Iron-based superconducting material with single-phase calcium-fluorine structure and method for preparing same

A superconducting material, single-phase calcium technology, applied in the usage of superconducting elements, superconducting devices, superconducting/high-conducting conductors, etc., to achieve high superconducting transition temperature, reduce intermediate links, and save energy and time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

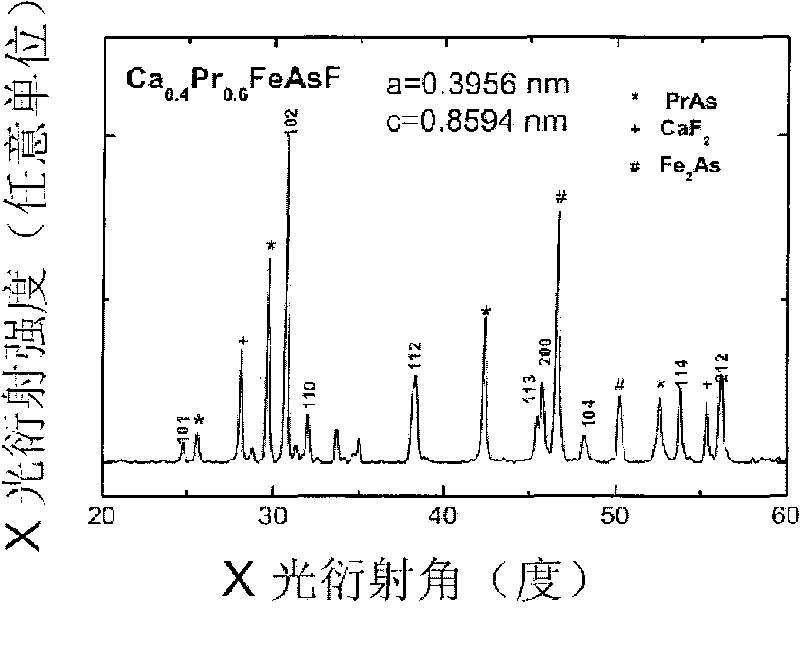

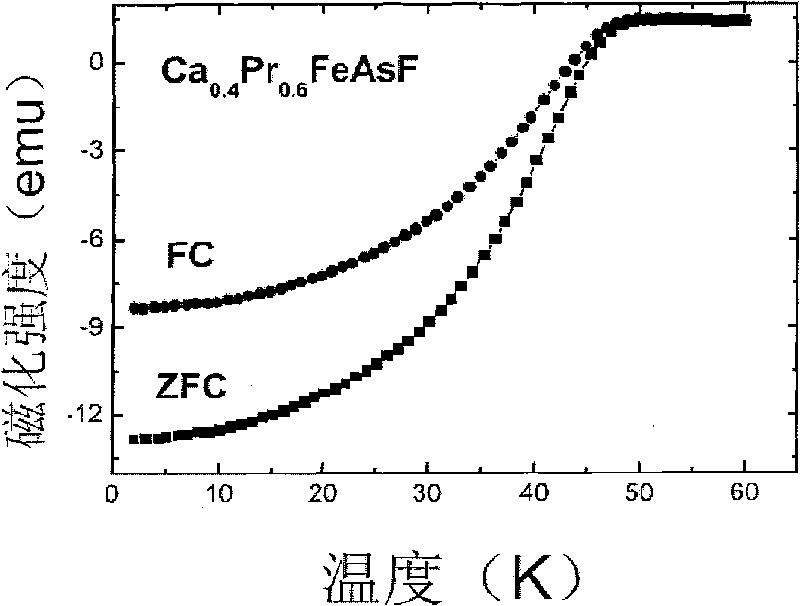

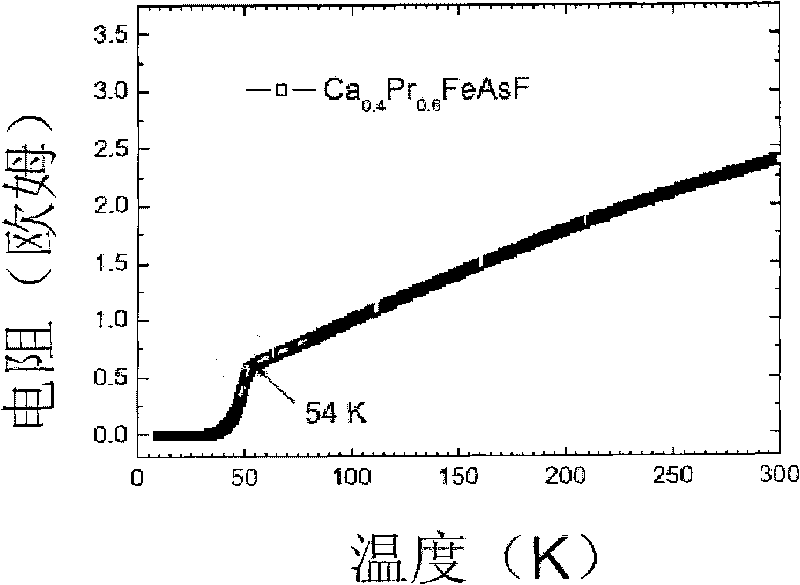

[0035] Direct synthesis of superconducting materials (Ca 1-x RE x ) FeAsF, wherein x=0.6, Re=Pr; Concrete steps are as follows

[0036] 1) Step 1: Preparing the precursor: using a solid-state reaction method, mix and grind 99.5% pure As particles and 99% pure Ca metal flakes (or Pr metal) at a molar ratio of 1:1 (as long as the grinding is uniform ), and then pressed into a small disc with a diameter of 10mm, wherein the tablet pressure is 2Mpa; sealed in a high vacuum (the vacuum in the tube is less than 10 -5 Pa) in a quartz tube or a high-melting-point metal tube, first slowly raise the temperature to 500°C for 12 hours, and then sinter at 780°C for 5-10 hours to obtain the CaAs or PrAs precursor;

[0037] 2) Step 2: Synthesis: Take the two precursors prepared in step 1), including CaAs and PrAs;

[0038] CaAs, PrAs, Fe powder and FeF 2 The powder is weighed according to the molar ratio of (1-x): (x): 0.5: 0.5;

[0039] Among them x=0.6; Namely according to (Ca 1-x PR...

Embodiment 2

[0042] Synthesis of superconducting materials (Ca 1-x RE x ) FeAsF, where x=0.6, RE=Nd, the operation steps are as follows

[0043] 1) Step 1: Precursor preparation: using a solid state reaction method, mix and grind 99.5% pure As particles and 99% pure Ca metal flakes (or Nd metal) at a molar ratio of 1:1, and then press them into a diameter of 10mm Small discs (tabletting pressure 3Mpa), sealed in a high-vacuum quartz tube or a high-melting point metal tube, first slowly raised the temperature to 500 ° C for 12 hours, and then sintered at 780 ° C for 10 hours, That is, CaAs or NdAs compounds are obtained;

[0044] 2) Step 2: Synthesis: take the precursor prepared in step 1), including CaAs and NdAs;

[0045] with Fe and FeF 2 , by (1-x): (x): 0.5: 0.5 molar ratio weighing;

[0046] Among them x=0.6; Namely according to (Ca 1-x Nd x ) FeAsF cationic stoichiometric weighing, mixing and grinding (grinding process can also be carried out in an inert gas glove box), then t...

Embodiment 3

[0049] Synthesis of superconducting materials (Ca 1-x RE x ) FeAsF, where x=0.6, RE=La, the operation steps are as follows

[0050] 1) Step 1: Precursor preparation: using a solid state reaction method, 99.5% pure As particles and 99% pure Ca metal flakes (or La metal) were mixed and ground at a molar ratio of 1:1, and then pressed into a diameter of 10mm Small discs (tabletting pressure 3Mpa), sealed in a high-vacuum quartz tube or a high-melting point metal tube, first slowly heated to 500 ° C for 12 hours, and then sintered at 780 ° C for 10 hours , to obtain CaAs or LaAs compounds;

[0051] 2) Step 2: Synthesis: take the precursor prepared in step 1), including CaAs and LaAs;

[0052] with Fe and FeF 2 , by (1-x): (x): 0.5: 0.5 molar ratio weighing;

[0053] Among them x=0.6; Namely according to (Ca 1-x La x ) FeAsF cationic stoichiometric weighing, mixing and grinding (grinding process can also be carried out in an inert gas glove box), then tablet, sealed in high ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com