Preparation method of titanium oxide superconducting thin film

A technology of titanium oxide and superconducting thin film, which is applied in the field of preparation of titanium oxide superconducting thin film, to achieve the effect of simplifying the growth process and increasing the superconducting transition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

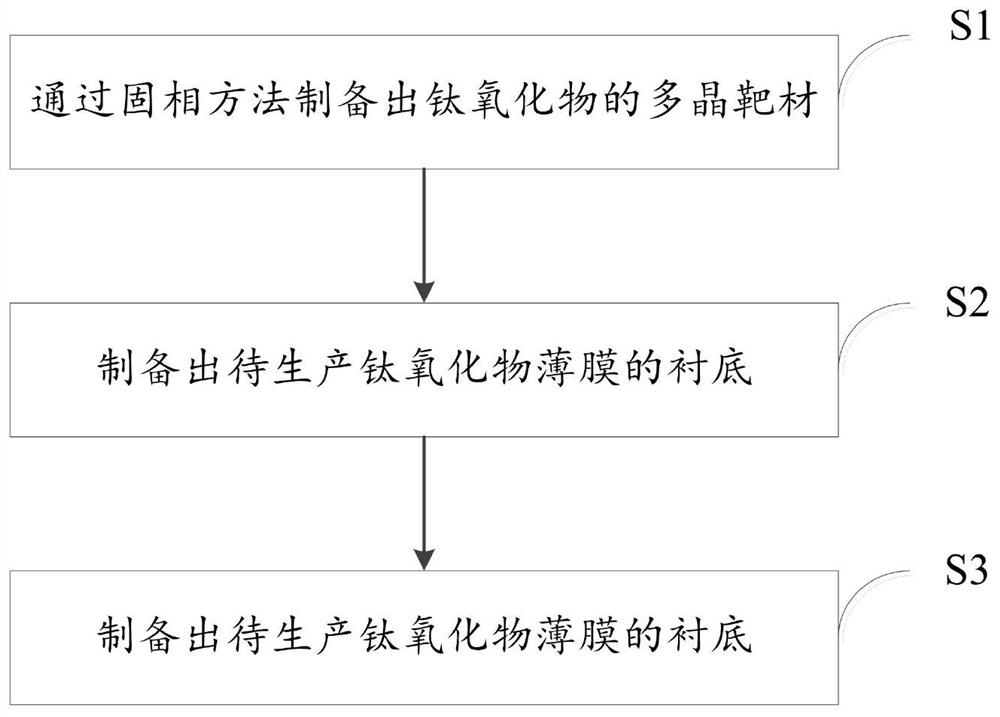

[0045] This embodiment one provides a kind of preparation method of titanium oxide superconducting thin film, such as figure 1 shown, including the following steps:

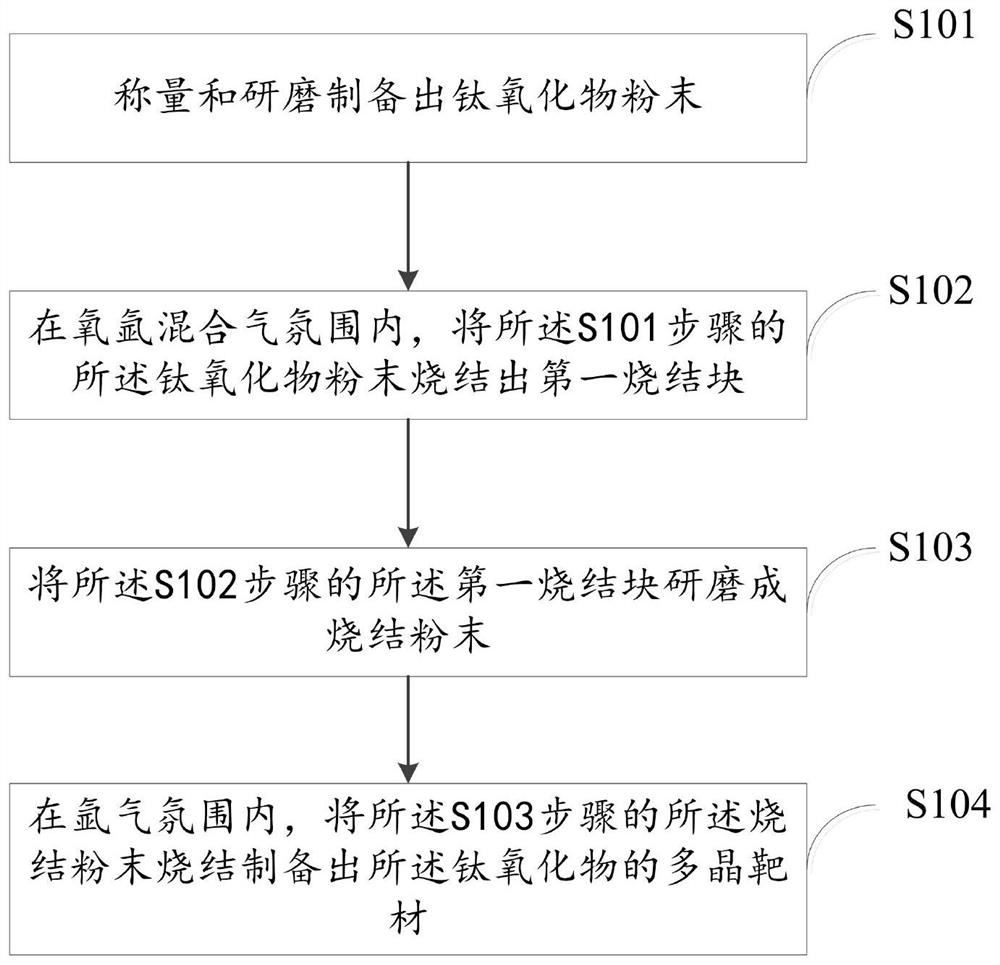

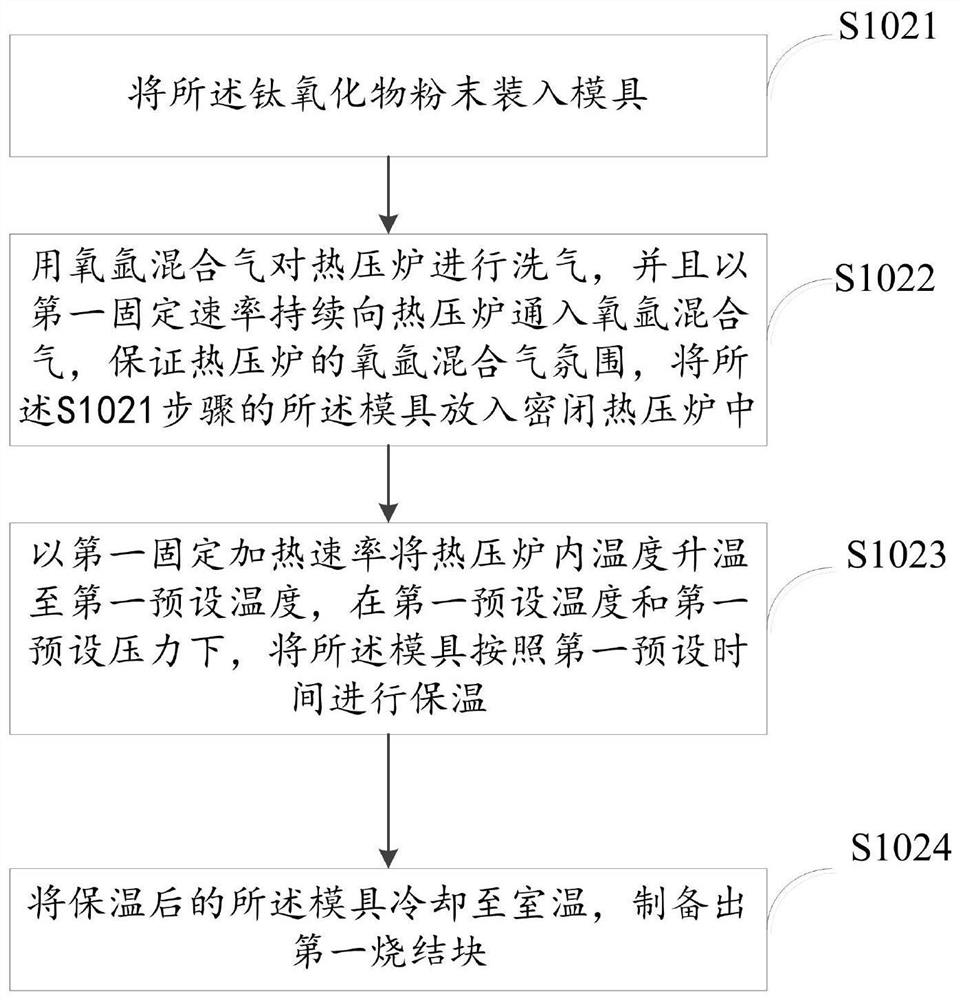

[0046] S1. A polycrystalline target of titanium oxide is prepared by a solid-state method;

[0047] S2. Prepare the substrate for the titanium oxide superconducting thin film to be produced;

[0048] S3, ablate the target material in the step S1 by using a pulsed laser deposition system, and make the ablated target material epitaxy on the substrate in the step S2 to prepare a titanium oxide superconducting thin film.

[0049] Specifically, the polycrystalline target material of the titanium oxide is partially Ti2 o 3 Has been transformed into Ti 3 o 5 polycrystalline target.

[0050] Specifically, the substrate is a hexagonal oxide substrate, and the hexagonal oxide substrate is α-Al 2 o 3 , however, the hexagonal oxide substrate includes but is not limited to α-Al 2 o 3 , where α-Al 2 o 3 It is a typi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com