Preparation method of hollow tubular composite oil absorption material

An oil-absorbing material and tubular technology, which is applied in the field of preparation of hollow tubular composite oil-absorbing materials, can solve the problems of inability to realize efficient adsorption and separation of oil-water system, scale application limitations, etc., and achieve convenient on-site use, high oil absorption rate, and simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

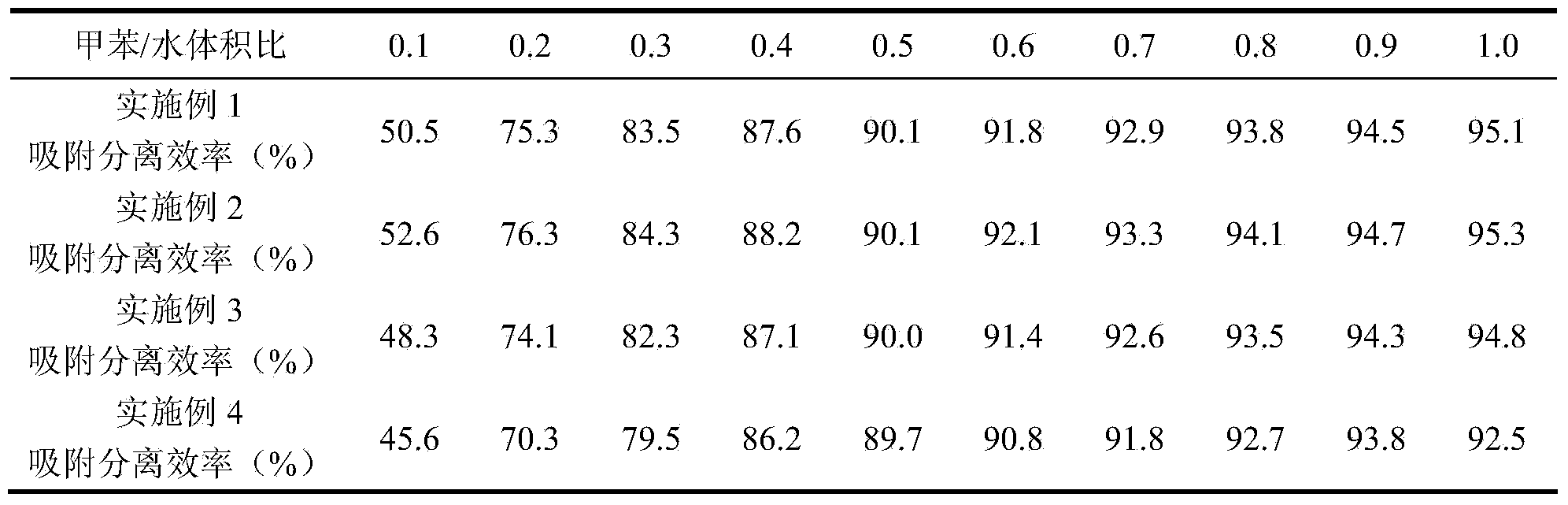

Examples

preparation example Construction

[0012] A further feature of the preparation method of the present invention is that when the N,N-dimethylacetamide content in the step (1) is 0, the preparation method also includes the following two steps (3) and (4):

[0013] (3) Prepare a methyl silicone oil solution; add 100-1500mL xylene and 25-1600μL methyl silicone oil as a dispersant into the container, stir evenly, and prepare a methyl silicone oil solution;

[0014] (4) Dipping and coating of methyl silicone oil film; immerse the hollow tubular porous polymer material treated by dipping and coating of graphene dispersion into xylene solution containing methyl silicone oil, let it stand for coating for 5-10 minutes, take it out and put it Put it into a vacuum oven with a negative pressure of -0.1MPa, and treat it at 100-150°C for 12-14 hours until it is completely dry, and then a hollow tubular composite oil-absorbing material with graphene as the surface adsorption layer and a hollow tubular porous polymer material as...

Embodiment 1

[0026] (1) Prepare a graphene dispersion; add 500mL dispersant ethanol and 0.08g graphene into the container, ultrasonically disperse for 20 minutes, and prepare a graphene dispersion;

[0027] (2) Dipping and coating graphene adsorption layer; 0.4g hollow tubular polyurethane sponge (hollow tubular polyurethane sponge specifications: inner diameter 5mm, tube wall thickness 10mm, length 50mm, average pore diameter 0.1mm, porosity 70% ) into the graphene dispersion liquid, let it stand for 5 minutes, then put the hollow tubular polyurethane sponge in a vacuum oven with a negative pressure of -0.1MPa, and treat it at 150°C for 6 hours until it is completely dry, take it out and weigh it immediately, and the hollow tubular sponge is obtained. Composite oil-absorbing material. The mass of the obtained graphene adsorption layer accounts for 7% of the mass of the hollow tubular polyurethane sponge.

[0028] The maximum static adsorption capacity of the obtained hollow tubular compo...

Embodiment 2

[0030] (1) Prepare the graphene dispersion; add 500mL of dispersant ethanol and 0.08g of graphene, 19.7g of DMAc, and ultrasonically disperse for 40min in the container to prepare the graphene dispersion.

[0031] (2) Dipping and coating graphene adsorption layer; 0.4g hollow tubular polyurethane sponge (hollow tubular polyurethane sponge specifications: inner diameter 5mm, tube wall thickness 10mm, length 50mm, average pore diameter 0.15mm, porosity 70% ) into the graphene dispersion, let it stand for 30 minutes, then take it out and put it into a vacuum oven with a negative pressure of -0.1MPa. In order to speed up the volatilization of the dispersant ethanol and DMAc, set the oven temperature to 100°C and treat it at 100°C for 12h , until it is completely dry, take it out and weigh it, and the hollow tubular composite oil-absorbing material is obtained. The mass of the obtained graphene adsorption layer accounts for 9% of the mass of the hollow tubular polyurethane sponge. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Tube wall thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com