A rapid preparation of high-quality fese 0.5 te 0.5 Superconducting polycrystalline method

A fese0.5te0.5, high-quality technology, applied in chemical instruments and methods, selenium/tellurium compounds, inorganic chemistry, etc., to achieve the effects of simplified process flow, convenient preparation process, and shortened process cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Fe powder with a purity of 99.99%, Te lumps with a purity of 99.99%, and Se particles with a purity of 99.99% are prepared in the air at an atomic ratio of 1:0.5:0.5 and put into a quartz tube with one end sealed. middle. Seal the other port of the quartz tube containing the raw material powder with an acetylene welding torch. Put the quartz tube with the raw materials sealed at both ends into a quartz tube with a larger diameter, and seal the two ends. Put the above-mentioned quartz tube with a larger diameter sealed at both ends into a box furnace and sinter at 880 degrees for 3 days. After the box furnace is naturally cooled to room temperature, high-quality FeSe can be obtained. 0.5 Te 0.5 Superconducting polycrystalline.

Embodiment 2

[0034] Fe powder with a purity of 99.99%, Te lumps with a purity of 99.99%, and Se particles with a purity of 99.99% are prepared in the air at an atomic ratio of 1:0.5:0.5 and put into a quartz tube with one end sealed. middle. Seal the other port of the quartz tube containing the raw material powder with an acetylene welding torch. Put the quartz tube with the raw materials sealed at both ends into a quartz tube with a larger diameter, and seal the two ends. Put the above-mentioned quartz tube with a larger diameter sealed at both ends into a box furnace and sinter at a temperature of 880 degrees for 5 days. After the box furnace is naturally cooled to room temperature, high-quality FeSe can be obtained. 0.5 Te 0.5 Superconducting polycrystalline.

Embodiment 3

[0036]Fe powder with a purity of 99.99%, Te lumps with a purity of 99.99%, and Se particles with a purity of 99.99% are prepared in the air at an atomic ratio of 1:0.5:0.5 and put into a quartz tube with one end sealed. middle. Seal the other port of the quartz tube containing the raw material powder with an acetylene welding torch. Put the quartz tube with the raw materials sealed at both ends into a quartz tube with a larger diameter, and seal the two ends. Put the above-mentioned quartz tube with a larger diameter sealed at both ends into a box furnace and sinter at a temperature of 850 degrees for 3 days. After the box furnace is naturally cooled to room temperature, high-quality FeSe can be obtained. 0.5 Te 0.5 Superconducting polycrystalline.

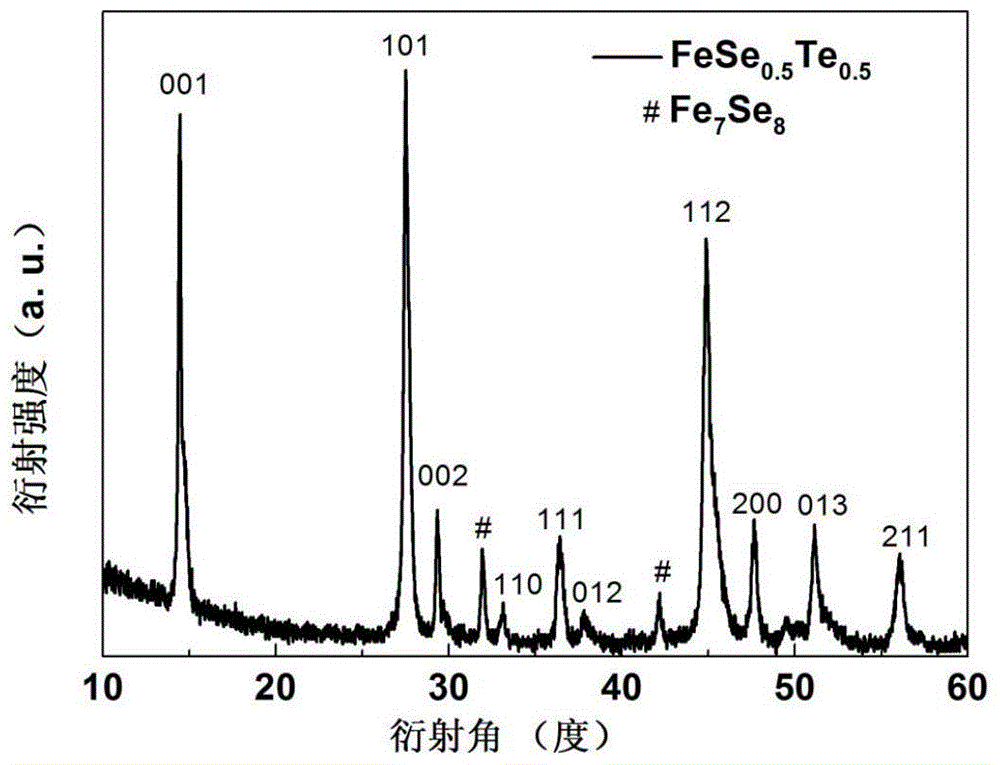

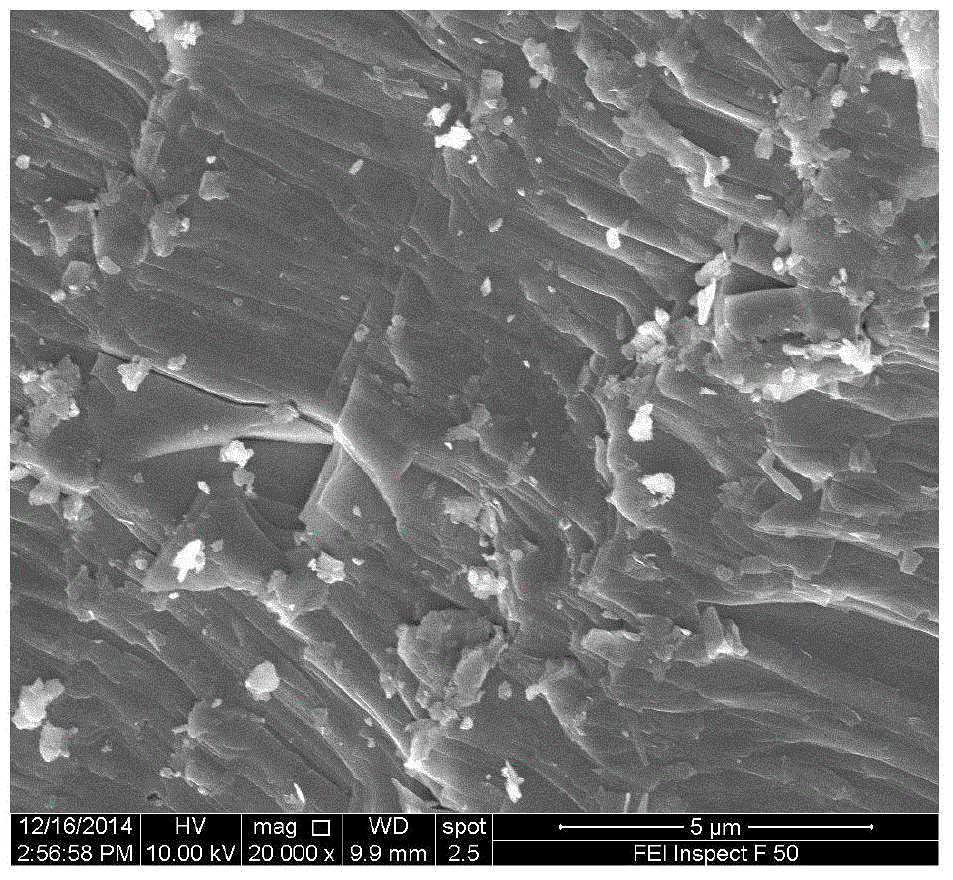

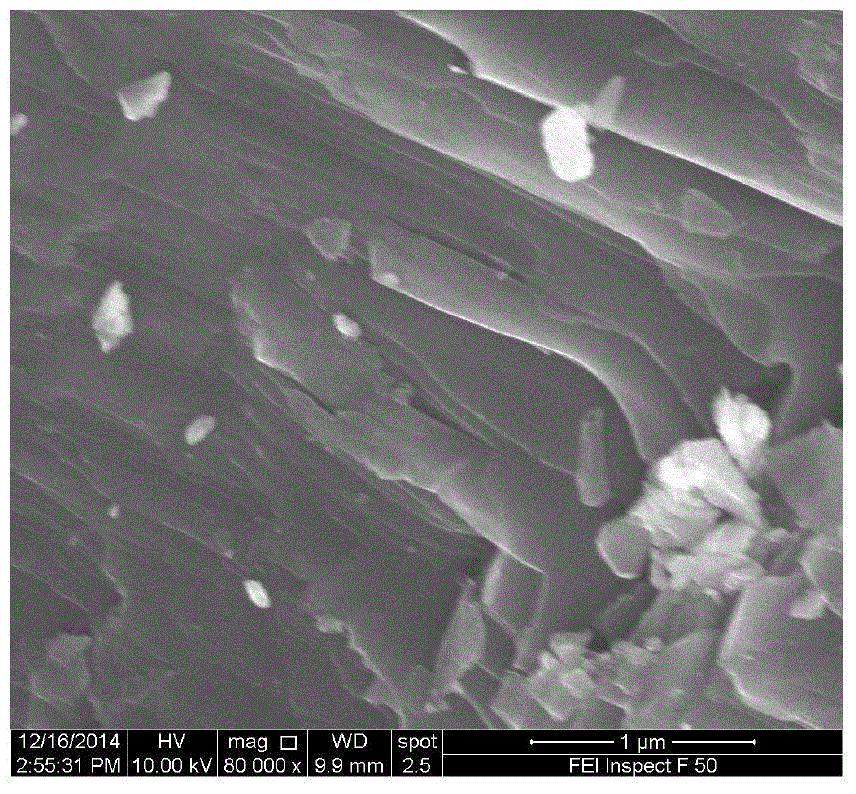

[0037] combine Figure 1 to Figure 4 The superconducting polycrystals obtained in the above examples will be described. Such as figure 1 As shown, FeSe 0.5 Te 0.5 A polycrystalline superconducting phase has formed. figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com