Graphene ribbon modified polymer-based foam material and preparation method and application thereof

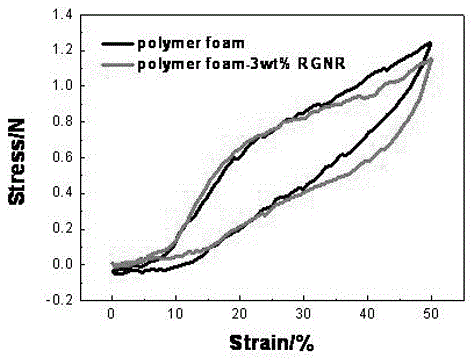

A graphene ribbon, foam material technology, applied in chemical instruments and methods, water/sludge/sewage treatment, adsorbed water/sewage treatment, etc., can solve problems such as difficult adsorption capacity, and achieve good compression-resilience mechanical properties , The effect of high oil absorption rate and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Configuration of graphene oxide tape aqueous solution: take the graphene oxide tape viscous solution with a predetermined concentration and add deionized water to dilute to a concentration of 0.8mg / ml.

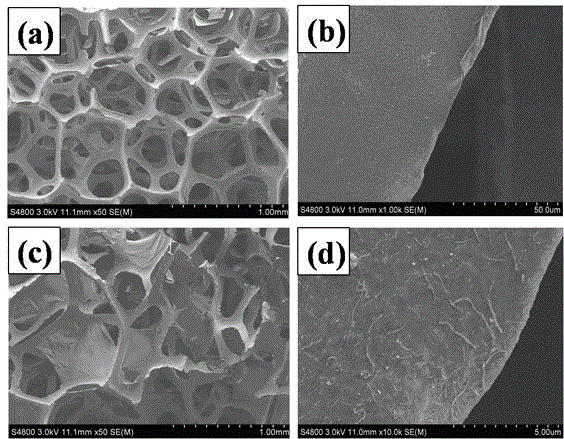

[0029] (2) Preparation of polyurethane foam material modified with graphene oxide tape: Take 25ml of graphene oxide tape water solution with a concentration of 0.8mg / ml, soak 25×25×10mm polyurethane foam in it, and use extrusion and vacuum defoaming Method Fully infiltrate the foam, then take it out and place it on a copper grid, and dry it with air blast.

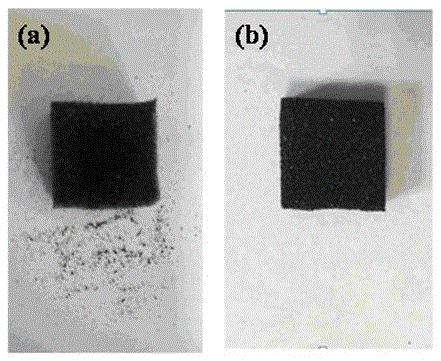

[0030] (3) Preparation of graphene-modified polyurethane foam material: take the above-mentioned graphene oxide-modified polyurethane foam material, place it in the upper middle part of the reaction kettle, add ammonia water dropwise at the bottom, and place it in a 90°C oven for 4 hours in an airtight manner. That is, a graphene ribbon-modified polyurethane foam material 1 with a graphene ribbon mass percentage...

Embodiment 2

[0034] (1) Configuration of graphene oxide tape aqueous solution: Take the graphene oxide tape viscous solution with a predetermined concentration and dilute it with deionized water to a concentration of 1.1 mg / ml.

[0035] (2) Preparation of graphene oxide tape-modified polyurethane foam material: Take 25ml of graphene oxide tape water solution with a concentration of 1.1mg / ml, soak 25×25×10mm polyurethane foam in it, and use extrusion and vacuum defoaming methods. Method Fully infiltrate the foam, then take it out and place it on a copper grid, and dry it with air blast.

[0036] (3) Preparation of graphene-modified polyurethane foam material: take the above-mentioned graphene oxide-modified polyurethane foam material, place it in the middle and upper part of the reaction kettle, add hydrazine hydrate dropwise at the bottom, and place it in an oven at 90°C for 3 hours in an airtight manner. That is, a graphene ribbon-modified polyurethane foam 2 with a graphene ribbon mass p...

Embodiment 3

[0041] (1) Configuration of the aqueous solution of octadecyltrimethoxysilane modified graphene oxide: Take the aqueous solution of octadecyltrimethoxysilane modified graphene oxide with a predetermined concentration and add deionized water to dilute to the concentration The content of octadecyltrimethoxysilane in the modified graphene oxide is about 25wt%.

[0042] (2) Preparation of graphene oxide tape-modified polyurethane foam material: Take 35ml of graphene oxide tape water solution with a concentration of 0.8mg / ml, soak 25×25×10mm polyurethane foam in it, and use extrusion and vacuum defoaming Method Fully infiltrate the foam, then take it out and place it on a copper grid, and dry it with air blast.

[0043] (3) Preparation of graphene-modified polyurethane foam material: Take the above-mentioned graphene oxide-modified polyurethane foam material, soak it in 50ml of hydrazine hydrate aqueous solution with a volume ratio of 1:25, and reduce it at 80°C for 3h. That is, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com