Patents

Literature

41results about How to "Effectively adjust viscosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Carbon fiber modified non-solvent polyurethane surface layer resin for sports shoe leather, as well as preparation method and application of carbon fiber modified non-solvent polyurethane surface layer resin

ActiveCN106397722AGuaranteed to be environmentally friendlyGuaranteed stabilityPolyurea/polyurethane coatingsFootwearPolyresinHydrolysis

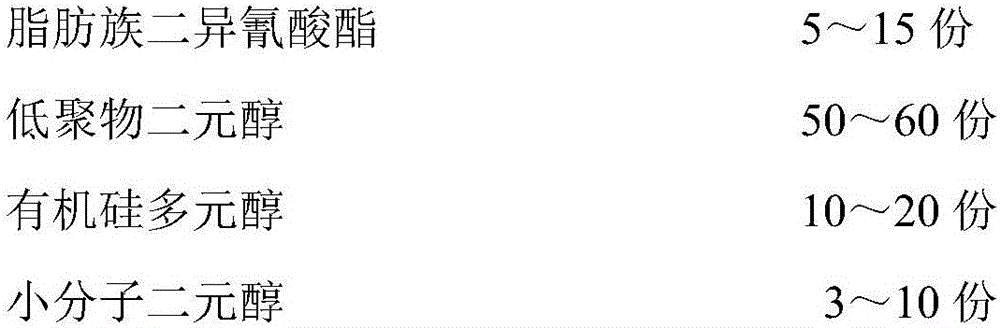

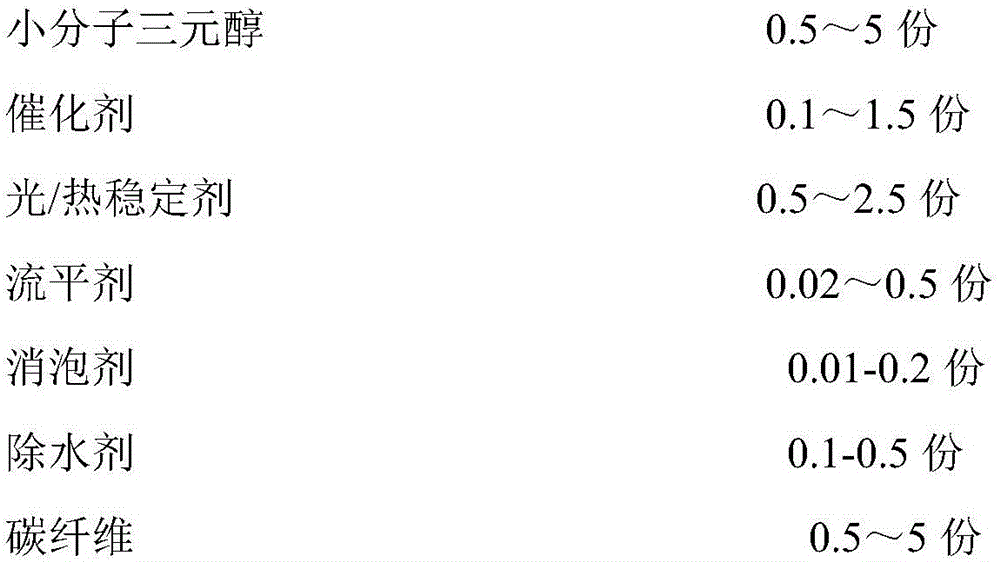

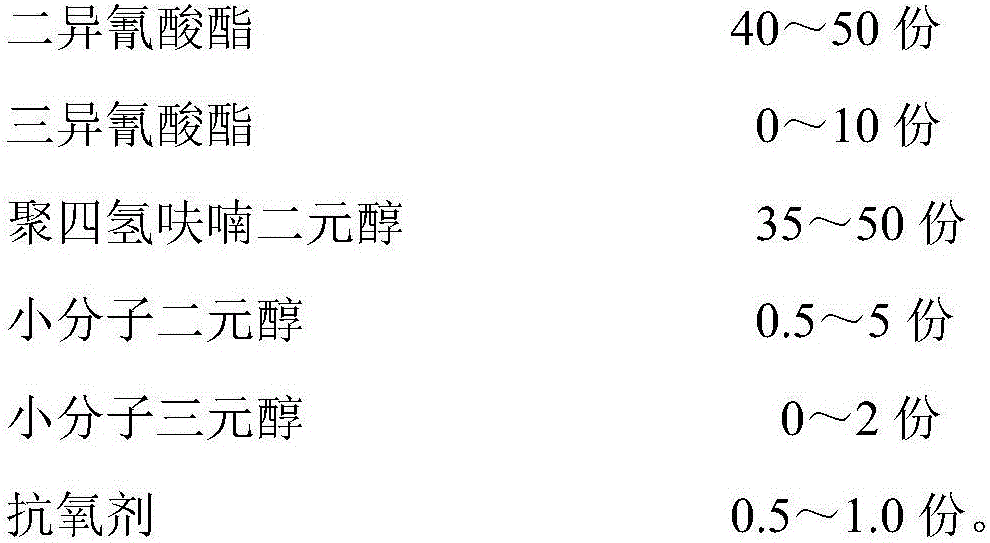

The invention belongs to the field of synthetic leather, and provides carbon fiber modified non-solvent polyurethane surface layer resin for sports shoe leather. The resin is formed by mixing a component A and a component B according to mass percent being 2:1 to 1:2, wherein the component A comprises 5 to 15 parts of aliphatic diisocyanate, 50 to 60 parts of low polymer dihydric alcohol, 10 to 20 parts of organosilicone polyhydric alcohol, 3 to 10 parts of micromolecule dihydric alcohol, 0.5 to 5 parts of micromolecule trihydric alcohol, 0.1 to 1.5 parts of a catalyst, 0.5 to 2.5 parts of a light / heat stabilizer, 0.02 to 0.5 part of a flatting agent, 0.01 to 0.2 part of a defoamer, 0.1 to 0.5 part of a dehydrator, and 0.5 to 5.0 parts of carbon fiber; the component B comprises 40 to 50 parts of aliphatic diisocyanate, 0 to 10 parts of triisocyanate, 35 to 50 parts of polytetrahydrofuran dihydric alcohol, 0.5 to 5 parts of micromolecule dihydric alcohol, 0 to 2 parts of micromolecule trihydric alcohol, and 0.5 to 1.0 part of a light / heat stabilizer. The invention further provides a preparation method and application of the resin. The tangential breaking strength of carbon fiber modified resin coating can reach 130kN / m or above; for non-solvent sports shoe leather prepared through the method, the peeling strength can reach 90N / 3 cm or above and the hydrolysis resistance can reach 10 weeks or above.

Owner:HEFEI ANLI POLYURETHANE NEW MATERIAL

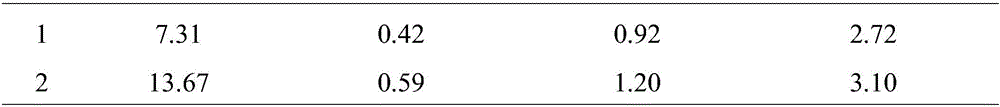

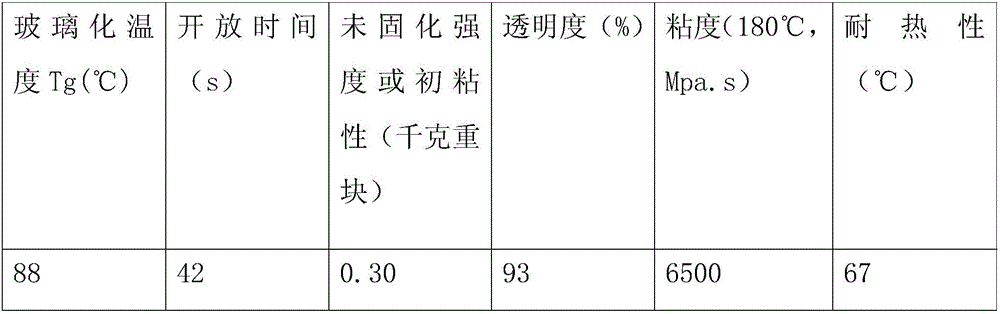

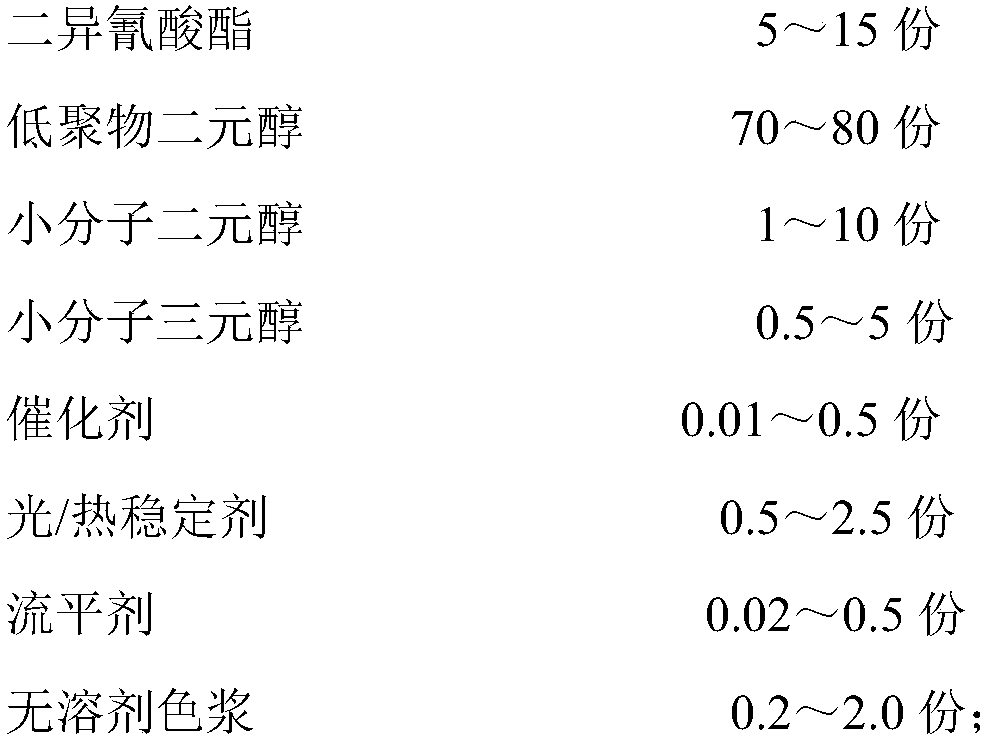

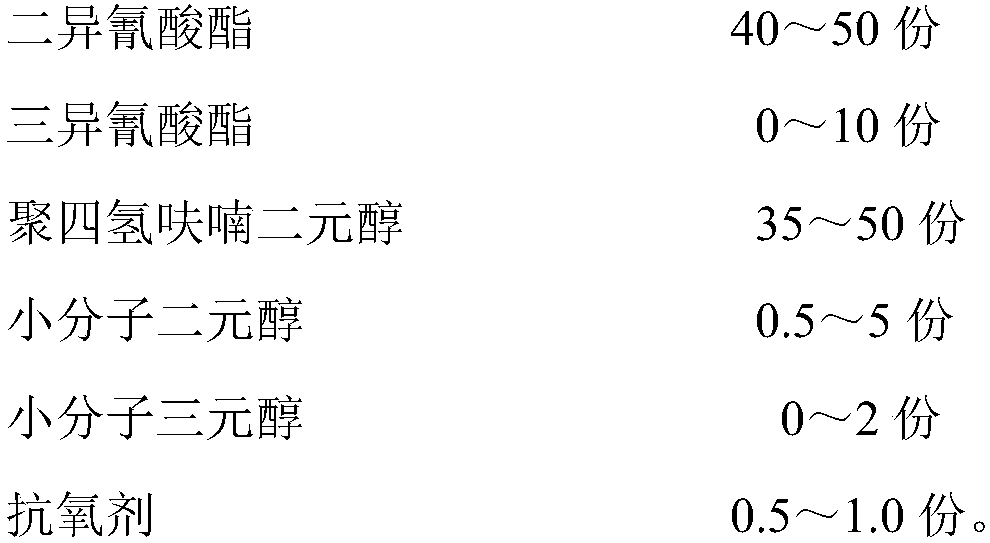

Solvent-free interlayer polyurethane resin for automotive trim leather and preparation method thereof

ActiveCN106220817AReduce usageGuaranteed to be environmentally friendlyRoad vehiclesTextiles and paperOligomerAlcohol

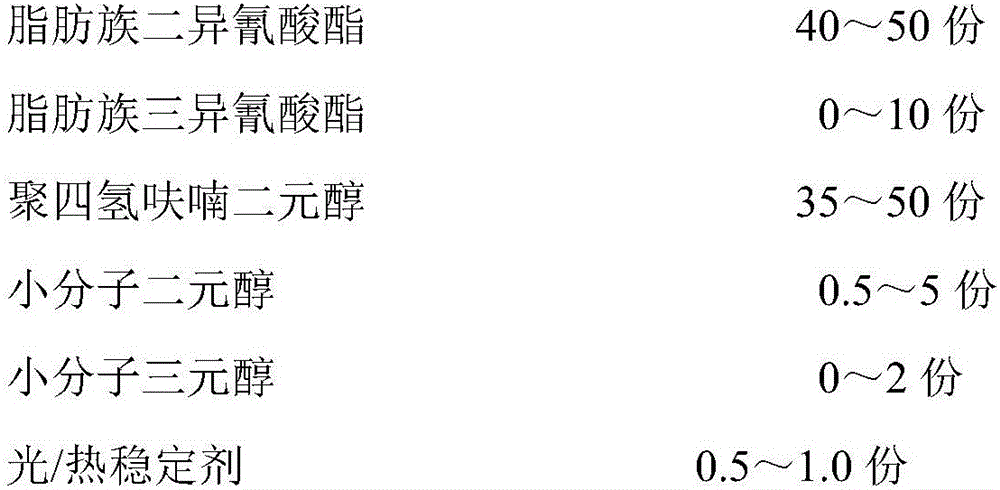

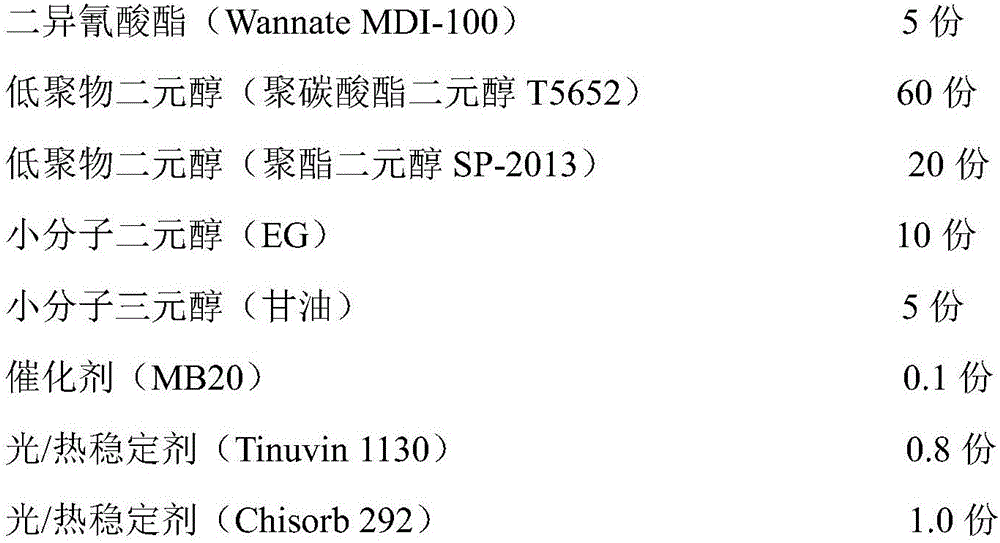

The invention provides a solvent-free interlayer polyurethane resin for automotive trim leather and preparation method thereof. The solvent-free interlayer polyurethane resin is composed of an A component and a B component in a mass ratio of (2.5: 1)-(1: 2.5) through the mixing; the A component is composed of diisocyanate, oligomer dihydric alcohol, micromolecular dihydric alcohol, micromolecular trihydric alcohol, catalyst, light / heat stabilizer, flatting agent and solvent-free color paste; the B component is composed of diisocyanate, triisocyanate, oligomer dihydric alcohol, micromolecular dihydric alcohol, micromolecular trihydric alcohol and antioxidant. The polyurethane resin prepared by the method disclosed by the invention can be used as the interlayer for the automotive trim leather, the high temperature durable performance and various mechanical properties of the automotive leather can be effectively guaranteed while meeting the hydrolysis resistance of the automotive leather product; the peeling strength of the prepared automotive leather product reaches up to 145N / 3cm, the hydrolysis resistance can reach the condition that the peeling strength still reaches up to 135N / 3cm after 10 weeks.

Owner:HEFEI ANLI POLYURETHANE NEW MATERIAL

Epoxy polyurethane anticorrosive coating capable of resisting light aging and preparation method

InactiveCN101597455AImproves photoaging performanceEffectively adjust viscosityAnti-corrosive paintsEpoxy resin coatingsEpoxyPhosphate

The invention discloses an epoxy polyurethane anticorrosive coating capable of resisting light aging and a preparation method; A component is prepared by mixing, stirring and grinding epoxy resin with medium molecular weight, hydroxyl-containing polyester resin, dimethylbenzene, butyl acetate, titanium pigment, ultraviolet absorber, talcum powder, mica powder, organosiloxane, isopropyl tri (dioctylpyrophosphato) titanate, poly-organic phosphate and the like; B component is prepared by mixing and stirring diphenylmethane diisocyanate and biuret. A component and B component are uniformly mixed according to weight ratio of 4:1 to be used. The epoxy polyurethane anticorrosive coating is capable of resisting light aging and has excellent corrosion resistance against acid, alkali and salt and salt fog resistance. The invention is external anticorrosive preferential coating for steel structures under severe environment such as chemical factories, refineries and the like.

Owner:CNPC RES INST OF ENG TECH

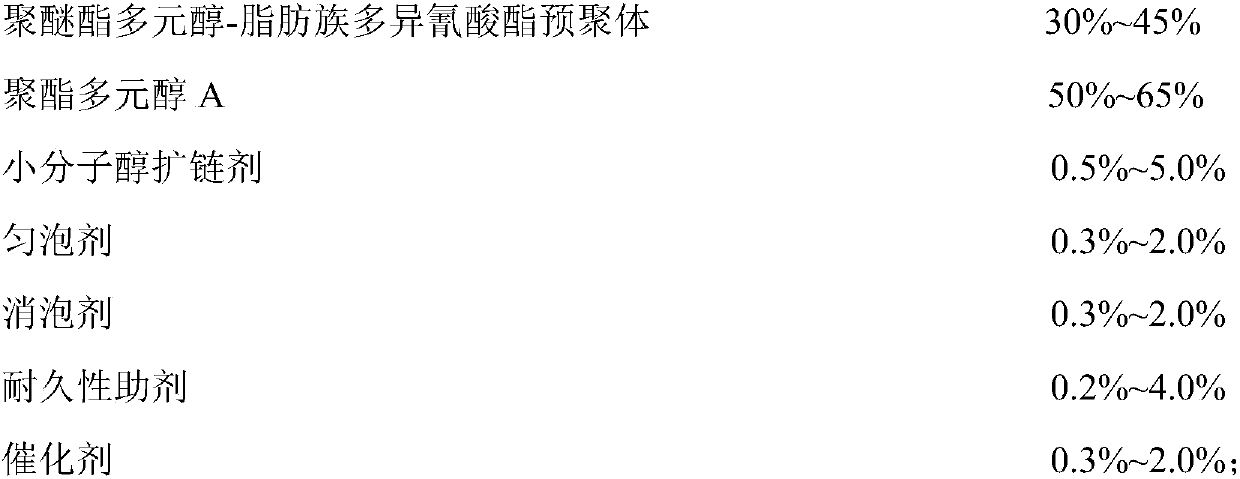

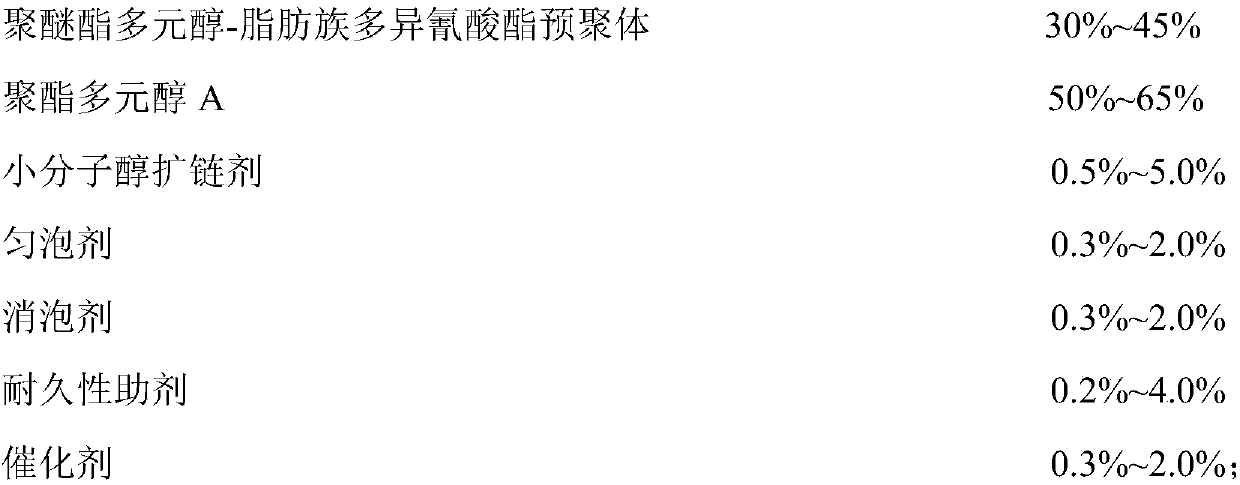

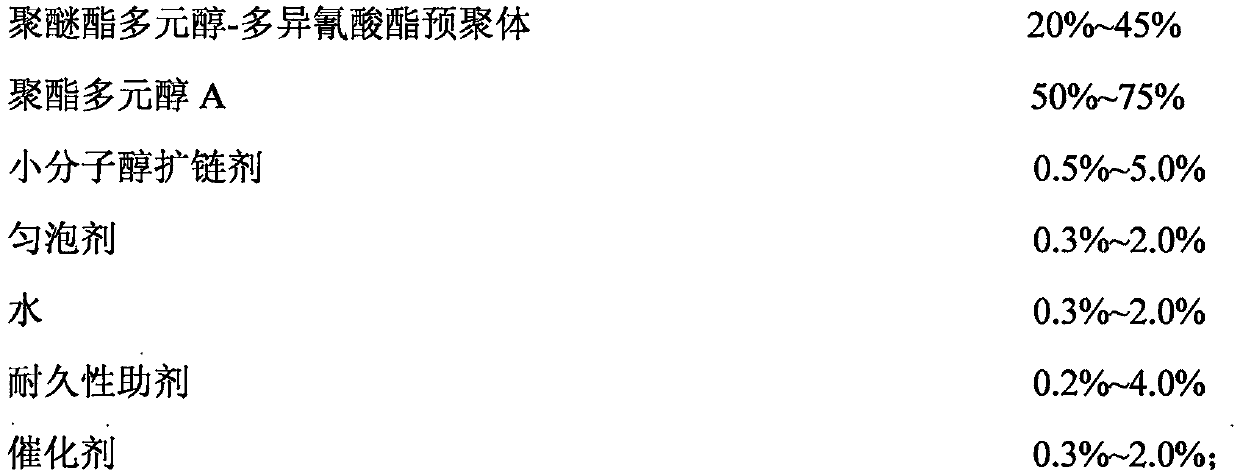

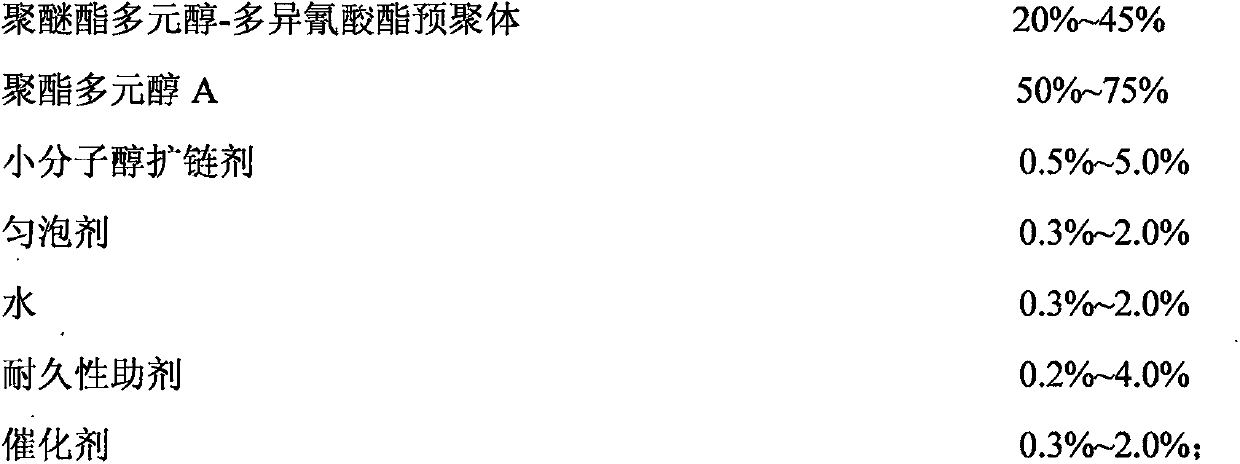

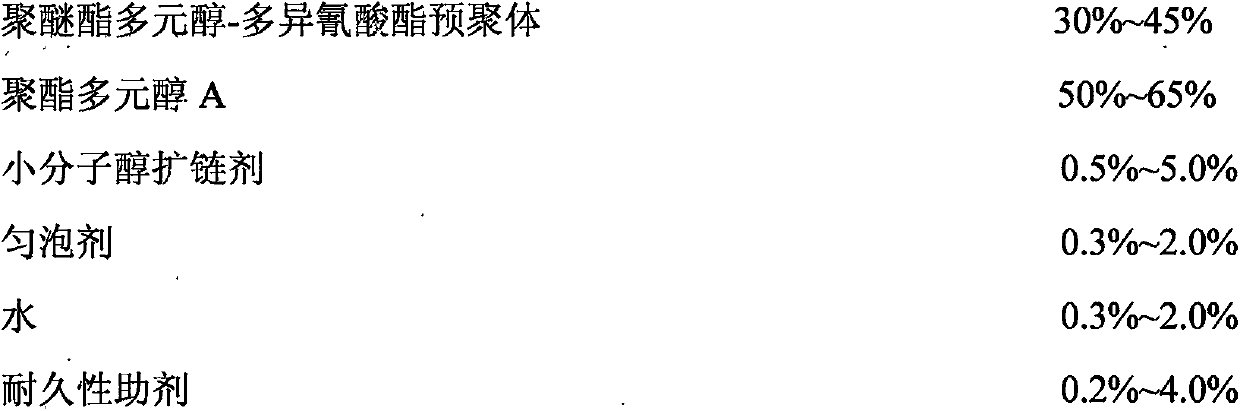

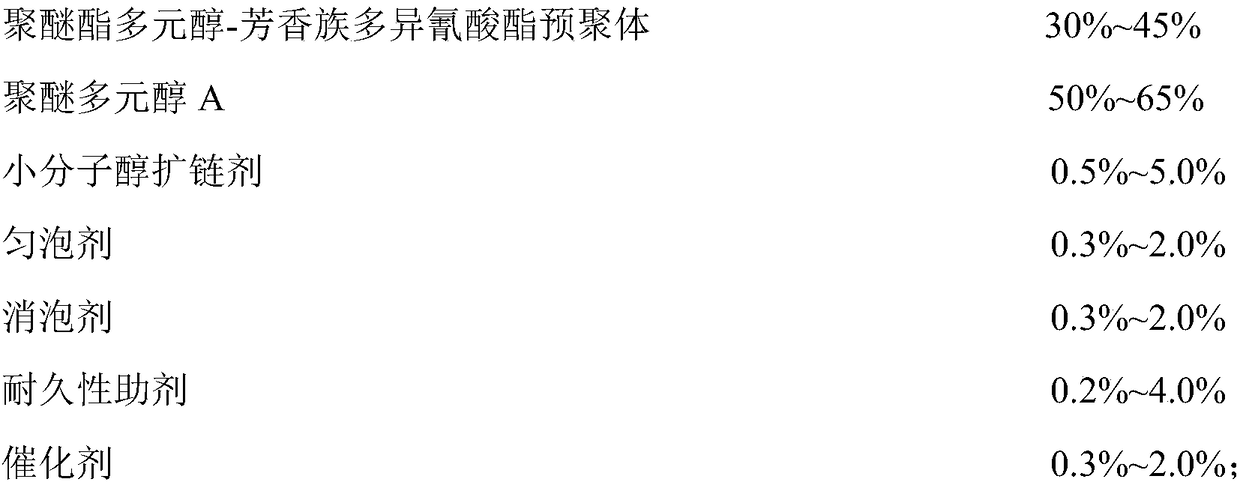

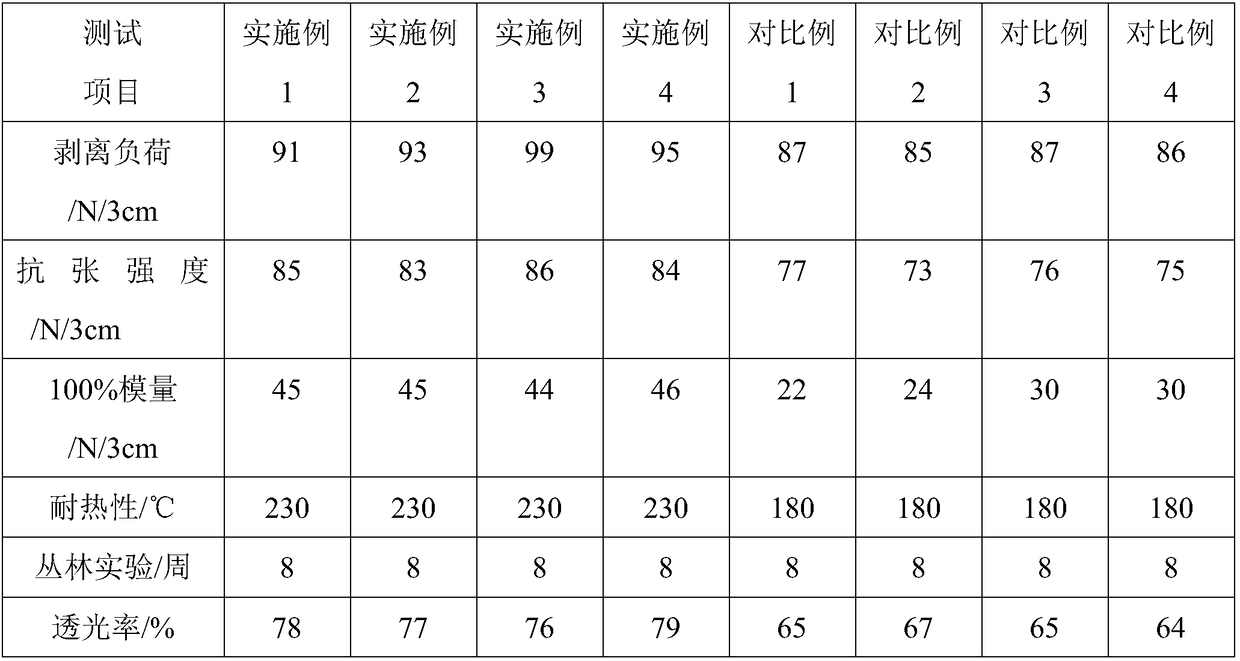

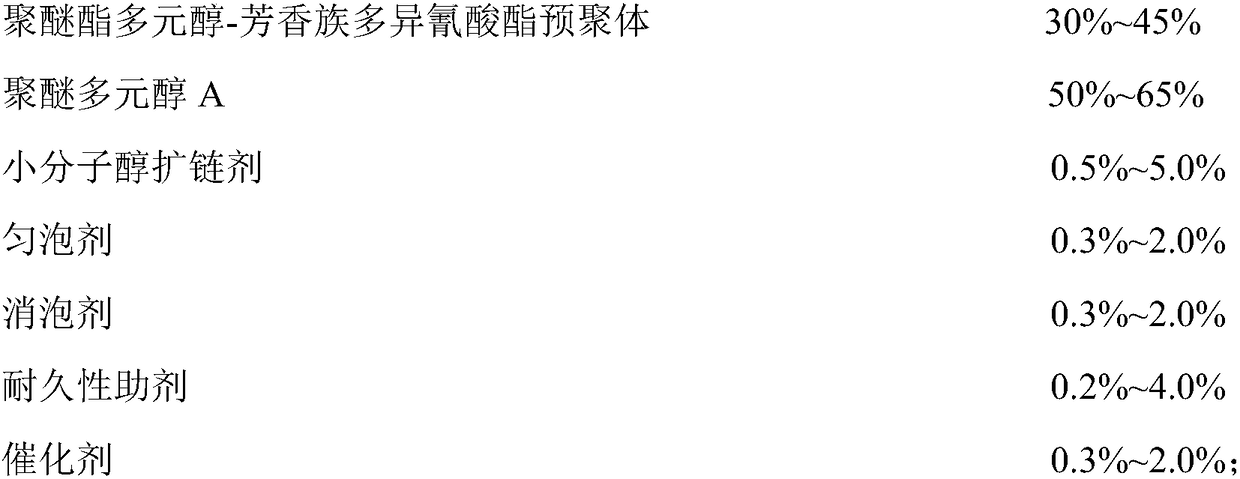

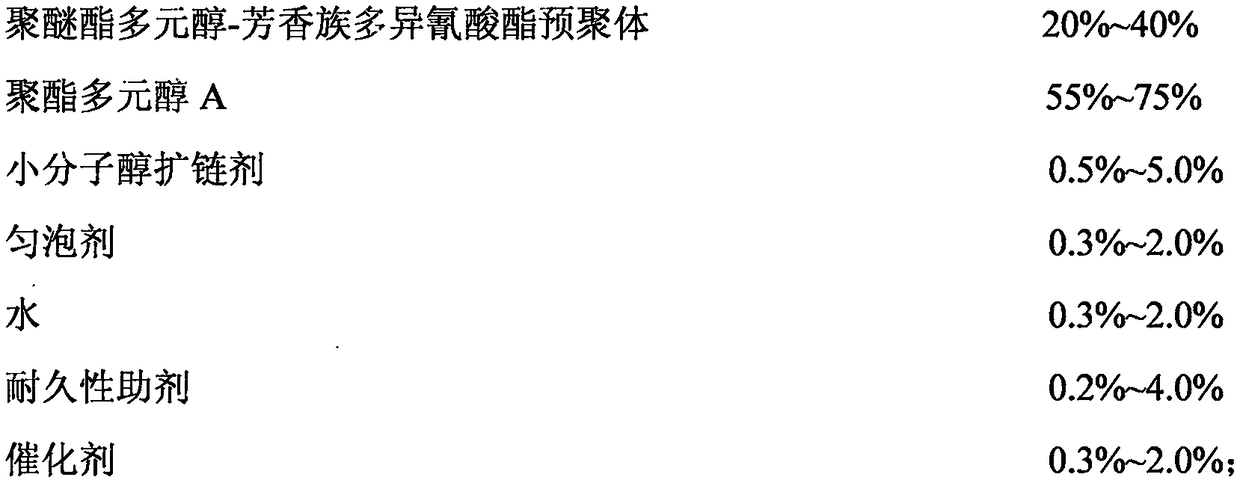

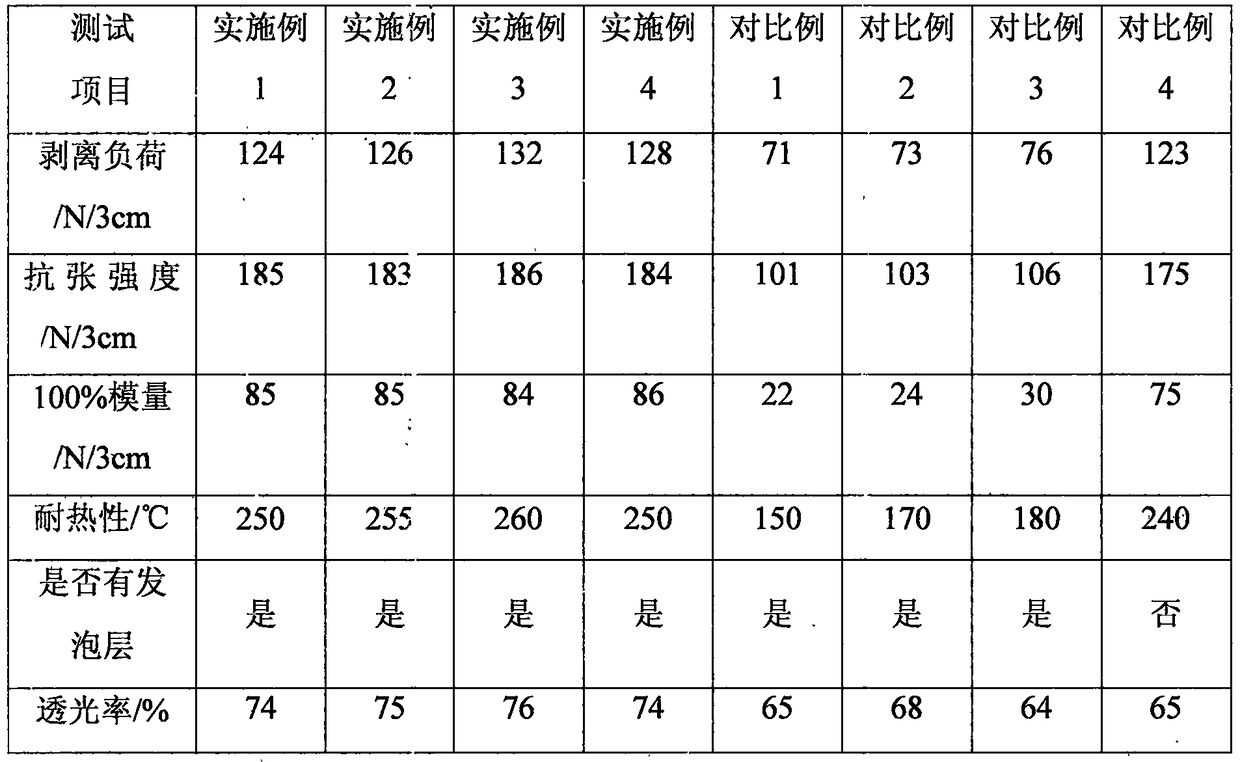

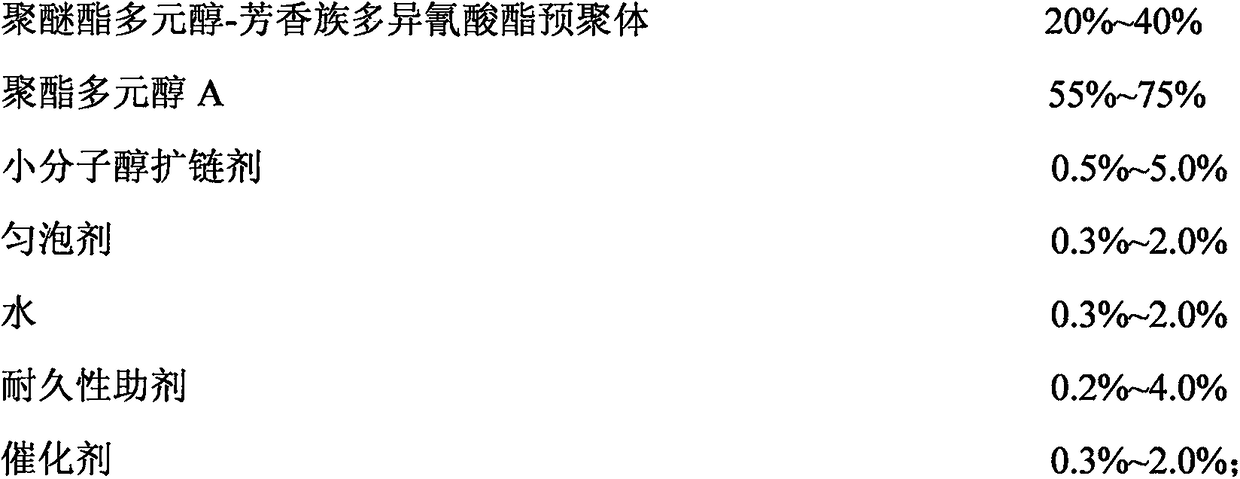

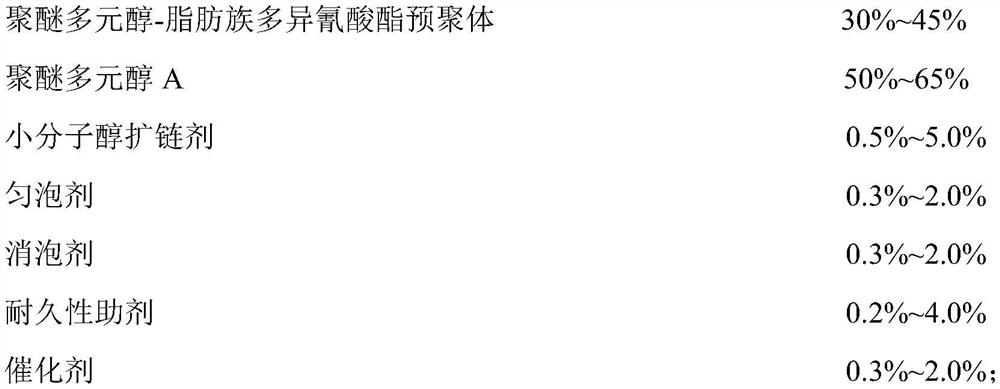

Blocked high-temperature resistant integrated solvent-free polyurethane resin for leather, and preparation method and application thereof

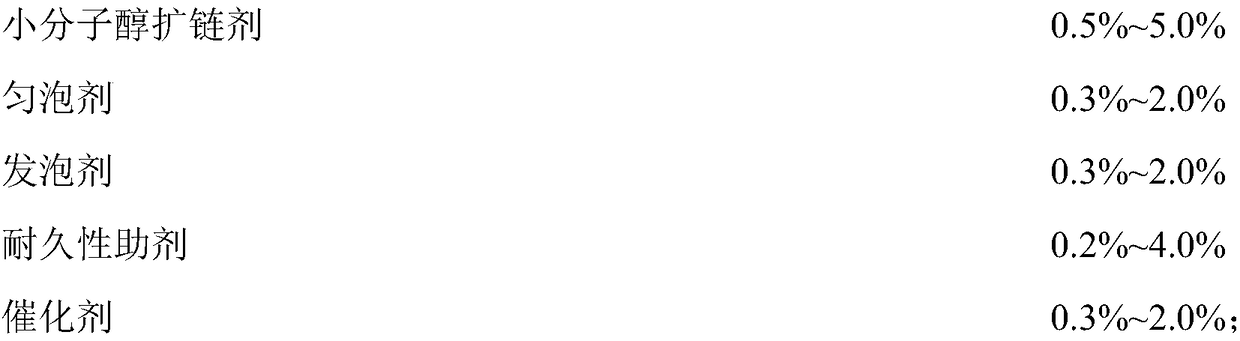

InactiveCN108570137AStrong production operabilityLow costPolyurea/polyurethane coatingsTextiles and paperPolyesterFoaming agent

Blocked high-temperature resistant integrated solvent-free polyurethane resin for leather, and a preparation method and application thereof are disclosed. The polyurethane resin comprises a resin component A and a resin component B. The resin component A comprises a polyether ester polyol-polyisocyanate prepolymer, polyester polyol, a small molecule alcohol chain extender, a foaming agent and a catalyst. The resin component B comprises diisocyanate, polyester polyol and a NCO blocking agent. The blocking agent is one or more selected from phenol, nitrophenol, 2-pyridinol, 3-hydroxyquinoline, triphenylmethanethiol, hexanethiol, dodecanethiol, 3,5-dimethylpyrazole, 1,2,4-triazole, 2-methyl imidazoline, 2-ethyl-4-methylimidazole, caprolactam, N-methylacetamide, phenylacetamide, bisulfate or amine. The polyurethane resin can be used for preparing high-temperature resistance solvent-free polyurethane synthetic leather. The production efficiency is high. Equipment specially used for solvent-free leather synthesis is not needed, operable time is long after product mixing and stability is high.

Owner:ZHEJIANG HUAFON SYNTHETIC RESIN

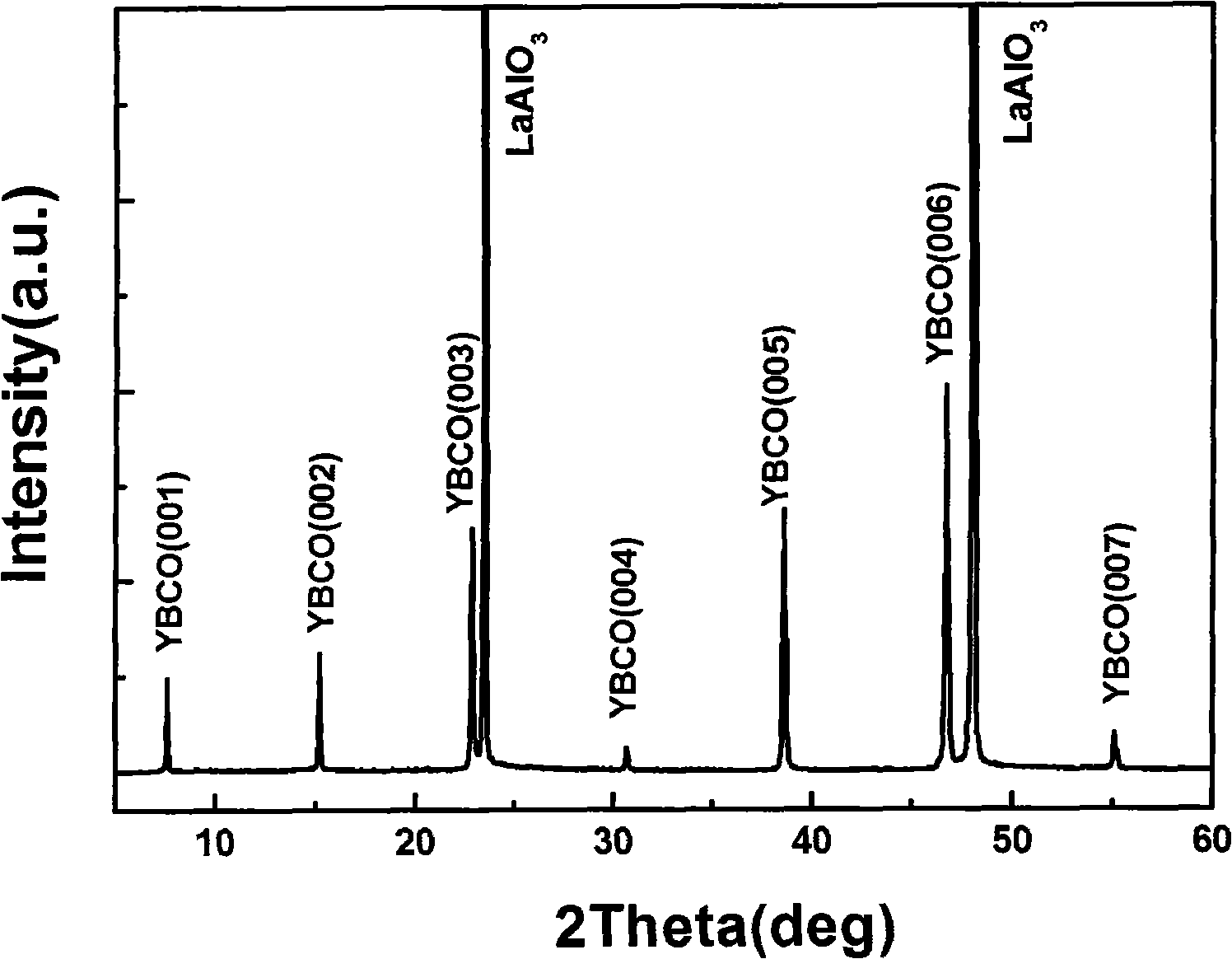

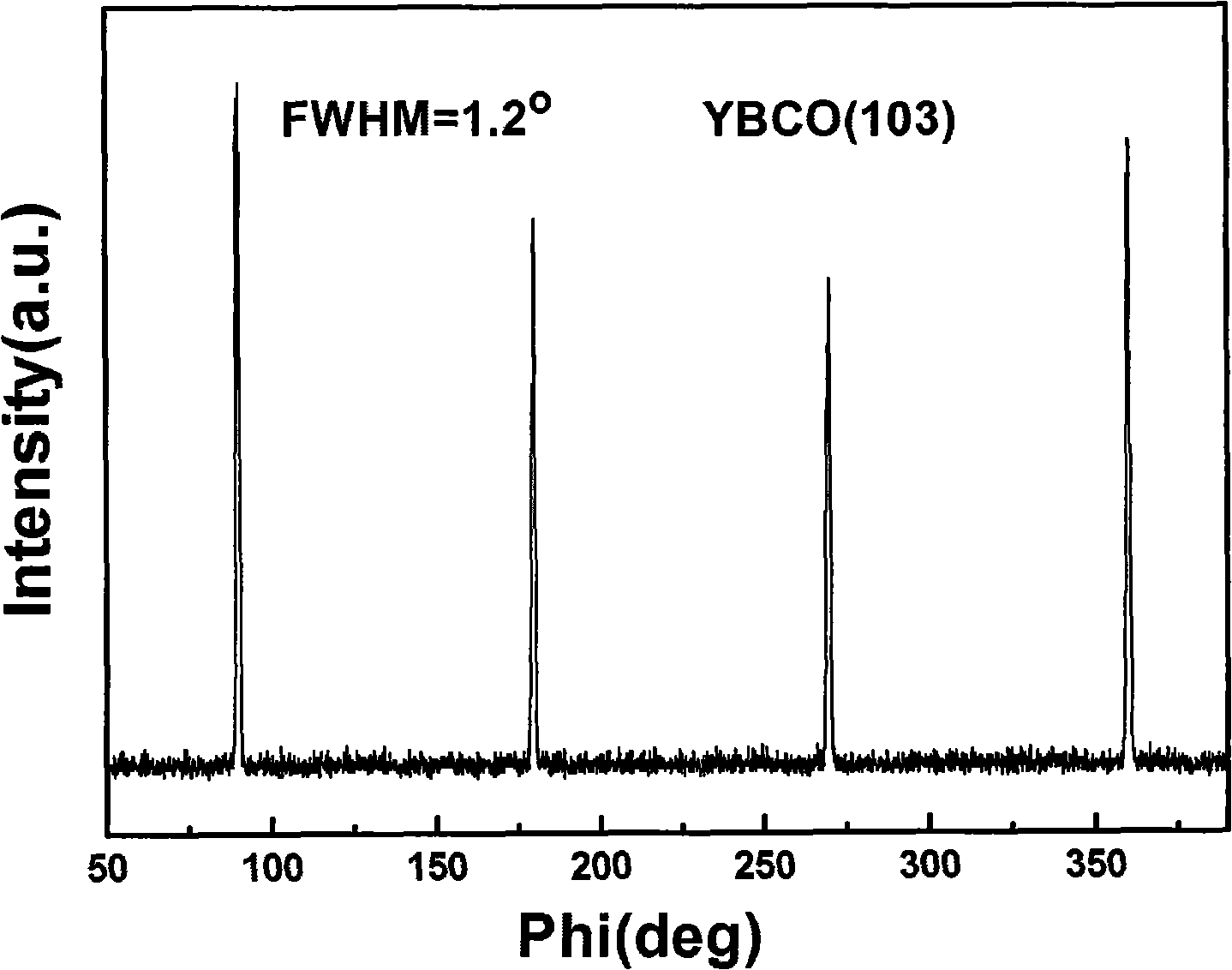

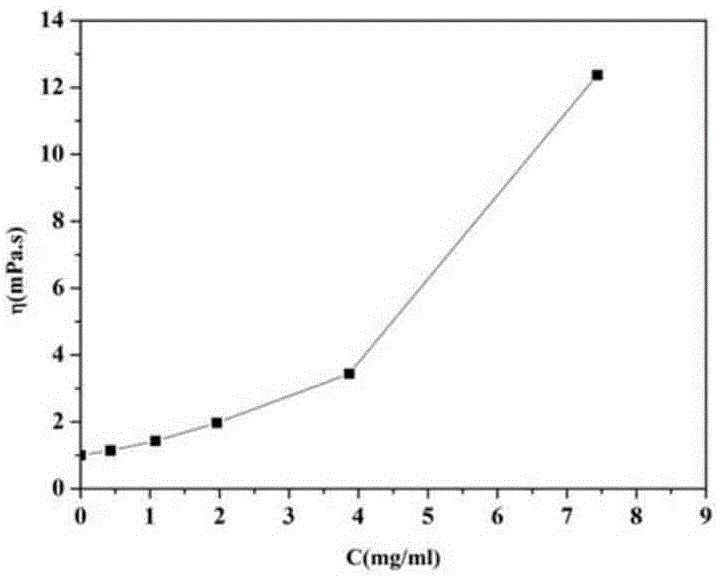

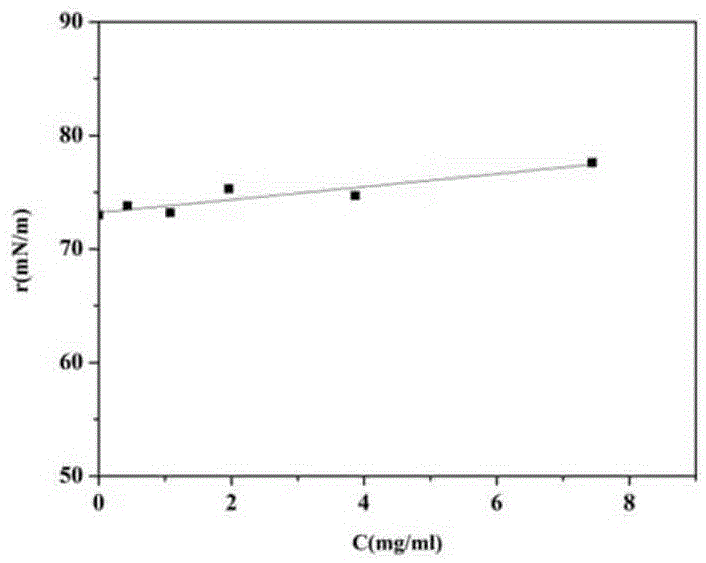

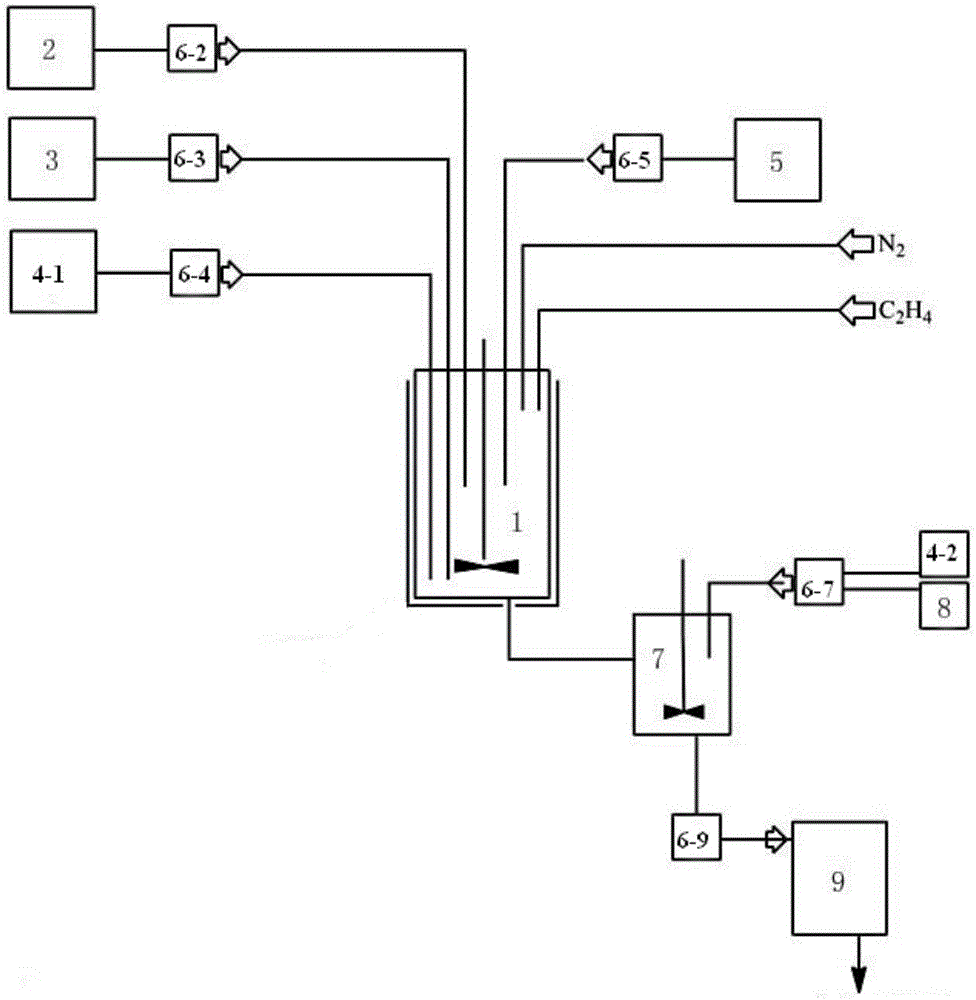

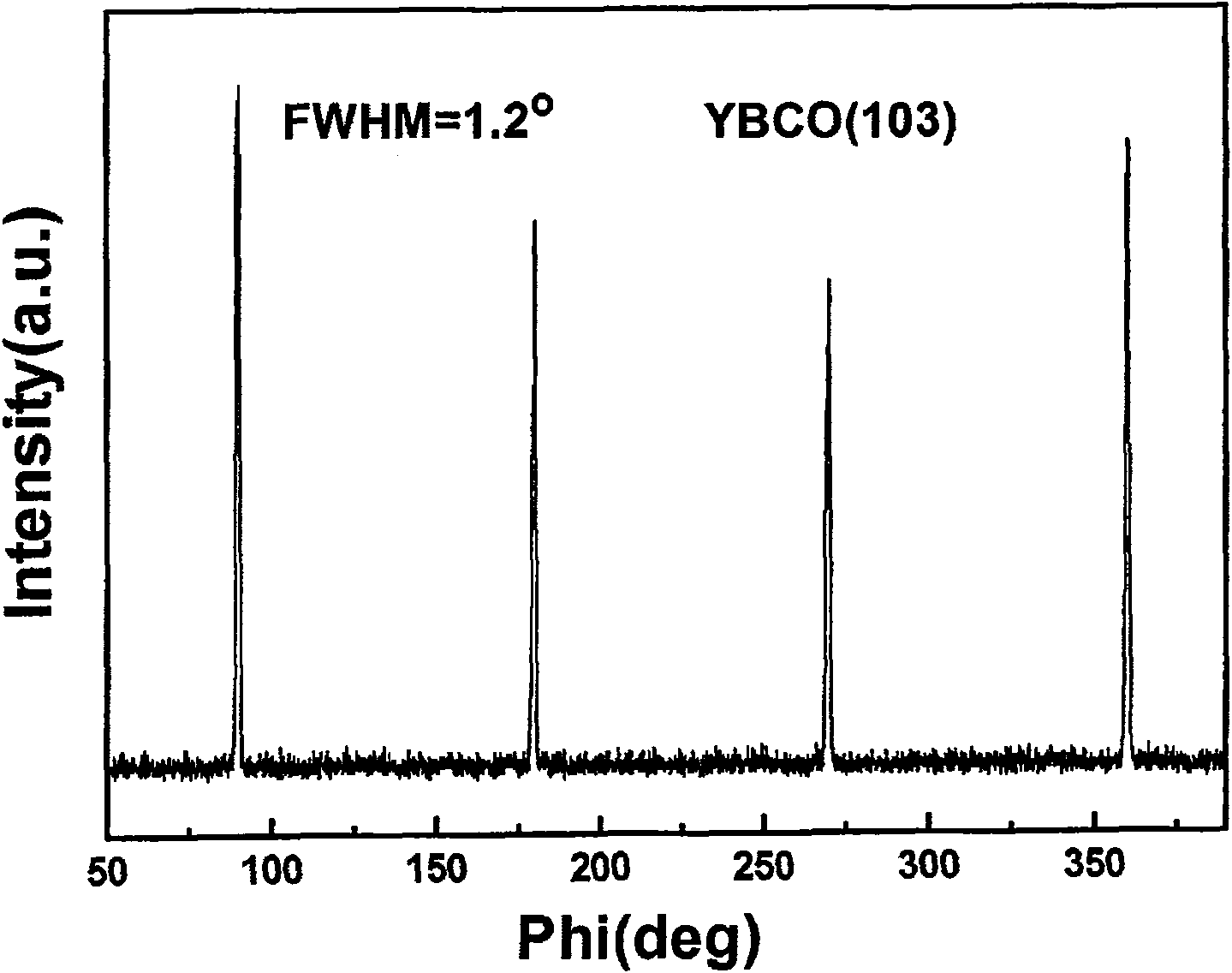

Method for polymer-assistant depositing high temperature superconducting coating conductor superconducting layer

InactiveCN101271956AReduce formationImprove current carrying capacitySuperconductor device manufacture/treatmentFurnace temperatureElectrical conductor

A macromolecule-assisted method of deposition for a superconducting layer of a high-temperature superconductivity coating electrical conductor has the preparation method as follows: a. dissolving rare-earth acetate, barium acetate and cupric acetate in monoprop with a stoichiometric proportion that rare-earth: barium: cupric equals to 1:2:3 to acquire a precursor solution; b. adding PVB, PEG or PVP into the precursor solution with the weight ratio of 2-8:100 to acquire a coating colloid; c. coating the coating colloid on a substrate and heating for drying; d. placing the substrate in a tubular furnace to carry out decomposition heat treatment; e. rapidly heating up the furnace temperature to 800-900 DEG C under moist argon atmosphere for 5-15min, then lowering the temperature to 750-780 DEG C for 1-3 hours, and then lowering the temperature to 350-500 DEG C under the argon atmosphere for low temperature oxygen-permeation annealing treatment, and the superconducting layer is acquired by cooling. The method has the advantages of low cost and simple technique, which is applied to industrialized production; the superconducting layer prepared is characterized by high biaxial texture, flat and dense surface and good superconductivity.

Owner:SOUTHWEST JIAOTONG UNIV

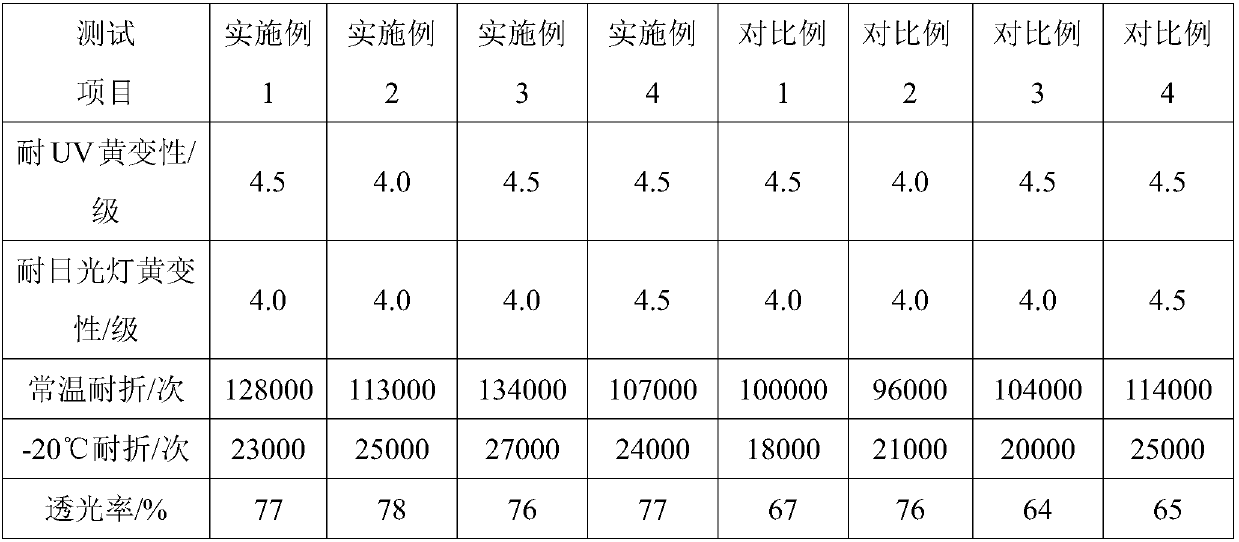

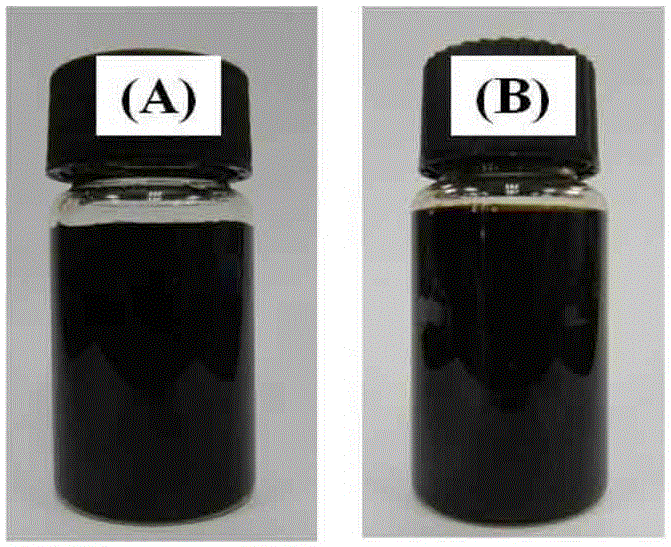

Solvent-free, non-yellowing, high-transparency and high-brightness polyurethane resin for leather as well as preparation method and application

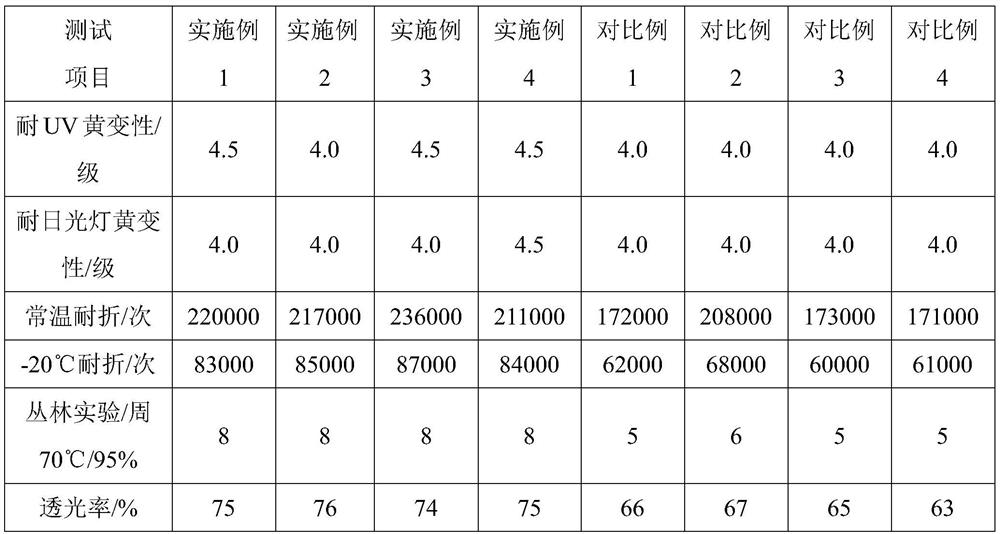

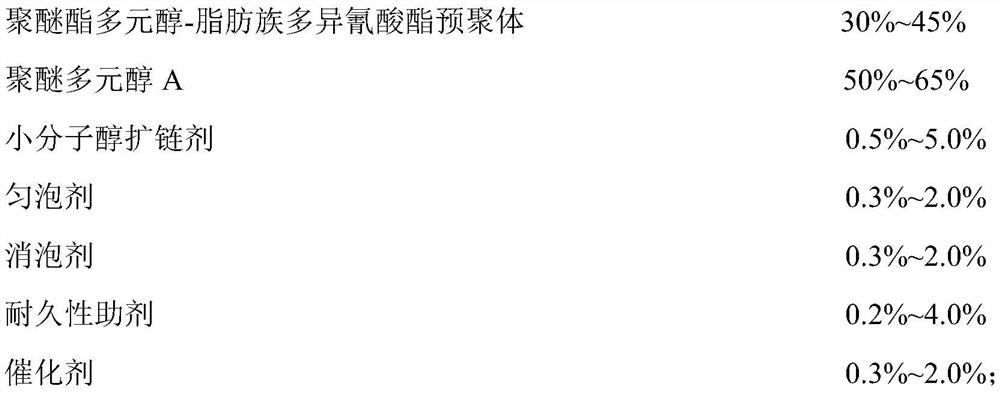

InactiveCN108017770AImprove yieldTranslucent surfacePolyurea/polyurethane coatingsSurface layerRoom temperature

The invention discloses solvent-free, non-yellowing, high-transparency and high-brightness polyurethane resin for leather as well as a preparation method and application. The solvent-free, non-yellowing, high-transparency and high-brightness polyurethane resin is prepared from a resin component A and a resin component B, wherein the mass ratio of the resin component A to the resin component B ranges from (7 to 3) to (1 to 3). The resin component A contains a polyether ester polyol-aliphatic polyisocyanate pre-polymer with the mass percent of 30 percent to 45 percent and the resin component B contains aliphatic diisocyanate with the mass percent of 20 percent to 60 percent. A surface layer of synthetic leather is coated with the solvent-free, non-yellowing, high-transparency and high-brightness polyurethane resin for the leather, disclosed by the invention, and the synthetic leather has a non-yellowing, high-transparency and high-brightness aesthetic extent; in a production process, a curing speed is rapid and the rate of finished products is high; the anti-yellowing grade is greater than or equal to grade 4; the room-temperature folding resistance and the low-temperature folding resistance are high and the surface is transparent and bright.

Owner:ZHEJIANG HUAFON SYNTHETIC RESIN

Polyurethane resin for solvent-free leather and preparing method and application thereof

The invention discloses polyurethane resin of solvent-free synthetic leather and a preparing method and application thereof. The polyurethane resin of the solvent-free synthetic leather comprises a resin component A and a resin component B, wherein the resin component A is prepared from, by weight, 20-45% of polyether ester polyol-polyisocyanates prepolymer and 0.3-2.0% of water, the resin component B is prepared from, by weight, 20-60% of diisocyanate, and the mass ratio of the resin component A to the resin component B is 3:1-1:3. When the polyurethane resin of the solvent-free synthetic leather is used for producing the synergic leather, what is only needed is to scrape solvent-free resin so that a surface layer structure, an adhesive layer structure and a foaming layer structure can beprovided, the technology process is simple, and the physical and mechanical performance is excellent.

Owner:ZHEJIANG HUAFON SYNTHETIC RESIN

Polyurethane resin used for non-solvent leather with high brightness and bending resistance, preparation method and application

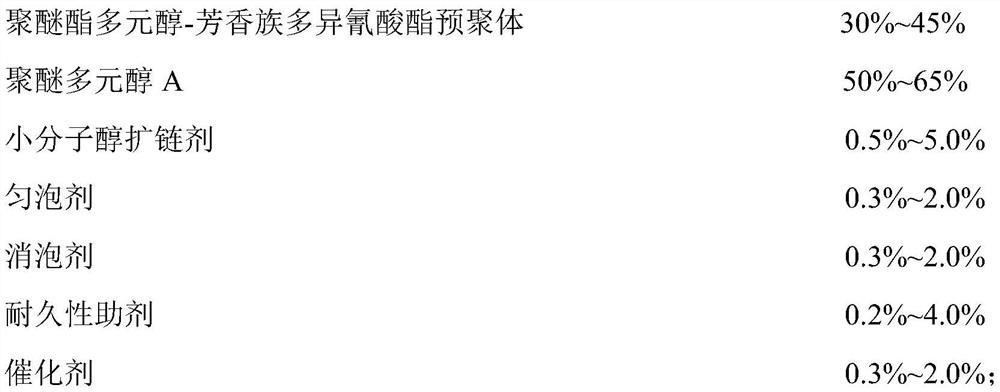

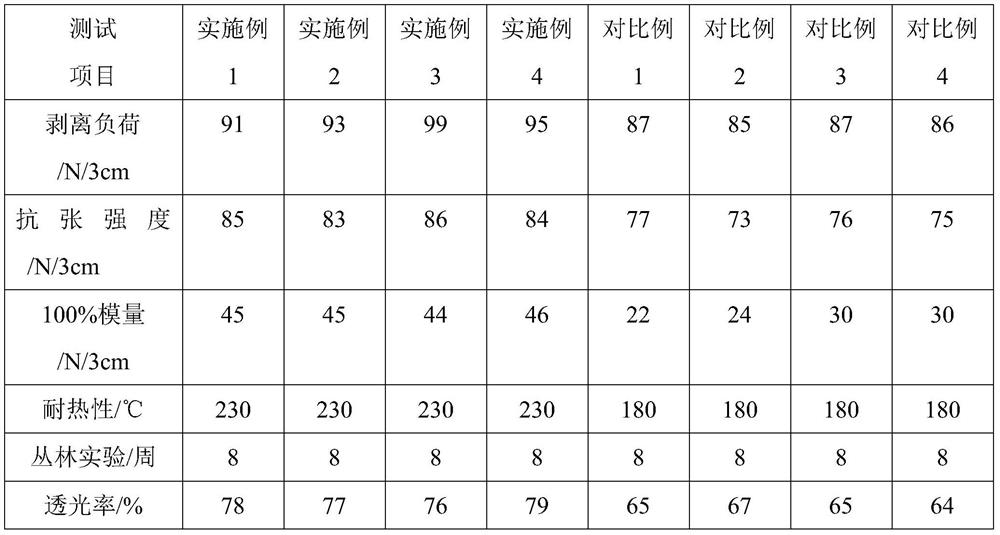

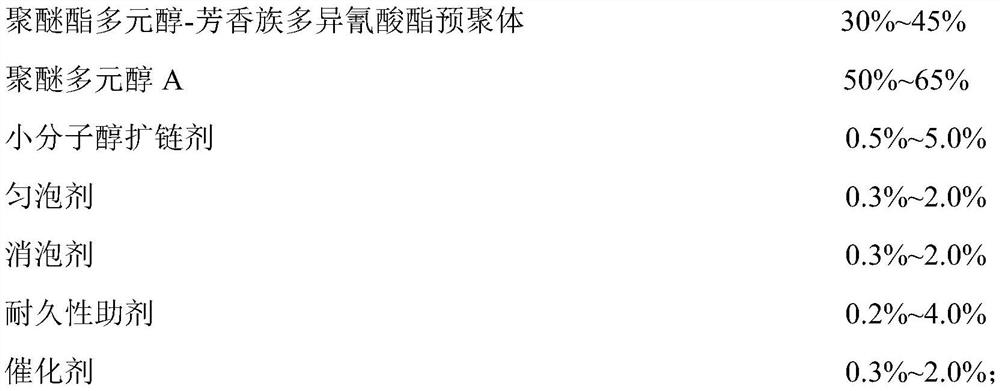

ActiveCN108252115AHigh transparency and high brightness aestheticsHigh peel strengthPolyurea/polyurethane coatingsTextiles and paperPrepolymerIsocyanate

The invention discloses a polyurethane resin used for non-solvent leather with high brightness and bending resistance, a preparation method and application. The polyurethane resin used for non-solventleather with high brightness and bending resistance comprises a resin component A and a resin component B; the resin component A comprises 30% to 45% of ether-ester polyhydric alcohol-aromatic polyisocyanates prepolymer; the resin component B comprises 15% to 60% of aromatic diisocyanate. The resin can be used for preparing polyurethane synthetic leather, the synthetic leather is high in brightness and attractive in appearance, the physical and mechanical properties, such as bending resistance, of the synthetic leather are improved preferably, the production operability of the non-solvent synthetic leather in the mass production process is improved, and the matching stability of the resin component A and the resin component B during machining is guaranteed.

Owner:ZHEJIANG HUAFON SYNTHETIC RESIN

Graphene oxide ink as well as preparation method and application thereof

ActiveCN105860667AProcess stabilityUniform processSingle layer grapheneInksComputer printingMicrofiltration membrane

The invention discloses graphene oxide ink as well as a preparation method and application thereof. The graphene oxide ink is prepared from graphene oxide, surfactant and solvent as raw materials, and counted by mass fraction, the graphene oxide accounts for 0.1%-0.5%, the surfactant accounts for 0.05%-0.5% and the rest is solvent. The preparation method comprises steps of dispersing the graphene oxide in the solvent, adding the surfactant to obtain a mixed solution, and carrying out filtering with a micro-filtration membrane to obtain the graphene oxide ink. The graphene oxide ink can be applied to an inkjet printer, and particularly can be used for preparing a graphene flexible circuit through an inkjet printer. The graphene oxide ink and the preparation method thereof disclosed by the invention have the advantages of greenness, environment protection, low cost, simple preparation and the like, and the graphene oxide ink applied to a common home inkjet printer can meet the market requirement.

Owner:NAT UNIV OF DEFENSE TECH

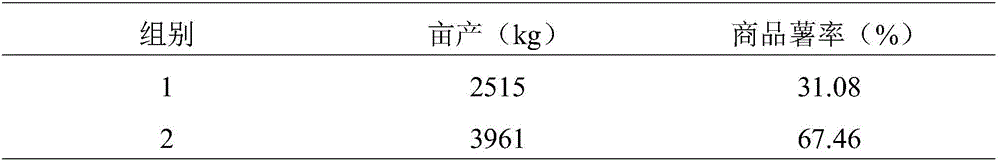

Soilless culture method for potato seedlings

InactiveCN106212225AActive promotionAvoid pollutionCalcareous fertilisersBio-organic fraction processingAgricultural scienceSolanum tuberosum

The invention belongs to the field of agriculture cultivation, and particularly relates to a soilless culture method for potato seedlings. Local agricultural wastes mostly existing in the Inner Mongolia are used, and the seedling soilless culture method is make according to the actual conditions of local potato planting and is suitable for seedling growth, low in cost and simple in step; limits to soil cultivation are removed, the cultivation field of potatoes is enlarged, factory-like and automation development of potatoes are promoted better and faster, and the method has wider market prospects and higher application value.

Owner:INNER MONGOLIA JIAHENG AGRI TECH CO LTD

Polyurethane resin for high temperature resistant integrated solvent-free leather as well as preparation method and application of the polyurethane resin

InactiveCN108164675AGood workmanshipIncrease productivityCoatingsTextiles and paperPolyolSurface layer

The invention discloses a polyurethane resin for high temperature resistant integrated solvent-free leather as well as a preparation method and application of the polyurethane resin. The polyurethaneresin for high temperature resistant integrated solvent-free leather comprises a resin A component and a resin B component, wherein the resin A component comprises 20%-40% by weight percentage of a polyether ester polyol-aromatic polyisocyanate prepolymer and 0.3%-2.0% by weight percentage of water; and the resin B component comprises 15%-85% by weight percentage of aromatic diisocyanate. Only knife coating of one knife of the solvent-free resin is needed when the polyurethane resin for high temperature resistant integrated solvent-free leather is used for producing synthetic leather, and thenthe produced synthetic leather can have a surface layer, bonding layer and foaming layer structure, the process is simple, and the high temperature resistance is excellent.

Owner:ZHEJIANG HUAFON SYNTHETIC RESIN

Formula of health-care product adopting natto freeze-dried powder and ginkgo biloba extract as main materials

ActiveCN104256583AEffectively adjust viscosityEffectively regulate blood fatNatural extract food ingredientsFood ingredient functionsFormularyDisease

The invention relates to the field of health-care products and particularly relates to a formula of a health-care product adopting natto freeze-dried powder and ginkgo biloba extract as main materials. The formula is characterized in that the ingredients in the formula comprises the following materials by weight percent: 18-22% of natto freeze-dried powder, 12-16% of ginkgo biloba extract, 18-22% of semen cassiae extract, 18-22% of radix puerariae extract, 8-12% of hawthorn extract, 8-12% of barbary wolfberry fruit powder, 3-7% of ginseng extract, 0.18-0.22% of vitamin C, 0.013-0.017% of vitamin E, 0.001-0.003% of vitamin B1, 0.001-0.003% of vitamin B6, 0.000004-0.000007% of vitamin B12, 0.0003-0.0006% of folic acid and the balance being starch slurry, and the sum of all the ingredients is 100%. The formula has the effects of effectively adjusting the blood viscosity, reducing the blood fat, dissolving the thrombus, dilating the blood vessel, removing free radicals, resisting oxidation, enhancing the immunity of a human body and reducing the morbidity of cardiovascular and cerebrovascular diseases of middle and old aged people, and the formula has important and positive significance on protection of the cardiocerebral vascular system of the middle and old aged people and promotion of the development of the physical health of the middle and old aged groups.

Owner:河南佳禾康生物食品科技有限公司

Flexible transparent conductive electrode

InactiveCN108417294AGuaranteed uniformityEffective dispersionConductive layers on insulating-supportsNon-conductive material with dispersed conductive materialAlcoholKetone solvents

The present invention discloses a flexible transparent conductive electrode. The flexible transparent conductive electrode is formed by transparent flexible base materials and a silver nanowire coating layer covering the surface of the transparent flexible base materials. The preparation method of the flexible transparent conductive electrode comprises the following steps of: adding silver nanowire aqueous dispersion, waterborne acrylate resin, triethylene tetramine, 1-2 parts of methyl p-tolyl sulfone, 0.1-0.3 parts of hydrogenated castor oil and mixed solvent into a vacuum mixer for vacuum defoamation and uniform mixing to obtain mixed liquor, wherein the concentration of the silver nanowire aqueous dispersion is 2-10 mg / mL, and the mixed solvent is made by mixing alcohols solvent and ketones solvent; drying a wet film in a vacuum drying oven with 150 DEG C for 3-10 min, and taking out the wet film after the wet film is completely volatilized, namely obtaining the flexible transparent conductive electrode. The flexible transparent conductive electrode reduces the conductive resistance rate, further avoids stacking of the silver nanowires, ensures the conductive uniformity and improves the light transmittance.

Owner:ZHEJIANG OUREN NEW MATERIALS CO LTD

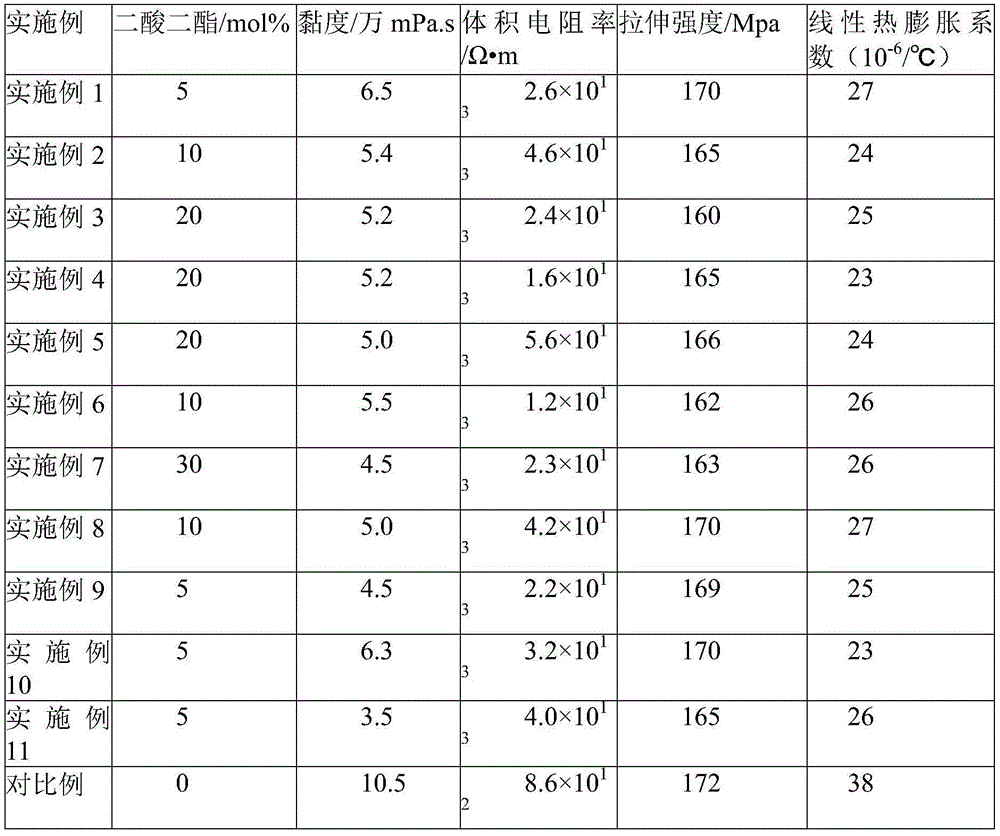

Low-viscosity polyamide acid copolymer, preparation method of polyamide acid copolymer and polyimide film

The invention discloses a low-viscosity polyamide acid copolymer, a preparation method of the polyamide acid copolymer and a polyimide film. The method for preparing the low-viscosity polyamide acid copolymer comprises the following steps: carrying out a reaction of aromatic diamine, a diacid diester monomer and aromatic dianhydride in an aprotic polar solvent, thereby obtaining the product, wherein the diacid diester monomer is selected one or a combination of more than two of dimethyl phthalate, diethyl phthalate and dibutyl phthalate; the addition amount of the diacid diester is 5-30mol% of the usage amount of the aromatic dianhydride. Due to the addition of the diacid diester and the control of addition amount of the diacid diester relative to the aromatic dianhydride, the viscosity of the system is effectively regulated, and finally a polyimide prepolymer (the polyamide acid copolymer) with low viscosity is obtained, so that the leveling property and operability of the polyamide acid copolymer are improved, the drying and film-forming speed is high, and the finally prepared polyimide film has further excellent mechanical property and insulating property.

Owner:GUILIN ELECTRICAL EQUIP SCI RES INST

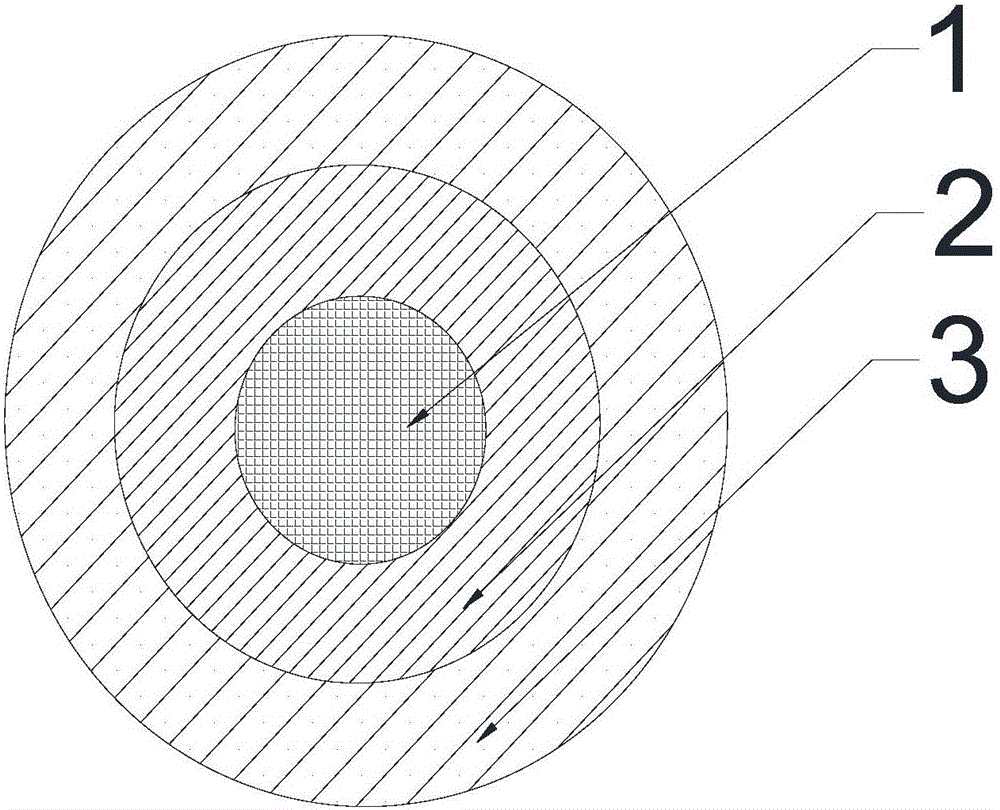

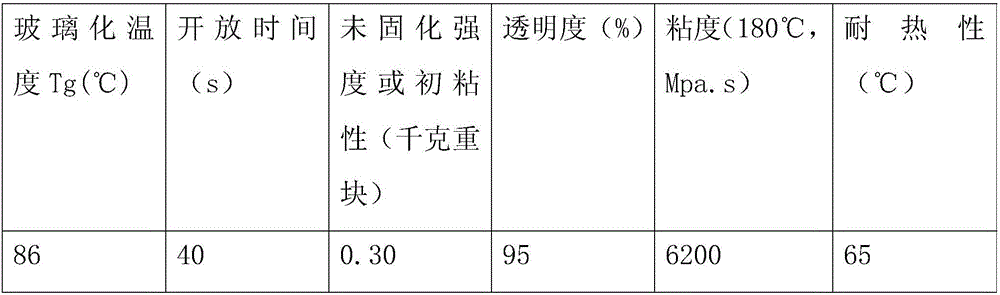

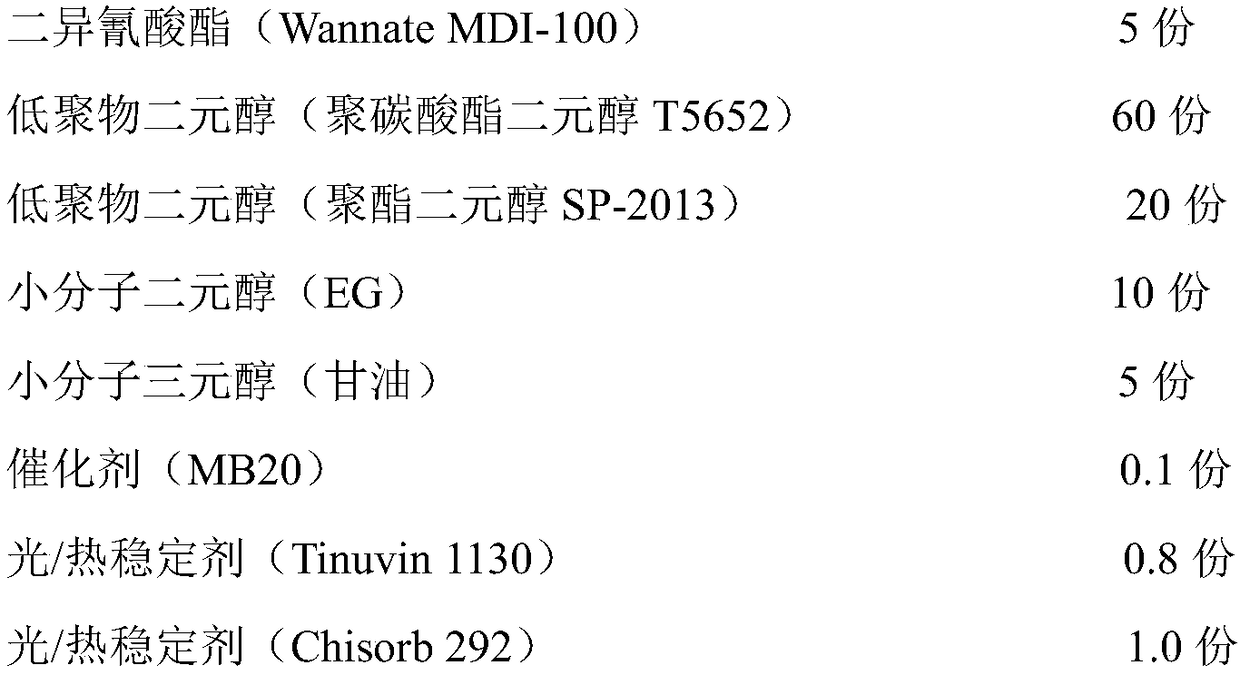

Invisible optical cable and self-adhering coating glue

InactiveCN105969252AHigh transparencyExtended opening hoursWax adhesivesMacromolecular adhesive additivesWaxPetroleum

The invention relates to an invisible optical cable and a self-adhering coating glue. The invisible optical cable sequentially comprises a natural-color optical fiber, a transparent tight sheath layer and a self-adhering coating layer from interior to exterior, wherein the self-adhering coating layer adopts a self-adhering coating glue; the self-adhering coating glue comprises the following components in percentage by weight: 40% to 45% of ethylene-ethyl acrylate copolymer, 11% to 15% of tackifier, 25% to 30% of synthetic wax or petroleum derivative wax, and the balance of other additives. The invisible optical cable has the advantages that by setting the prescription ratio of ethylene-ethyl acrylate copolymer, tackifier, and synthetic wax or petroleum derivative wax, the transparency of the self-adhering coating layer after curing is higher, the open time is longer, the uncuring strength or initial viscosity is higher, the construction is more convenient, and the construction property of the invisible optical fiber is improved.

Owner:HANGZHOU FUTONG COMM TECH CO LTD

Asphalt regeneration agent and preparation method of same

InactiveCN108192362AGood compatibilityEffectively adjust viscosityBuilding insulationsPlasticizerAsphalt

The invention discloses an asphalt regeneration agent, wherein the asphalt regeneration agent includes, by mass, 40-50% of a softening agent, 20-30% of a plasticizer, and 15-30% of a performance improver. A preparation method includes steps of: 1) preparing the raw materials according to mass percentage ratio; 2) preheating a reaction kettle to 150-160 DEG C; 3) adding the softening agent, stirring the mixture for 5-8 min, adding the plasticizer according to the mass ratio, and continuously stirring the mixture for 3-5 min; 4) cooling the mixture to 100-120 DEG C and adding the performance improver, stirring the mixture for 2-3 min, and standing and cooling the mixture at normal temperature to prepare the asphalt regeneration agent.

Owner:威海迈凯新材料科技有限公司

Preparation method of frankincense shower gel

ActiveCN103655331ARelieve sorenessRelieve heel painCosmetic preparationsToilet preparationsShower gelJoint arthralgia

The invention relates to a preparation method of a frankincense shower gel. The frankincense shower gel is prepared from the following raw materials by weight: 60-80g of frankincense, 400-500g of pure water, 8-10g of a soybean glue thickener, 8-10g of an amino acid foamer, 20-30g of sweet almond oil, 5-8g of grapefruit essential oil, 5-8g of citrus essential oil and 5-8g of lavender essential oil. The frankincense is cleaned, fried and crushed to prepare roasted frankincense which not only has the functions of relieving muscular soreness, heel pain and arthralgia, but also has the effect of sterilizing and reliving itch. The sweet almond oil is added, so that the frankincense shower gel has the function of moisturizing and moistening skins to effectively improve the water shortage condition of skins and prevent the body skins from losing water, and meanwhile, the frankincense shower gel effectively softens, relieves and protects skins. Furthermore, as the grapefruit essential oil, the citrus essential oil and the lavender essential oil are adopted to prepare the frankincense shower gel, the normal functions of the skin cells can be balanced and adjusted, so that the skins are transparent and glossy. The grapefruit essential oil, the citrus essential oil and the lavender essential oil are safer due to pure nature of extracted plants, so that the shower gel has unique and natural faint scent.

Owner:东莞市星泽日用品有限公司

A kind of middle layer polyurethane resin for solvent-free automotive interior leather and preparation method thereof

ActiveCN106220817BReduce usageGuaranteed to be environmentally friendlyRoad vehiclesTextiles and paperOligomerAlcohol

The invention provides a solvent-free interlayer polyurethane resin for automotive trim leather and preparation method thereof. The solvent-free interlayer polyurethane resin is composed of an A component and a B component in a mass ratio of (2.5: 1)-(1: 2.5) through the mixing; the A component is composed of diisocyanate, oligomer dihydric alcohol, micromolecular dihydric alcohol, micromolecular trihydric alcohol, catalyst, light / heat stabilizer, flatting agent and solvent-free color paste; the B component is composed of diisocyanate, triisocyanate, oligomer dihydric alcohol, micromolecular dihydric alcohol, micromolecular trihydric alcohol and antioxidant. The polyurethane resin prepared by the method disclosed by the invention can be used as the interlayer for the automotive trim leather, the high temperature durable performance and various mechanical properties of the automotive leather can be effectively guaranteed while meeting the hydrolysis resistance of the automotive leather product; the peeling strength of the prepared automotive leather product reaches up to 145N / 3cm, the hydrolysis resistance can reach the condition that the peeling strength still reaches up to 135N / 3cm after 10 weeks.

Owner:HEFEI ANLI POLYURETHANE NEW MATERIAL

Nanowhisker leveling thickener for paint and preparation method thereof

InactiveCN105985668ARegulate fluidityGood dispersionCoatingsPigment treatment with macromolecular organic compoundsSlagPerformance index

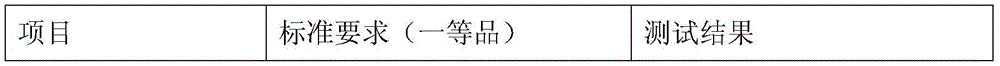

The invention discloses a nanowhisker leveling thickener for paint and a preparation method thereof. The nanowhisker leveling thickener is prepared from, by weight, 24-36 parts of attapulgite, 13-25 parts of sericite, 16-28 parts of dolomite, 20-30 parts of kyanite, 15-25 parts of phyllite, 8-16 parts of waste ardealite, 5-10 parts of carbide slag, 3-6 parts of sodium sulfate, 2-5 parts of barium fluoride, 1-3 parts of molybdenum trioxide, 6-12 parts of a modifier A and 4-8 parts of a modifier B. The nanowhisker leveling thickener is excellent in thickening and leveling performance, evident in sagging prevention effect and capable of effectively adjusting paint viscosity and preventing sagging of coatings, thick-layer paint can be achieved, and performance indexes of the prepared paint all reach national standard requirements on first-grade products.

Owner:MINGGUANG FEIZHOU NEW MATERIAL

Preparation method of low-brittleness 3D (Three-dimensional) printing mortar

InactiveCN108178608AImprove water resistanceHigh strengthAdditive manufacturing apparatusWater bathsParaffin wax

The invention discloses a preparation method of low-brittleness 3D (Three-dimensional) printing mortar. The preparation method comprises the following steps: evenly mixing magnesium phosphate cement,portland cement, montmorillonoid, medical stone powder, talcum powder and cocoanut fibers to obtain premix; stirring carrageenan, sodium alginate and water, carrying out microwave processing, adding into liquid paraffin, stirring in an ice-water bath, adding a sodium hydroxide solution to be evenly stirred, cooling, and filtering to obtain a composite microsphere; evenly stirring the composite microsphere, an air entraining agent, a water reducer, polyvinyl alcohol, sepiolite powder and water, and adding the premix to be evenly stirred to obtain the low-brittleness 3D printing mortar. According to the preparation method, which is put forward by the invention, for the low-brittleness 3D printing mortar, the obtained mortar has the advantages of good water tolerance, small heat conduction coefficient, good thermal insulation effect, high strength and lowered brittleness.

Owner:WUHU LINYI ELECTRONICS SCI & TECH

A formula of health care products based on natto freeze-dried powder and ginkgo leaf extract

ActiveCN104256583BLower serum cholesterol levelsCold medicineMetabolism disorderAntinoxious agentsBiotechnologyGinkgo Biloba Leaf Extract

The invention relates to the field of health care products, in particular to a formula of health care products based on natto freeze-dried powder and ginkgo leaf extract, which is characterized in that: the formula is according to the mass ratio: natto freeze-dried powder 18~22 %, Ginkgo biloba extract 12~16%, Cassia seed extract 18~22%, Pueraria root extract 18~22%, Hawthorn extract 8~12%, Lycium barbarum powder 8~12%, Ginseng extract 3~7% , Vitamin C? 0.18~0.22%, Vitamin E? 0.013~0.017%, vitamin B1? 0.001~0.003%, vitamin B6? 0.001~0.003%, vitamin B12? 0.000004~0.000007%, folic acid 0.0003~0.0006%, the rest is starch slurry, the sum of the above components is 100%, The formula of the present invention can effectively regulate blood viscosity, reduce blood fat, dissolve thrombus, expand blood vessels, scavenge free radicals, resist oxidation, enhance human immunity, reduce the incidence of cardiovascular and cerebrovascular diseases in middle-aged and elderly people, and protect the cardiovascular and cerebrovascular systems of middle-aged and elderly people. It is of great and positive significance to promote the physical and healthy development of the middle-aged and elderly population.

Owner:河南佳禾康生物食品科技有限公司

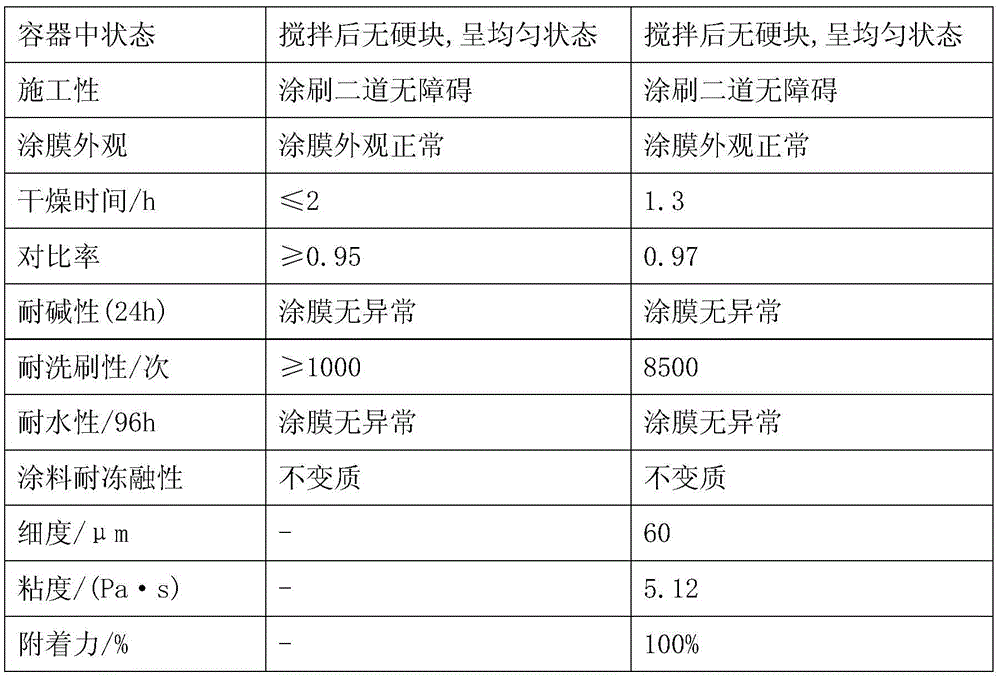

Method for preparing EVA emulsion by adding alcohol solvent

The present invention provides a method for preparing an EVA emulsion by adding an alcohol solvent. The method comprises: in a water phase solvent, carrying out an emulsion copolymerization reaction on ethylene and a vinyl acetate (VAc) monomer, and adding an alcohol compound as a second solvent during the copolymerization process. According to the present invention, the method has advantages of polymerization rate controlling, significantly-reduced product viscosity, particle morphology and toughness strength maintaining, and polymerization reaction time shortening; and the obtained EVA emulsion product has advantages of good stability, moderate VAc content and excellent performance, and can meet different needs.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for polymer-assistant depositing high temperature superconducting coating conductor superconducting layer

InactiveCN100565953CReduce formationImprove current carrying capacitySuperconductor device manufacture/treatmentFurnace temperatureElectrical conductor

A macromolecule-assisted method of deposition for a superconducting layer of a high-temperature superconductivity coating electrical conductor has the preparation method as follows: a. dissolving rare-earth acetate, barium acetate and cupric acetate in monoprop with a stoichiometric proportion that rare-earth: barium: cupric equals to 1:2:3 to acquire a precursor solution; b. adding PVB, PEG or PVP into the precursor solution with the weight ratio of 2-8:100 to acquire a coating colloid; c. coating the coating colloid on a substrate and heating for drying; d. placing the substrate in a tubular furnace to carry out decomposition heat treatment; e. rapidly heating up the furnace temperature to 800-900 DEG C under moist argon atmosphere for 5-15min, then lowering the temperature to 750-780 DEG C for 1-3 hours, and then lowering the temperature to 350-500 DEG C under the argon atmosphere for low temperature oxygen-permeation annealing treatment, and the superconducting layer is acquired by cooling. The method has the advantages of low cost and simple technique, which is applied to industrialized production; the superconducting layer prepared is characterized by high biaxial texture, flat and dense surface and good superconductivity.

Owner:SOUTHWEST JIAOTONG UNIV

Flame-retardant polyether polyol and preparation method thereof

The invention discloses flame-retardant polyether polyol and a preparation method thereof. The preparation method comprises the following steps: weighing 3 parts (mole fraction) of a formaldehyde solution, and adjusting the pH value of the formaldehyde solution by using a 0.1 M NaOH solution until the the formaldehyde solution is slightly alkaline; adding 0.5-1 part (molar fraction) of dicyandiamide, carrying out heating to 75 DEG C, carrying out a hydroxymethyl reaction, adding 1 part of melamine after complete dissolution, and continuing reacting for 1.5 hours after a formed system is completely dissolved into clear liquid; and weighing 20 parts (in a weight ratio with melamine) of polyether polyol, carrying out heating to 80 DEG C, dropwise adding hydroxymethylate into the polyether polyol, and continuing reacting for 2 hours. According to the invention, polyhydroxymethyl melamine is obtained through hydroxymethylation reaction of melamine and formaldehyde, and then undergoes condensation with polyether, thereby obtaining the flame-retardant polyether polyol; and the flame-retardant polyether polyol has the characteristics of no toxicity and efficient flame retardance, and is halogen-free, efficient and flame-retardant, and moreover, system viscosity can be effectively adjusted by adjusting a ratio of dicyandiamide to melamine.

Owner:福建省天骄化学材料有限公司 +1

Spun silk liquid foundation and preparation method thereof

PendingCN114288218AEffectively adjust viscosityAdjustable viscosityCosmetic preparationsMake-upGlycerolOil phase

The invention relates to the field of cosmetics, and particularly discloses a spun silk liquid foundation and a preparation method thereof, and the spun silk liquid foundation is prepared from the following raw materials: hydrogenated polyisobutene, siloxane polymers, glycerol, toner, carbomer, a stabilizer, a neutralizer, a preservative, essence and the balance of a composite humectant. The preparation method of the liquid foundation comprises the following preparation steps: step 1, uniformly mixing the composite humectant, the glycerol and the carbomer to prepare a water phase; uniformly mixing hydrogenated polyisobutene, a siloxane polymer and a stabilizer to obtain an oil phase; step 2, adding toner into the oil phase, and stirring and dispersing uniformly to obtain a colored oil phase; and step 3, adding the colored oil phase into the water phase at a constant speed, homogenizing for 5-8 minutes under the condition of 1000-1500rpm, then adding the neutralizer, the preservative and the essence, and uniformly stirring and dispersing to obtain the liquid foundation. The liquid foundation prepared by the invention has the advantages of excellent smearing feeling, good stability, excellent high temperature resistance and excellent cold resistance.

Owner:SHANGHAI CO FUN BIOTECH

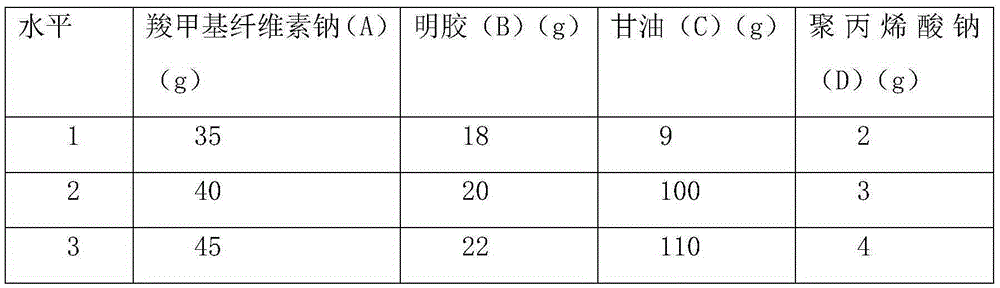

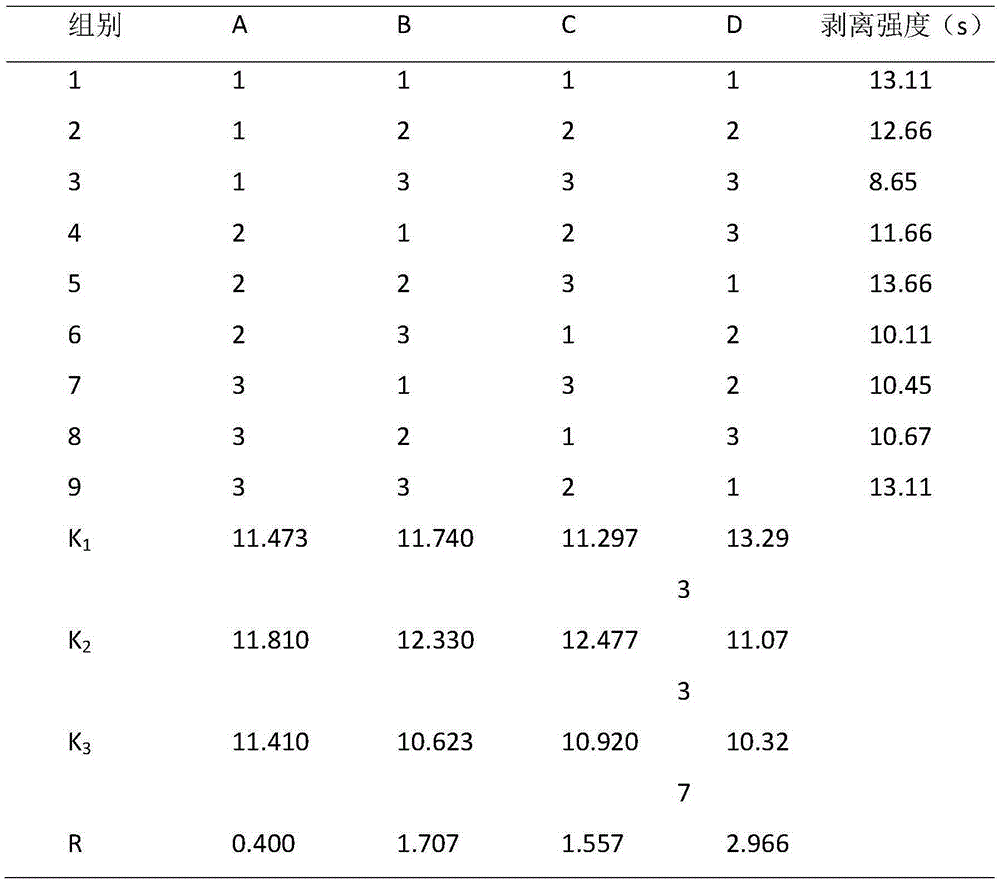

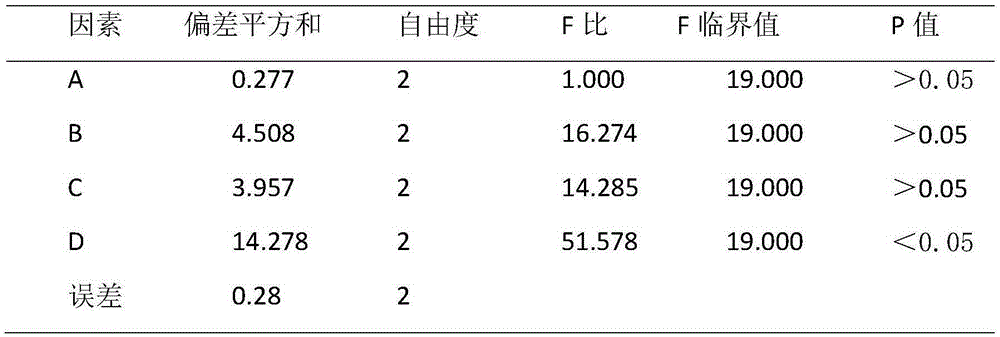

Tibetan medicine ash bark bone setting cataplasm and preparation method thereof

InactiveCN105267610AImprove adhesionReduce the presence of air bubblesAntipyreticAnalgesicsBiomedical engineeringTibetan medicine

The invention discloses Tibetan medicine ash bark bone setting cataplasm and a preparation method thereof. Proper matrixes and the proportion thereof are screened through an experiment, part of medicinal materials are smashed and used as medicine and diluents, and the obtained cataplasm has few bubbles, is good in adhesiveness and needs no auxiliary paster.

Owner:SHANDONG JINHE DRUG RES DEV

Solvent-free, non-yellowing, high-brightness, tortuous-resistant polyurethane leather resin and its preparation method and application

ActiveCN108164674BImprove bending resistanceStrong production operabilityTextiles and paperPolymer sciencePolyol

The invention discloses a solvent-free, non-yellowing, high-transparency, highlight and bending-resistance polyurethane leather resin, and a preparation method and an application thereof. The solvent-free, non-yellowing, high-transparency, highlight and bending-resistance polyurethane leather resin comprises a resin A component and a resin B component; the ratio of the resin A component to the resin B component is 3:1 to 1:2 in mass, and the resin A component contains 30 wt%-45 wt% of a polyether polyol-aliphatic polyisocyanate prepolymer, and the resin B component contains 15 wt%-60 wt% of aliphatic diisocyanate. A synthetic leather surface layer is coated with the solvent-free, non-yellowing, high-transparency, highlight and bending-resistance polyurethane leather resin, synthetic leather is endowed with high-transparency and highlight aesthetic degree, and the bending resistance and other physical and mechanical properties of the non-yellowing synthetic leather are further improved;the bending strength at normal temperature is more than or equal to 200 thousand times, the bending resistance at the temperature of -20 DEG C is more than or equal to 50 thousand times, the synthetic leather is resistant to hydrolysis for 8 weeks, and the yellowing resistance level is more than or equal to 4.

Owner:ZHEJIANG HUAFON SYNTHETIC RESIN

Marine diesel oil and preparation method thereof

InactiveCN104789281AIncrease oxygen contentImprove combustion effectLiquid carbonaceous fuelsOil and greasePetroleum product

The invention discloses marine diesel oil which is prepared from the following components in percentage by weight: 40-70% of a waste oil distillate, 10-25% of desulfurized heavy aromatics, 15-30% of a grease deodorizer distillate, 5-15% of C3-C5 fusel and 0.5-1.2% of polyacrylate. The marine diesel oil disclosed by the invention fully utilizes part of waste resources and renewable energy sources, can alleviate exploitation and consumption of petroleum resources, and is wide in source of raw materials, low in cost and good in economical benefit. The marine diesel oil is rich in oxygen, good in combustion property, full in combustion, high in heat efficiency, few in tail gas emission pollutant and low in sulfur content, the mechanical corrosivity and discharge of sulfide are reduced, and the marine diesel oil can be widely applied to the application field of ships using petroleum diesel such as fishing vessels, transport ships and collecting ships. The marine diesel oil disclosed by the invention is good in starting performance, small in quantity of black smoke and low in noise, the nozzle is not blocked, carbon is not deposited, the operation is strong and the accelerating performance is good, so that the marine diesel oil is the reproducible marine diesel oil which can utilize waste resources and fully replace existing petroleum diesel.

Owner:舟山冉升能源科技有限公司

Preparation method of 3D printing mortar with high thermal insulation performance

InactiveCN108083759AImprove water resistanceHigh strengthAdditive manufacturing apparatusSodium BentoniteIce water

The invention discloses a preparation method of 3D printing mortar with high thermal insulation performance. The method comprises the following steps: uniformly mixing magnesium phosphate cement, Portland cement, wollastonite, coal gangue, mica powder and glass fibers to obtain a premix; uniformly stirring composite microspheres, an air entraining agent, a water reducing agent, cellulose ether, bentonite and water, adding the premix, and uniformly stirring the mixture to obtain the 3D printing mortar with high thermal insulation performance. The composite microspheres are prepared with the process as follows: agarose, sodium carboxymethyl cellulose and water are stirred at the rate of 1200-1400 r / min, microwave processing is performed under the power of 350-420 W, the obtained solution isadded to liquid paraffin, stirring is performed in an ice-water bath at the rate of 20-90 r / min, a sodium hydroxide solution is added, the mixed solution is stirred uniformly, cooled and filtered, andthe composite microspheres are obtained. With adoption of the preparation method of the 3D printing mortar with high thermal insulation performance, the mortar has the advantages of good water resistance, small heat conductivity coefficient, good thermal insulation effect, high strength and reduced brittleness.

Owner:WUHU LINYI ELECTRONICS SCI & TECH

Polyurethane resin for solvent-free high-transparency tortuosity-resistant leather and its preparation method and application

ActiveCN108252115BHigh peel strengthHigh tensile strengthPolyurea/polyurethane coatingsTextiles and paperPolymer sciencePolyol

The invention discloses a polyurethane resin used for non-solvent leather with high brightness and bending resistance, a preparation method and application. The polyurethane resin used for non-solventleather with high brightness and bending resistance comprises a resin component A and a resin component B; the resin component A comprises 30% to 45% of ether-ester polyhydric alcohol-aromatic polyisocyanates prepolymer; the resin component B comprises 15% to 60% of aromatic diisocyanate. The resin can be used for preparing polyurethane synthetic leather, the synthetic leather is high in brightness and attractive in appearance, the physical and mechanical properties, such as bending resistance, of the synthetic leather are improved preferably, the production operability of the non-solvent synthetic leather in the mass production process is improved, and the matching stability of the resin component A and the resin component B during machining is guaranteed.

Owner:ZHEJIANG HUAFON SYNTHETIC RESIN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com