Banana cellulose crystallite/polylactic acid aerogel and preparation method and use thereof

A technology of cellulose microcrystals and polylactic acid, which is applied in fiber raw material processing, textiles and papermaking, etc., can solve the problems of banana stems and leaves polluting the environment, and achieve good oil absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

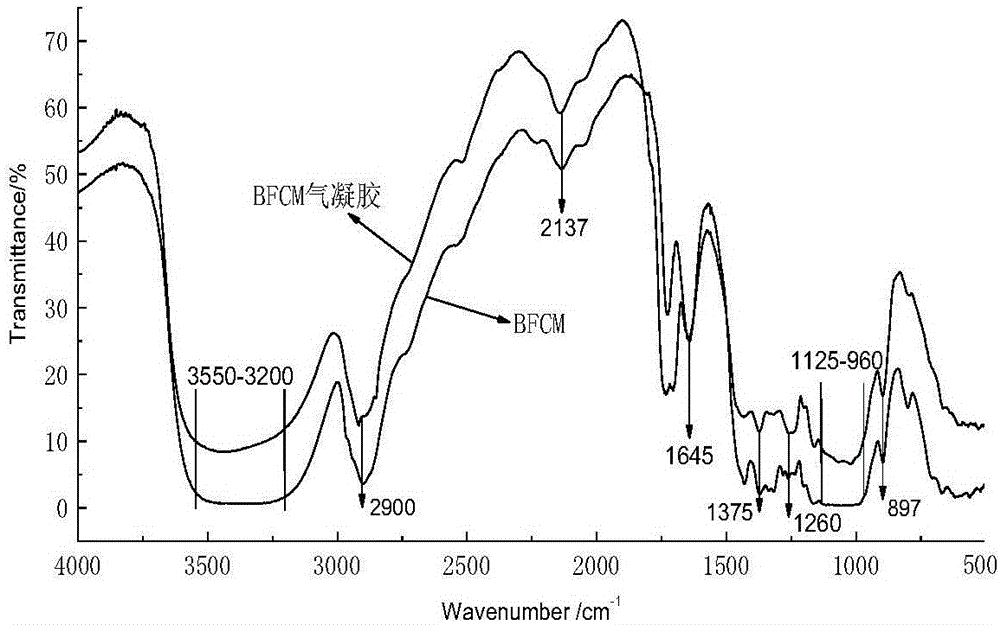

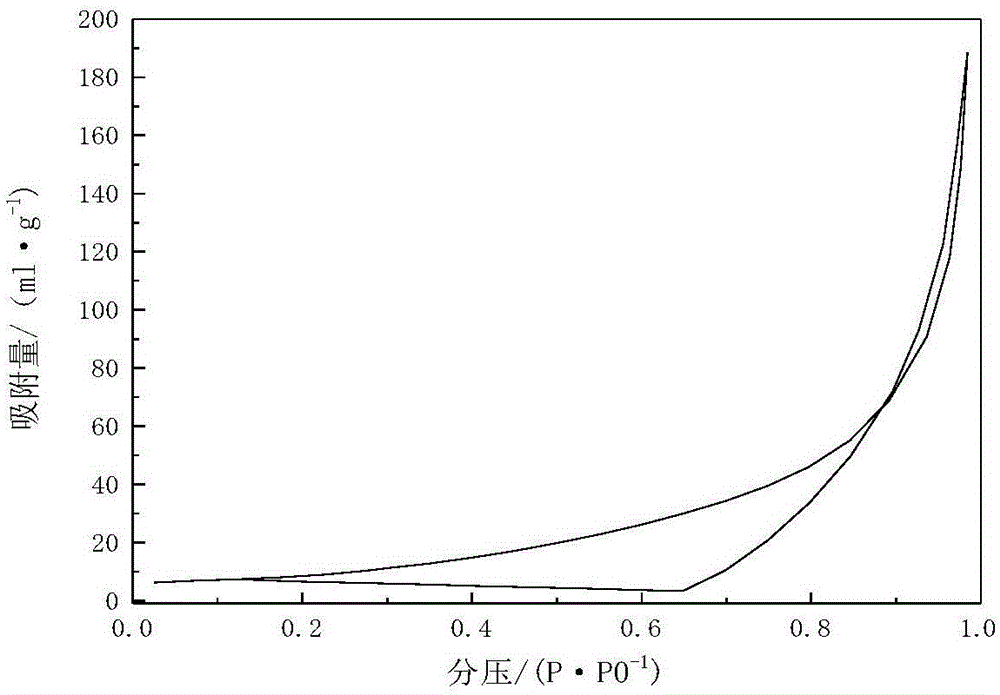

[0052] Figure 1~ Figure 7 Shown, the present invention provides a kind of preparation method of banana cellulose microcrystal / polylactic acid airgel, comprises the steps:

[0053] Step 1. Preparation of banana cellulose microcrystalline hydrogel: take banana cellulose microcrystals and ionic liquid according to the mass ratio of 1:20, and mix the banana cellulose microcrystals and ionic liquid, and then keep the temperature at 100°C Reflux and condense for 3 hours under the protection of nitrogen, then add acetic anhydride whose mass is 1.5 times the mass of the banana cellulose microcrystals for modification, and then continue to stir at a temperature of 90°C for 3 hours under the protection of nitrogen to obtain banana fiber vegan microcrystalline hydrosol; and,

[0054] Step 2, prepare banana cellulose microcrystal / polylactic acid airgel: first take polylactic acid and methylene chloride according to the mass volume ratio of 1.8:10, and dissolve the polylactic acid in met...

Embodiment 1

[0075] 1.1 Main raw materials and equipment

[0076] Table 1 Main raw materials

[0077]

[0078] Table 2 Main instruments and equipment

[0079]

[0080]

[0081] 2 Experimental steps

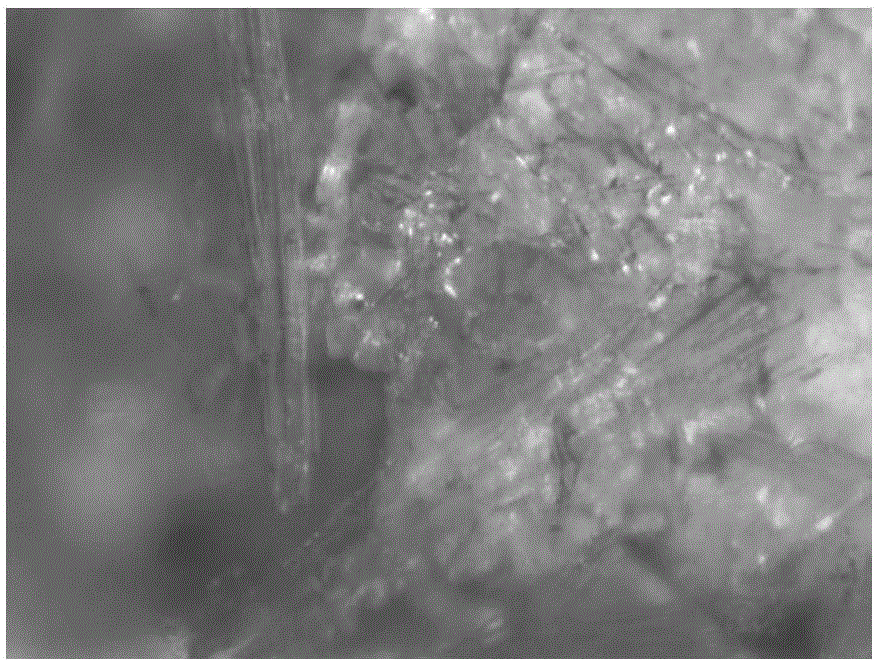

[0082] 2.1 Production of banana fibrils

[0083] First, the banana stems are peeled off, cut into long strips with a width of about 4 cm, then dehydrated in the sun, and finally placed in a vacuum drying oven at a constant temperature of 60°C for drying. In this experiment, the chemical method is used to extract fiber from banana stems. The process is: pre-acid treatment→alkaline treatment→simmering→washing and bleaching→acid. The cost of this method is very low, and the preparation method is simple. Banana fiber.

[0084] The present invention adopts following steps to process banana stem bast:

[0085] (1) Beat the banana bark, rinse it with water, and dry it for later use. In this way, a large part of impurities can be removed in advance, and it can be used for a long time af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com