Patents

Literature

62 results about "Self-diffusion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

According to IUPAC definition, self-diffusion coefficient is the diffusion coefficient of species when the chemical potential gradient equals zero. Here, is the activity of the species in the solution and is the concentration of . This term is commonly assumed to be equal to the tracer diffusion determined by watching the movement of an isotope in the material of interest.

Copper alloy and liquid-crystal display device

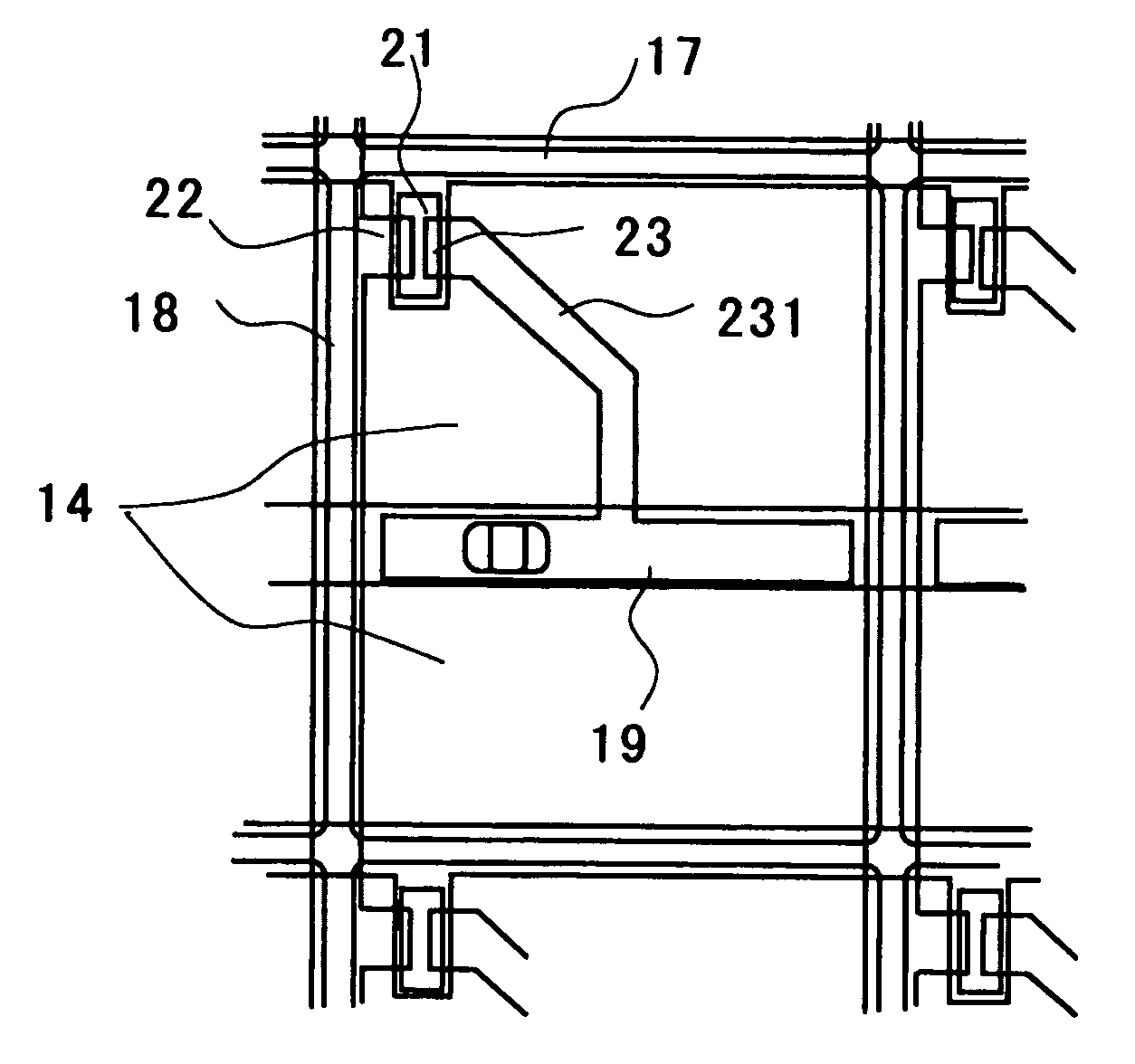

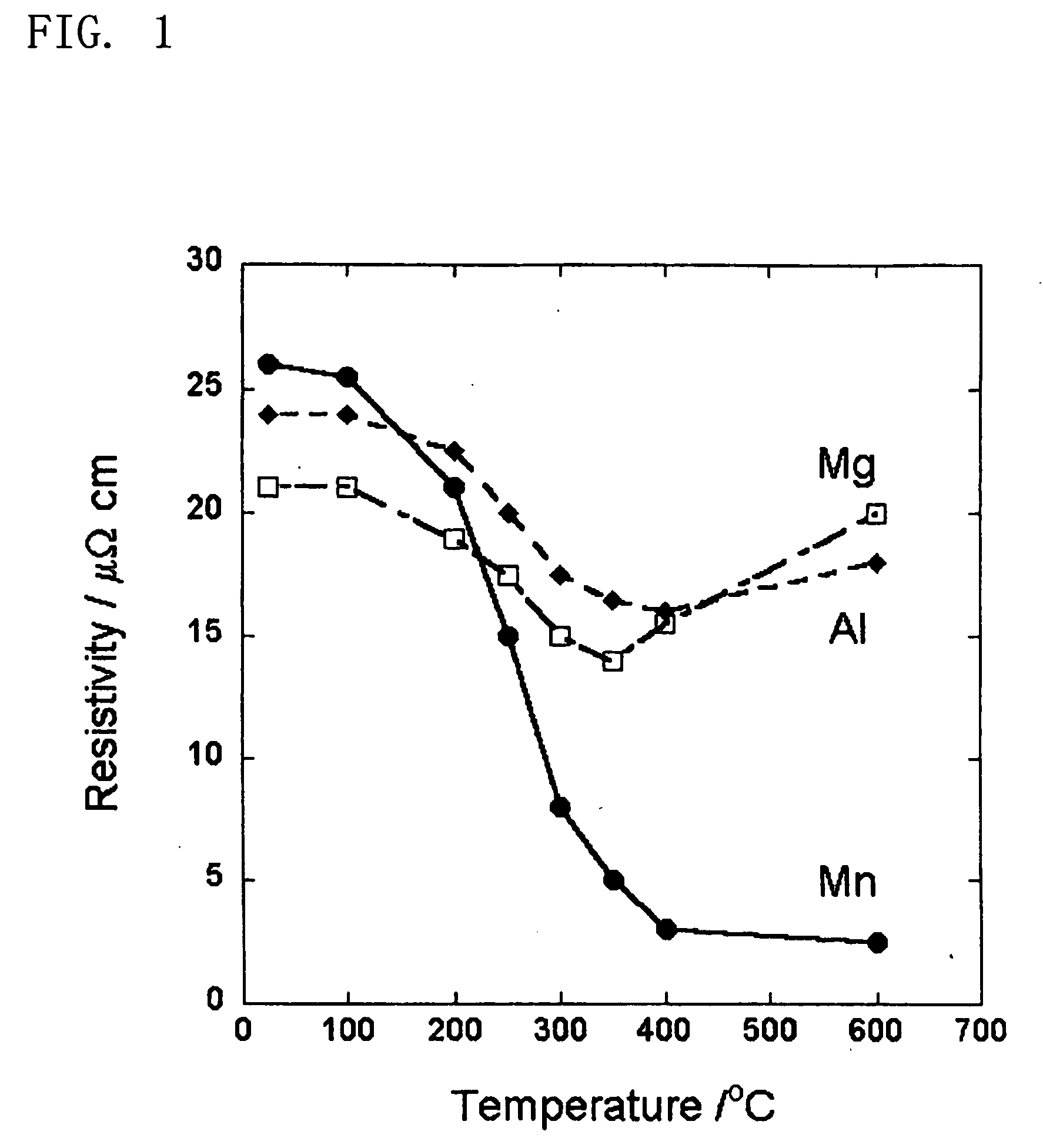

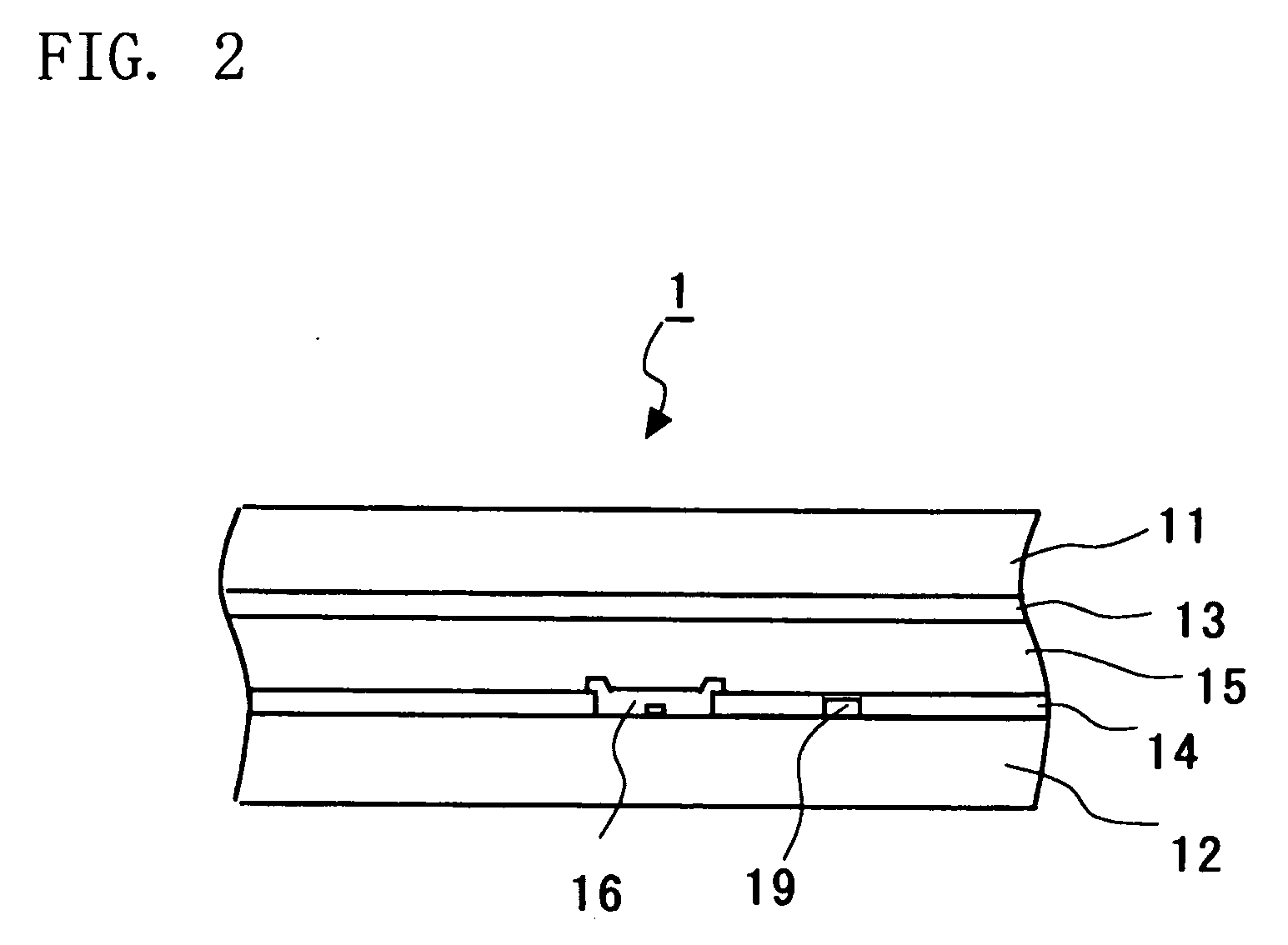

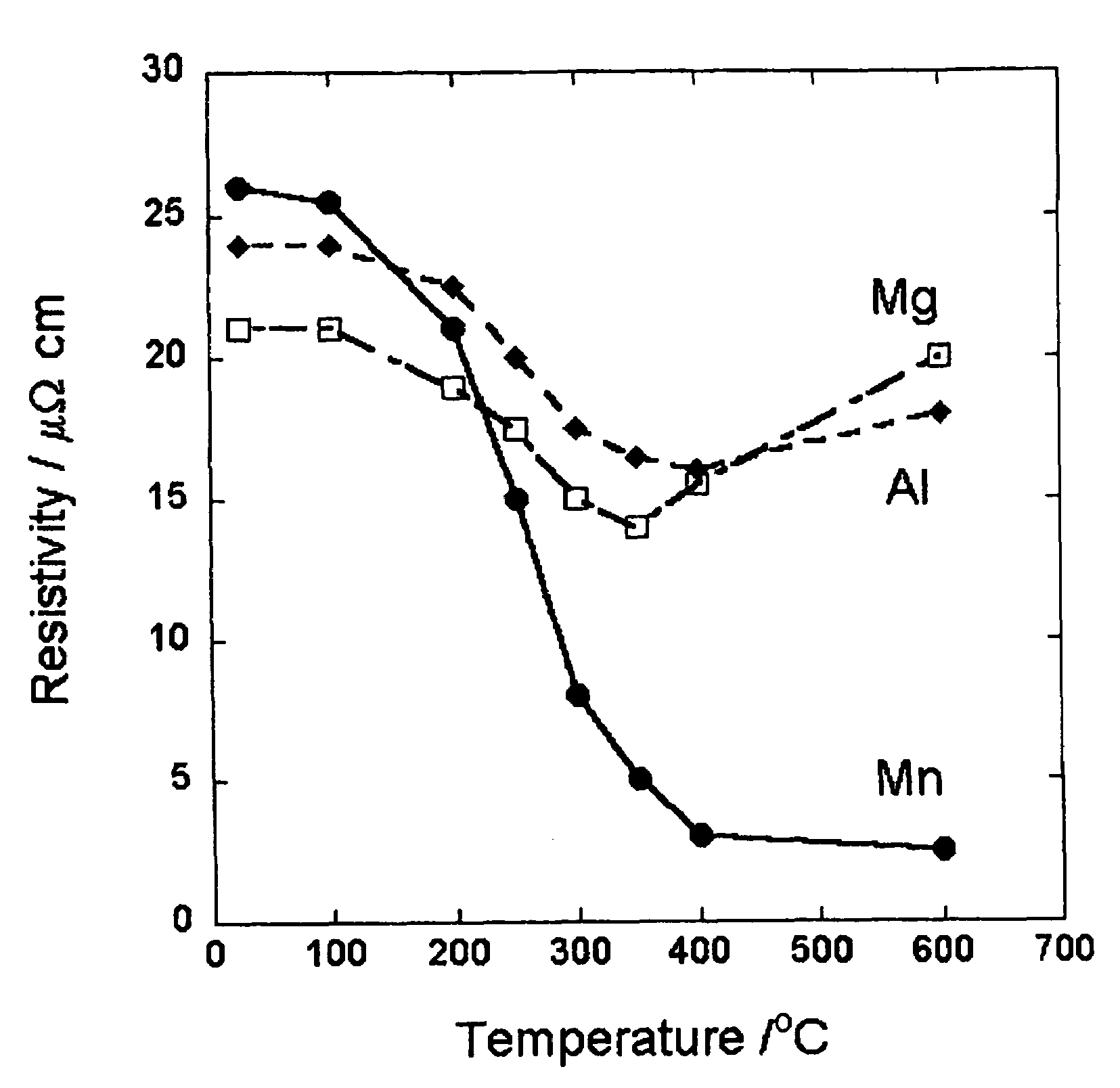

ActiveUS20070002239A1Well formedSolid-state devicesSemiconductor/solid-state device manufacturingDiffusionSelf-diffusion

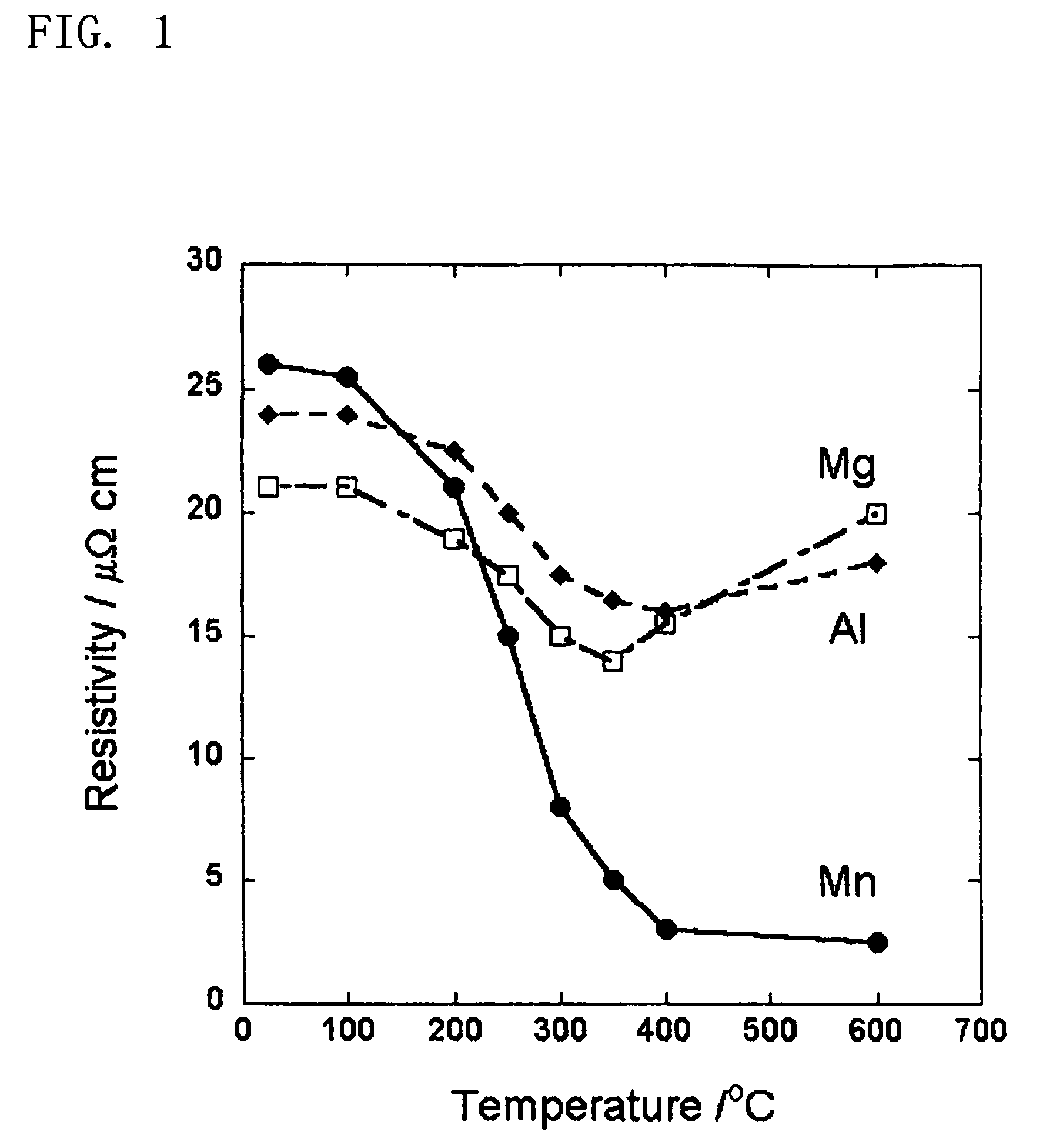

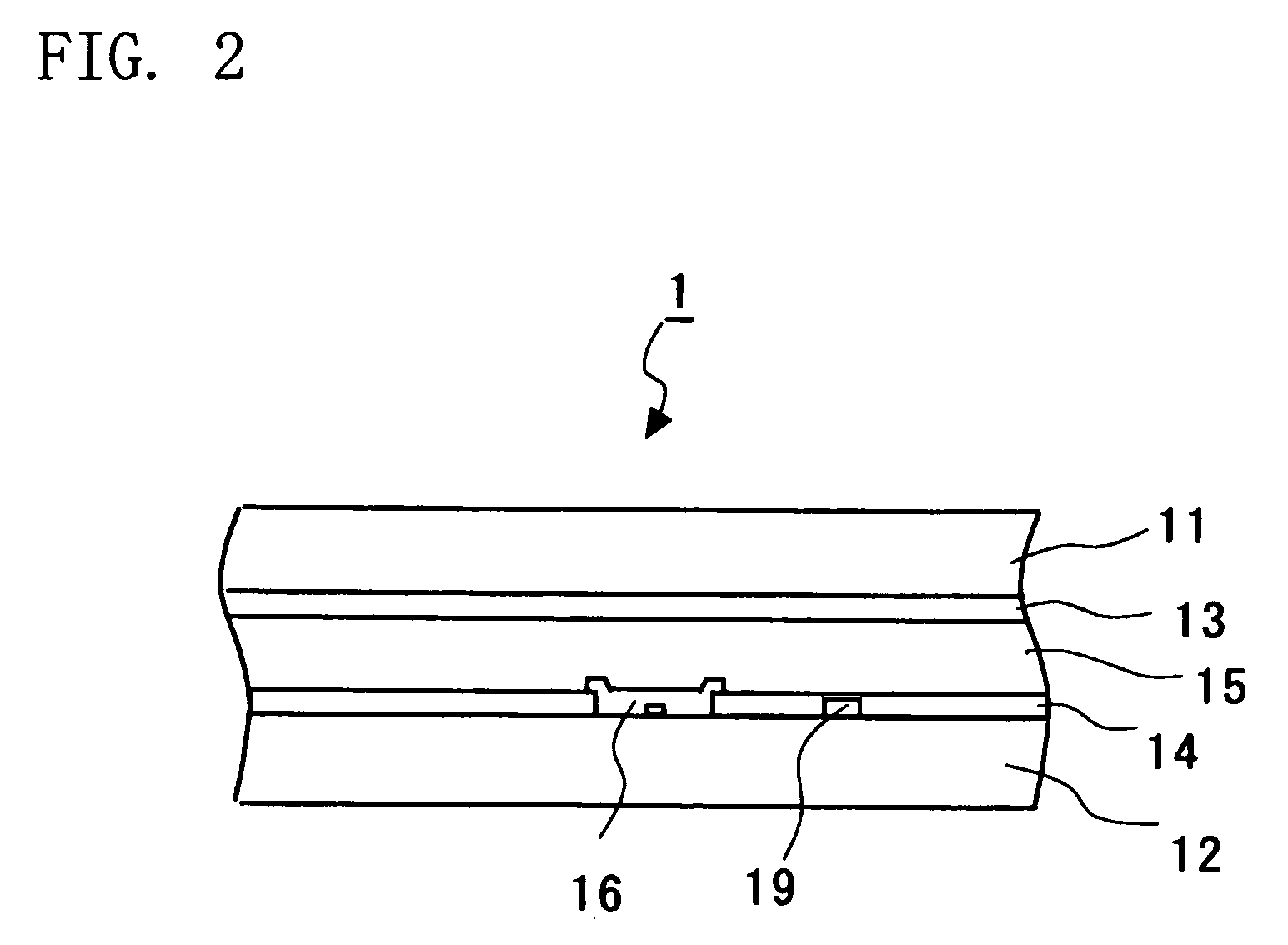

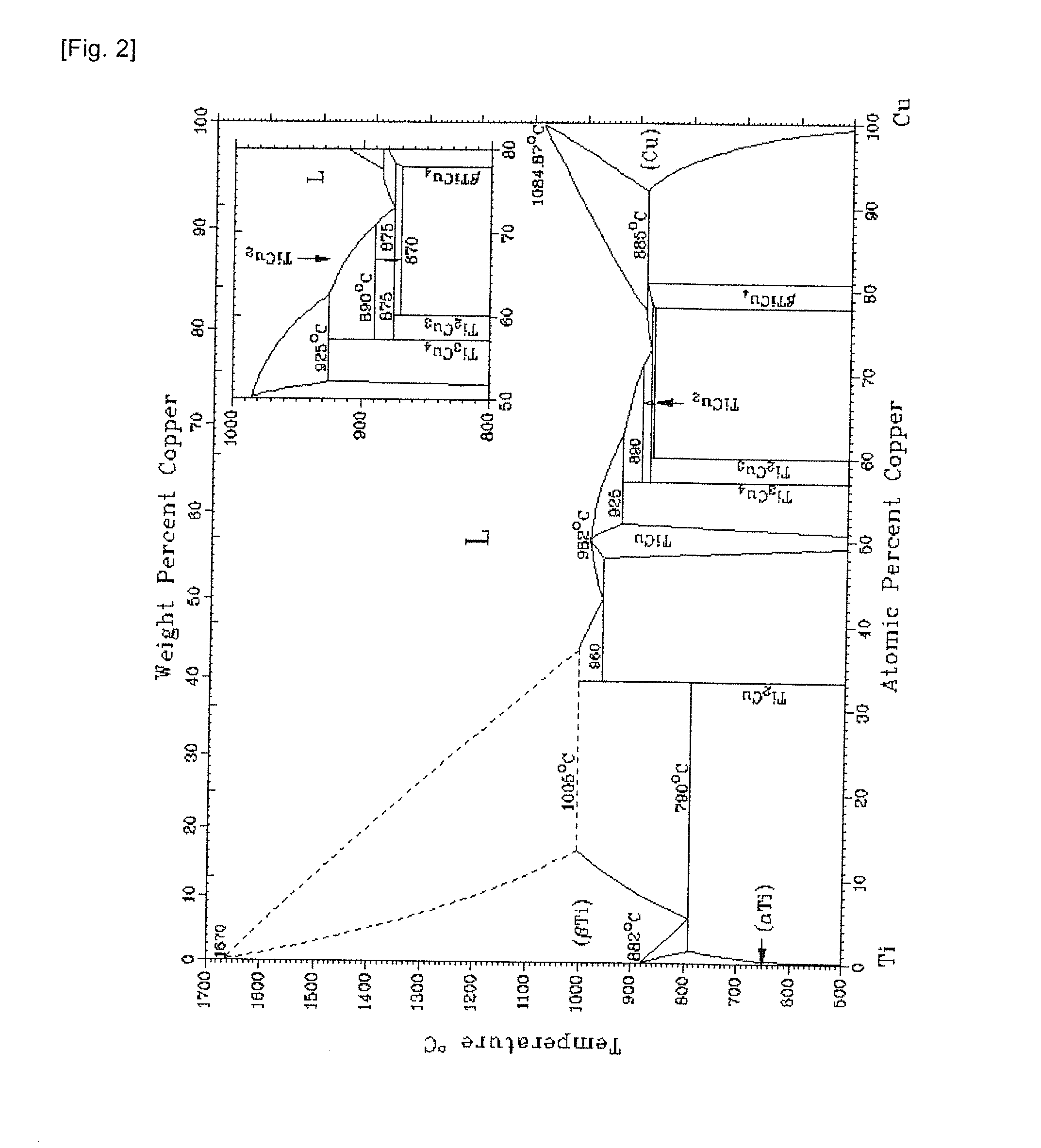

To provide a highly conductive Cu alloy which is advantageous in that an alloying element added to Cu is first reacted with oxygen contained in a gas atmosphere or solid in contact with the Cu member to form an oxide film which can prevent oxidation of Cu. The copper alloy comprises copper (Cu) containing an inevitable impurity, and an element added to the copper, wherein the added element is capable of being dissolved in the copper in an amount of 0.1 to 20 at. %, wherein the added element has an oxide formation free energy smaller than that of Cu and has a diffusion coefficient in Cu larger than the self-diffusion coefficient of Cu.

Owner:XENOGENIC DEV LLC

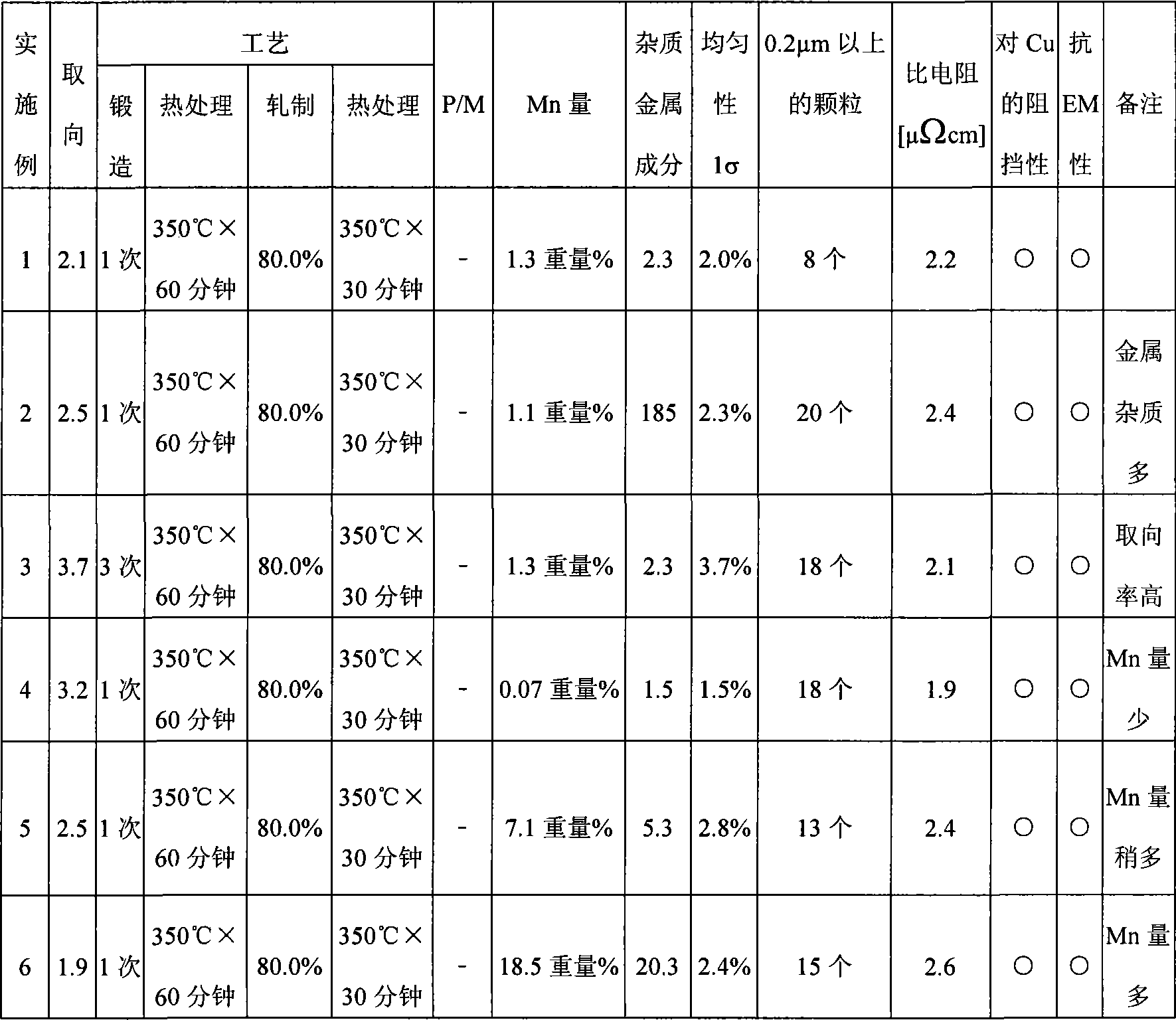

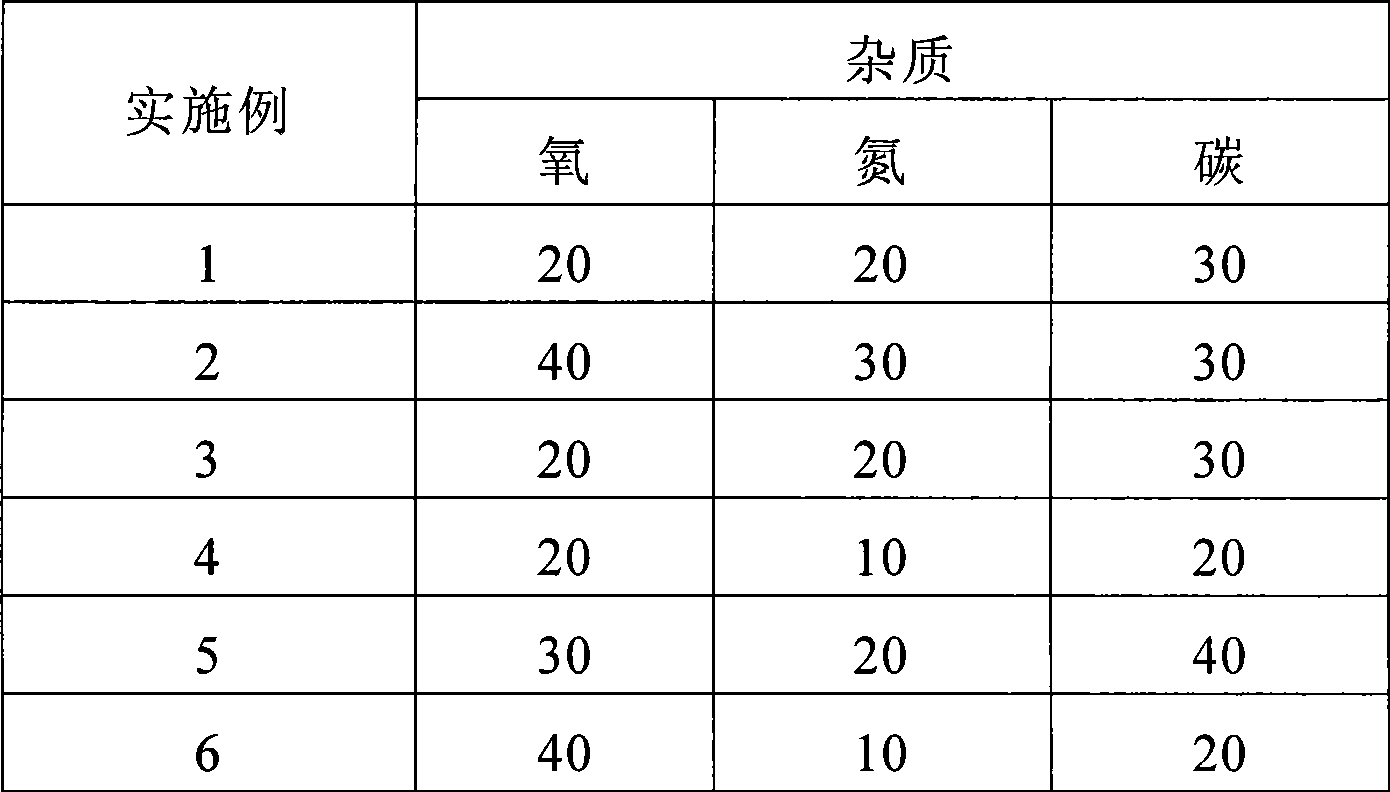

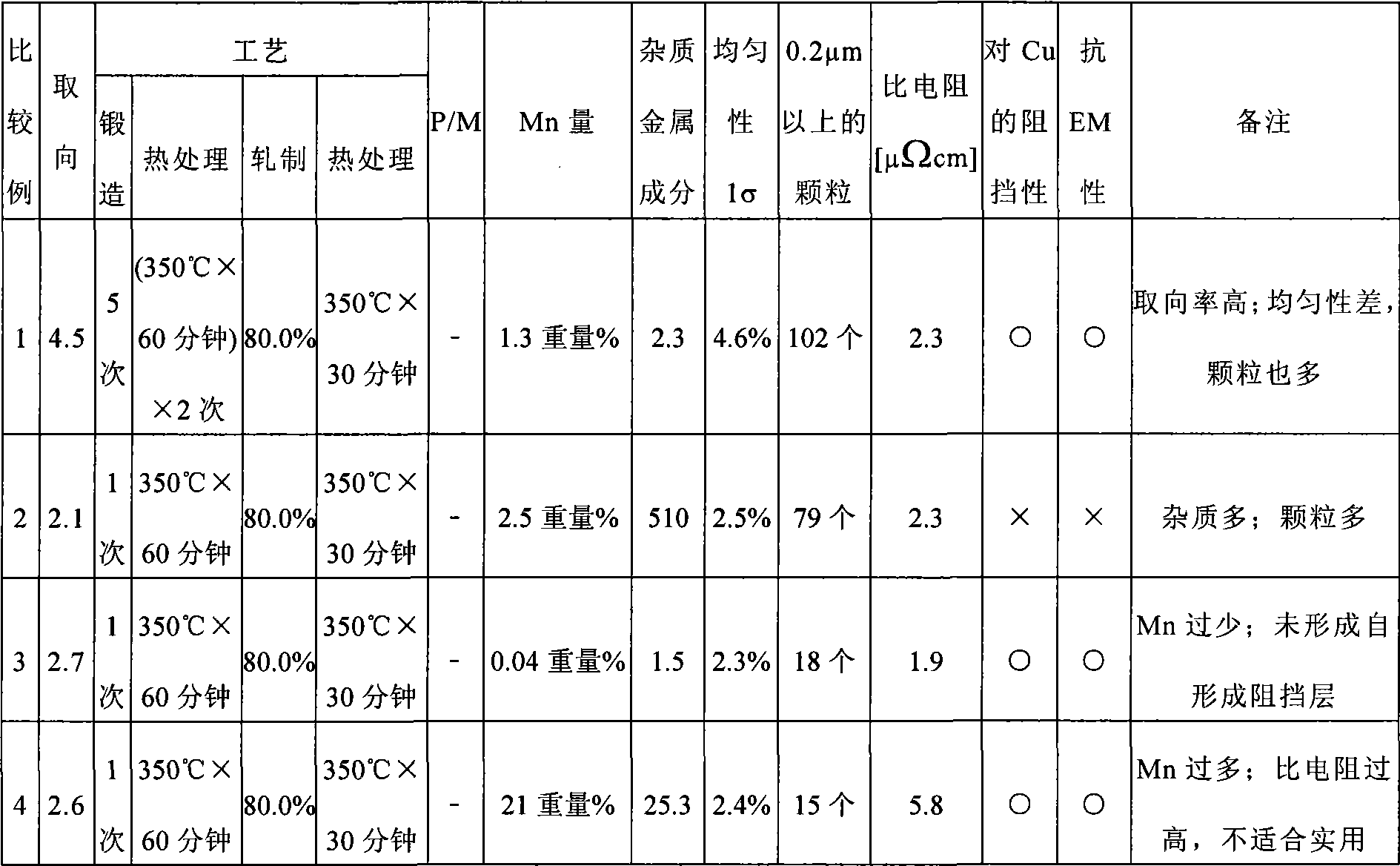

Cu-Mn Alloy Sputtering Target and Semiconductor Wiring

InactiveUS20100013096A1Functional deteriorationStrong oxidizing powerCellsSemiconductor/solid-state device detailsSelf-diffusionDeposition process

Proposed is a Cu—Mn alloy sputtering target, wherein the Mn content is 0.05 to 20 wt %, the total amount of Be, B, Mg, Al, Si, Ca, Ba, La, and Ce is 500 wtppm or less, and the remainder is Cu and unavoidable impurities. Specifically, provided are a copper alloy wiring for semiconductor application, a sputtering target for forming this wiring, and a manufacturing method of a copper alloy wiring for semiconductor application. The copper alloy wiring itself for semiconductor application is equipped with a self-diffusion suppression function for effectively preventing the contamination around the wiring caused by the diffusion of active Cu, improving electromigration (EM) resistance, corrosion resistance and the like, enabling and facilitating the arbitrary formation of a barrier layer, and simplifying the deposition process of the copper alloy wiring for semiconductor application.

Owner:JX NIPPON MINING& METALS CORP

Copper alloys and liquid-crystal display device

ActiveUS7626665B2Well formedSolid-state devicesSemiconductor/solid-state device manufacturingDiffusionFree energies

To provide a highly conductive Cu alloy which is advantageous in that an alloying element added to Cu is first reacted with oxygen contained in a gas atmosphere or solid in contact with the Cu member to form an oxide film which can prevent oxidation of Cu. The copper alloy comprises copper (Cu) containing an inevitable impurity, and an element added to the copper, wherein the added element is capable of being dissolved in the copper in an amount of 0.1 to 20 at. %, wherein the added element has an oxide formation free energy smaller than that of Cu and has a diffusion coefficient in Cu larger than the self-diffusion coefficient of Cu.

Owner:XENOGENIC DEV LLC

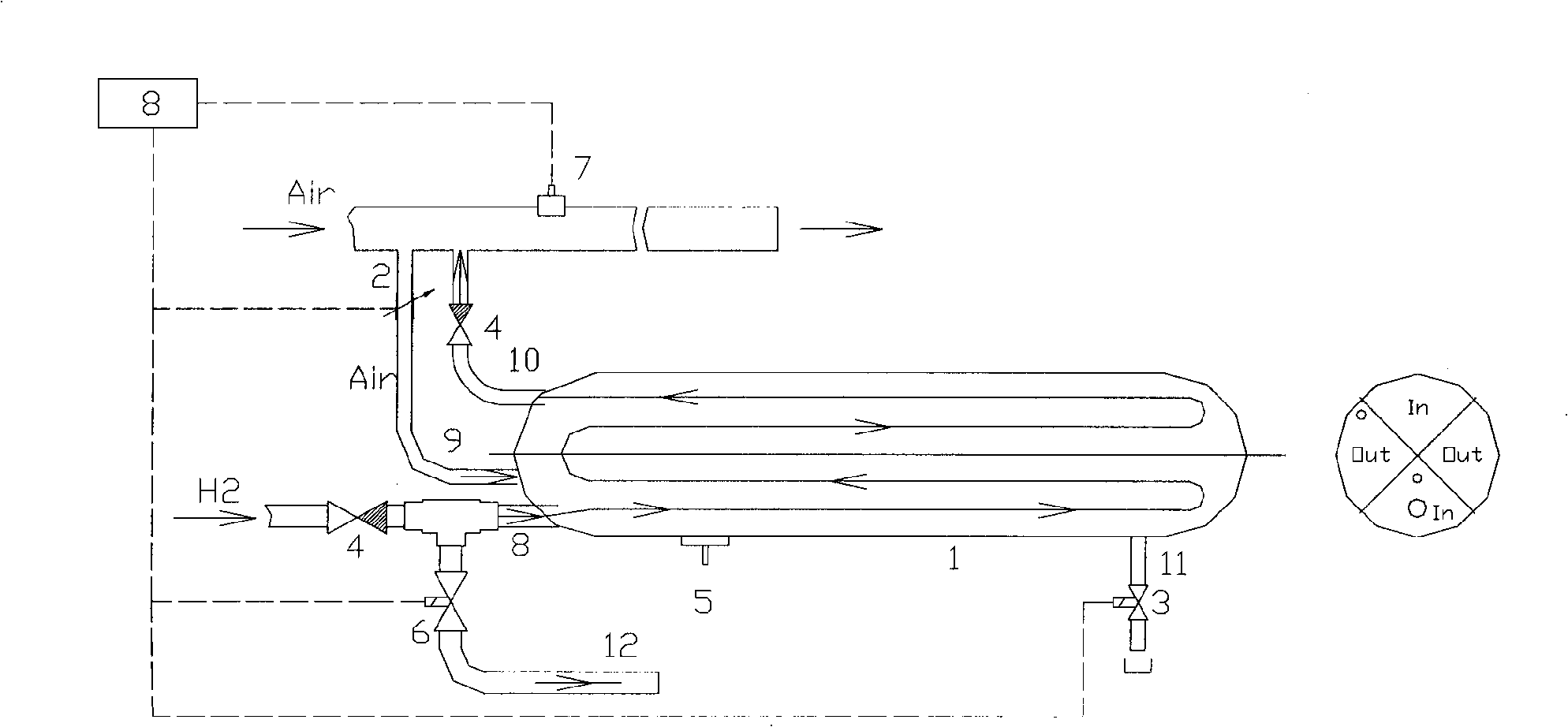

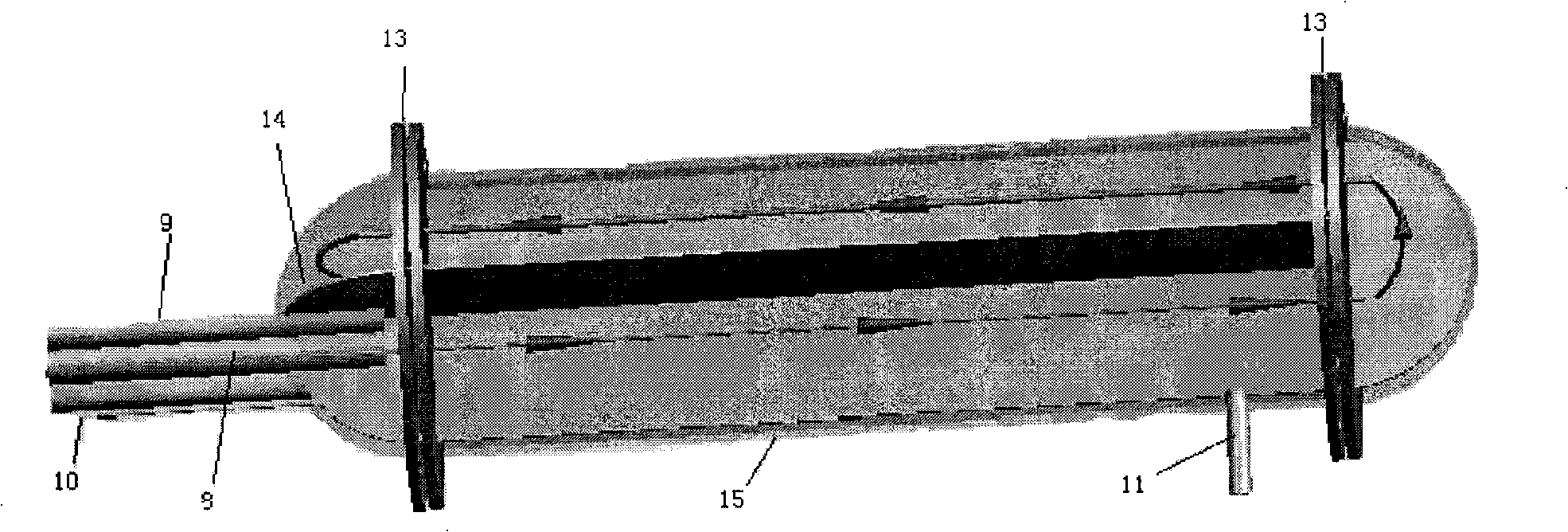

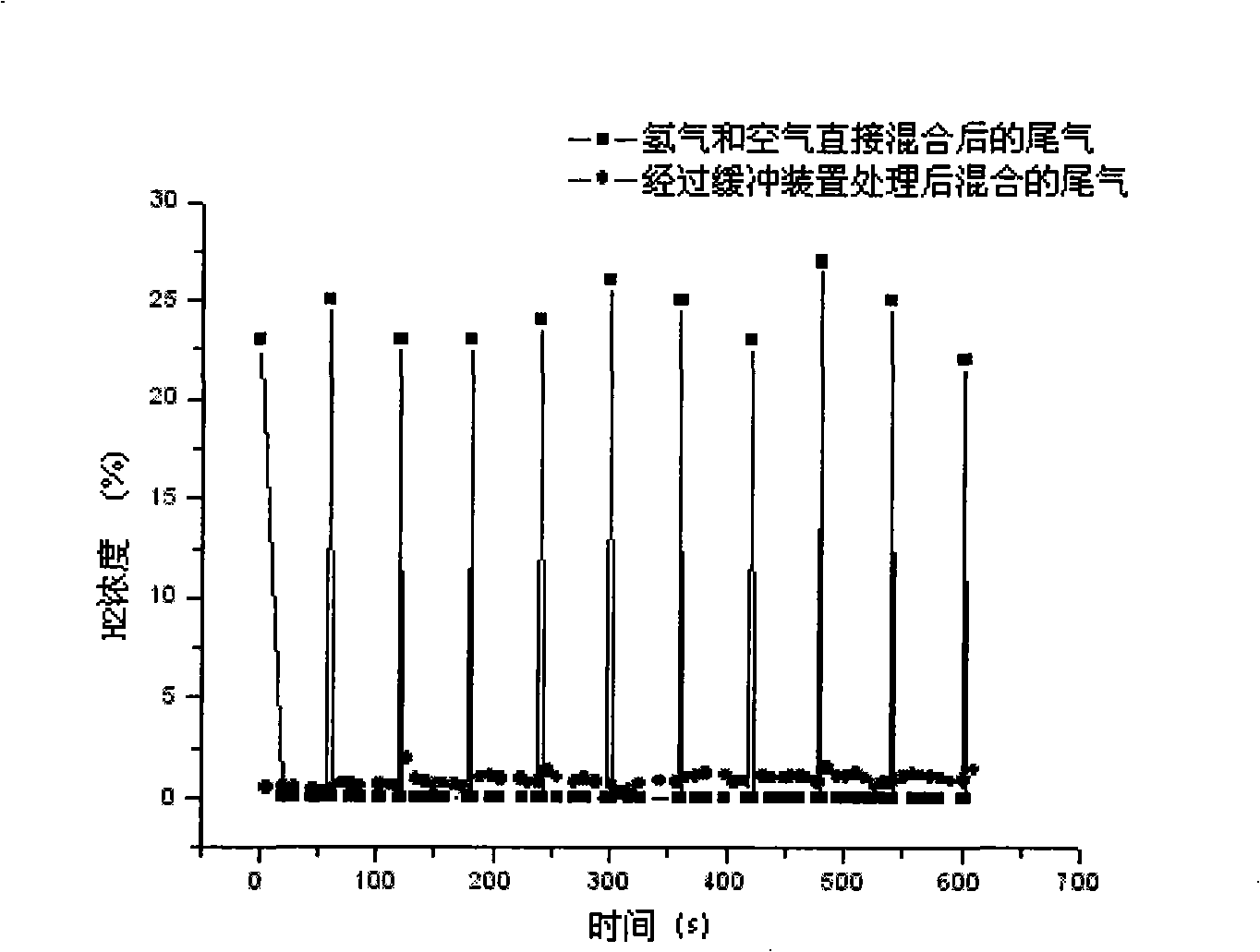

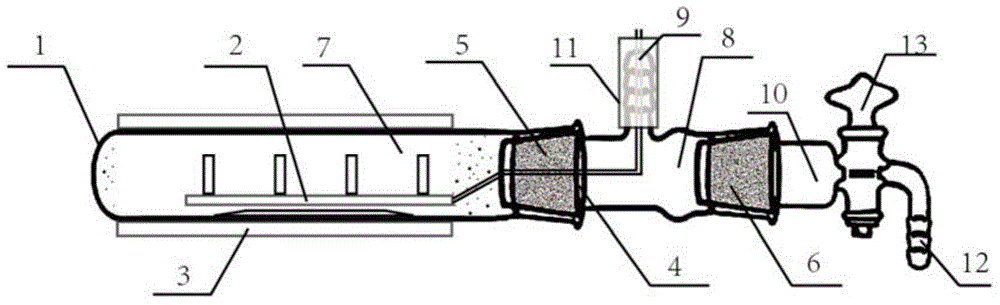

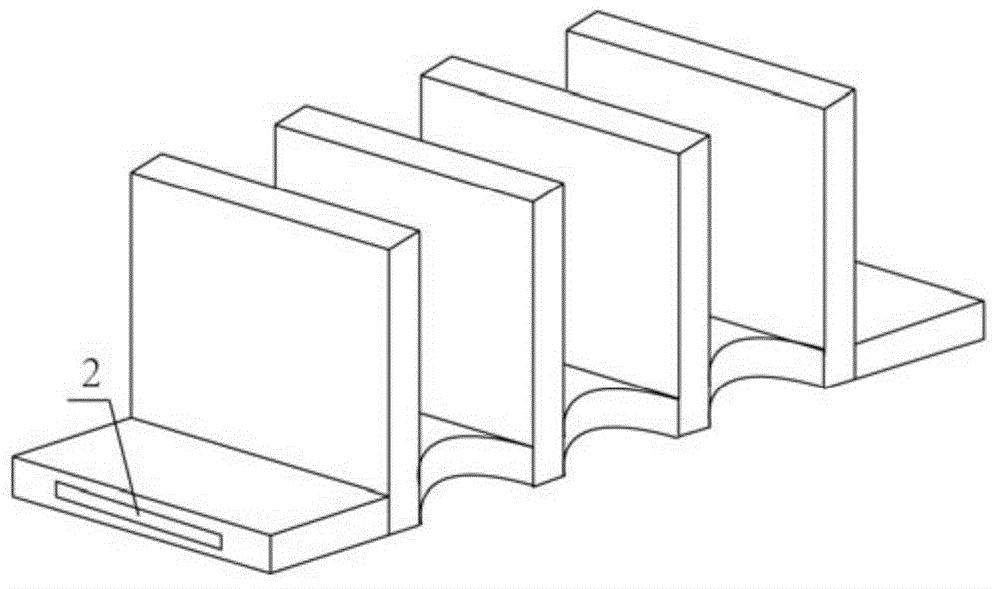

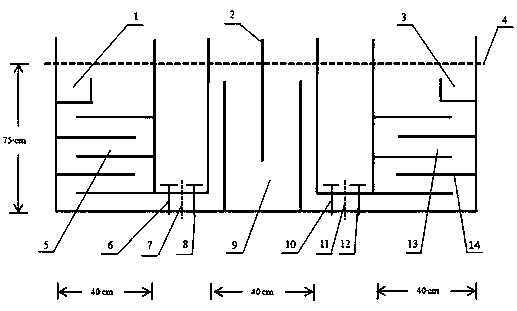

Exhaust processing method and apparatus for safety dumping of fuel cell automobile hydrogen gas

ActiveCN101409353AReduce hydrogen concentrationGood buffer dilution treatment effectFuel cellsPropulsion unit gas exhaustFlame arresterExhaust valve

The invention discloses a tail gas buffer dilution treatment method for safe emission of hydrogen from a fuel cell vehicle and a device thereof. The device comprises a hydrogen buffer, a flow control valve, a draining valve, a flame arrester, an earth terminal, an emergency hydrogen exhaust valve, a hydrogen sensor and a control module. The pulse hydrogen emitted from an anode side of the fuel cell is firstly buffered by the buffer, and a small stream of air introduced from an air path emitted from the cathode side dilutes and sweeps the hydrogen in the buffer; then the diluted hydrogen emitted from the buffer and the gas from a main air pipeline are mixed, thus the volume concentration of the tail hydrogen emitted from the fuel cell vehicle is controlled below the explosion limit concentration 4%, and the purified water discharged from a condenser can be recycled. The tail gas buffer dilution treatment device utilizes the techniques of self-diffusion, multi-tube pass buffer, air mixing and exchange, expansion, condensation and the like to buffer and dilute the hydrogen-containing tail gas emitted from the fuel cell vehicle and separate the water and gas in the hydrogen-containing tail gas, thus eliminating the possible fire hazard and ensuring the safe running of the fuel cell vehicle.

Owner:TONGJI UNIV

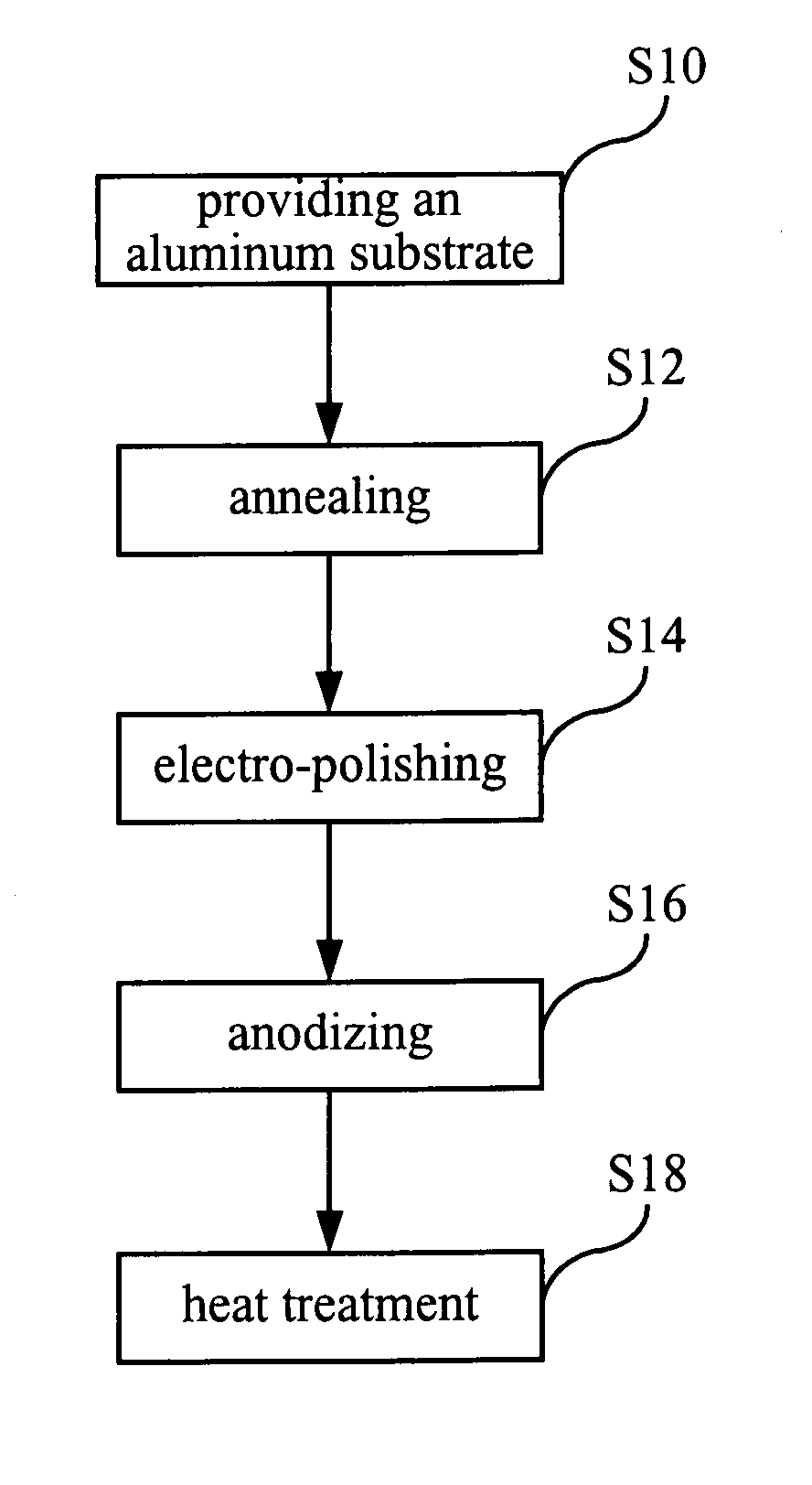

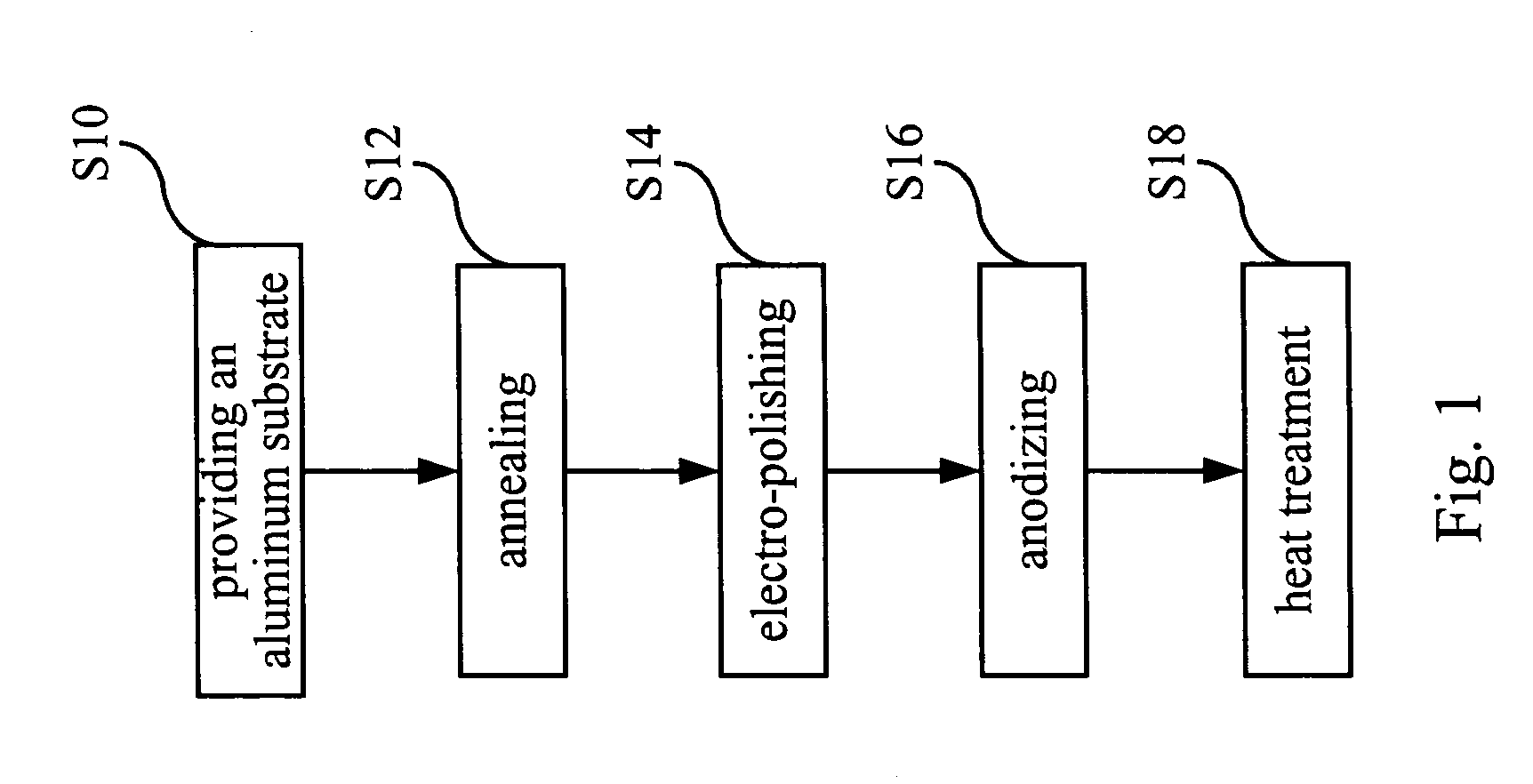

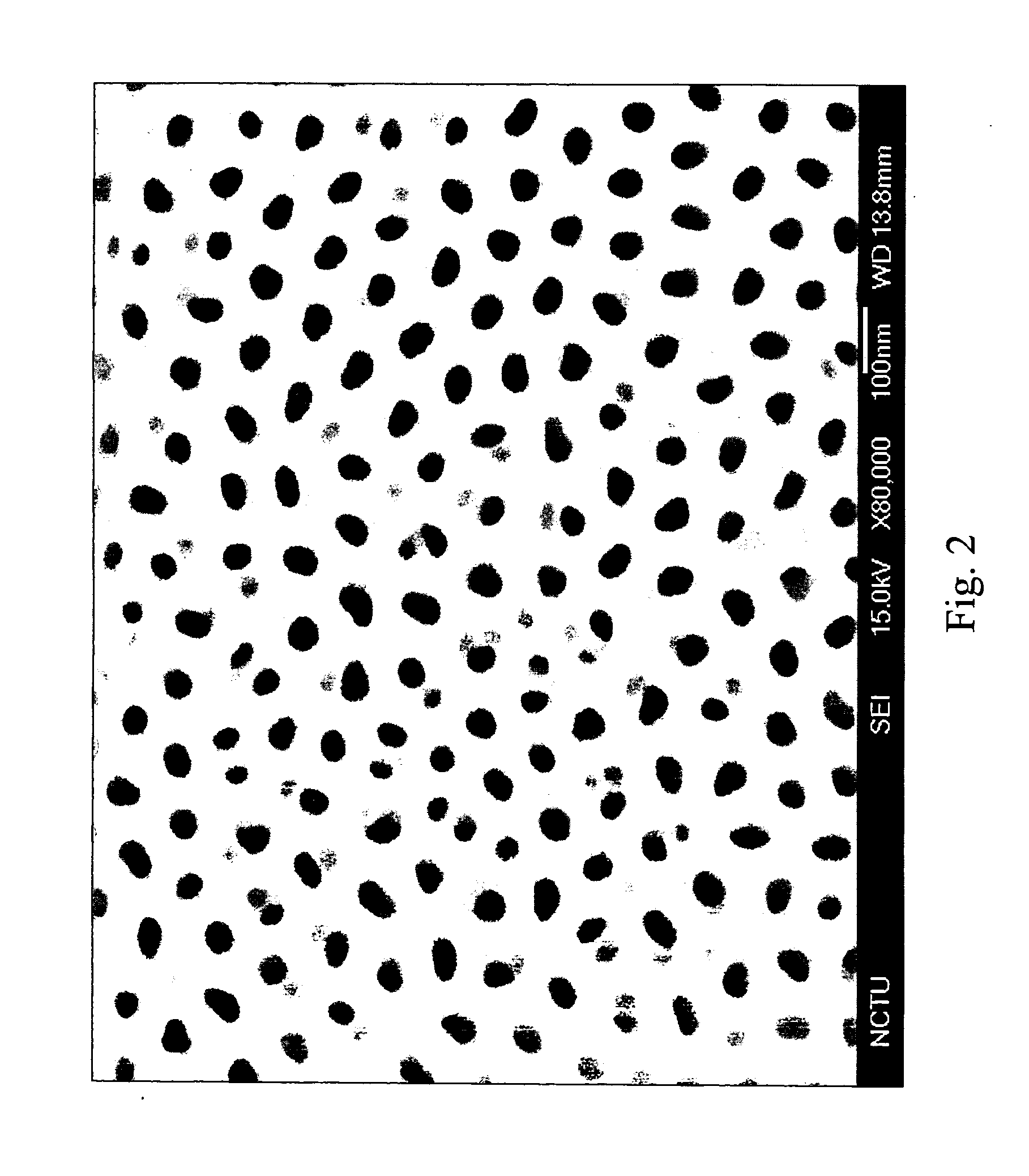

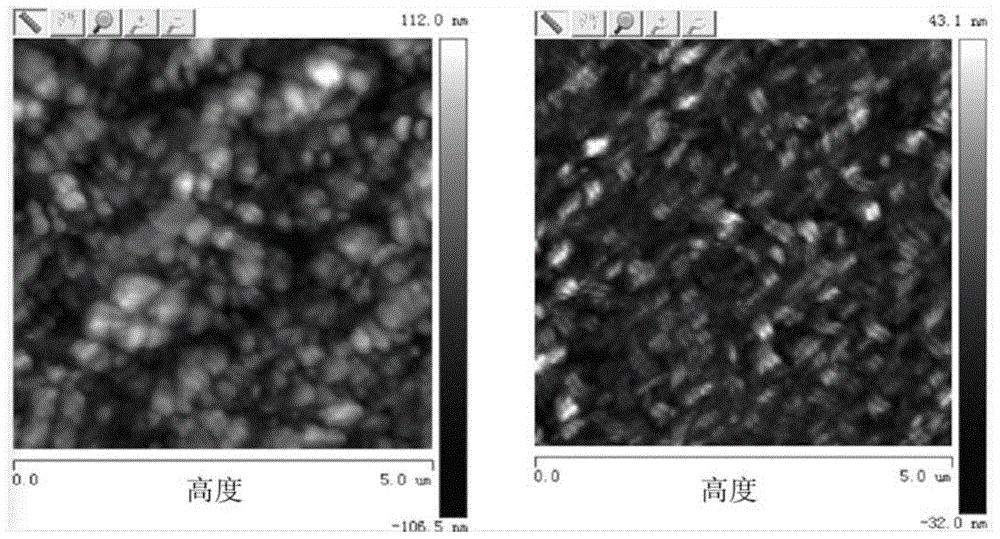

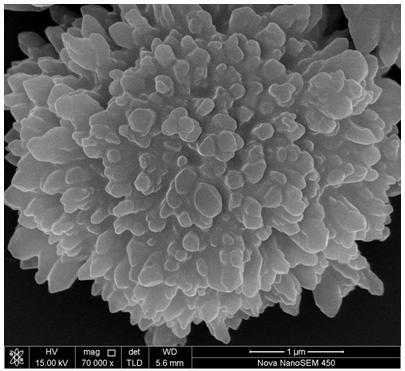

Method of manufacturing aluminum oxide film with arrayed nanometric pores

InactiveUS20060049059A1Easy to operateLow costMaterial nanotechnologyAnodisationSelf-diffusionOptoelectronics

The present invention pertains to a method of manufacturing an aluminum oxide film with arrayed nanometric pores, wherein a commercial aluminum substrate is provided firstly; then the aluminum substrate is annealed and then electro-polished in order to have a mirror-like surface, and then anodized in order to form a aluminum oxide film with a plurality of nanometric pores, which are aligned in array, and then annealed in order that an oxidation reaction can happen thereon and generates oxide, which via self-diffusion, fills some of smaller pores with the pores size being uniformed; lastly a pore-widening is undertaken in order to increase the diameters of the pores. The present invention can accomplish the nanometric pores aligned in array and with an uniform pore diameter, and simultaneously have the advantages of simplified manufacturing process, easier operational control and reduced cost.

Owner:NAT CHIAO TUNG UNIV

Cu-Mn alloy sputtering target and semiconductor wiring

ActiveCN101473059AWith self-diffusion inhibition functionSimplify the forming processSemiconductor/solid-state device detailsSolid-state devicesSelf-diffusionImpurity

Owner:JX NIPPON MINING & METALS CORP

High-purity copper-manganese-alloy sputtering target

InactiveUS20140158532A1Avoid pollutionGood effectCellsElectric discharge tubesSputteringSelf-diffusion

Provided is a high-purity copper-manganese-alloy sputtering target comprising 0.05 to 20 wt. % of Mn, 2 wt ppm or less of C, and the remainder being Cu and inevitable impurities, wherein in formation of a film on a wafer by sputtering the target, the number of particles composed of C, at least one element selected from Mn, Si, and Mg, or a compound composed of C and at least one element selected from Mn, Si, and Mg and having a diameter of 0.20 μm or more is 30 or less on average. Particle generation during sputtering can be effectively suppressed by thus adding an appropriate amount of Mn element to copper and controlling the amount of carbon. In particular, a high-purity copper-manganese-alloy sputtering target that is useful for forming semiconductor copper alloy line having a self-diffusion suppression function is provided.

Owner:JX NIPPON MINING& METALS CORP

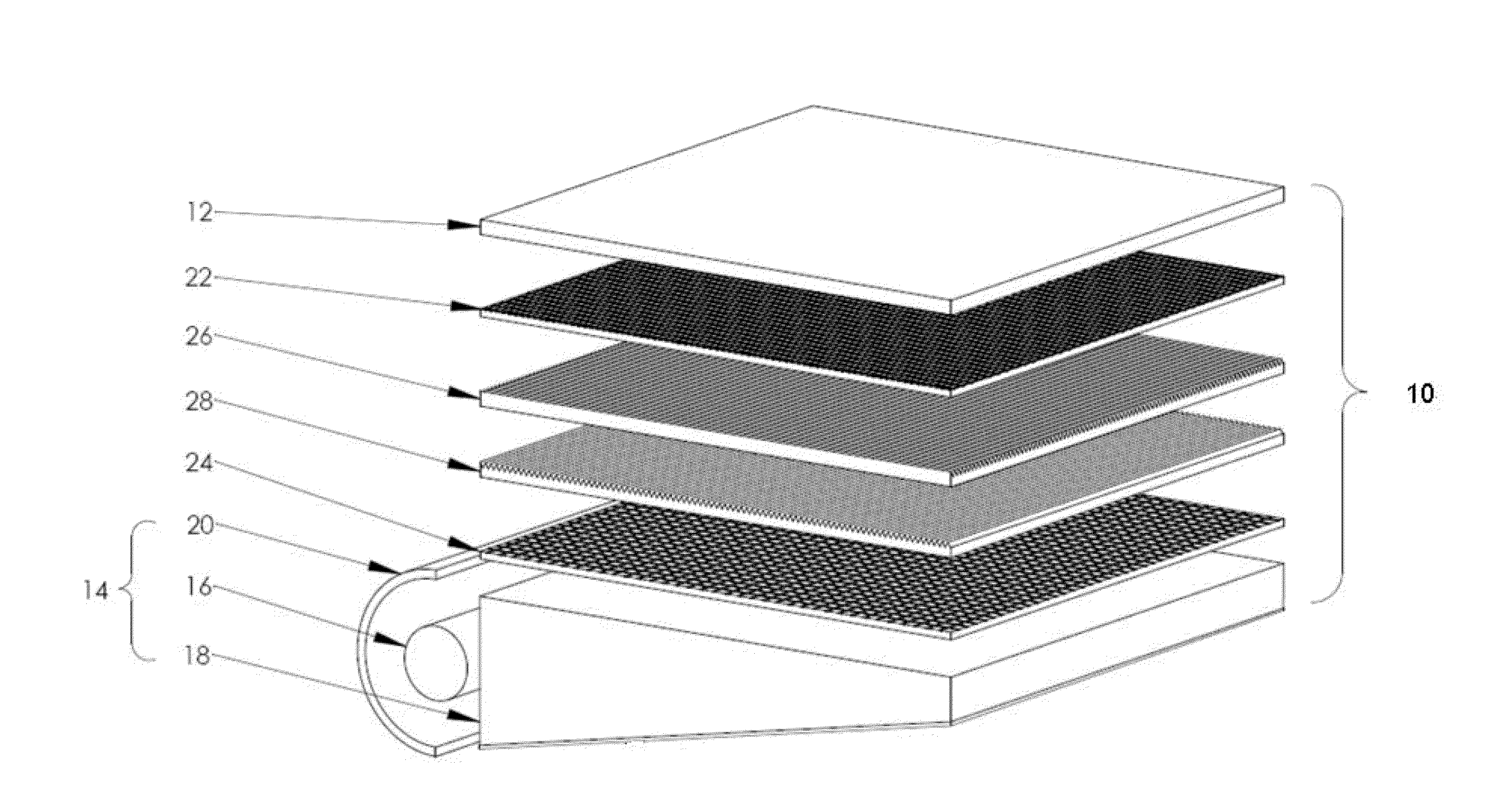

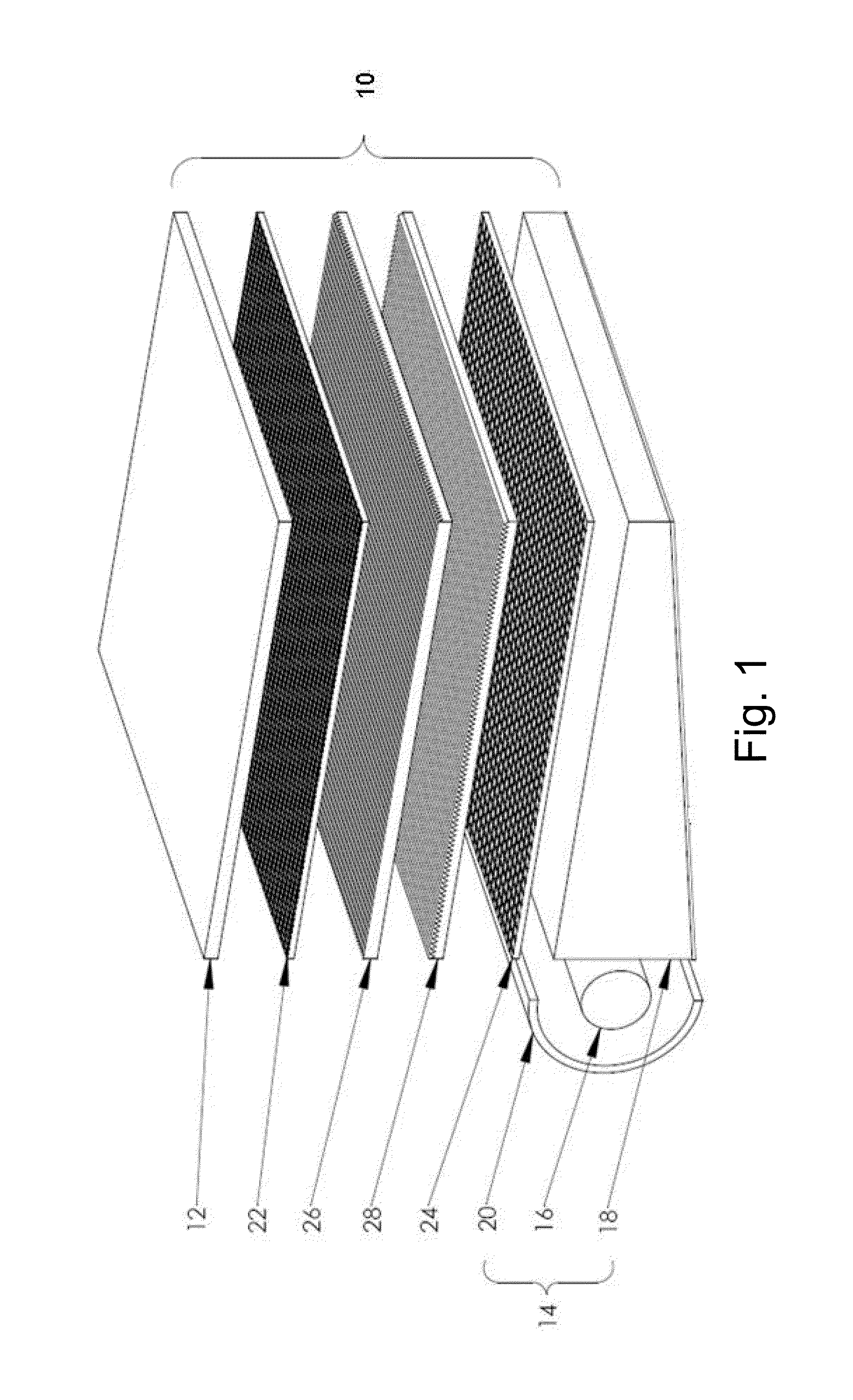

Multi-function composite optical film

A composite optical film has the functions of brightness enhancement, self-diffusion and defect blocking. The film comprises: a structured substrate including a structured light incidence surface and a light emitting surface opposite the structured light incidence surface, wherein the structured light incidence surface includes longitudinal prism structures or longitudinal lens structures transversely arranged in rows; a support base plate adjacent to the light emitting surface of the structured substrate, the support base plate having a light incidence surface on one side and a light emitting surface on another side opposite the light incidence surface, wherein at least one of the light incidence surface and the light emitting surface has a plurality of buried particles, and at least one portions of the buried particles are protruded on the light emitting surface of the support base plate.

Owner:UBRIGHT OPTRONICS CORP

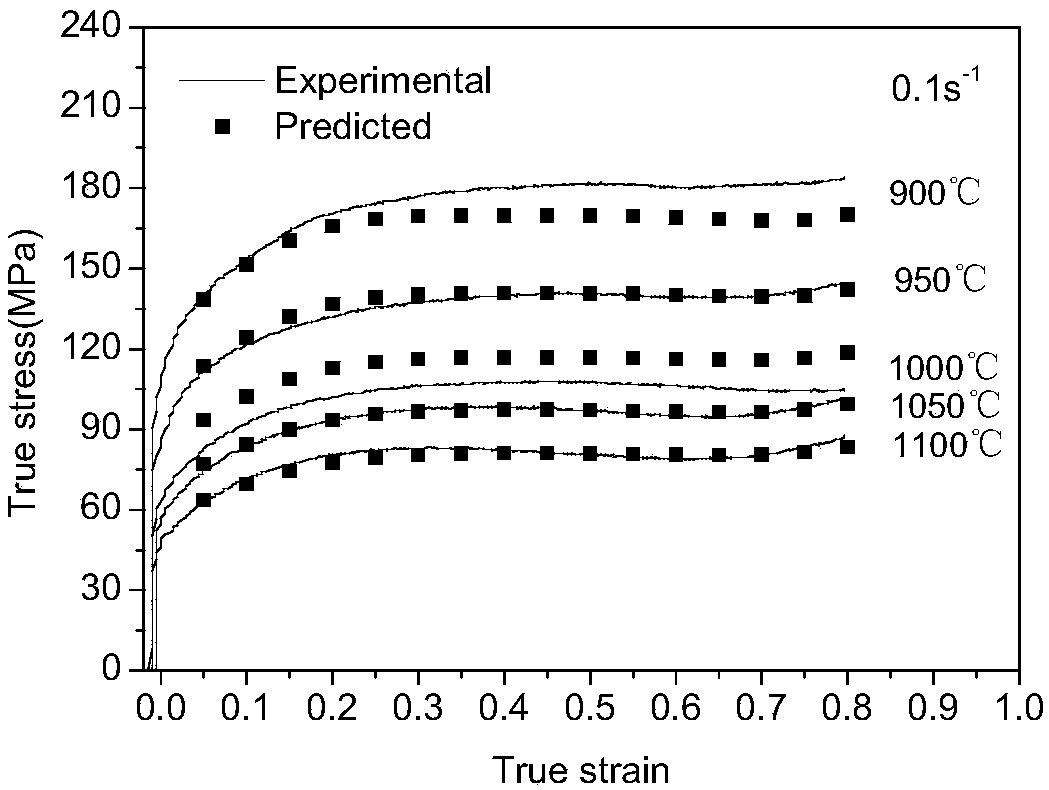

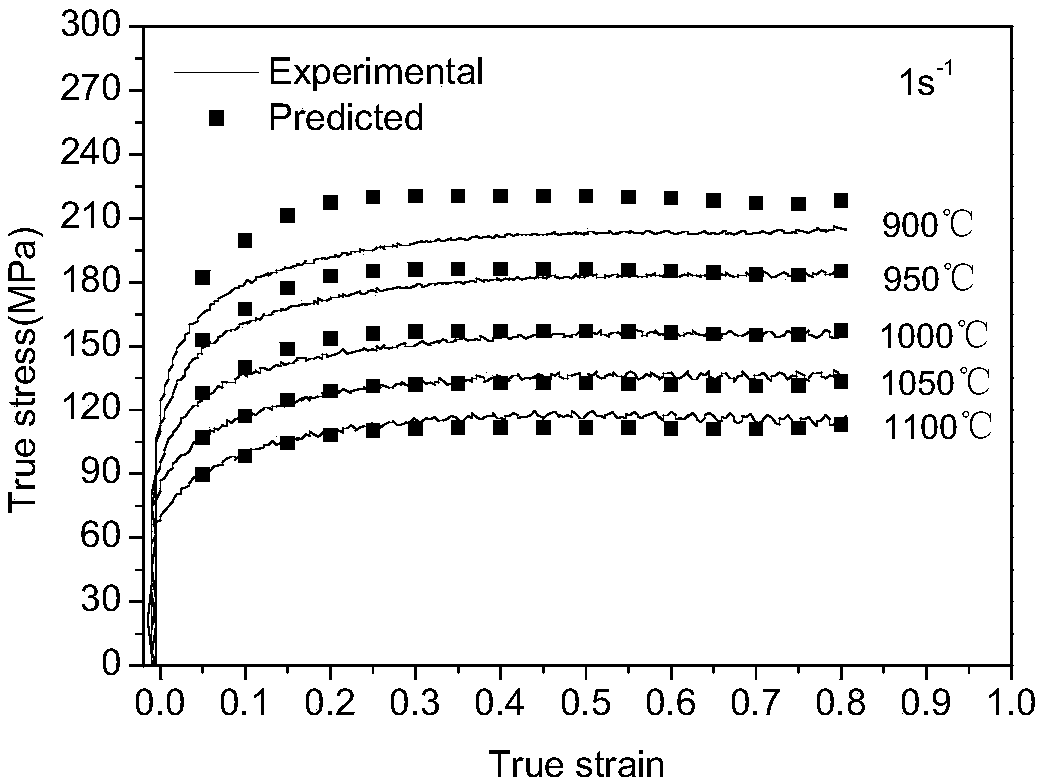

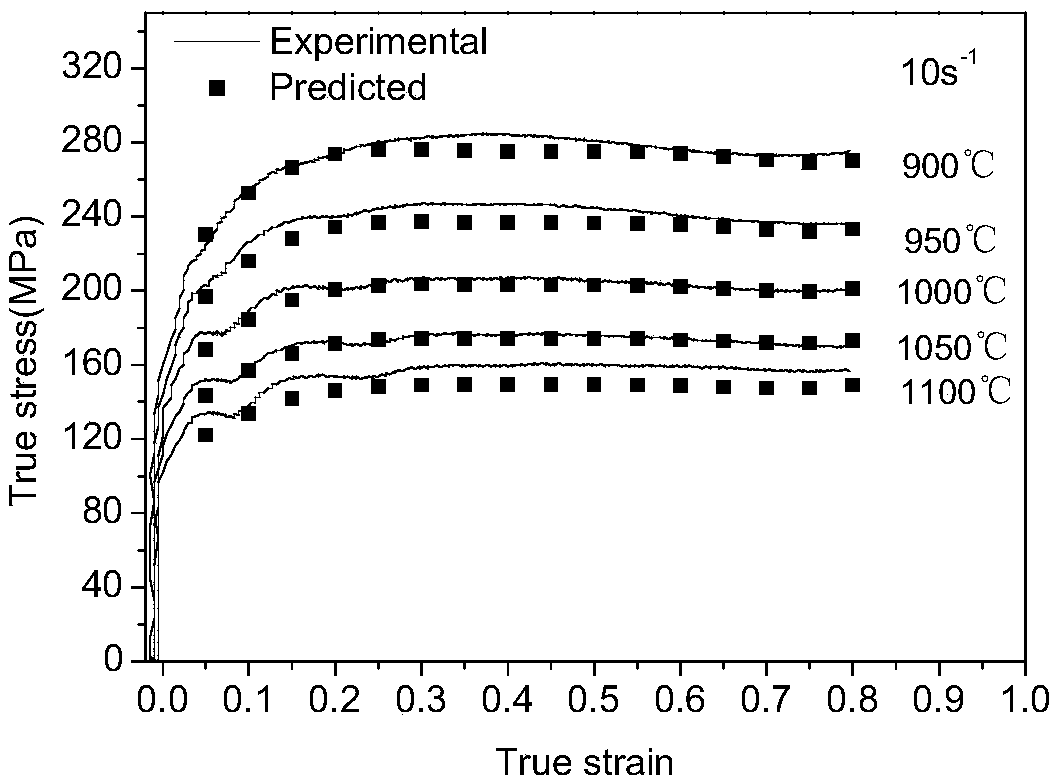

Determination method of thermal-deformation microstructure evolution mechanisms and thermal machining performance of C-Mn-Al high-strength steel

InactiveCN108595827AJudgment evolution mechanismJudgment of workabilityGeometric CADDesign optimisation/simulationSelf-diffusionMachining process

The invention belongs to the technical field of high-strength steel machining engineering, and particularly relates to a determination method of thermal-deformation microstructure evolution mechanismsand thermal machining performance of C-Mn-Al high-strength steel. According to the method, firstly, a high-temperature compression test is carried out on the novel C-Mn-Al high-strength steel, and true stress-true strain curve data of the steel are obtained; then a rheology stress prediction model of the steel is established, model selection is based on creep theory, a class of constitutive models which are of relationships of Young's modulus and a self-diffusion coefficient of austenite and temperature and have physics bases are considered, and the established constitutive model can accurately predict rheology stress of the steel; a thermal-deformation machining graph of the steel is established, and microstructures are combined to determine the microstructure evolution mechanisms of different regions in the machining graph. The constitutive model of thermal deformation and the machining graph are combined, the thermal-deformation rheology stress and thermal-deformation power dissipation efficiency under arbitrary deformation conditions are analyzed, thus the corresponding microstructure evolution mechanisms and thermal machining performance information are obtained, and resultshave great significance for thermal machining process control of the high-strength steel.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Preparation of self-diffusion salt tolerant acroleic acid high hydroscopicity resin

The invention relates to a preparation method of self-dispersing salt-resistance type acrylic high-absorbent resin; the method is characterized in that the method comprises the following steps: (1) refined acrylic acid and metacrylic acid ester or acrylic ester is added into a reaction kettle, and organic mixed solvent, compound cross linkers, and evocating agents are added; (2) stirring and polymerization are carried out under the protection of nitrogen, and the reaction temperature is controlled to be 45-50 DEG. C, and the polymerization reaction is carried out until the reaction mixture changes into a viscous suspending liquid (the required time is a plurality of hours); (3) the polymer is displaced in a one-port flask, and then the organic mixed solvent is removed; and (4) vacuum drying and grinding are carried out for obtaining the self-dispersing salt-resistance type acrylic high-absorbent resin which is thin white powder. The method overcomes the disadvantages in the prior art, leads the polymerized products to have uniform molecular weight, rapid dispersing speed and good salt resistance; in addition, the transparency is high; and the method has simple process, is economic and reasonable, and is suitable for industrial production.

Owner:NANJING WELL CHEM

Method for preparing organic ammonium metal halide film

InactiveCN104404478AImprove diffractionStrenuous exerciseChemical vapor deposition coatingChemical reactionCharge carrier mobility

The invention discloses a method for preparing an organic ammonium metal halide film. A half-closed type carrier gas free hot wall type low-pressure chemical vapor deposition method process is adopted to prepare the organic ammonium metal halide film. The method comprises the following steps: firstly, preparing a metal halide (MX2) film on a quartz substrate by using a dry method or a wet method, and transferring the metal halide (MX2) film into a glass tube for annealing, wherein one end of the glass tube is sealed and the other end is grounded; secondly, transferring the energy to organic ammonium (AX) powder inside the glass tube through a hot wall, forming steam blocks through self-diffusion of AX steam in low vacuum, performing chemical reaction on MX2 with a hot substrate to generate the film which is uniform in thickness, good in appearance, high in light absorption rate and smooth in surface, and performing in-situ annealing so as to generate the AMX3 film which is dense in structure and high in crystallinity degree. The method has the advantages that in-situ annealing can be performed in the film formation process, continuous vacuuming is not needed, the preparation time is shortened, the energy consumption is reduced, the filming efficiency is high, the charge capture trap in the film is reduced, and the carrier mobility is increased.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

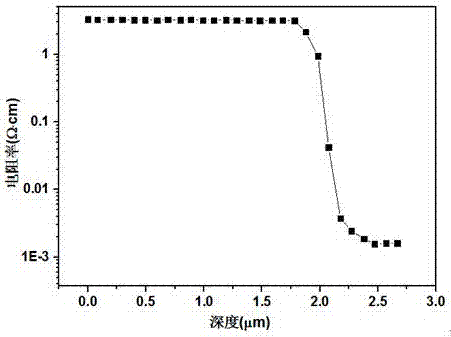

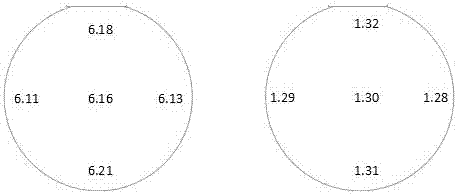

Method for preparing silicon epitaxial wafer for step recovery diode

ActiveCN107012506AMeet the use requirementsReduce widthPolycrystalline material growthSemiconductor/solid-state device manufacturingLow speedSelf-diffusion

The invention discloses a method for preparing a silicon epitaxial wafer for a step recovery diode. According to the preparation method, the problem in the conventional silicon epitaxial wafer process for the step recovery diode that the width of a transition area cannot be controlled is solved. A two-section growth manner is adopted in the epitaxial layer growth process, purging is performed for a period of time by using hydrogen with repeatedly changeable flow, impurities are continuously diluted and discharged out of a reaction chamber of an epitaxial furnace, and the first section of the epitaxial layer grows at a low temperature and a low speed, so that the gas phase self-doping influence is reduced, the structure of the transition area is improved, and then purging is performed for a period of time again by using the hydrogen with the repeatedly changeable flow, the second section of the epitaxial layer rapidly grows at a high temperature, and finally, the target thickness and electrical resistivity are achieved. Due to the optimized epitaxial process, control of substrate impurity self-diffusion factors under a normal pressure is realized, and the width of the transition area is narrowed, so that the width accounts for 13-15% of the thickness percentage of the epitaxial layer, and the use requirement of the step recovery diode is met.

Owner:CHINA ELECTRONICS TECH GRP NO 46 RES INST

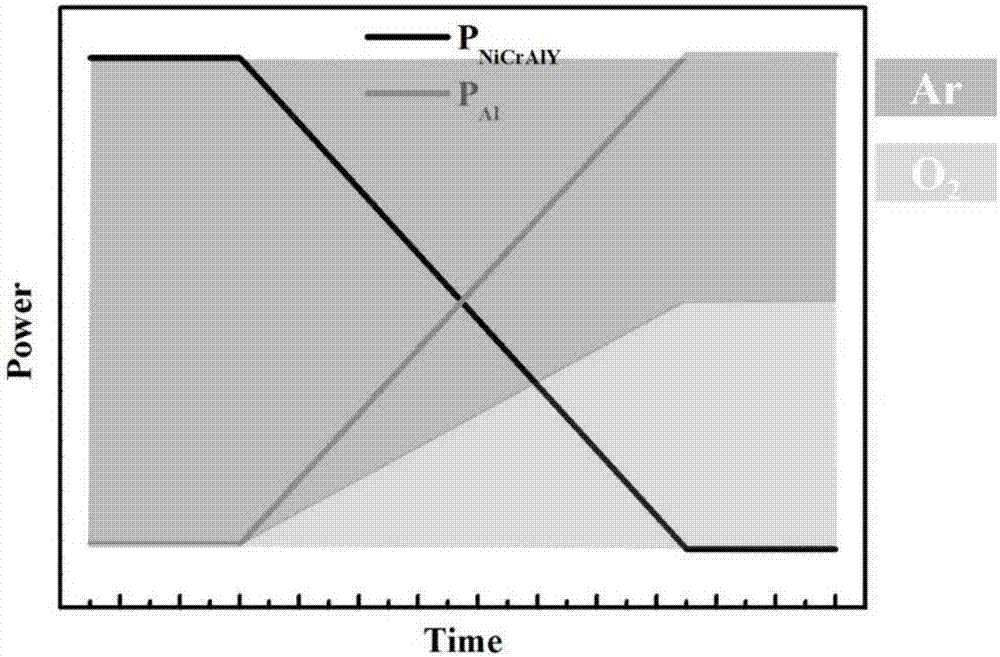

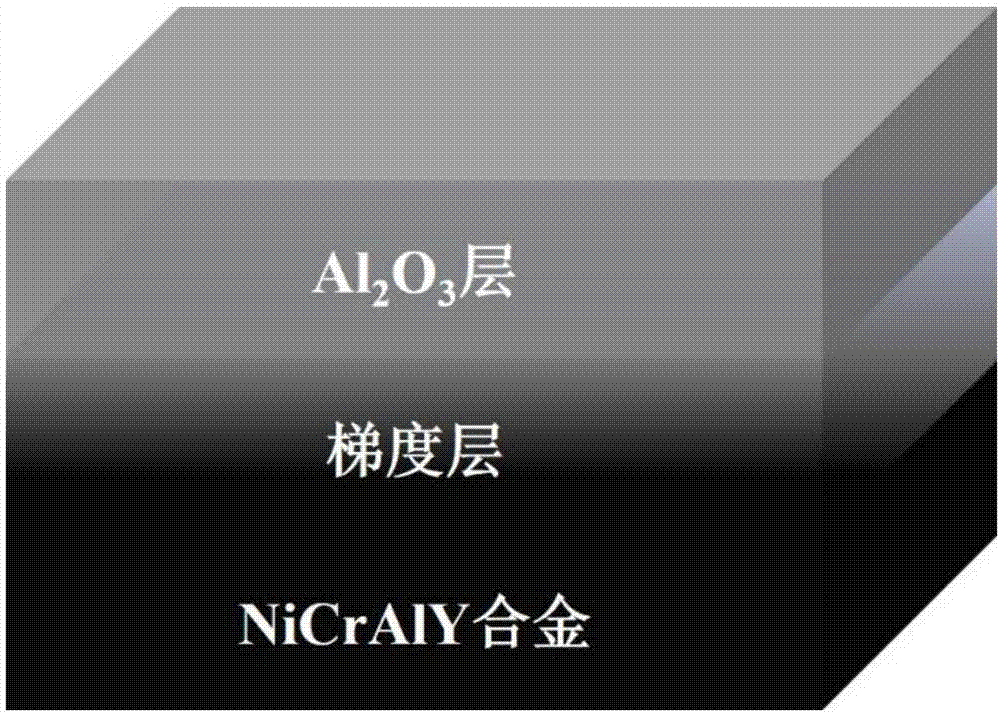

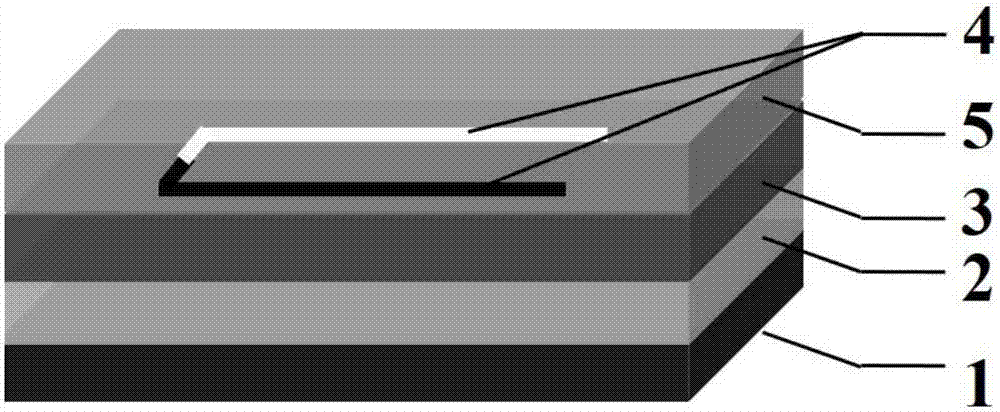

Gradual transition layer for metal-based film sensor and preparation method

ActiveCN107574415ASlow self-diffusionAvoid excessive oxidationVacuum evaporation coatingSputtering coatingAlloyOxygen

The invention provides a gradual transition layer for a metal-based film sensor and a preparation method and belongs to the technical field of film sensors. The gradual transition layer comprises three layers of structures including a NiCrAlY alloy layer, a NiCrAlY alloy and Al2O3 gradient layer and an Al2O3 layer from bottom to top in sequence, wherein in the NiCrAlY alloy and Al2O3 gradient layer located in the middle, the concentration of NiCrAlY alloy decreases gradually in the growth direction of the film, and the concentration of Al2O3 increases gradually in the growth direction of the film. Compared with an existing transition layer, the gradual transition layer has the advantages that the heat treatment temperature is reduced by 200-400 DEG C; the heat treatment time is shortened by 50% or more; self-diffusion of nickel base alloy during high-temperature treatment and the rate and degree of mutual diffusion of the nickel base alloy and the NiCrAlY alloy are retarded; meanwhile,the heat treatment atmosphere is changed from a traditional oxygen-enriched environment to the atmospheric environment, and excessive oxidation of elements in the nickel base alloy is avoided to someextent.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

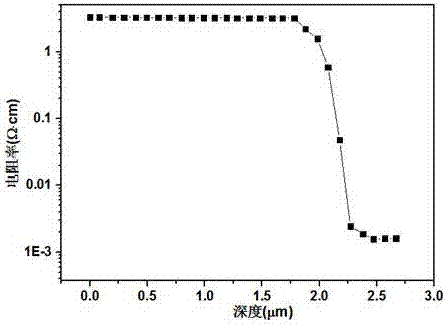

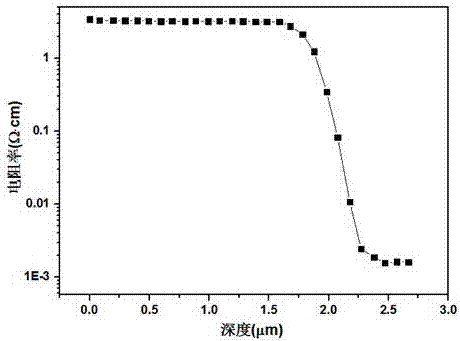

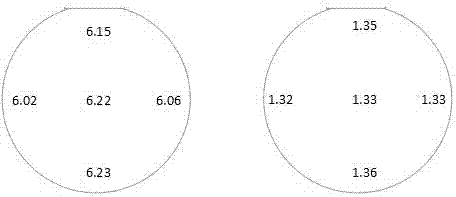

Preparation method for silicon epitaxy sheet for transient voltage restraining diode

ActiveCN107099840AMeet the use requirementsImprove uniformityPolycrystalline material growthSemiconductor/solid-state device manufacturingSlip lineSelf-diffusion

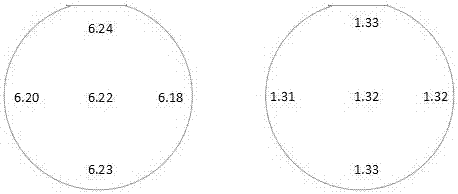

The invention discloses a preparation method for a silicon epitaxy sheet for a transient voltage restraining diode. According to the preparation method, a gas flow field and a base temperature field are adjusted and an epitaxy technology is optimized, for solving the problem of uniformity control on thickness and resistivity of a present technology for a silicon epitaxy sheet for a transient voltage restraining diode. The control on a self-diffusion process of substrate impurities is realized through the optimization for the epitaxy technology; the high uniformity of the thickness and resistivity of the silicon epitaxy sheet is guaranteed; the surface is free from the defects of stacking fault, dislocation, slip line, fog, and the like; the nonuniformity of the thickness and resistivity of the silicon epitaxy sheet prepared according to the method is below 2%; the scope of average thickness of the silicon epitaxy sheet is 6.10-6.25 micrometers and the scope of average resistivity is 1.25-1.35 ohms.cm, so that the use requirement for the transient voltage restraining diode is met.

Owner:CHINA ELECTRONICS TECH GRP NO 46 RES INST

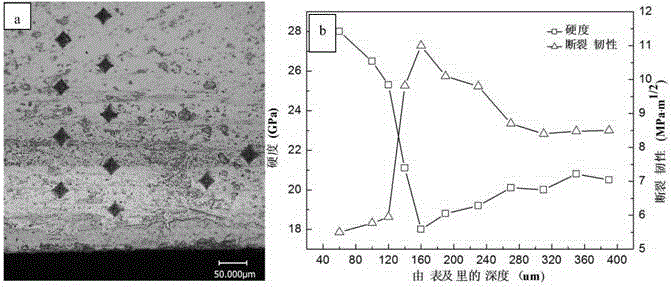

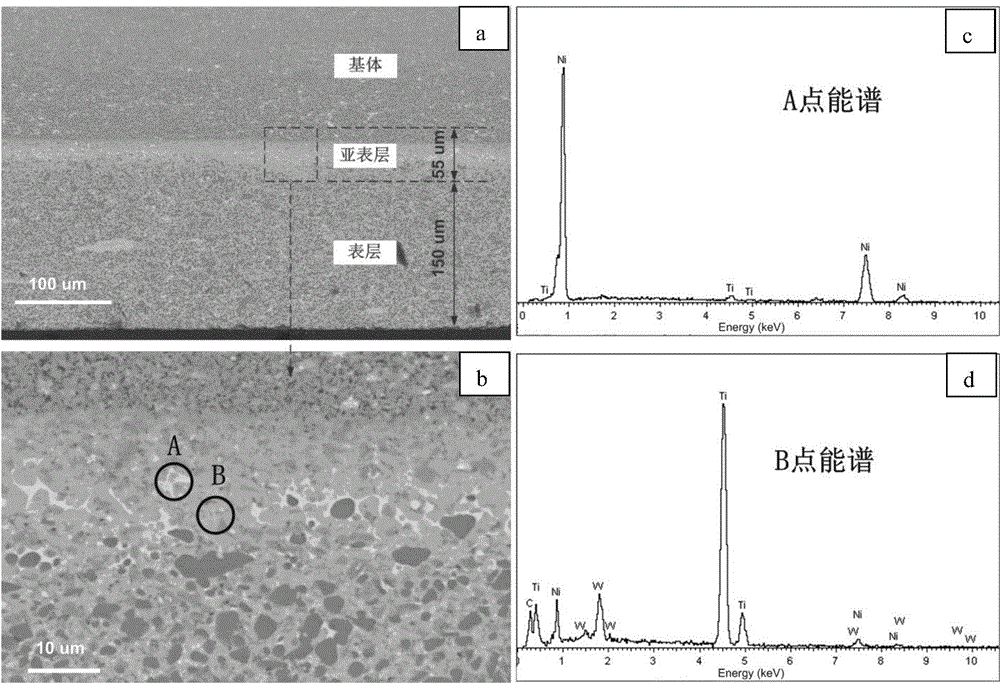

Self-diffusion gradient functional compound cutting tool material and preparation method thereof

ActiveCN103949647AIncreased microhardnessStrong resistance to crack growthMetal layered productsSelf-diffusionSurface layer

The invention relates to a self-diffusion gradient functional compound cutting tool material and a preparation method thereof. The preparation method comprises the following steps: grinding ultrafine Ti(C5N5) powder, ultrafine WC powder, nanometer Ni powder and nanometer Mo powder into matrix compound powder; grinding TiB2-TiC eutectic powder, Al2O3 powder, ultrafine VC powder and nanometer Ni powder into surface compound powder; weighting little surface compound powder, pouring into a graphite jig and compacting; weighting the matrix compound powder, putting onto the compacted surface compound powder, and then compacting; weighting a little surface compound powder, putting onto the compacted matrix compound powder, and then compacting; putting into a vacuum high-temperature sintering furnace, directly heating and slowly pressurizing and sintering. According to the invention, the self-diffusion gradient functional compound cutting tool material with excellent compatibility and interface bonding of interlayer components is prepared through diffusion and sintering. The self-diffusion gradient functional compound cutting tool material has the characteristics of hard and wear-resisting surface, tough subsurface stratum, surface layer peeling prevention, strong whole body and breaking resistance.

Owner:上海艾梯夫机械科技有限公司

Preparation method of bonding alloy wire

InactiveCN106935523ALow costSphericalSolid-state devicesSemiconductor/solid-state device manufacturingSelf-diffusionMegasonic cleaning

The invention discloses a preparation method of a bonding alloy wire. The preparation method comprises the following steps that: (1) 99.995% silver is purchased, and the 99.995% silver is made into a silver sheet; (2) intermediate alloy is made; (3) vertical melting is performed; (4) wire drawing is performed; (5) intermediate annealing is performed; (6) wire drawing is performed again; (7) annealing is performed; (8) winding is performed; and (9) vacuum packaging is performed. According to the preparation method of the invention, when wire drawing is performed to obtain a wire rod of 70 to 100 microns, and an intermediate annealing process is additionally adopted to eliminate stress, so that wire drawing is smoother, and wire fracture can be better avoided; after a finished wire is annealed, surface treatment is performed on the finished wire, and therefore, a bonding effect of self-diffusion of the bonding alloy wire can be effectively avoided, and the yield of the finished product can be improved; surface residues of the alloy wire can be effectively reduced, and the quality of the product is improved. According to the preparation method of the invention, an ultrasonic cleaning system is utilized to effectively clean lubricating fluid on the surface of the alloy wire, and therefore, surface residues on the surface of the alloy wire can be effectively reduced, and the quality of the product can be improved.

Owner:深圳金斯达应用材料有限公司

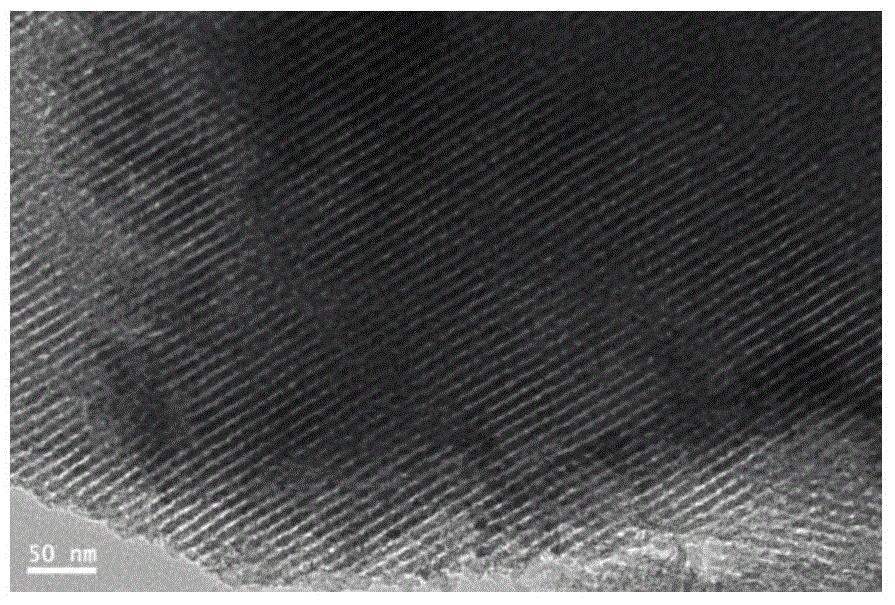

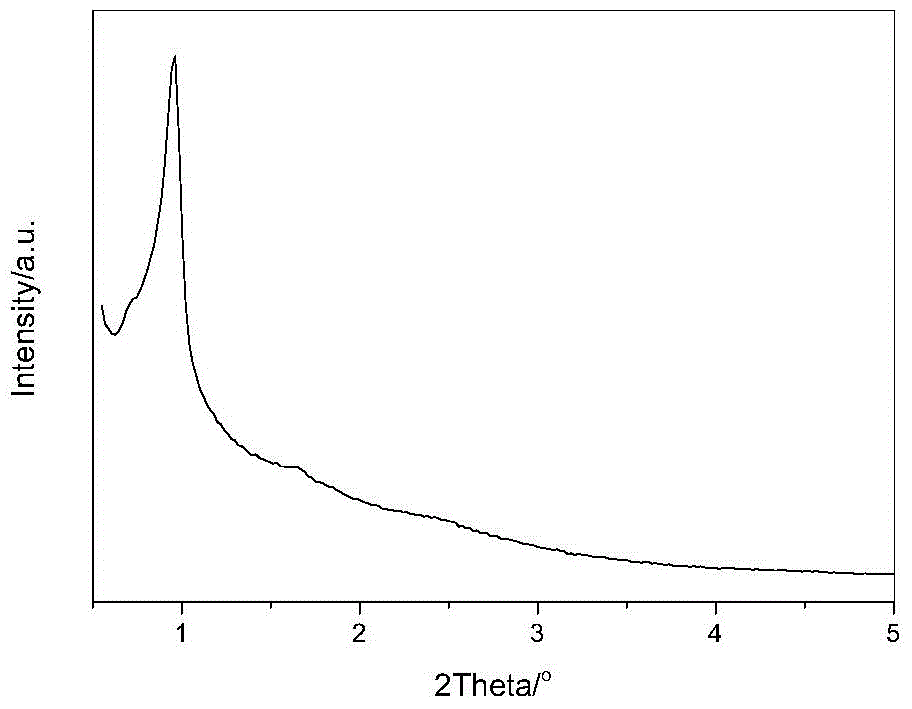

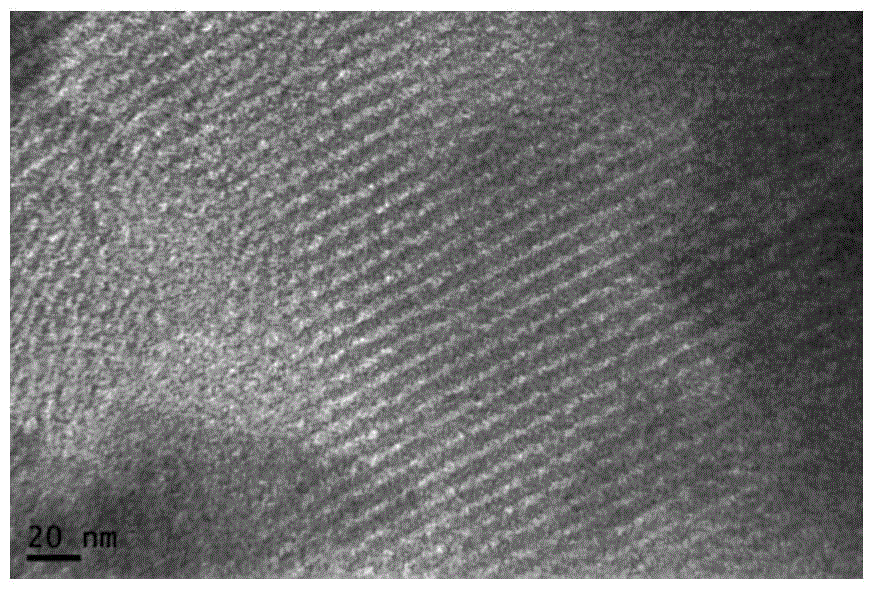

Preparation method of ordered mesoporous carbon material

The invention discloses a preparation method of an ordered mesoporous carbon material, wherein the method comprises the steps: 1) at room temperature, placing a structure-directing agent and a carbon precursor in a reactor; 2) at the temperature of 50-350 DEG C, carrying out heat treatment for 10-720 minutes; and 3) roasting the product obtained in the step 2) at the temperature of 400-800 DEG C and in an inert atmosphere, and thus obtaining the ordered mesoporous carbon material. The method for direct heating of solid mixtures is adopted, while the structure-directing agent, the carbon precursor and a functionalized precursor are subjected to molecular-level self-diffusion balance, the self-assembly process is completed, and then the ordered mesoporous carbon material or functionalized mesoporous carbon material is obtained through roasting; therefore, mechanical grinding and the separation problem between a mesoscopic-phase intermediate and equipment due to grinding are completely avoided, the operation is simplified, the cost is reduced, and the synthesized mesoporous carbon material has good mesoscopic orderliness and larger specific surface area and pore volume.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

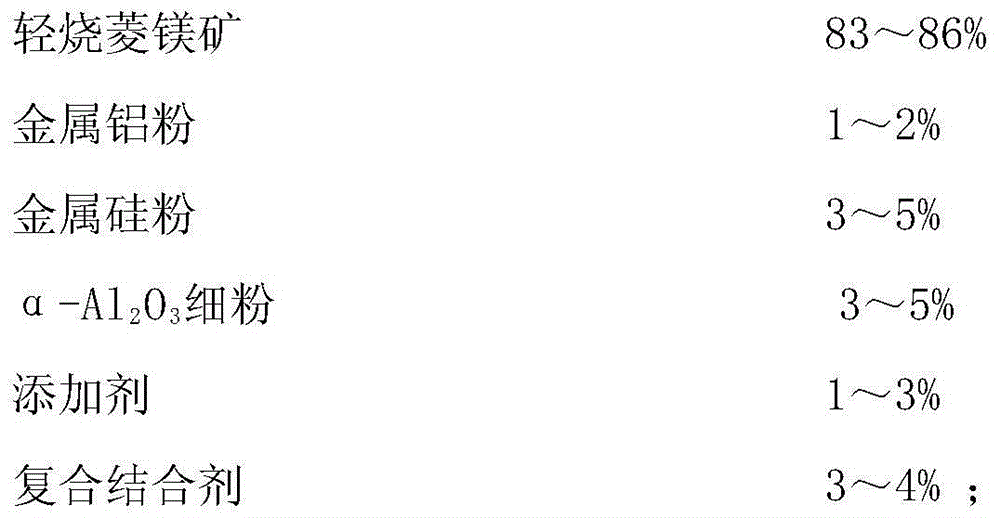

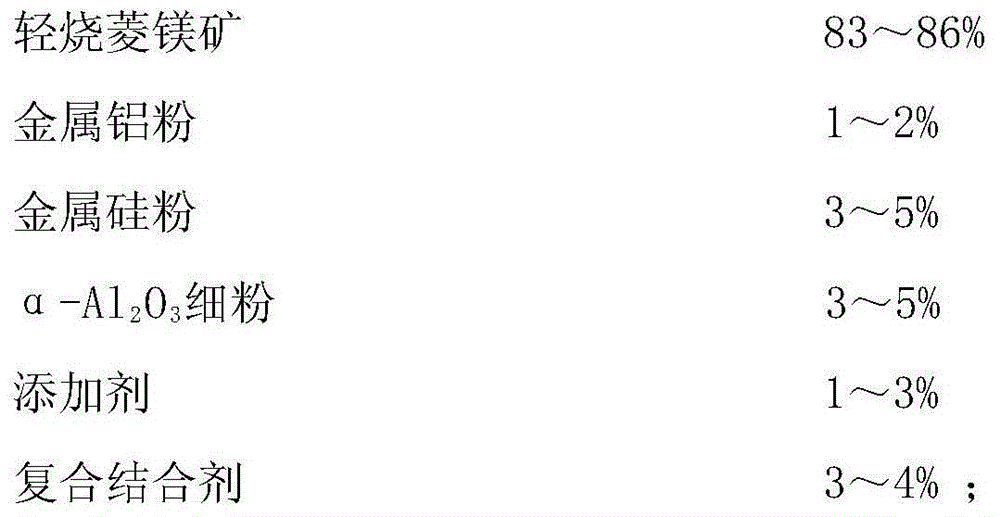

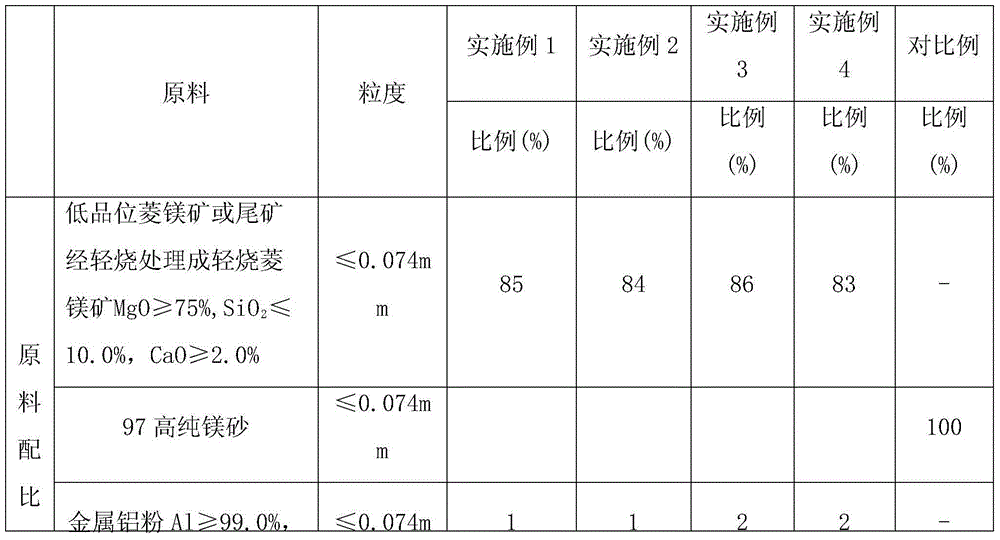

Magnesium-base composite refractory raw material and preparation method thereof

The invention discloses a magnesium-base composite refractory raw material and a preparation method thereof. The technical scheme is as follows: the preparation method comprises the following steps: preparing light-burned magnesite from 83-86% of low-grade magnesite or tailings, adding 1-3% of additive, 1-2% of metal aluminum powder, 3-5% of metal silicon powder, 3-5% of alpha-Al2O3 fine powder and 3-4% of composite binder, co-grinding, mixing, compression-moulding, baking and carrying out high-temperature nitridation firing to obtain the magnesium-base composite refractory raw material. Compared with the common high-purity magnesite refractory raw material, the magnesium-base composite refractory raw material has favorable thermal shock resistance, favorable erosion resistance and other high-temperature service properties. The composite additive is added on the basis of the existing impurity components of the low-grade magnesite and tailings, and a self-diffusion high-temperature nitrizing treatment process is utilized to change the matrix composition and liquid-phase distribution, thereby enhancing the comprehensive utilization ratio of the low-grade magnesite and tailings.

Owner:鞍山盈丰新材料科技有限公司

Flocculating and dehydrating method for treating waste slurry in process for preparing polyaluminum chloride by aluminium ash method

ActiveCN106517729AReach recovery rateHigh recovery rateSludge treatment by de-watering/drying/thickeningAluminium chlorideZeta potential

The invention discloses a flocculating and dehydrating method for treating waste slurry in a process for preparing polyaluminum chloride by an aluminium ash method. The method comprises the following steps: firstly Zeta potential of the waste slurry in the process for preparing polyaluminum chloride is adjusted by using an anionic surfactant sodium alkyl sulfate; a polyaluminum chloride solution is separated, rest waste slurry is precipitated, the solid content of the waste slurry is adjusted, cation-type polyacrylamide is added, cation-type polyacrylamide is dispersed based on self-diffusion and stirring, and flocculation and dehydration are carried out; finally, after flocculation and dehydration, the waste slurry is filtered, in order to realize solid-liquid separation. The solid content of the waste slurry is improved from 60.0%-62.5% from 50.0-55.0%, slurry with high acid solution content is converted into loose blocks, the treated waste slurry can be directly transported, in order to facilitate disposal and recycling. In addition, the volume of the waste slurry is reduced by about 21% by the flocculating and dehydrating method, and 20-30% of the volume of the polyaluminum chloride solution is recycled. The Zeta potential of the waste slurry is adjusted for realizing flocculating and dehydrating effects, and the method has theoretical significance and practical value in industrial production process.

Owner:NANJING UNIV OF SCI & TECH

Copper-Titanium Alloy Sputtering Target, Semiconductor Wiring Line Formed Using the Sputtering Target, and Semiconductor Element and Device Each Equipped with the Semiconductor Wiring Line

InactiveUS20140110849A1Good effectImprove corrosion resistanceCellsSemiconductor/solid-state device detailsIn planeElectrical resistance and conductance

A copper-titanium alloy sputtering target comprising 3 at % or more and less than 15 at % of Ti and a remainder made up of Cu and unavoidable impurities, wherein a variation (standard deviation) in hardness is within 5.0 and a variation (standard deviation) in electric resistance is within 1.0 in an in-plane direction of the target. Provided are: a sputtering target for forming a copper-titanium alloy wiring line for semiconductors capable of causing the copper alloy wiring line for semiconductors to be equipped with a self-diffusion suppressive function, effectively preventing contamination around the wiring line caused by diffusion of active Cu, improving electromigration (EM) resistance, corrosion resistance and the like, enabling the arbitrary formation of a barrier layer in a simple manner, and uniformizing film properties; a copper-titanium alloy wiring line for semiconductors; and a semiconductor element and a device each equipped with the semiconductor wiring line.

Owner:JX NIPPON MINING& METALS CORP

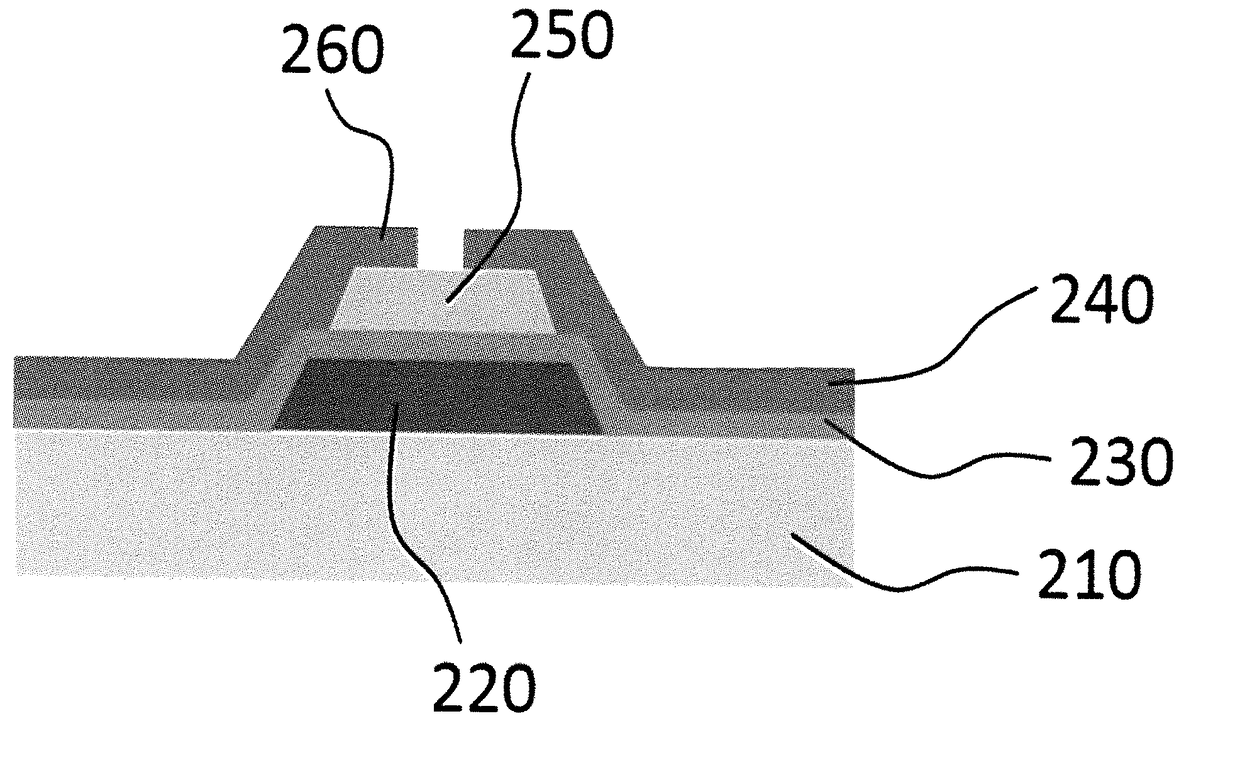

Lateral epitaxial technique based longitudinal structure AlGaN/GaN HEMT device and manufacture method thereof

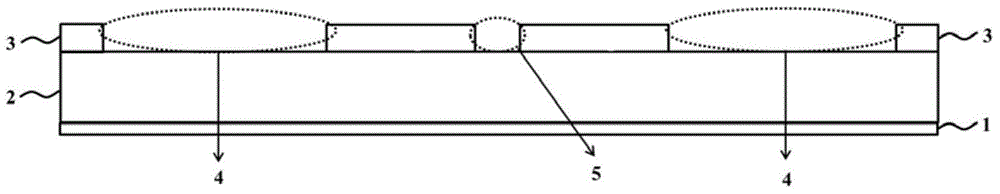

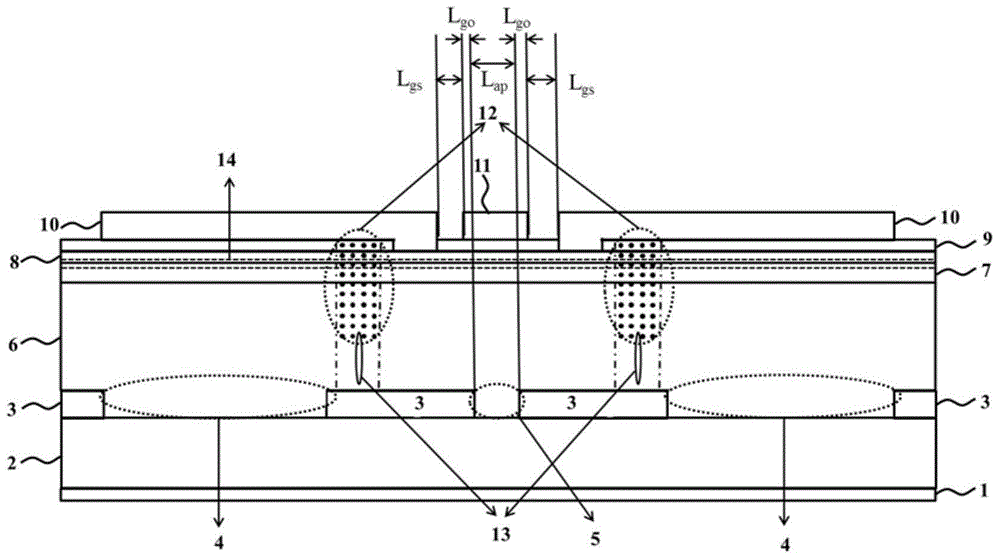

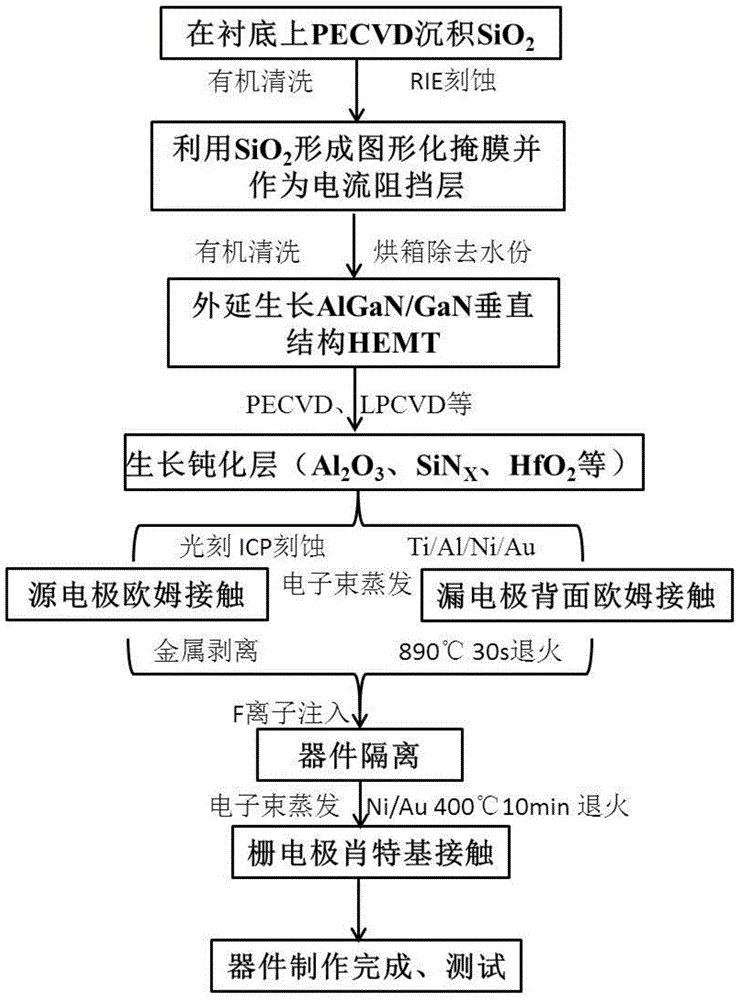

ActiveCN104659089ARaise the barrier heightImprove crystal qualitySemiconductor/solid-state device manufacturingSemiconductor devicesElectricitySelf-diffusion

The invention discloses a lateral epitaxial technique based longitudinal structure AlGaN / GaN HEMT device and a manufacture method thereof. The device comprises a substrate, a current blocking layer and an epitaxial layer, wherein the current blocking layer is formed on the substrate; the epitaxial layer laterally epitaxially grows on the current blocking layer; a current conducting through hole is formed in the current blocking layer. According to the invention, the current blocking layer acts as an insulation layer, so that the problems that the two-dimensional electron gas concentration, self-diffusion, high electricity leakage and the like are caused by ion implantation damage due to Mg doping, barrier height improvement by Mg ion implantation and formation of a similar insulation layer by Al ion implantation in a traditional technology can be solved; meanwhile, the defects of high cost, long time consumption, technology complexity and the like due to secondary epitaxial growth are also prevented; in addition, a clearance region formed by incomplete healing is isolated via F ion implantation, so that the clearance region is not involved in the device structure, and the problems of electric leakage and the like caused by the clearance region are relieved effectively.

Owner:SUZHOU NENGWU ELECTRONICS TECH

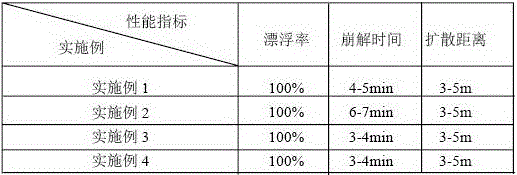

Water surface self-diffusion floating granules and preparation method thereof

InactiveCN106172464AGood floatationSmall particle sizeBiocideAnimal repellantsSelf-diffusionBULK ACTIVE INGREDIENT

The invention discloses water surface self-diffusion floating granules and a preparation method thereof and belongs to the field of pesticide processing. The water surface self-diffusion floating granules are composed of 0.5-70% of pesticide active ingredient, 0.5-60% of buoyancy auxiliary, 0.2-30% of water surface extender, 0.05-10% of dispersant, 0.1-5% of wetting agent, 5-20% of disintegrant and the balance of filler. The preparation method includes: 1), sanding the pesticide active ingredient into a water suspension or an oil suspension; 2), well mixing the buoyancy auxiliary, the water surface extender, the dispersant, the wetting agent, the disintegrant and the filler, well mixing with size ground well in the step 1), adding a certain amount of water for kneading granulation. Wet sanding is adopted in the preparation method, so that no dust is generated in the preparation process; the granules prepared by the method are small in grain size after being disintegrated in water and can form a film which is more continuous; by adding a diffusant with excellent performance, the granules can automatically diffuse on the water surface, diffusion distance and speed and disintegration speed can be adjusted, and the granules can automatically avoid when coming across obstacles and don't get together around the obstacles to cause pesticide damage; the water surface self-diffusion floating granules are an ideal self-diffusion floating granule preparation.

Owner:YANGZHOU SPED CHEM

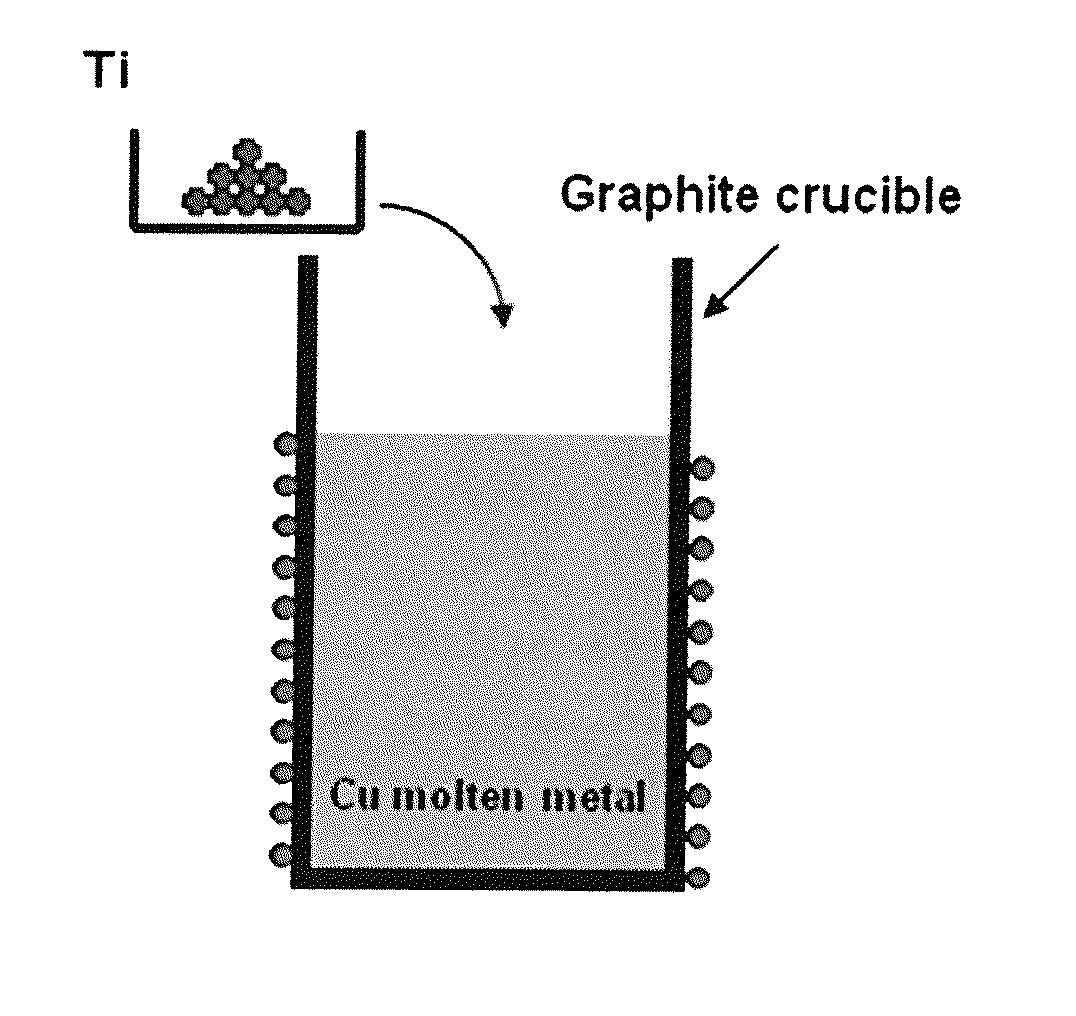

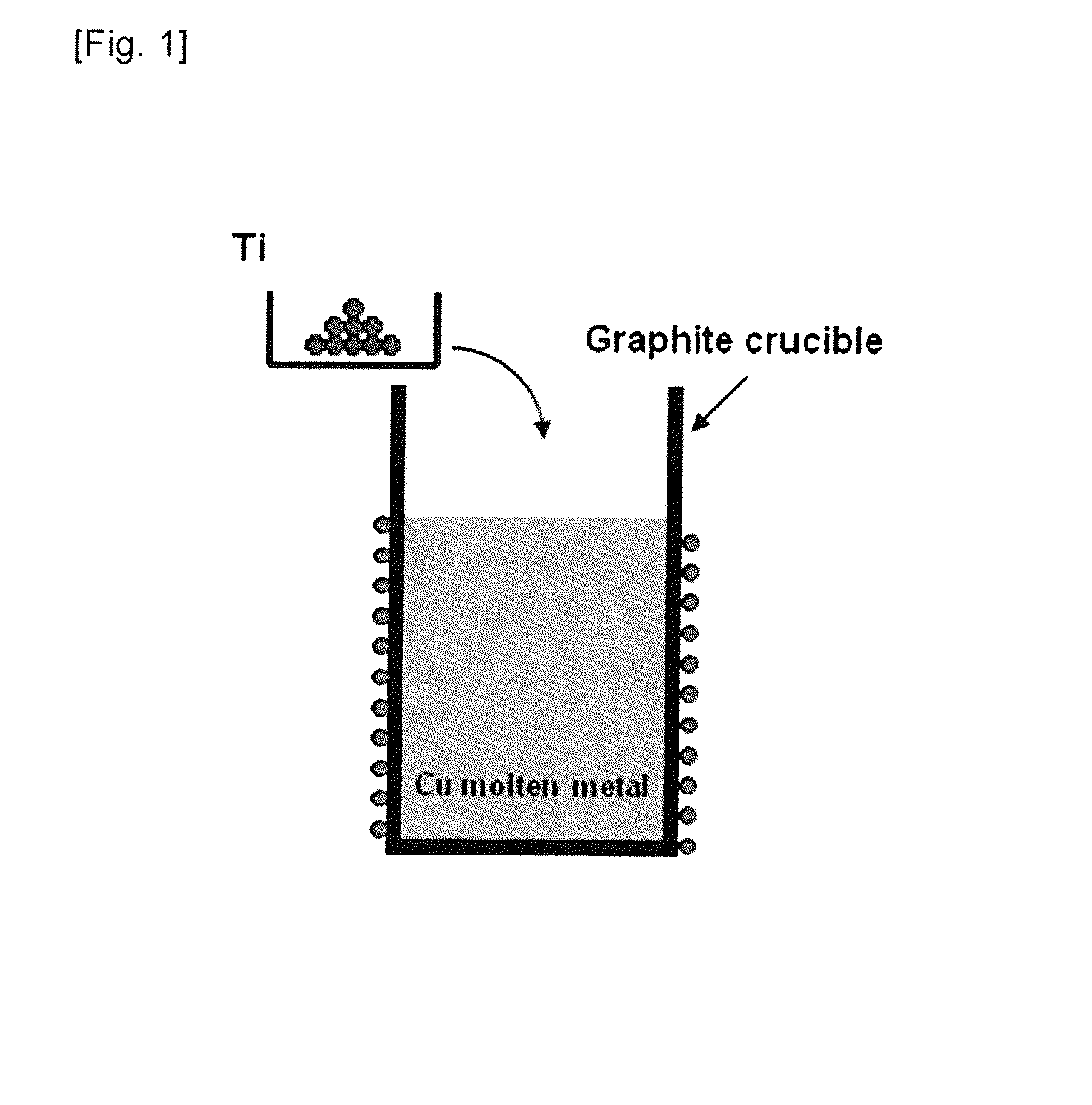

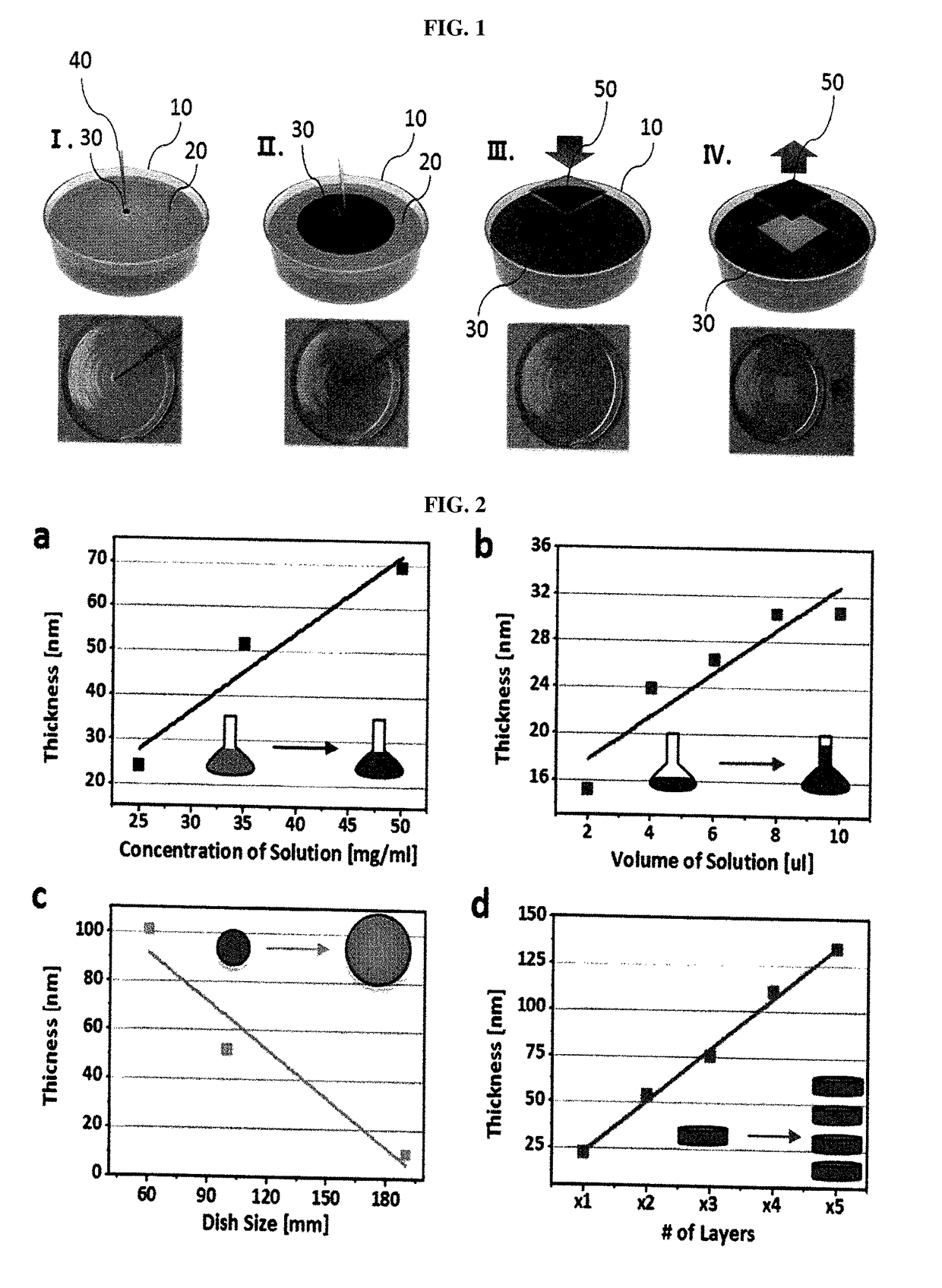

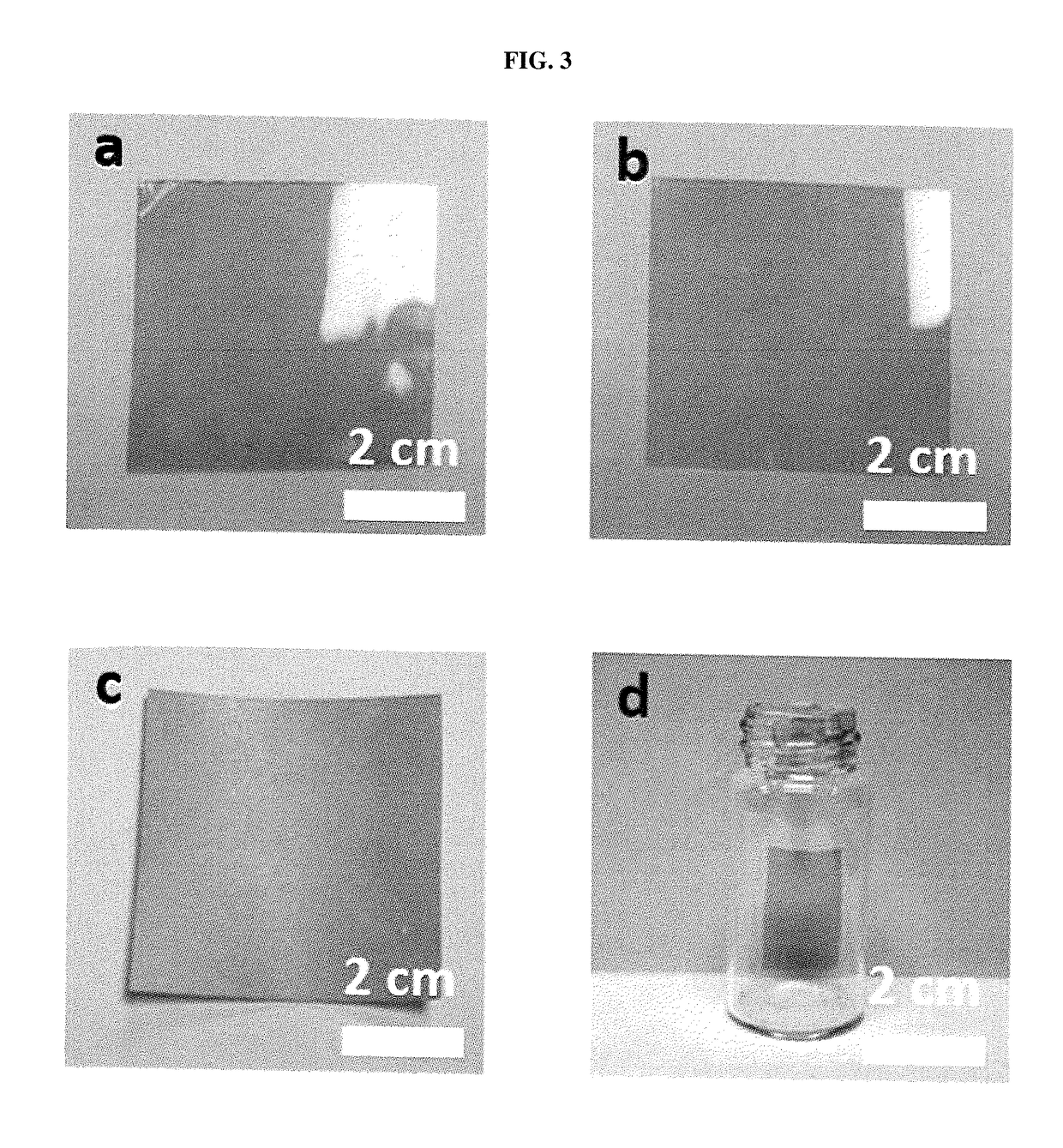

Ultra-fast method for preparing organic/inorganic thin film by using self-diffusion effects

ActiveUS20180212148A1Prevent bulk materialSimple processLiquid surface applicatorsFinal product manufactureSelf-diffusionUltra fast

According to the present invention, an ultra-fast method for preparing an organic / inorganic thin film by using self-diffusion effects comprises the steps of: forming a solution by dissolving one or more organic / inorganic materials in a solvent; forming an organic / inorganic thin film by supplying the formed solution onto a liquid substrate; and transferring the formed thin film to a substrate, wherein the step of forming an organic / inorganic thin film forms a thin film on the liquid substrate from the organic / inorganic materials through the occurrence of a self-diffusion phenomenon caused by a difference in surface tension between the liquid substrate and the solution, and through the occurrence of the evaporation of the solvent and the dissolution process of the solvent to the liquid substrate.

Owner:KOREA ADVANCED INST OF SCI & TECH

Self diffusion spreading oil on water surfaces and preparation method thereof

InactiveCN106212447ASolve the problem of not being easily dissolved by solventsCreate pollutionBiocideAnimal repellantsSelf-diffusionWear particle

The invention concretely discloses self diffusion spreading oil on water surfaces and a preparation method thereof. The spreading oil comprises the following components in percentages by weight: 10-60% of a pesticide active component, 1-5% of a dispersant, 0.5-5%of a wetting agent, 1-3% of a suspending agent, 5-30% of a water surface spreading agent, and the balance being a filling material. The spreading oil is prepared by production technology which comprises the following steps: the pesticide active component, the dispersant, the wetting agent, the suspending agent, the water surface spreading agent and the filling material are added into a high shear emulsifying machine; after the components are mixed by the high shear emulsifying machine, the mixture is milled in a sand milling machine until particle size reaches 2-5 [mu]m to obtain the spreading oil. The water surface spreading agent with excellent performance is added in the preparation process of the spreading oil; the spreading oil can automatically diffuse on the water surface, the diffusion distance can be adjusted by an auxiliary agent, the diffusion speed can be adjusted too, and the spreading oil can automatically avoid barriers when facing barriers; a layer of film is formed on a water surface, and the film can diffuse along the water surface; a wet method is used in the preparation method, so that a problem that original drugs are not easy to dissolve in solvents is solved, polar solvents are not used, surrounding environments are not polluted, and preparation cost is low.

Owner:YANGZHOU SPED CHEM

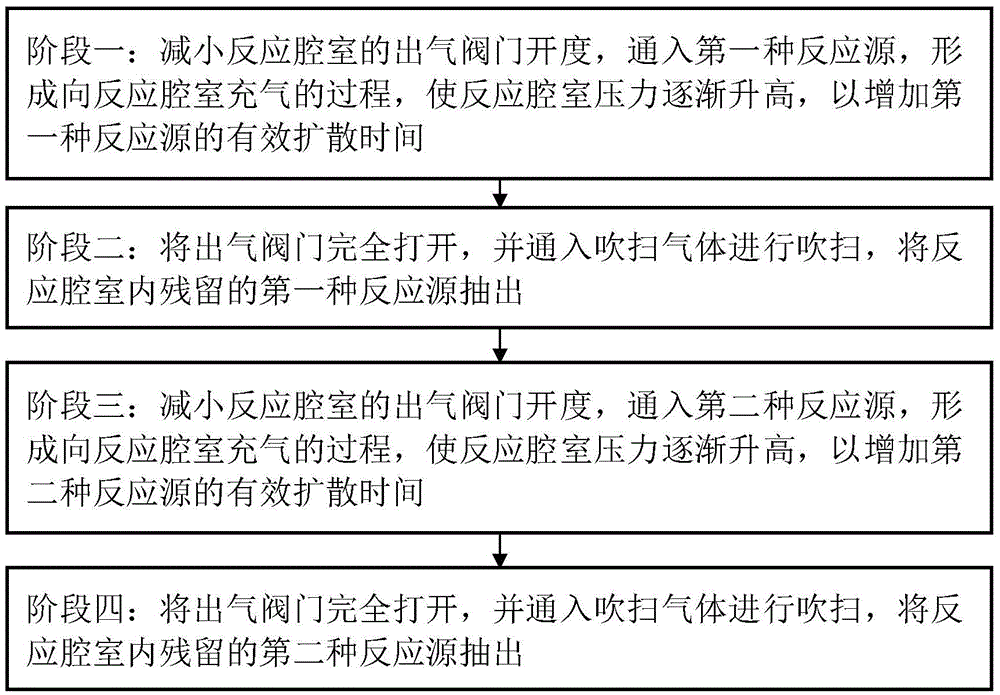

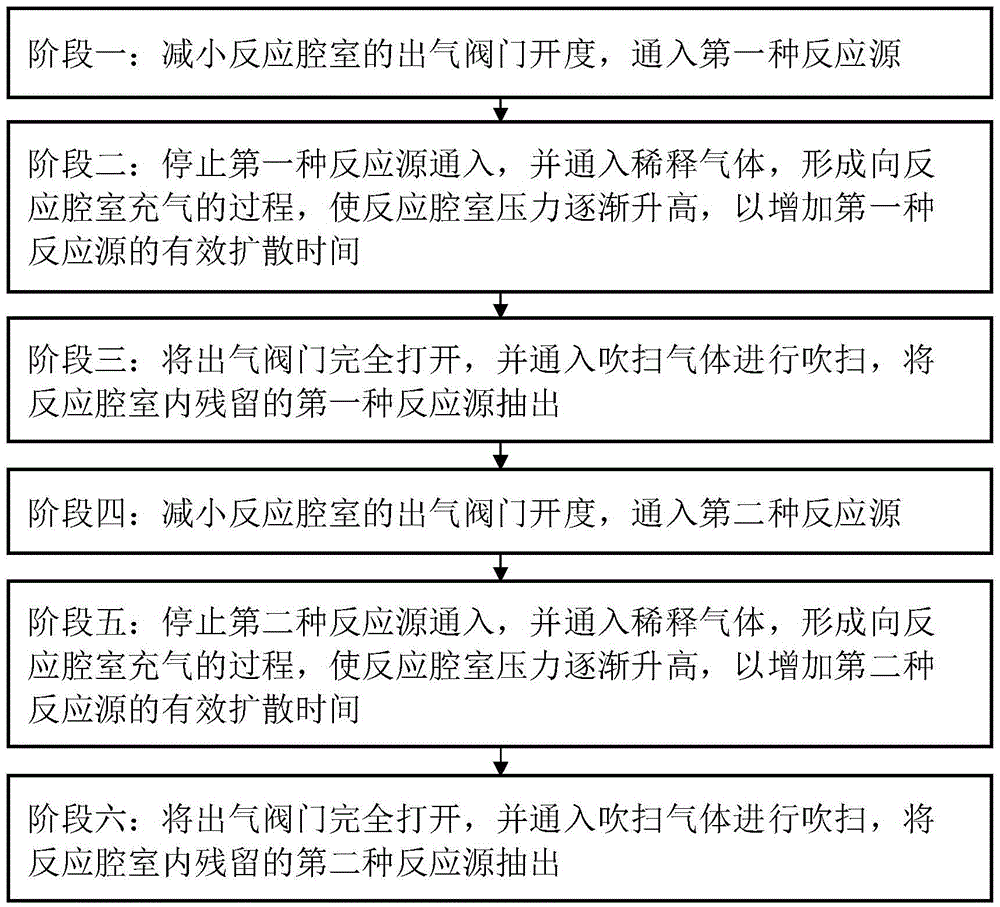

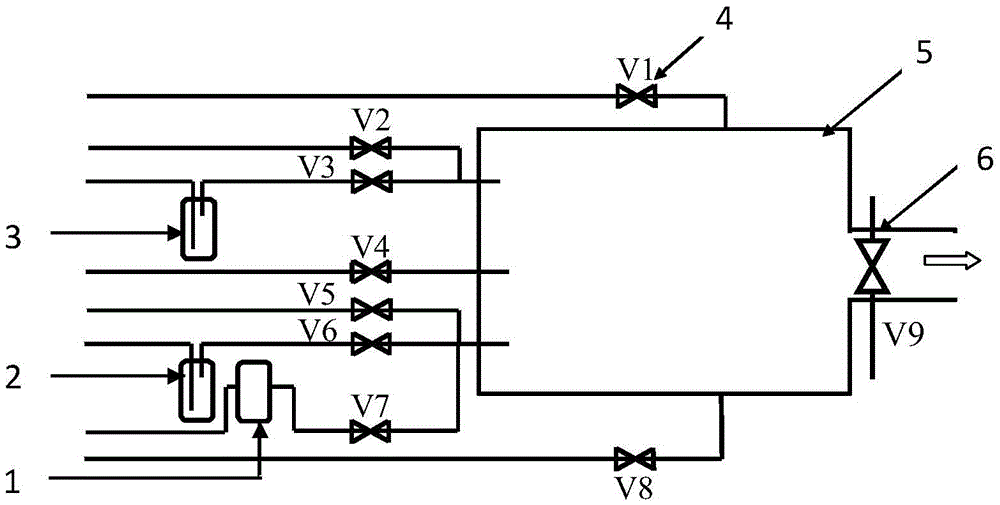

Implementation method for preparing thin film through atomic layer deposition technology

InactiveCN105568256AFacilitated DiffusionIncrease effective diffusion timeChemical vapor deposition coatingSelf-diffusionControl system

The invention discloses an implementation method for preparing a thin film through an atomic layer deposition technology. A self-diffusion type ALD technology is provided, and opening and closing of a gas outlet valve of a reaction chamber are used for controlling diffusion of reaction sources in the reaction chamber; through the manner that the reaction sources are led in during the technological process, opening of the gas outlet valve is reduced or the gas outlet valve is closed, and therefore pressure inside the reaction chamber is increased, and the effective diffusion time of the reaction source is prolonged; diluent gas is added in the technology circulating process to promote diffusion of the reaction sources, on one hand, the utilization rate of the reaction sources can be improved, and the technology cost is reduced; and on the other hand, the requirement for a pressure control system of the reaction chamber can be reduced, and therefore the equipment cost can be reduced. Meanwhile, due to the fact that diffusion of the reaction sources in the reaction chamber is longer, uniformity of a prepared thin film can be further improved.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

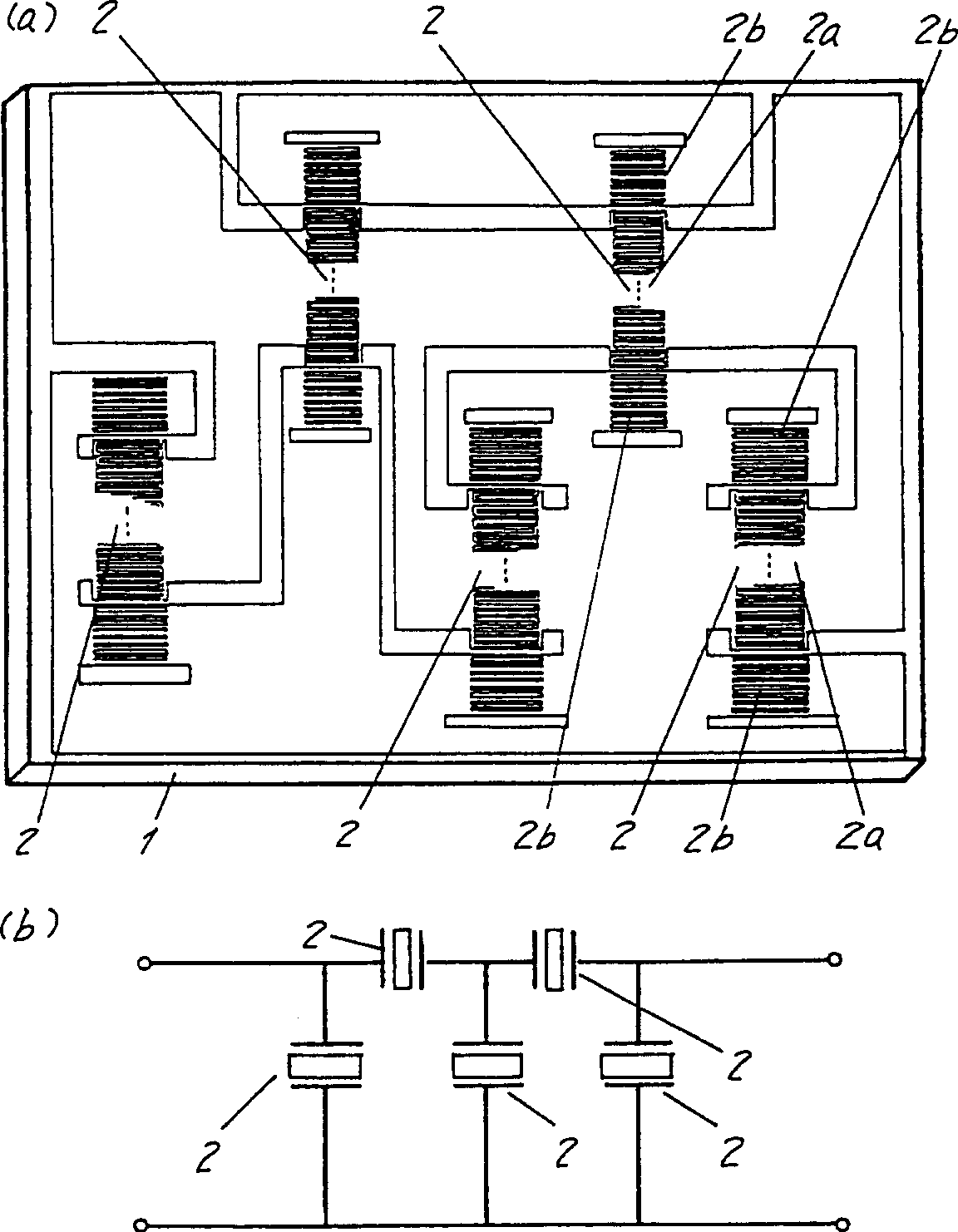

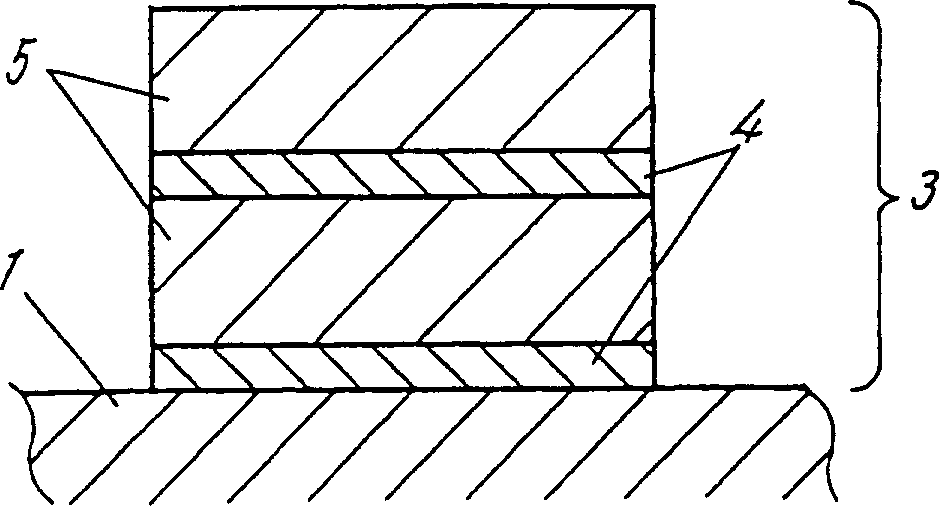

Surface acoustic wave device and production method thereof and mobile communication equipment using it

InactiveCN1263646ANo characteristic deteriorationElectrical-mechanical transformations have no effectImpedence networksMachines/enginesSelf-diffusionRoom temperature

The invention relates to the elastic surface acoustic wave device and production method thereof and mobile communication equipment using it. An electrode material for a elastic surface acoustic wave device comprising laminates in at least two stages, each laminate being formed by laminating a second metal layer (5) on a first metal layer (4), wherein the first metal layer (4) uses a metal having a diffusion coefficient to Al which is smaller than a self-diffusion coefficient of Al, and the second metal layer (5) uses a ternary or higher Al alloy in which at least two kinds of metals, at least one kind of metal solid-dissolved to Al at room temperature and at least one kind of metal which segregates in an Al grain boundary or forms an intermetallic compound with Al at room temperature are added, whereby a surface acoustic wave device excellent in power resistance, capable of using a conventional pattern forming technique, being thermally stable and preventing an insertion loss increase can be provided.

Owner:SKYWORKS PANASONIC FILTER SOLUTIONS JAPAN

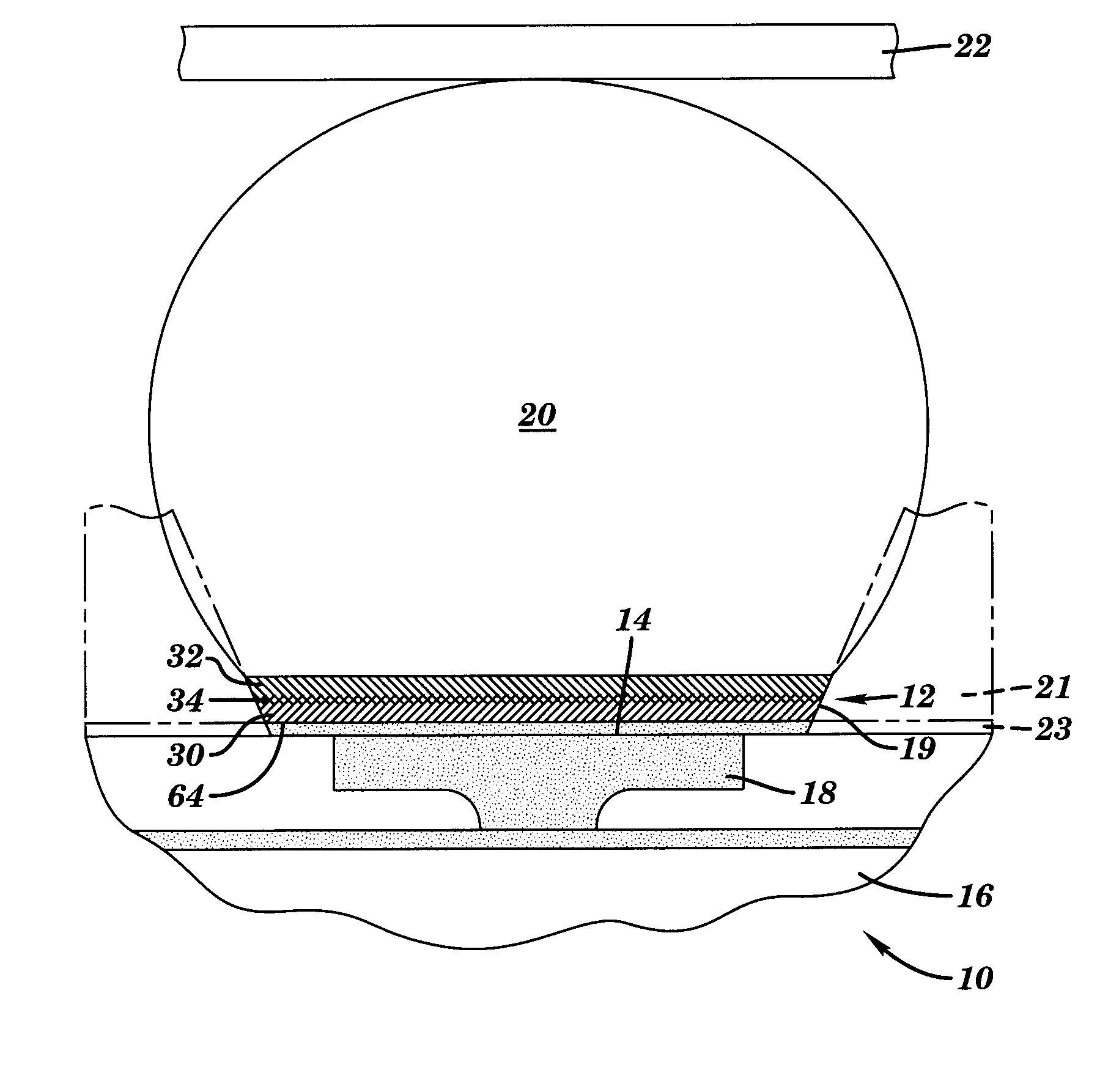

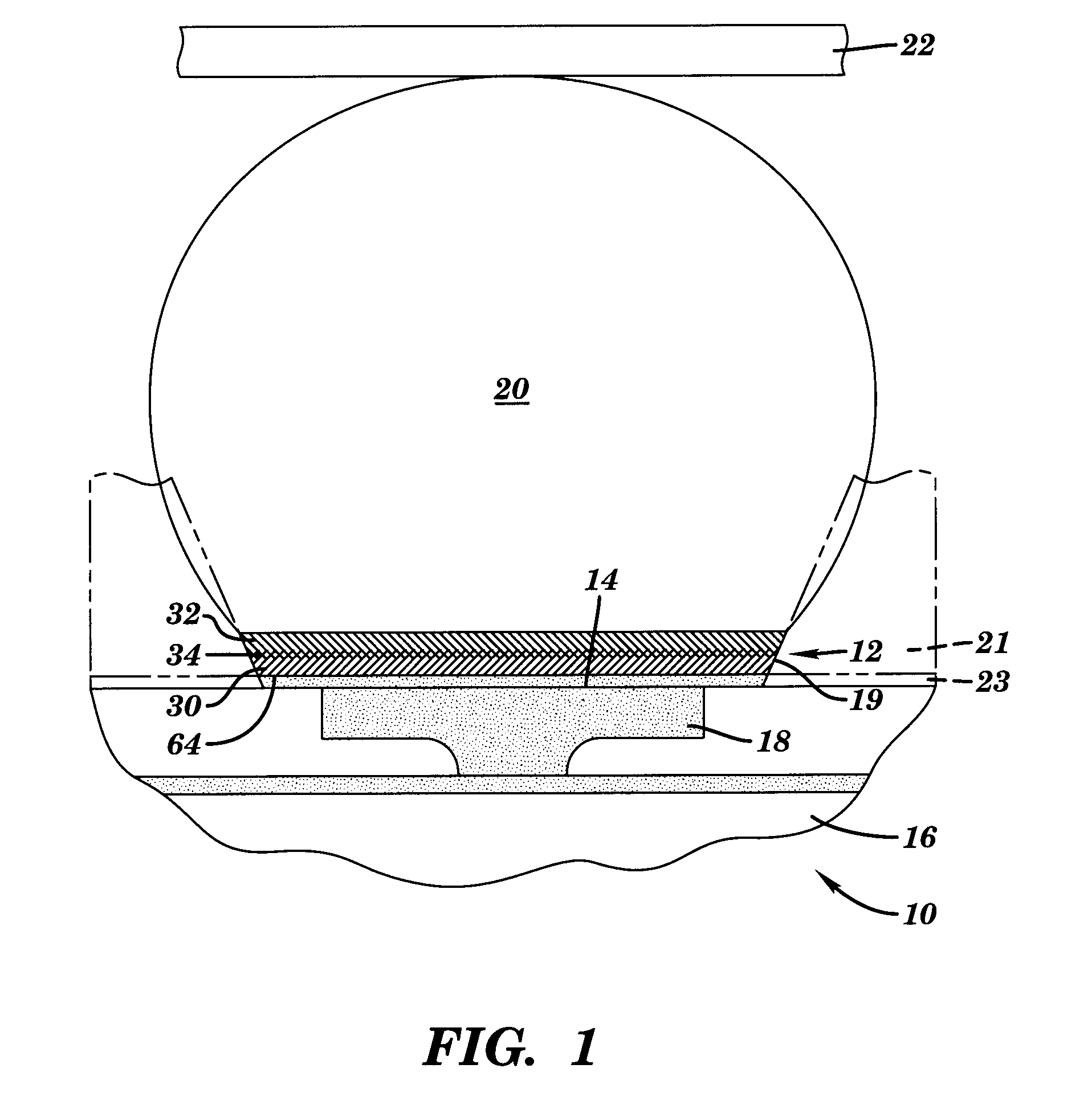

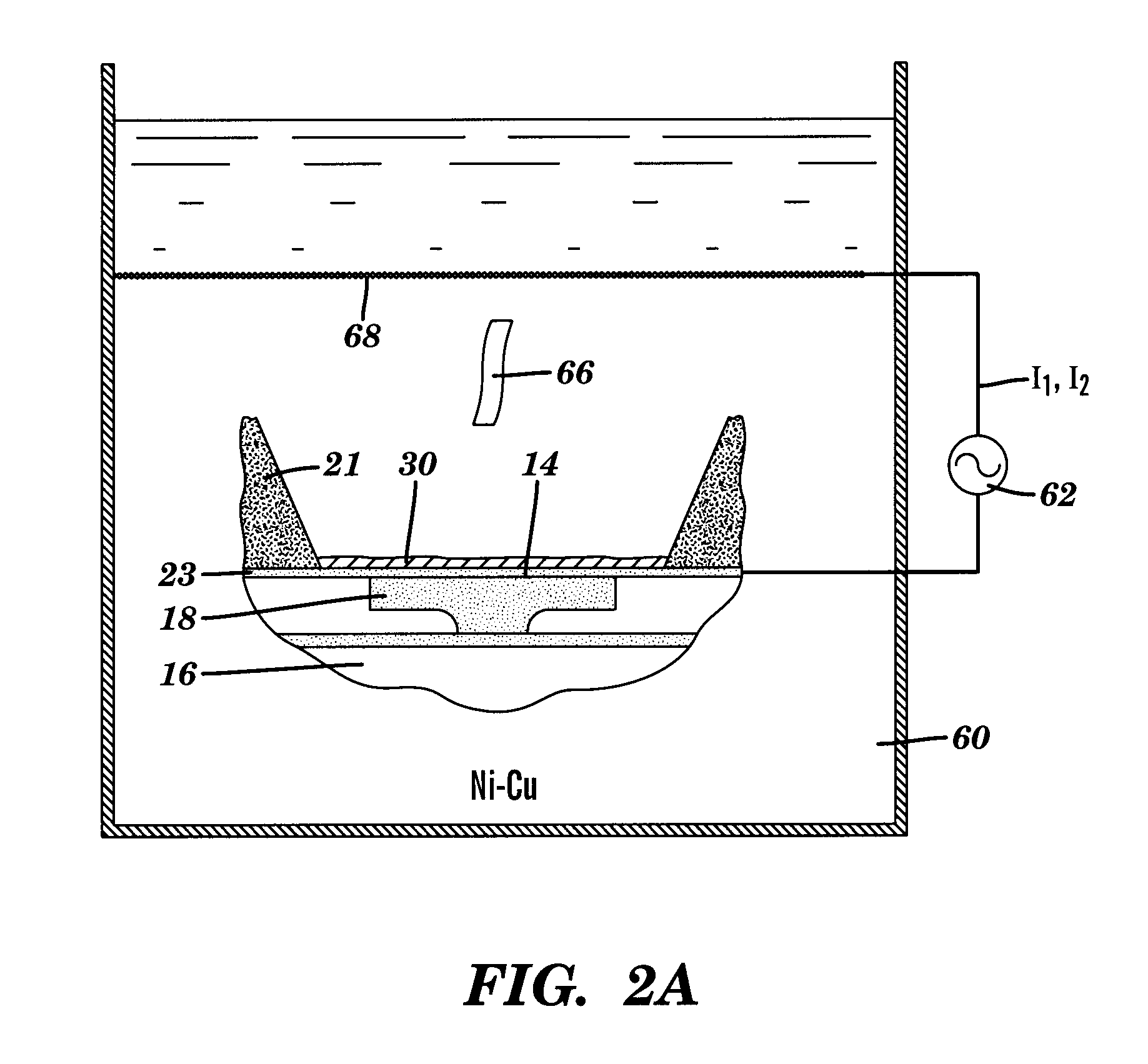

Barrier for interconnect and method

InactiveUS6992389B2Improve reliabilityImprove protectionSemiconductor/solid-state device detailsSolid-state devicesHigh current densityEngineering

A method of creating a multi-layered barrier for use in an interconnect, a barrier for an interconnect, and an interconnect including the barrier are disclosed. The method includes creating the multi-layered barrier in a recess of the device terminal by use of a single electroplating chemistry to enhance protection against voiding and de-lamination due to the diffusion of copper, whether by self-diffusion or electro-migration. The barrier includes at least a first layer of nickel-rich material and a second layer of copper-rich material. The barrier enables use of higher current densities for advanced complementary metal-oxide semiconductors (CMOS) designs, and extends the reliability of current CMOS designs regardless of solder selection. Moreover, this technology is easily adapted to current methods of fabricating electroplated interconnects such as C4s.

Owner:INT BUSINESS MASCH CORP

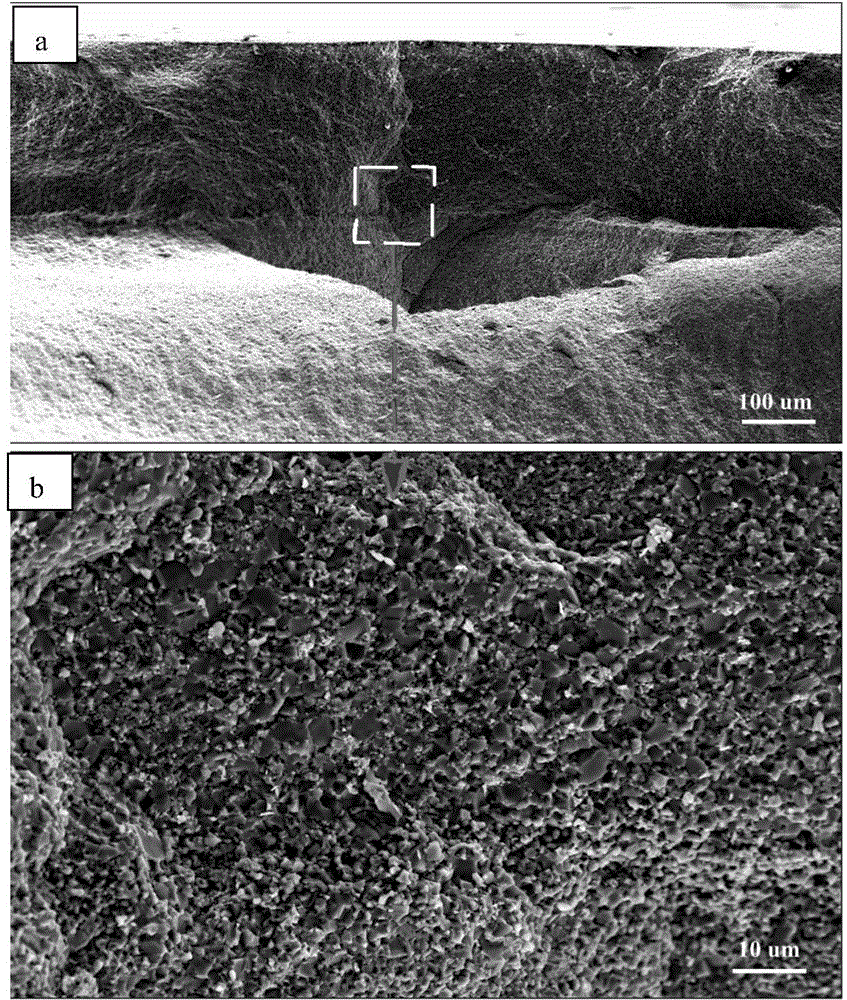

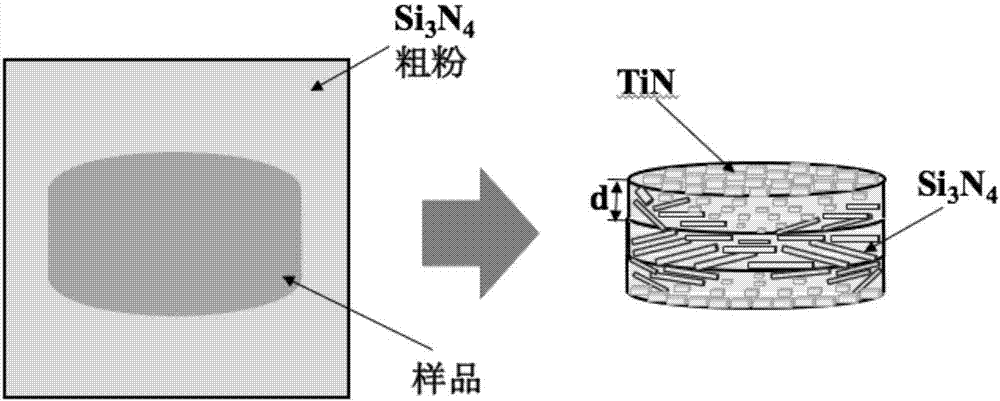

Method for preparing Si3N4 gradient material through self-diffusion

The invention discloses a method for preparing a Si3N4 gradient material through self-diffusion. The method comprises steps as follows: Si3N4 and MO2 powder are taken as raw materials, wherein M is Ti, Zr or Hf, MgO-Re2O3 is taken as a sintering aid, the components are mixed and dried, and mixed powder is obtained; after the mixed powder is subjected to isostatic cool pressing, a sample is embedded in the powder, the mixture is put in a sintering furnace, and the Si3N4 gradient material is obtained finally. A gradient MN layer is formed on the surface of the Si3N4 material prepared with the method, and MN as a high-hardness and wear-resistant conductive phase can allow direct coating treatment on the surface of Si3N4 ceramic while improving surface hardness and wear resistance of the Si3N4ceramic; relative density is higher than 95%, surface hardness is 18-25 GPa, fracture toughness is 10-14 MPa.m<1 / 2>, bending strength is 1000-1500 Mpa, and gradient layer thickness is 10-200 mu m.

Owner:GUANGDONG UNIV OF TECH

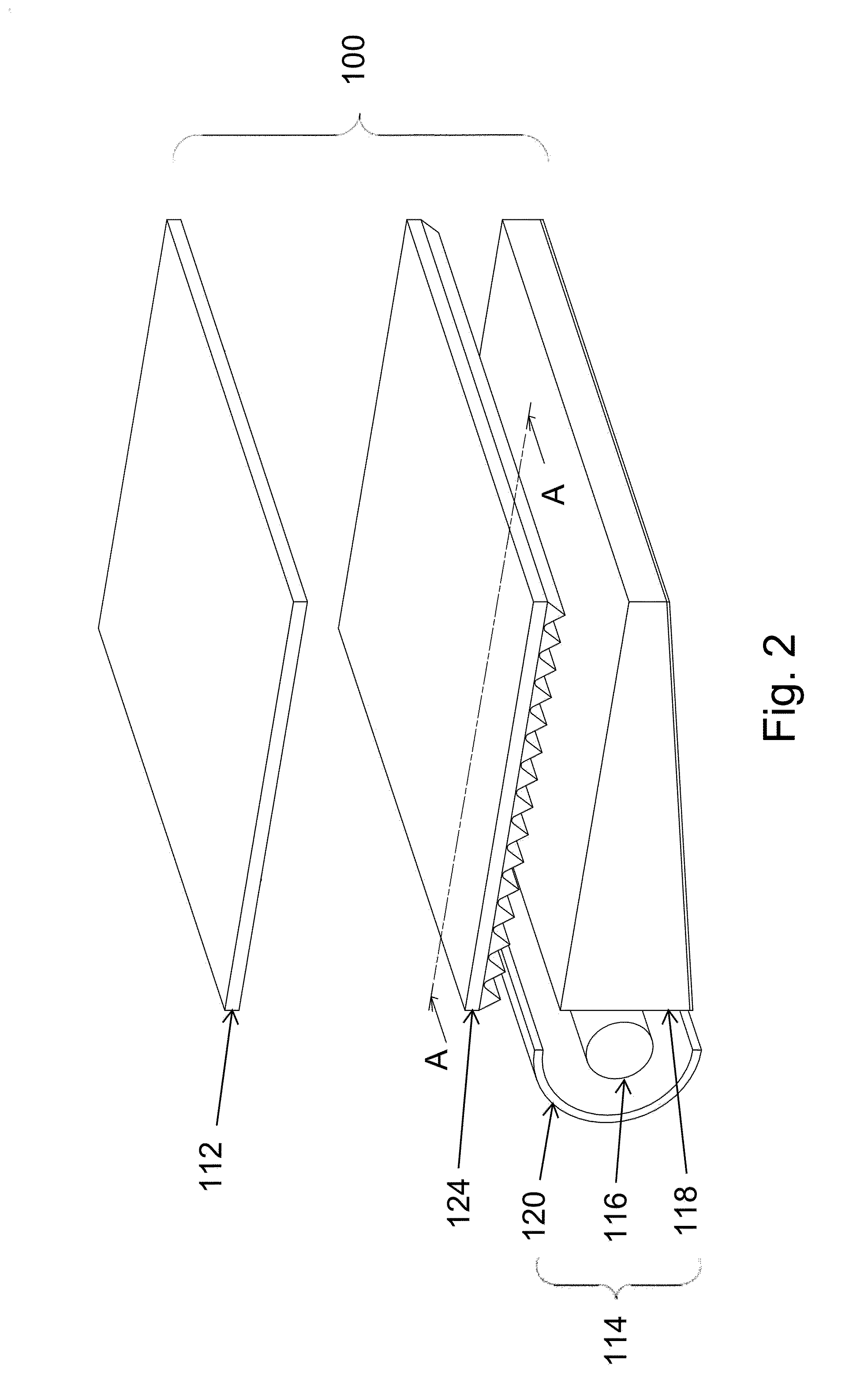

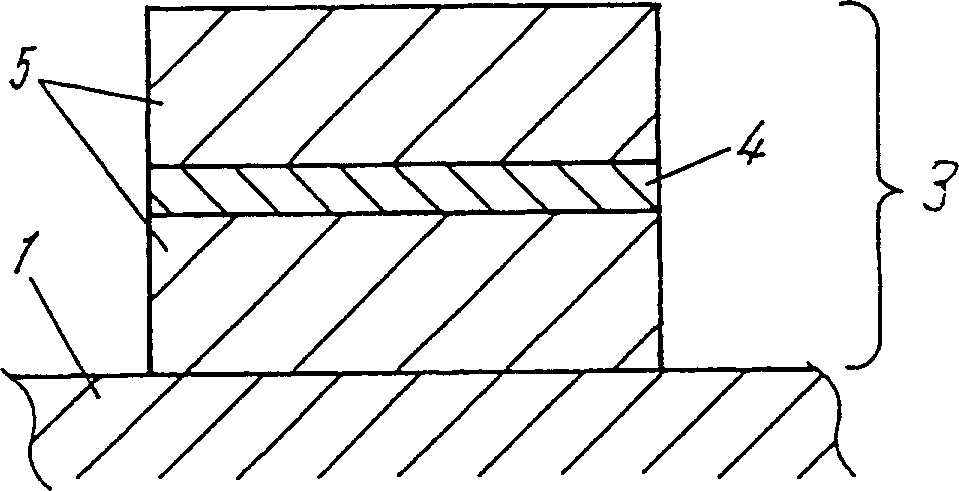

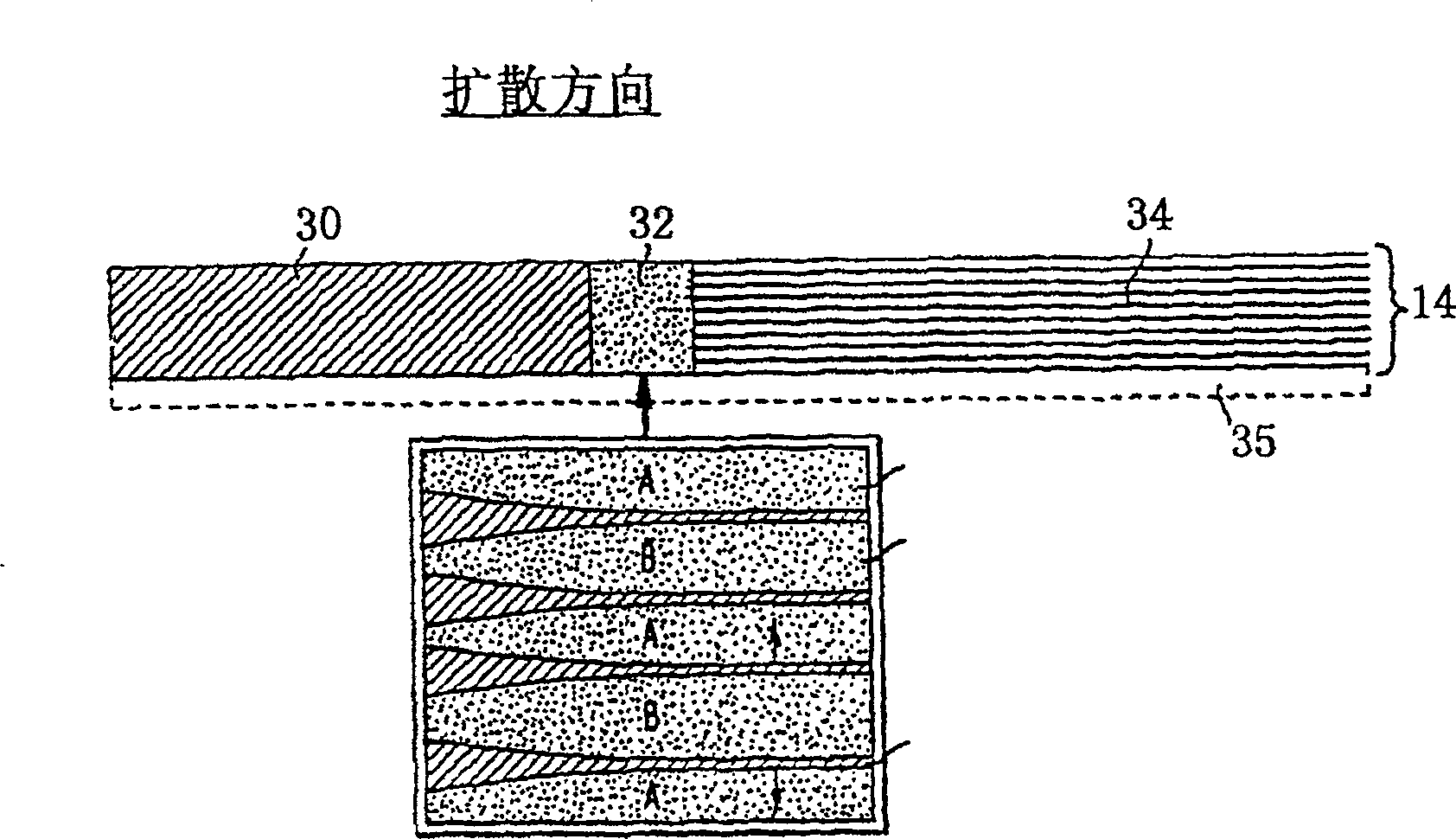

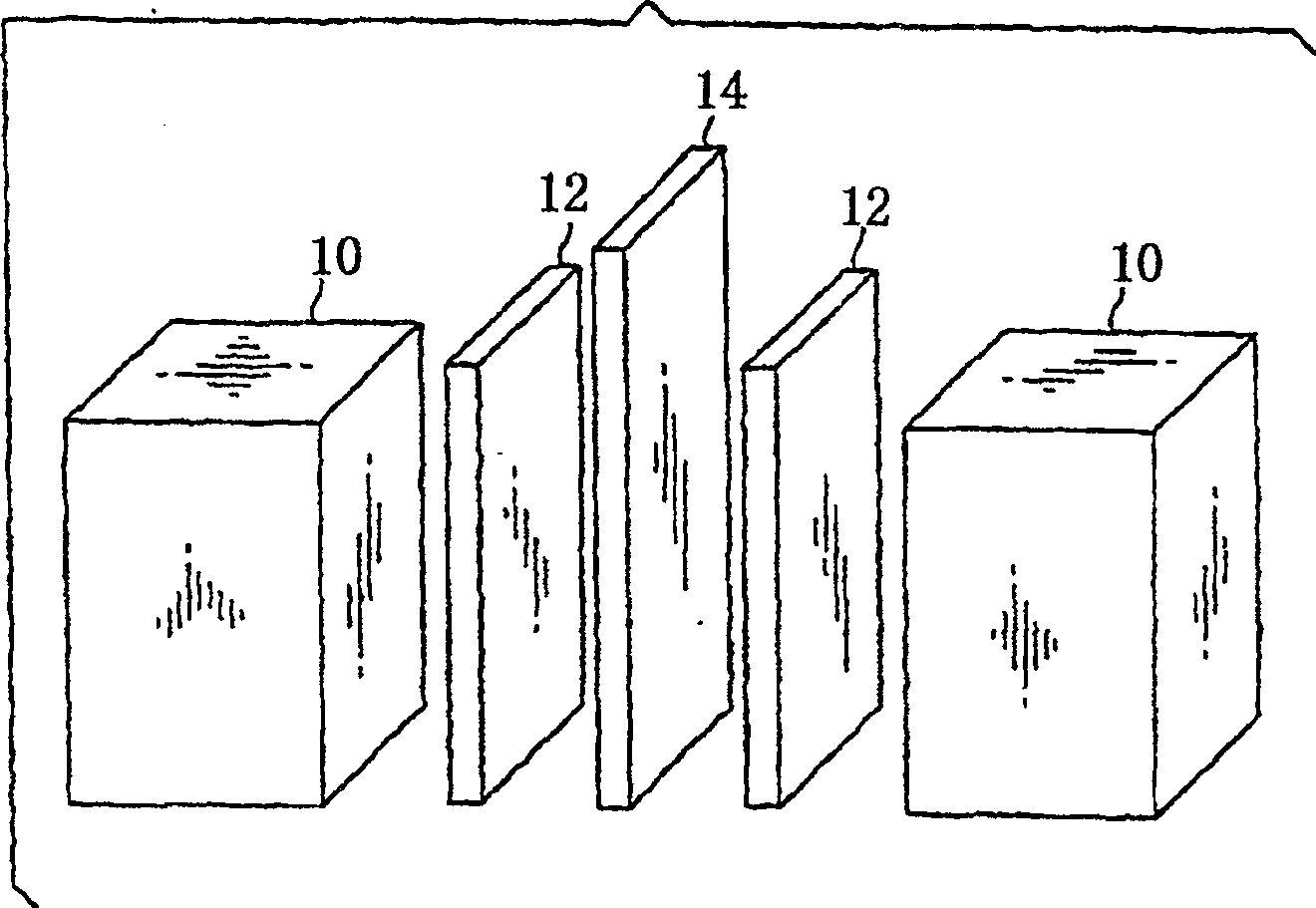

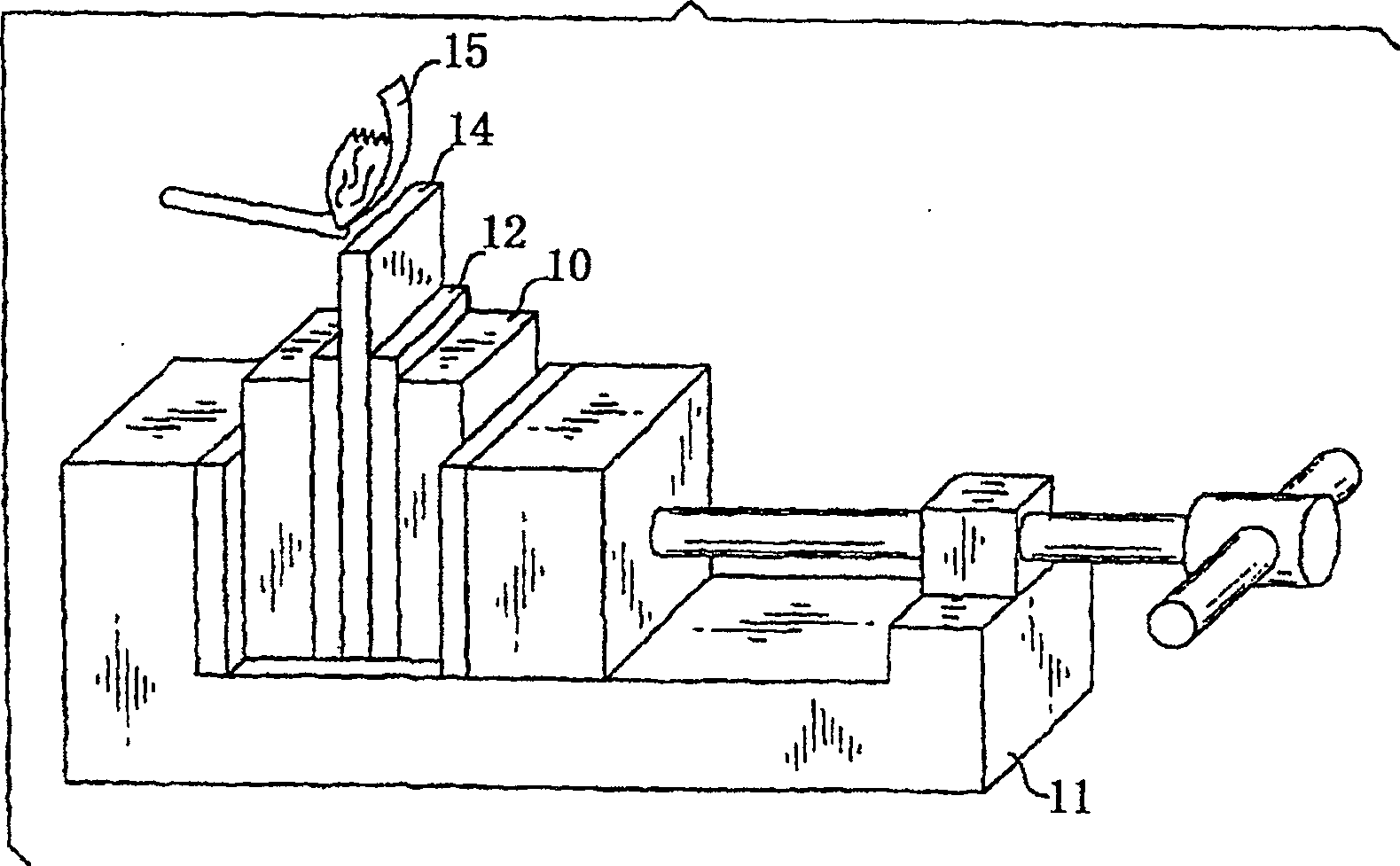

Composite reactive multilayer foil

InactiveCN100513038CFirmly connectedImprove connection fastnessExothermal chemical reaction heat productionVacuum evaporation coatingSelf-diffusionPolymer science

Reactive foils and their uses are provided as localized heat sources useful, for example, in ignition, joining and propulsion. An improved reactive foil (14) is preferably a freestanding multilayered foil structure made up of alternating layers (16, 18) selected from materials that will react with one another in an exothermic and self-propagating reaction. Upon reacting, this foil supplies highly localized heat energy that may be applied, for example, to joining layers, or directly to bulk materials that are to be joined. This foil heat-source allows rapid bonding to occur at room temperature in virtually an environment (e.g., air, vacuum, water, etc.). If a joining material is used, the foil reaction will supply enough heat to melt the joining materials. If no joining material is used, the foil reaction supplies heat directly to at least two bulk materials, melting a portion of each bulk, which upon cooling, form a strong bond. Additionally, the foil (14) may be designed with openings that allow extrusion of the joining (or bulk) material through the foil to enhance bonding.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

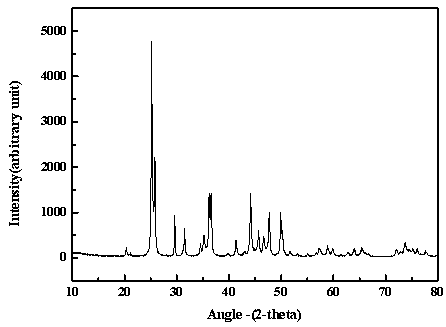

Method and device for preparing strontium carbonate crystals through self-diffusion at room temperature

InactiveCN109133136AReduce consumptionImprove production efficiencyStrontium carbonatesStrontium carbonateSelf-diffusion

The invention relates to a method and a device for preparing strontium carbonate crystals through self-diffusion at room temperature. According to the method, with strontium dichloride hexahydrate andammonium hydrogen carbonate as reactants and glycine as a biomimetic control agent, granular strontium carbonate crystals are prepared; the method comprises the following specific steps: in a reaction device, adding a first batch of the strontium dichloride hexahydrate and the ammonium hydrogen carbonate, then adding 0.020% of a glycine solution, reacting for 24h by standing at room temperature,supplementing a second batch of the reactants and a third batch of the reactants, respectively continuing reacting for 24h by standing, filtering a reaction product, washing for three times by using distilled water, and drying for 1h at 105 DEG C to obtain the granular strontium carbonate crystals with the grain diameter of 110-440nm, wherein the product purity is higher than or equal to 99% and the yield is 96-98%. The reaction device consists of a reactor 1 (5), a reactor 2 (9) and a reactor 3 (13). The method and the device have the advantages of high preparation efficiency, simple and convenient operation, high technological stability, low energy consumption, low production cost and the like.

Owner:NANCHANG HANGKONG UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com