Patents

Literature

99 results about "Superconducting transition temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

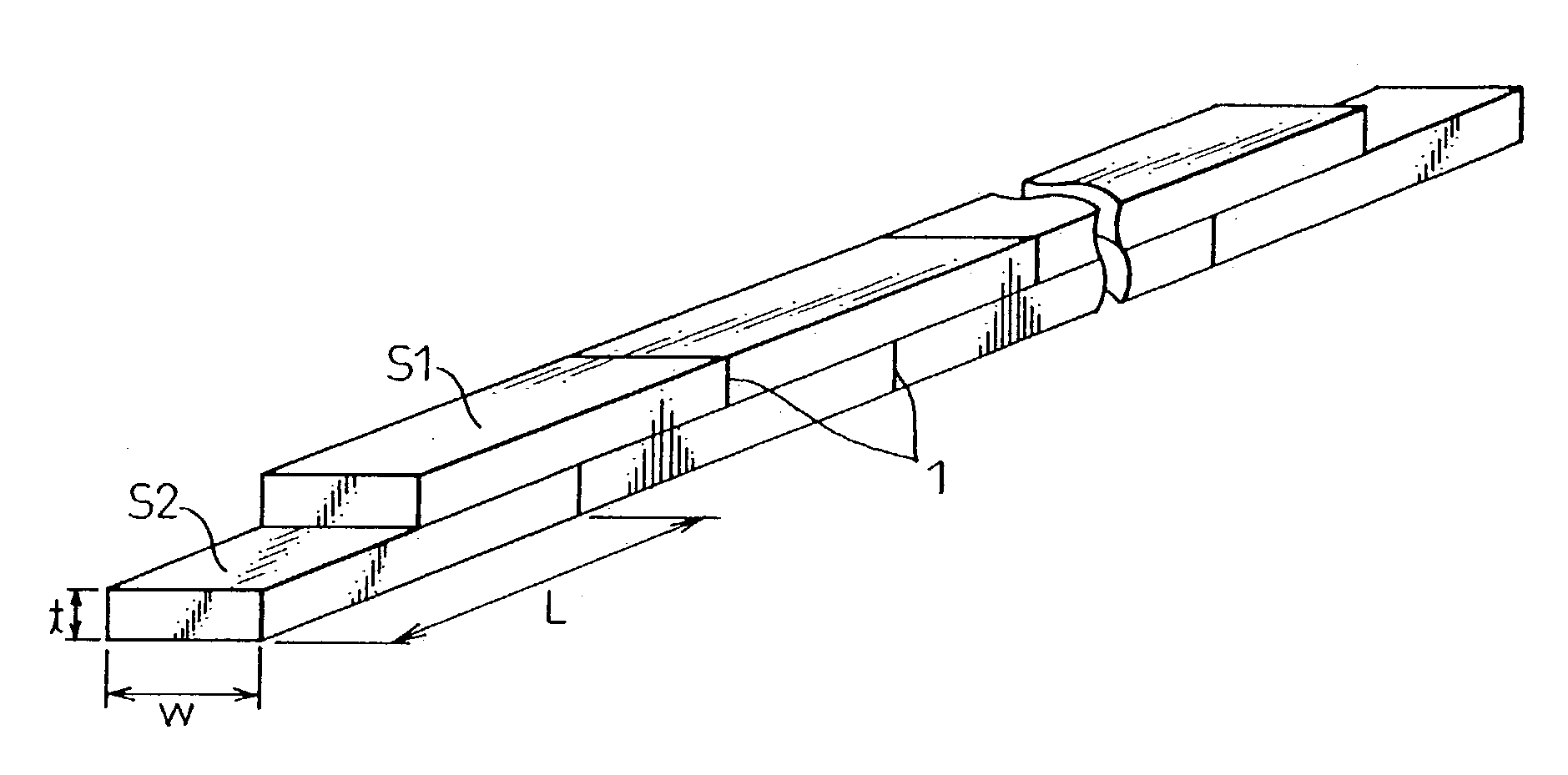

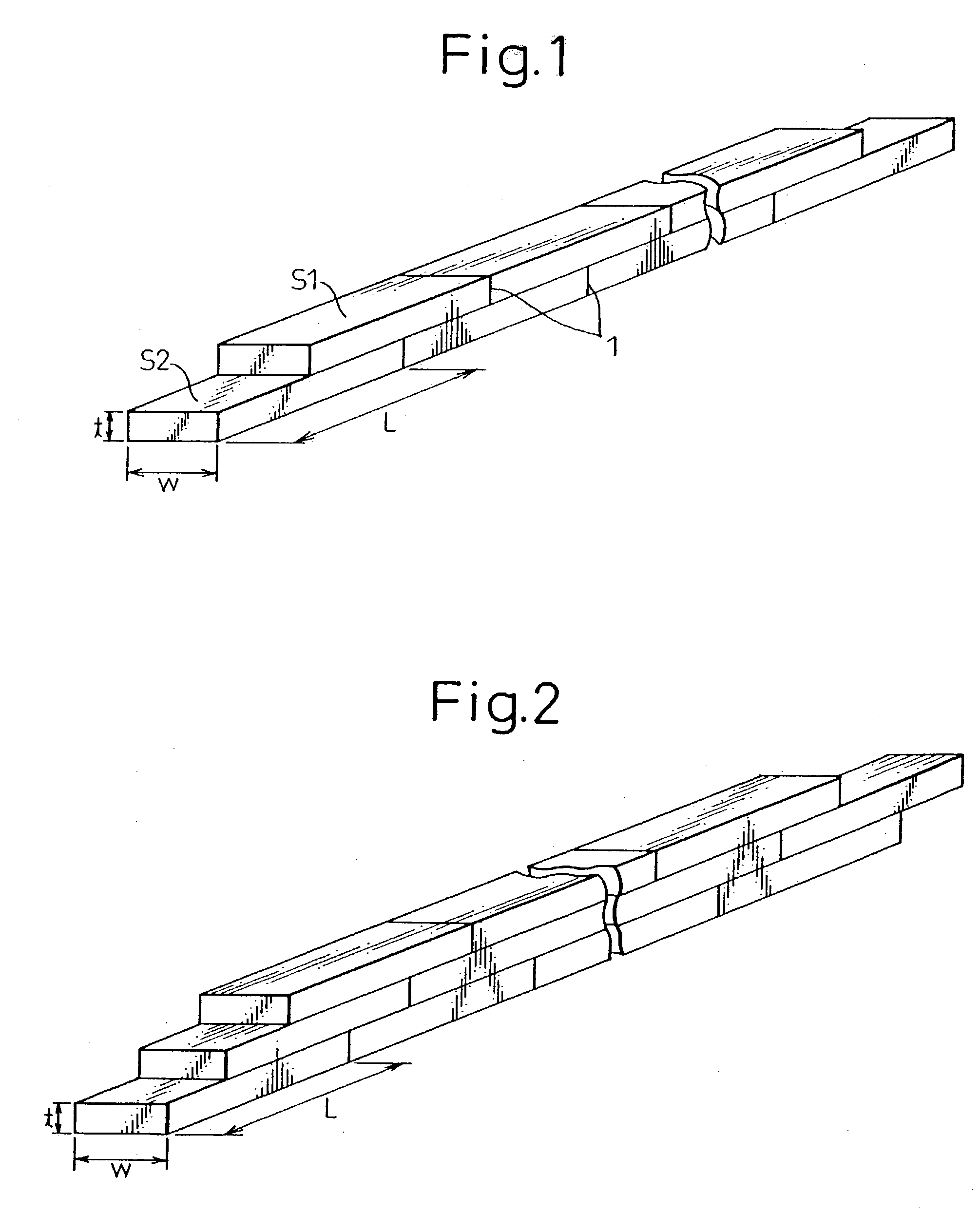

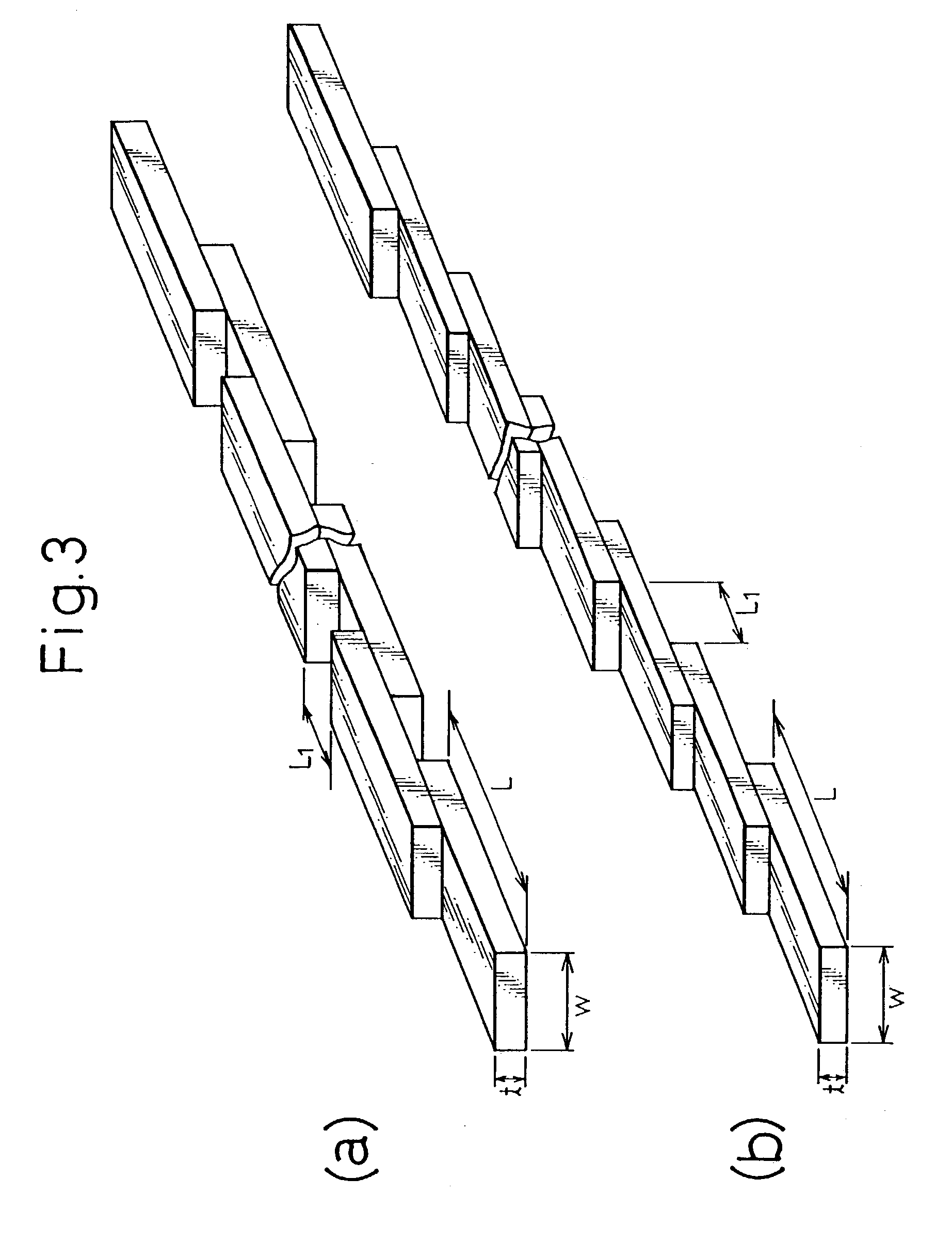

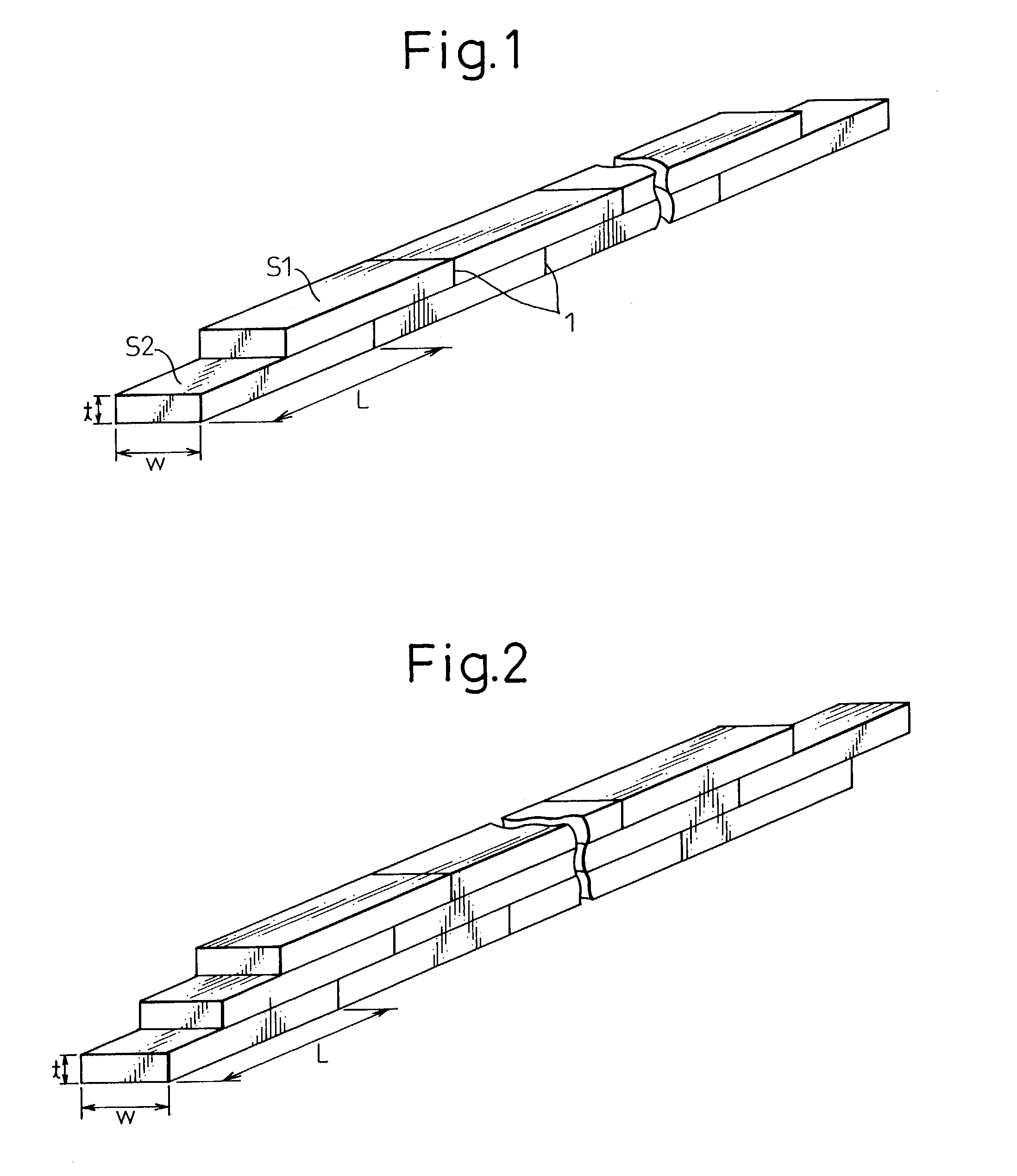

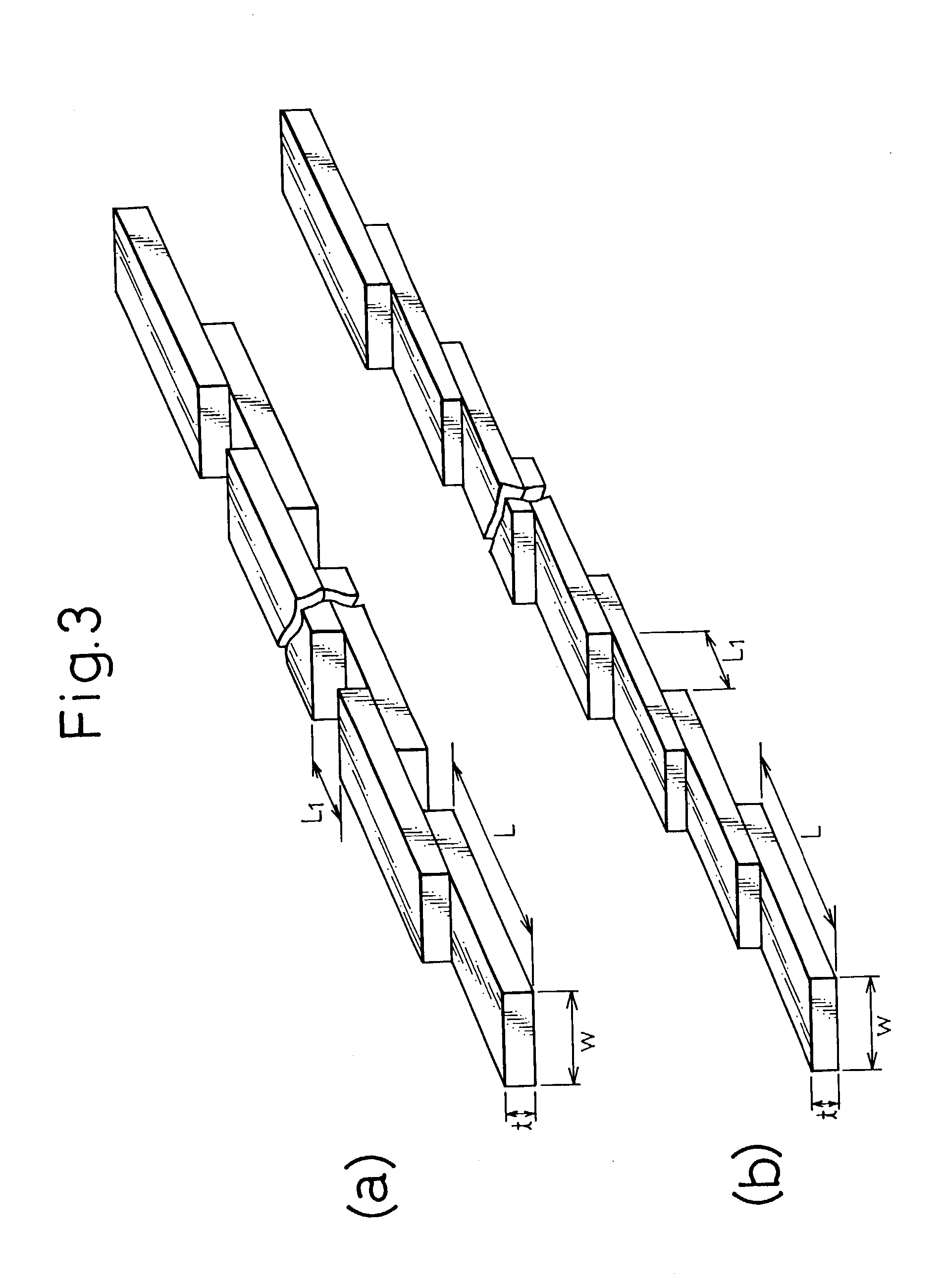

Low resistance conductors, processes of production thereof, and electrical members using same

InactiveUS20030213611A1Low resistivityEconomical priceNon-insulated conductorsSuperconductors/hyperconductorsElectrical resistance and conductanceElectrical conductor

A conductor obtained by connecting a plurality of superconductors by normal conductivity or a conductor comprised of superconductors and normal conductors, said low resistance conductor using superconductors characterized in that an apparent specific resistance of said conductor at below a superconducting transition temperature of said superconductors is lower than the specific resistance of copper at that superconducting transition temperature.

Owner:NIPPON STEEL CORP

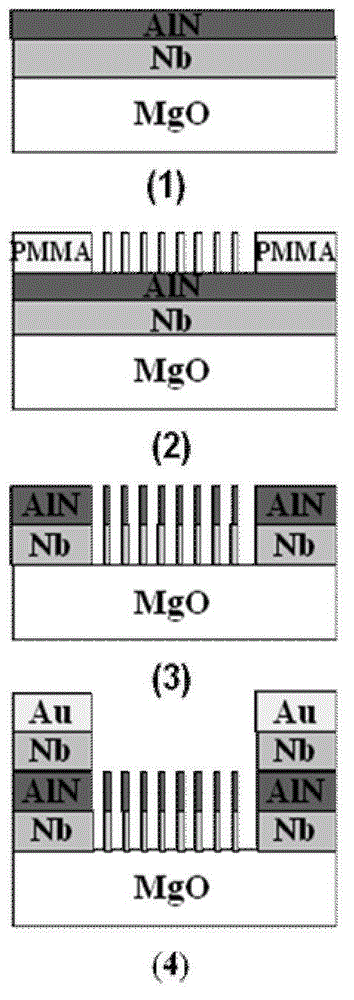

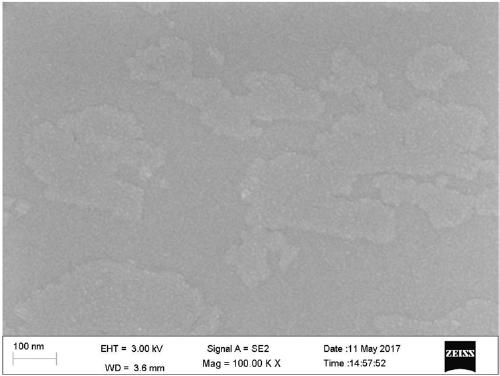

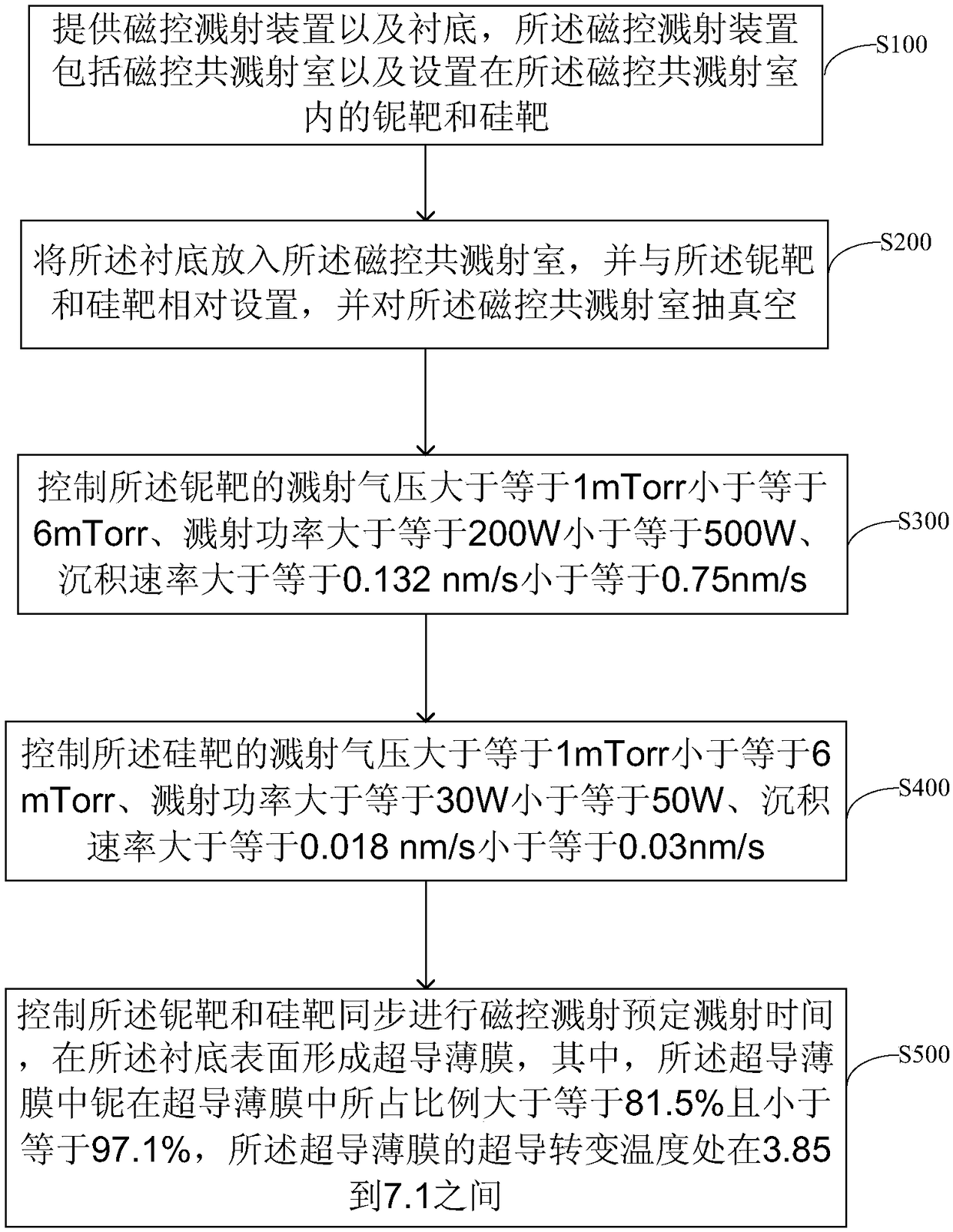

Manufacturing method for nanowire single-photon detector based on specially doped superconducting niobium film material

ActiveCN102916083AProtected superconducting propertiesIncrease the critical current densityVacuum evaporation coatingSputtering coatingNanowireNiobium

The invention discloses a manufacturing method for a nanowire single-photon detector based on a specially doped superconducting niobium film material. The manufacturing method comprises the following steps: carrying out ultrasonic cleaning and blow-drying on a substrate; carrying out Ar ion cleaning; growing a specially doped superconducting Nb film in a direct current magnetron sputtering way; carrying out spin-coating on an electron beam resist, carrying out electron beam lithography on the electron beam resist, and drawing a wire pattern with the width not more than 100nm on the electron beam resist; etching in a reaction ion etching way, and transferring the line pattern onto the Nb film to form a Nb nanowire; cleaning the residual electron beam resist, carrying out spin-coating on a photoresist on the surface of a sample, and forming an electrode pattern on the photoresist in a deep ultraviolet exposure way; and growing an electrode. According to the manufacturing method, the difficult problems of low superconducting transition temperature, low critical current density and short photoresponse wavelength of an SNSPD (Superconducting Nanowire Single Photon Detector) manufactured by the conventional Nb material are solved.

Owner:NANJING UNIV

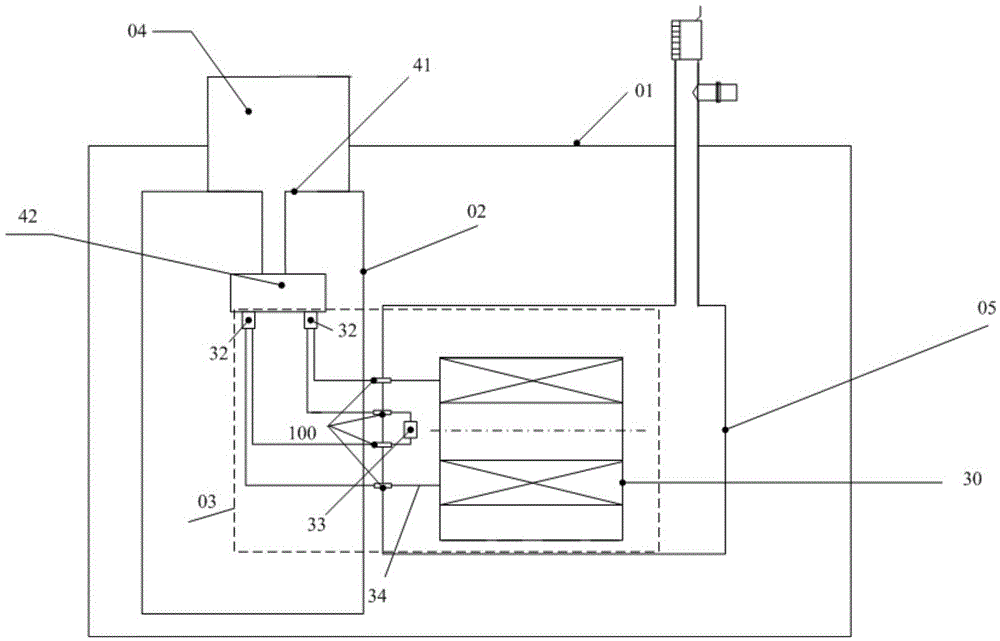

Superconducting magnet

ActiveCN105655084AEasy to replaceImprove stabilitySuperconducting magnets/coilsClosed loopSuperconducting Coils

The invention provides a superconducting magnet which comprises a vacuum container and a refrigerator. A cold screen and a superconducting coil are arranged in the vacuum container; superconducting wires are wound on a coil framework to form the superconducting coil, and two free ends of the superconducting coil are connected with a superconducting switch by superconducting connectors to form a closed superconducting circuit; the refrigerator is arranged on the vacuum container and comprises a primary cold head and a secondary cold head, and the primary cold head is thermally connected with the cold screen; the superconducting wires are made of superconducting materials with critical superconducting transit temperatures higher than 35 K; the superconducting connectors are made of superconducting welding flux with a low melting point, can be cooled by the aid of the secondary cold head or cooling media and accordingly can be assuredly in superconducting states. Compared with low-temperature closed-loop superconducting magnets in the prior art, the superconducting magnet has the advantage of high superconducting stability.

Owner:NINGBO JANSEN SUPERCONDUCTING TECH CO LTD

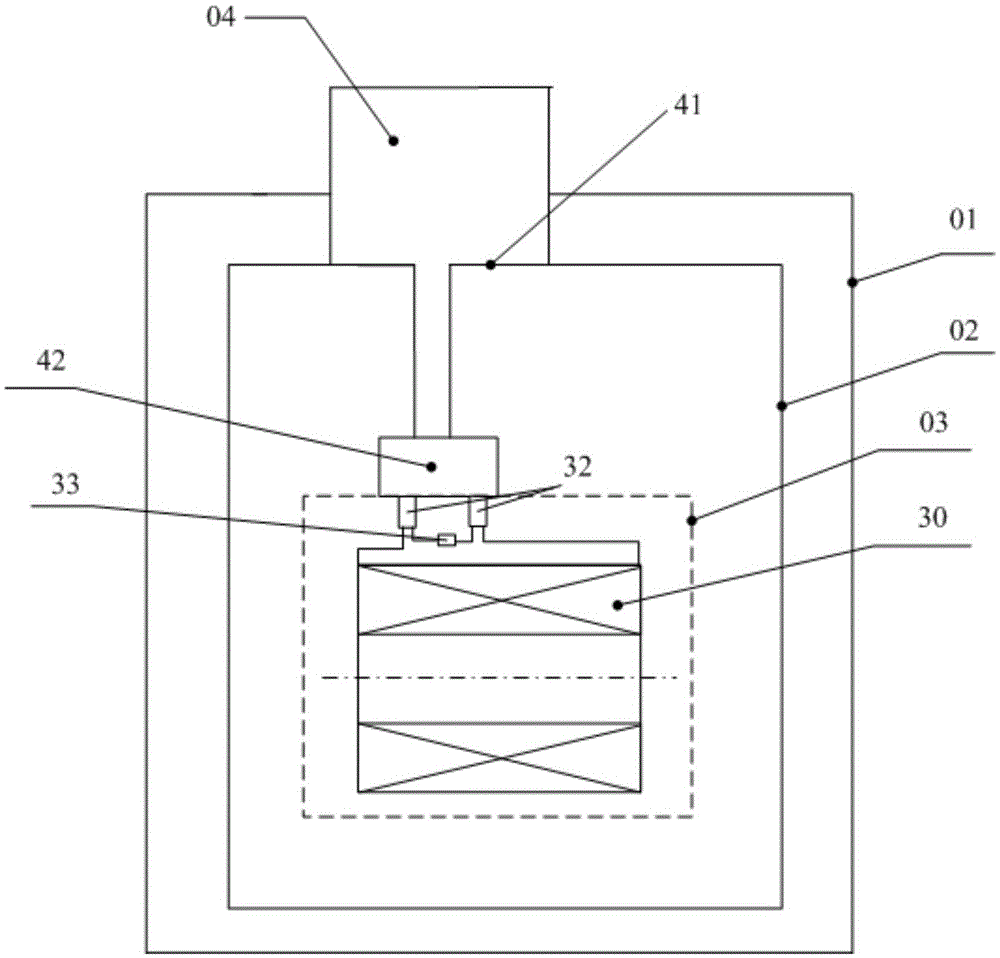

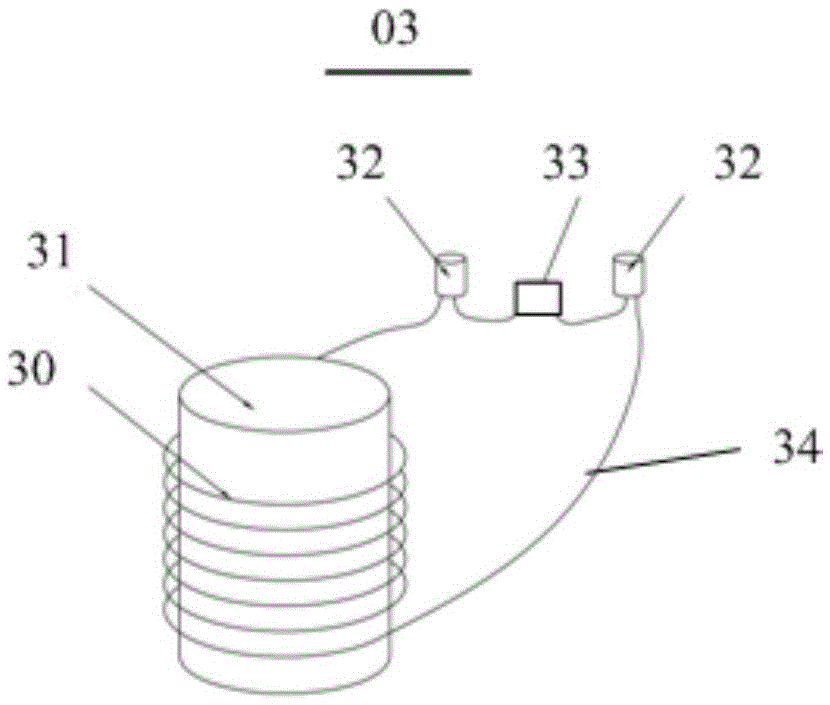

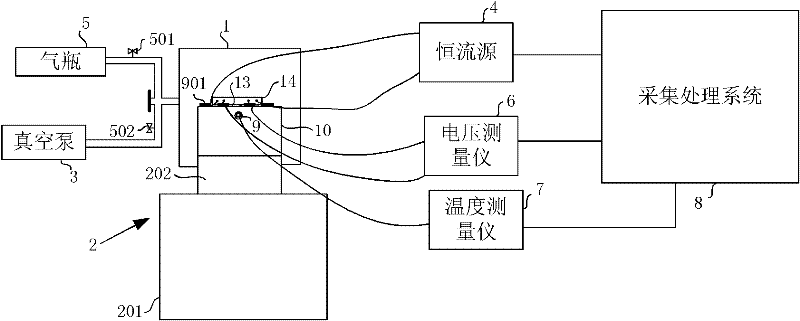

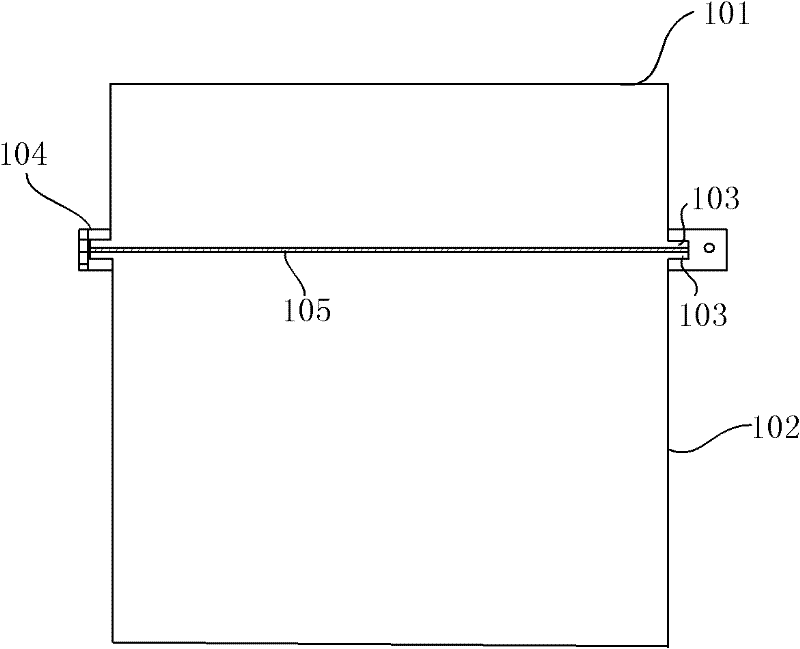

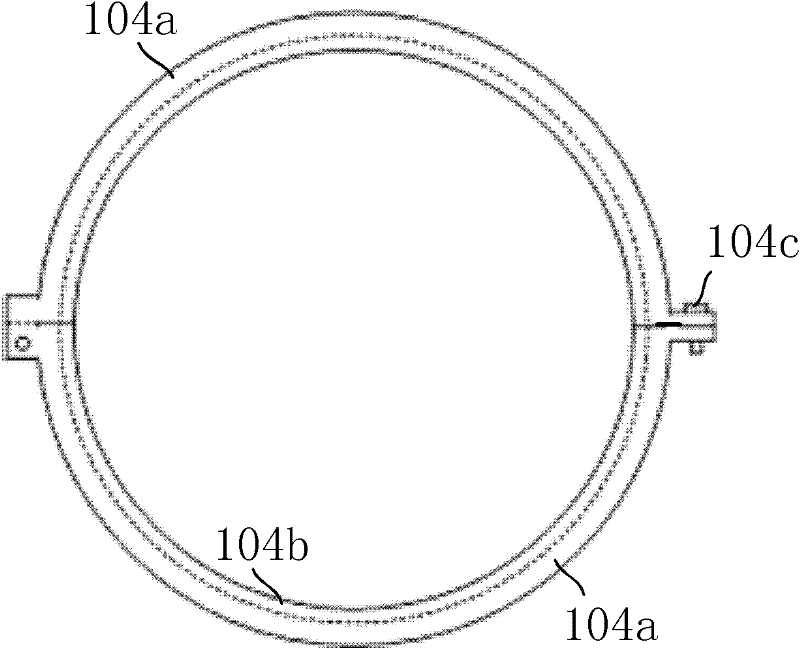

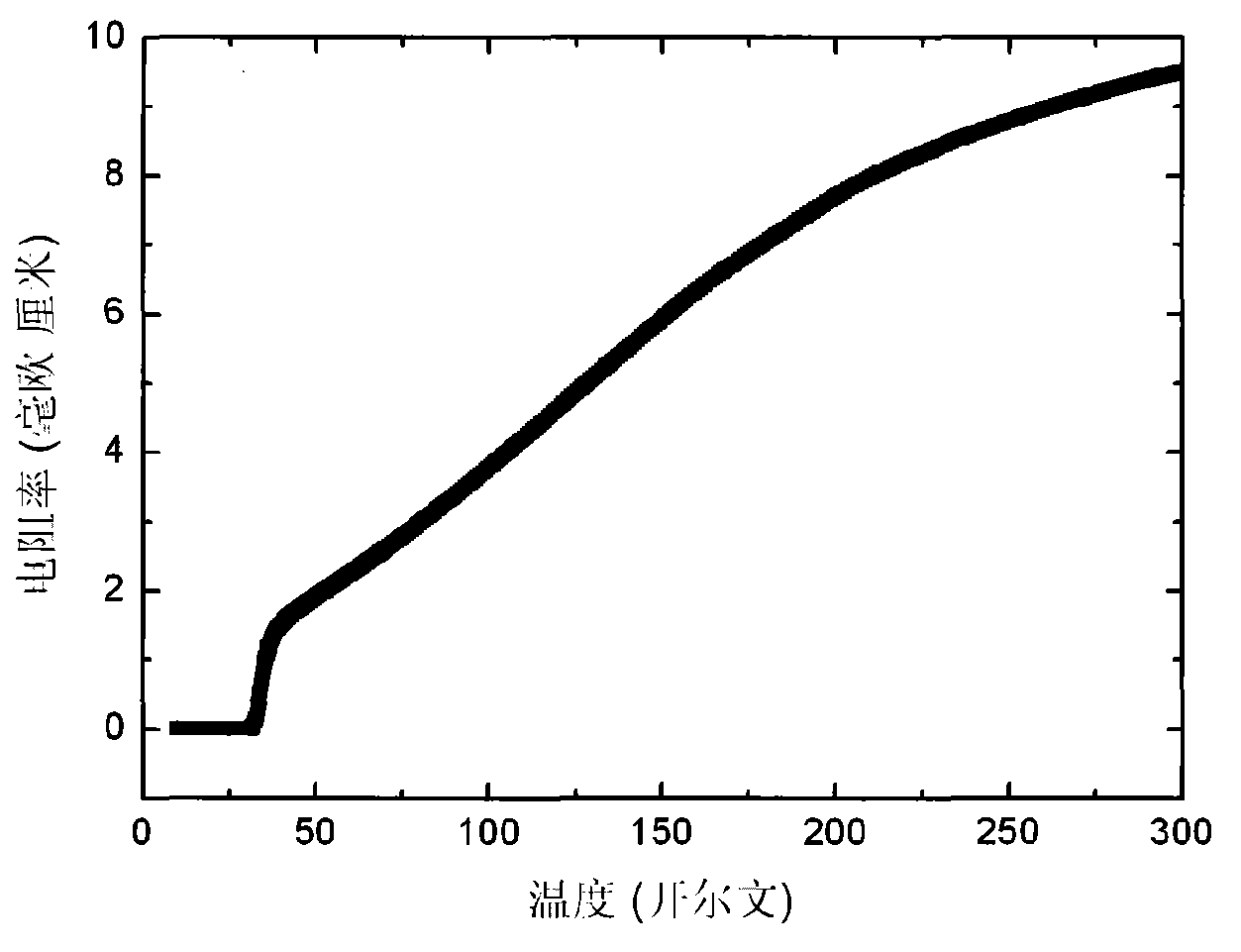

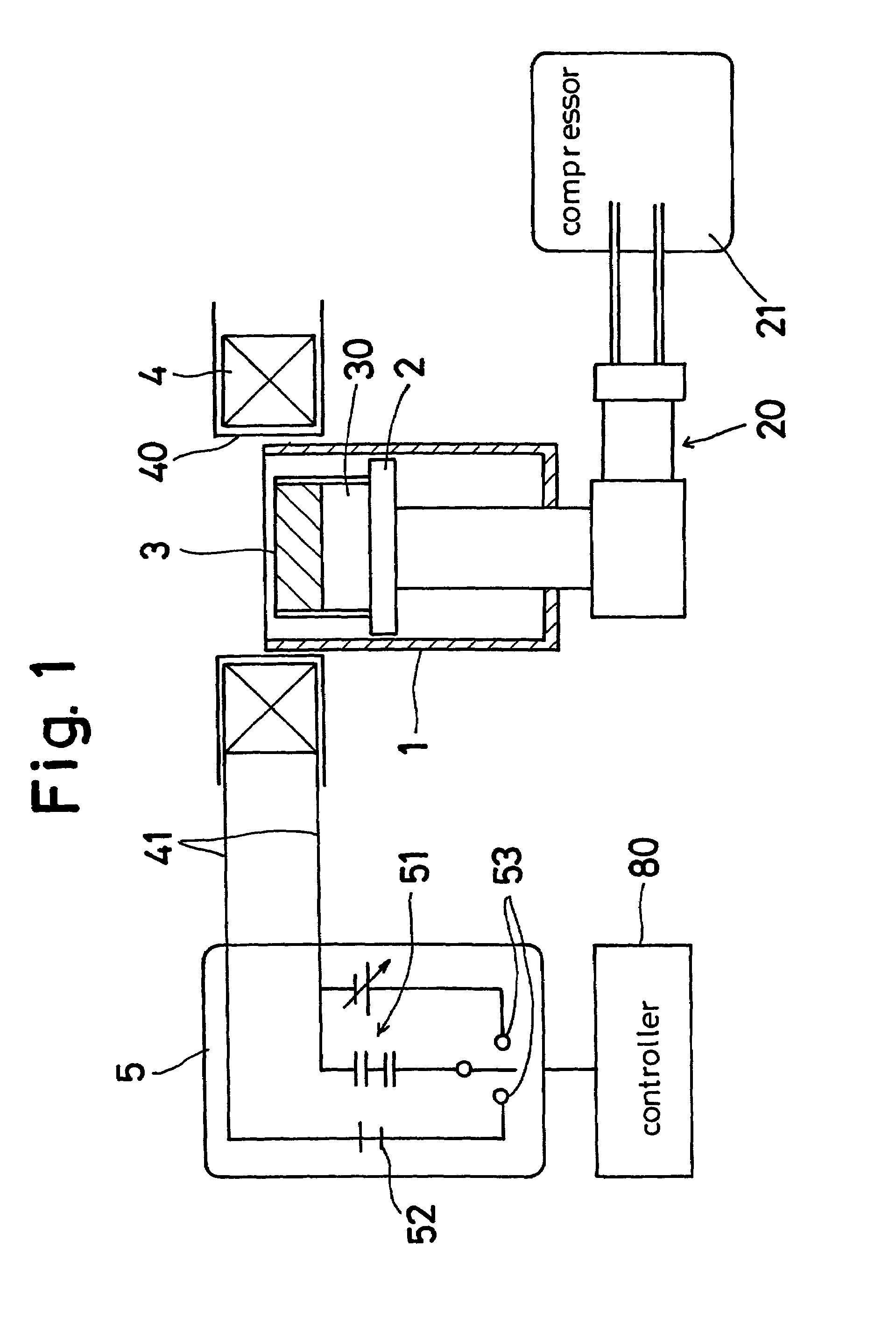

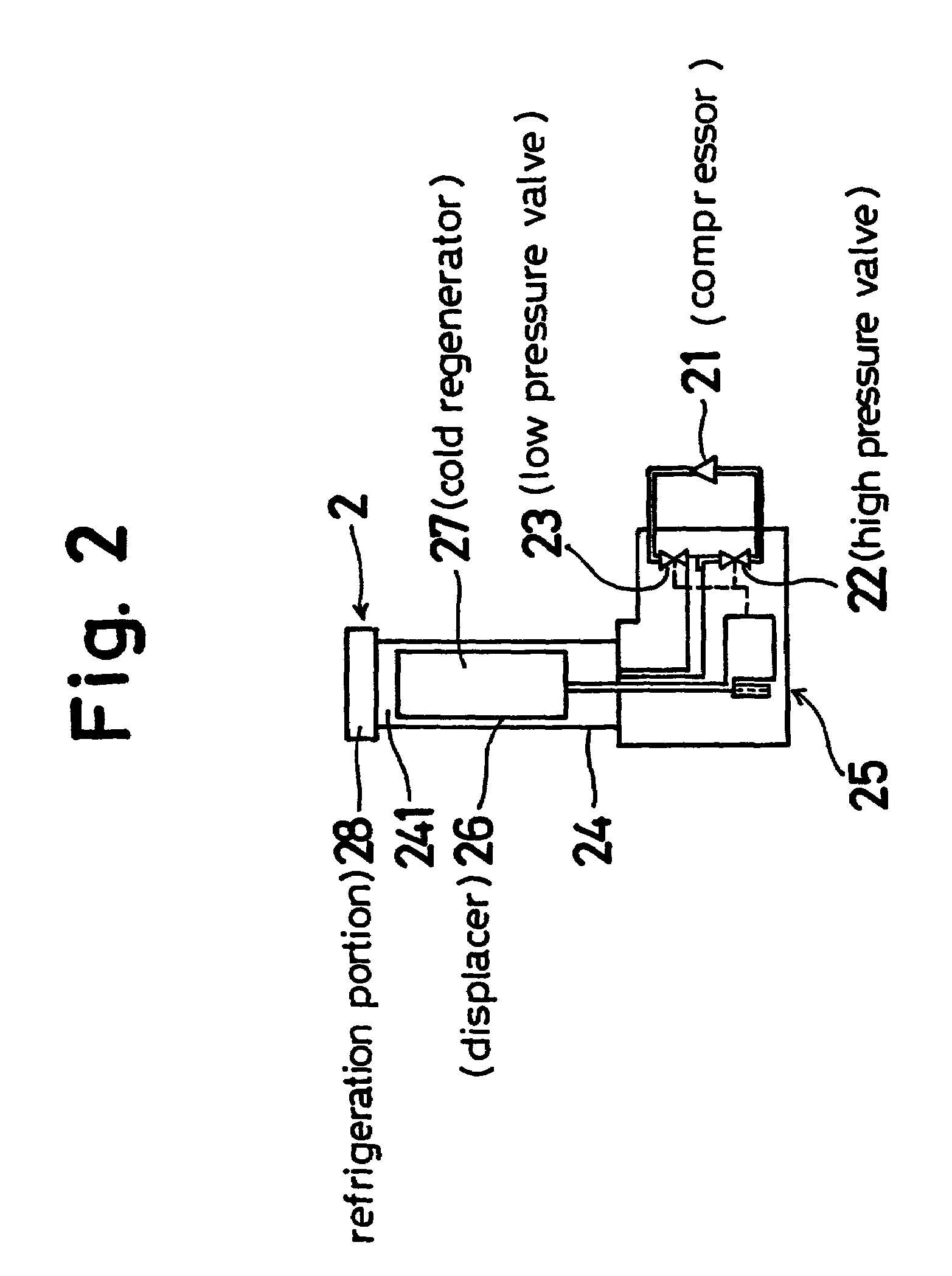

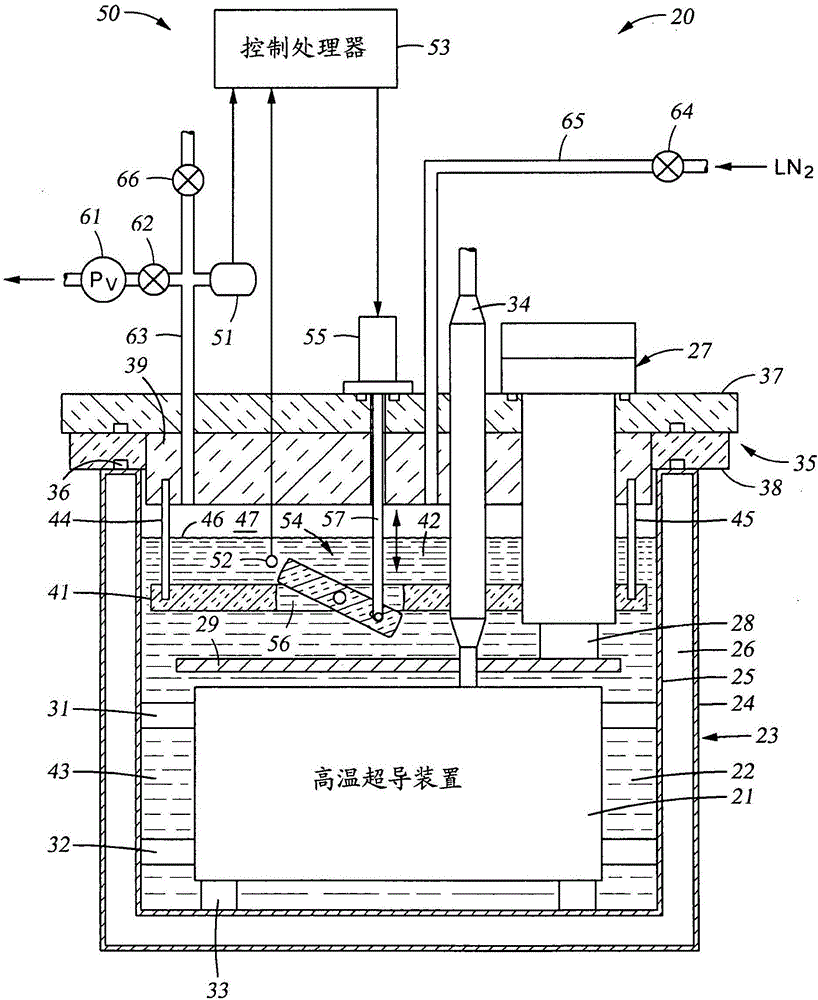

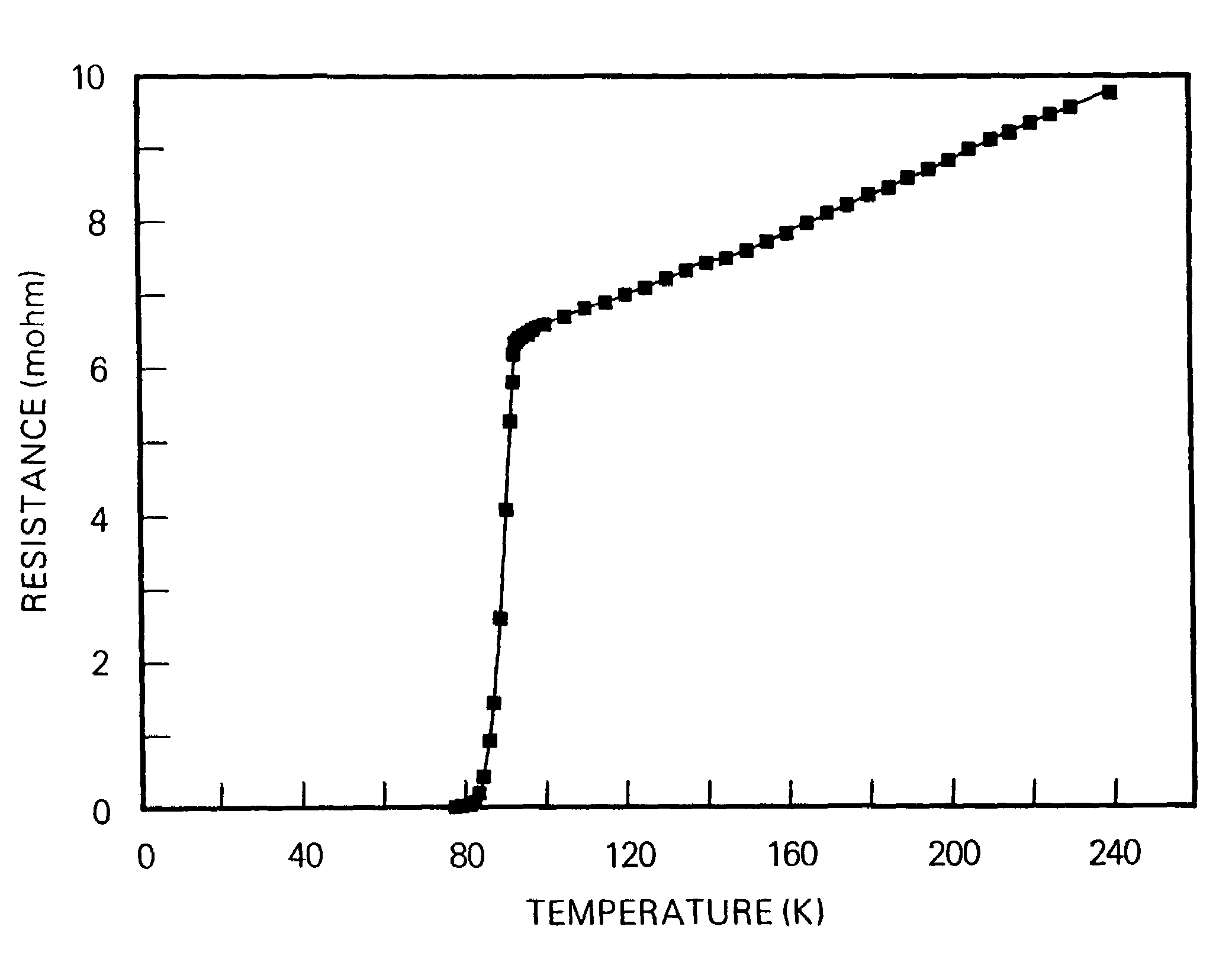

Device and method for measuring superconducting transition temperature of high temperature superconducting material

ActiveCN102305804AGood insulation performanceGuaranteed accuracyInvestigating phase/state changeElectrical resistance and conductanceHigh-temperature superconductivity

The invention discloses a device and a method for measuring the superconducting transition temperature of a high temperature superconducting material, and belongs to the field of superconducting electronics. The method comprises the following steps that: the high temperature superconducting material to be measured is put into a closed vacuum chamber and is refrigerated by a compression refrigerating machine; a constant current source applies current to the high temperature superconducting material to be measured; a voltage measuring instrument sends the voltage data of the high temperature superconducting material to be measured to an acquisition and processing system; a temperature measuring instrument receives and displays the temperature of the high temperature superconducting materialto be measured, which is measured by a temperature sensor, and sends the temperature to the acquisition and processing system; and the acquisition and processing system stores the temperature data and the voltage data of the high temperature superconducting material to be measured, which are sent by the temperature measuring instrument and the voltage measuring instrument, and generates the change curve of the resistance of the high temperature superconducting material to be measured along with the temperature, so that the superconducting transition temperature of the high temperature superconducting material to be measured is determined. By the device and the method, the superconducting transition temperature of the high temperature superconducting material to be measured can be accurately measured, and certain practical value for the performance inspection of the prepared high temperature superconducting material is achieved.

Owner:北京鼎臣世纪超导科技有限公司

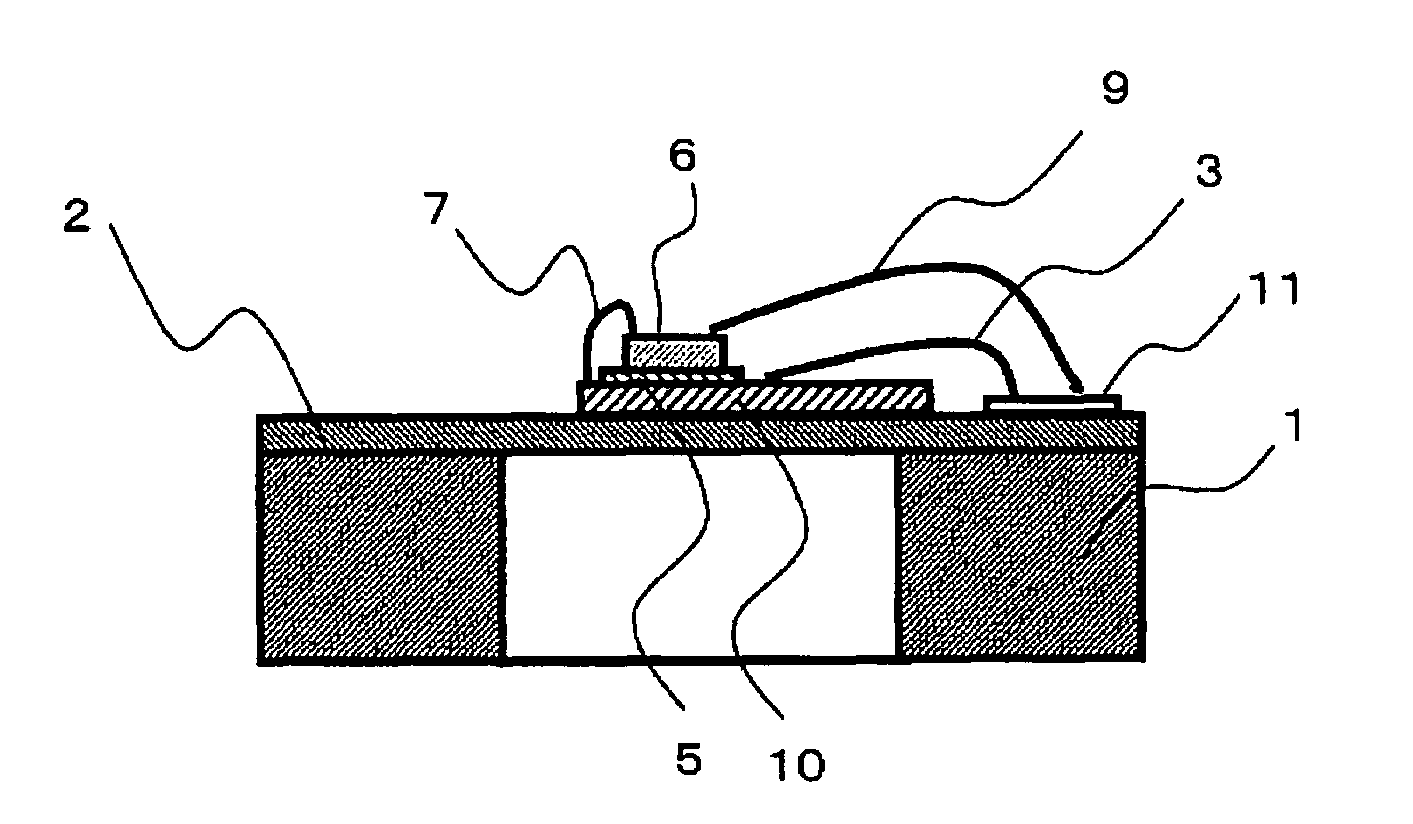

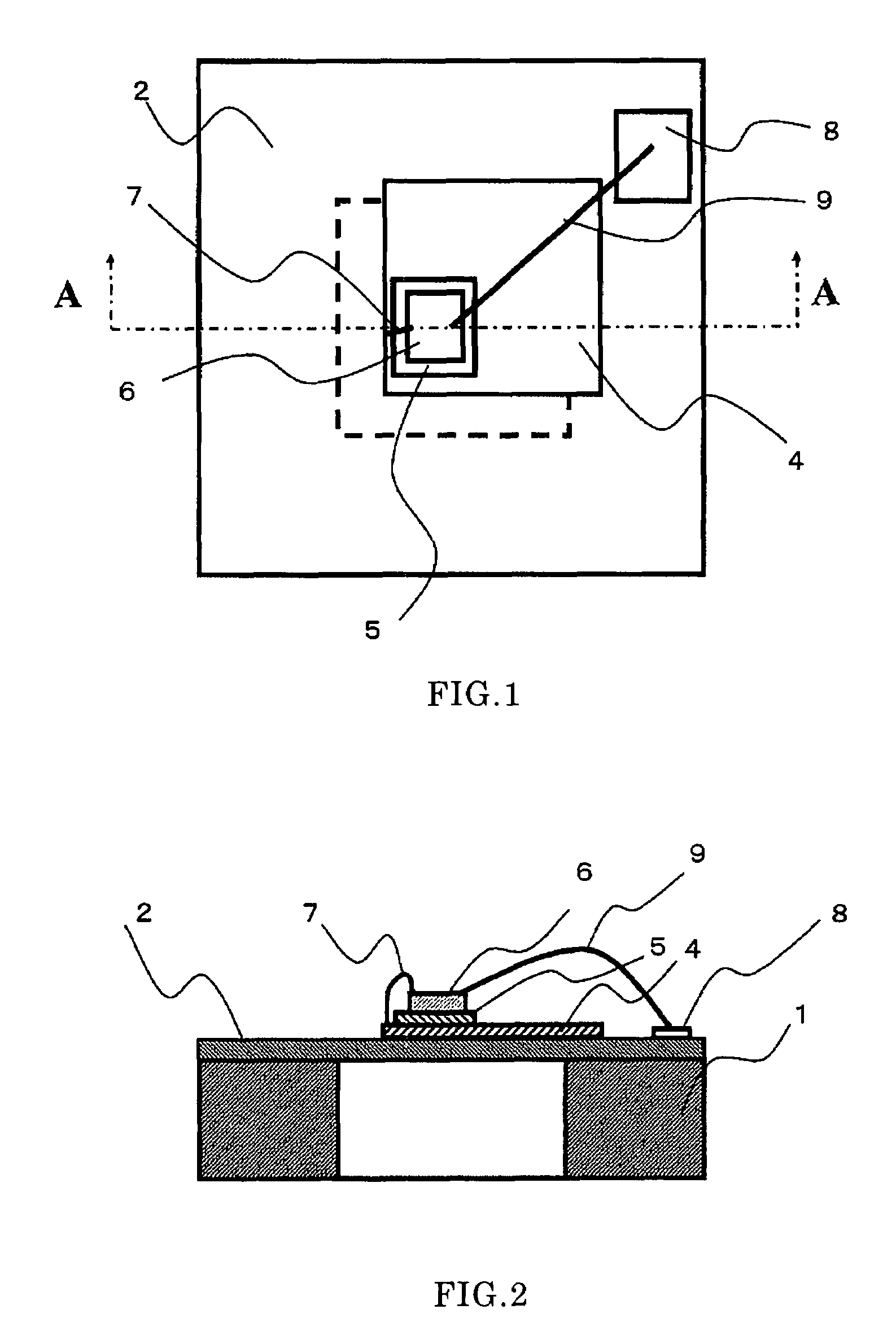

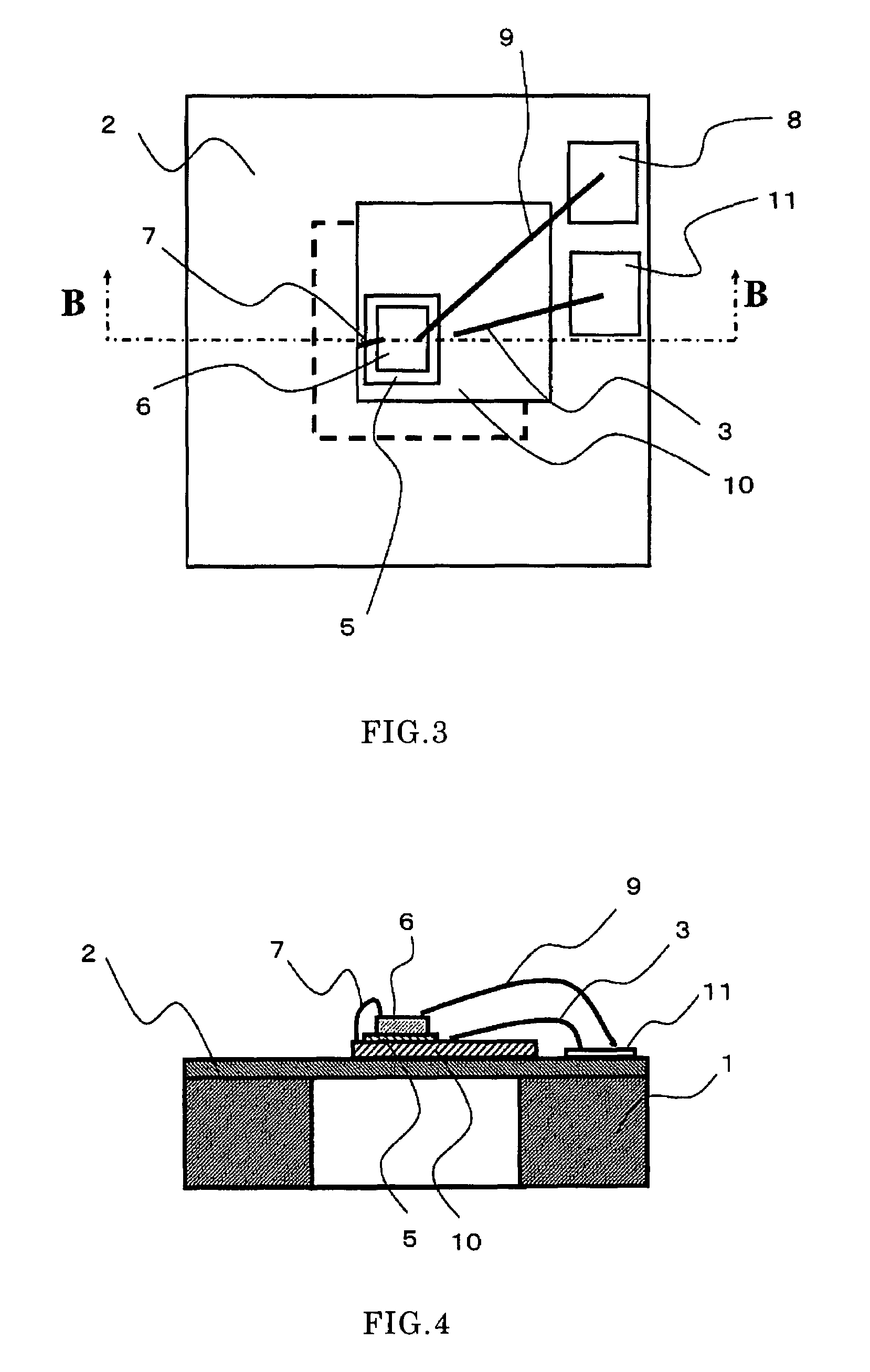

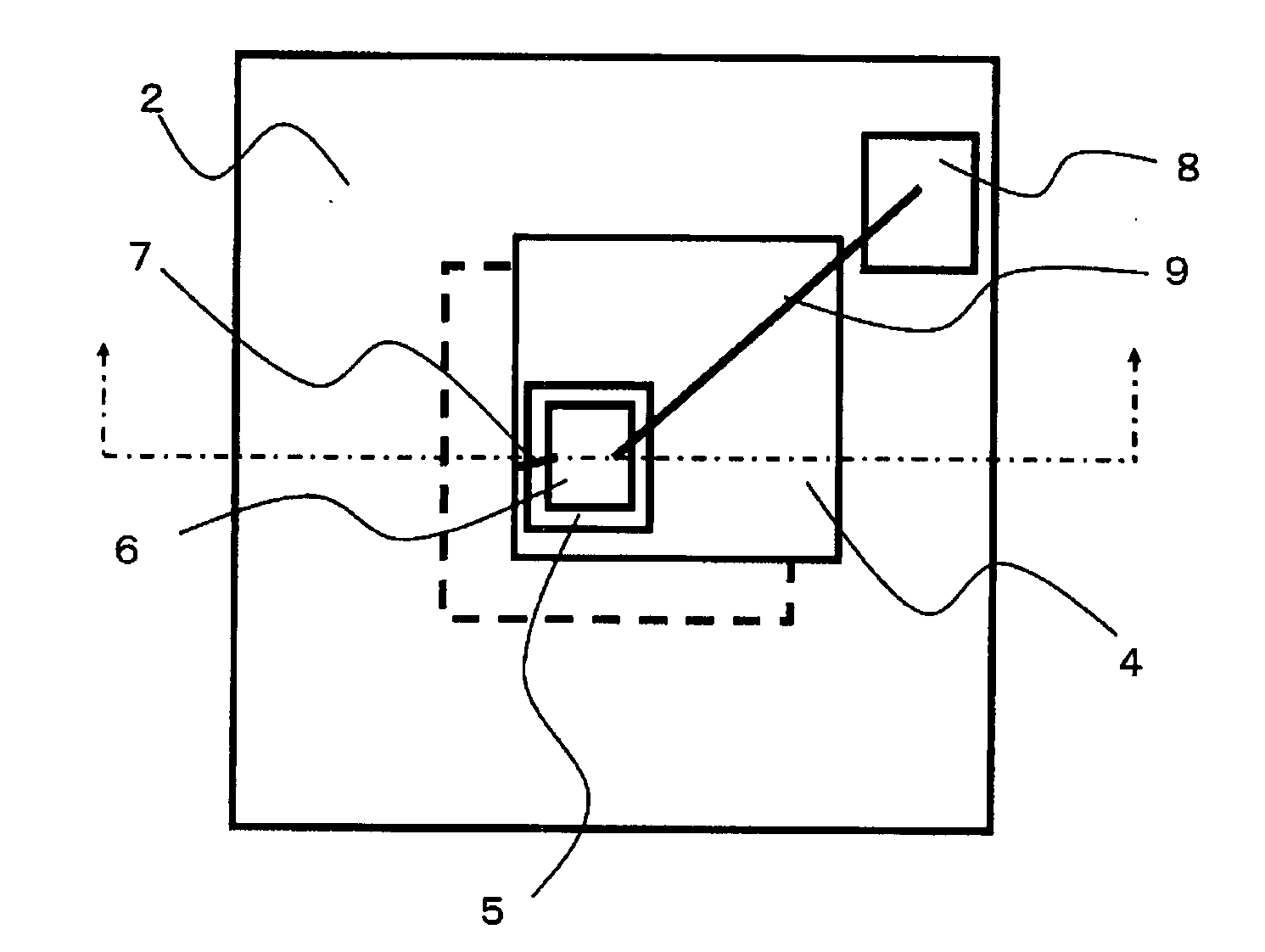

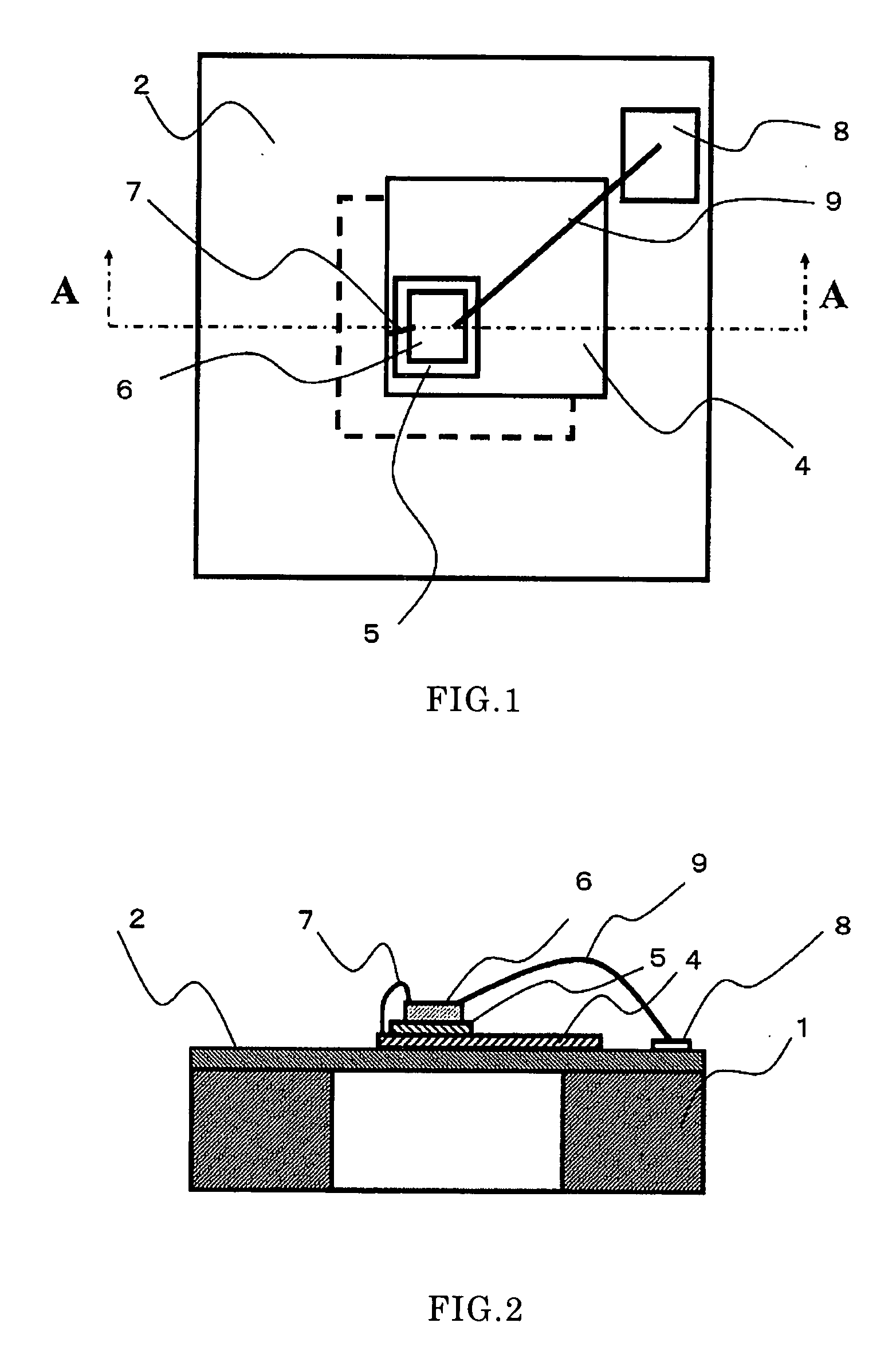

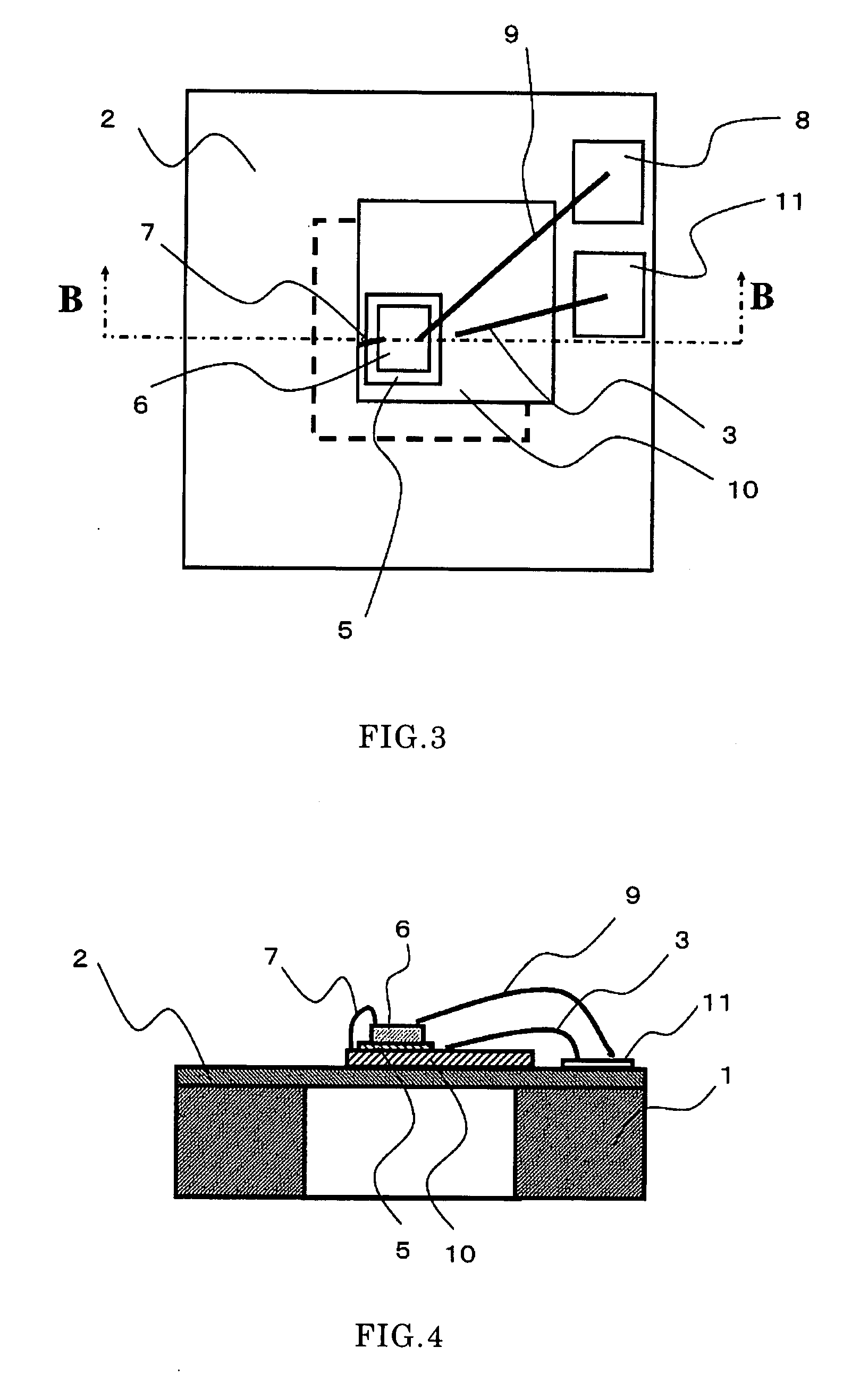

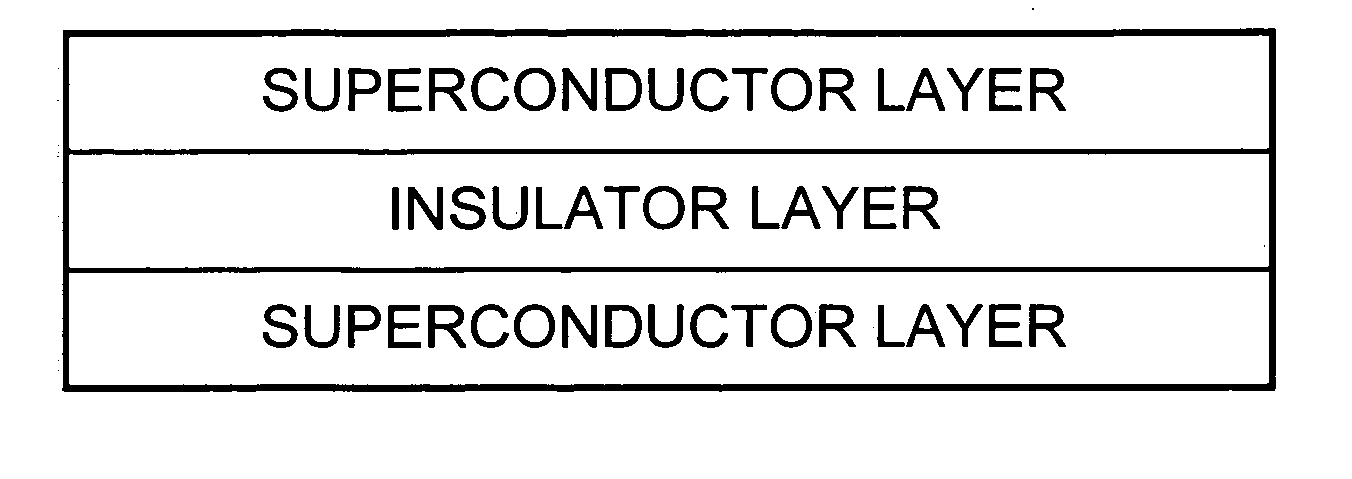

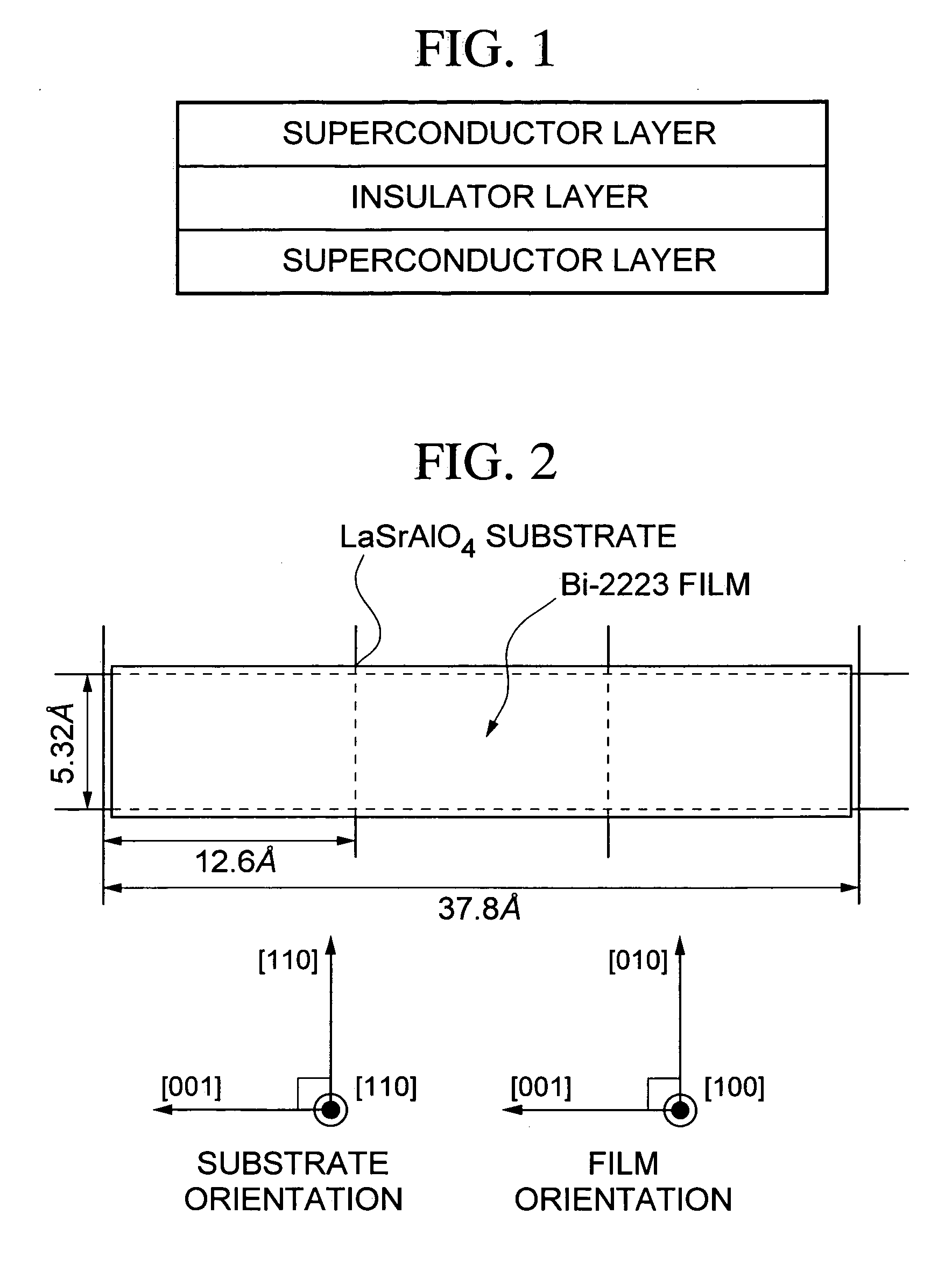

Superconducting X-ray detector and X-ray analysis apparatus using the same

InactiveUS7589323B2Reduce sensitivityImproved energy resolutionDigital data processing detailsAnimal undercarriagesSoft x rayHeat flow

To provide a superconducting X-ray detector capable of carrying out a measurement by a high energy resolution by restraining a reduction in a sensitivity by a self magnetic field. A superconducting X-ray detector comprising a temperature detector 6 for detecting a temperature change by heat generated when an X-ray is absorbed, and a heat link 3 for controlling a heat flow amount of escaping the generated heat to a support board i, wherein the temperature detector 6 comprises a heat conducting multilayer thin film, the superconducting X-ray detector is constituted by a structure of providing a superconductor layer 4 above the heat link 3 and providing an insulating member 2 between the superconductor layer 4 and the temperature detector 6, the superconductor layer 4 and the temperature detector 6 are connected by a superconducting wiring 7 and uses materials by which superconducting transition temperatures of the superconductor layer 4 and the superconducting wiring 7 are higher than a superconducting transition temperature of the temperature detector 6.

Owner:HITACHI HIGH TECH SCI CORP

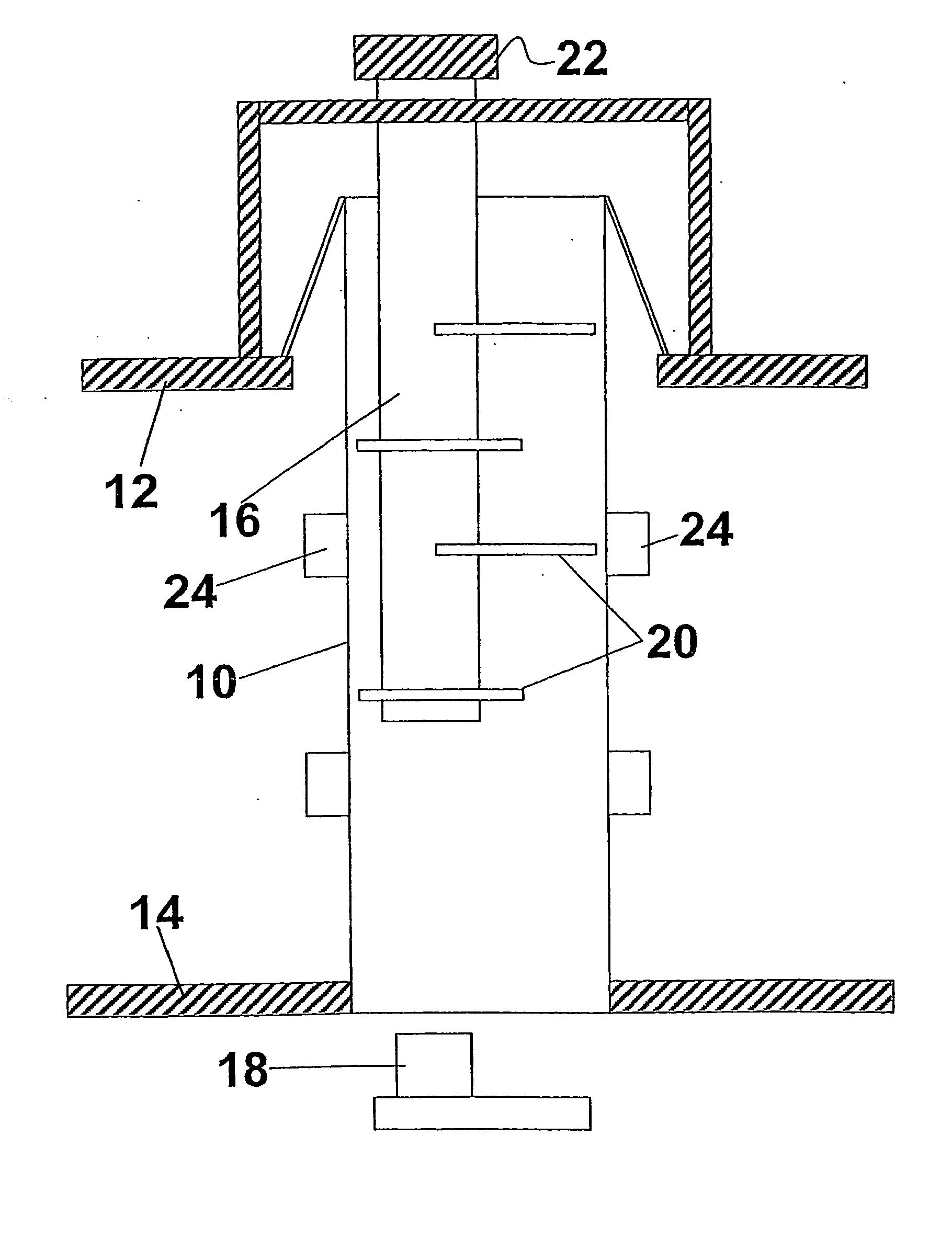

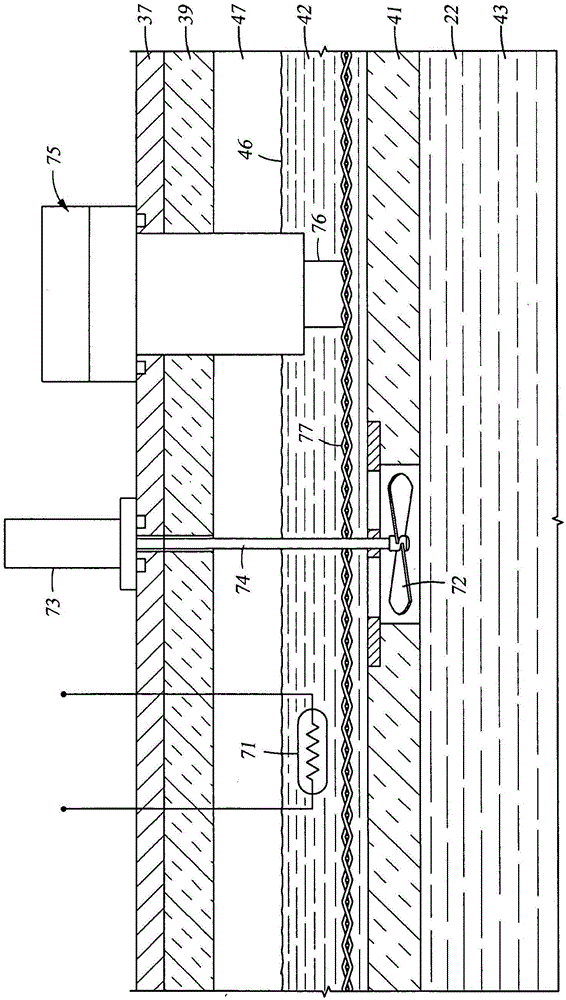

Cryogenic assembly

ActiveUS20050204751A1Smooth connectionReduce differential pressureContainer filling methodsCompression machinesTransformerSuperconducting transition temperature

The present invention relates to a cryostat having a service neck for access to a superconducting magnet. In many cryogenic applications components, e.g. superconducting coils for magnetic resonance imaging (MRI), superconducting transformers, generators, electronics, are cooled by keeping them in contact with a volume of liquefied, the whole cryogenic assembly being known as a cryostat. In order to operate a superconducting magnet, it must be kept at a temperature below its superconducting transition temperature. A cryostat must provide access to the vessel containing the liquefied helium for the initial cooling of the magnet to its low operating temperature, for periodic refilling of systems where there is a loss of helium, and provide sufficient access whereby to enable operation and maintenance of the magnet. The present invention seeks to provide an access neck to a cryostat such as helium vessel with a minimum heat load and accordingly provides a cryostat assembly, wherein a service neck comprising at least one positive and one negative current lead is arranged such that one of the leads is formed by the neck tube wall and the space between a neck tube wall and the second current lead forms a gas path for venting and / or filling or other services.

Owner:SIEMENS HEALTHCARE LTD +1

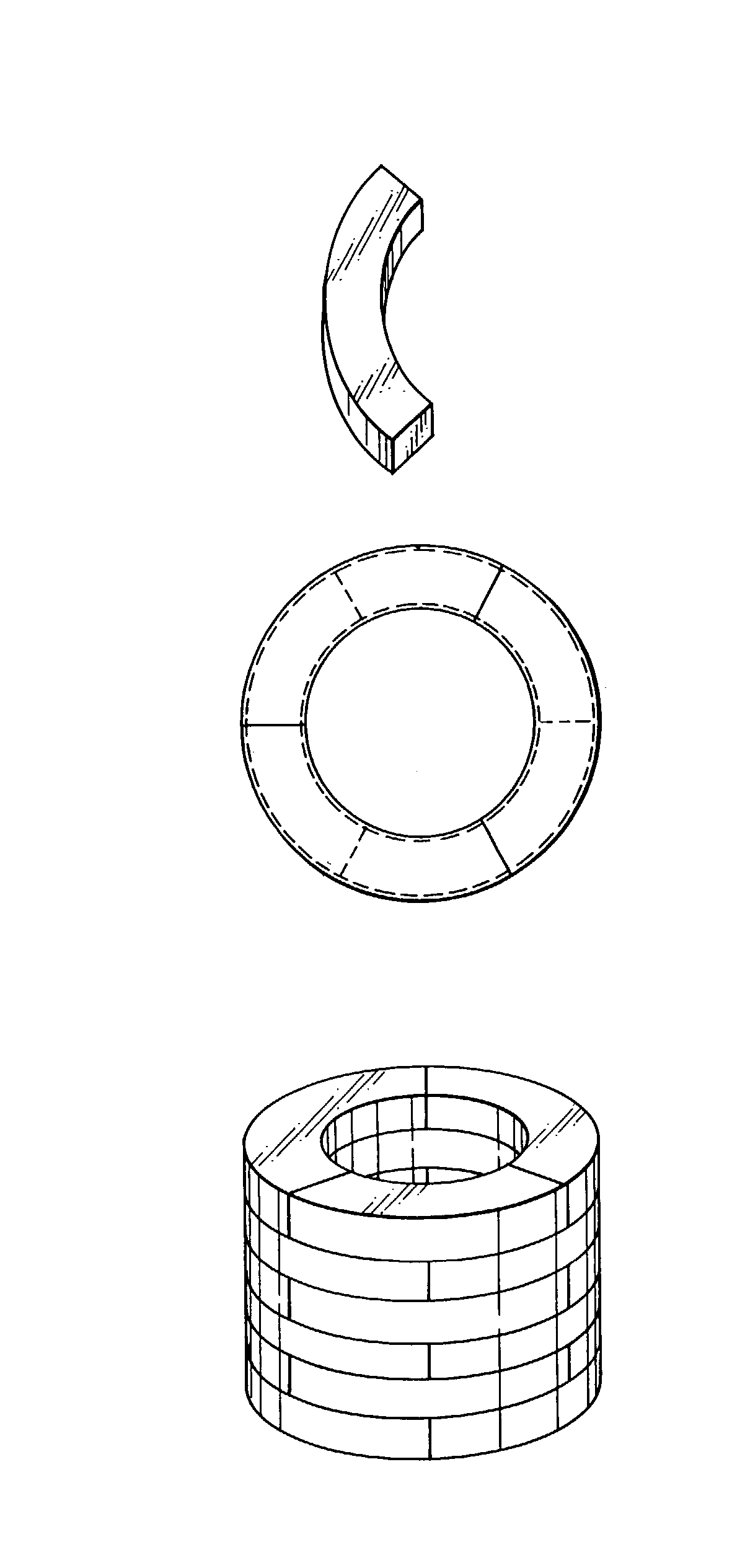

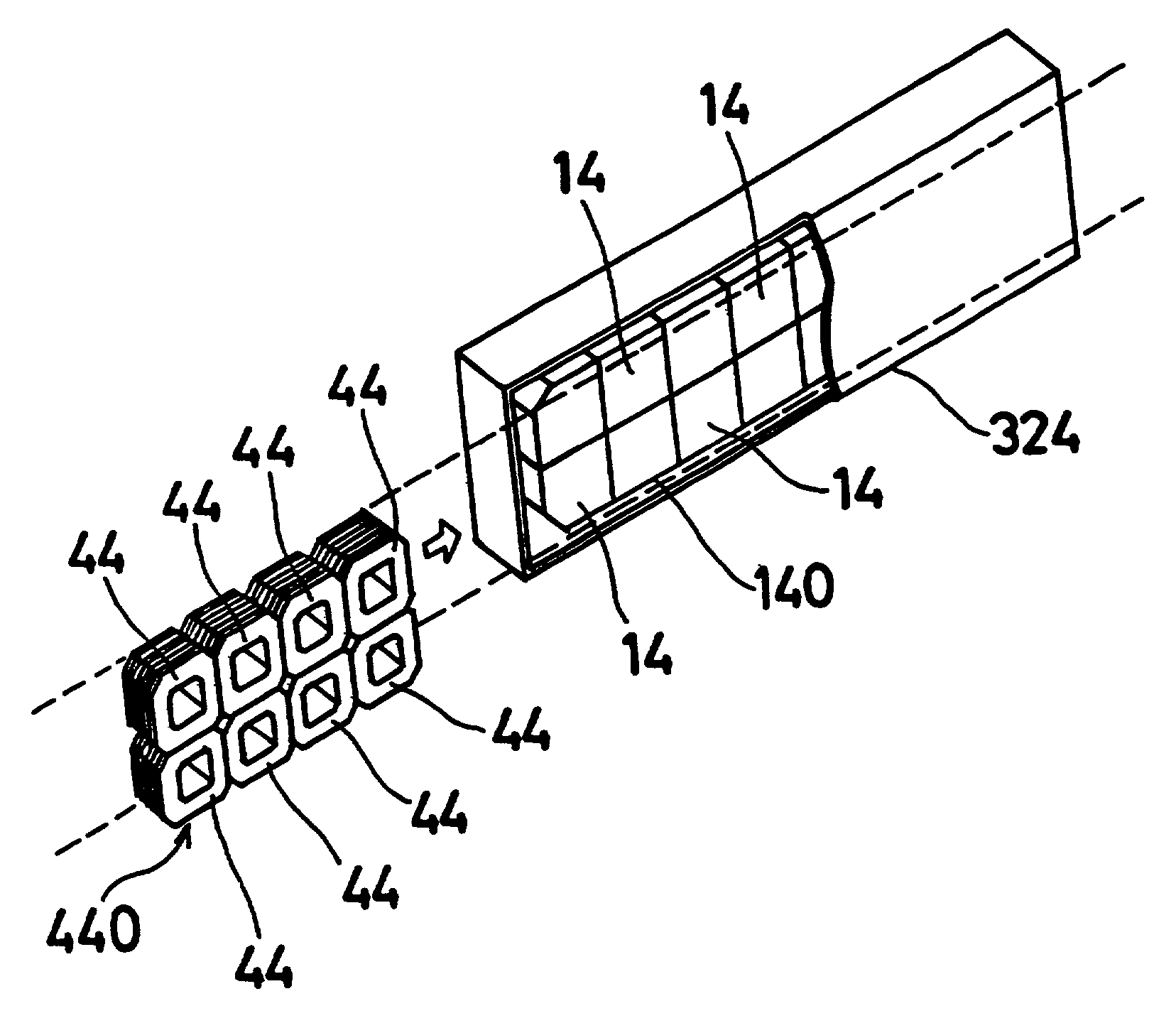

Superconducting magnet apparatus and method for magnetizing superconductor

A cold head is disposed in an insulating container and cooled by a refrigerator. A superconductor is disposed in the insulating container, contacting the cold head, and is cooled to its superconduction transition temperature or lower by heat conduction. A magnetizing coil is disposed outside the insulating container for applying a magnetic field to the superconductor. Control is performed so that a magnetic field determined considering the magnetic field to be captured by the superconductor is applied. A pulsed magnetic field is applied to the superconductor a plurality of times. Each pulsed magnetic field is applied when the temperature of the superconductor is a predetermined temperature or lower. A maximum pulsed magnetic field is applied at least once in an initial or intermediate stage of the repeated application of pulsed magnetic fields. After that, a pulsed magnetic field equal to or less than the maximum pulsed magnetic field is applied. Pulsed magnetic fields are repeatedly applied while the temperature of the superconductor is lowered. A pulsed magnetic field is applied when the temperature T0 of a central portion of the superconductor is the superconduction transition temperature or lower and the temperature of a peripheral portion is higher than T0. The temperature of the entire superconductor is brought close to T0 to apply another pulsed magnetic field. The magnetizing coil faces at least one of two opposite sides of the superconductor to apply pulsed magnetic fields to the superconductor in its magnetization direction.

Owner:AISIN SEIKI KK

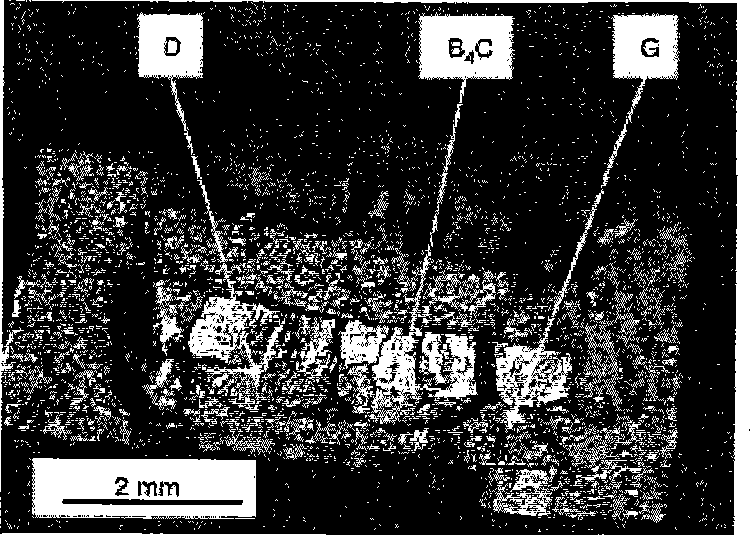

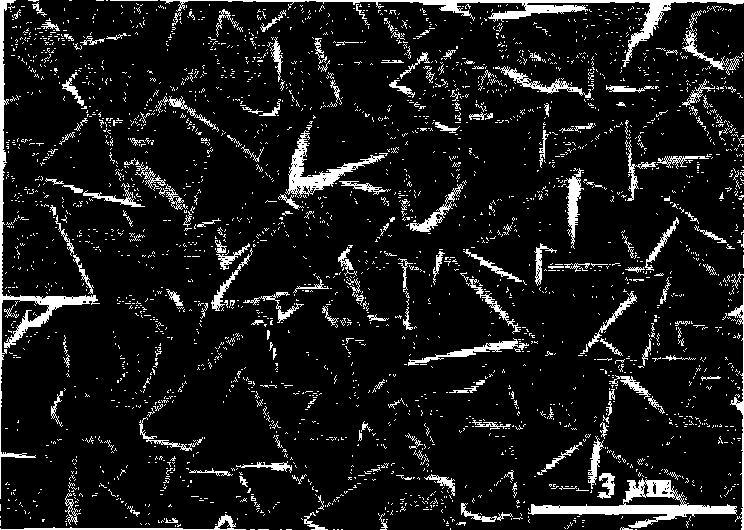

Preparation of boron doped diamond superconduction material

InactiveCN101481792ACurb churnIncrease concentrationChemical vapor deposition coatingGas phaseChemical vapor deposition

The invention relates to a preparation method of boron dope diamond superconducting material, including the following steps: traditional synthetic boron dope diamond technology is used for carrying out pretreatment on an internal cavity body, a clean substrate is placed on the substrate pad of the inner cavity after pretreatment, and the traditional hot-filament chemical vapor deposition method is used for depositing a diamond film transition layer; the deposit growth conditions are as follows: the voltage bias applied on the substrate is zero, reaction gases of methane and hydrogen are led in through two paths, the volume ratio of the two paths of gases is (2-10): 100, the temperature of the substrate is in the range from 800 DEG to 1000 DEG by adjusting the distance between the substrate and the filament, the gas pressure is 20-60 Torr, and the growth time lasts 0.5-1.5 hours; the growth conditions of compositing the diamond film transition layer are remained, and the boron dope diamond superconducting material is continuously grown for at least 3 hours to obtain the boron dope diamond superconducting material. The method not only has the advantages of low cost and high flexibility but also obtains the boron dope diamond superconducting material with higher carrier concentration and higher superconducting transition temperature.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Superconducting magnesium boride thin-film and process for producing the same

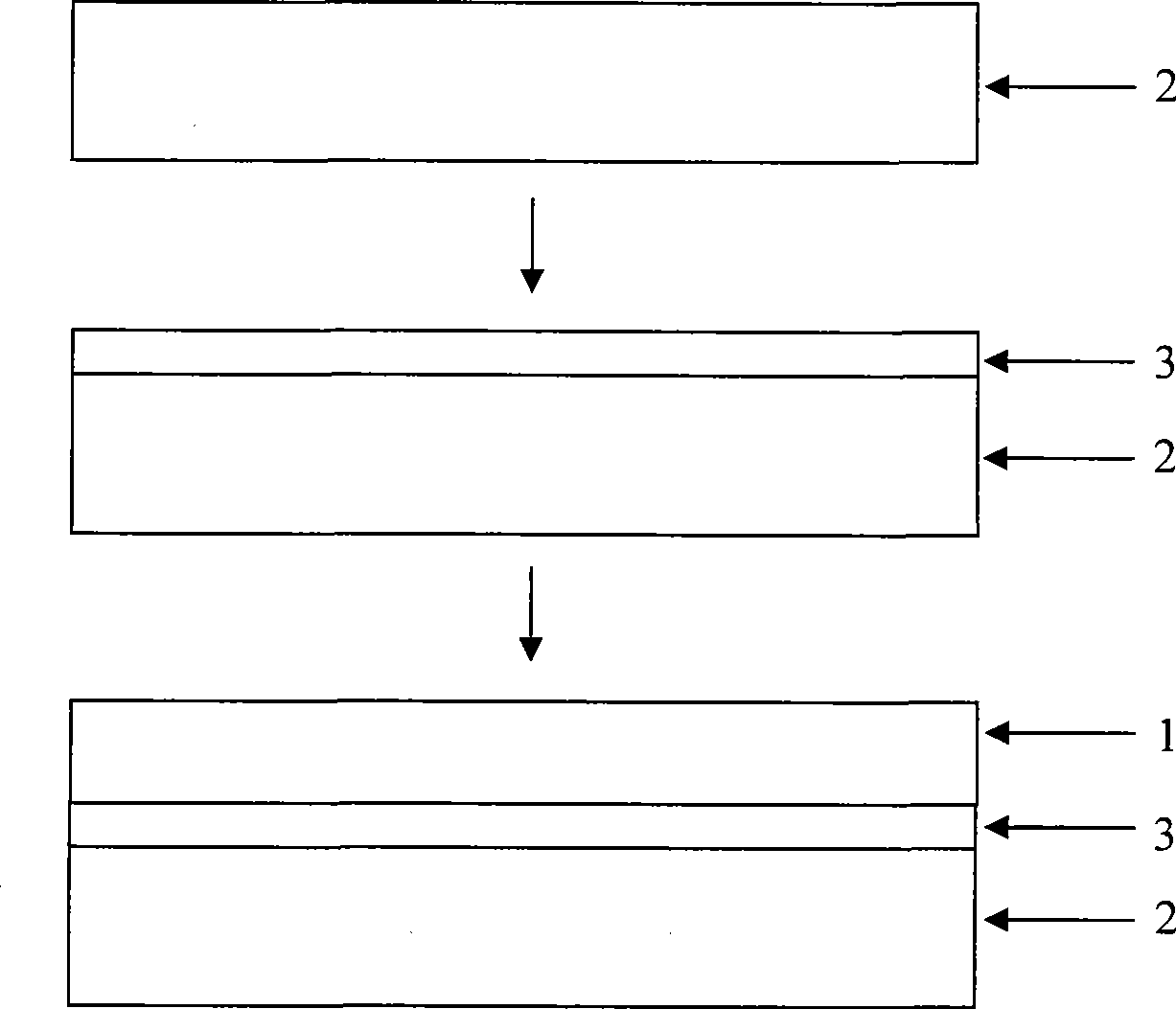

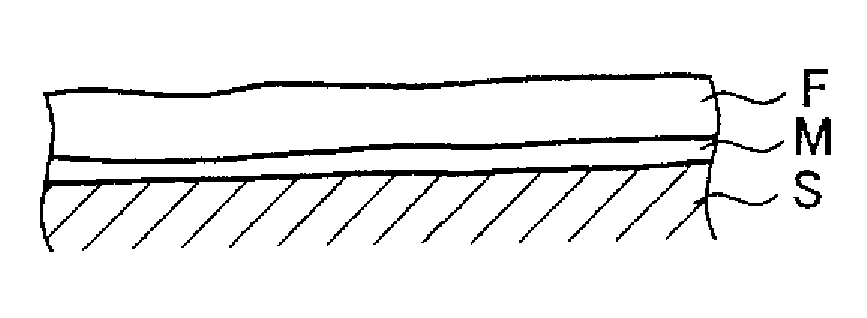

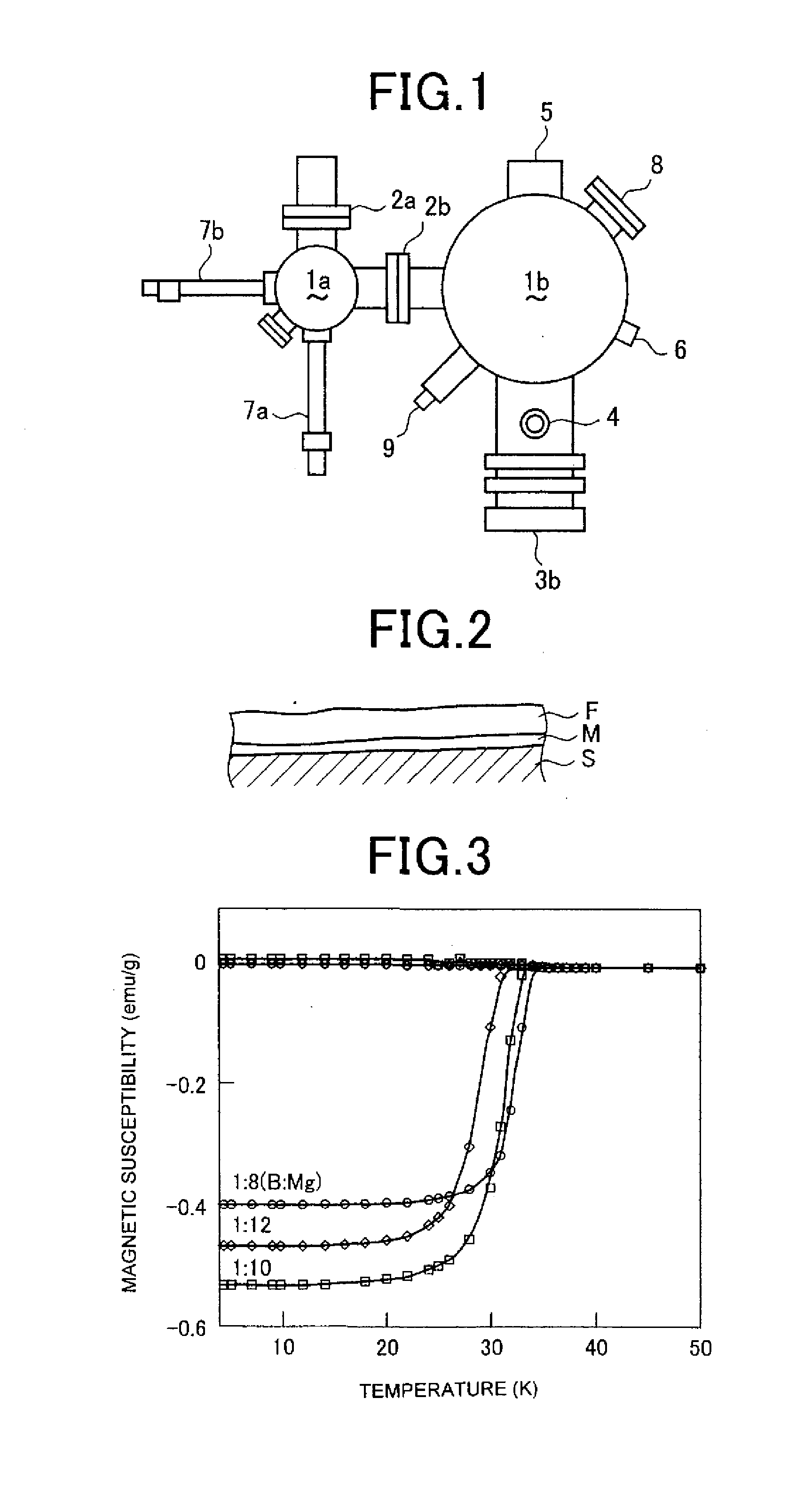

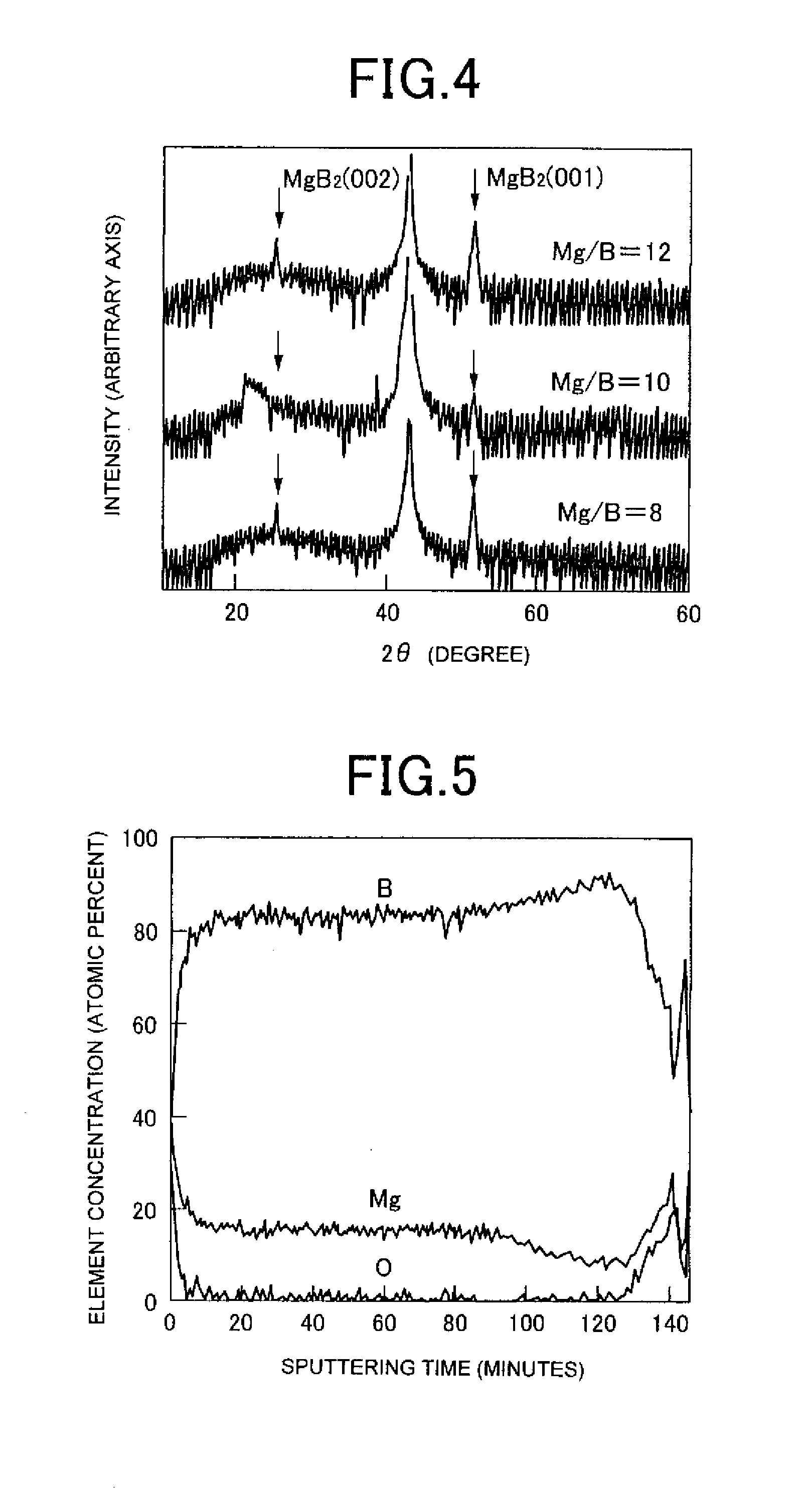

InactiveUS20090062128A1High crystallinityPromote film formationSuperconductors/hyperconductorsElectric discharge heatingMetallurgyCrystallinity

A magnesium boride thin film having a B-rich composition represented by the general formula of MgBx (x=1 to 10) and a superconducting transition temperature of 10K or more has superior crystallinity and orientation and is used as a superconducting material. This thin film is formed by maintaining a film forming environment in a high vacuum atmosphere of 4×10−5 Pa or less, and simultaneously depositing Mg and B on a substrate maintained at a temperature of 200° C. or less so as to grow the film at a growth rate of 0.05 nm / sec or less. It is preferable to supply an Mg vapor and a B vapor into the film forming environment at an Mg / B molar ratio of 1 / 1 to 12 / 1.

Owner:IWATE UNIVERSITY

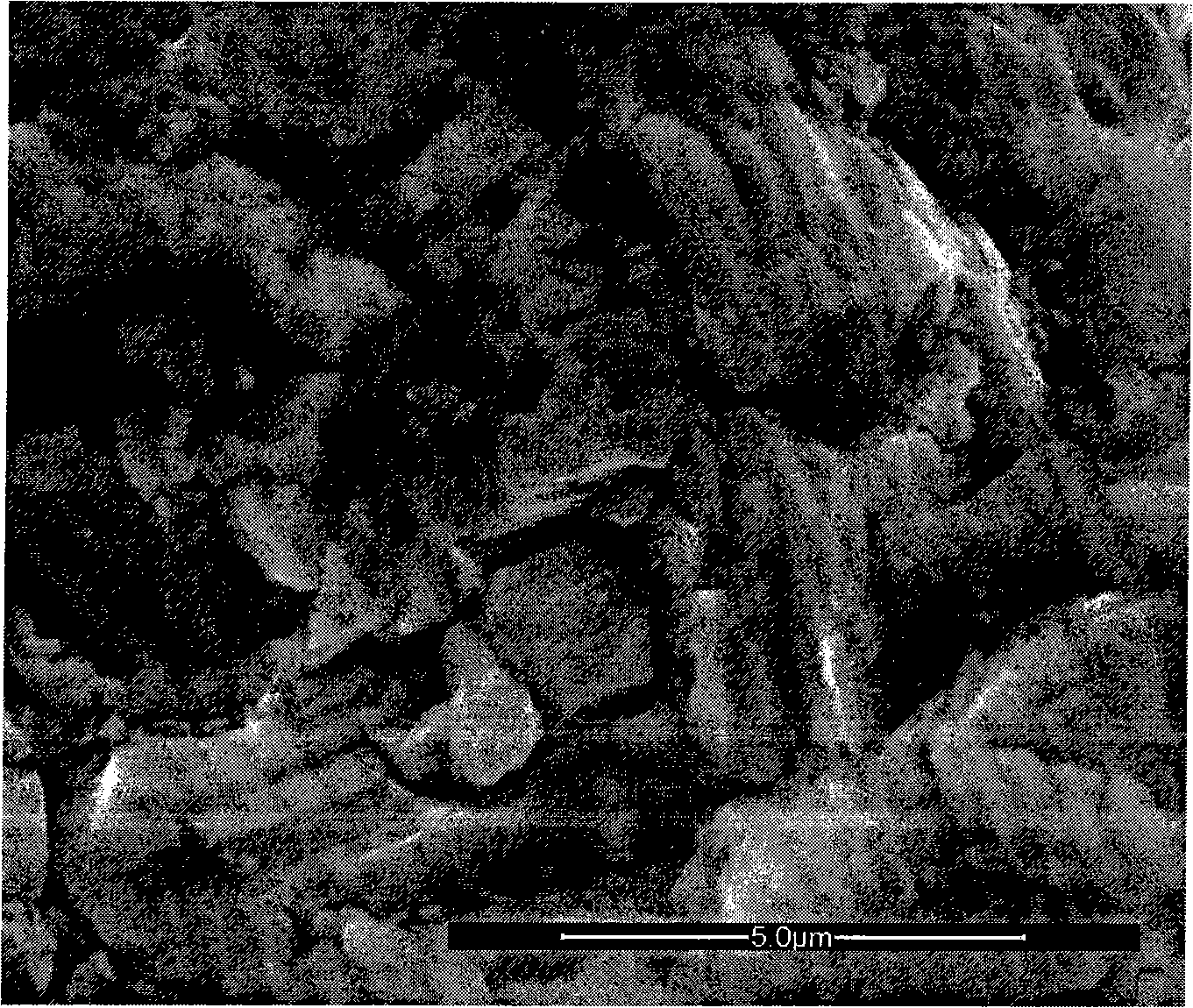

Preparation method iron based SmFeAsO1-xFx superconducting wire

InactiveCN101345103AEvenly distributedIncrease the critical current densitySuperconductors/hyperconductorsSuperconductor devicesCritical magnetic fieldSuperconducting transition temperature

The invention provides a preparation method of an iron-based SmFeAsO<1-x>Fx superconducting wire, comprising the steps as follows: a: material preparation: the material is prepared according to the stoichiometry of the iron-based superconducting material SmFeAsO<1-x>Fx (wherein, x is not more than 0.35 and not less than 0.15, the raw materials such as SmAs, Fe, Fe2O3 and FeF3 are weighed, grinded, uniformly mixed, arranged into a Tantalum pipe, fully fixed and compacted; the two ends of the Tantalum pipe are sealed; b: wire preparation: the Tantalum pipe is sheathed into a copper pipe and rotatablely forged; subsequently, the wire with the diameter of 1.8-2.2mm is formed by pulling and drawing; c: burning: the wire is arranged in a quartz pipe and sealed in vacuum and then put into a sintering furnace; under the protection of inert gas, the temperature of the wire is increased to 1150-1170 DEG C at the speed of 100-150 DEG C / hour, the temperature is kept for 36-50 hours and the wire is cooled with the furnace. The method of the invention has the advantages of simple technology and facilitating industrial production, and the compactness, high purification, stable superconducting performance, high superconducting conversion temperature and high critical magnetic field of the prepared iron-based SmFeAsO<1-x>Fx superconducting wire.

Owner:SOUTHWEST JIAOTONG UNIV

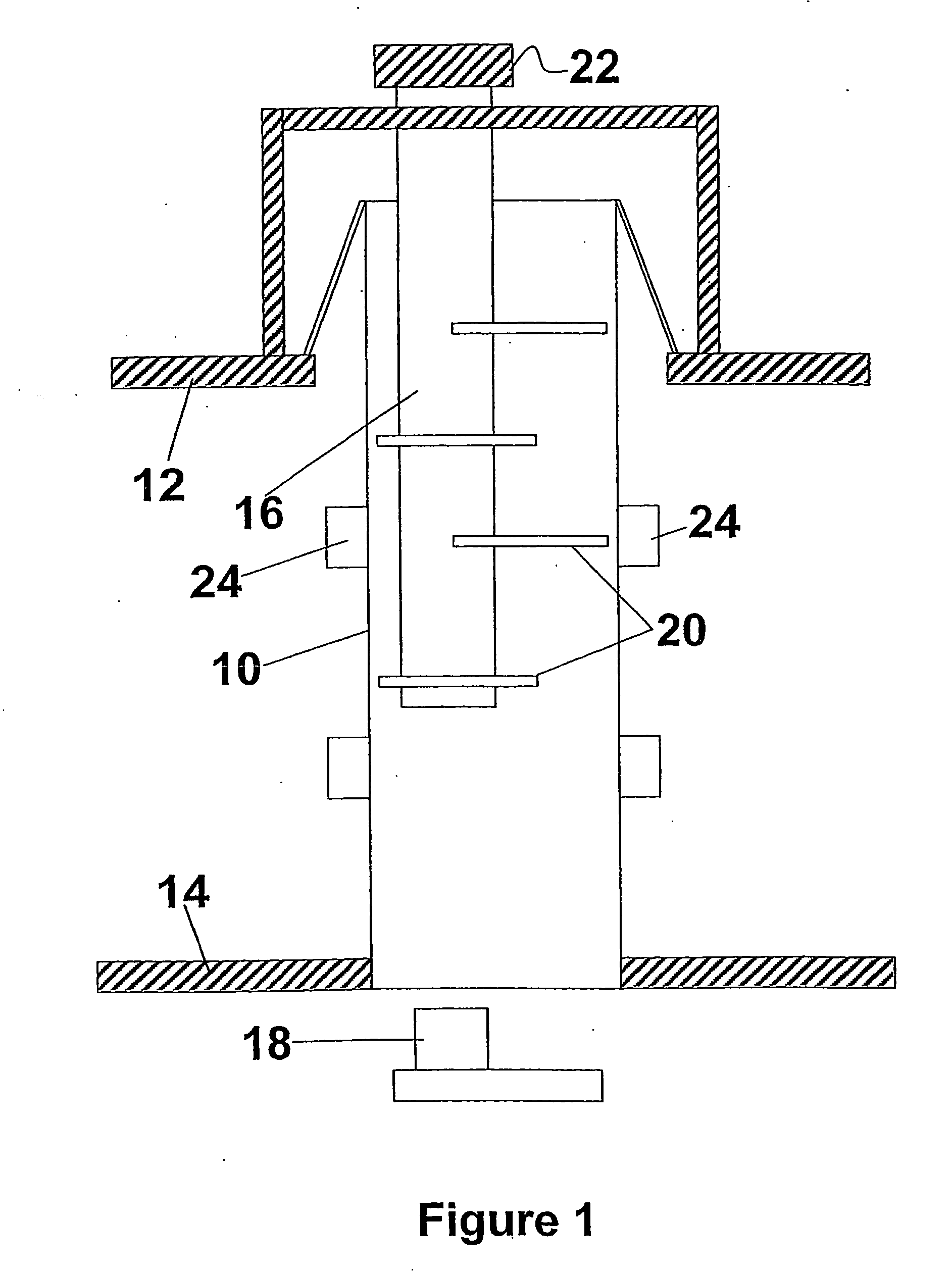

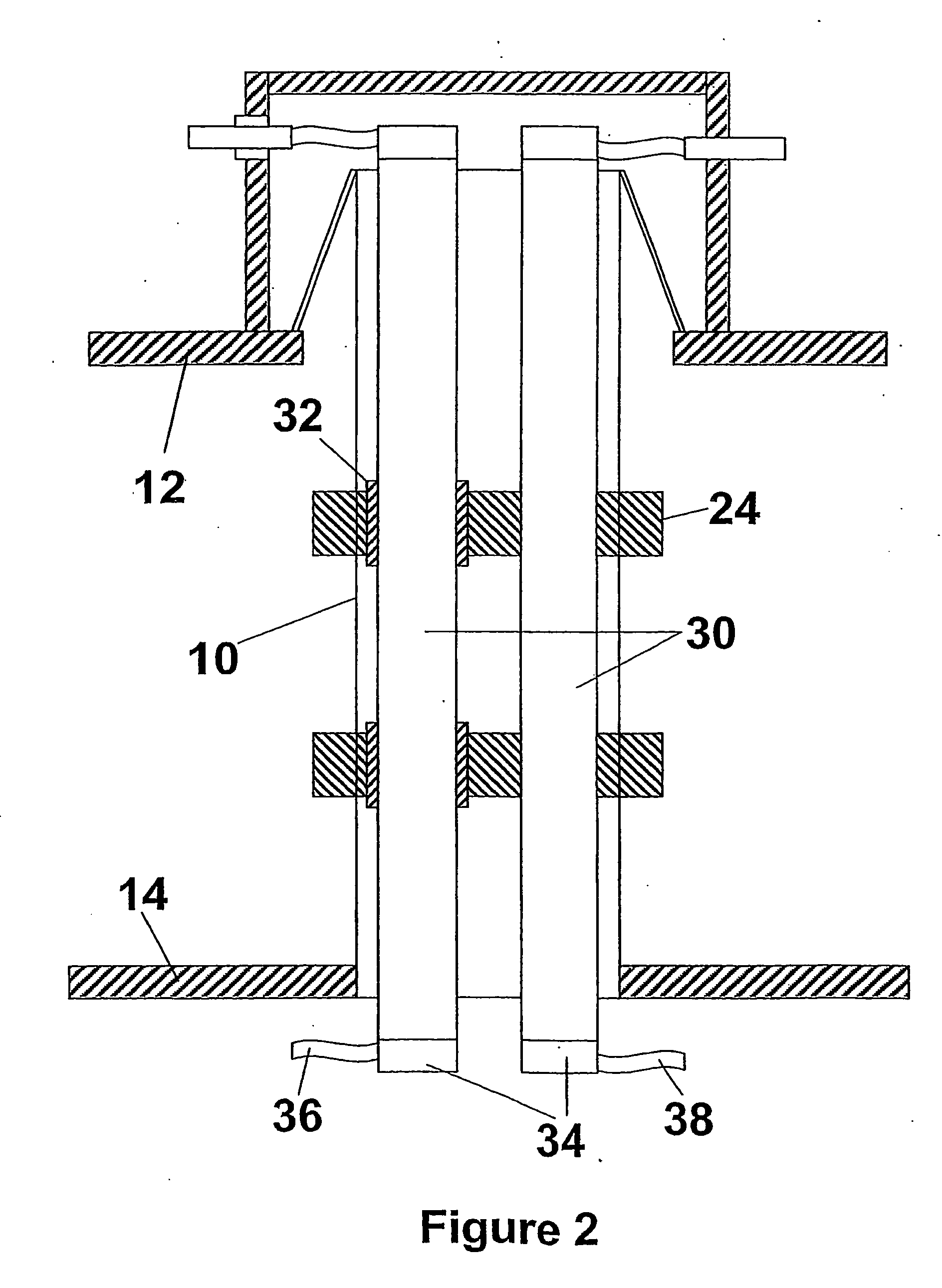

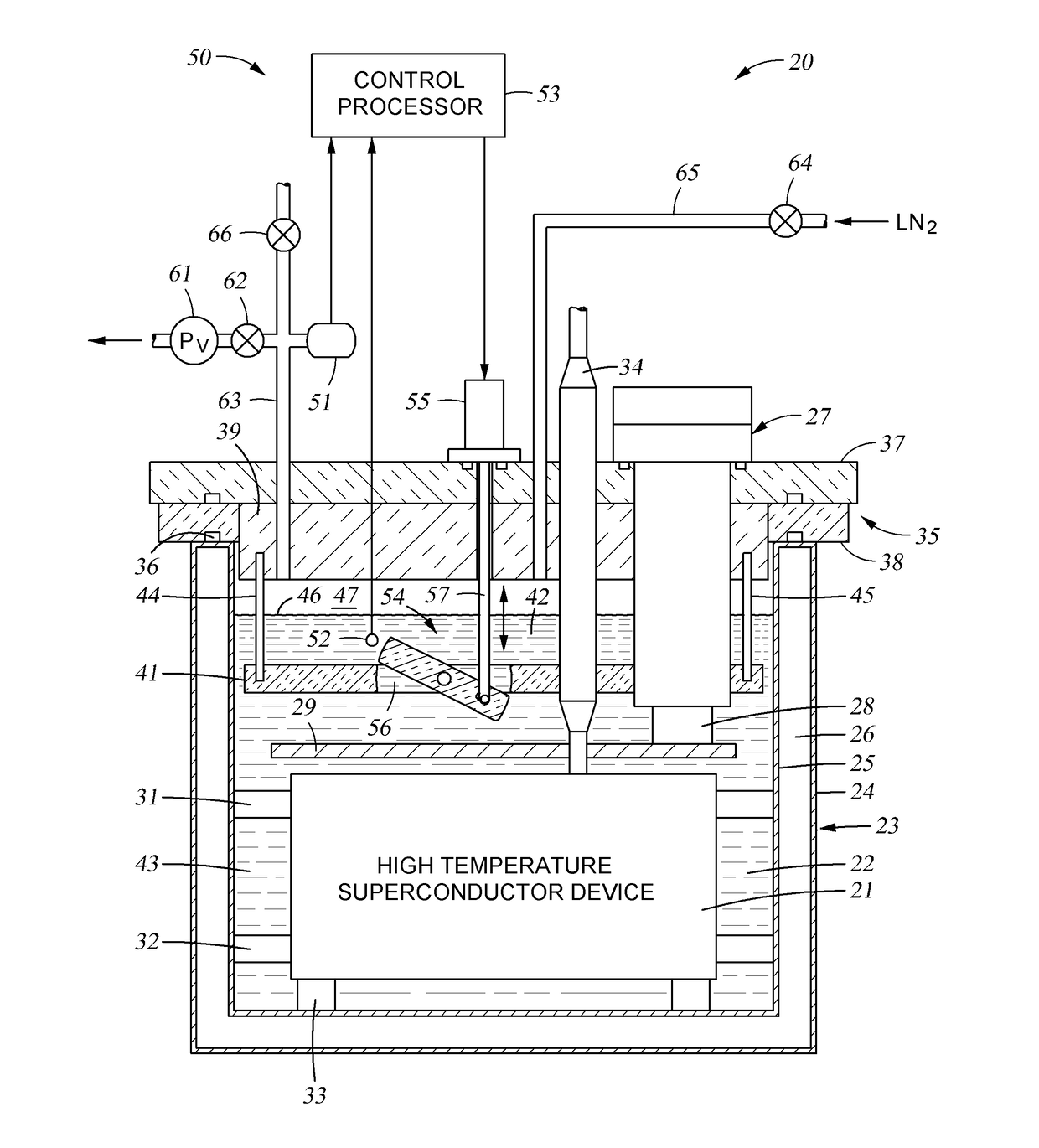

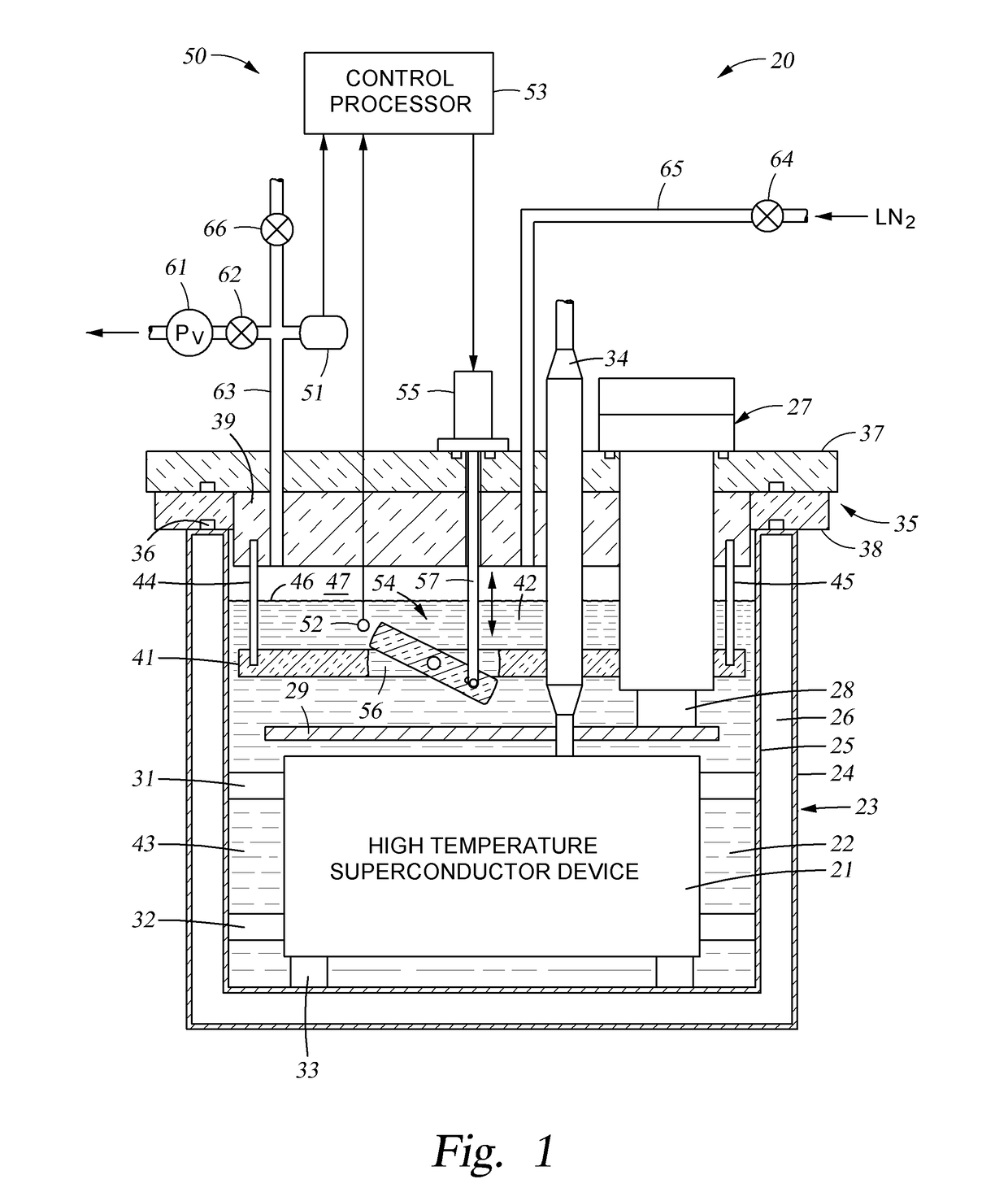

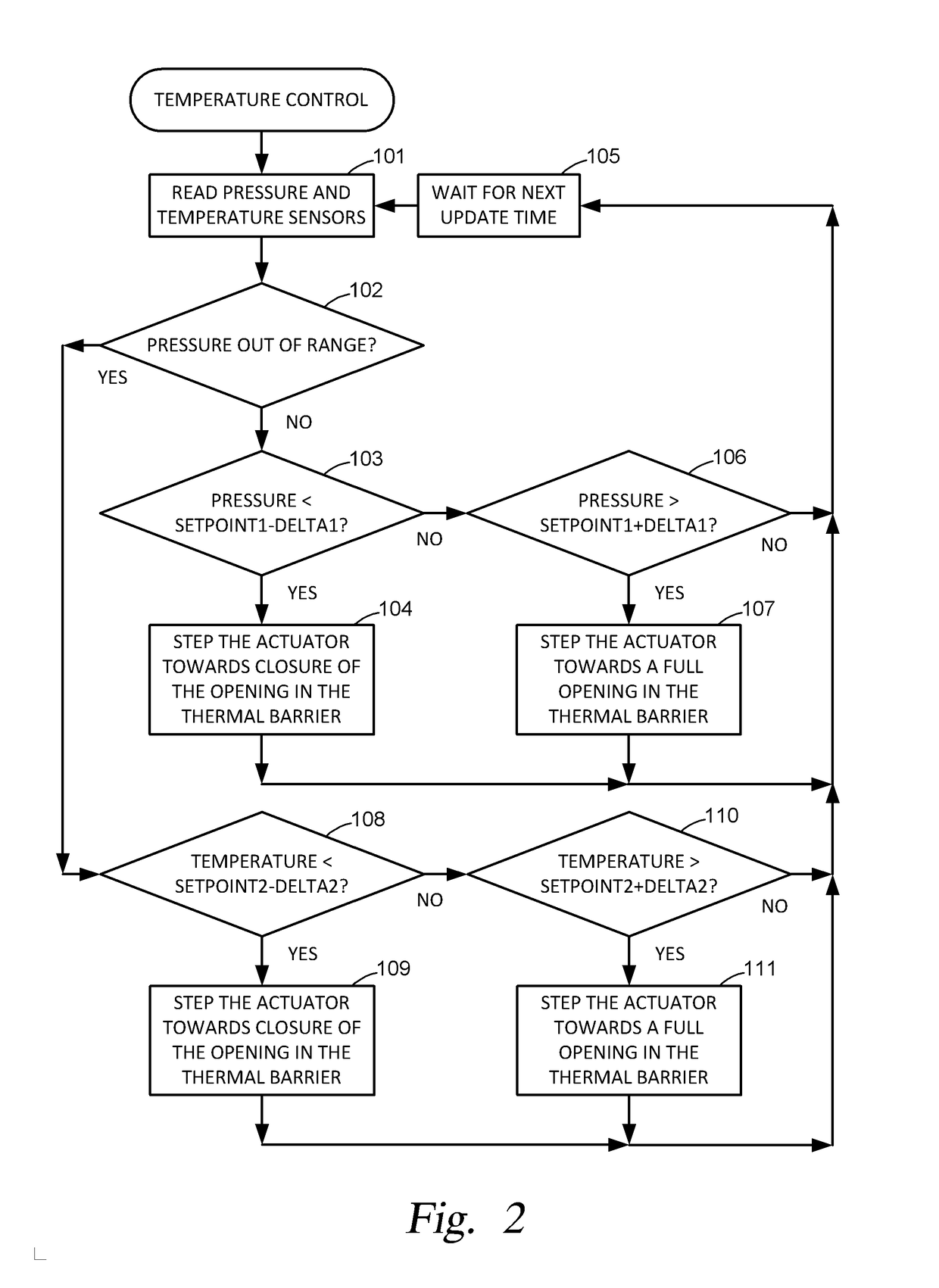

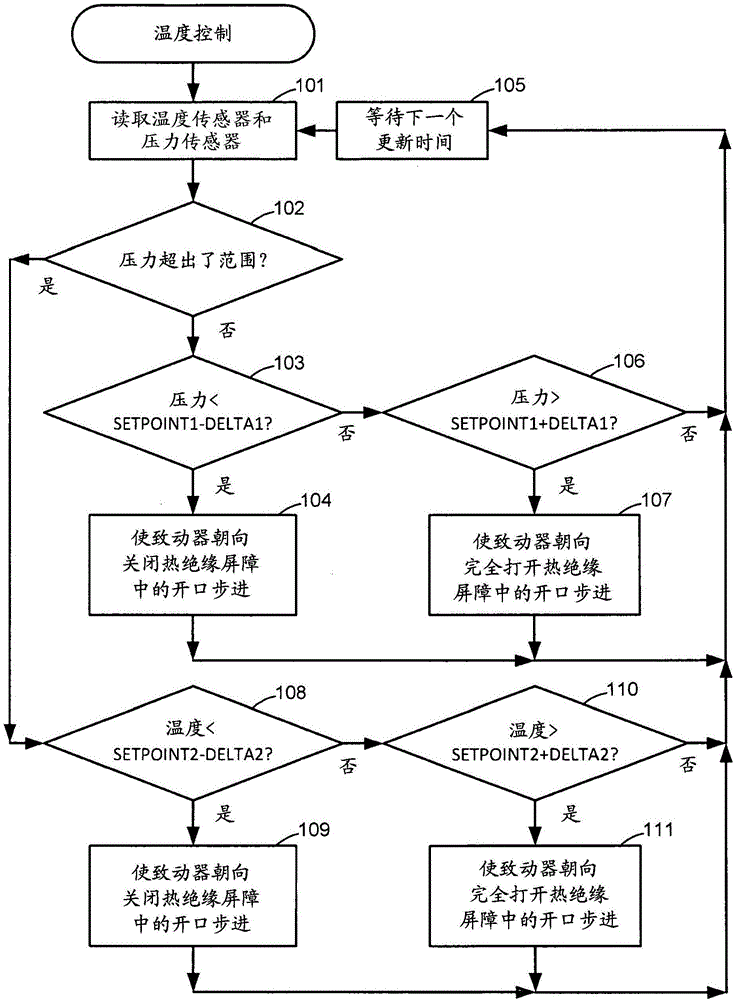

Method and apparatus for cryogenic cooling of hts devices immersed in liquid cryogen

ActiveUS20170205124A1Refrigeration devicesMachines using refrigerant evaporationElectrical conductorThermal insulation

A thermally insulated vessel contains a thermal insulation barrier defining an upper compartment above the barrier and a lower compartment below the barrier. The compartments are interconnected by a passage to allow pressure equalization. High temperature superconductor is mounted within the lower compartment for immersion in the liquid cryogen. A cryogenic refrigerator has a cold head thermally coupled to the high temperature superconductor for maintaining the high temperature superconductor below a superconductive transition temperature. A temperature controller maintains a temperature of the liquid cryogen in the upper compartment at a temperature of at least a boiling point of the liquid cryogen at atmospheric pressure when the lower compartment and at least a portion of the upper compartment are filled with the liquid cryogen.

Owner:FABRUM IP HLDG LTD

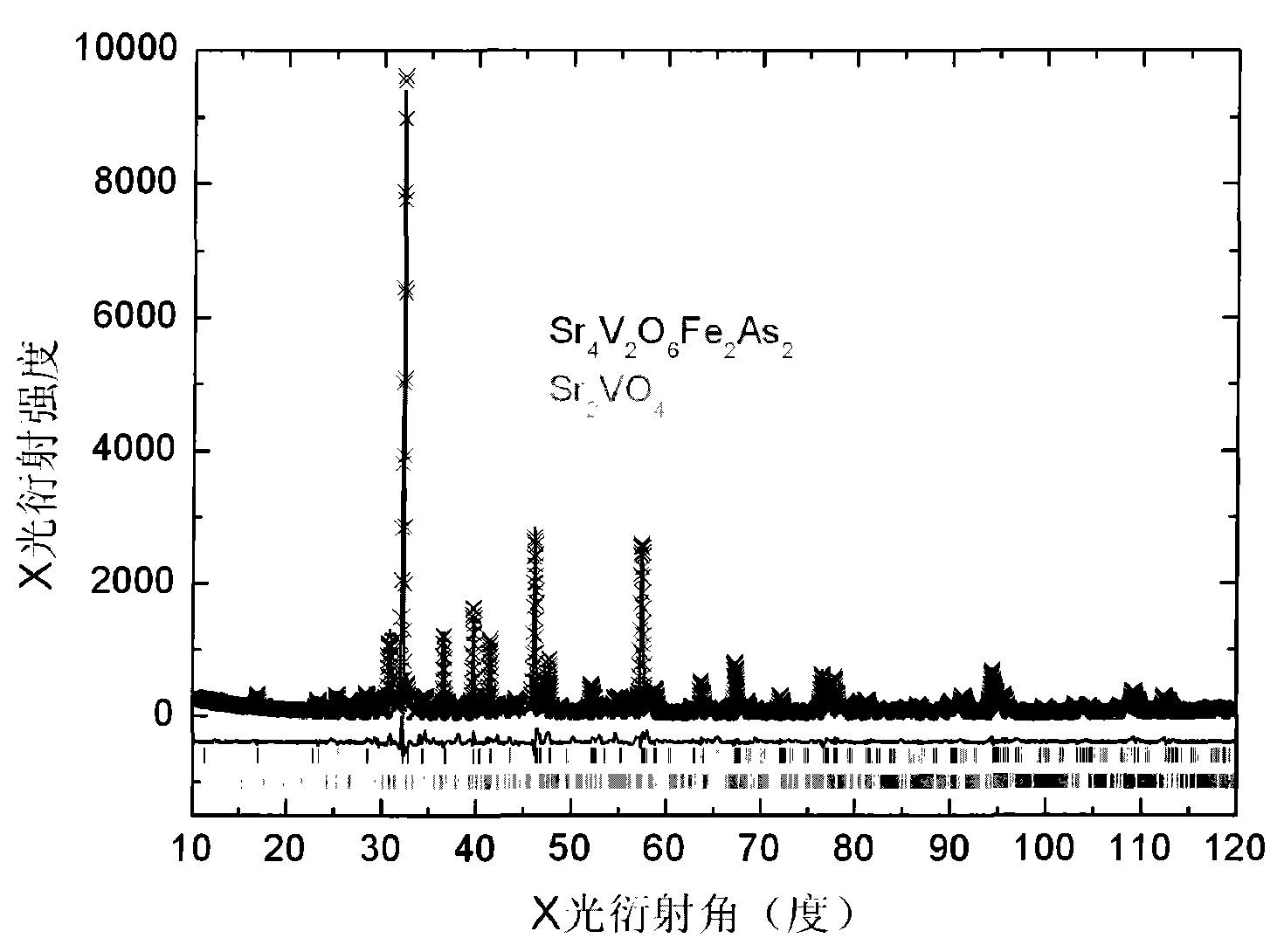

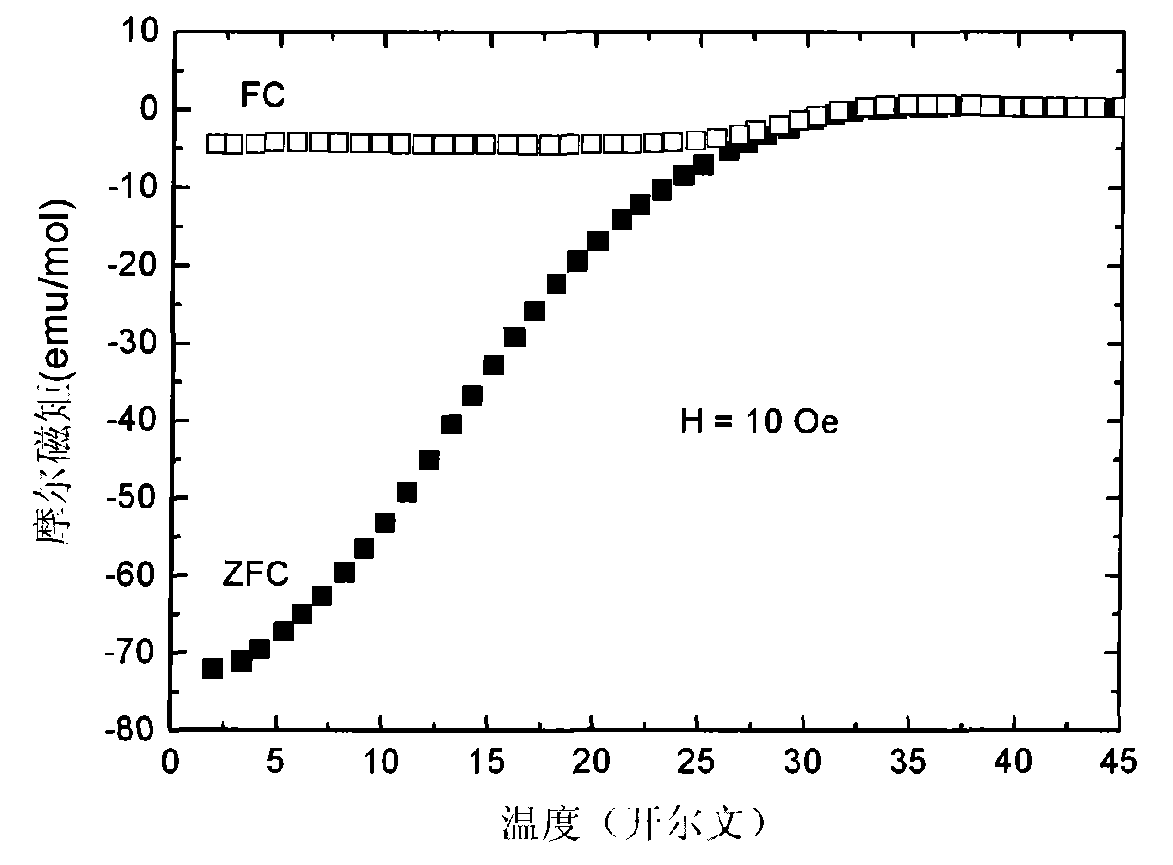

Perovskite structure-based single-phase iron-based superconductive material and preparation method thereof

InactiveCN101993247AGood superconducting stabilityHigh critical fieldChemical reactionSuperconducting transition temperature

The invention relates to a perovskite structure-based single-phase iron-based superconductive material and a preparation method thereof. The material has a two-dimensional laminar structure, and the composition is shown by the formula of Sr4V2O6Fe2As2. The preparation method of the material comprises the following steps of: preparing a SrAs precursor sample and an FeAs precursor sample; mixing the precursors, Sr0, V2O3, Fe and the like by using a solid-state chemical reaction method; and reacting at a high temperature to directly synthesize a perovskite layer-based iron-based superconductive material. Compared with other known iron-based superconductors, the material has higher bidimensionality. The material has electronic carrier characteristics, carrier concentration of 1,020 to 1,022 / cm<3> and superconductive transformation temperature of about 40K. An upper critical magnetic field of the material at a low temperature is estimated to be greater than 250 teslas, so that the material is probably applied to superconductive power transmission, strong magnetic field generation and the like. In addition, the material can also be used in a superconductive filter and the like. The preparation method is simple.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Passivated niobium cavities

ActiveUS7151347B1High quality factorAssuring long-term chemical stabilityKlystronsAcceleratorsUltra-high vacuumSuperconducting transition temperature

A niobium cavity exhibiting high quality factors at high gradients is provided by treating a niobium cavity through a process comprising: 1) removing surface oxides by plasma etching or a similar process; 2) removing hydrogen or other gases absorbed in the bulk niobium by high temperature treatment of the cavity under ultra high vacuum to achieve hydrogen outgassing; and 3) assuring the long term chemical stability of the niobium cavity by applying a passivating layer of a superconducting material having a superconducting transition temperature higher than niobium thereby reducing losses from electron (cooper pair) scattering in the near surface region of the interior of the niobium cavity. According to a preferred embodiment, the passivating layer comprises niobium nitride (NbN) applied by reactive sputtering.

Owner:JEFFERSON SCI ASSOCS LLC

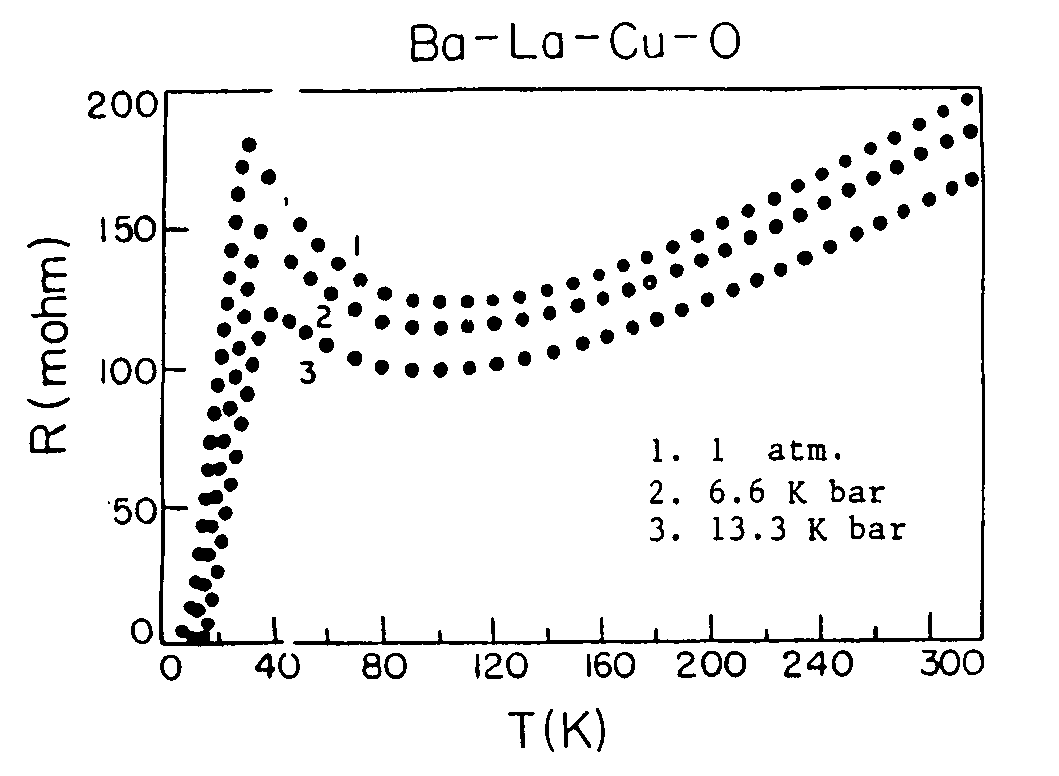

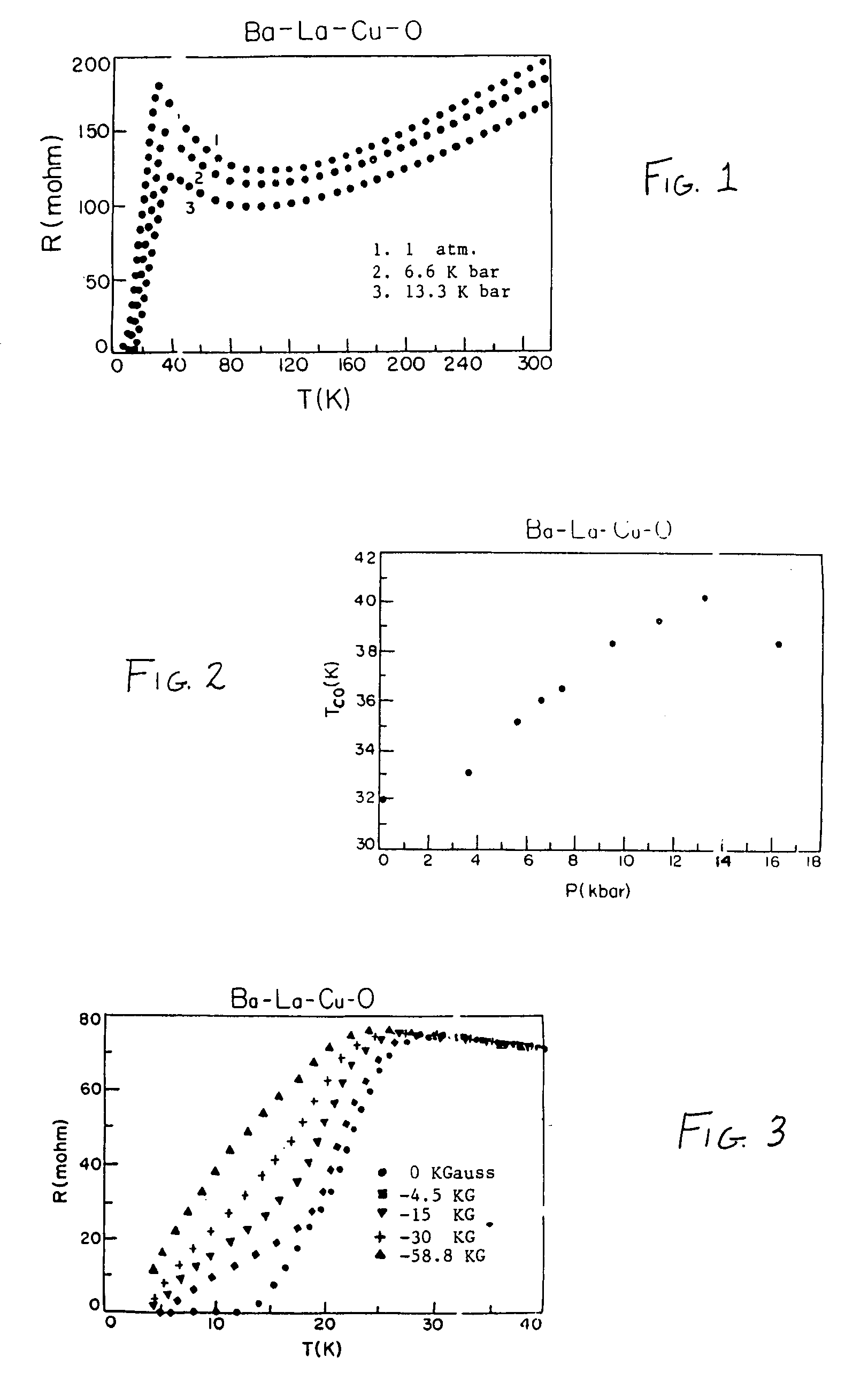

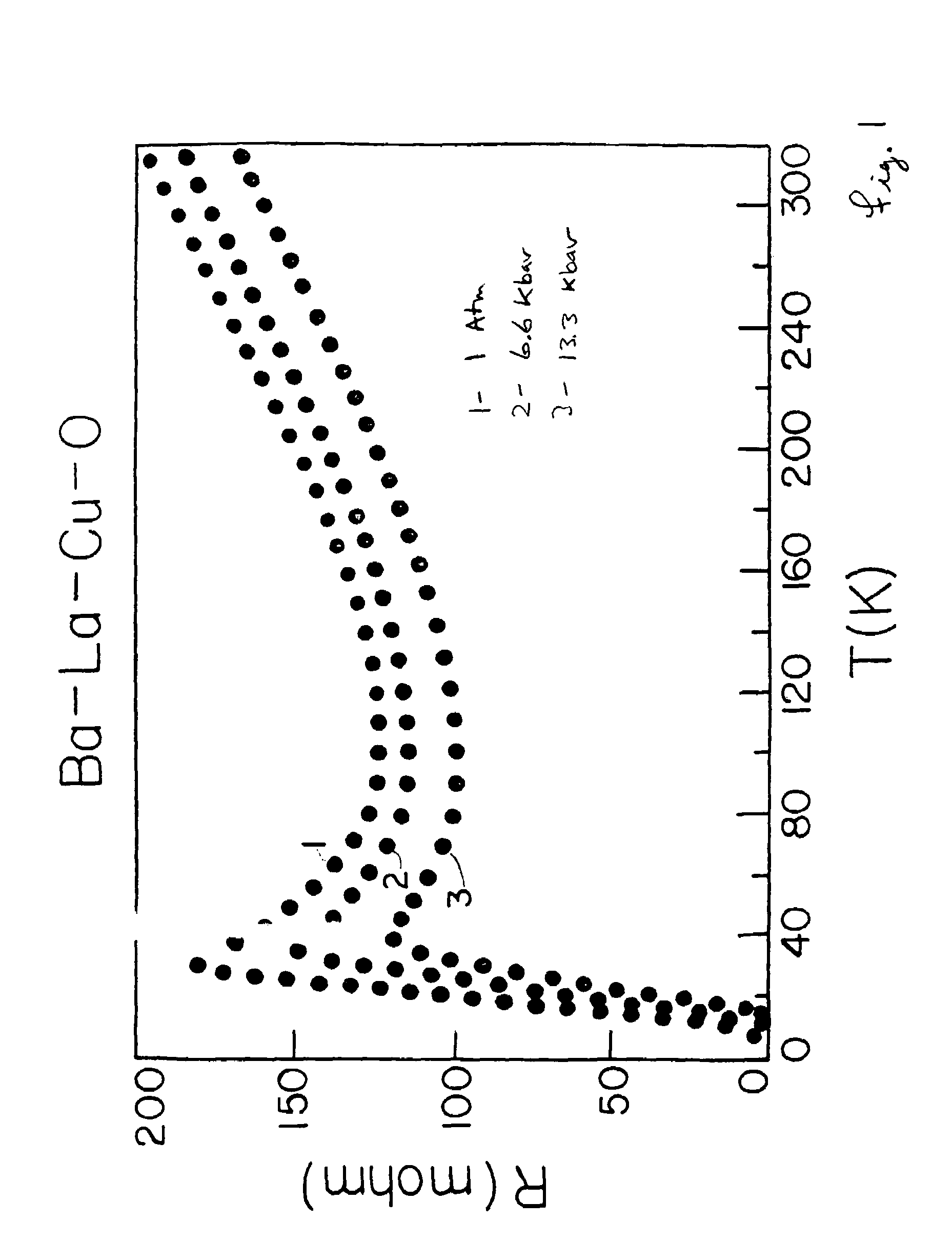

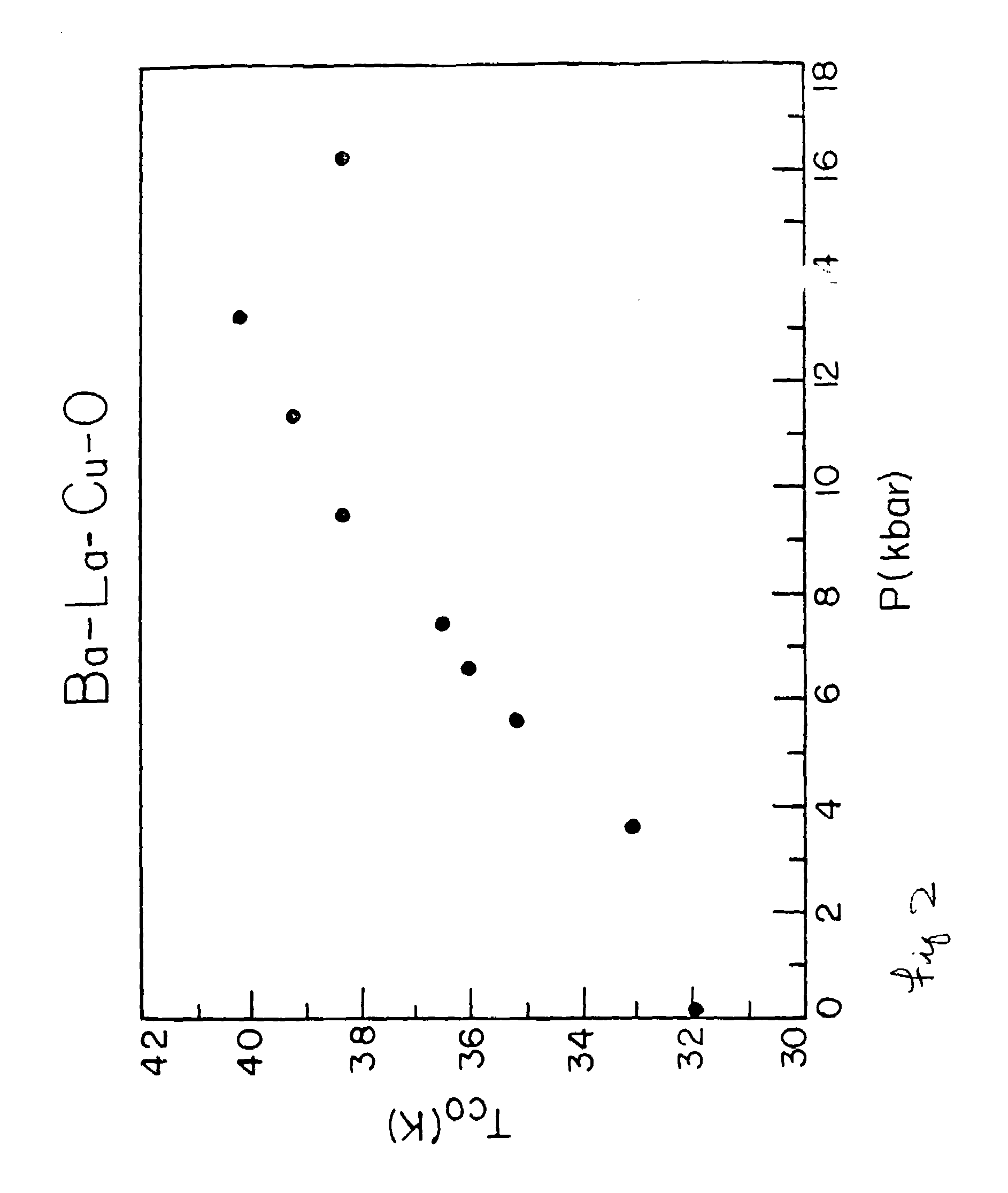

Superconductivity in square-planar compound systems

InactiveUS7056866B1Easy transitionReduce spacingTantalum compoundsZirconium compoundsLutetiumNiobium

Described is a superconducting composition comprising an oxide complex of the formula [L1−xMx]aAbOy wherein L is lanthanum, lutetium, yttrium, or scandium; A is copper, bismuth, titanium, tungsten, zirconium, tantalum, niobium, or vanadium; M is barium, strontium, calcium, magnesium or mercury; and “a” is 1 to 2; “b” is 1; and “x” is a number in the range of 0.01 to 1.0; and “y” is about 2 to about 4. The oxide complexes of the invention are prepared by a solid-state reaction procedure which produces an oxide complex having an enhanced superconducting transition temperature compared to an oxide complex of like empirical composition prepared by a coprecipitation—high temperature decomposition procedure. With an oxide complex prepared by the solid-state reaction of the invention a transition temperature as high as 100°K has been observed even under atmospheric pressure.

Owner:UNIV HOUSTON SYST

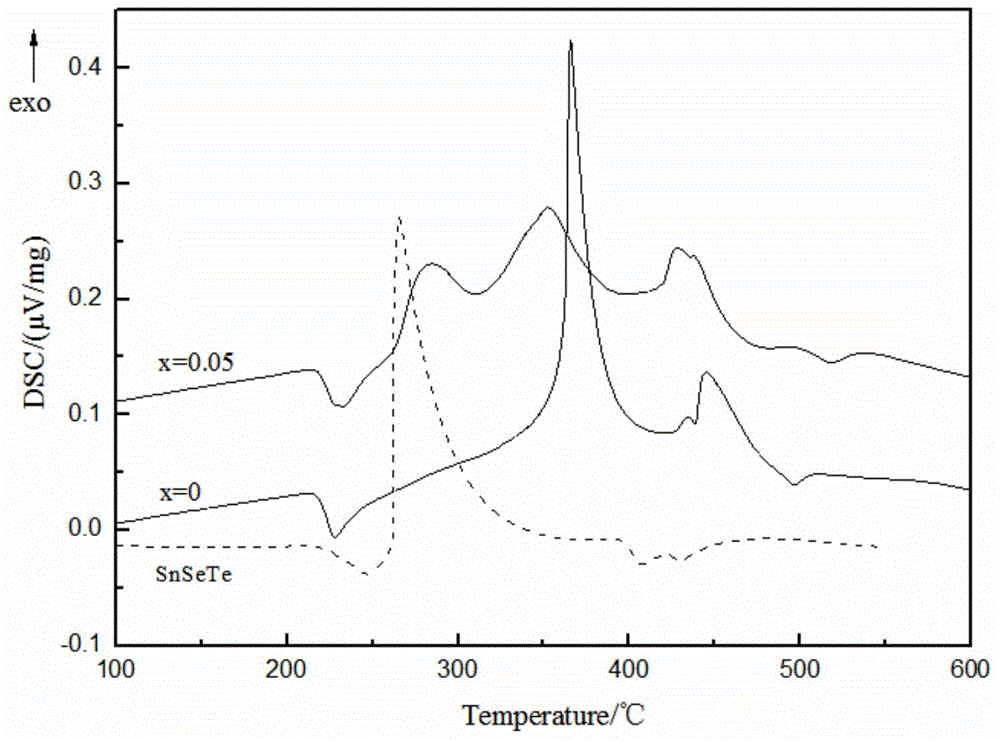

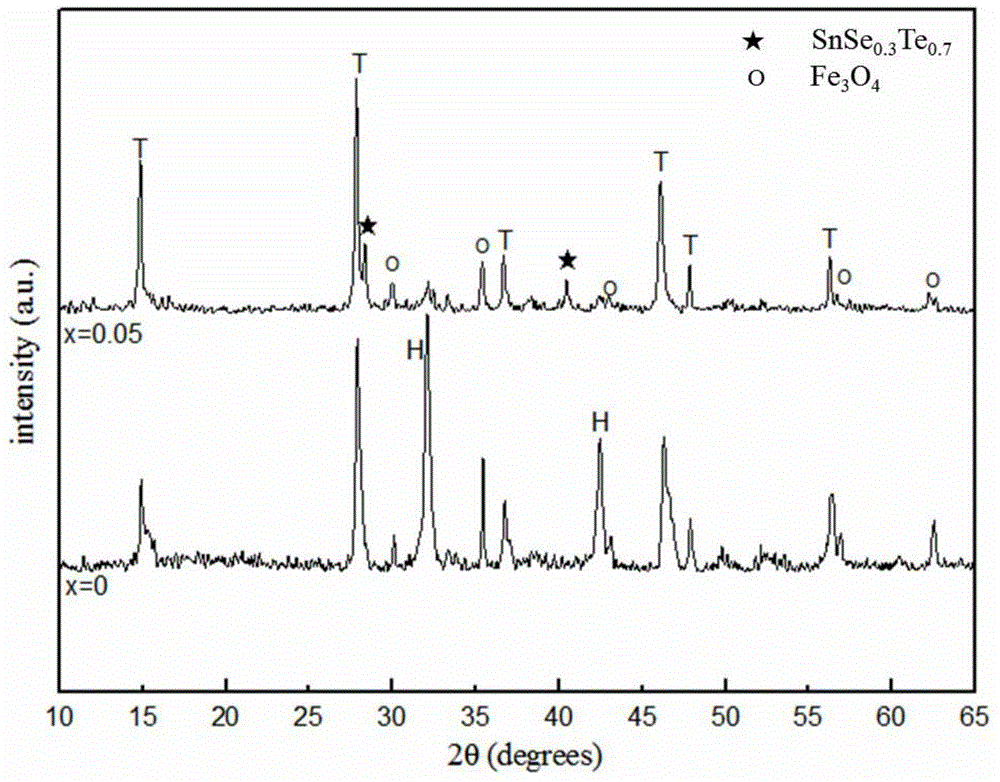

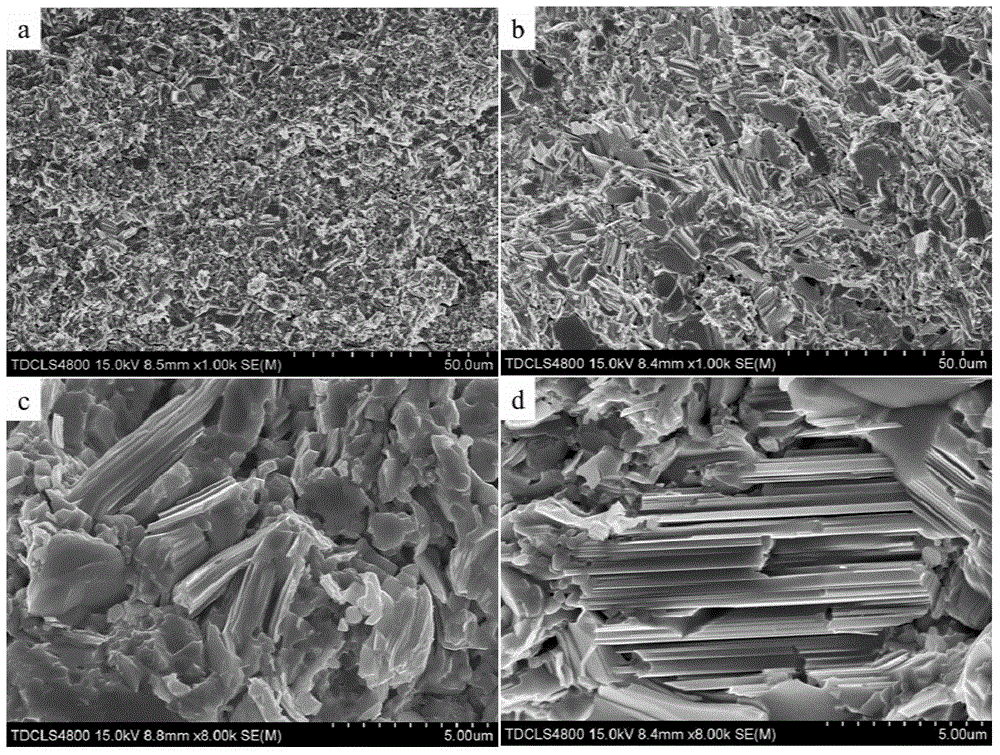

Method for improving superconducting performance of Sn-added FeSe1/2Te1/2 superconductor

ActiveCN104445097APromote formationSimple manufacturing methodSelenium/tellurium compundsRoom temperatureSuperconducting transition temperature

The invention relates to a method for improving the superconducting performance of a Sn-added FeSe0.5Te0.5 superconductor. The method comprises the steps of mixing Sn powder and FeSe0.5Te0.5 powder in a weight ratio of 0.05: 1, and sufficiently grinding the mixture in an agate mortar for 20-30 minutes; and then preparing into a flake under the pressure of 6-8MPa, finally putting the flake into a high-temperature differential scanning calorimeter, heating to 600 DEG C under the protection of flowing high-purity argon, preserving the heat for 5-10 hours, and cooling to room temperature. A fact that a Sn-Se-Te liquid phase generated by reaction between Sn and FeSe0.5Te0.5 can accelerate the transformation from a non-superconducting phase to a superconducting phase is discovered for the first time and is favorable for forming a superconducting laminar structure so that the superconducting transition temperature of the structure is finally significantly improved, thus providing an important clue for optimizing a preparation process of an iron-based superconductor, illuminating an iron-based superconducting mechanism and promoting the development of the superconducting theory.

Owner:TIANJIN UNIV

Superconducting X-Ray Detector And X-Ray Analysis Apparatus Using The Same

InactiveUS20070291902A1Improved energy resolutionReduce sensitivityMaterial analysis using wave/particle radiationSolid-state devicesSoft x rayHeat flow

To provide a superconducting X-ray detector capable of carrying out a measurement by a high energy resolution by restraining a reduction in a sensitivity by a self magnetic field. A superconducting X-ray detector comprising a temperature detector 6 for detecting a temperature change by heat generated when an X-ray is absorbed, and a heat link 3 for controlling a heat flow amount of escaping the generated heat to a support board 1, wherein the temperature detector 6 comprises a heat conducting multilayer thin film, the superconducting X-ray detector is constituted by a structure of providing a superconductor layer 4 above the heat link 3 and providing an insulating member 2 between the superconductor layer 4 and the temperature detector 6, the superconductor layer 4 and the temperature detector 6 are connected by a superconducting wiring 7 and uses materials by which superconducting transition temperatures of the superconductor layer 4 and the superconducting wiring 7 are higher than a superconducting transition temperature of the temperature detector 6.

Owner:HITACHI HIGH TECH SCI CORP

Low resistance conductor, processes of production thereof, and electrical members using same

InactiveUS20030132023A1Low resistivityEconomical priceNon-insulated conductorsSuperconductors/hyperconductorsElectrical resistance and conductanceElectrical conductor

A conductor obtained by connecting a plurality of superconductors by normal conductivity or a conductor comprised of superconductors and normal conductors, said low resistance conductor using superconductors characterized in that an apparent specific resistance of said conductor at below a superconducting transition temperature of said superconductors is lower than the specific resistance of copper at that superconducting transition temperature.

Owner:ORACLE INT CORP +1

Method for preparing Nb3Al superconducting wire precursor

ActiveCN105304208AReduce AC loss valueSuppress couplingSuperconductors/hyperconductorsSuperconductor devicesIngotSuperconducting transition temperature

The invention discloses a method for preparing an Nb3Al superconducting wire precursor. The method comprises the steps of preparing a single-core composite rod by means of a Nb rod, a Ta-containing foil and a Cu pipe; rolling a prepared single-core composite rod for forming a hexagonal rod with a regular hexagonal cross section; loading a plurality of prepared hexagonal rods into a Cu packaging pipe and sealing, thereby forming a composite blank ingot; preparing a Cu-packaged composite rod from the prepared composite blank ingot through a heat extrusion processing procedure; and preparing an Nb3Al superconducting wire precursor lead through a plurality of drawing processing procedures. The Nb3Al superconducting wire precursor prepared according to the method of the invention has functions of effectively suppressing coupling between superconducting performance core filaments and remarkably reducing AC loss of a final superconducting wire under a precondition that superconducting performances such as superconducting transition temperature, critical current density and upper critical magnetic field are not ensured.

Owner:西部超导材料科技股份有限公司

Superconducting magnet apparatus and method for magnetizing superconductor

InactiveUS7026901B2Magnet usedImprove portabilityCompression machinesMagnetsSuperconducting CoilsMagnetization

Owner:AISIN SEIKI KK

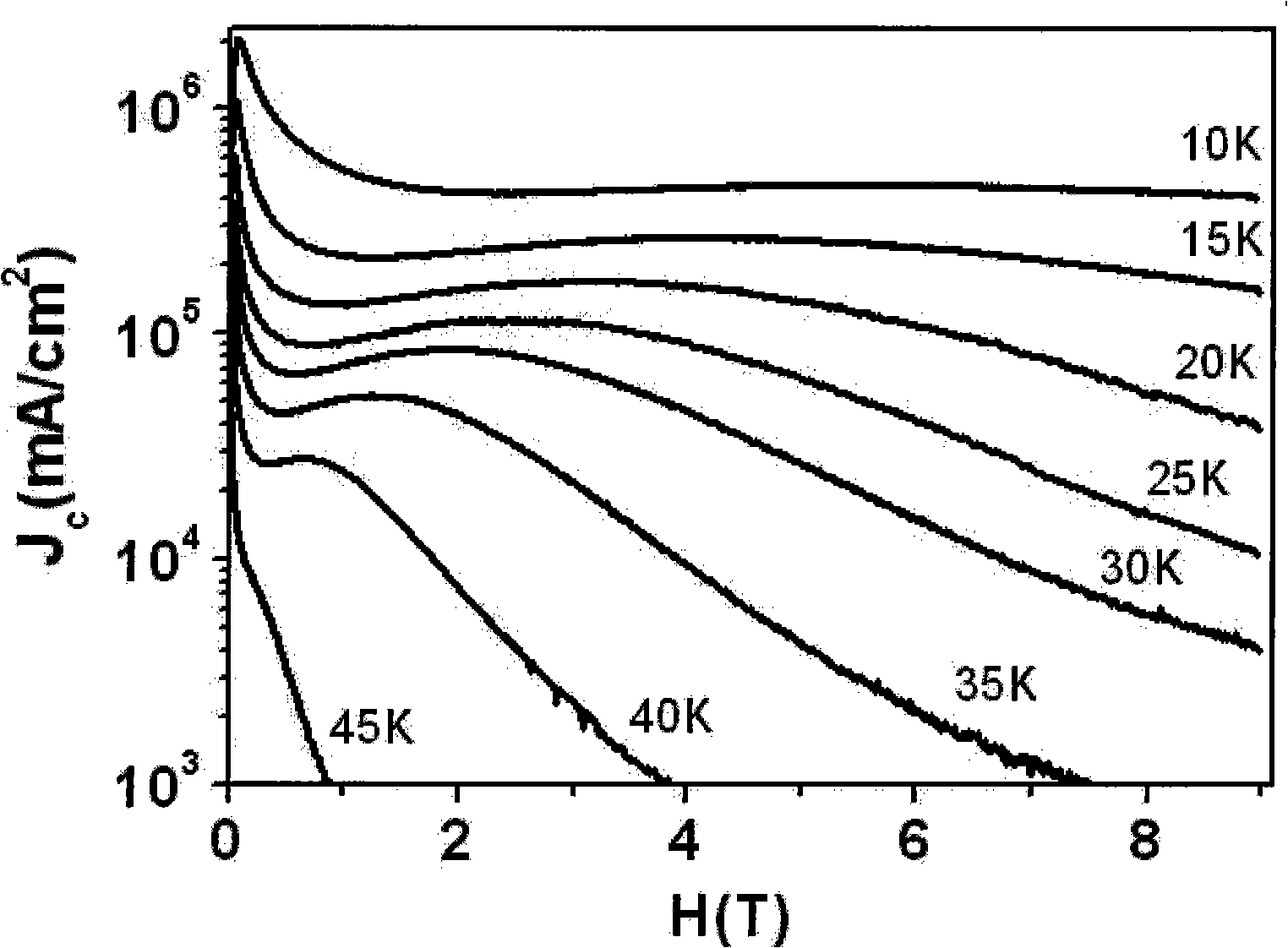

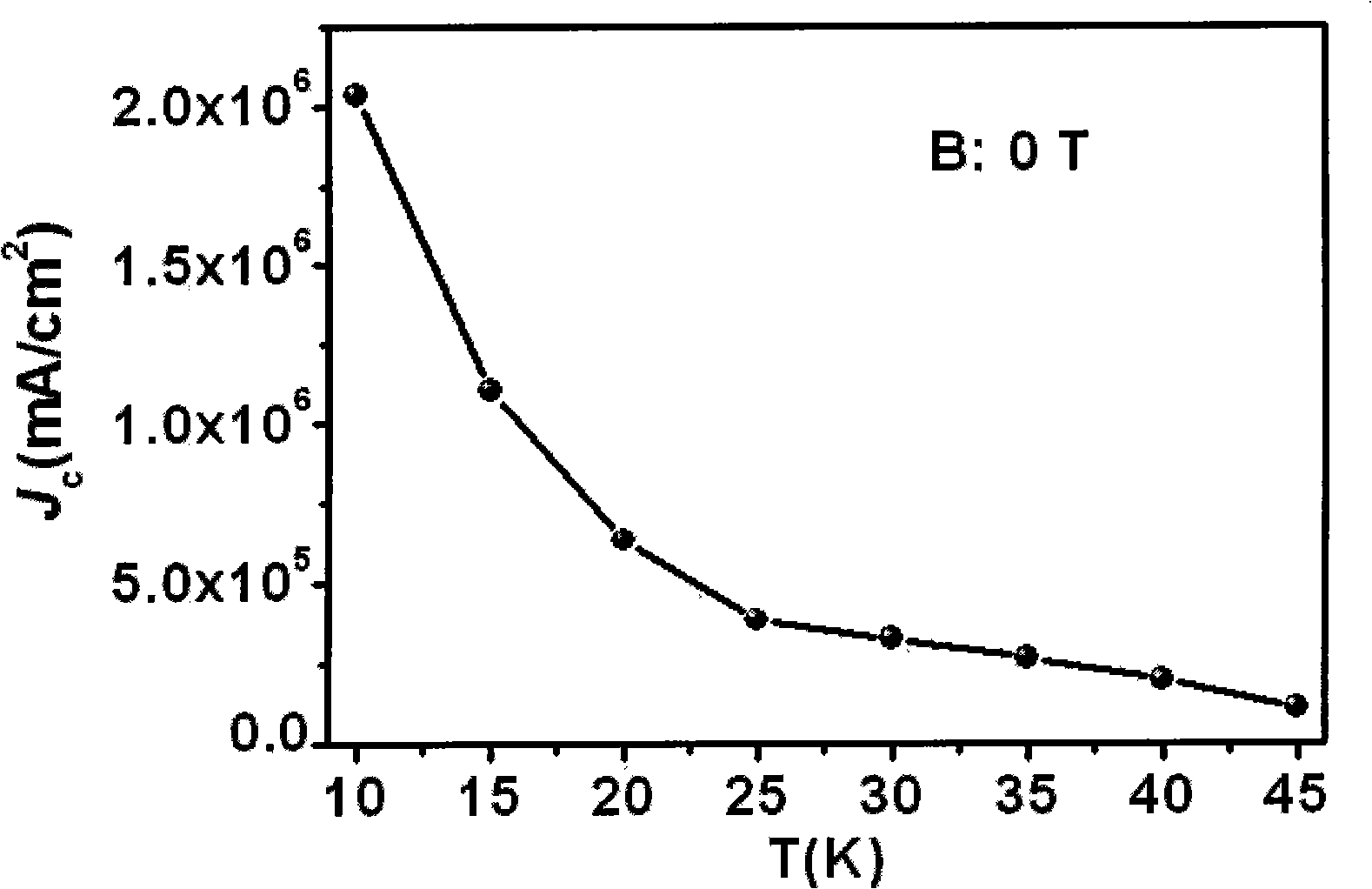

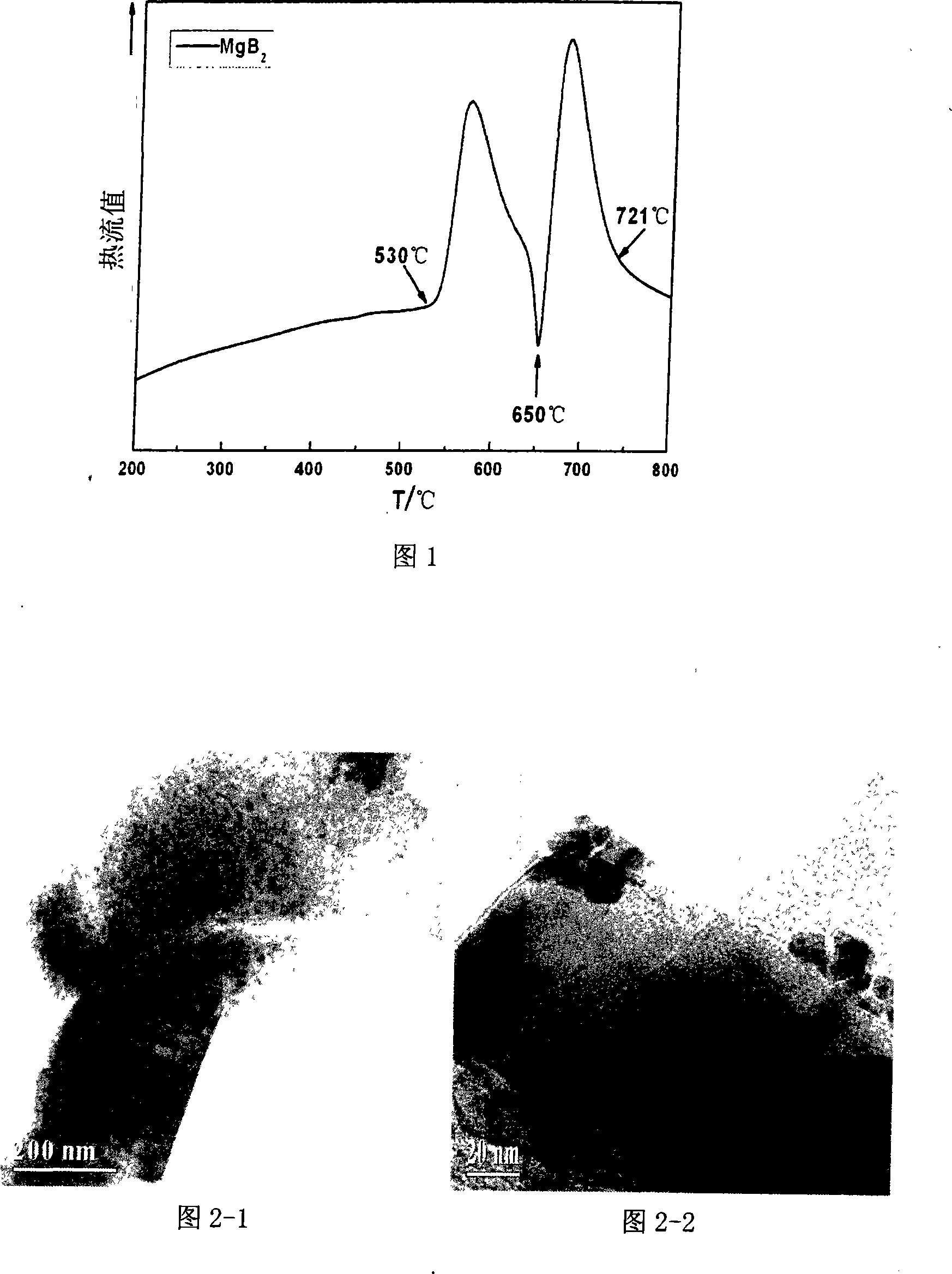

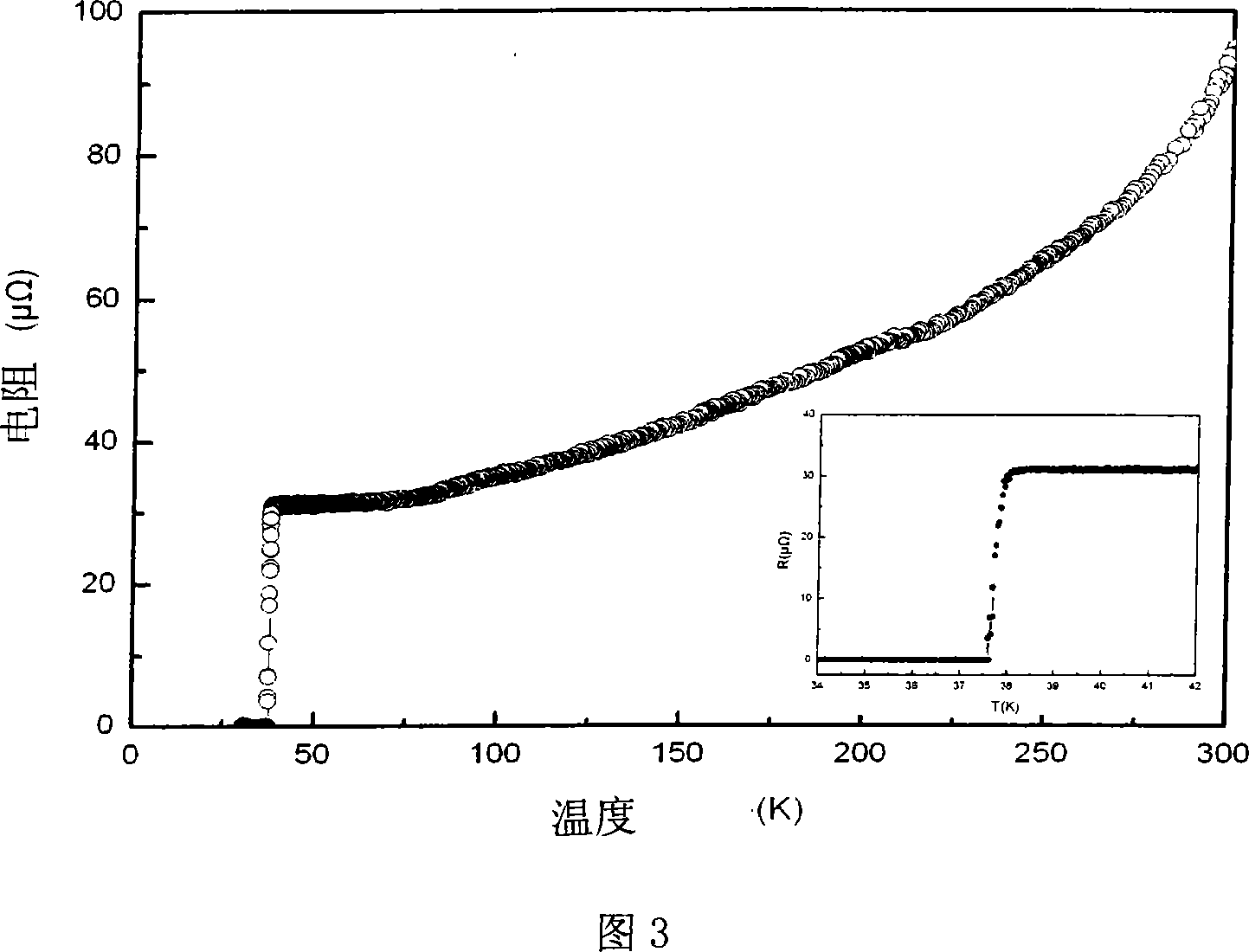

Low-temperature fast powder sintering method for superconductive MgB2 nano particle

InactiveCN101186306AUniform sizeEasy to prepareSuperconductors/hyperconductorsMetal boridesFlux pinningRoom temperature

The invention discloses a low-temperature fast powder sintering method for a superconduct nano-particle MgB2, which comprises the steps: magnesium powder and amorphous boron are mixed according to atomic ratio: Mg:B is equal to 1-1.5:2, then the compound is grinded for 0.3 to 2 hours and is pressed into block under the pressure of 2-7MPa; the block is added into a heating device and is added with argon, and the temperature raises to 980K - 1010K at the speed of 20 - 40K / min, then the temperature lowers to room temperature at the speed of 40 - 50K / min, and the superconduct nano-particle MgB2 is made. The diameter of MgB2 of the invention is about 10 to 20nm; Tc value is up to 38.5K, when the MgB2 nano particles are used for measuring superconducting transition temperature, which can not only maintain superconducting transition temperature close to theoretical value, but also be taken as the center of flux pinning, thereby enhancing critical current density.

Owner:TIANJIN UNIV

Method for preparing MgB2 superconductive material

InactiveCN1569633ASimple manufacturing processGood superconducting propertiesSuperconductors/hyperconductorsMetal boridesCrucibleFree cooling

The invention relates to a process for preparing MgB2 superconducting material which comprises the steps of, grinding B2O3 and Mg powder under the protection of oinert gas, loading the grinded raw material into ceramic crucible, sintering the crucible in vacuum pit furnace, naturally cooling down to room temperature in vacuum or under the inert gas protection status.

Owner:SHANGHAI UNIV

Method and apparatus for cryogenic cooling of hts devices immersed in liquid cryogen

ActiveCN106663735ASuperconductor detailsRefrigeration devicesHigh-temperature superconductivityElectrical conductor

A thermally insulated vessel contains a thermal insulation barrier defining an upper compartment above the barrier and a lower compartment below the barrier. The compartments are interconnected by a passage to allow pressure equalization. High temperature superconductor is mounted within the lower compartment for immersion in the liquid cryogen. A cryogenic refrigerator has a cold head thermally coupled to the high temperature superconductor for maintaining the high temperature superconductor below a superconductive transition temperature. A temperature controller maintains a temperature of the liquid cryogen in the upper compartment at a temperature of at least a boiling point of the liquid cryogen at atmospheric pressure when the lower compartment and at least a portion of the upper compartment are filled with the liquid cryogen.

Owner:法布鲁姆知识产权控股有限公司

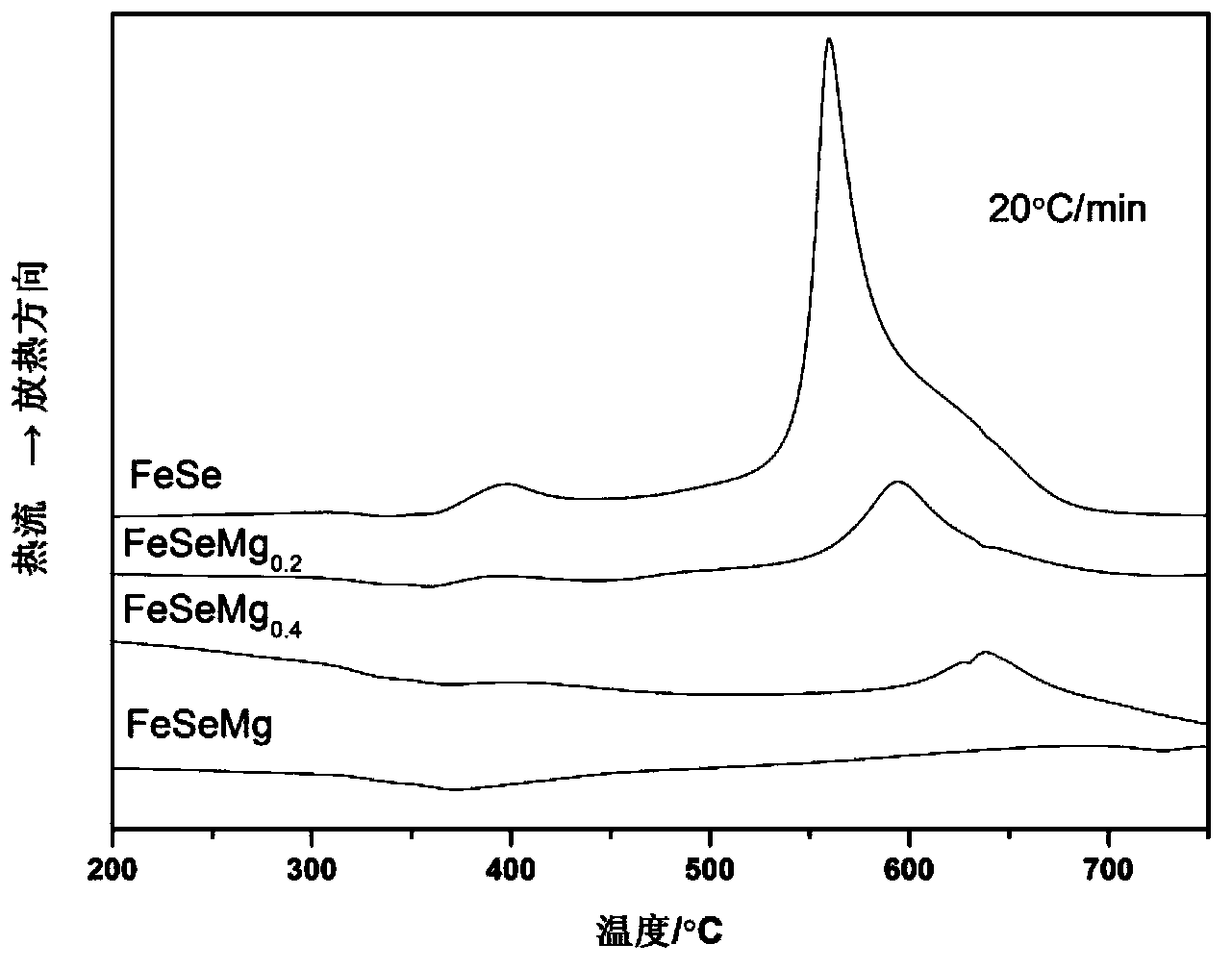

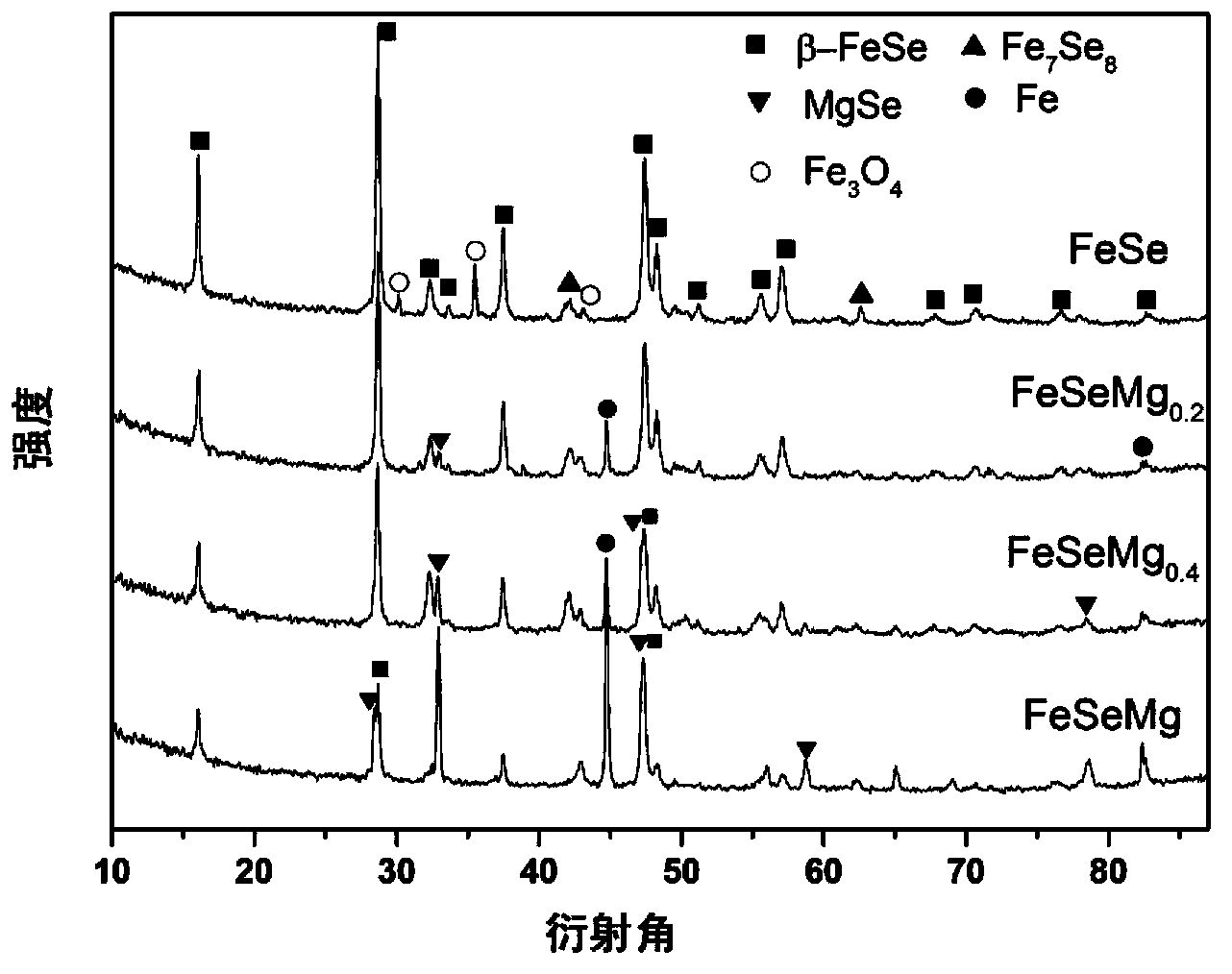

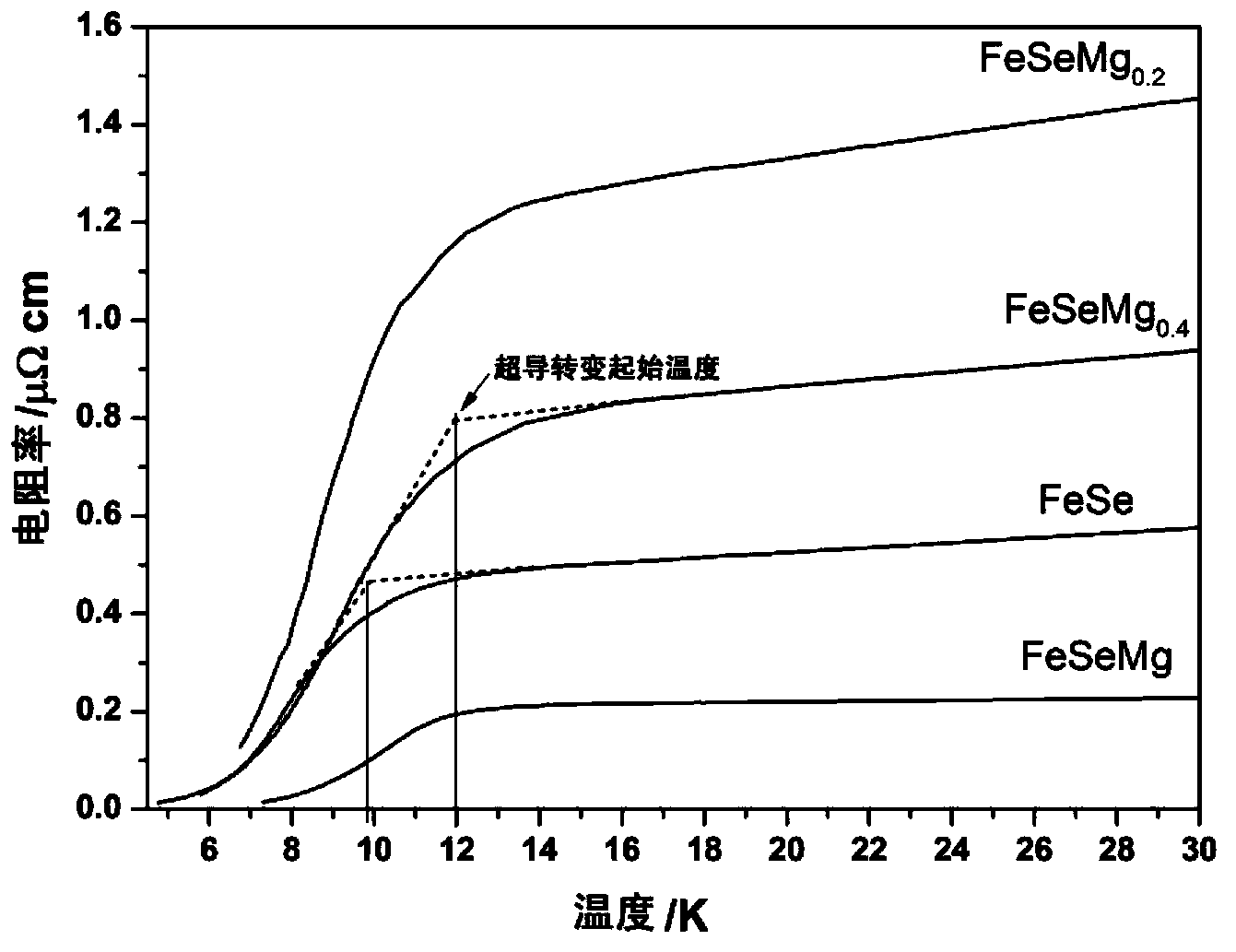

Method for improving FeSe superconducting transition temperature by adding Mg

ActiveCN103360073ASynthetic sintering technology is simple and easyPromote practical progressRoom temperatureLattice constant

The invention relates to a method for improving the FeSe superconducting transition temperature by adding Mg. The method comprises the following steps of: milling Fe powder and Se powder in an agate mortar or a planetary ball mill at the atomic ratio of Fe:Se=1: (0.90-1.05), pressing the mixture to obtain a thin sheet, placing the thin sheet into a high temperature differential scanning calorimeter or a tubular sintering furnace, sintering the thin sheet in a thermally insulating mode at 600-700 DEG C for 18-48 hours, cooling the sintered thin sheet to room temperature, again milling the sintered FeSe block into powder, milling the Mg powder and the FeSe powder in the agate mortar or the ball mill at the atomic ratio of (0.2-1):1, pressing the mixed powder to obtain the thin sheet, sintering the thin sheet in the high temperature differential scanning calorimeter or the tubular sintering furnace in the thermally insulating mode at 700-800 DEG C for 0.5-1 hour, and cooling the sintered thin sheet to room temperature, wherein the MgSe coexists with the unreacted FeSe to influence the lattice constant of the FeSe so that the superconducting transition temperature of the FeSe is increased from 9.8K to 12.1K, and the increase range is above 20%.

Owner:TIANJIN UNIV

High transition temperature superconducting compositions

Described is a superconducting composition comprising an oxide complex of the formula [L1−xMx]aAbOy wherein L is lanthanum, lutetium, yttrium or scandium; A is copper, bismuth, titanium, tungsten, zirconium, tantalum, niobium, or vanadium; M is barium, strontium, calcium, magnesium or mercury; and “a” is 1 to 2; “b” is 1; “x” is a number in the range of 0.01 to 0.5 and preferably 0.075 to 0.5; and “y” is about 2 to about 4. The oxide complexes of the invention are prepared by solid-state reaction procedure which produce oxide complexes having enhanced superconducting transition temperatures compared to an oxide complex of like empirical composition prepared by a coprecipitation—high temperature decomposition procedure. With a solid-state reaction prepared oxide complex of the invention a transition temperature as high as 100° K has been observed even under atmospheric pressure.

Owner:UNIV HOUSTON SYST

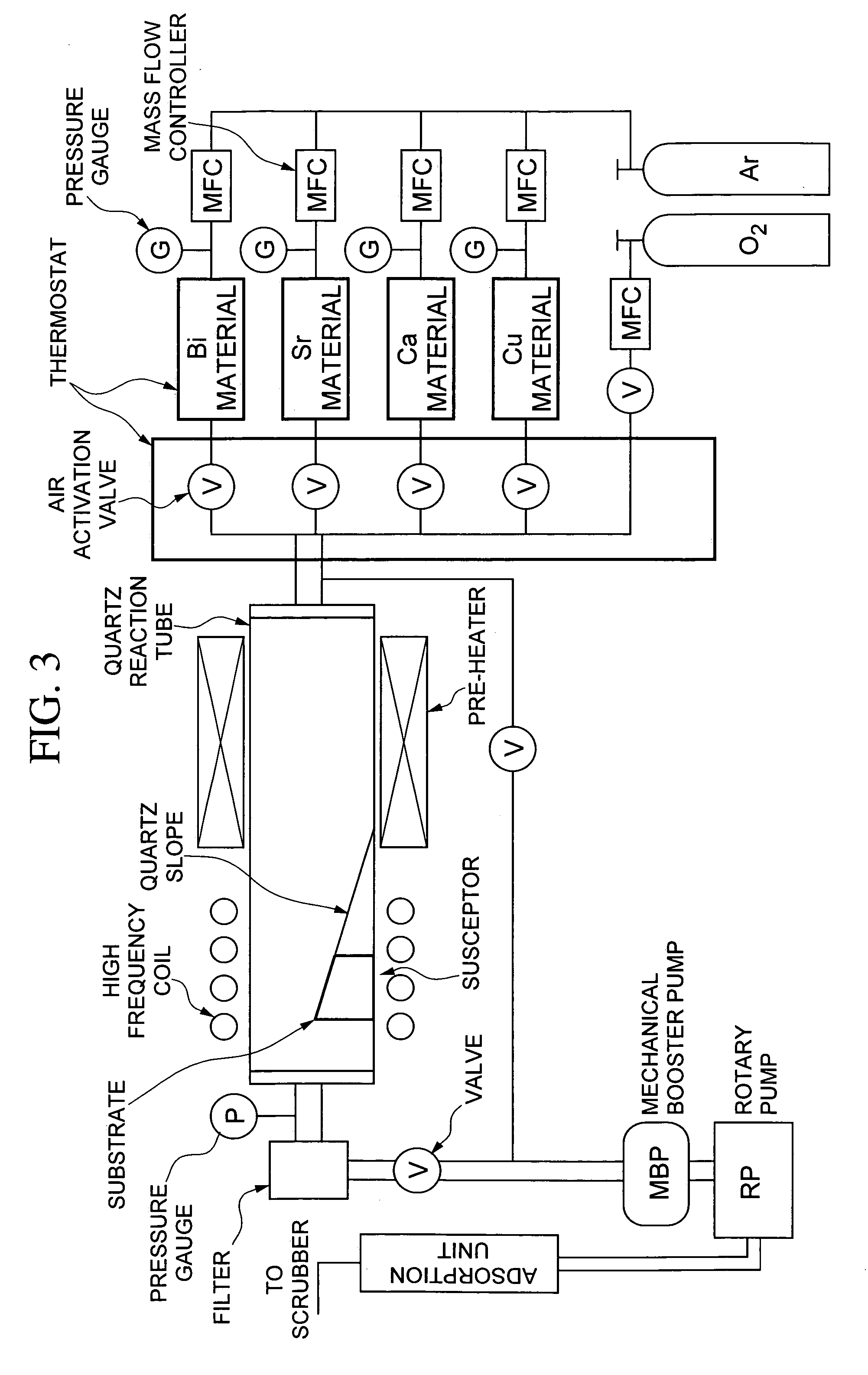

Bismuth based oxide superconductor thin films and method of manufacturing the same

InactiveUS20060084578A1Improve performancePolycrystalline material growthSuperconductors/hyperconductorsElectrical conductorSingle crystal substrate

A Bi-based oxide superconductor thin film whose c-axis is oriented parallel to the substrate and whose a-axis (or b-axis) is oriented perpendicular to the substrate, is manufactured in order to obtain a high performance layered Josephson junction using a Bi-based oxide superconductor. The method of manufacturing an a-axis oriented Bi-based oxide superconductor thin film, involves an epitaxial growth process using an LaSrAlO4 single crystal substrate of a (110) plane or a LaSrGaO4 single crystal substrate of a (110) plane, for which the lattice constant matches well with a (100) plane of a Bi-2223 oxide superconductor. By this method, rather than the normally easily obtained Bi-2212, an a-axis oriented film of Bi-2223 showing an extremely high superconductive transition temperature even for a Bi-based oxide superconductor can be selectively manufactured.

Owner:ENDO KAZUHIRO

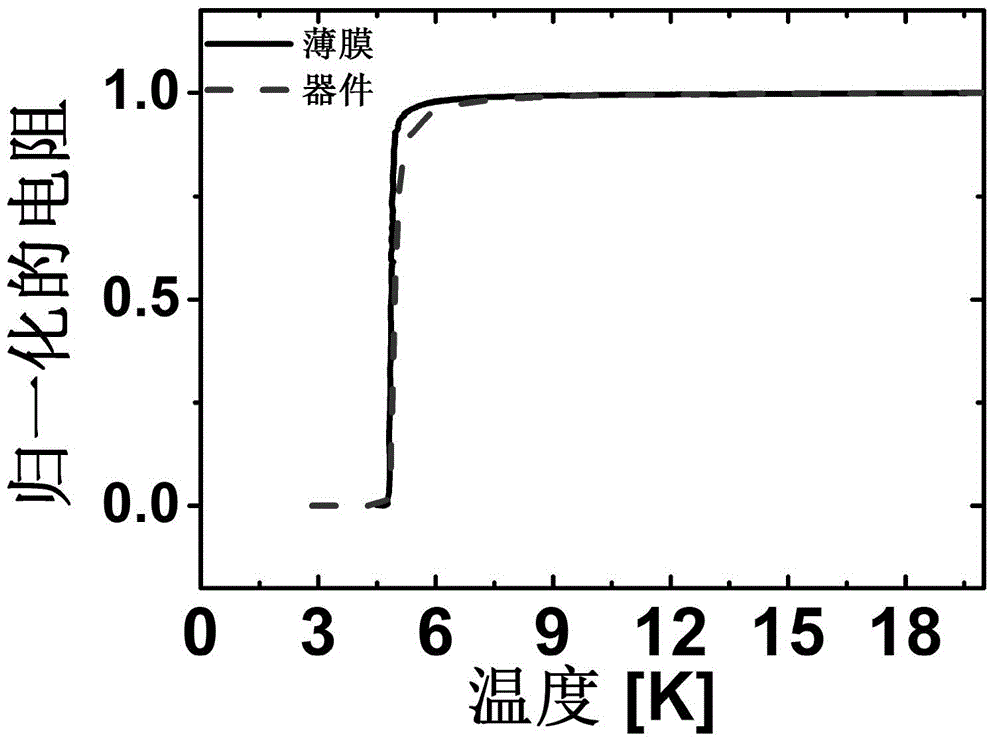

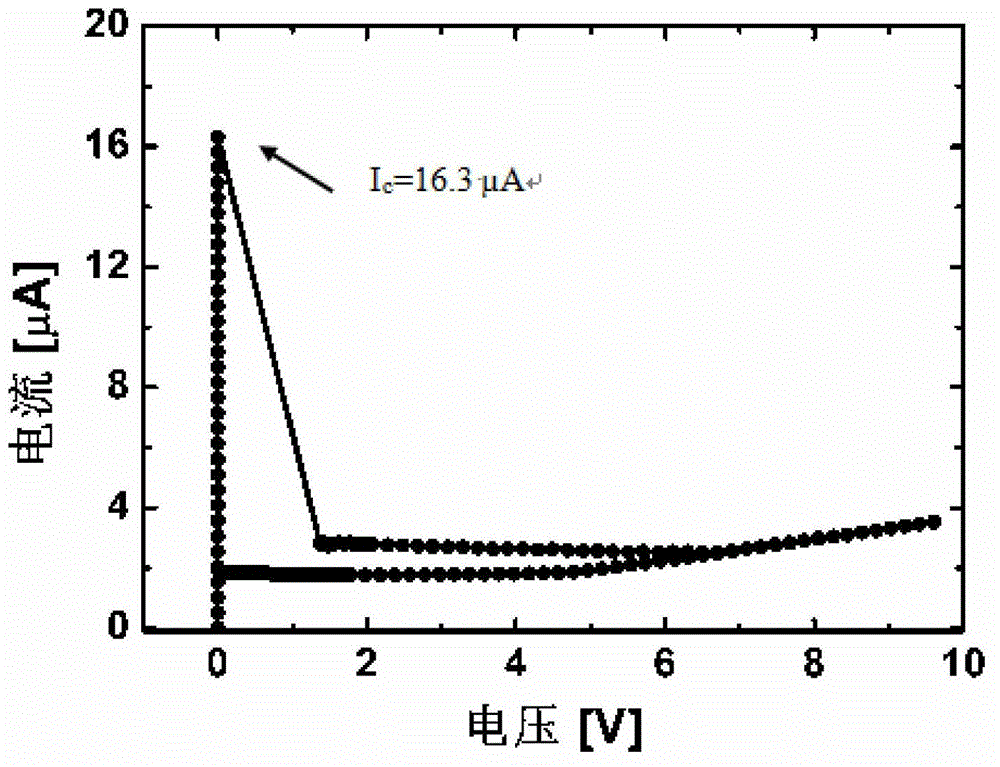

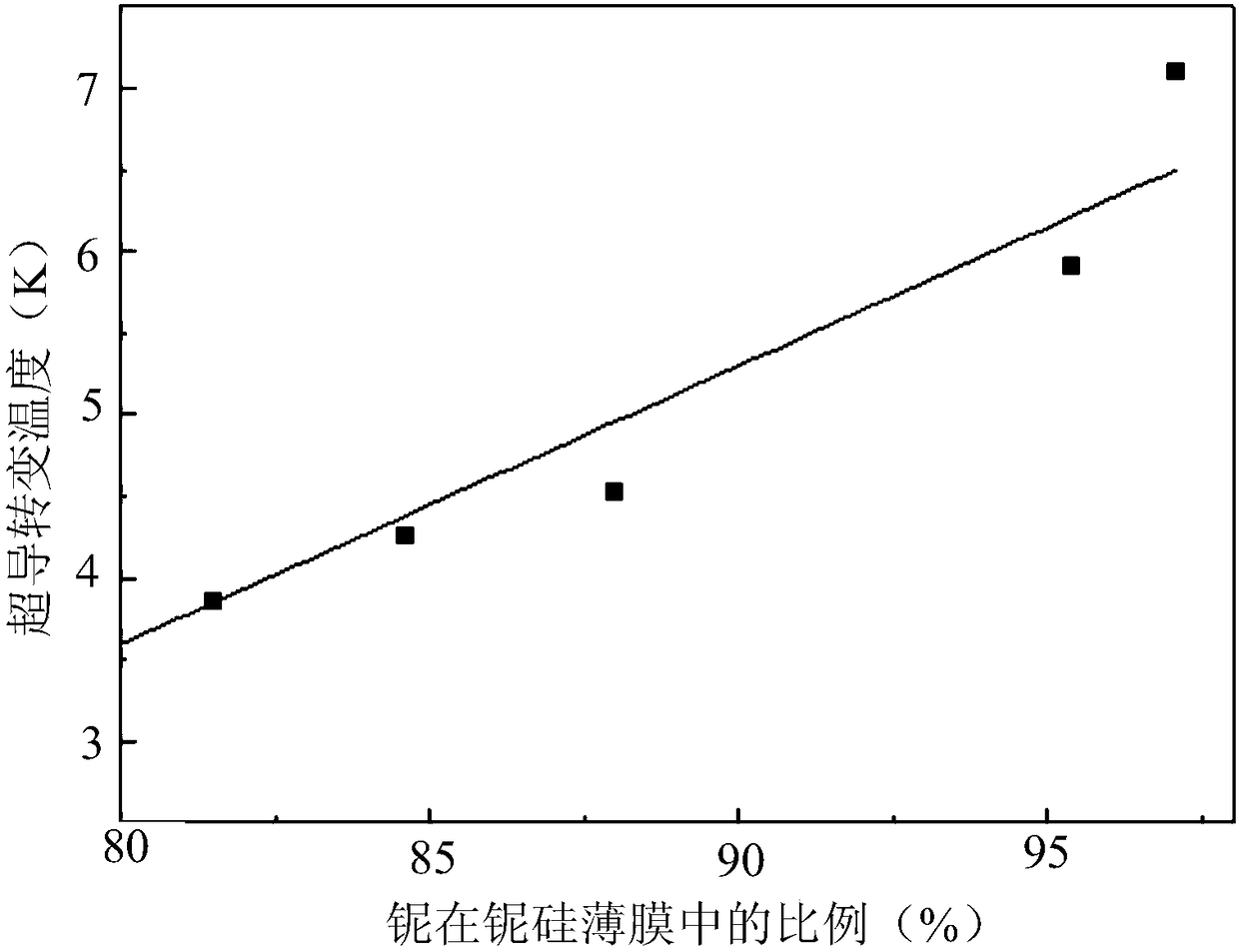

Superconducting film, preparation method thereof, superconducting quantum interference device and inductive superconducting edge detector

ActiveCN109285942ARealize the process is simpleEasy to processVacuum evaporation coatingSputtering coatingNiobiumSuperconducting transition temperature

The invention relates to a superconducting film. The components of the superconducting film includes niobium and silicon, wherein the proportion of niobium in the superconducting film is greater thanor equal to 81.5% and less than or equal to 97.1%, and the superconducting transition temperature of the superconducting film ranges from 3.85K to 7.1K. The superconducting film provided by the invention can realize the change of the superconducting transition temperature only by controlling the proportion of niobium, thereby being simple in implementation process, and being easy to process and prepare.

Owner:NAT INST OF METROLOGY CHINA

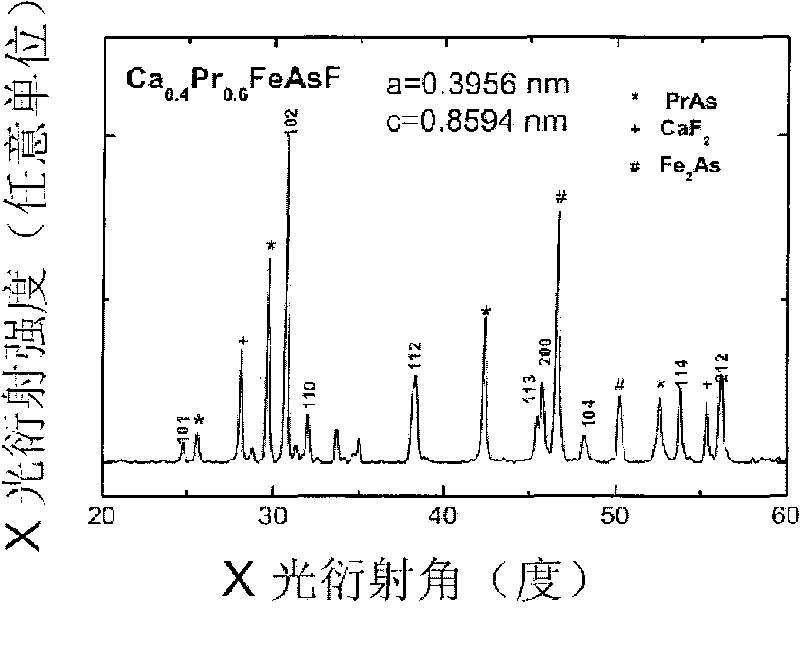

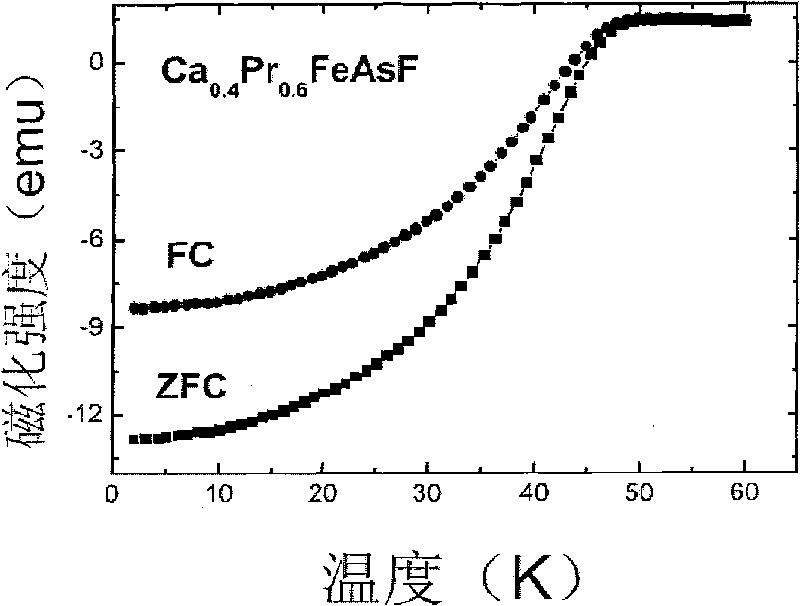

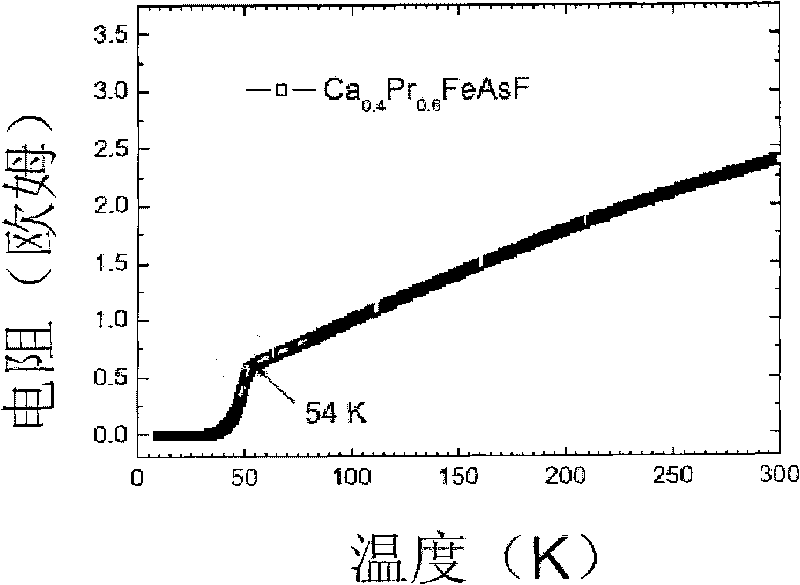

Iron-based superconducting material with single-phase calcium-fluorine structure and method for preparing same

InactiveCN101747040ARaise the superconducting transition temperatureChange charge concentrationSuperconductors/hyperconductorsSuperconductor devicesChemical reactionRare earth

The invention relates to an iron-based superconducting material and a method for preparing the same. The composition of the material is expressed by the following formula: (Ca1-xREx)FeAsF, wherein x is more than 0.2 and less than 0.6; and RE maybe La, Ce, Pr, Nd or Sm. The method for preparing the material comprises the following steps of: preparing samples of precursors of CaAs and REAs; and using rare earth metallic ions to partially replace Ca ions at a high temperature by the solid-state chemical reaction method and the ion doping mechanism so as to obtain the iron-based superconducting material with a calcium-fluorine structure. The superconducting transition temperature of the superconducting material is 30 to 56K, and the preparation method is simple; and the upper critical magnetic field of the superconducting material at a low temperature is estimated to be 120 teslas, so that the superconducting material is applicable in fields of superconducting power transmission, generation of strong magnetic fields and the like.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

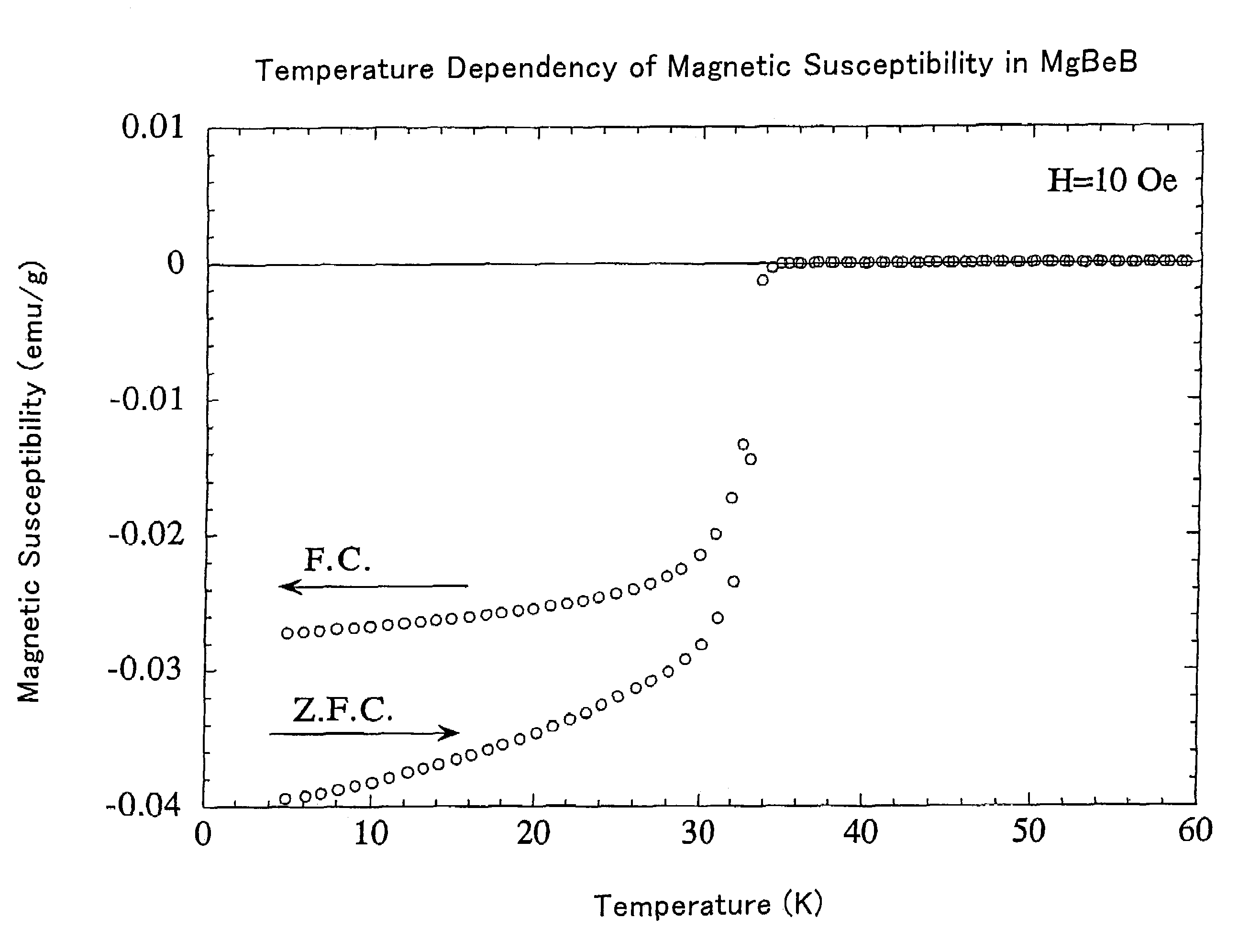

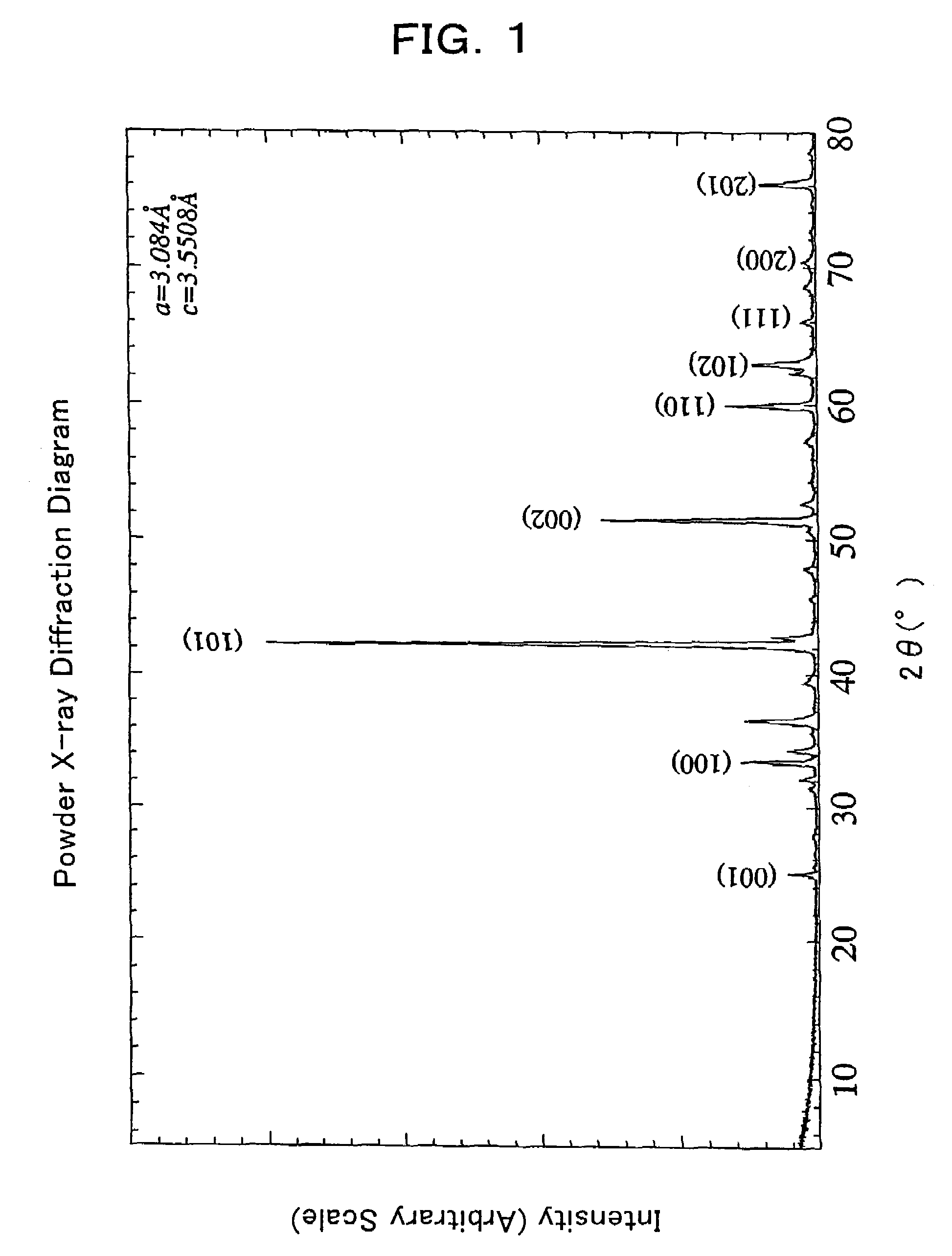

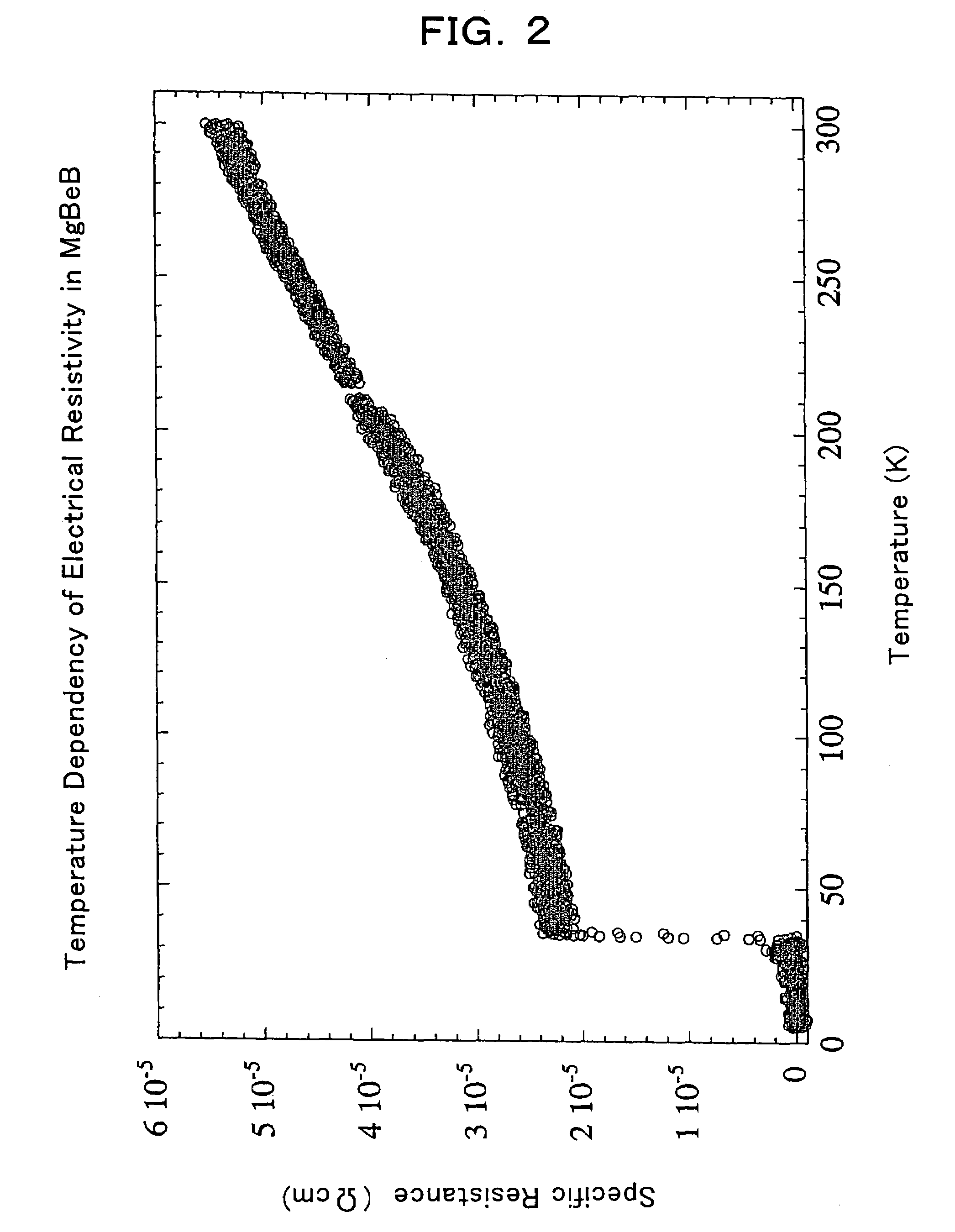

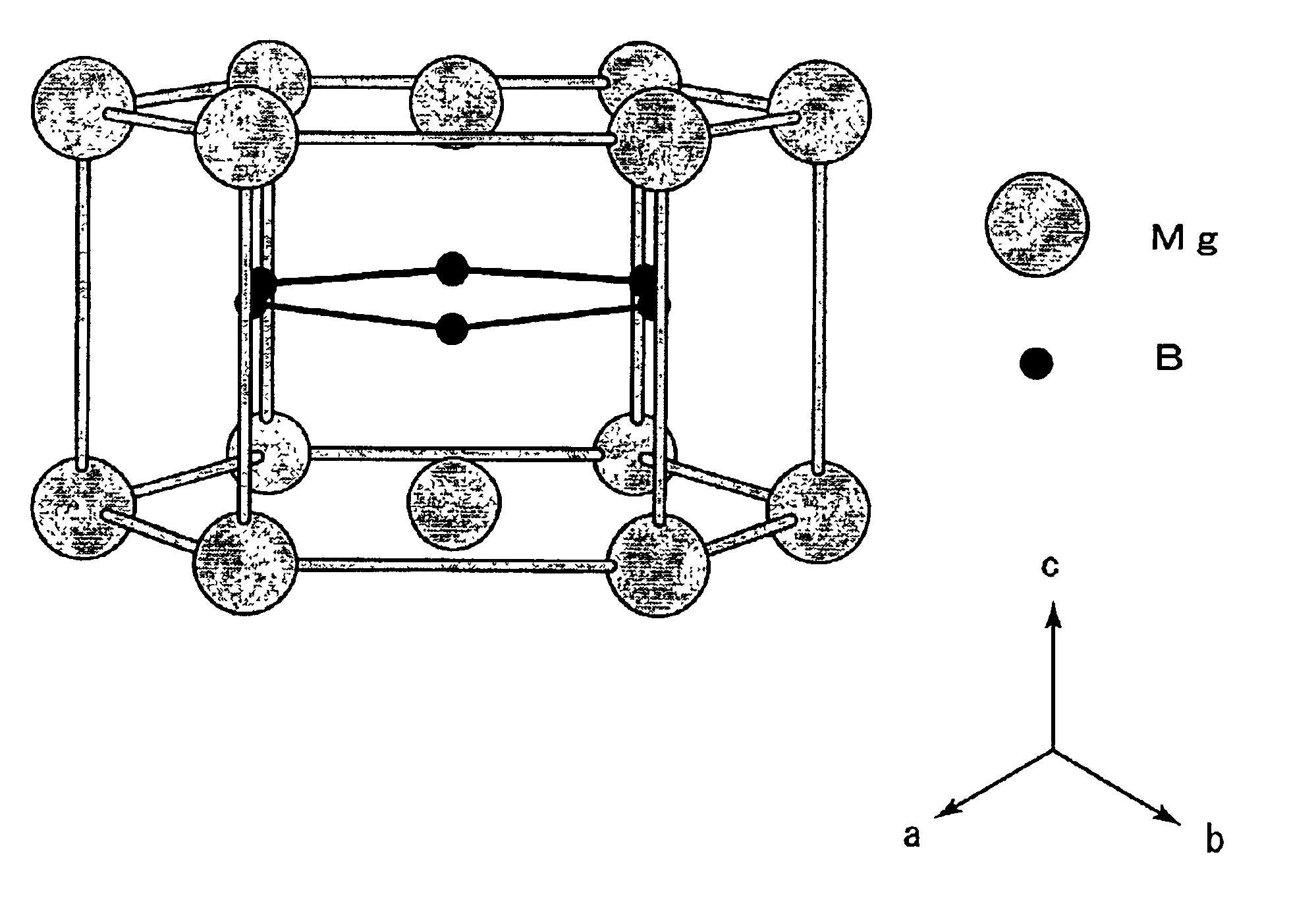

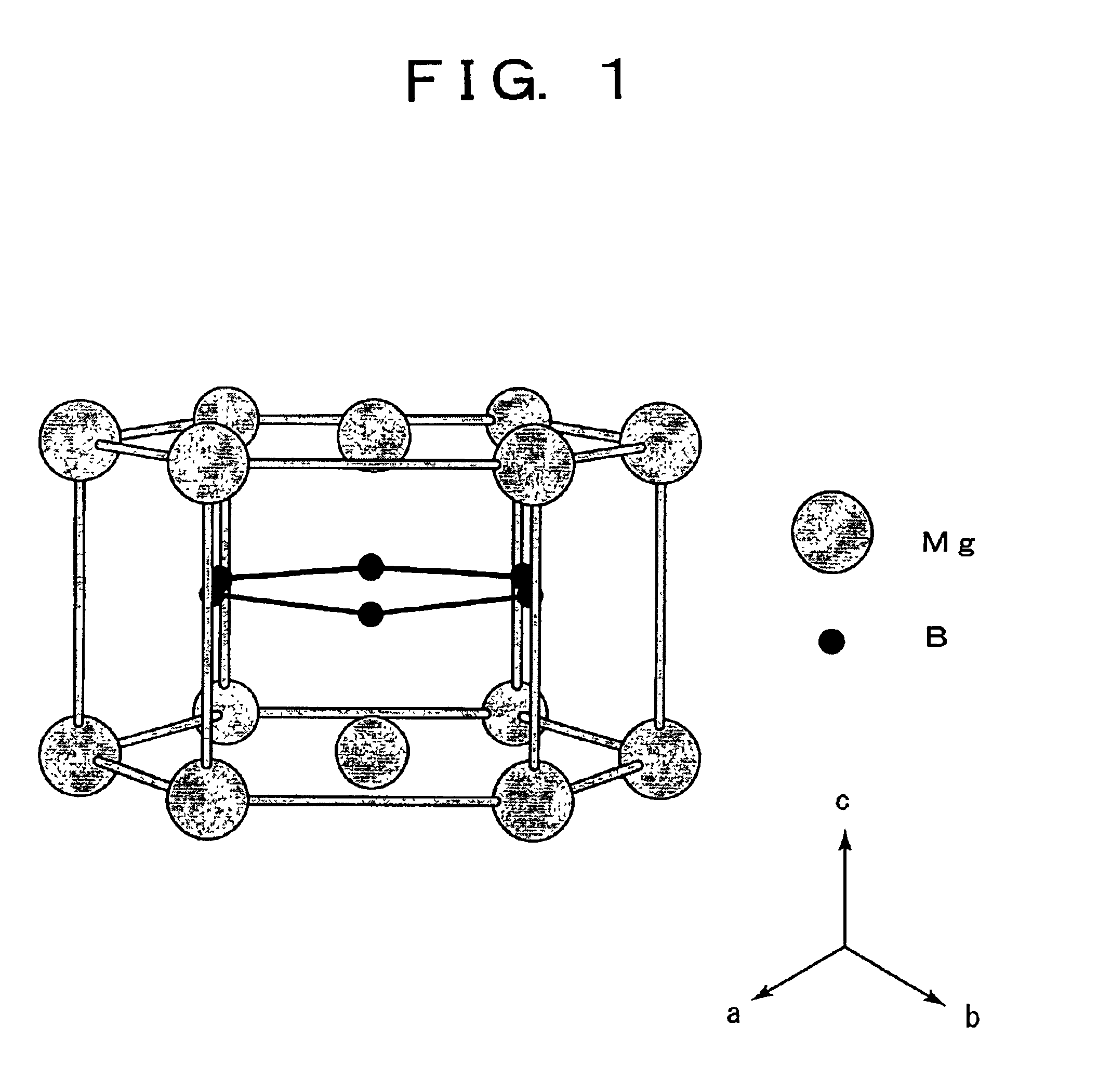

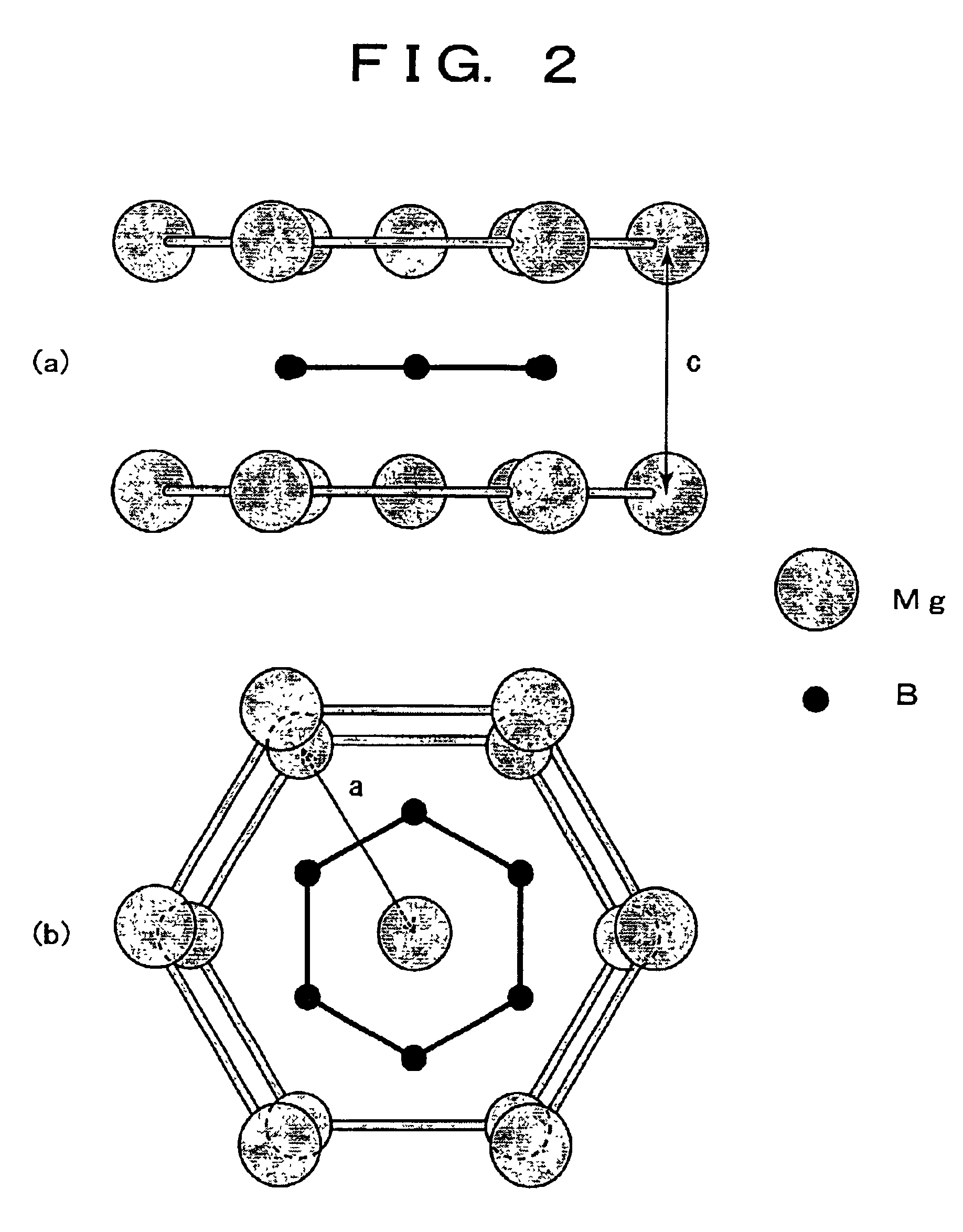

Intermetallic compound superconducting material comprising magnesium and beryllium and alloy superconducting material containing the intermetallic compound

InactiveUS7445681B2Easy to makeRaise the transition temperaturePolycrystalline material growthSuperconductors/hyperconductorsSuperconducting transition temperatureDuctility

There are provided an intermetallic-compound superconductor that is high in superconducting transition temperature, and an alloy superconductor that is high in superconducting transition temperature and excels in malleability and ductility, as well as a method of making such a superconductor with good reproducibility and at a low cost of manufacture. This entirely new intermetallic compound superconductor is made of magnesium (Mg) and beryllium (Be) and has a chemical composition expressed by formula: Mg1Be2, has a hexagonal AlB2 type crystallographic structure and has a superconducting transition temperature (Tc) of 35 K. An alloy containing this intermetallic compound excels in malleability and ductility and constitutes the alloy superconductor having a superconducting transition temperature (Tc) of 35 K and being low in specific resistance for normal conduction at a temperature ranging from the superconducting transition temperature to a room temperature. In the method of manufacture, a Mg containing feedstock powder and a Be containing feedstock powder are mixed together to form a mixture thereof which is, e.g., hot pressed to produce a semiconductor product.

Owner:JAPAN SCI & TECH CORP

Intermetallic compound superconductors and alloy superconductors, and method for their preparation

InactiveUS6956011B2Easy to makeRaise the transition temperatureSuperconductors/hyperconductorsSuperconductor detailsChemical compositionCrystal structure

There are provided an intermetallic compound superconductor that is high in superconducting transition temperature, and an alloy superconductor that is high in superconducting transition temperature and excels in malleability and ductility, as well as a method of making such a superconductor with good reproducibility and at a low cost of manufacture. This entirely new intermetallic compound superconductor is made of magnesium (Mg) and boron (B) and has a chemical composition expressed by formula: Mg1B2, has a hexagonal AlB2 type crystallographic structure and has a superconducting transition temperature (Tc) of 39 K. An alloy containing this intermetallic compound excels in malleability and ductility and constitutes the alloy superconductor having a superconducting transition temperature (Tc) of 39 K. In the method of manufacture, a Mg containing feedstock powder and a B containing feedstock powder are mixed together to form a mixture thereof which is, e.g., hot pressed to produce a semiconductor product.

Owner:AKIMITSU JUN +1

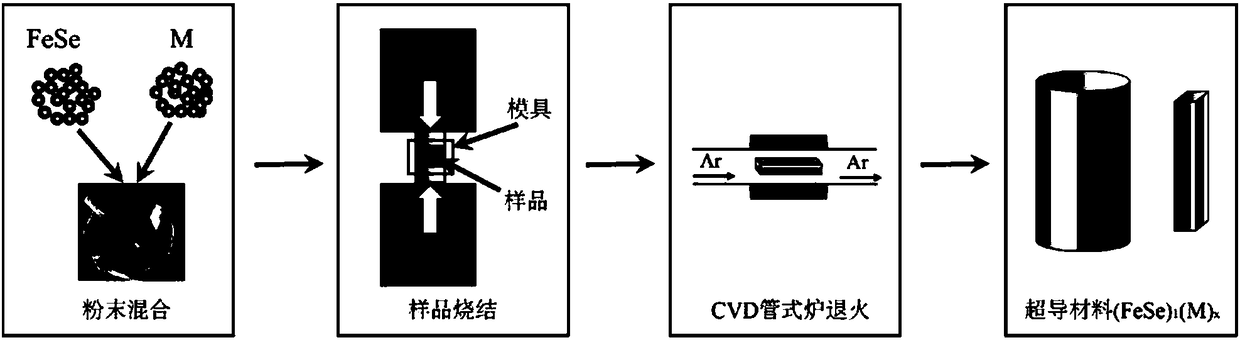

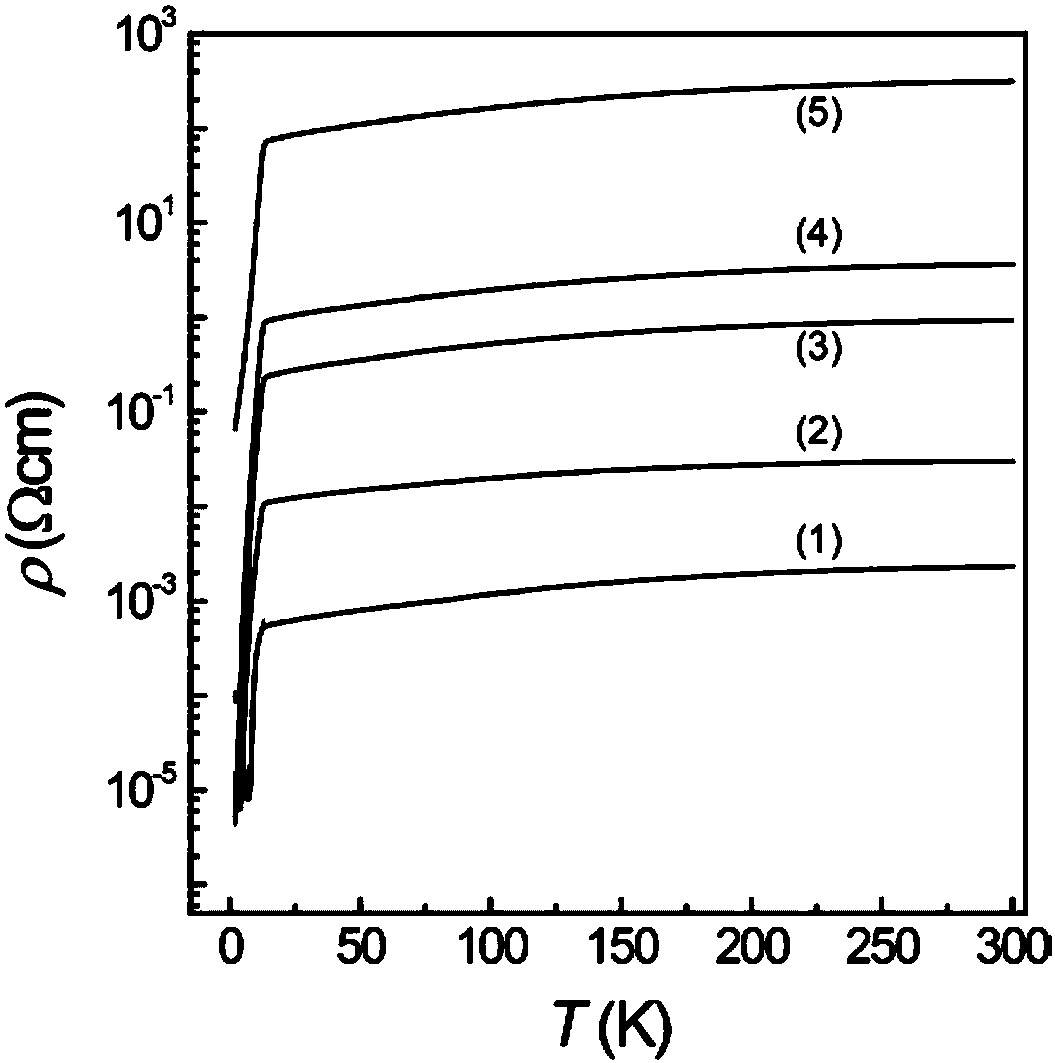

Method for preparing iron selenium superconducting material by spark plasma sintering technology

ActiveCN108666045APromote formationSuppression of FeSe non-superconducting phaseSuperconductors/hyperconductorsSuperconductor devicesSuperconducting CoilsSuperconducting transition temperature

The invention discloses a method for preparing iron selenium superconducting material by spark plasma sintering technology. The chemical formula of the iron selenium superconducting material is (FeSe)1(M)x, wherein the insulator M is one or more of SrTiO3, BaTiO3 and MgO, and the molar ratio of iron selenium (FeSe) to the insulator M is 1:x. The method for preparing the material includes: solid powder mixing, spark plasma sintering (SPS) and annealing. The powder of iron selenium and the powder of the insulator M are weighed respectively according to a certain molar ratio of 1:x, after mechanically grinding and mixing for a certain time, the mixed powder is subjected to spark plasma sintering at a suitable pressure and temperature, and then the sintered sample is annealed under suitable conditions to obtain (FeSe)1(M)x material. The material has a stable superconducting performance, and the superconducting transition temperature is between 10.10K and 13.44K. The material is not sensitive to the raw material ratio, and the value of x ranges from 0.2 to 15. Meanwhile, the material has a high upper critical field which can be up to 16.6T to 26.7T. Thereby the material can be applied in the fields of electric energy, superconducting magnets, biology, medical technology, communication, and microelectronics.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com