Sulfur and nitrogen codoped graphene-based aerogel and preparation method thereof

An alkene-based aerogel, graphene-based technology, applied in graphene, chemical instruments and methods, other chemical processes, etc., can solve the problem of graphene aerogel with large pore size, secondary heavy metal pollution in water, small specific surface area, etc. problems, to achieve the effect of good recycling performance, avoiding metal pollution in water, and high adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] Graphene oxide in the present application can be commercially available graphene oxide, and can also be prepared according to the preparation method of other documents, and the application provides a kind of preparation method of graphene oxide, and its steps are:

[0042]Slowly add 18g of potassium permanganate and 3g of sodium nitrate into 138mL of concentrated sulfuric acid in an ice bath at 0°C, while mechanically stirring at a speed of 200-500rpm. After the potassium permanganate and sodium nitrate are completely dissolved, slowly Add 3g of expanded graphite, after the expanded graphite is completely stirred evenly, seal it and place it in the refrigerator, and keep it warm at 0°C for 24h; then transfer the reaction system to a constant temperature oil bath at 35°C and stir for 30min, then slowly add deionization dropwise while heating up Water, add a total of 300mL of deionized water dropwise, at this time the temperature just rises to 98°C, keep stirring at 98°C f...

Embodiment 1

[0044] A preparation method of sulfur and nitrogen co-doped graphene-based airgel,

[0045] (1) 80 mg of graphene oxide was added to 40 mL of deionized water, and dispersed by ultrasonic for 1 h until uniformly mixed to obtain a 2 mg / mL graphene oxide aqueous solution.

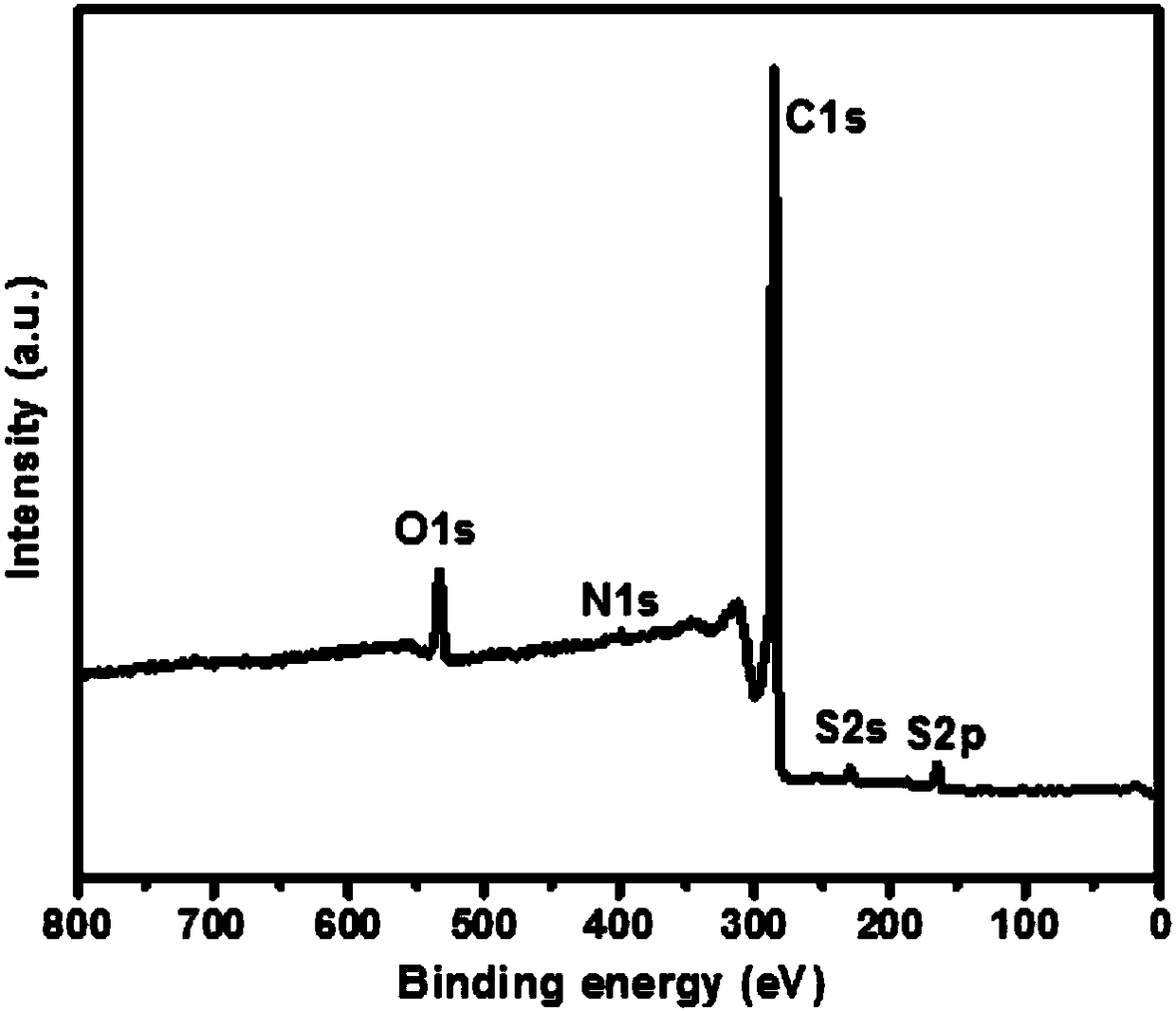

[0046] (2) Weigh 1.6 g of thiourea as a source of sulfur and nitrogen, mix it with the graphene oxide aqueous solution obtained in step (1), and ultrasonically dissolve it completely for 15 minutes to obtain a mixed aqueous solution of graphene oxide and thiourea.

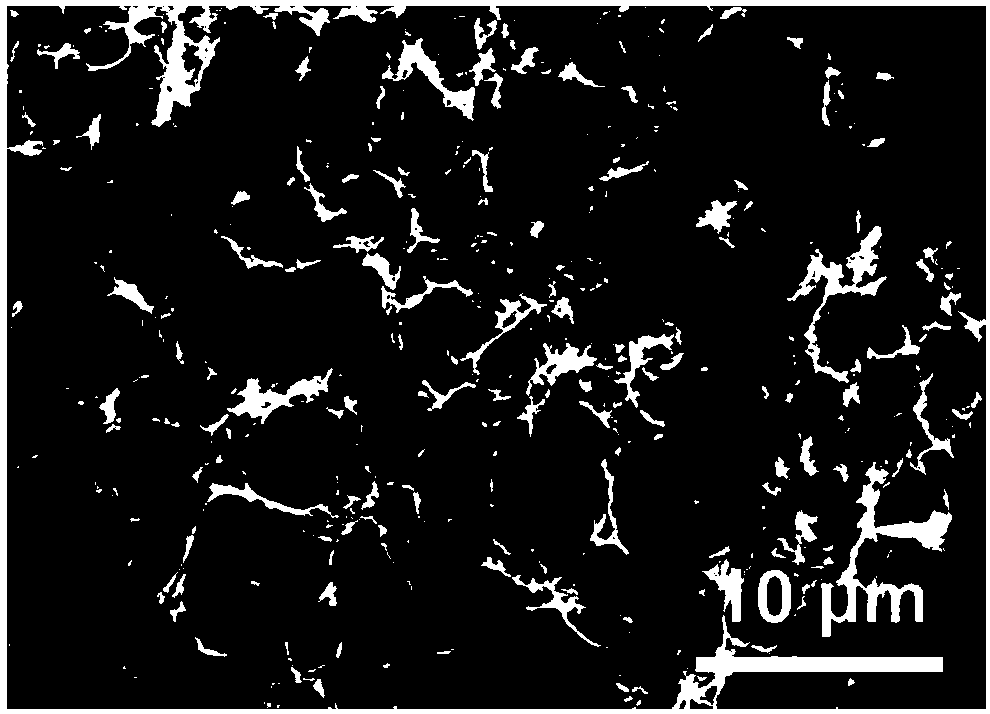

[0047] (3) Transfer the mixed aqueous solution obtained in step (2) to a high-pressure reactor with a volume of 50 mL, and conduct a hydrothermal reaction at a constant temperature of 160 ° C for 12 hours. After natural cooling, a sulfur-nitrogen co-doped graphene hydrogel precursor is obtained. body.

[0048] (4) Soak the sulfur-nitrogen co-doped graphene hydrogel precursor prepared in step (3) in deionized water for 48 hours, and change the deio...

Embodiment 2

[0063] A preparation method of sulfur and nitrogen co-doped graphene-based airgel,

[0064] (1) Add 120 mg of graphene oxide into 40 mL of deionized water, and ultrasonically disperse for 2 hours until uniformly mixed to obtain a 3 mg / mL graphene oxide aqueous solution.

[0065] (2) Weigh 3.6g of thiourea as a source of sulfur and nitrogen, mix it with the graphene oxide aqueous solution obtained in step (1), and ultrasonically dissolve it completely for 20 minutes to obtain a mixed aqueous solution of graphene oxide and thiourea.

[0066] (3) Transfer the mixed aqueous solution obtained in step (2) to a high-pressure reactor with a volume of 50 mL, and conduct a hydrothermal reaction at a constant temperature of 200 ° C for 8 hours. After natural cooling, a sulfur-nitrogen co-doped graphene hydrogel precursor is obtained. body.

[0067] (4) Soak the sulfur-nitrogen co-doped graphene hydrogel precursor prepared in step (3) in deionized water for 72 hours, during which time th...

PUM

| Property | Measurement | Unit |

|---|---|---|

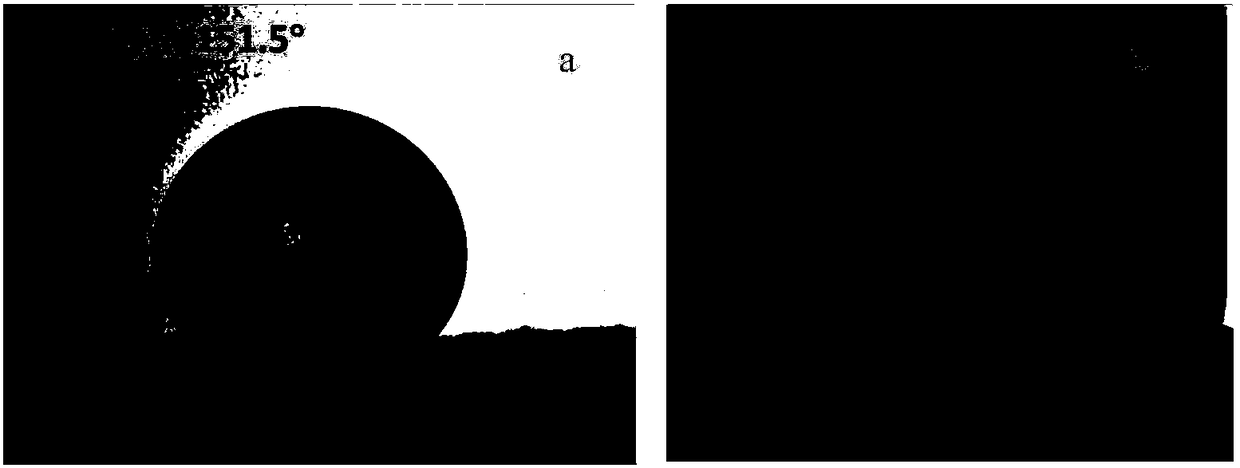

| water contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com