Special offshore deoiling oil absorbent felt and method for preparing oil absorbent felt

A technology of oil-absorbing felt and oil-absorbing fiber, which is applied in separation methods, chemical instruments and methods, filtration and separation, etc. It can solve the problems of inability to exert oil absorption effect, inability to achieve oil absorption, limited oil absorption performance, etc., and achieve light weight and enhanced use Effect, the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

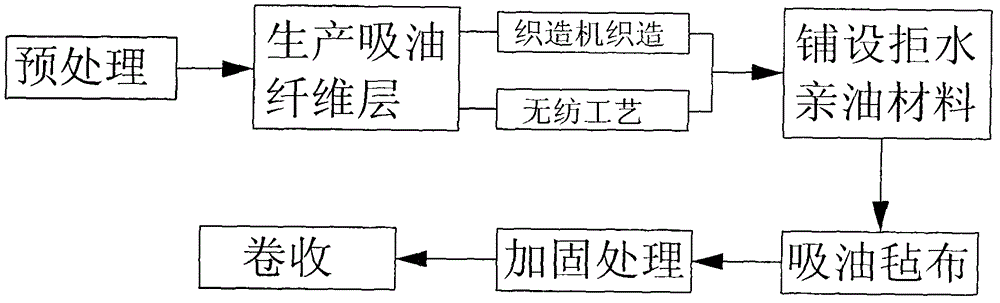

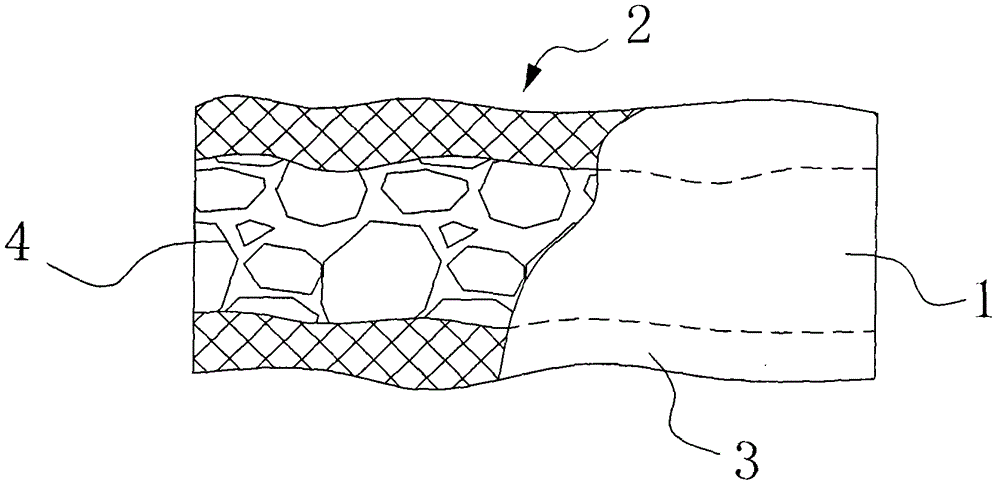

[0032] An oil-absorbing felt cloth for offshore oil removal, comprising an oil-absorbing felt body 2 with an oil-absorbing gap 1 made of oil-absorbing fibers, the oil-absorbing felt body 2 includes two layers of oil-absorbing fiber layers 3, and the oil-absorbing fiber layer 3 is made of The oil-absorbing fiber can be selected from one or more of polypropylene fiber, ultra-high molecular weight polyethylene fiber, polyester fiber or nylon. The oil-absorbing felt body 2 can be obtained by a weaving machine, or by a traditional non-woven fabric production process. The oil-absorbing gap 2 formed between the two layers of oil-absorbing fiber layers 3 is filled with water-repellent and lipophilic materials 4, and the water-repellent and lipophilic materials 4 filled in the oil-absorbing felt body 2 are regenerated fibers processed from waste fabrics, oil-absorbing One or more of cotton, oil-absorbing sponge, polypropylene fiber, polyethylene fiber or polyester fiber. The two oil-a...

Embodiment 2

[0046] The same part of this embodiment and embodiment 1 will not be described again, and the difference is that another application of the present invention is that the water-repellent and lipophilic material 4 filled in the oil-absorbing felt body 2 can be selected from dry Enteromorpha. The dried enteromorpha is obtained by soaking fresh enteromorpha with water-repellent and lipophilic additives and then drying.

[0047] Specifically: in the pretreatment of step (1), the fresh Enteromorpha is dehydrated, then immersed in a water-repellent and lipophilic auxiliary agent, and dried for later use. The water-repellent and lipophilic auxiliary agent is silicone oil auxiliary agent. additives or fluororesin additives. The surface treatment of Enteromorpha can effectively turn garbage into useful materials. As an oil-absorbing material, its oil absorption rate can reach about 1:20, which is better than many current oil-absorbing materials, and its flame retardancy is better; Enter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com