Patents

Literature

695results about How to "High oil absorption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

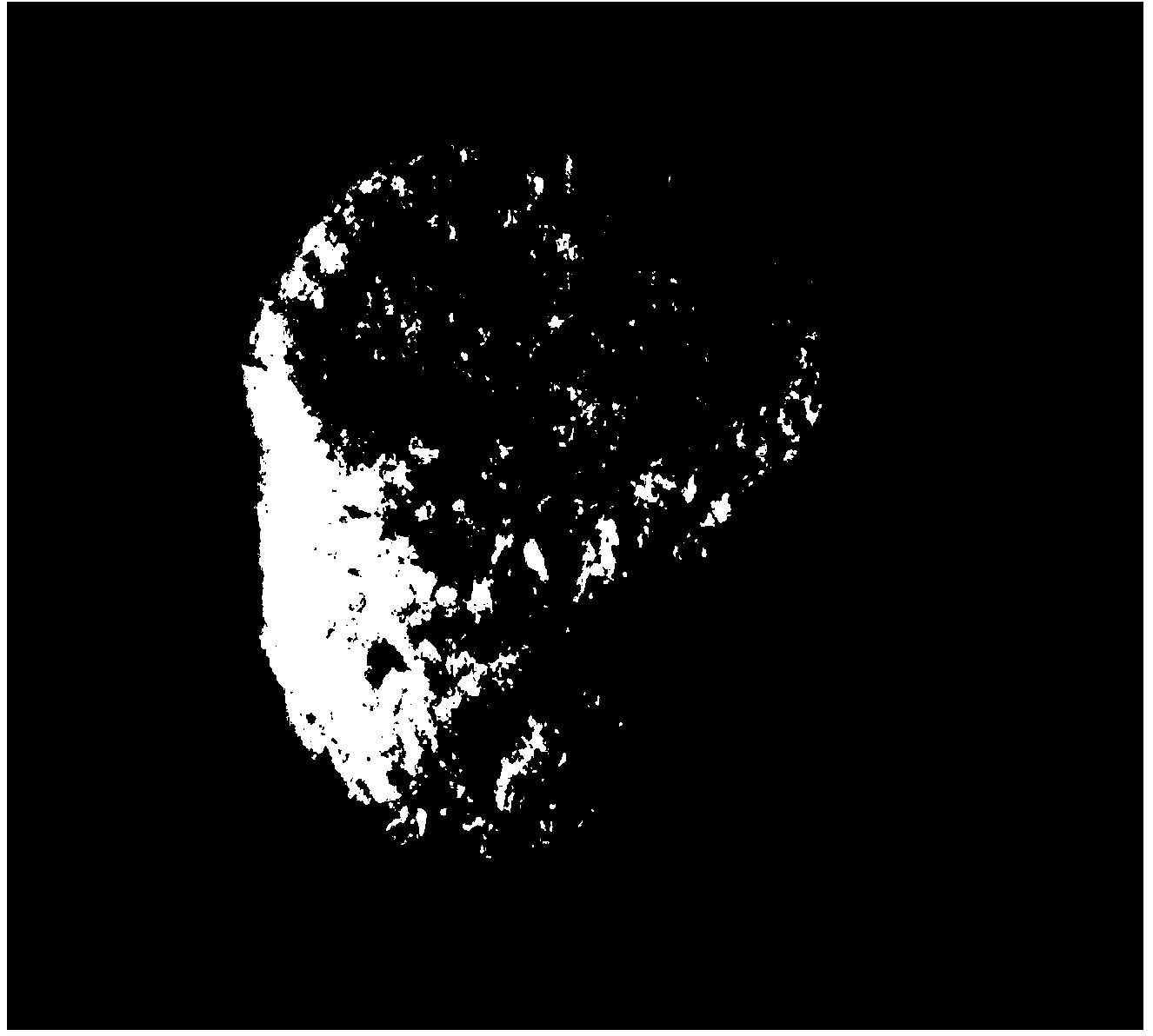

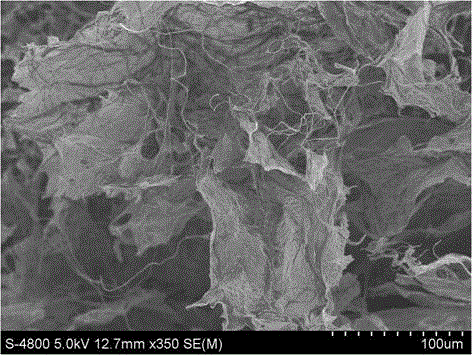

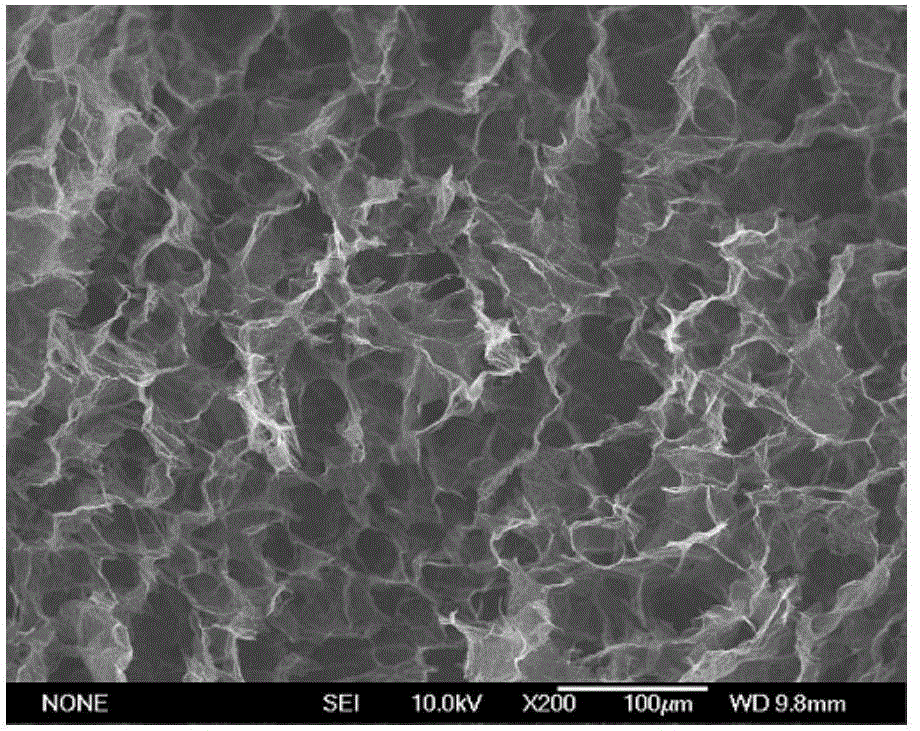

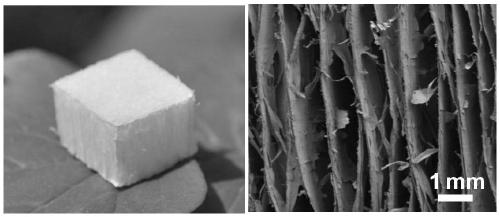

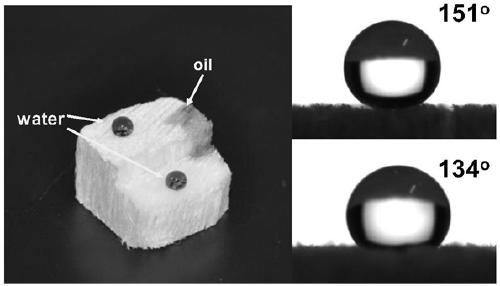

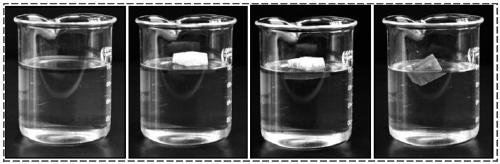

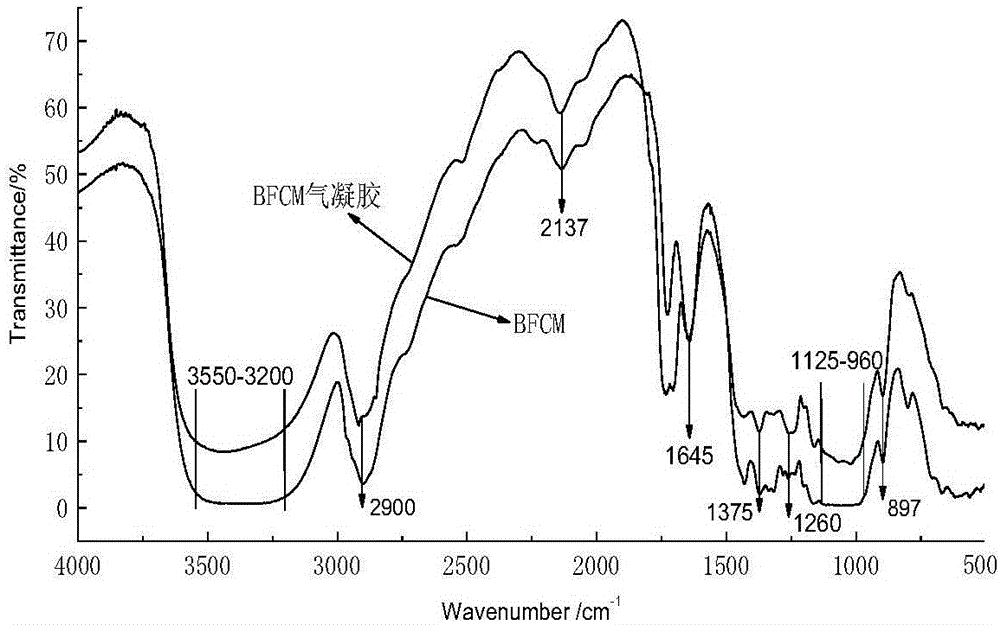

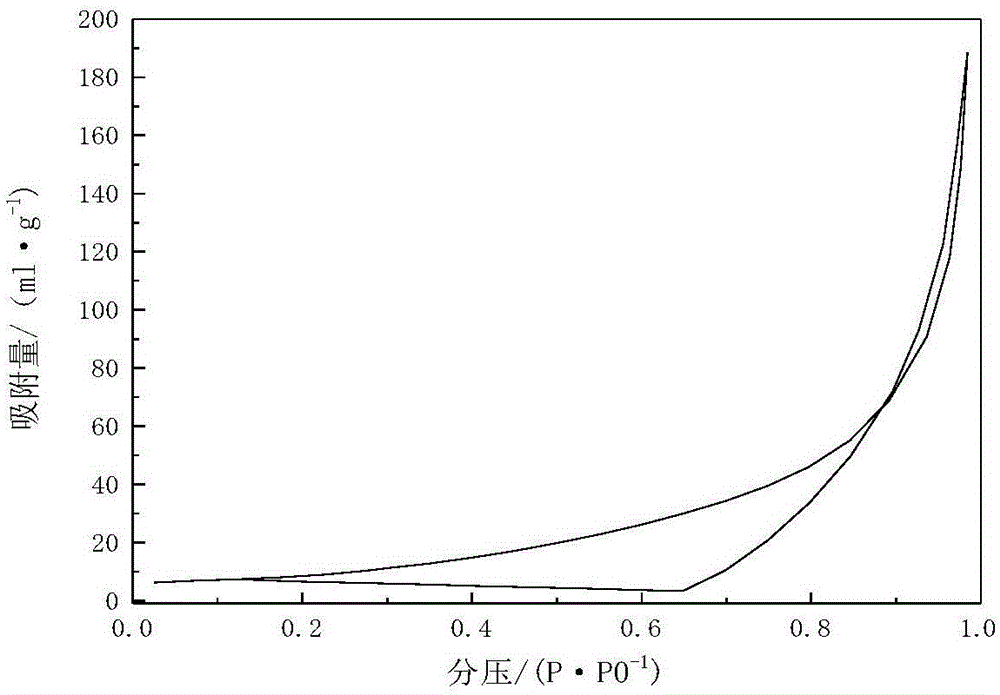

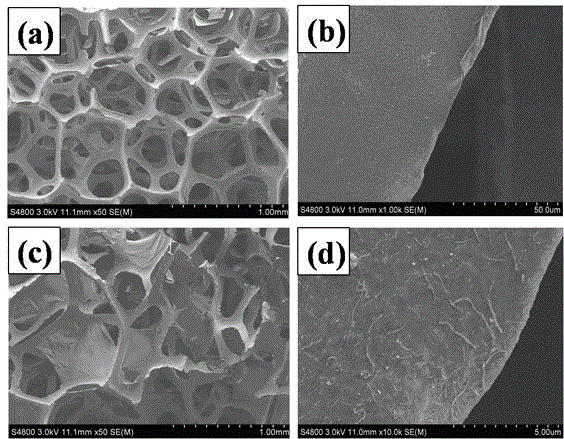

Preparation method of ultralight and hydrophobic nano fibrillated cellulose aerogel with high oil absorption

InactiveCN103756006ASolve the defect of strong hydrophilicityLow densityCoatingsEnvironmental resistanceCellulose

The invention discloses a preparation method of an ultralight and hydrophobic nano fibrillated cellulose aerogel with high oil absorption, and relates to a preparation method of cellulose aerogel. The method disclosed by the invention aims to solve the problem that existing cellulose aerogel which is lower in oil absorption multiplying power and strong in hydrophilicity is not suitable for oil-water separating materials. The method comprises the following steps: I, preparing cellulose aqueous liquor; II, preparing a nano fibrillated cellulose aqueous dispersion liquid; III, preparing a strongly gelatinous nano fibrillated cellulose aqueous dispersion liquid; IV, freezing and drying; and V, carrying out hydrophobic modification to obtain the ultralight and hydrophobic nano fibrillated cellulose aerogel with high oil absorption. The preparation method of the ultralight and hydrophobic nano fibrillated cellulose aerogel with high oil absorption is simple in preparation process, wide in source of raw materials, low in cost and environment-friendly and green. The invention relates to the preparation method of the ultralight and hydrophobic nano fibrillated cellulose aerogel with high oil absorption.

Owner:NORTHEAST FORESTRY UNIVERSITY

Oil absorbing fibre and perparing method thereof

InactiveCN1584148ABroaden the fieldLarger specific surface area for oil absorptionWet spinning methodsMonocomponent synthetic polymer artificial filamentFiberBenzoyl peroxide

The invention relates to a kind of oil-absorbed fiber and its producing method. Its prescription is: 100% polymer monomer, 10-40% of potential gemel agent, 0.1-0.5% solicitation, 0.5-1% dispersant. Moreover the water-like body is 3-4 times more in volume than polymer monomer. The polymer monomer is methacrylate monomer involving butyl methacrylate, the potential gemel agent is 2-hydroxyethyl methacrylate, the solicitation is benzoyl peroxide, and dispersant is poly-vinyl-alcohol. The process is (1) use water-suspending polymerization to produce butyl methacrylate under 70-80 deg.C for blending and polymerizing for 8-10 hours. (2) dissolve the polymer into proper solvent to deploy 20-25% liquid and then insert potential gemal agent and solicitation to polymerize for 3-5 hours under 75-80 deg.C to obtain the original liquid. (3) take off dunking. (4) spin using one of wet or dry method or both, (5) treat with fibre for 10-60 minutes under 120-165 deg.C to obtain the production. The solvent discussed above is one of DMF, DMAC or dimethoxysulfoxide.

Owner:TIANJIN POLYTECHNIC UNIV

Three-dimensional oil-water separating material based on static spinning technology and preparation method thereof

ActiveCN104674384AWon't breakImprove continuityFilament/thread formingArtificial filament heat treatmentFiberPolymer science

The invention provides a three-dimensional oil-water separating material based on the static spinning technology and a preparation method thereof, belonging to the technical field of water treatment. The method specifically comprises the following steps: (a) preparing a static spinning solution; (b) selecting a proper solvent to directly receive static spinning nano fibers to obtain a nano fiber solution; (c) shaping and freezing the nano fiber solution, and drying through a freezing drying machine to obtain the three-dimensional nano fibers; (d) pre-oxidizing, carbonizing and activating the three-dimensional nano fibers to obtain three-dimensional carbon nano fibers; (e) wrapping the three-dimensional carbon nano fiber glue with lipophilic and hydrophobic films so as to obtain the final three-dimensional oil-water separating material. According to the preparation method of the three-dimensional oil-water separating material, the composition and structure of the material are easily controlled; the mechanical performance and hydrophobic performance of the materials can be effectively improved; the oil-water separating effect is good; the material can be recycled and has a wide application prospect in the oil-water separation field.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI +1

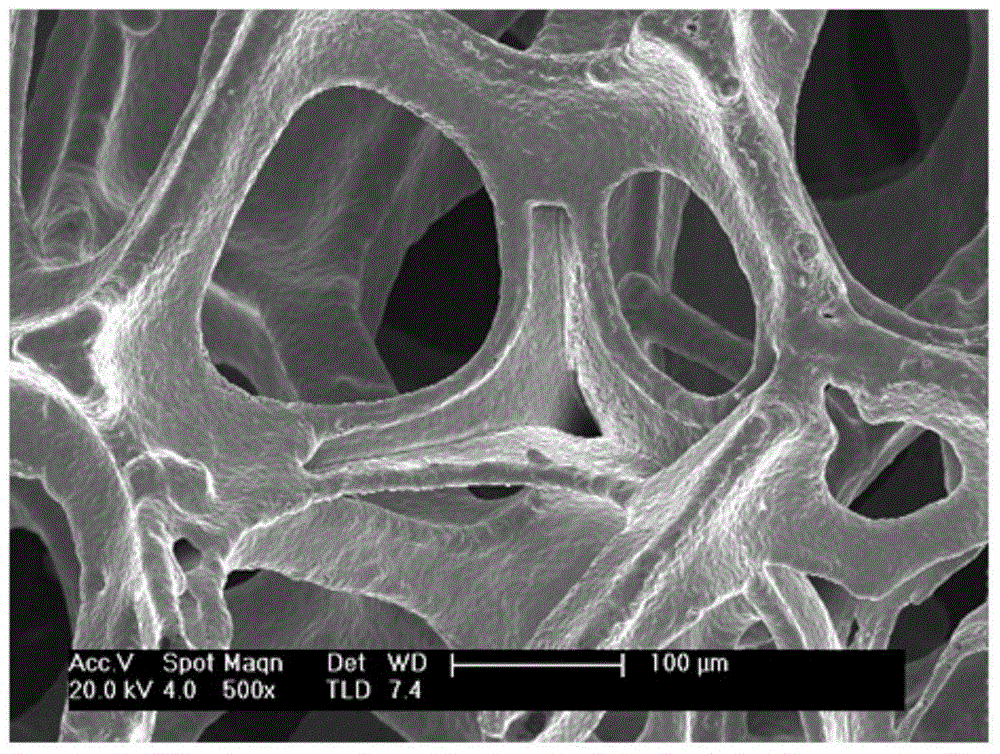

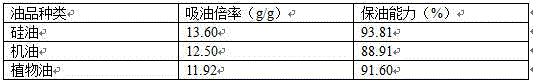

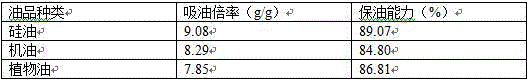

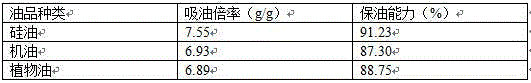

High oil absorption polyurethane foam and preparation method thereof

ActiveCN101987884AHigh oil absorptionFast oil absorptionOther chemical processesChemical recyclingChlorobenzeneKerosene

The invention relates to a high oil absorption polyurethane foam which comprises the following components in parts by weight: 20 to 40 parts of isocyanate, 35 to 60 parts of polyol, 0.5 to 3 parts of catalyst, 0.5 to 3 parts of foam stabilizer, 5 to 10 parts of foaming agent, 2 to 10 parts of opening agent,5 to 20 parts of flame retardant, 5 to 15 parts of silicon rubber spherical micro powder and 0.5 to 2 parts of coupling agent. The preparation method comprises the following technology steps of weighing, prepolymerization, dispersing, polymerization foaming reaction, curing and peeling at room temperature and cutting. The high oil absorption polyurethane foam can be used for the absorption and recycle of various oil products (crude oil, engine oil, diesel fuel, gasoline, kerosene and the like) on water surfaces, ground or surfaces of other objects, and various oil soluble organic compounds (benzene, methylbenzene, dimethylbenzene, chloroform, nitrobenzene, chlorobenzene and the like). The invention has the advantages of simple technology and low cost, obviously improves the dispersing effect of the silicon rubber spherical micro powder in a polymerization system by using ultrasonic technique, and greatly increase the oil absorption quantity and oil absorption rate of the polyurethane foam by adding the silicon rubber spherical micro powder.

Owner:CHINA BLUESTAR CHENGRAND CO LTD +1

Preparation method of durable super-hydrophobic super-oleophylic foamy copper for oil and water separation

ActiveCN104888498ALarge specific surface areaImprove bindingLiquid/solution decomposition chemical coatingLiquid separationNano structuringEtching

The invention provides a preparation method of durable super-hydrophobic super-oleophylic foamy copper for oil and water separation. The preparation method comprises the followings steps: firstly, the foamy copper is sequentially put in an ethanol solution and an acetone solution for ultrasonic cleaning and treated with a hydrochloric acid aqueous solution to remove oil stain and oxide skin; for the cleaned foamy copper, a chemical etching or electrochemical deposition method is used to pre-roughen a foamy copper framework so as to improve the membrane-based binding force; then, a dip-coating-sintering method is adopted to obtain a ZnO crystal seed layer on the surface of the framework, and a compact ZnO array nano structure grows in an oriented manner through a chemical bath manner so as to improve the strength and stability of a film layer; finally, fluoridation is performed on the foamy copper to realize the super-hydrophobic super-oleophylic feature and the oil and water separation function. Through the pre-roughening of the foamy copper framework and the compactly arranged zinc oxide nano structure, the strength of the film layer and the membrane-based binding force can be improved, and the damaging and falling behavior of the film layer during oil and water separation by the foamy copper can be reduced, so that the durable oil and water separation capacity of the foamy copper can be improved.

Owner:SOUTHEAST UNIV

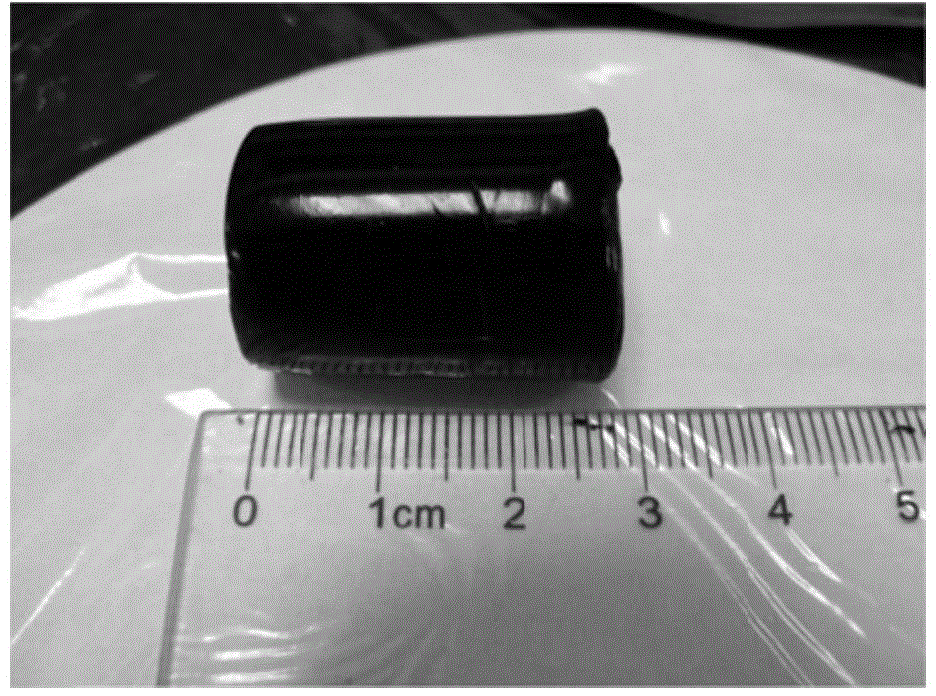

Preparation method of hollow tubular composite oil absorption material

ActiveCN103521199ASimple preparation processHigh oil absorptionFatty/oily/floating substances removal devicesOther chemical processesCvd grapheneDimethylformamide

The invention discloses a preparation method of a hollow tubular composite oil absorption material. The preparation method adopts the process of: 1. preparing a graphene dispersion solution by adding 100-1500mL of a dispersant, graphene accounting for 20-30% of the total mass of a hollow tubular porous polymer material, and N, N-dimethylacetamide accounting for greater than 0 and less than or equal to 6% of the total mass of the dispersant, and conducting ultrasonic dispersion treatment for 20-40min, with the dispersant including ethanol, N-methyl pyrrolidone, tetrahydrofuran or dimethylformamide; and 2. dip coating a graphene adsorption layer: dipping the hollow tubular porous polymer material into the graphene dispersion solution, performing standing coating for 5-60min, then putting the material into a vacuum oven with a negative pressure of -0.1MPa, carrying out treatment at 100-150DEG C for 6-12h till complete drying, thus obtaining the hollow tubular composite oil absorption material. And the mass content of the adsorption layer accounts for 5-10% of the mass of the hollow tubular porous polymer material.

Owner:TIANJIN POLYTECHNIC UNIV

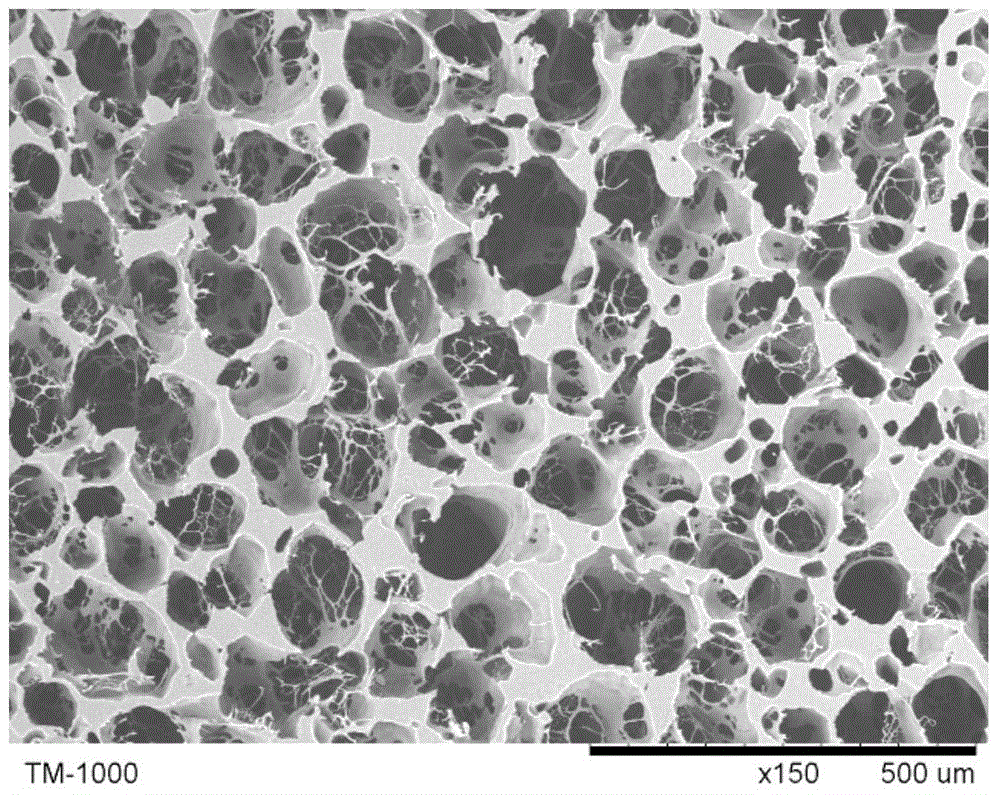

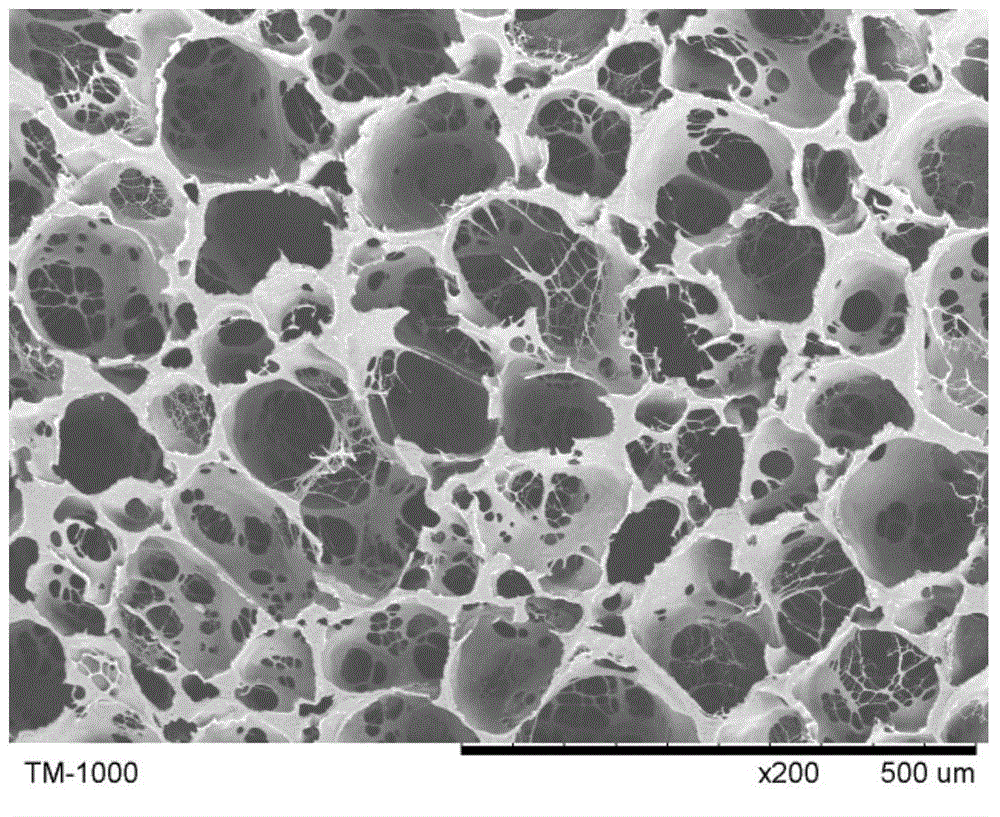

High oil absorption composite material containing cellulose waste filler and preparation method thereof

ActiveCN101550261AGood oil absorption performanceMany types of oil absorptionDispersed mediaCellulose

The invention relates to a high oil absorption composite material containing cellulose waste filler and a preparation method thereof. The composite material takes acrylic ester multipolymer high oil absorption resin as base material, in which the cellulose waste in the shape of island is uniformly dispersed in the base material. The preparation includes the following steps of: the preparation of the base material, namely the acrylic ester multipolymer high oil absorption resin; the preparation of the cellulose waste filler; the blending of the high oil absorption resin and the cellulose waste filler to prepare the high oil absorption composite material. Compared with the prior art, the composite material has the following advantages of excellent oil absorption performance, the availability to absorb a plurality of oils, high oil absorption percentage and good fat-binding performance. The key technology of the invention lies in the acrylic ester multipolymer oil absorption resin, which has wide raw material source, takes water accounting for 60-80 percent as dispersing medium, and the technology is simple and easily controllable. The filler is natural cellulose waste with the particle diameter of 0.25-0.035mm. The waste can be bagasse, corn cob, peanut shells and sawdust powder, and has wide source, belongs to resource recycling area, conforms to the national policy of sustainable development and is simple, safe and environment-friendly in preparation process.

Owner:飞潮(上海)新材料股份有限公司

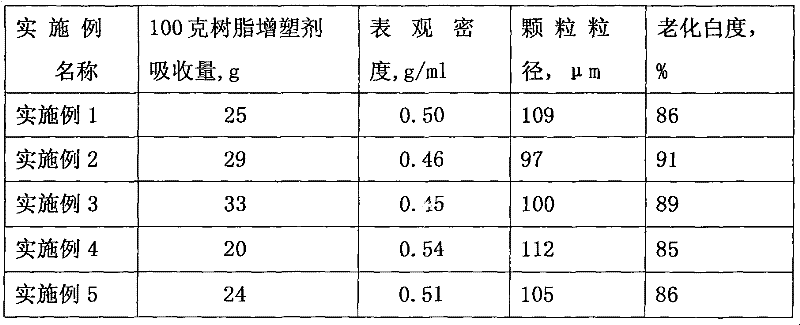

Polyvinyl alcohol, preparation method and applications

The invention provides polyvinyl alcohol. The polyvinyl alcohol is characterized in that the average polymerization degree is no higher than 500, the blocking degree is 0.50-0.85, and the alcoholysis degree is 35mol%-65mol%. The provided polyvinyl alcohol with a low polymerization degree, a low alcoholysis degree and a low viscosity has especially excellent viscosity stability. When the provided polyvinyl alcohol is used for a vinyl polymer suspension polymerization reaction, the monomer droplet disperse dispersion capability is strong, the dispersion stability is good, and the provided polyvinyl alcohol is free from vinyl polymer polymerization conditions. The pores of the prepared vinyl polymers are distributed uniformly and the porosity is high. The removal performance of reaction residual monomers is good, the absorption capability of added plasticizers is excellent during the subsequent processing process, the processing properties are excellent, plasticizing time can be shortened, and the fisheye number is decreased.

Owner:CHINA PETROCHEMICAL CORP +1

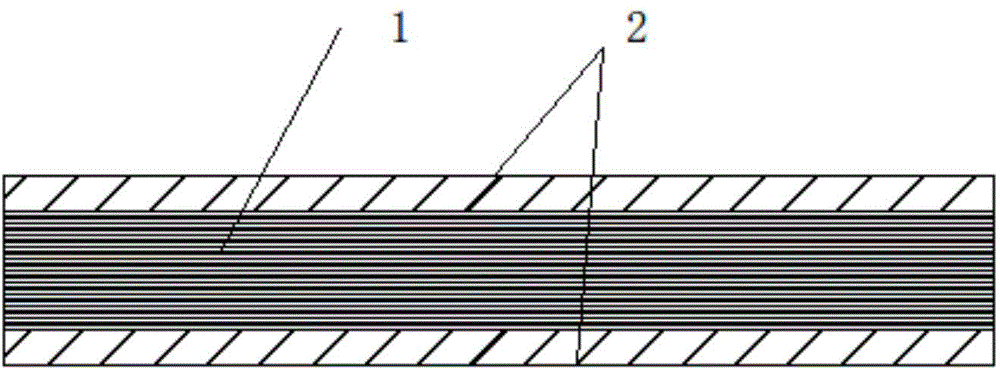

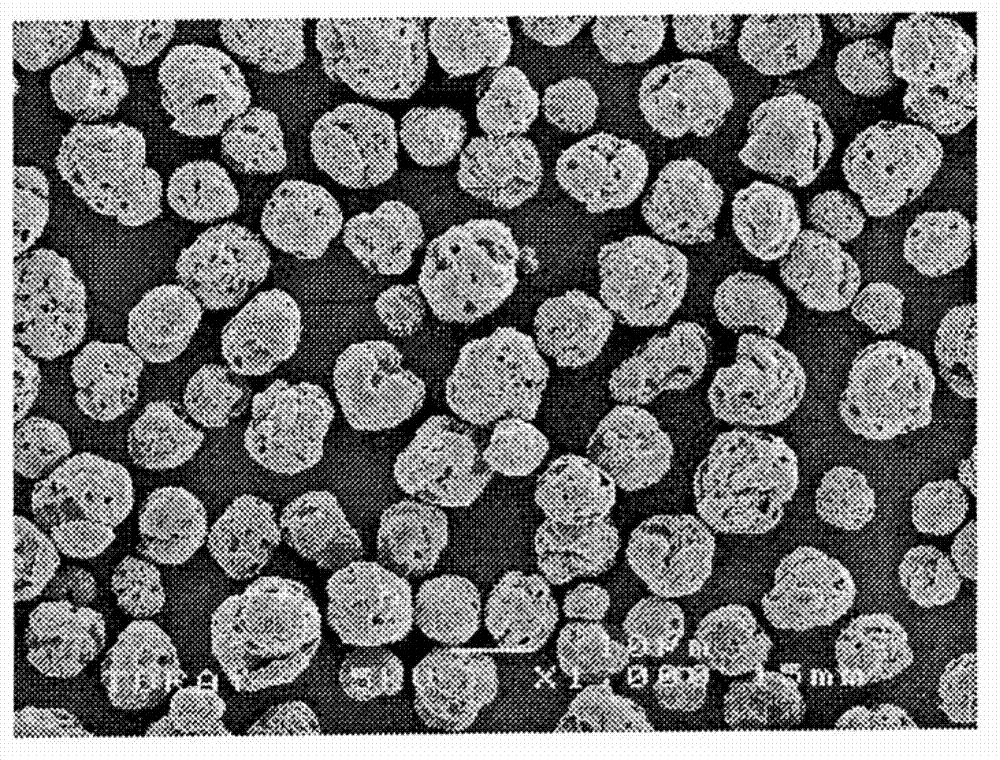

Preparation method of polyvinyl chloride resin with high oil absorption rate

The invention provides a preparation method of polyvinyl chloride resin with high oil absorption rate, which is implemented by the following steps of: adding vinyl chloride, deionized water, an initiation system, a dispersion system and a function assistant into a polymerizer; under a certain polymerization temperature, reacting for a certain time, adding a terminator and then obtaining polyvinylchloride suspension; and removing an unreacted vinyl chloride monomer, centrifuging suspension, drying, and obtaining the polyvinyl chloride resin, wherein the function assistant is the mixture of several of C4-C10 nalkane and isoparaffin of the nalkane. By the method disclosed by the invention, the particle state of the polyvinyl chloride resin is improved, the interior of the obtained resin is loose and porous, so that the obtained resin has high voidage, uniform void distribution and high oil absorption rate.

Owner:CHINA PETROLEUM & CHEM CORP

Hydrophilic oil absorption cotton

ActiveCN104383899AImprove adsorption capacityFast oil absorptionFatty/oily/floating substances removal devicesOther chemical processesFiberAdjuvant

The invention relates to hydrophilic oil absorption cotton. The oil absorption cotton consists of a hydrophilic and oleophylic adjuvant layer and a filtering layer covering the adjuvant layer, wherein the hydrophilic and oleophylic adjuvant layer is prepared from a super-amphiphilic material; the filtering layer is prepared from composite filtering cotton; the composite filtering cotton comprises a filtering cotton layer; active carbon particles are uniformly distributed in the filtering cotton layer; nonwoven cloth thin layers which are difficult to defiber are arranged on the top surface and the bottom surface of the filtering cotton; the super-amphiphilic material is a macromolecular carbon nano composite material; the composite material contains a nano-level space consisting of a hydrophilic polymer chain section and an oleophylic polymer chain section which are regularly arrayed. The hydrophilic oil absorption cotton has dual effects of oil absorption and water absorption; the filtering layer and the hydrophilic and oleophylic adjuvant layer are of multihole structures; on the premise of guaranteeing high oil absorption rate, the oil absorption rate is also increased.

Owner:浙江黎盛新材料科技有限公司

Preparation method of cellulose-based oil-absorption material

InactiveCN101565488AImprove featuresThe solution cannot solve the high oil absorption at the same timeOther chemical processesCelluloseFuel oil

The invention relates to a preparation method of cellulose-based oil-absorption material, which includes the steps of: after activating process for plant cellulose, adding polyvinyl alcohol aqueous solution, stirring and heating under nitrogen protection, adding evocating agent, reaction monomer and cross linker, heating under stirring, remaining constant temperature, precipitating and filtering product, washing with hot water, drying and obtaining cellulose-based oil-absorption material. The method has the advantages of: simple operation, moderate reaction condition, plant cellulose basic raw material, low synthetic production cost, oil-absorption ability, especially high oil-absorption ability for heavy oil; the obtained product not only has biodegradability of cellulose, but also has high oil-absorption ability of lipophilic monomer, thereby solving the difficult problem that common oil-absorption materials cannot have high oil-absorption ability and biodegradability at the same time.

Owner:XINJIANG UNIVERSITY

Method for producing microparticles of polylactic acid-based resin, microparticles of polylactic acid-based resin and cosmetic using same

ActiveCN103201319AEasy to manufactureHigh oil absorptionCosmetic preparationsMake-upMicroparticleSolvent

Provided are: a method for producing microparticles of a polylactic acid-based resin; porous microparticles of a polylactic acid-based resin, said microparticles having a small particle diameter, showing a high oil absorption ability and being appropriately usable for cosmetics; smooth-surfaced microparticles of a polylactic acid-based resin, said microparticles having a spherical form, showing a narrow particle diameter distribution and being appropriately usable for toners; and a cosmetic using the aforesaid microparticles of a polylactic acid-based resin. The method for producing microparticles of a polylactic acid-based resin comprises: dissolving a polylactic acid-based resin (A) and a polymer (B), which is different from polylactic acid-based resins, in an ether-type organic solvent (C); applying a shear force thereto to form an emulsion; and then contacting the emulsion with a poor solvent of the polylactic acid-based resin (A). According to this production method, porous microparticles of the polylactic acid-based resin, said microparticles having a fusion enthalpy of the polylactic acid-based resin (A) of 5 J / g or greater, having a small particle diameter and showing a high oil absorption ability, and smooth-surfaced microparticles of the polylactic acid-based resin, said microparticles having a fusion enthalpy less than 5 J / g, having a spherical form and showing a narrow particle diameter distribution, can be provided.

Owner:TORAY IND INC

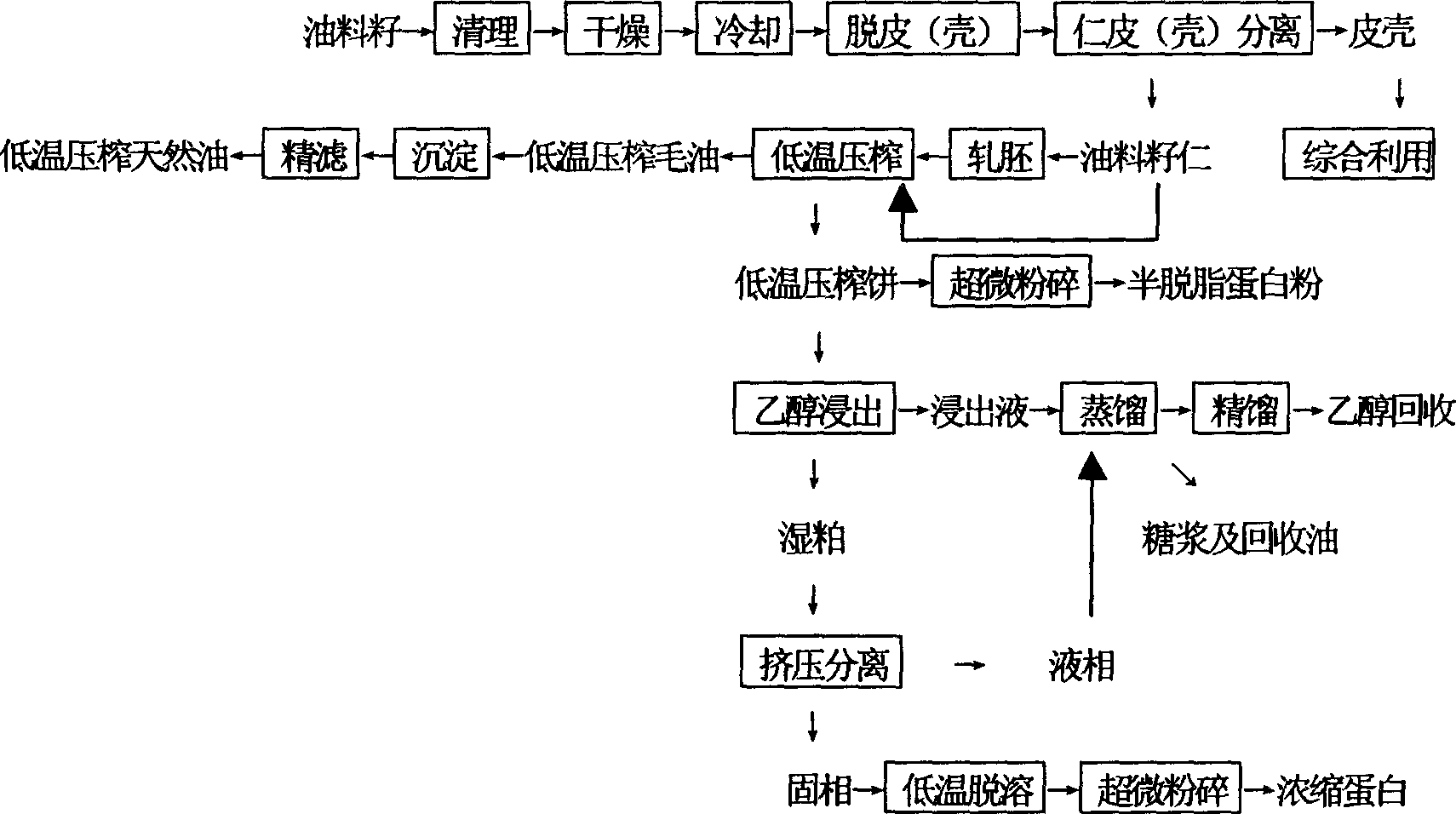

Low temperature oil preparation and protein in oil-bearing materials preparation method

InactiveCN1840623ALow in phospholipidsLight colorProtein composition from vegetable seedsFatty-oils/fats productionMaterials preparationLeachate

The related preparation method for oil and oil protein comprises: cleaning material, drying till water content in 2-10%; cooling to ambient temperature, peeling or shelling more than 90%, separating core and seedcase to obtain the oiling seed with 0.5-10% seedcase; after rolling or not, expressing with low-temperature device at 20-70Deg to obtain crude oil and cake; depositing, fine filtering to obtain the objective oil; super grinding the cake to prepare semi-degreased protein powder, or soaking to obtain leachate for recovery and wet dreg to recover ethanol and grind for protein powder.

Owner:WUHAN POLYTECHNIC UNIVERSITY +1

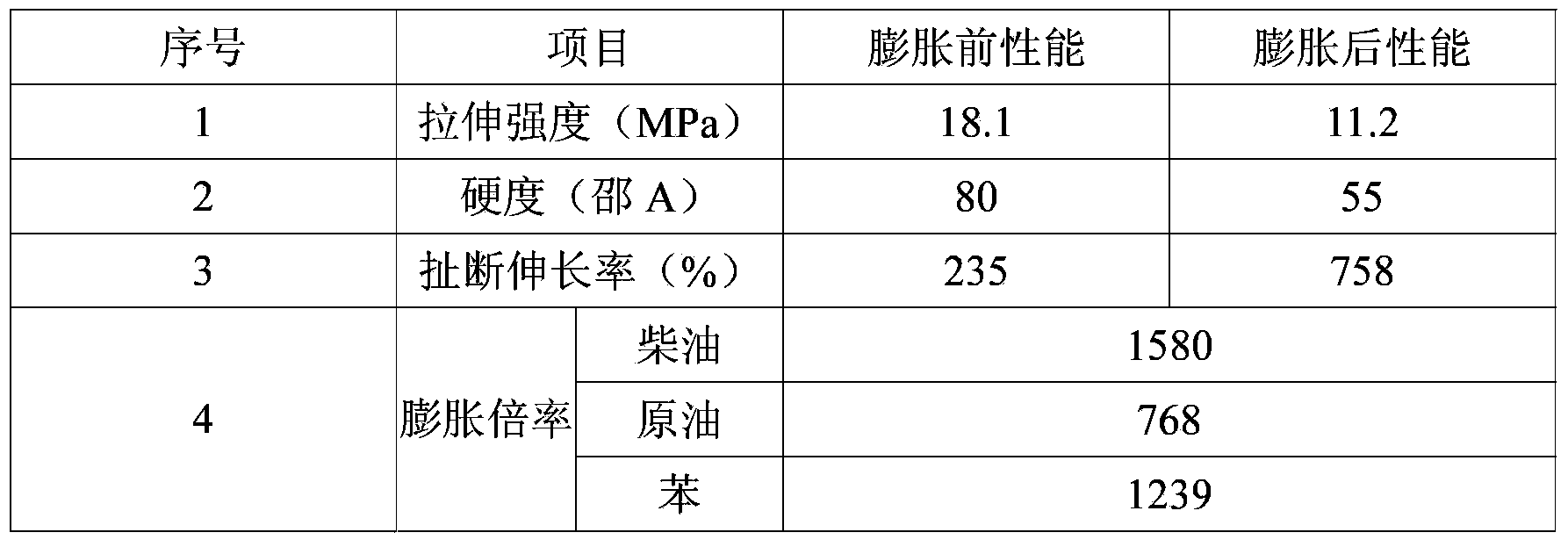

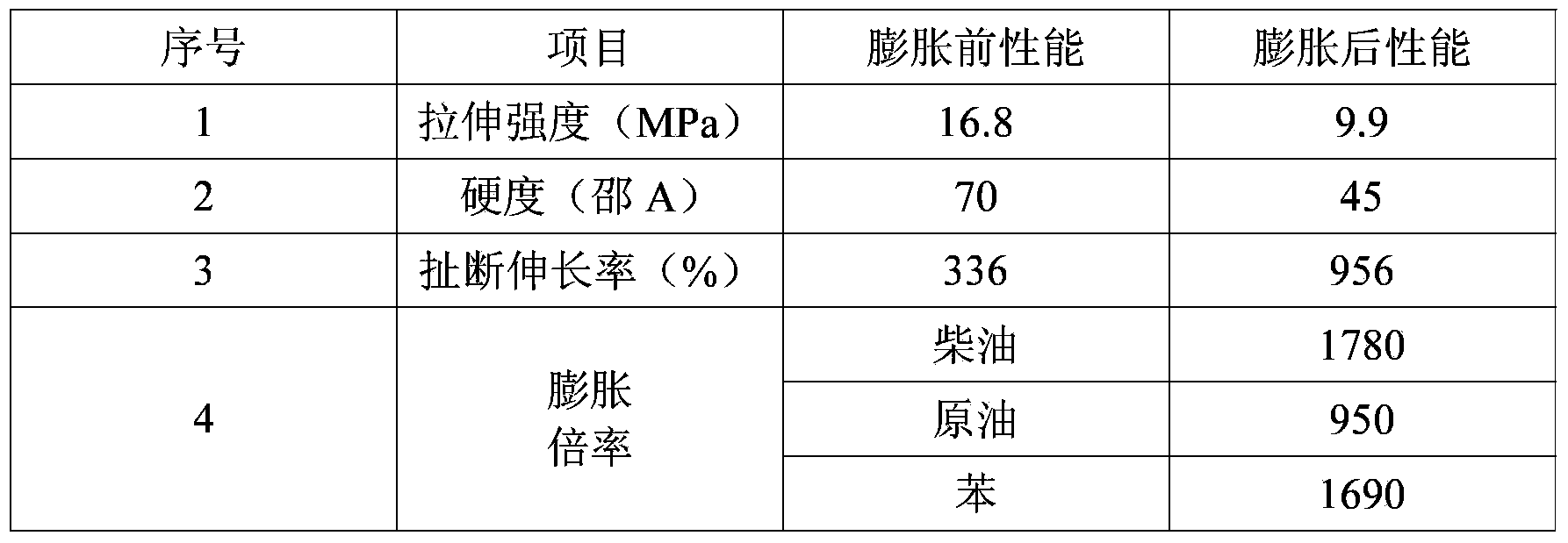

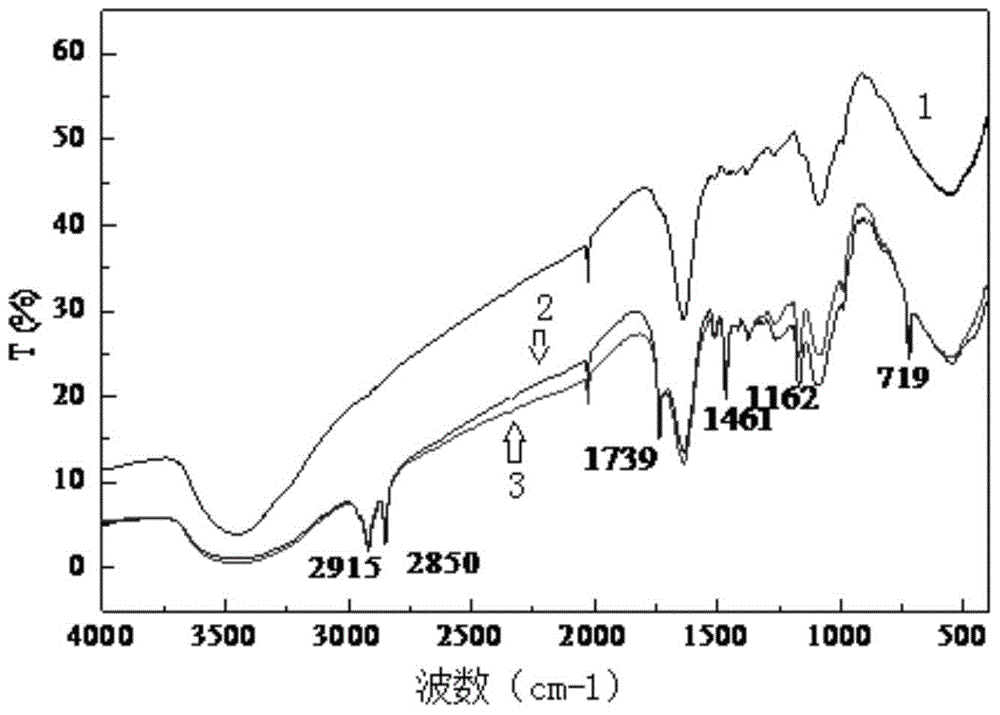

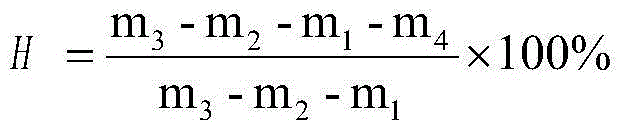

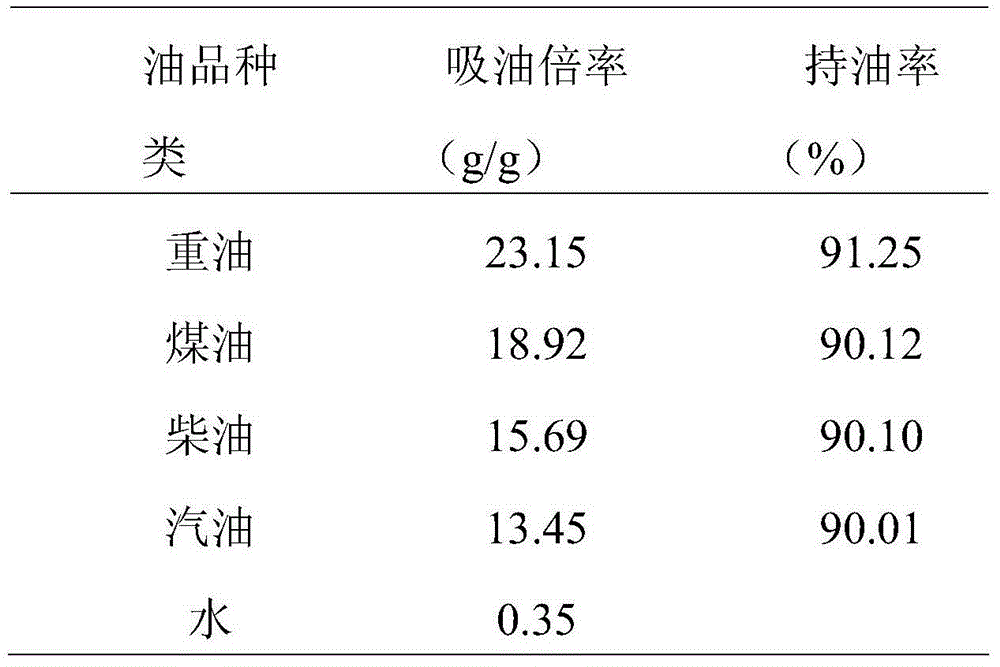

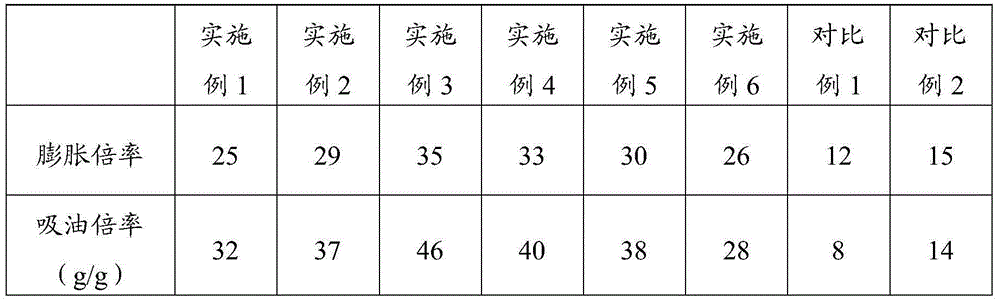

Oil-absorptive resin and oil-absorptive expanding rubber comprising same

ActiveCN103848935AHigh expansion ratioGood oil absorption performanceDrilling compositionActive agentPorosity

The invention provides oil-absorptive resin and oil-absorptive expanding rubber comprising the same. The oil-absorptive resin comprises the following components in parts by weight: 60 to 75 parts of polymer monomer, 0.5 to 2.5 parts of catalyst, 0.5 to 1 part of initiator, 0.01 to 0.03 part of cross-linking agent and 25 to 30 parts of dispersing phase. The invention also provides expanding rubber comprising the oil-absorptive resin. The oil-absorptive expanding rubber comprises the following components in parts by weight: 100 parts of rubber, 40 to 100 parts of oil-absorptive resin, 40 to 80 parts of reinforcing agent, 10 to 20 parts of softening agent, 0.5 to 2 parts of vulcanizing agent, 0.5 to 2 parts of promoter, 0.5 to 2 parts of anti-aging agent and 6 to 8 parts of active agent. By utilizing the characteristic of the oil-absorptive resin that the oleophylic group (ester group) is interactively affine to oil molecules to absorb the oil, the prepared oil-absorptive resin has porosity, so that the expanding rubber utilizing the oil-absorptive resin has better oil-absorptive effect in comparison with the traditional oil-absorptive expanding rubber, and the pressure resisting effect is also improved.

Owner:PETROCHINA CO LTD

Preparation method of oil absorbing material by taking palm fiber as basic material

ActiveCN104624162ARich pore structureOptimized areaFatty/oily/floating substances removal devicesOther chemical processesParaffin waxChemical synthesis

The invention relates to a preparation method of an oil absorbing material, and the oil absorbing material is prepared by subjecting a basic material namely palm fibers to hydrophobic modification. The preparation method comprises the following steps: washing palm fibers, drying palm fibers, cutting the palm fibers into sections with a length of 0.5 to 5 cm; putting the palm fibers into a hydrophobic agent solution, soaking for 10 to 120 minutes at a temperature of 25 to 100 DEG C, taking out the palm fiber containing a hydrophobic agent, and quickly drying so as to obtain the modified oil absorbing material; wherein the hydrophobic agent is composed of paraffin, palm wax, or a mixture of paraffin and palm wax, the addition amount of the hydrophobic agent is 0.01 to 0.2 times of the weight of the palm fibers, the solvent is one or more of carbon tetrachloride, vinyl acetate, ethanol, and benzene, and the addition amount of the solvent is 20 to 800 times of the weight of the hydrophobic agent. Cheap and easily-available natural plant palm is taken as the raw material, the oil absorbing material is prepared by carrying out hydrophobic modification on the palm fibers, and compared with the oil absorbing materials prepared through chemical synthesis, the provided oil absorbing material has the advantages of low cost, biodegradability, and excellent oil absorbing performance.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Method for preparing oil absorption material from cellulose and alkyl acrylate by graft copolymerization

InactiveCN101565487AReduce manufacturing costHigh oil absorptionOther chemical processesVegetable oilCerium

The invention relates to a method for preparing oil absorption material from cellulose and alkyl acrylate by graft copolymerization, which includes the steps of: pulverizing plant cellulose raw material into massive material for placing into nitric acid aqueous solution containing cerium ionic initiator, stirring, removing excess pretreatment fluid, washing residual cerium ion by distilled water to pH=7.0, after vacuum filtration placing the material into the nitric acid aqueous solution, adding copper sheet for inhibiting forming of homopolymer, adding reaction monomer and cross linker with nitrogen protection and stirring, heating with stirring, remaining constant temperature, precipitating and filtering product, washing with water and ethanol respectively, drying, and then obtaining the cellulose-based oil absorption material. The method has the advantages of: simple operation, moderate reaction condition, plant cellulose basic raw material, high oil-absorption ability for vegetable oil and heavy oil with larger viscosity. The product not only has biodegradability of cellulose, but also has high oil-absorption ability of lipophilic monomer, thereby solving the difficult problem that common oil-absorption materials cannot have high oil-absorption ability and biodegradability at the same time.

Owner:XINJIANG UNIVERSITY

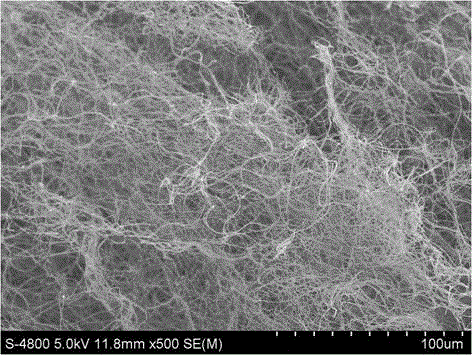

Graphene hydrogel, graphene aerogel as well as preparation method and application thereof

ActiveCN106032274AAdjustable densityHigh densityOther chemical processesAlkali metal oxides/hydroxidesHigh energyFreeze-drying

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

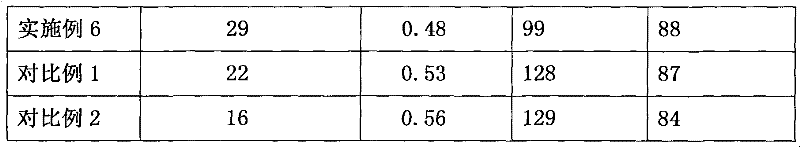

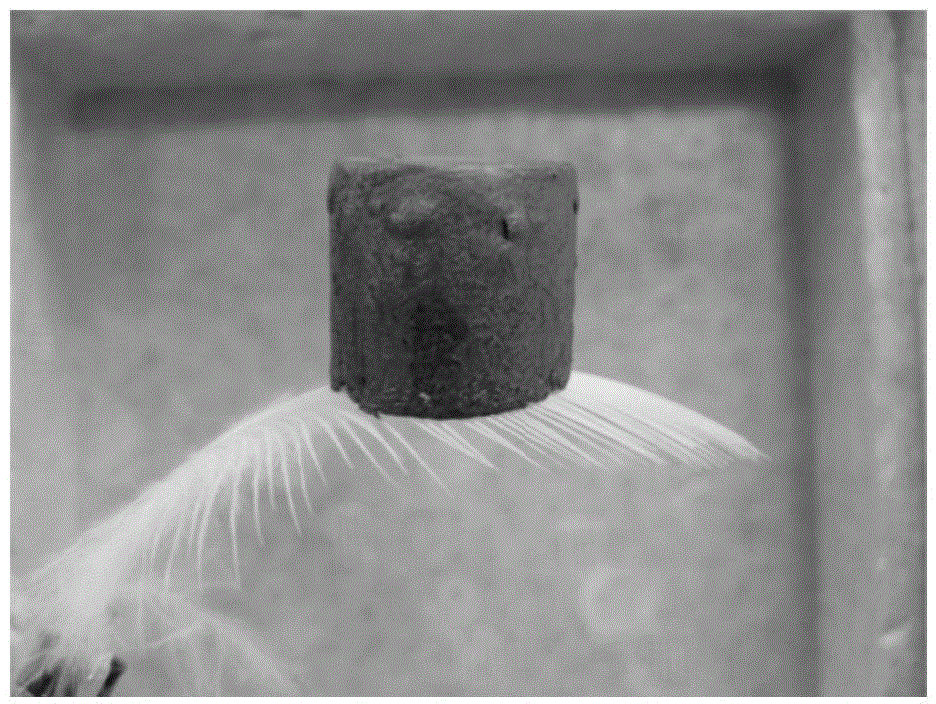

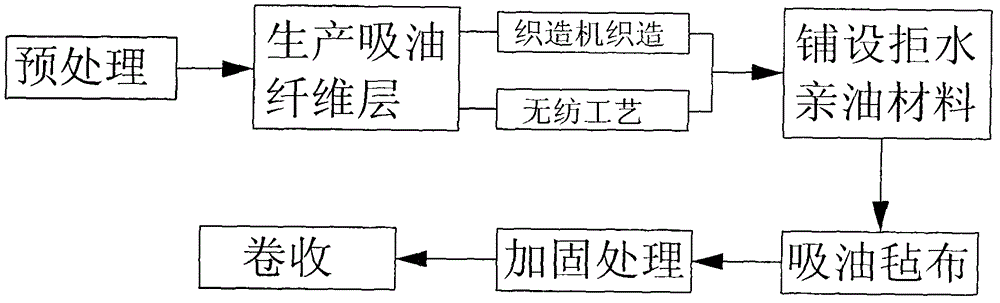

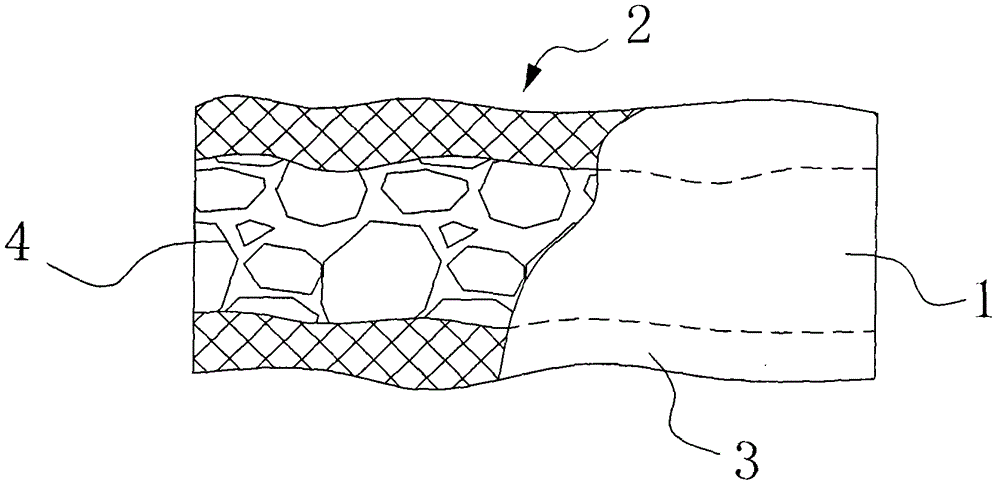

Special offshore deoiling oil absorbent felt and method for preparing oil absorbent felt

ActiveCN104874232AReduce manufacturing costExtended service lifeFiltration separationLiquid separationBlock effectPetroleum engineering

The invention discloses a special offshore deoiling oil absorbent felt. The special offshore deoiling oil absorbent felt comprises an oil absorbent felt body which is prepared from an oil absorbent fiber, is provided with an oil absorbent clearance part, and comprises two oil absorbent fiber layers; the oil absorbent clearance part formed between the two oil absorbent fiber layers is filled with a water-repellency oleophylic material, and the two oil absorbent fiber layers and the water-repellency oleophylic material are solidified integrally. The preparation method comprises the following steps: (1) pretreatment, namely preparing the water-repellency oleophylic material for filling for later use, and selecting an oil absorbent fiber for later use; (2) producing an oil absorbent fiber layer; (3) laying a water-repellency oleophylic material; (4) solidifying; and (5) coiling. An oil containment boom prepared from enteromorpha has good oil blocking and oil absorption performances, the use effect of the oil containment boom can be enhanced, the oil containment boom can float on the water surface for a long time after oil absorption, can not sink or deform, and has good oil absorbing and blocking effects.

Owner:THE FIRST INST OF OCEANOGRAPHY SOA

Method for preparing high oil absorption resin

A process for preparing the resin with high oil absorptivity from styrene and long-chain olefin monomer CnH2n, where n is equal to or greater than 4, includes such steps as preparing the low-cross-linked polystryrene or styrene copolymer, immersing it in solvent or long-chain olefin monomer or their mixture, and alkylating reaction. Its advantages are high content of gel and oil absorptivity, and low cost.

Owner:NANJING UNIV OF SCI & TECH

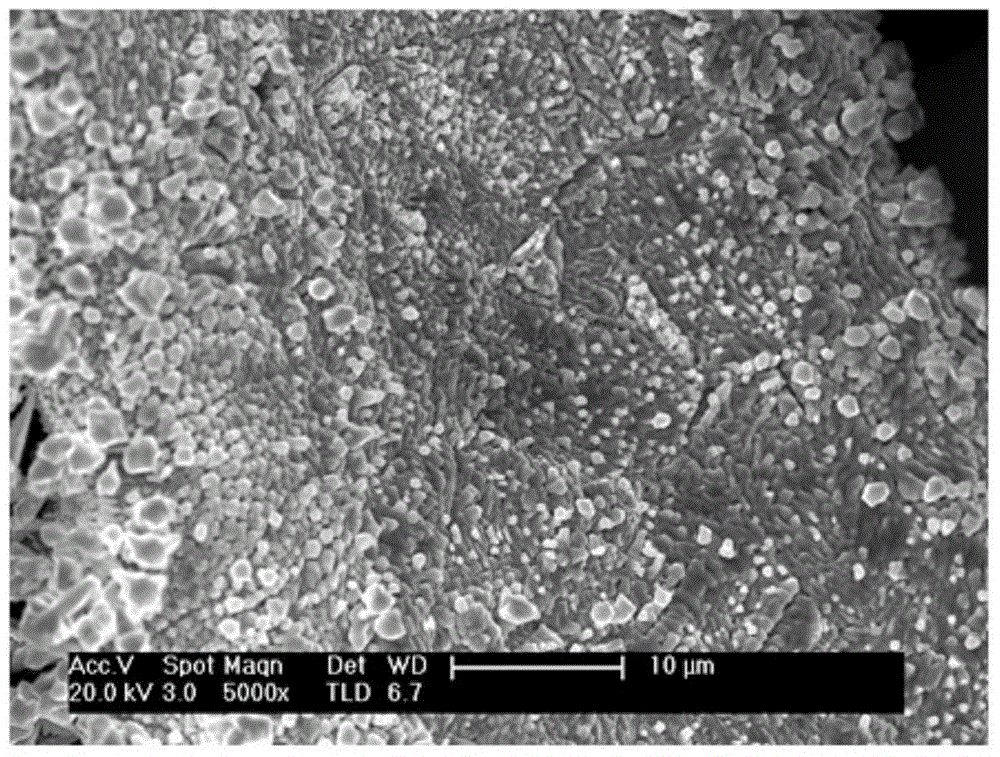

Preparation method of collagen-based porous oil-absorbing material

InactiveCN104971702AEasy constructionIncrease the areaOther chemical processesAlkali metal oxides/hydroxidesFiberCollagen fiber

The invention relates to a preparation method of a collagen-based porous oil-absorbing material, and relates to the technical field of biomass resource recycling and environment-friendly oil-absorbing materials. A collagen-based porous oil-absorbing material preparation method provided by the invention comprises the steps that: (1) lime-expanded pelt scraps before tanning are cut into small pieces; pretreatments such as deliming, degreasing and dehydration are carried out, such that hide powder fiber is obtained; (2) the prepared hide powder fiber is dispersed in a buffering solution containing an epoxysilane coupling agent or polydimethylsiloxane for modification, such that hydrophobic lipophilic hide powder fiber is obtained; and (3) the modified hide powder fiber obtained in the step (2) is dispersed in water; and forming and drying ae carried out, such that the collagen-based porous oil-absorbing material is obtained. The method provided by the invention has the advantages of simple operation and low cost. The prepared oil-absorbing material has hydrophobic lipophilic properties and a porous structure. The material also has biodegradability and relatively high oil-absorbing capacity. Therefore, a novel application approach is developed for the high-value conversion and utilization of hide collagen fiber solid wastes.

Owner:SICHUAN UNIV

Wooden sponge oil-absorbing material and preparation method thereof

InactiveCN109608683AWide variety of sourcesSimple manufacturing methodWood treatment detailsCoatingsEnvironmentally friendlyFreeze dry

The invention discloses a wooden sponge oil-absorbing material. The wooden sponge oil-absorbing material is obtained by performing wood bleaching by using light wood as a raw material, removing lignin, removing hemicellulose, performing freeze drying and performing silanization treatment. The invention also discloses a preparation method of the wooden sponge oil-absorbing material. The preparationmethod provided by the invention creatively uses the natural renewable wood as the raw material for the first time to prepare the porous oil-absorbing material through a top-down strategy, is economical, high-efficient, green, environmentally friendly, simple in preparation process, and wide in raw material source, can be produced in a large scale, and has good promotion and application prospects.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

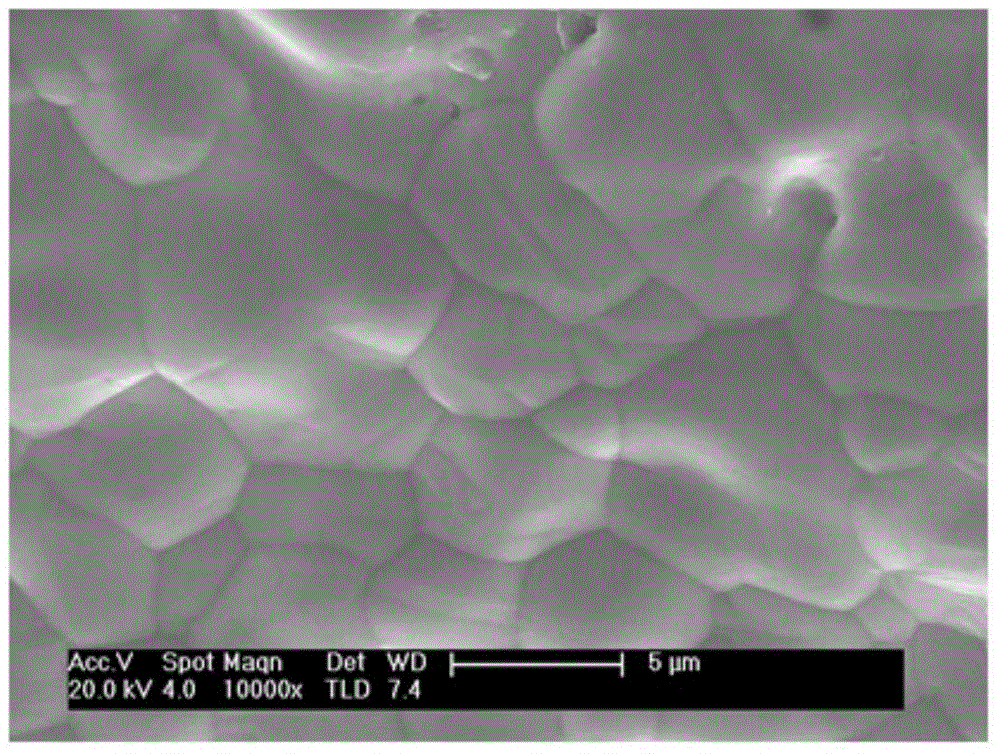

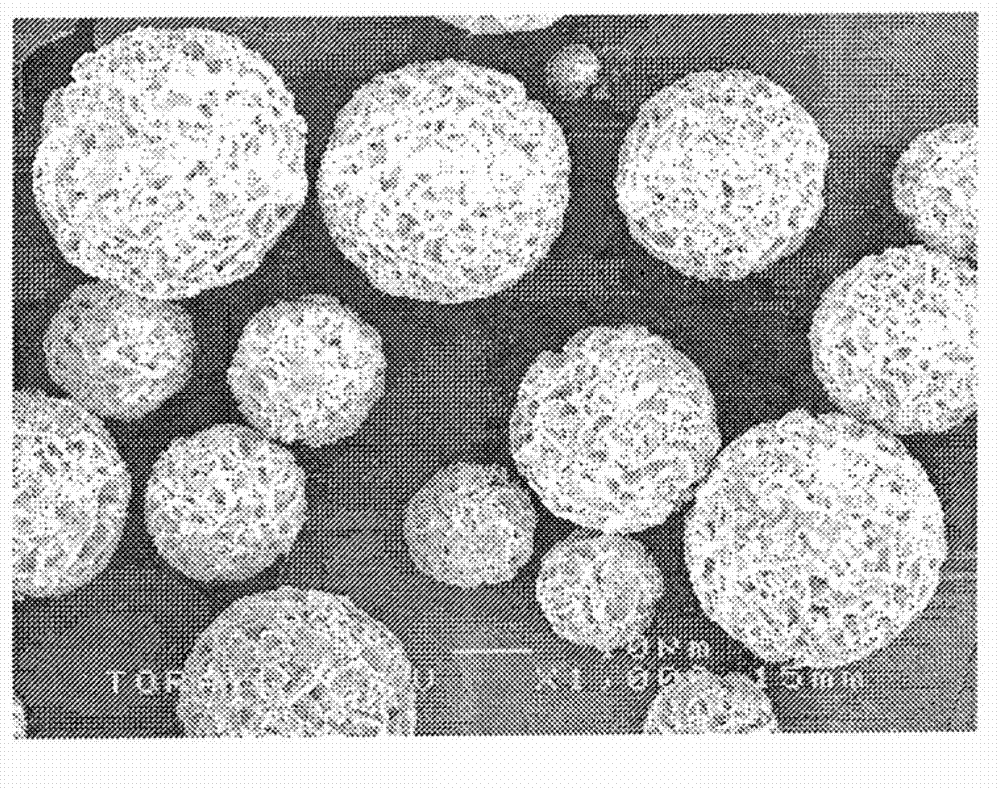

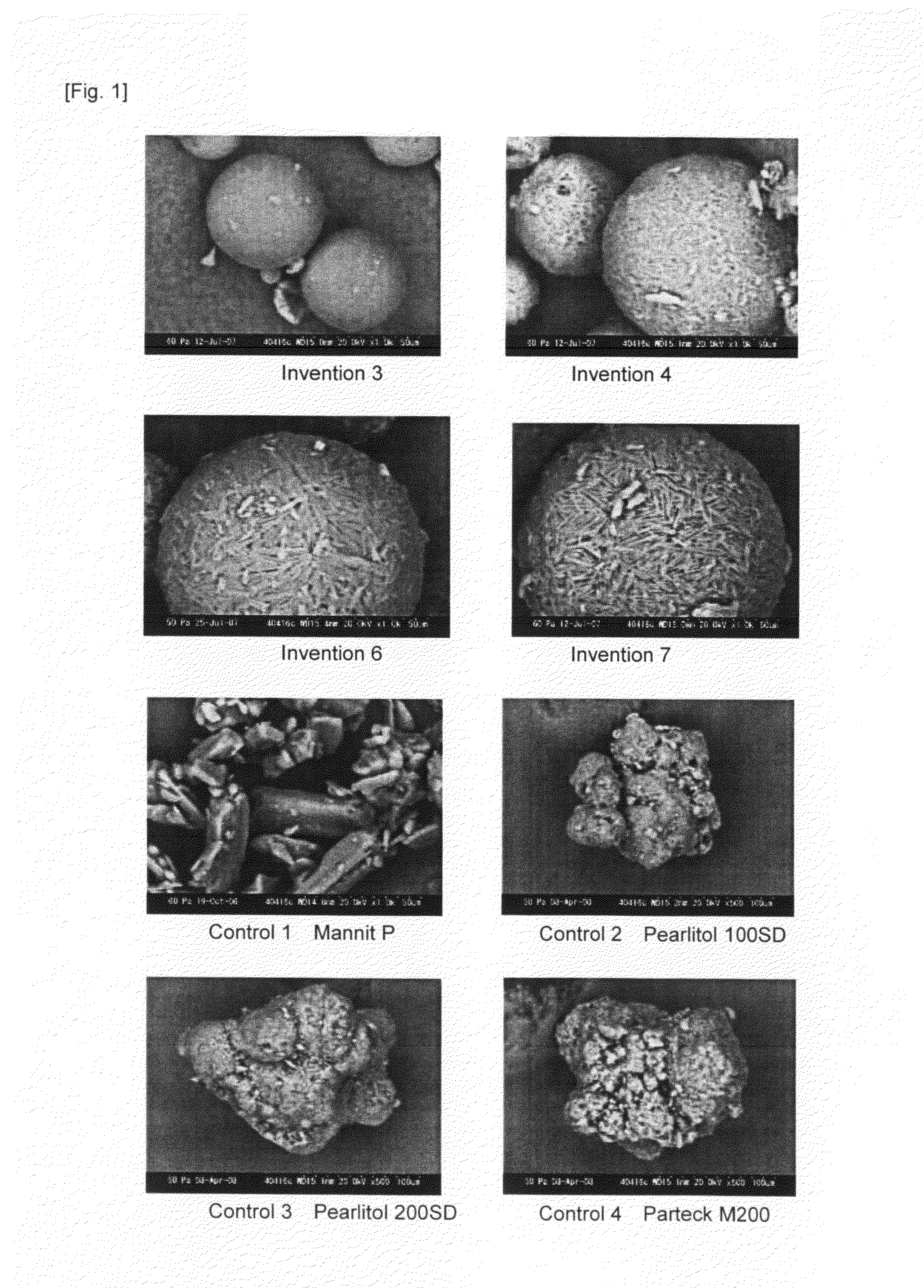

Spherical particle of crystalline mannitol

InactiveUS20100167052A1Improve liquidityHigh oil absorptionPowder deliverySynthetic resin layered productsMANNITOL/SORBITOLHardness

[Summary][Problems] To provide extremely-spherical-three-dimensional-shaped particles of crystalline mannitol containing large hollows and gaps inside.[Solution] Spherical particles of crystalline mannitol made by spray drying, extremely spherical (having an aspect ratio of 1.0 to 1.2), high oil absorption rates according to test method A, wherein powder has a mean particle diameter of 15 to 165 μm, a loose bulk density of 0.35 to 0.60 and an angle of repose of 30 to 50 degrees, and has a hardness of 7 to 20 kgf, when directly compressed.

Owner:MITSUBISHI SHOJI FOODTECH CO LTD

Preparation method and application of hollow MnO2@SiO2 nanomaterial modified polyurethane foam

ActiveCN106902767AIncrease oil storage spaceHigh oil absorptionOther chemical processesWater contaminantsIron oxideSilicon dioxide

The invention belongs to the field of functional polymer materials, and relates to preparation of compound polyurethane foam, in particular to a preparation method and application of hollow MnO2@SiO2 nanomaterial modified polyurethane foam. The method comprises the steps of preparing iron oxide by a hydrothermal method, wrapping silicon dioxide by a template method, preparing MnO2@SiO2 by the hydrothermal method, performing modification by using a silane coupling agent KH570 to form a hydrophobic and oleophylic modified MnO2@SiO2 nanomaterial, and finally, uniformly dispersing the modified MnO2@SiO2 nanomaterial in polyurethane foam for free foaming to form the polyurethane foam with good oil absorbency. The hollow MnO2@SiO2 nanomaterial-polyurethane foam 3D (three dimensional) oil absorption material with a 3D porous structure is obtained by compounding the hydrophobic modified hollow MnO2@SiO2 nanomaterial and the polyurethane foam material; the hydrophobicity of a polyurethane material is improved obviously; an oil storage space is increased; and the oil absorbency is effectively improved. The method and the application have the characteristics of simple operation, low cost, environment friendliness, easy separation, greenness, environmental protection, energy conservation and relatively good practicality.

Owner:南京贸群新材料有限公司

Banana cellulose crystallite/polylactic acid aerogel and preparation method and use thereof

ActiveCN105017541ARealize comprehensive utilizationEasy to handlePaper material treatmentCelluloseNitrogen

The invention discloses a preparation method of a banana cellulose crystallite / polylactic acid aerogel. The preparation method comprises the following steps: step one, taking banana cellulose crystallite and ionic liquid and blending the banana cellulose crystallite and the ionic liquid, then performing reflux condensation for 3 hours under the protection of nitrogen at the constant temperature of 100 DEG C, then adding acetic oxide for modification, and then continuously stirring for 3 hours at the temperature of 90 DEG C under the protection of nitrogen to obtain a banana cellulose crystallite hydrosol; and step two, firstly taking polylactic acid and dichloromethane in the mass-to-volume ratio of 1.8: 10, dissolving the polylactic acid in the dichloromethane, then putting the banana cellulose crystallite hydrosol obtained in the step one into the dichloromethane dissolved with the polylactic acid, and then blending to obtain a crude banana cellulose crystallite / polylactic acid aerogel product. The invention also discloses the banana cellulose crystallite / polylactic acid aerogel. The invention also discloses use of the banana cellulose crystallite / polylactic acid aerogel for oil absorption.

Owner:GUANGXI TEACHERS EDUCATION UNIV

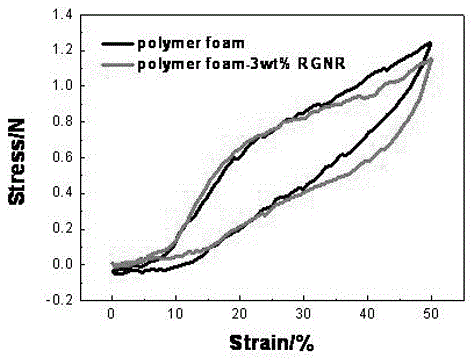

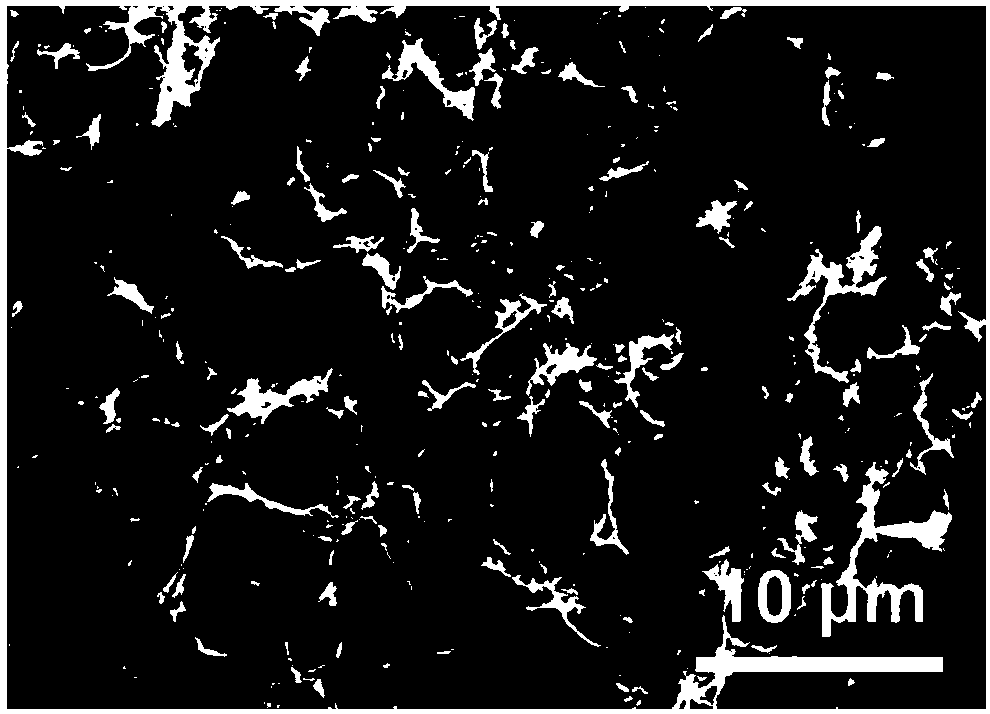

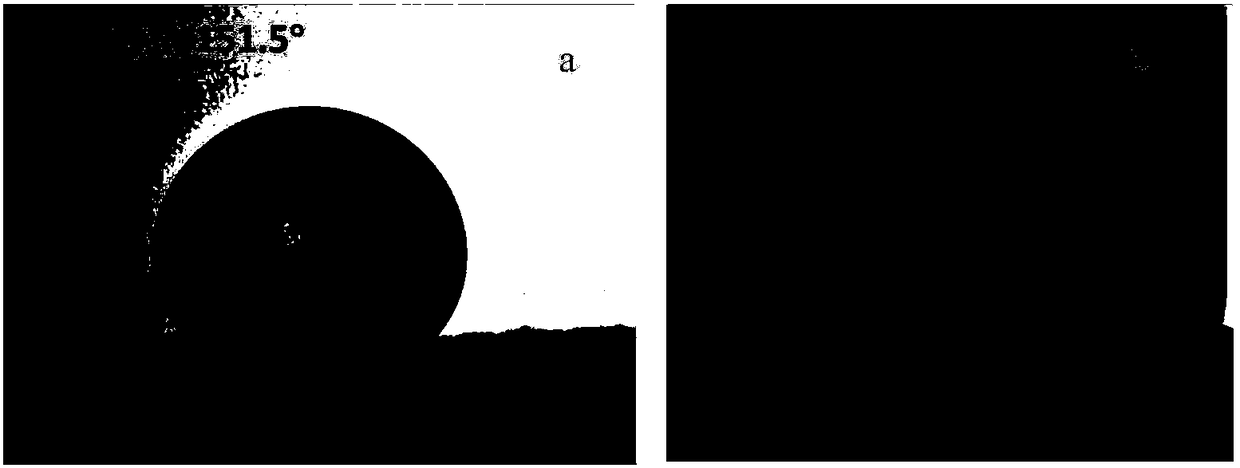

Graphene ribbon modified polymer-based foam material and preparation method and application thereof

ActiveCN105647159AOvercoming the difficulty of direct and firm adsorption on polymer-based foamsImprove hydrophobicityWater/sewage treatment by sorptionCarbon fibersCarbon nanofiber

The invention belongs to the technical field of functional composite materials, and provides a graphene ribbon modified polymer-based foam material and a preparation method and application thereof in order to solve the problems that a carbon tube and carbon nanofiber as hydrophobic materials are difficultly adsorbed onto the surface of polymeric foam and the adsorption capacity is high. The water contact angle of the graphene ribbon modified polymer-based foam material is more than or equal to 130 degrees, and the foam material is made of 85-99% by weight of foam and 1-15% by weight of grapheme ribbons. The prepared modified foam has the advantages of good hydrophobicity, high oil absorption rate, good compression-resilience mechanical performance, reuse and the like, the preparation method is simple, quick and easy to operate, and the raw materials are cheap and easy to obtain. The application prospects are great on sewage treatment, oil water separation and other aspects.

Owner:HANGZHOU NORMAL UNIVERSITY

Engineering fibre manufacturing technique for polyester reclaiming material road

InactiveCN101265611AReduce manufacturing costSave resourcesFilament manufactureHeating/cooling textile fabricsPolyesterCircular economy

The invention discloses a polyester recycled material road used technical fiber production process, which includes the following steps: dosing, batch charging, vibratory screening, feeding, pre-drying, drying or tackifying drying, adding nucleator, screw extrusion, melt filtrating, spinning, tow cooling, rolling and oiling, reciprocating tank falling, bunching, drafting, tension-setting, passing through a crimping machine, and shrink-setting. The invention improves the prior polyester recycled material technical fiber production process, and can adopt the polyester recycled material to produce the eligible road used technical fiber with low cost, environmental protection, and saved resource; which accords with the present nation called circulating economic developing ideology. The product quality completely achieves the quality standard of the road used technical fiber at home and abroad.

Owner:谭亦武 +1

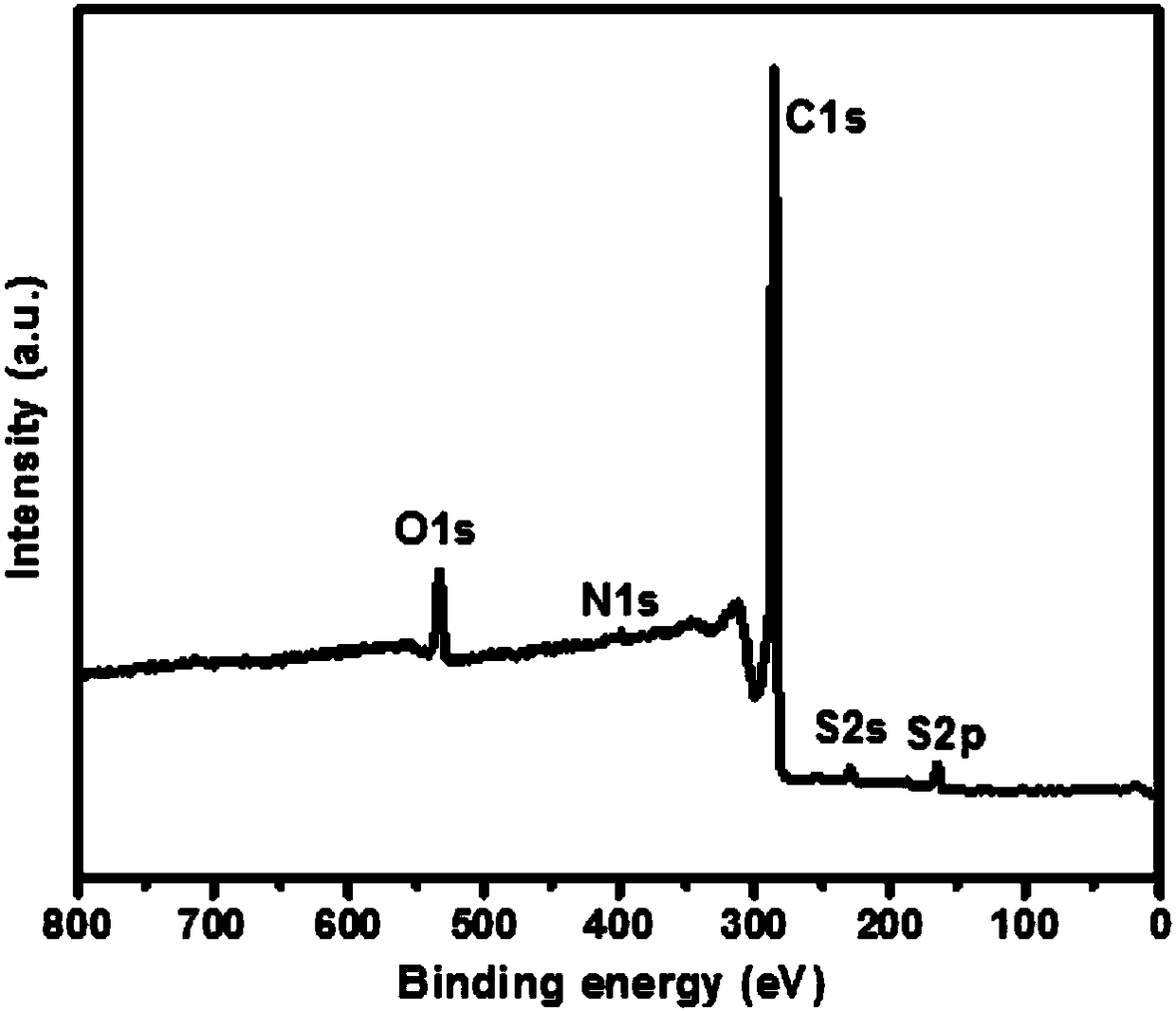

Sulfur and nitrogen codoped graphene-based aerogel and preparation method thereof

ActiveCN108439372AImprove hydrophobicityAvoid pollutionFatty/oily/floating substances removal devicesOther chemical processesThioureaFreeze-drying

The invention discloses a sulfur and nitrogen codoped graphene-based aerogel and a preparation method thereof. The preparation method comprise the following steps: preparing a sulfur and nitrogen codoped graphene hydrogel precursor from graphene oxide and thiourea by a hydrothermal synthesis technology, performing vacuum freeze drying on the precursor, and carbonizing the dried precursor to obtainthe sulfur and nitrogen codoped graphene-based aerogel. The sulfur and nitrogen codoped graphene-based aerogel prepared by the method has the advantages of super hydrophobic property, lipophilic property, good mechanical property, and high oil and organic solvent absorption rate. Additionally, the preparation method has the advantages of simplicity, wide sources of raw materials, greenness and environmental protection.

Owner:SHANDONG UNIV

Preparation method of graphene-modified hydrophobic oil-absorbing sponge

The invention provides a preparation method of graphene-modified hydrophobic oil-absorbing sponge. The preparation method comprises the following steps: preparing a graphene oxide suspension; ultrasonically washing polyurethane sponge by using ethanol and pure water respectively; adding a hydrazine hydrate reducing agent and the clean polyurethane sponge into the graphene oxide suspension, placingin a microwave chemical reactor, and performing a reduction reaction for 30-60min under a microwave heating condition; ultrasonically dispersing the polyurethane sponge in an ultrasonic cleaner, andwashing away excess graphene on the surface of the polyurethane sponge by using pure water; drying the polyurethane sponge cleaned in the step (4) in a drying oven with the temperature of 80-120 DEG C, and immersing the dried polyurethane sponge in a dimethylsiloxane solution, performing an immersion reaction for 4-7 hours, squeezing residual liquid in gaps of the polyurethane sponge, and drying in the drying oven with the temperature of 80 DEG C to obtain the graphene-modified hydrophobic oil-absorbing sponge. By the preparation method of the graphene-modified hydrophobic oil-absorbing sponge, the gap ratio is large, the oil-absorbing performance is high and the rebounding compressibility is good.

Owner:JINAN JIAXING TECH

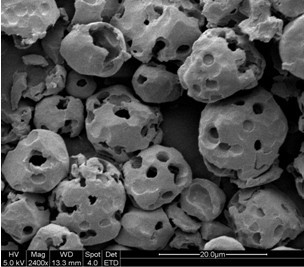

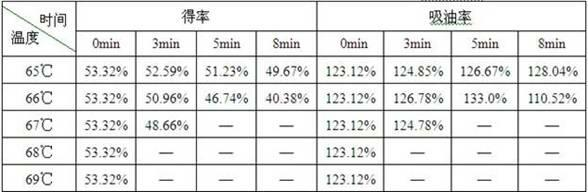

Method for preparing porous starch with high oil absorption rate through preprocessing starch

ActiveCN102533908ASimple preprocessingGood effectTobacco preparationCosmetic preparationsNutrientSolvent

The invention relates to a method for preparing porous starch with high oil absorption rate through preprocessing starch, belonging to the field of starch industry. The method comprises the following steps of: with corn starch as a raw material, preprocessing the raw material, namely size mixing, before enzymolysis, carrying out transient heat-moisture treatment at a temperature near a range of being lower than the gelatinization point, and preparing the porous starch with high oil absorption rate by adopting a complex enzyme method. The prepared porous starch has larger porosity and specific surface area, lower stacking density and favorable oil absorbability and water absorbability; the porous starch can keep remarkable structural integrity in water and other solvents; and the oil absorbability of the porous starch reaches 133.0 percent, and compared with the porous starch prepared without preprocessing, the porous starch prepared by adopting the method disclosed by the invention has the oil absorbability which is increased by 8.0 percent. When the porous starch adsorbed with clove oil is added into a tobacco sheet raw material, the prepared cigarette has remarkably-reduced irritation and dry sensation during smoking. When the porous starch adsorbed with coenzyme Q10 is added into an O / W-type facial cream emulsion, nutrient substances are slowly released and can be sufficiently absorbed by skin when the O / W-type facial cream emulsion is used. The method disclosed by the invention is simple and effective, unnecessary to increase equipment and free of byproducts and has wide application prospect.

Owner:JIANGNAN UNIV

Open-cell polymer foam material and preparation method therefor

The present invention provides a preparation method for an open-cell polymer foam material. The preparation method comprises the following steps of: a, weighing the following materials in parts by weight: 100 parts of polypropylene, 0.5-5 parts of a nucleating agent, 10-100 parts of ethylene-containing polyolefin and 1-30 parts of open-cell fillers; b, uniformly mixing polypropylene, the nucleating agent, ethylene-containing polyolefin and the open-cell fillers to obtain a mixture; adding the mixture into an extruder, and introducing supercritical-state carbon dioxide at a 1 / 5-1 / 3 part of a screw rod of the extruder; extruding and carrying out foaming to obtain the open-cell polymer foam material containing the open-cell fillers, wherein the open-cell polymer foam material contains the open-cell fillers comprising a plurality of first openings; and c, immersing the open-cell polymer foam material containing the open-cell fillers into an etching solution so as to etch the open-cell fillers to form a plurality of second openings, thereby obtaining the open-cell polymer foam material. The present invention further provides the open-cell polymer foam material. The open-cell polymer foam material has the advantages of a high open-cell ratio and good oil absorption ratio.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com