Water surface self-diffusion floating granules and preparation method thereof

A water surface expander and self-diffusion technology, applied in the field of pesticides, can solve the problems of complex process, complex operation, coarse particles, etc., and achieve the effects of excellent floating performance, excellent disintegration performance and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

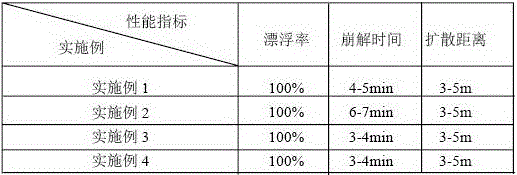

Examples

Embodiment 1

[0028] Example 1: 10% pyrazosulfuron-quinclorac floating granules

[0029] quinclorac 9%, pyrazosulfuron 1%, expanded perlite 20%, dioctyl sulfosuccinate sodium salt 6%, lignosulfonate 2%, sodium lauryl sulfate 2%, sulfuric acid Ammonium 15%, cornstarch topped up to 100%.

[0030] Mix quinclorac, pyrazosulfuron-methyl, lignosulfonate, and sodium lauryl sulfate with a certain amount of water, and then sand them with a sand mill for 1 hour; mix other additives and fillers Uniform, mixed with the above-mentioned sand-milled slurry, the mixed material is put into a kneader and kneaded, the kneaded material is granulated by an extrusion granulator, dried and sieved, and it is ready after passing the test.

Embodiment 2

[0031] Embodiment 2: 10.5% bensulfuron-methyl pretilachlor

[0032] Bensulfuron-methyl 1%, pretilachlor 9.5%, glass microspheres 15%, sodium dialkyl sulfosuccinate 4%, lignosulfonate 2%, sodium lauryl sulfate 2%, carboxymethyl Sodium starch 8%, cornstarch make up to 100%.

[0033] First mix pretilachlor, bensulfuron-methyl, lignosulfonate, and sodium lauryl sulfate with a certain amount of water, and then use a sand mill for sanding for 1 hour; mix other additives and fillers evenly , mixed evenly with the above-mentioned sand-milled slurry, the mixed material is put into a kneader and kneaded, the kneaded material is granulated by an extrusion granulator, dried and sieved, and it can be tested after passing the test.

Embodiment 3

[0034] Embodiment 3: 1% thiamethoxam floating granule

[0035] Thiamethoxam 1%, plastic micro-hollow body 15%, siloxane series 4%, sodium naphthalenesulfonate formaldehyde condensate 2%, wetting and penetrating agent T2%, potassium chloride 15%, diatomaceous earth to 100 %.

[0036] First mix thiamethoxam, naphthalenesulfonate sodium formaldehyde condensate, and wetting and penetrating agent Fast T with a certain amount of water, and then use a sand mill for sand grinding for 1 hour; mix other additives and fillers evenly, and mix with the above The slurry is sanded and mixed evenly, and the mixed material is put into a kneader for kneading, and the kneaded material is granulated by an extrusion granulator, dried and sieved, and it is ready after passing the test.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com