Quick-drying caulking agent with stain-resistant function

A caulking agent and functional technology, applied in the field of quick-drying caulking agent, can solve the problems of affecting the appearance and the caulking agent is prone to mildew, etc., and achieve the effect of improving stain resistance, reducing labor costs, and accelerating condensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] It is prepared from the following components by mass: 15 parts of white Portland cement, 20 parts of aluminate cement, 5 parts of hemihydrate gypsum, 2 parts of anhydrous gypsum, 5 parts of calcium powder, 40 parts of quartz sand, Shrinkage reducing agent 0.5 parts, water repellent 1 part, defoamer 2 parts, cellulose ether 1.5 parts.

[0036] The strength grade of white Portland cement is required to be 42.5. The type of aluminate cement is CA-50. The specification of calcium powder is 200-400 mesh. The specification of quartz sand is 70-140 mesh. The shrinkage reducing agent is polyoxyethylene type shrinkage reducing agent. The water-repellent agent is a silicone water-repellent agent. The defoamer is a mineral oil defoamer. The cellulose ether is hydroxyethyl methylcellulose ether. The redispersible latex powder is ethylene-vinyl acetate copolymer.

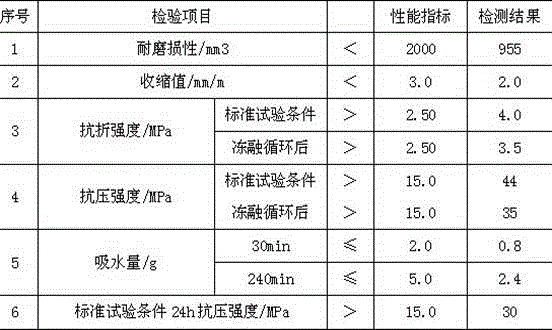

[0037] Construction according to above-mentioned preparation technology and instructions for use, each performan...

Embodiment 2

[0040] It is prepared from the following components by mass: 5 parts of white Portland cement, 30 parts of aluminate cement, 4 parts of hemihydrate gypsum, 0 parts of anhydrous gypsum, 5 parts of calcium powder, 45 parts of quartz sand, Shrinkage reducing agent 0.5 parts, water repellent 1.5 parts, defoamer 2 parts, cellulose ether 1 part.

[0041] The strength grade of white Portland cement is required to be 42.5. The type of aluminate cement is CA-60. The specification of calcium powder is 200-400 mesh. The specification of quartz sand is 70-140 mesh. The shrinkage reducing agent is polyoxyethylene type shrinkage reducing agent. The water-repellent agent is a silicone water-repellent agent. The defoamer is a mineral oil defoamer. The cellulose ether is hydroxyethyl methylcellulose ether. The redispersible latex powder is ethylene-vinyl acetate copolymer.

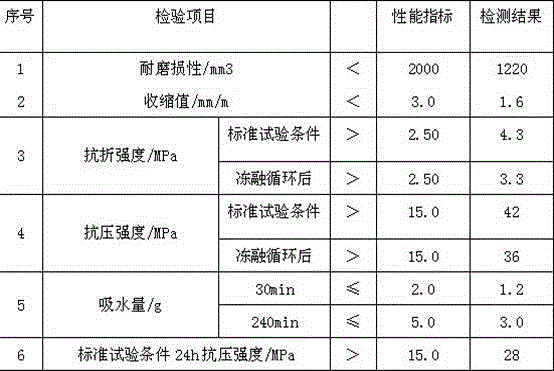

[0042] Construction according to above-mentioned preparation technology and instructions for use, each performanc...

Embodiment 3

[0045] It is prepared from the following components by mass: 20 parts of white Portland cement, 15 parts of aluminate cement, 7 parts of hemihydrate gypsum, 0 parts of anhydrous gypsum, 5 parts of calcium powder, 46 parts of quartz sand, 0.5 parts of shrinkage reducing agent, 0.5 parts of water-repellent agent, 0.5 parts of defoaming agent, and 0.5 parts of cellulose ether.

[0046] The strength grade of white Portland cement is required to be 52.5. The type of aluminate cement is CA-50. The specification of calcium powder is 200-400 mesh. The specification of quartz sand is 70-140 mesh. The shrinkage reducing agent is polyoxyethylene type shrinkage reducing agent. The water-repellent agent is a silicone water-repellent agent. The defoamer is a mineral oil defoamer. The cellulose ether is hydroxyethyl methylcellulose ether. The redispersible latex powder is ethylene-vinyl acetate copolymer.

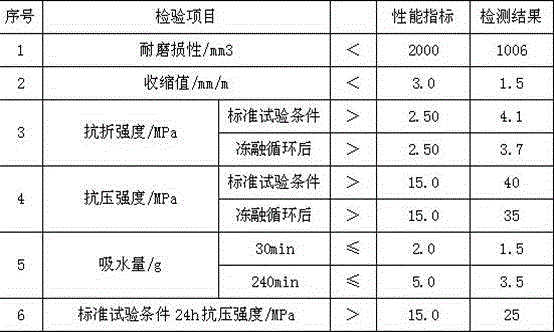

[0047] Construction according to above-mentioned preparation technology and in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com