A kind of metal-based superconducting tape and preparation method thereof

A technology of superconducting tape and metal base tape, which is applied in the field of superconductors, achieves huge commercial value, reduces preparation costs, and has the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] In this embodiment, the preparation method of the metal-based superconducting tape includes the following steps:

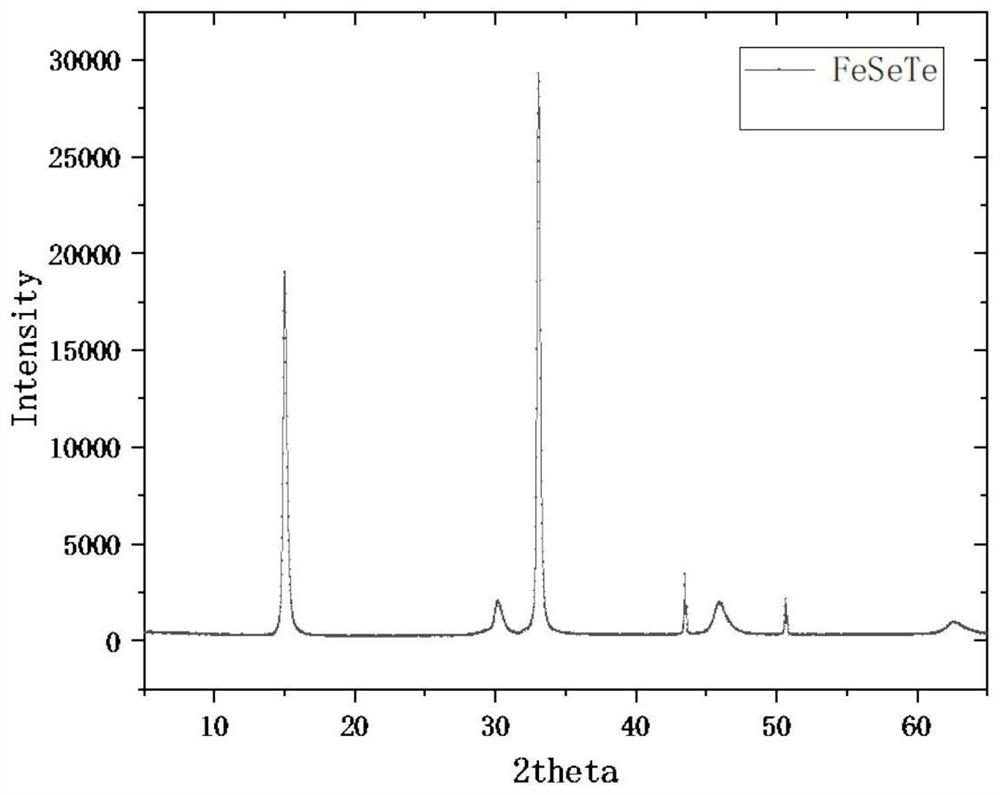

[0052] 1) Iron, selenium and tellurium are mixed in a molar ratio of 1:0.2:0.8 and then ground into powder, and the sieve balance of the powder passing through a 200-mesh sieve is 1%. The ground powder is mixed and compressed into tablets, and packaged. Heating to 500°C in a quartz tube and holding for 10h, sintering at 750°C for 12h, cooling down, and cooling to room temperature to obtain a target.

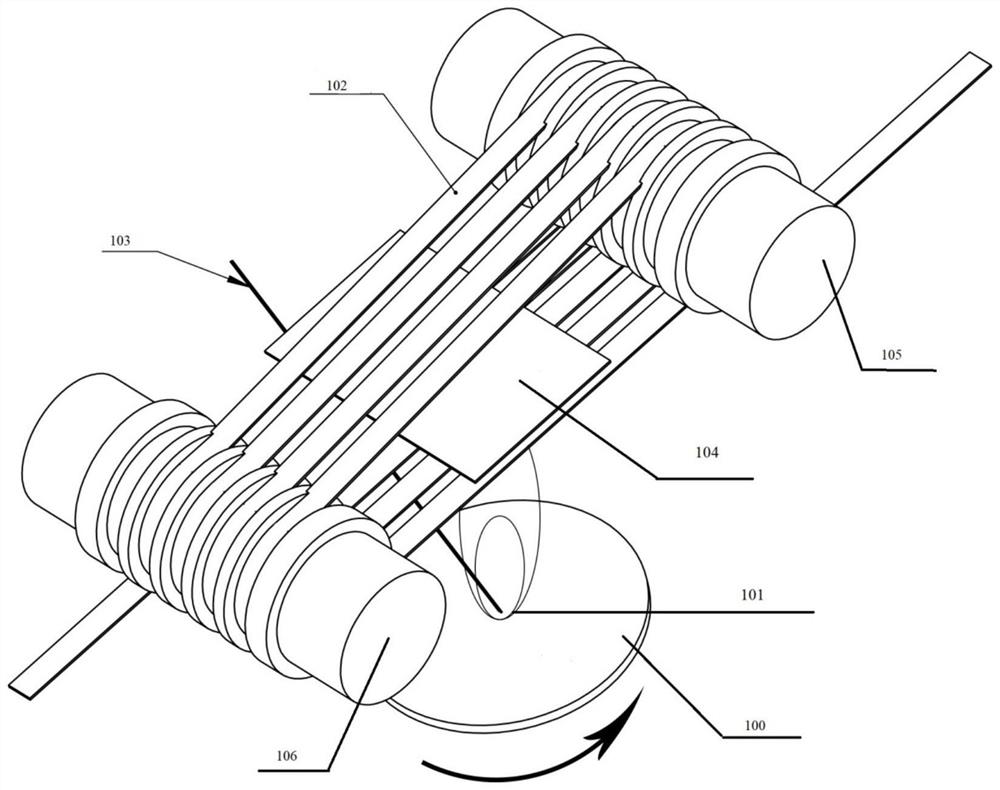

[0053] 2) Put the prepared target material on the target base of the vacuum coating chamber of the multi-channel pulsed laser deposition system, and simultaneously wrap the metal base tape of C276 Hastelloy material on the unwinding of the vacuum coating chamber of the multi-channel pulsed laser deposition system. In the plate, the vacuum coating chamber is evacuated to a vacuum degree of 4 × 10 -7 Torr.

[0054] 3) Start to use the multi-channel pulsed lase...

Embodiment 2

[0058] In this embodiment, the preparation method of the metal-based superconducting tape includes the following steps:

[0059] 1) Iron, selenium and tellurium are mixed in a molar ratio of 1:0.3:0.7 and then ground into powder, and the sieve balance of the powder passing through a 200-mesh sieve is 1%. The ground powder is mixed and compressed into tablets, and packaged. Heating to 500°C in a quartz tube and holding for 10h, sintering at 750°C for 12h, cooling down, and cooling to room temperature to obtain a target.

[0060] 2) Put the prepared target material on the target base of the vacuum coating chamber of the multi-channel pulsed laser deposition system, and simultaneously wrap the metal base tape of C276 Hastelloy material on the unwinding of the vacuum coating chamber of the multi-channel pulsed laser deposition system. In the plate, the vacuum coating chamber is evacuated to a vacuum degree of 3 × 10 -7 Torr.

[0061] 3) Start to use the multi-channel pulsed lase...

Embodiment 3

[0068] In this embodiment, the preparation method of the metal-based superconducting tape includes the following steps:

[0069] 1) Iron, selenium and tellurium are mixed in a molar ratio of 1:0.4:0.6 and then ground into powder. The powder passes through a 200-mesh sieve with a sieve balance of 1%. The ground powder is mixed and compressed into tablets, and packaged. Heating to 500°C in a quartz tube and holding for 10h, sintering at 750°C for 12h, cooling down, and cooling to room temperature to obtain a target.

[0070] 2) Put the prepared target material on the target base of the vacuum coating chamber of the multi-channel pulsed laser deposition system, and simultaneously wrap the metal base tape of Ni-W alloy material on the unwinding of the vacuum coating chamber of the multi-channel pulsed laser deposition system. In the plate, the vacuum coating chamber is evacuated to a vacuum degree of 4 × 10 -7 Torr. Among them, the content of W in the Ni-W alloy material is 4 at...

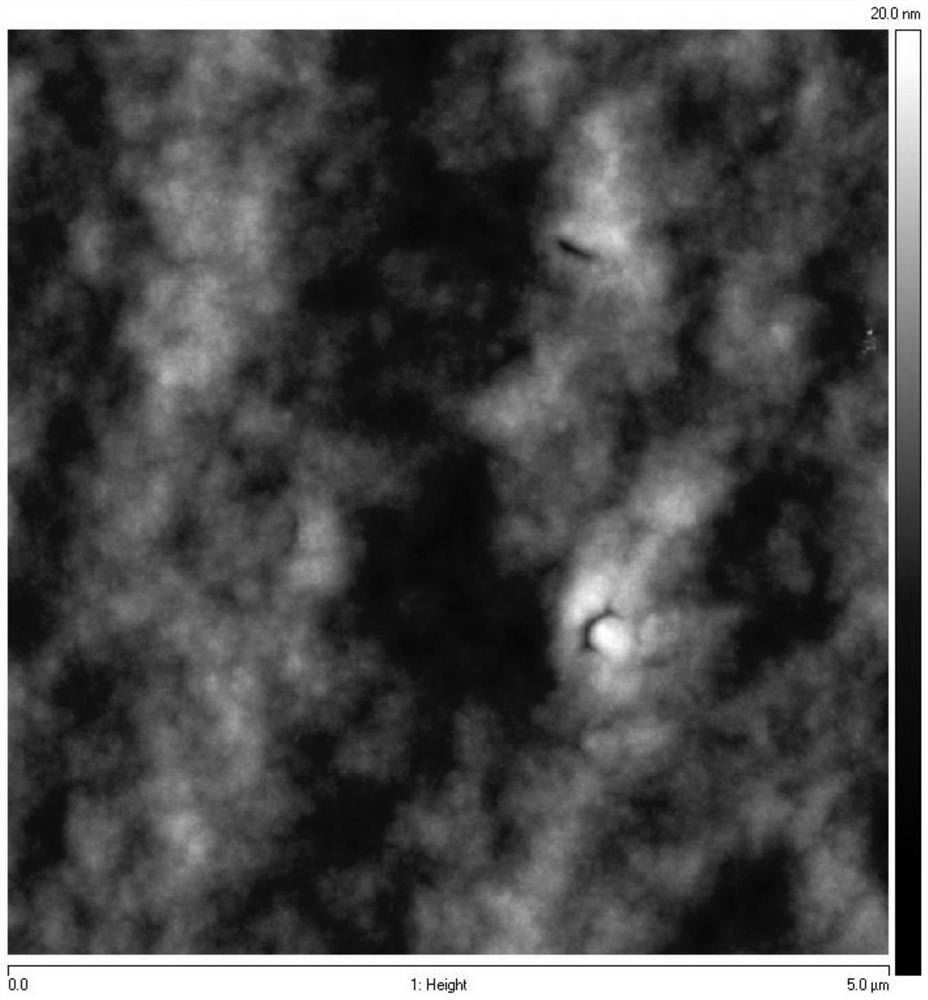

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com