Method for polymer-assistant depositing high temperature superconducting coating conductor superconducting layer

A polymer-assisted, high-temperature superconducting technology, used in the manufacture/processing of superconductor devices, can solve the problems of expensive equipment, reduced film superconductivity, pores and micro-cracks, etc. Thick, inexpensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0034] A kind of specific embodiment of the present invention is:

[0035] A method for polymer-assisted deposition of a high-temperature superconducting coating conductor superconducting layer, the specific method of which is:

[0036] a. Preparation of precursor solution: dissolving yttrium acetate, barium acetate, and copper acetate in propionic acid according to the stoichiometric ratio of rare earth: barium: copper in a ratio of 1:2:3 to obtain a precursor solution.

[0037] b. Preparation of coating colloid: In the precursor solution, add 3 parts of polyvinyl butyral (PVB) macromolecular additives and stir well to obtain a uniform and transparent coating colloid with a certain viscosity.

[0038]c. Colloid coating and drying: Spin coating is used for coating, that is, the colloid is dropped on the substrate and rotated with a coater to obtain a uniform coating film, and then dried at 100°C for 20 minutes.

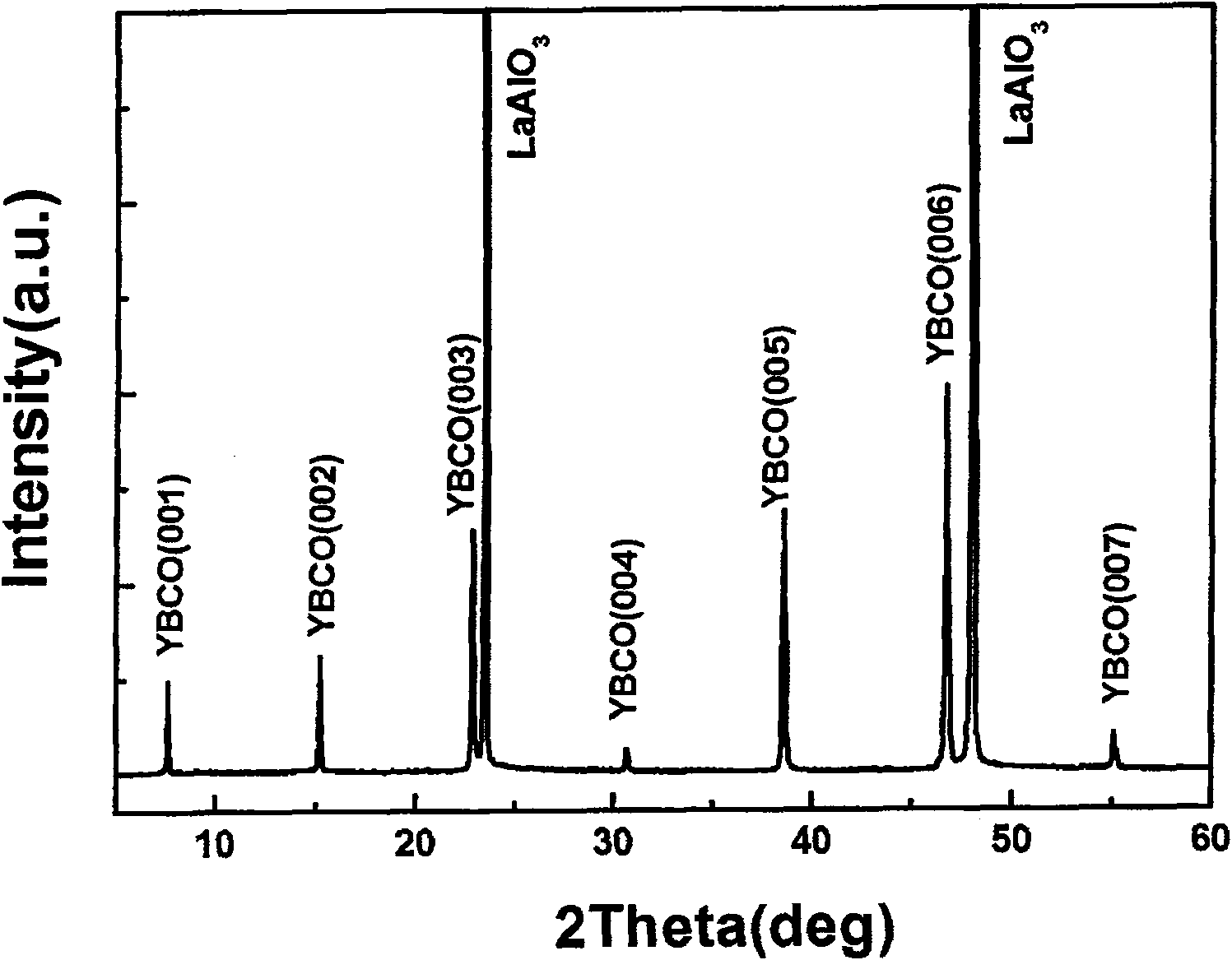

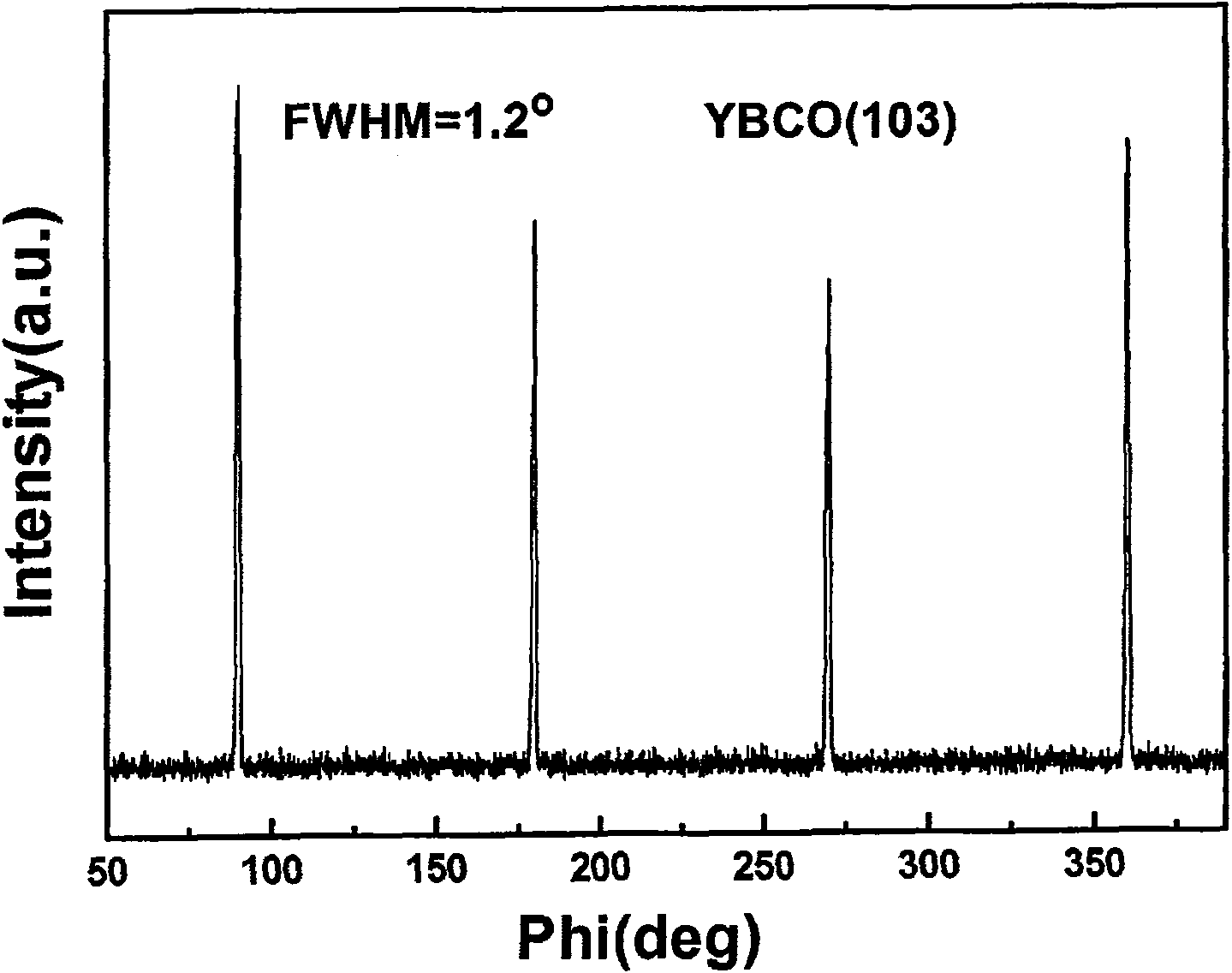

[0039] d. Decomposition heat treatment: In a dry argon atmosphe...

Embodiment 2

[0043] This example is basically the same as Example 1, the difference is:

[0044] In the preparation of the precursor solution in step a, the rare earth acetate is dysprosium acetate.

[0045] In the d-step decomposition heat treatment process, the temperature is raised from room temperature to 135°C at a rate of 3°C / min in a dry argon atmosphere, and then water vapor with a dew point of 20°C is introduced into the furnace, and argon gas is introduced at the same time to form moist argon At this time, the temperature was raised to 450°C at a rate of 1°C / min, and the temperature was kept for 0.75 hours.

[0046] In the phase-forming heat treatment of step e, water vapor with a dew point of 30°C and argon gas are introduced into the tube furnace in the upward step to form a humid argon protective atmosphere, and the furnace temperature is rapidly raised at 25°C / min To 840°C, keep warm for 5 minutes; then cool down to 775°C at 7°C / min, keep warm for 1 hour, and finally drop to...

Embodiment 3

[0049] This example is basically the same as Example 1, the difference is:

[0050] In the preparation of the precursor solution in step a, the rare earth acetate is gadolinium acetate.

[0051] In the preparation of the coating colloid in step b, 5 parts of polyethylene glycol (PEG) was added to the precursor solution as a polymer material additive.

[0052] The drying in step c is 150° C. for 15 minutes.

[0053] In the d-step decomposition heat treatment process, the temperature is raised from room temperature to 125°C at a rate of 2°C / min in a dry argon atmosphere, and then water vapor with a dew point of 15°C is introduced into the furnace, and argon gas is introduced at the same time to form moist argon At this time, the temperature was raised to 470°C at a rate of 0.25°C / min, and kept for 1 hour.

[0054] During the phase-forming heat treatment in step e, water vapor with a dew point of 35°C and argon gas are passed into the tube furnace in step d to form a humid argo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com