, extrusion, cutting, steam curing and other processes. Red mud: magnesium slag: active mineral materials (blast furnace slag, yellow phosphorus slag, fly ash): the mass ratio of lime is 45-50: 35-40: 10-15: 2-5; the mass ratio of batch material to water is :100:32~35. Active mineral materials can be used alone or mixed and matched. The moisture content of the red mud in the ingredients of the present invention can be as high as 65% or more, and the traditional vacuum extruder can be used for raw and bad production. The operation is simple, the product is easy to build, the green body hardens quickly, the static maintenance time is short, and the occupied space is small. Low energy consumption. The product has high strength, high carbonation coefficient, high softening coefficient, low water absorption, alternating humidity and heat resistance, good frost resistance, and no efflorescence.

Owner:KUNMING UNIV OF SCI & TECH

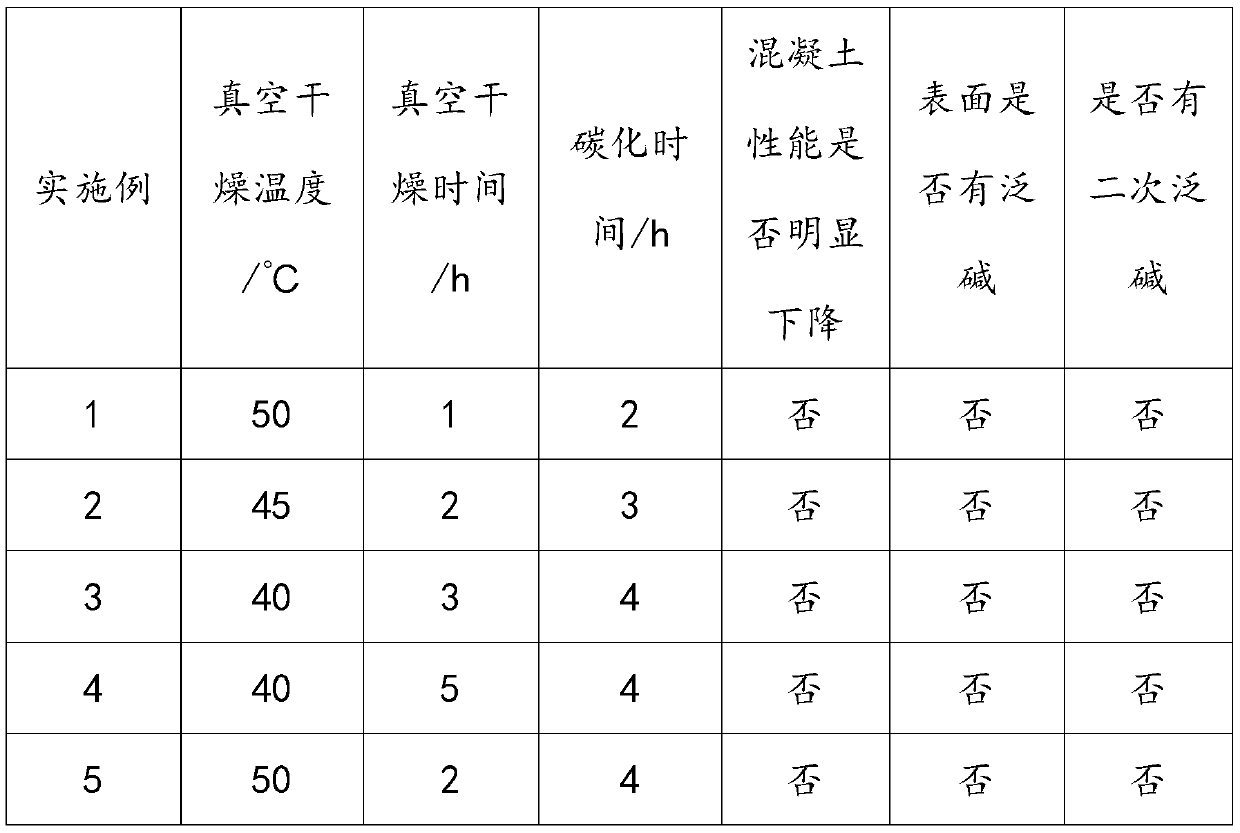

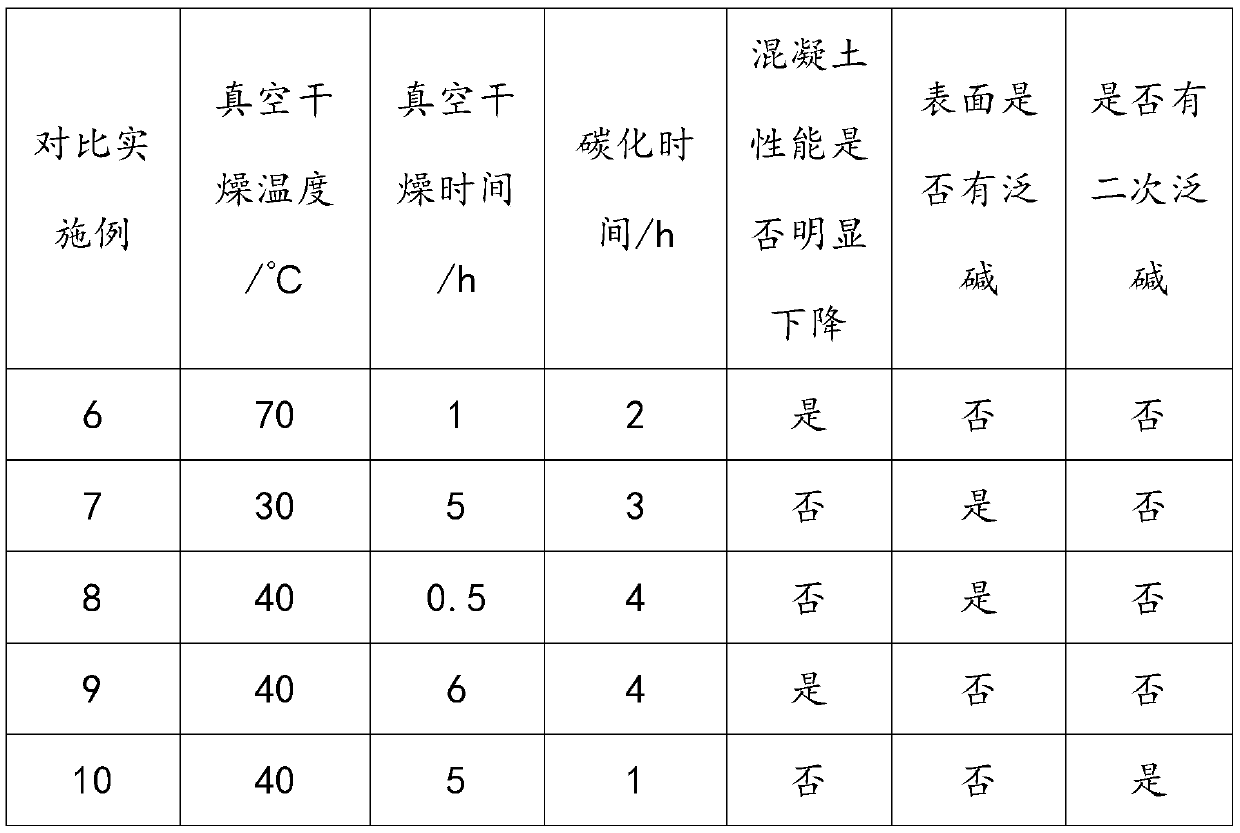

Method for treating surface of transfer printing concrete

InactiveCN110480811ASolve the ubiquitous problemSolve chromatic aberrationCeramic shaping apparatusEngineeringVacuum drying

The invention discloses a method for rapidly treating the surface of transfer printing concrete. The method solves the problem that the color difference is caused due to the fact that the surface of existing transfer printing concrete is prone to whiskering. According to the technical scheme, the method comprises the following steps: putting the just-scoured transfer printing concrete into a vacuum drying oven for vacuum drying; and then carrying out surface accelerated carbonation treatment on the dried transfer printing concrete. The method has a remarkable anti-whiskering effect, is stableand reliable, and is capable of effectively improving the yield and impression quality of the transfer printing concrete.

Owner:HUBEI UNIV OF TECH

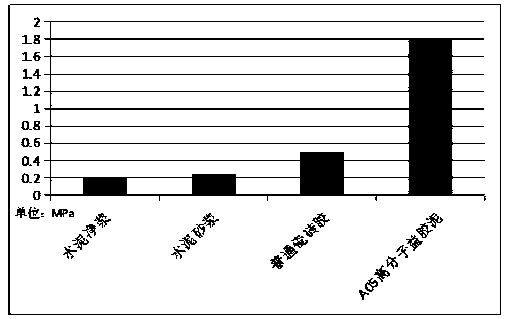

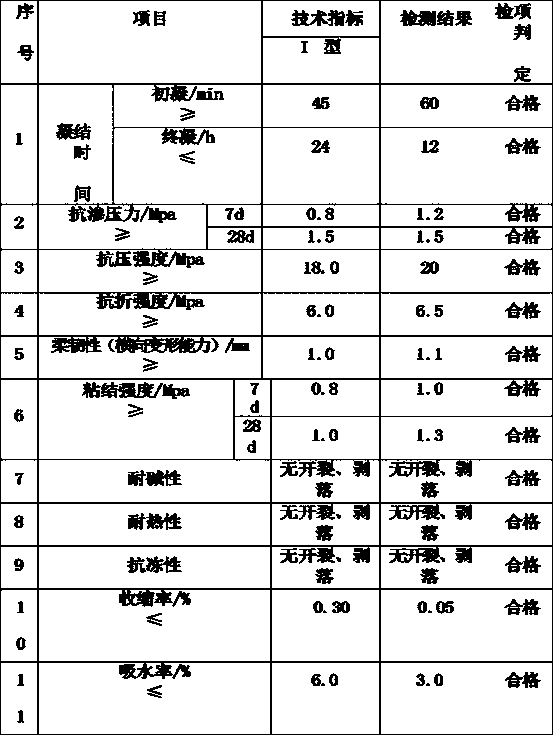

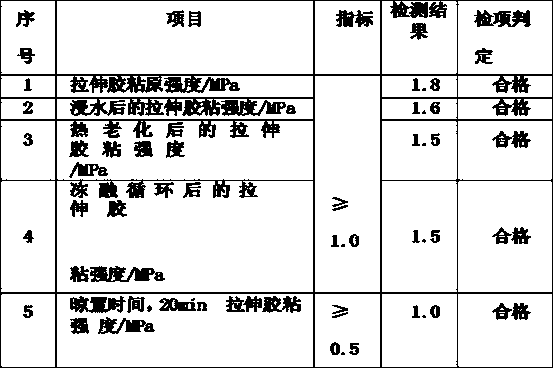

Novel construction scheme of garden waterscape building

InactiveCN109914175ASolve the ubiquitous problemNot ubiquinolinSingle unit pavingsTemporary pavingsPolymer modifiedBrick

The invention relates to a novel construction scheme of a garden waterscape building. The novel construction scheme of the garden waterscape building comprises the following operation steps: base surface pouring, base surface treatment, brick material paving and pasting and brick joint treatment, wherein the top layer during the base surface pouring is cement mortar; a waterproof layer needs to bescraped on the mortar base surface in batch for overall covering and sealing during the base surface treatment; a polymer modified cement-based binder is used for brick material paving and pasting; and waterproof and weather-resistant joint filling materials with efflorescence inhibition are selected for brick joint treatment. The novel construction scheme of the garden waterscape building can effectively solve problems of efflorescence, hollowing and falling of decorative stone materials of the garden waterscape often exposed in practice; and the novel construction scheme can effectively solve common problems of efflorescence, hollowing and falling of decorative bricks and the like of the garden waterscape building by performing waterproofing and impermeability treatment on the base surface with 'K66 polymer cement waterproof mortar' of Lejiang Brand and pasting the decorative bricks with 'A05 polymer plaster' of Lejiang Brand.

Owner:GUANGZHOU LEJIANG BUILDING MATERIALS CO LTD

Method for synergistically preparing baking-free steaming-free cured bricks from squeezed fine silt and lithium slag obtained after lepidolite beneficiation based on carbon curing

ActiveCN114031341ASolve storage problemsHigh strengthSolid waste managementCeramicwareCompression moldingBrick

The invention discloses a method for synergistically preparing a baking-free steaming-free cured brick from squeezed fine silt and lithium slag obtained after lepidolite beneficiation based on carbon curing, belonging to the technical field of solid waste treatment and resource utilization. The baking-free steaming-free cured brick comprises the following components by weight: 50-90 parts of the lithium slag, 0-50 parts of the squeezed fine silt, 10-25 parts of a curing agent, and 10-14 parts of water. According to the preparation method, the lithium slag and the squeezed fine silt which are byproducts in production of lithium carbonate from lepidolite are used as main raw materials; dissolution of alkali and sulfur in the lithium slag can be accelerated through raw material grain composition optimization and curing agent excitation, so excitation effect is further promoted; and the high-strength baking-free steaming-free cured brick with a volume weight of 2730 kg / m<3> can be obtained through compression molding and carbon curing. The method is wide in application range and mature in preparation technology; the formed brick does not need to be maintained, so the production efficiency of brick making is improved, the problem that the surface of the cured brick is prone to saltpetering is solved, and production cost is reduced; and resource utilization of the lepidolite byproduct slag is achieved, the problems of solid waste pollution and land occupation are reduced, and the environment-friendly and application requirements of the market for building materials are met.

Owner:江西省建材科研设计院有限公司

Light-weight fiber reinforced cement board and manufacturing method thereof

ActiveCN101781106BHigh tensile strengthHigh impact strengthSolid waste managementCement boardMixed materials

The invention provides a light-weight fiber reinforced cement board. The light-weight fiber reinforced cement board comprises 100 parts of cement, 20 parts of silicon powder, 15 parts of calcium powder, 5 to 10 parts of expanded perlite, 4 parts of paper pulp, 5 to 15 parts of wood fibers, 5 to 10 parts of wood powder, 1 to 2 parts of polypropylene fibers, 0.8 part of methyl cellulose, 1 to 3 parts of sodium chloride, 1 to 3 parts of sodium sulphate, 2 to 3 parts of sodium silicate, and 230 to 300 parts of water. The invention also discloses a method for manufacturing the light-weight fiber reinforced cement board, which comprises the following steps of: 1, weighing each component according to formula; 2, placing the weighed dry materials into a mixer for uniformly mixing; 3, preparing wet materials, placing the mixed materials obtained by the step 2 into a kneader, adding water and the wet materials into the mixed materials, and kneading the mixture; and 4, placing the kneaded slurryinto a mold, performing compression moulding by using a plate fluidizing machine, and then demolding. The manufacturing method greatly improves the tensile strength, the impact strength, the water-retaining property, and the extrusion property of the materials.

Owner:BEIJING NEW BUILDING MATERIALS PLC

High build decorative paint

The invention discloses an isopropanol-modified cement-based dry powder type decorative paint. The paint is evenly mixed with a certain quantity of water to obtain high build decorative paint. The high build decorative paint has the advantages of good weather resistance, no efforescence, water prevention, ventilation, low cost and good decoration.

Owner:XIAOGAN HENGSHENG BUILDING ENERGY SAVING MATERIALS

Indoor stone laying processing method

InactiveCN109797954AAchieve the purpose of blockingNo ubiquitous problemsBuilding constructionsCement coatingsRough surfaceSand blasting

The invention relates to the technical field of stone construction process, in particular to an indoor stone laying processing method, and aims to solve the problem that existing stone laying is hardin facing antiskid and anti-alkali processing. According to the technical scheme, the method includes the steps of S1, cleaning stone, and subjecting the stone to natural air drying or drying; S2, performing sand blasting on the dried stone; S3, preparing a waterproof curing agent, and evenly coating the surface of the stone with the curing agent to achieve a permeation sealing effect, wherein thecuring agent is conveyed in the micropore capillary of the stone to reach the internal pores of the stone so as to achieve the purpose of overall blocking; S4, performing base layer processing beforelaying, and arranging an under-layer aluminum veneer and a honeycombed aluminum plate on the to-be-laid base layer, wherein the honeycombed aluminum plate is horizontally laid right above the under-layer aluminum veneer; S5, preparing a stone laying adhesive, and using the adhesive to lay the corresponding stone onto the corresponding honeycombed aluminum plate. By the method, stone facing saltpetering can be avoided, and cooperation with outdoor rough-surface stone can be achieved.

Owner:SUZHOU KELIDA BUILDING & DECORATION CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com