Patents

Literature

136 results about "Banana fiber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

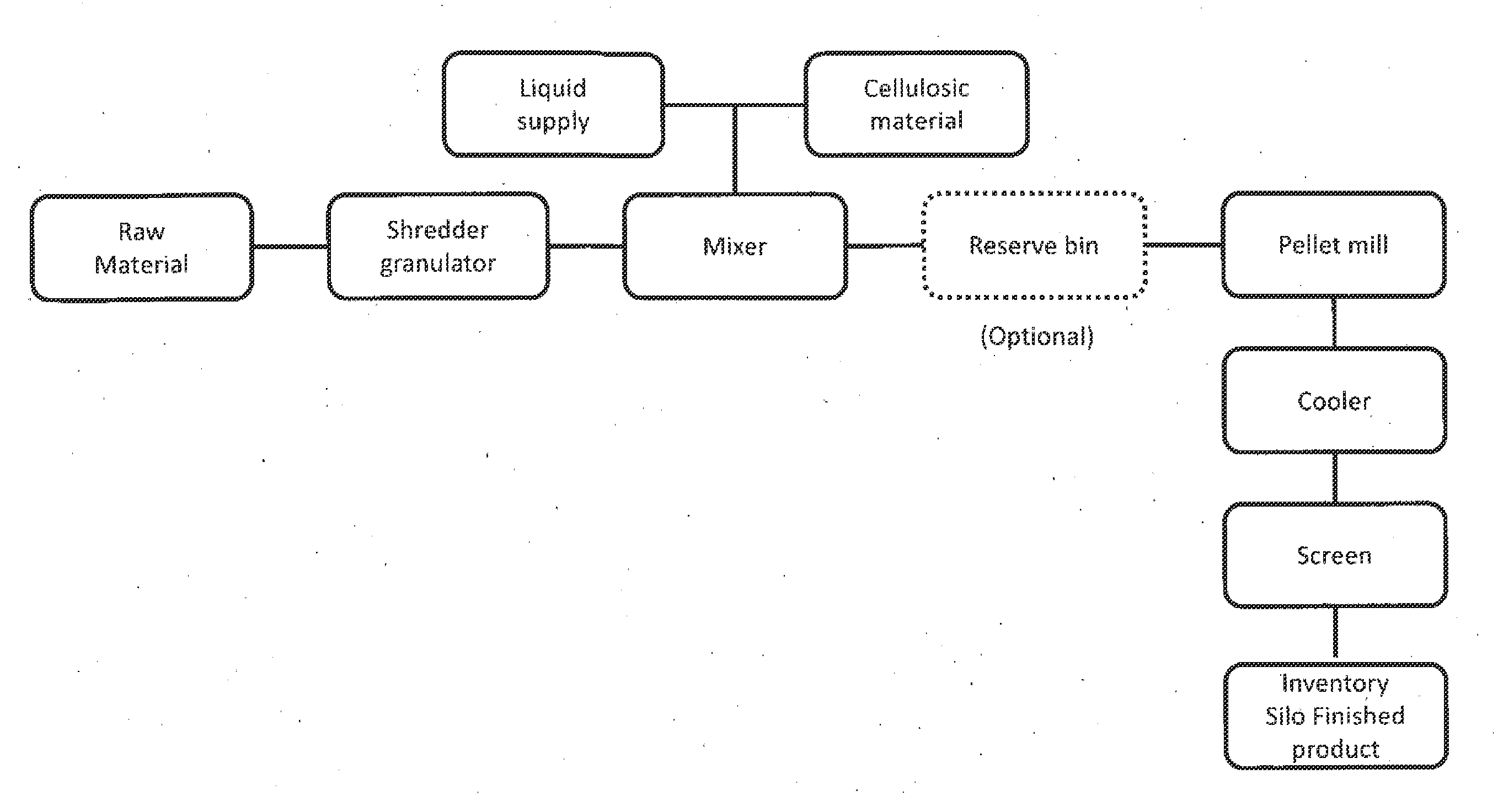

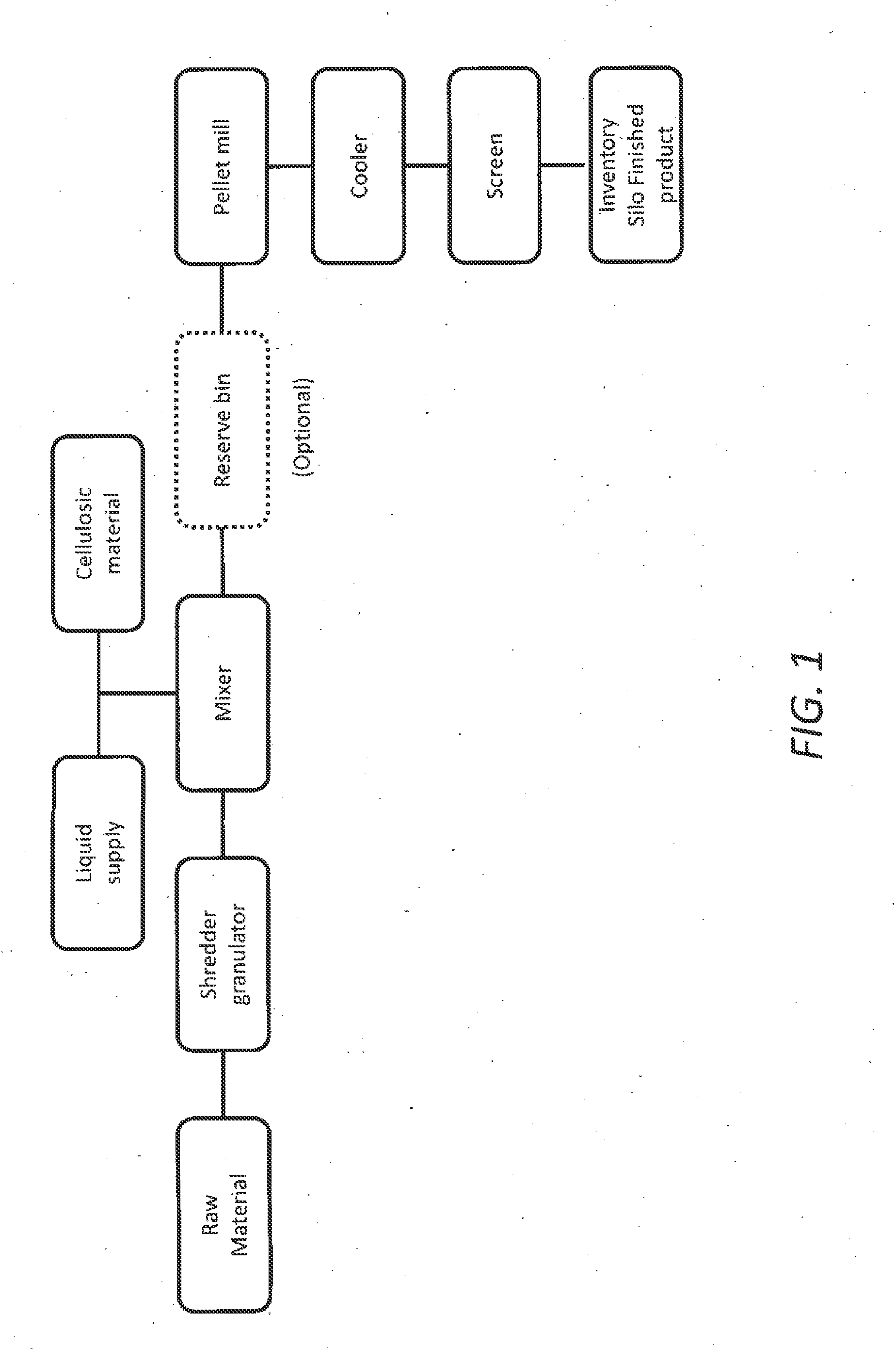

Multipurpose pellets and method of making same

A multipurpose pellet is provided comprising: from about 0.1% to about 100% by weight of a vegetable fiber chosen from cotton, bamboo fiber, rice fiber, esparto, papaya, coir, sisal, kapok, jute, ramie, flax, roselle hemp, hemp, kenaf, abaca, soybean fiber, okra fiber, vine fiber, banana fiber, rattan and nettlesjute; and from about 99.9% to about 0% by weight of cellulosic material.

Owner:LEFEBVRE ROBERT

Method for preparing banana cellulose nanofibers by using steam explosion technology

InactiveCN102586897ASimple processReduce manufacturing costVegetable materialChemical treatmentNanofiber

Owner:HAIKOU EXPERIMENTAL STATION CHINESE ACAD OF TROPICAL AGRI SCI

Vegetable fiber reinforced flame-retardant thermoplastic starch-based composite material and preparation method thereof

The invention belongs to a vegetable fiber reinforced flame-retardant thermoplastic starch-based composite material and a preparation method thereof. The composite material comprises the following raw materials in part by weight: 100 to 120 parts of starch, 30 to 50 parts of plasticizer, 5 to 30 parts of vegetable fibers and 5 to 40 parts of flame retardant. The banana fiber raw material used by the invention is agricultural waste, namely banana stems, and has low cost; and sisal fibers, jute fibers and the like can be produced industrially and the raw materials are easily obtained. The product can be prepared by simple controllable standard machine-shaping conditions. The finished product has excellent biodegradability, mechanical property and flame retardant property, can be used in the fields of package, automotive trim, household appliances and the like and avoid applying pressure to the environment after being scrapped. Meanwhile, the vegetable fiber reinforced flame-retardant thermoplastic starch-based composite material increases the additional value of the cash crops, increases farmer income and has important significance for reduction of white pollution.

Owner:GUANGXI TEACHERS EDUCATION UNIV

Banana fiber and its production and its blending wires and fabrics

InactiveCN1472372ALight materialGood hygroscopicityVegetable fibres from other vegetable matterYarnYarnFiber bundle

Provided is a banana fiber using a banana stem which is an industrial waste as a raw material, a method for producing the banana fiber, a union yarn composed of a staple fiber of the banana fiber and other fiber and a fiber structure prepared from the union yarn. The banana fiber is obtained by drying peeled temporary stem of banana and opening the fiber so as to have 10-50 mm average fiber length and 0.5-80 dtex average fineness. The method for producing the banana fiber comprises a step (a) for cutting stems of banana, a step (b) for peeling and removing colored epidermis of stems, a step (c) for peeling much bark constituting stems to provide a unit bark, a step (d) for taking out a fiber bundle by pressing the unit bark by a press, a step (e) for drying the fiber bundle, a step (f) for obtaining a monofilament from the dried fiber bundle and a step (g) cutting the monofilament into a definite length and obtaining the staple fiber.

Owner:NISSHINBO IND INC

Banana bast fiber and preparation method thereof

ActiveCN101736407AAntibacterial propertiesMoisture absorption and dehumidification fastMechanical fibre separationBacteriological rettingBreaking strengthFiber bundle

The invention discloses a method for preparing a banana bast fiber by adopting biological degumming, which is characterized by comprising the following steps of: preprocessing, inoculating, fermenting, inactivating, stamping and postprocessing. The prepared banana bast fiber has soft and loose appearance and uniform color and has no taste or obvious flaws; the fiber length is 80mm-200mm, the fiber count is 300Nm-500Nm, the breaking strength of fiber bundles is 3.5g / D-5.0g / D, and the residual gum content is 1.5 percent-3.2 percent. The biologically degummed banana bast fiber effectively removes the non-spinnable components of colloid, lignin, hemicellulose and the like and keeps the bacteria proofing, rapid moisture absorption and release of the self characteristics of the fiber, thereby ensuring the strength of the fiber; meanwhile, the banana fiber is kneaded and rolled by sterilization and machines before degumming, thereby ensuring the degumming effect and the smooth going of degumming and enabling the degummed fiber to be beneficial to the production and production development of the next working procedure.

Owner:湖南华升益鑫泰科技有限公司

Sound-absorbing and heat-preserving composite environment-friendly material for automotive upholstery and preparing method of sound-absorbing and heat-preserving composite environment-friendly material

InactiveCN105176023AHigh impact strengthHigh elongation at breakArtificial filament washing/dryingMelt spinning methodsEpoxyHibiscus

The invention discloses a sound-absorbing and heat-preserving composite environment-friendly material for an automotive upholstery. The sound-absorbing and heat-preserving composite environment-friendly material is prepared from, by weight, 100-103 parts of polylactic acid, 3.5-4 parts of nanometer antimonous oxide, 10-11 parts of decabromodiphenyl ethane, 25-27 parts of SEBS, 60-62 parts of hibiscus cannabinus fibers, 10-12 parts of banana fiber paste, 8-9.2 parts of cotton pulp, 2-2.5 parts of epoxy butyl oleate, 7-9 parts of expanded vermiculite, 5-6 parts of cork wood, 5-6 parts of arabic gum and a proper amount of water. According to the sound-absorbing and heat-preserving composite environment-friendly material, the banana fiber paste, the cork wood, the expanded vermiculite and other ingredients are adopted to be prepared into modified powder through a series of processes to be added into preparation of a steeping paste, treated mixed fibers maintain the good bending property, meanwhile, the heat-preserving, sound-insulating and vibration-reducing performance is further improved, and thus the sound-absorbing and heat-preserving composite environment-friendly material can meet the requirement of the functional automotive upholstery and is suitable for producing an instrument table top, a ceiling and the like of an automobile.

Owner:WUHU HUANRUI AUTO INTERIOR DECORATION

Technology of making paper and paper products by banana fibre

InactiveCN1621611AExtended service lifeQuality improvementCellulose material pulpingBreaking strengthPapermaking

The present invention is the process of making paper and paper product with banana fiber. Unlike common papermaking material, banana fiber is long, fine, soft and easy to separate, and may be beaten into pulp after separating and degluing without needing heating, soaking in alkali solution, etc. During the degluing, pollution-free brine or common bleaching chemical, such as calcium chloride, is used. Therefore, the process is fast and low in cost, and the effluent may be deposited for reuse or drained into fish pond as fish's feed. The paper and the paper product have good physical performance, including high tension strength, high breaking strength, good water tolerance, etc.

Owner:颜小平 +1

Method for preparing anti-flaming banana fiber epoxy resin composite material

A fire-retardation banana fiber epoxy resin composite material comprises the following components in weight percent: 30 percent of modified fire-retardation banana fiber, epoxy resin of 25 to 35 percent, curing agent of 25 to 35 percent, fire retardant of 5 to 15 percent, diluent agent of 3 to 5 percent, toughening agent of 1 to 3 percent and curing accelerating agent of 0.2 to 0.3 percent. The preparation of the composite material comprises the following steps that: a common method is adopted to extract banana fiber; after the coupling modification and the fire retarding treatment of the banana fiber are completed, raw materials are mixed evenly according to a formula; and finally, hot pressing, curing and forming are completed to obtain the material. The fire-retardation banana fiber epoxy resin composite material solves the problems of the compatibility and the fire retarding treatment between banana fiber and epoxy resin, thereby realizing the comprehensive application of banana stems and banana leaves as well as the treatment of agricultural wastes; meanwhile, the prepared composite material not only has the physical appearance of natural wood, but also has light mass, corrosion prevention, moisture prevention, insect prevention, fire prevention, high dimensional stability and excellent workability performance; moreover, the composite material can be recycled along with low product cost.

Owner:GUANGXI TEACHERS EDUCATION UNIV

Multifunctional plant fabric cloth

InactiveCN102776655AReasonable formulation of ingredientsLow costWoven fabricsYarnPolyesterEngineering

The invention provides a multifunctional plant fabric cloth which is prepared through a longitude-latitude machine by using a tatting technology. According to the multifunctional plant fabric cloth, warp yarns are the bended fiber rods comprising aloe fiber and natural cotton, and weft yarns are the blended fiber rods comprising banana fiber and polyester fiber; and the ratio of the number of strands of the warp yarns to the weft yarns is of 3:1. The multifunctional plant fabric cloth provided by the invention is reasonable in component preparation, and low in cost; the main components of the fiber rod are the natural plant fibers; the multifunctional plant fabric cloth has abundant sources of the raw materials; the prepared fabric cloth has high breathing performance and comfortable level in wearing; the fabric cloth can replace current synthetic fiber fabric cloth and natural fiber fabric cloth to certain extent; and moreover, the fabric cloth has special functions on whitening the skin, and resisting electromagnetic radiation and the like, and the practical value is greatly improved.

Owner:KUSN ZHOUSHI HUIHONG GARMENT FACTORY

Preparation method of banana fiber from banana stems and leaves by steam explosion degumming

InactiveCN101982571AReduce manufacturing costHigh yieldVegetable materialFibre treatment to obtain bast fibreResource utilizationWater vapor

The invention belongs to the resource utilization field of natural plant fiber, in particular relating to a preparation method of banana fiber from banana stems and leaves by steam explosion degumming. The method comprises the steps of performing steam explosion on the banana stems and leaves after cutting, and rinsing and bleaching to obtain the high quality banana fiber. The water steam is used as the medium in the steam explosion process without any addition of the chemical reagents, so the preparation method of the invention has no pollution. The steam explosion process degrades more than 90% of the pectin and the hemicellulose in the banana stems and leaves, degrades parts of the lignin, and completely separates the fibre bundles of banana stems and leaves from other components. The rinsing operation can remove other tissues except for the fiber, and the banana fiber is torn into the loose structure in the steam explosion process which facilitates the bleaching, the oil feeding and the loosening of the fiber and improves the fiber quality. The invention provides the novel preparation method of the banana fiber, which can reduce the degumming cost of the banana fiber, as well avoid the environmental pollution caused by the traditional degumming methods and enhance the fiber yield and quality.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Japanese banana fiber and its preparation method and uses

InactiveCN101187068AImprove qualityImprove spin performanceMechanical fibre separationYarnYarnRaw material

The invention relates to a musa fiber, which is prepared from stems of musa plants, which are used as raw materials, wherein the musa fiber comprises the following components: cellulose is 81-95 percent, hemicellulose is 1.0-5.0 percent, lignin is 1.0-2.8 percent, other components are pectin water soluble matter and is based on the dry weight of the musa fiber. The above musa fiber is prepared through the mechanical treatment, acid preimpregnation, washing, soda boil, washing, dehydration and oil supply, the above musa fiber is used to be spun into 10-60 single yarn, the process has low cost, compared with ancient process, the strength and the fineness of the made fiber are improved, and the process of preparing the musa fiber of the invention is also capable of being used to made mulberry fiber. The invention opens a new way for the development and utilization of phloem resources, has an important significance at the present that a part of prior fiber resources are run out, and accords with strategic demands of sustainable development.

Owner:吴苏明 +2

Scribbled of banana fiber and production method thereof

The invention provides scribbled of banana fiber and a production method thereof. The scribbled comprises 5-75% by weight of banana fiber and 25-95% by weight of other textile fiber, which are arranged in a longitudinal direction and mutually staggered, and are arranged in the longitudinal direction and mutually intersected and twisted together. The concrete preparation process comprises the following steps: preprocessing the banana fiber by oil solutions, distributing cotton by adopting a web of combed cotton, mixing the cotton, blowing, carding, drawing by three paths, roving, spinning and winding. Refined banana fiber is adopted as a raw material, the source of the raw material is abundant, the fineness of the fiber is high, and the banana fiber is spun and processed into the scribbled of the banana fiber as required by a user, after the banana fiber is preprocessed, has wide use range, is an optimal choice for high-grade underwear, leisure shirts, T-shirts, sweaters, socks, bedclothes and the like and meets the pursuit of people to the comfort and the health care of clothes.

Owner:苏州市利飞纺织品有限公司

Skin-relieving vegetable fiber fabric and preparation method thereof

ActiveCN103966685ABacteriostaticBreathableMonocomponent cellulose artificial filamentArtifical filament manufactureJojoba oilVegetable fibers

The invention relates to a skin-relieving vegetable fiber fabric and a preparation method thereof. The skin-relieving vegetable fiber fabric is prepared from the following raw materials by weight: 100-120 parts of 1-ethyl-3-methyl imidazole acetate, 4-5 parts of nanometer chitin, 1-2 parts of jojoba oil, 8-10 parts of water, 7-10 parts of plastic starch, 2-4 parts of polycaprolactone, 1-2 parts of whiting oil, 1-2 parts of vitamin E, 3-4 parts of lavender, 4-6 parts of rosemary, 10-14 parts of natural silk fiber, 54-58 parts of ramie, 25-27 parts of banana fiber, and 0.4-0.8 part of spinning auxiliaries. The skin-relieving vegetable fiber fabric adopts ramie as a raw material, so that the fabric has the performances of bacteriostasis, ventilation, cool, corrosion protection, mould prevention and sweat absorption; through the adoption of banana fiber and natural silk fiber, the gloss and softness of the fiber fabric are enhanced; through the adoption of vitamin, lavender and rosemary, the fiber fabric can be skin-relieving, the secretion of grease can be balanced, acne can be controlled, and inflammation can be eliminated; moreover, through the adoption of the spinning auxiliaries, spinning melt can be favorable in spinning property, the fiber fabric is fuzziness-free, is dyed uniformly, is excellent in the color and luster, and touches soft.

Owner:ANHUI YICAINI FIBER MATERIALS TECH

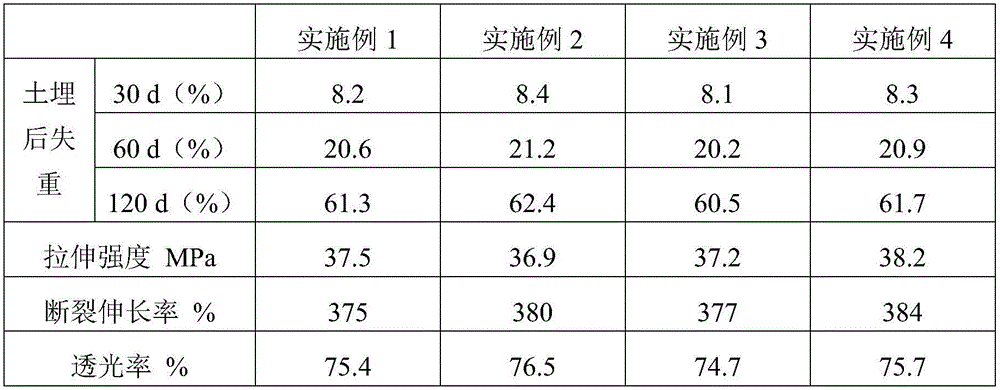

Plastic master batch capable of being fully degraded by environmental organisms, and preparation method thereof

The invention discloses a plastic master batch capable of being fully degraded by environmental organisms, and a preparation method thereof, and belongs to the field of plastics. The plastic master batch capable of being fully degraded by environmental organisms comprises, by weight, 15-25 parts of polybutylene succinate, 10-20 parts of polylactic acid, 5-10 parts of a plasticizer, 40-50 parts ofpotato starch, 16-20 parts of banana fibers, 10-14 parts of wollastonite powder, 8-12 parts of ricinoleate tetramer and 6-10 parts of sodium tripolyphosphate. A filler wollastonite powder is modifiedwith the sodium tripolyphosphate, and then cooperates with the banana fibers, so the mechanical properties of the plastic are enhanced, and the plastic keeps stable performances during use, can be used fully degraded by environmental organisms after being used, and is nontoxic, harmless and environmentally friendly.

Owner:山东天一生物降解塑业有限公司

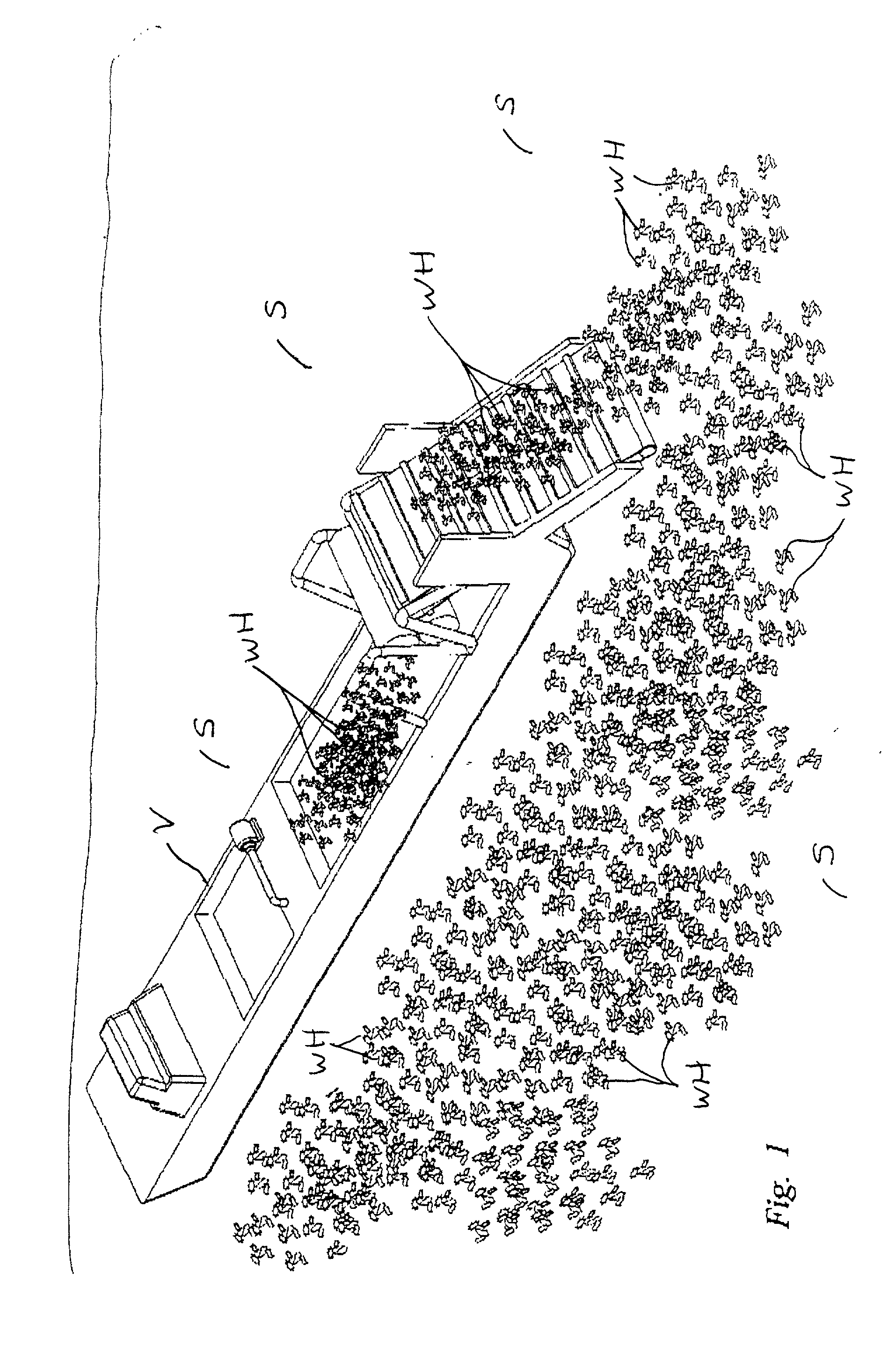

Compressed water-hyacinth fiber board and method of manufacture

InactiveUS20030015283A1Improve the heating effectGood electrical insulatorFibreboardLayered productsHuskWater Hyacinths

A fiber board for use as a construction material includes self adhering compressed fragments of water-hyacinth. The fiber board preferably additionally includes one of glue, sand, cement, sawdust, metal filings, dried rice husk, banana fiber, lime and coconut waste, integrated into the self adhering fragments of water hyacinth. A method of manufacturing a fiber board includes the steps of gathering quantities of water-hyacinth from the surfaces of bodies of water; chopping and pulping the quantities of water-hyacinth into fragments; providing the fragments with moisture; and compressing the moist fragments into a desired fiber board shape.

Owner:ECO BOARD

Method of using steam explosion technology to extract and degum banana fibers

The invention discloses a method of using a steam explosion technology to extract and degum banana fibers. The method comprises the following steps: (1) carrying out steam explosion extraction; (2) performing a pre-acid treatment; (3) cleaning; (4) carrying out enzymatic degumming; (5) carrying out steam explosion degumming; (6) performing primary bleaching; (7) performing secondary bleaching; and (8) carrying out a post treatment. At first a pre-acid treatment is carried out, and then biological enzymes and steam explosion are combined to effectively increase the yield of banana fiber. At the same time, the residual gum content of banana fibers is reduced, and thus the environment pollution is avoided.

Owner:HAIKOU EXPERIMENTAL STATION CHINESE ACAD OF TROPICAL AGRI SCI

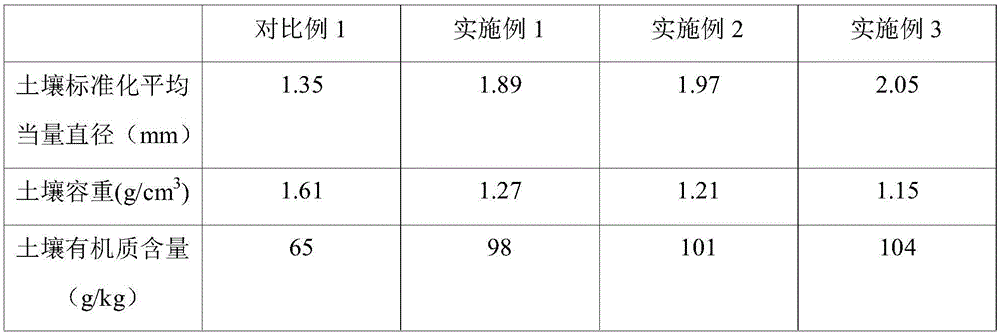

Soil conditioner for preventing soil hardening and preparation method of soil conditioner

InactiveCN106699355AReduce the degradation ratePrevent compactionCalcareous fertilisersBio-organic fraction processingMicrobial agentMonopotassium phosphate

The invention discloses a soil conditioner for preventing soil hardening. The soil conditioner is prepared from the following raw materials: rice husks, wheat hulls, banana fiber, cocoanut fiber, barks, turf, leguminous plant straws, bean cakes, vinasse, coffee residues, rape seed cakes, cottonseed cakes, fish meal, bone meal, medical stone powder, zeolite powder, bentonite, urea, ammonium sulfate, monopotassium phosphate, ferrous sulfate, magnesium sulfate, zinc sulfate, potassium chloride, calcium superphosphate, calcium peroxide, magnesium peroxide, borax, an agricultural water-retaining agent and a microbial agent. The invention further provides a preparation method of the soil conditioner for preventing soil hardening. The soil conditioner disclosed by the invention is low in raw material cost and scientific in component, and can well adjust the soil structure and prevent the soil hardening.

Owner:广西科茂信息咨询有限公司

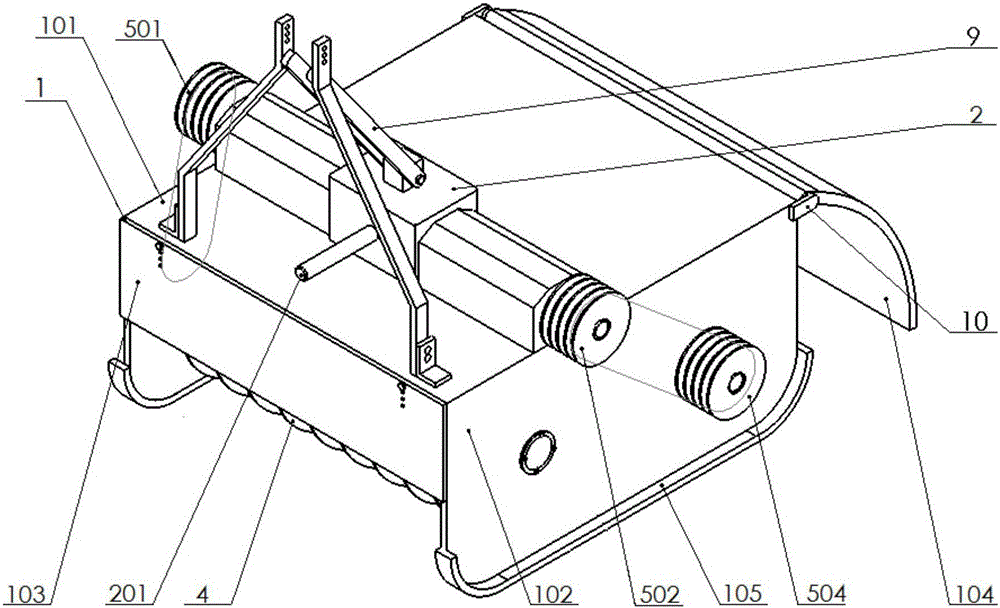

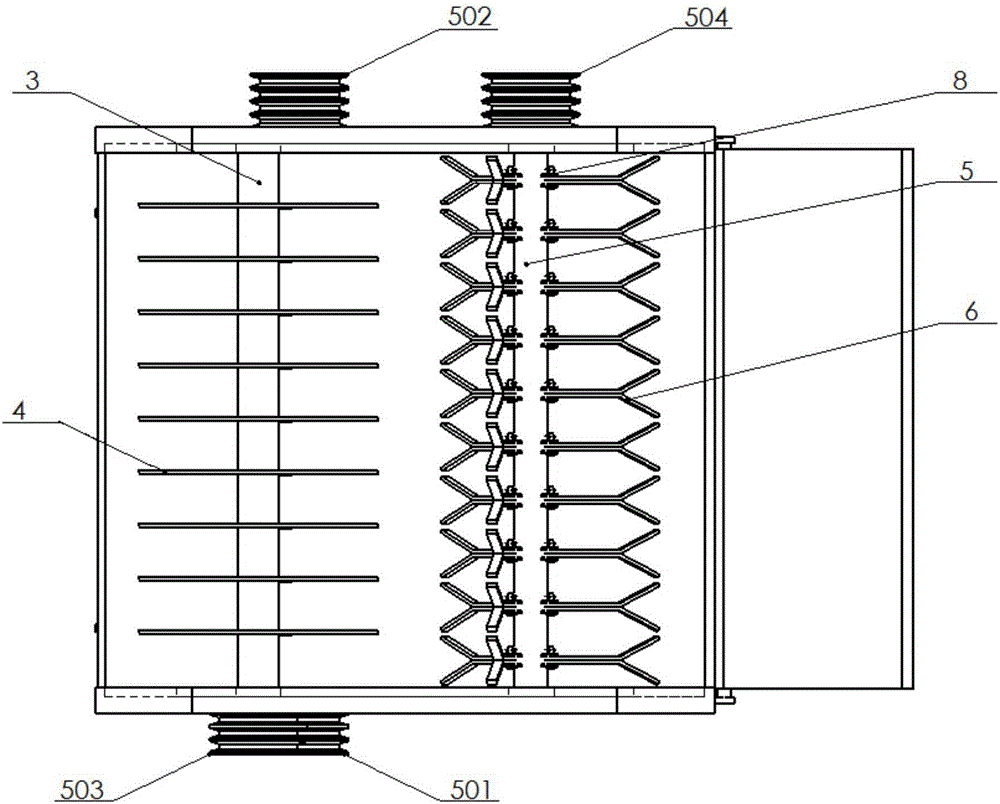

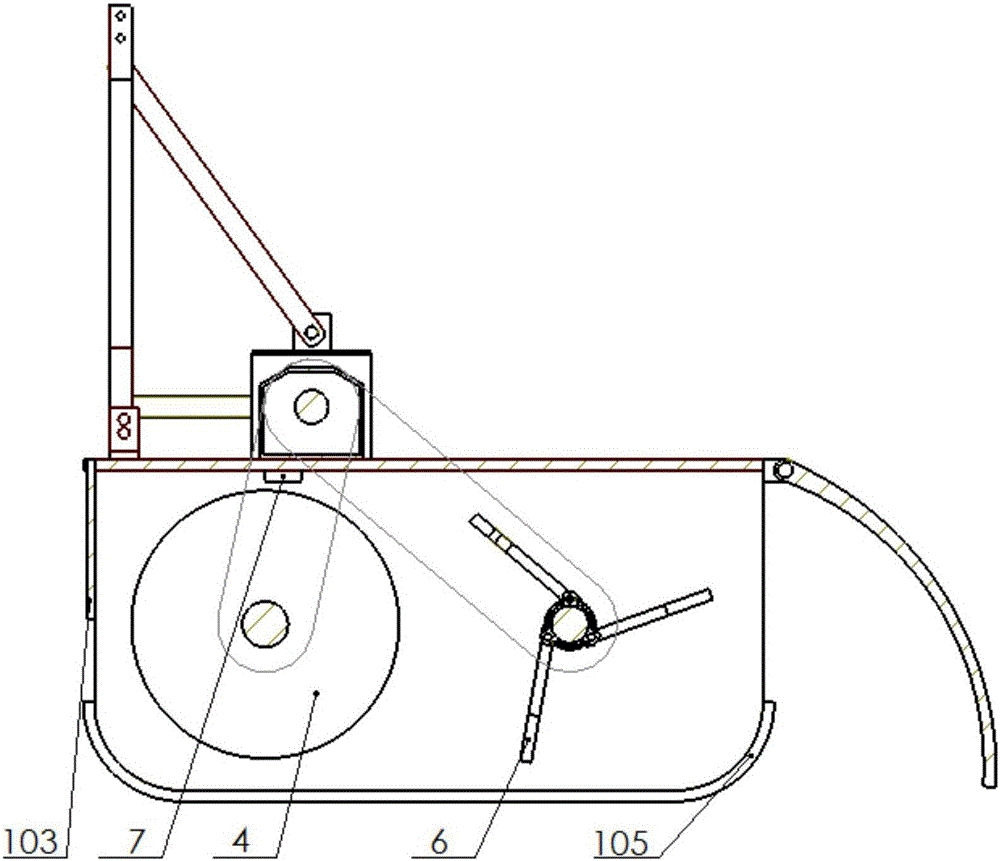

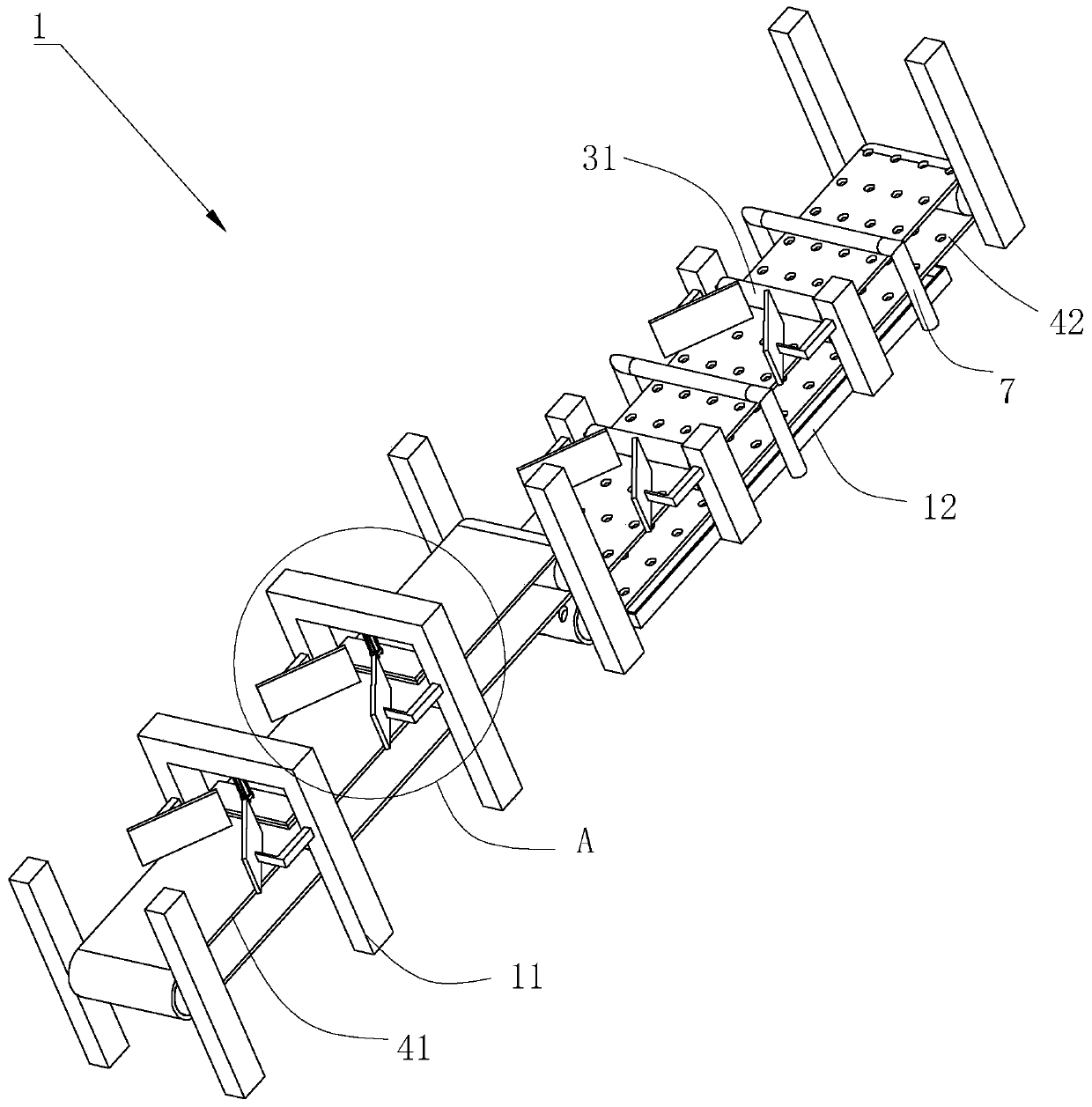

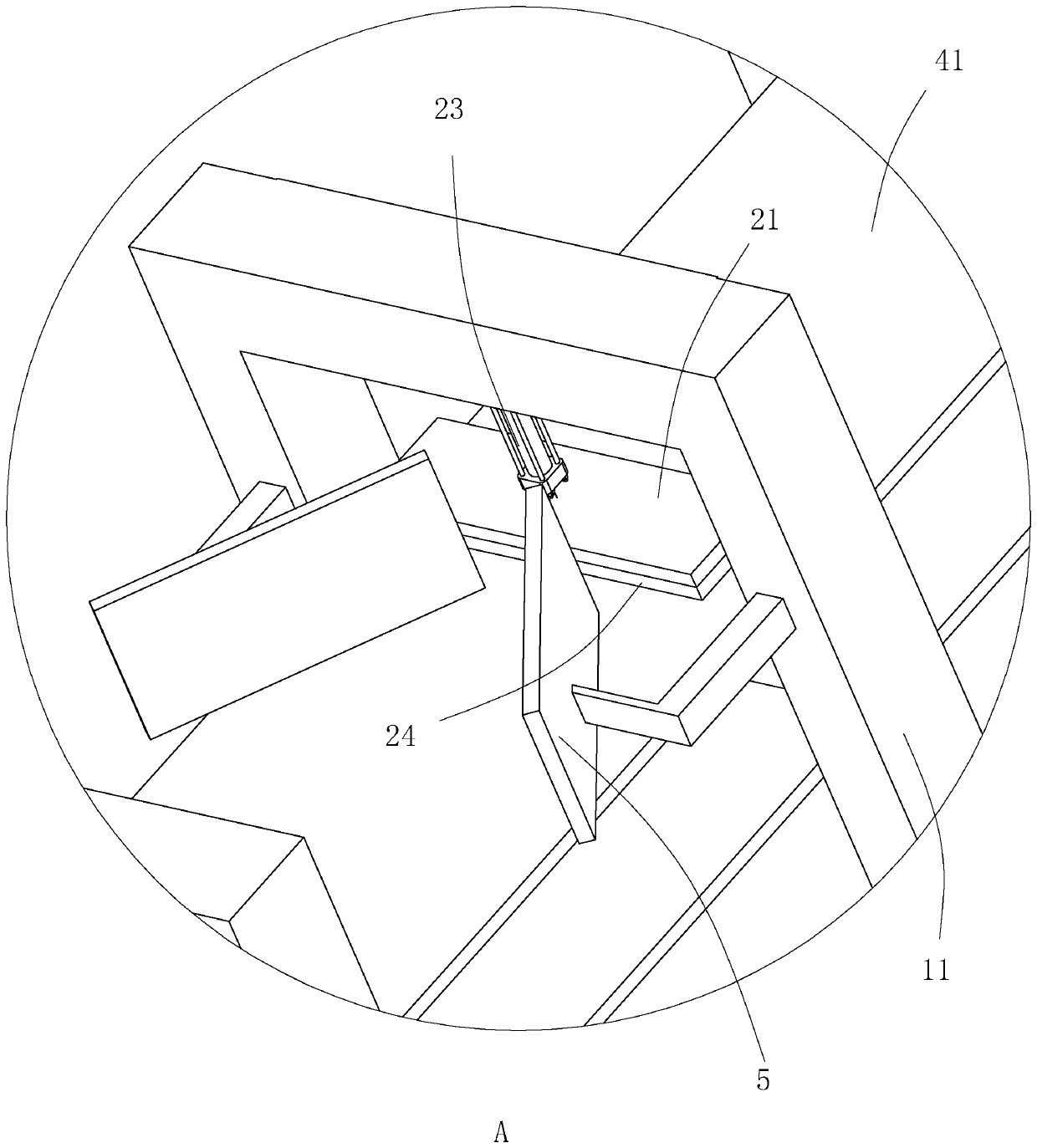

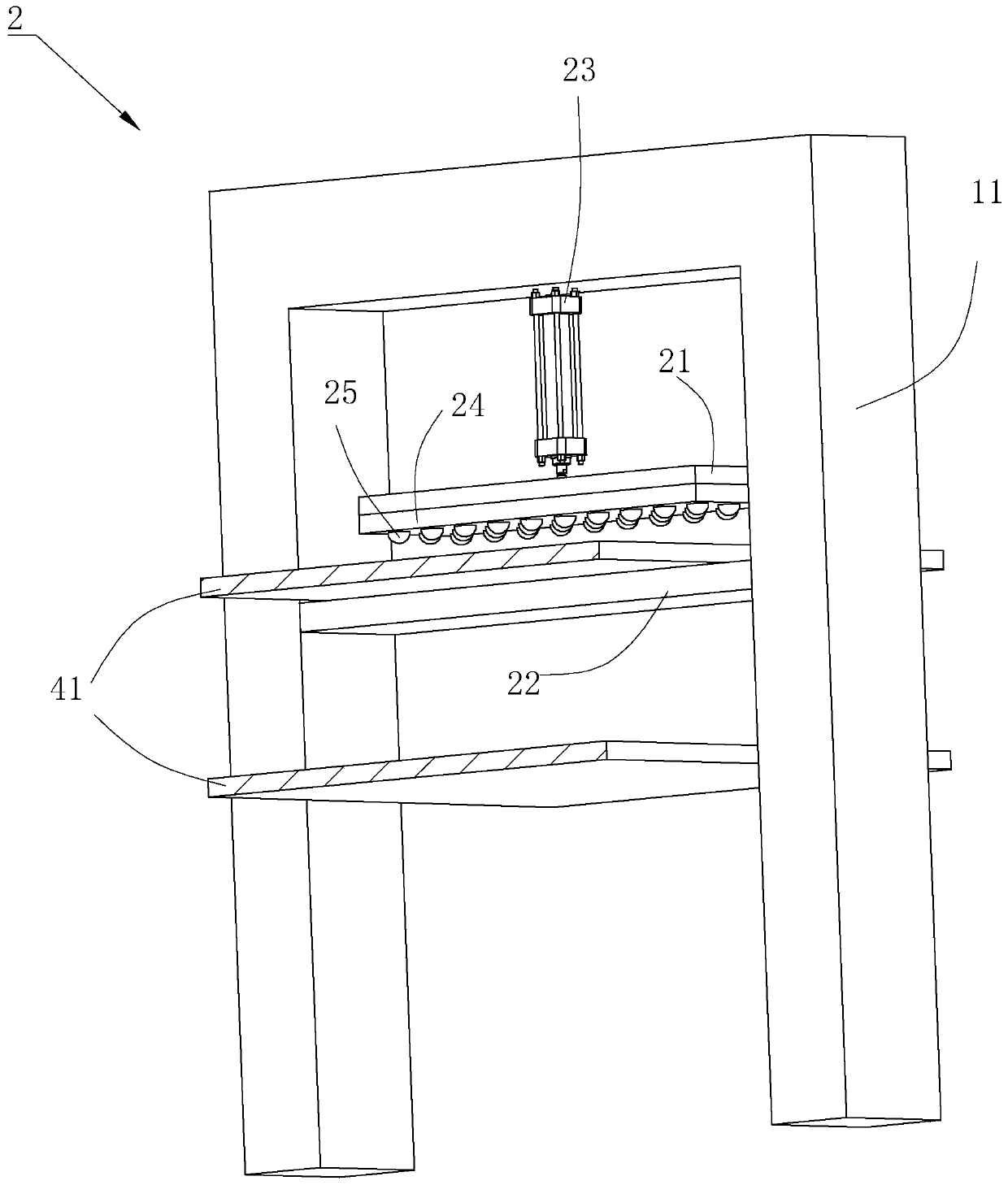

Dual-roller type banana stalk crushing and returning machine

InactiveCN105993372AImprove crushing efficiencySolve the problem of winding knife rollMowersCircular discEngineering

The invention relates to a dual-roller type banana stalk crushing and returning machine. The dual-roller type banana stalk crushing and returning machine comprises a machine frame, a three-point hitch linkage, a transmission device, a stalk shredding device and a stalk crushing device. Left and right ends of front and rear knife shafts are separately connected to left and right side plates through bearings, and the front and rear knife shafts are arranged in a front-and-back parallel manner; and disk coulters are distributed on the front knife shaft, and Y-shaped flail knives are distributed on the rear knife shaft. Further, straight-knife type fixed knives can be arranged just above the front knife shaft. When in work, the disk coulters or further the disk coulters and the straight-knife type fixed knives which are matched with each other are used for firstly chopping banana stalks into minor segments, and then, the Y-shaped flail knives on the rear knife shaft are used for carrying out pick-up crushing on the chopped stalks. The dual-roller type banana stalk crushing and returning machine has the advantages that the problem that knife rollers are wound by banana fibers is effectively solved, and meanwhile, the crushing effect is remarkably improved.

Owner:HAINAN UNIVERSITY

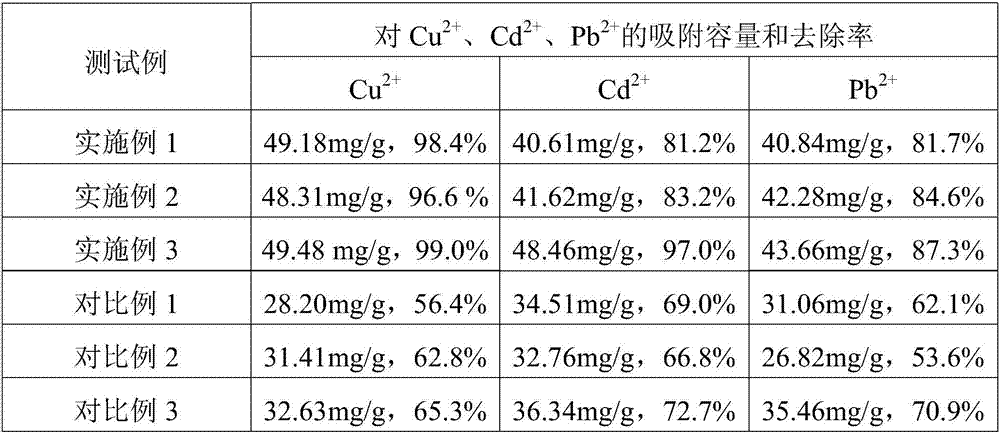

Preparation method and application of banana fiber chitosancomplex hydrogel

ActiveCN106964321AImprove solubilityQuality improvementOther chemical processesWater contaminantsCelluloseALLYL SUCROSE

The invention discloses a preparation method and application of banana fiber chitosancomplex hydrogel. The preparation method comprises the following steps: firstly, after banana fibers are cut, performing acid pickling, secondary soda boiling and washing on the banana fibers, so as to obtainbanana cellulose; then, dissolving the banana cellulose into ionic liquid, so as to obtain banana cellulose solution; meanwhile, dissolving chitosan powder into polyacrylic acid solution, so as to obtain chitosan solution; adding thechitosan solution into the banana cellulose solution for mixing and dissolving and accelerating effective crosslinking with a crosslinking agent in temperature rise, so as to obtain banana fiber chitosancomplex hydrogel solution; finally, washing, so as to obtain the banana fiber chitosancomplex hydrogel. The banana fiber chitosancomplex hydrogel prepared by the invention is strong in adsorption capacity for heavy metal ions, high in adsorption speed and good in biological compatibility and can be applied to treatment of heavy metal pollution in the environment, so that the environment improvement efficiency is improved favorably, and the banana fibers are fully utilized, therefore, a win-win effect is realized.

Owner:HAIKOU EXPERIMENTAL STATION CHINESE ACAD OF TROPICAL AGRI SCI

Disposable and degradable bowl and making method thereof

The invention discloses a disposable and degradable bowl and a making method thereof. The disposable and degradable bowl comprises a degradable bowl body and an inner film, and the degradable bowl body comprises, by weight, 30-40 parts of cassava starch, 20-25 parts of ramie fibers, 17-25 parts of banana fibers, 15-22 parts of melon seed shells, 30-40 parts of edible gum, 10-20 parts of polyvinyl alcohol, 12-15 parts of melamine formaldehyde resin powder, 2-5 parts of a cross-linking agent, 0.1-0.2 parts of aloe, 0.2-0.4 parts of pepper, 0.2-0.3 parts of ginkgo, 0.1-0.2 parts of onion and 0.3-0.4 parts of Folium Phyllostachys; and the inner film comprises, by weight, 30-40 parts of UV light-curable resin, 0.8-1.2 parts of rice straws and 0.5-1 parts of rice husks. The disposable and degradable bowl has the advantages of high strength, strong bonding force, easily available raw materials, no toxicity, no pollution, low cost, easiness in manufacturing, and easiness in degradation after being used.

Owner:GUANGXI TEACHERS EDUCATION UNIV

Production method of seamless knitted underwear with healthcare function

ActiveCN104313776AGood moisture wicking functionIncrease health functionFabric breaking/softeningWeft knittingMoisture absorptionBanana fiber

The invention relates to a production method of deep sea fish oil fiber, aloe fiber, pineapple fiber and banana fiber composite seamless knitted underwear with a healthcare function. The production method comprises a detergent washing process of deep sea fish oil fiber and aloe fiber blended yarns, a dyeing process of pineapple fiber and banana fiber blended yarns, a composite weaving process, a garment sewing process, a water washing process, a dewatering process, a moisture absorption, sweat releasing and finishing process, a soft finishing process, a dewatering process, a drying process and a steaming, burning and sizing process in sequence. The production method has a simple production process and is suitable for industrial production, and the seamless knitted underwear prepared through the production method has remarkable characteristics in the aspects of functionality, comfortableness, aesthetics and environmental protection property, and functionality, such as healthcare, and wearing comfortableness of knitted fabric are well embodied.

Owner:ZHEJIANG BONNY FASHION HLDG GRP CO LTD

Environment-friendly and durable sisal bag and preparation method thereof

InactiveCN107383432AHigh physical and mechanical strengthStrong water resistanceEnvironmental resistanceCarbon fibers

The invention discloses an environment-friendly and durable sisal bag and a preparation method thereof. The environment-friendly and durable sisal bag comprises raw materials in parts by weight as follows: sisal fibers, shengma fibers, ramie fibers, bamboo fibers, carbon fibers, banana fibers, konjac starch, polyvinyl alcohol, polyvinyl chloride, aromatic particles, negative ion mineral particles, thermoplastic polyurethane, titanium dioxide, laccase, agar, a plasticizer, a surfactant, a plant extract solution and an antibacterial agent. The natural degradable fibers including the sisal fibers, the shengma fibers, the ramie fibers, the bamboo fibers, the carbon fibers and the banana fibers are selected as the main raw materials, the plastic bag can be degraded rapidly in a natural state by means of combined use of titanium dioxide and the laccase, and by means of cooperation with other additives such as the plasticizer, the surfactant and the like, the environment-friendly and durable sisal bag is easy to degrade and has higher environmental resistance, water resistance, durability and antibacterial property.

Owner:GUANGXI TEACHERS EDUCATION UNIV

Novel degradable plastic bag and preparation method thereof

InactiveCN106543485AImprove performanceAlleviate the problem of high water absorptionCross-linkPolyvinyl alcohol

The invention discloses a novel degradable plastic bag and a preparation method thereof. The novel degradable plastic bag is prepared from the following raw materials in parts by weight: 60-70 parts of cassava starch, 30-40 parts of polyvinyl alcohol, 15-20 parts of sisal hemp fibers, 10-15 parts of ramie fibers, 7-15 parts of banana fibers, 30-40 parts of a clouding agent, 0.2-0.5 part of a cross-linking agent, 0.1-0.2 part of cactuses, 0.2-0.4 part of rosemary, 0.2-0.3 part of gingkoes, 0.1-0.2 part of cardamoms and 0.3-0.4 part of bamboo leaves. According to the novel degradable plastic bag, dried grafting fibers and mixed extract are prepared respectively, and than are highly mixed with the cassava starch, the clouding agent and the cross-linking agent and then internally mixed and molded; and different plant fibers and different properties of the mixed extract are compressively utilized, so that the preparation method has the beneficial effects that the mechanical properties and environment resistance of the degradable plastic bag are effectively improved.

Owner:GUANGXI TEACHERS EDUCATION UNIV

Novel breathable fabric

InactiveCN103726178AGood moisture absorption and air permeabilityStable structureWoven fabricsYarnDeodorantViscose

The invention discloses novel breathable fabric comprising bamboo fibers, linen fibers, banana fibers and viscose fibers. The novel breathable fabric is formed by interweaving warps and wefts, wherein the warps are formed by blending the bamboo fibers and the banana fibers; the wefts are formed by blending the linen fibers and the viscose fibers; the novel breathable fabric comprises, by weight, 42-51% of the warps and 49-58% of the wefts. By means of the mode, as the novel breathable fabric is formed by blending the multiple high-quality fibers, the novel breathable fabric has the excellent moisture absorption and breathable performance, is firm in structure, can be made into various summer clothes to be worn comfortably, and is antibacterial, deodorant and resistant to ultraviolet irradiation.

Owner:SUZHOU BAIBI TEXTILE TECH CO LTD

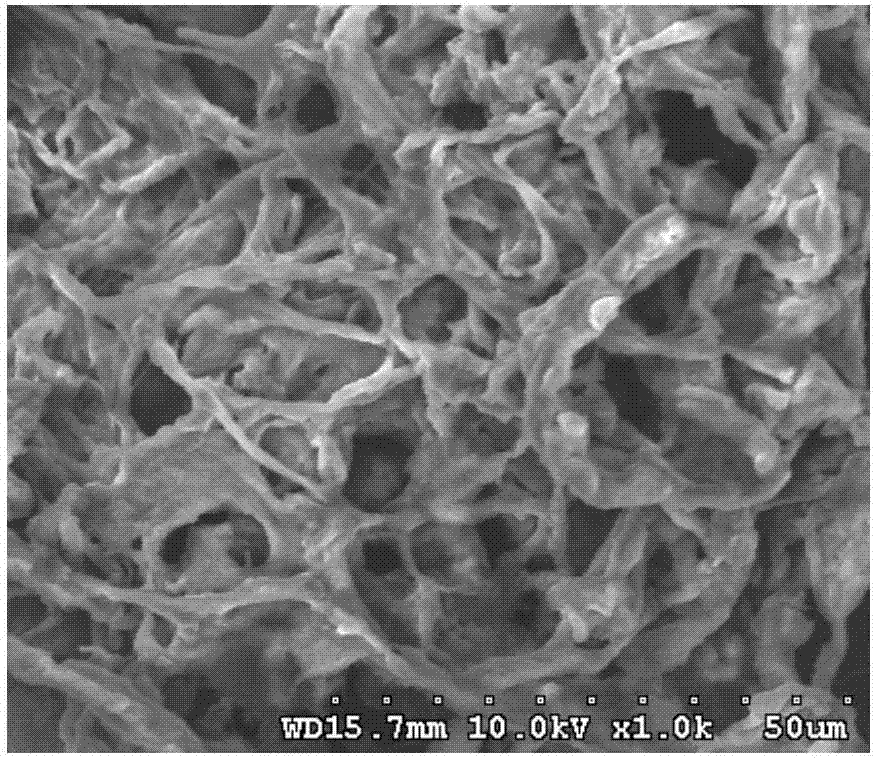

Banana fiber and banana peel fiber extraction process and device

ActiveCN110029399AGood browning reactionEasy to separateVegetable fibres from other vegetable matterVegetable materialSocial effectsNonwoven fabric

The invention relates to a banana fiber and a banana peel fiber extraction process and device. By extracting the banana peel fiber to serve as a raw material of fibers, banana peels which are a cheapfiber source can be utilized, and the social effect of environmental protection is achieved; moreover, the banana peels are rich in magnesium, phosphorus, zinc, amino acids and other various nutrientsand minerals and can have a moisturizing and anti-oxidization effect on the skin of the human body after being used as textile clothing, masks and the like. Compared with existing mask base cloths made from plant fibers such as cotton and linen and non-woven fabrics or protein fibers such as silk, the banana peel fiber has a soft and skin-fitting effect, the comfort of a user during mask application can be improved, the skin fitting effect is better, and the adsorption of mask essence by the skin can be improved.

Owner:上海棉芙生物科技有限公司

Light antibacterial sound absorbing cotton and preparing method

InactiveCN105133320AReasonable structureGood sound absorptionFibre typesNon-woven fabricsResin-Based CompositeDimethylammonium chloride

The invention discloses a light antibacterial sound absorbing cotton, prepared from the following raw materials in parts by weight: 40-60 parts of dacron fiber, 10-15 parts of chitosan fiber, 10-15 parts of banana fiber, 10-15 parts of ES fiber, 0.3-0.5 part of didecyl dimethyl ammonium chloride, 2-4 parts of shell powder, 1-2 parts of silane coupling agent KH-550, 0.1-0.2 part of borneol, 2-4 parts of olive oil, and 10-15 parts composite resin. The sound absorbing cotton has better full frequency sound absorbing capability, obviously improved acoustic performance, has characteristics of light weight, ventilation softness, high comfort level and good antibacterial performance, and is good in use performance, wide in suitable range and high in practicability.

Owner:WUHU HUANRUI AUTO INTERIOR DECORATION

Multifunctional banana fiber fabric

InactiveCN103526568AStable structureStable wear resistanceTextiles and paperCotton fibreMoisture absorption

The invention discloses multifunctional banana fiber fabric. The multifunctional banana fiber fabric is made of banana fibers, jute fibers, cotton fibers and viscose, wherein the banana fibers account for, by weight, 55%-58% of the multifunctional banana fiber fabric, the jute fibers account for, by weight, 8%-10% of the multifunctional banana fiber fabric, the cotton fibers account for, by weight, 22%-25% of the multifunctional banana fiber fabric, and the viscose accounts for, by weight, 7%-10% of the multifunctional banana fiber fabric. By means of the mode, the multifunctional banana fiber fabric has the advantages of being firm in structure and resistant to abrasion, and is good in moisture absorption and air permeability, antibacterial, mould proof, environmentally friendly in material, free of stimulation to the skin and suitable for being manufactured into various clothes or ornaments or articles of daily use.

Owner:WUJIANG SENHAO TEXTILE

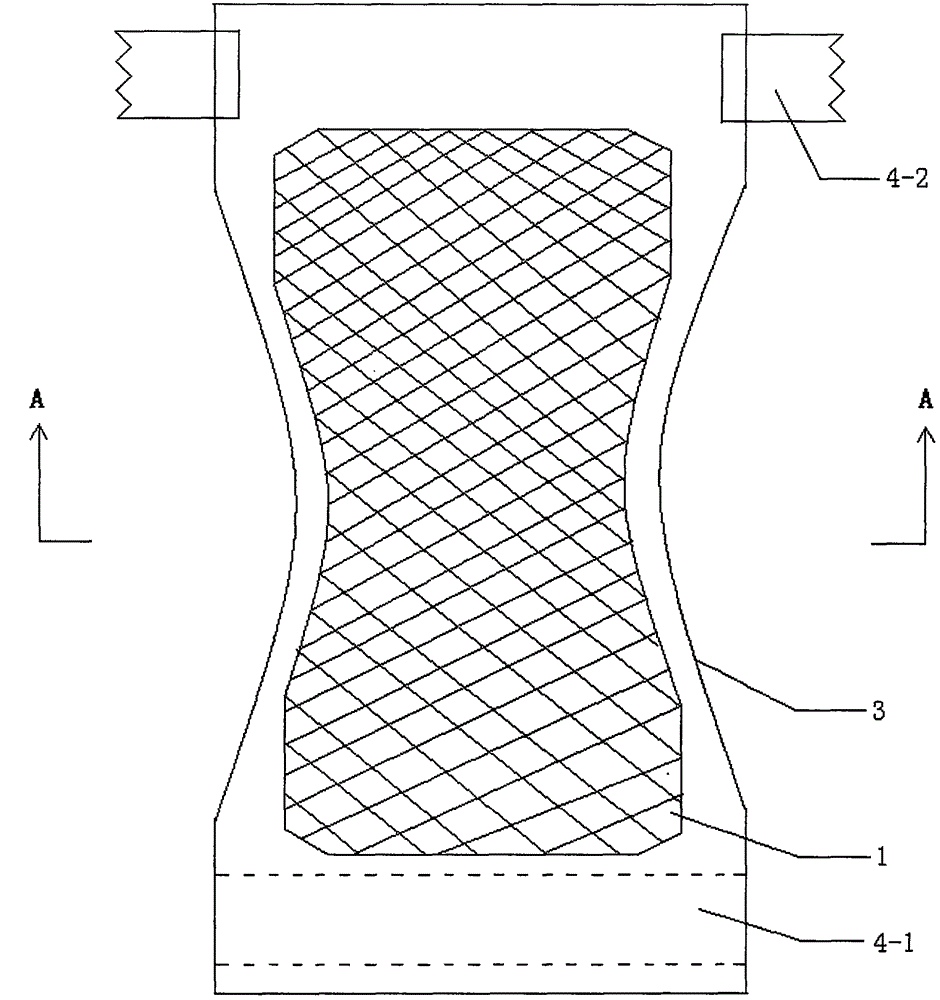

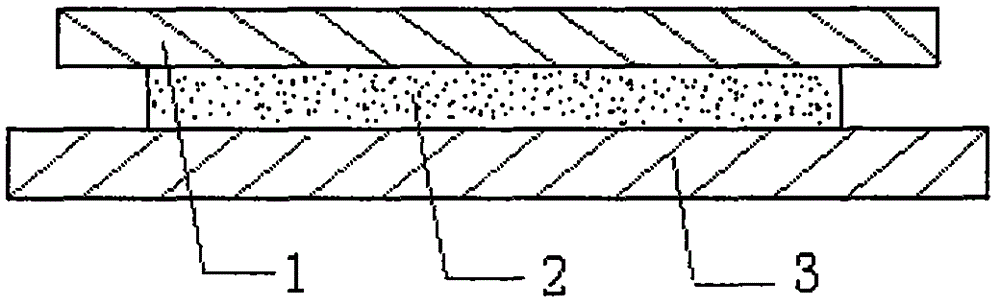

Paper diaper made from banana fiber mixed material

InactiveCN104983517AGood skin affinityHas natural antibacterial health functionAbsorbent padsBandagesMixed materialsPulp and paper industry

The invention relates to a paper diaper made from a banana fiber mixed material. The paper diaper made from the banana fiber mixed material comprises a paper diaper body and a diaper waist for connecting a front portion and a rear portion, wherein the paper diaper body comprises a first permeable layer, a middle absorption layer and a bottom layer leakage-proof layer. The first permeable layer is made from the banana fiber mixed material. The middle absorption layer contains microencapsulated active ingredients and is sealed in the banana fiber mixed material. The bottom layer leakage-proof layer is a non-water-permeable bottom film. The diaper waist for connecting the front portion and the rear portion comprises a front end and a rear end, a hook-and-loop fastener is arranged on two sides of the rear end respectively, and the hook-and-loop fasteners are respectively connected with an adhesion band at the front end, are zigzag and are convenient to tear. The paper diaper is dry and comfortable, is skin-friendly, has natural antibacterial and health-care functions and can effectively prevent diaper rash.

Owner:YANCHENG INST OF IND TECH

Tire Rubber Composition

InactiveUS20110207857A1Small coefficient of frictionIncreased frictional forceEngineeringWear resistance

An object thereof is to provide a tire rubber composition about which the ice braking-performance is largely improved while the tire-abrasion resistance is kept. In order to achieve the object, a tire rubber composition comprises a diene-based rubber component, and banana fiber in an amount of 0.1 to 20 parts by weight for 100 parts by weight of the diene-based rubber component.

Owner:TOYO TIRE & RUBBER CO LTD

Production method of warm-keeping fabric

InactiveCN108823732AElasticGood hygroscopicityConjugated cellulose/protein artificial filamentsArtificial filament heat treatmentTriethoxysilaneStearate

The invention discloses a production method of a warm-keeping fabric. The production method comprises the following steps that 1, modified wool fiber, cotton fiber, banana fiber, gamma-aminopropyl triethoxysilane are mixed, then the mixture is fed into a twin-screw extruder, polyurethane resin, a warm-keeping enhancer, barium stearate and deionized water are sequentially added, and repeated extrusion is performed, wherein the stirring speed is 85-95 r / min, and the stirring time is 25-35 minutes. By adopting the production method of the warm-keeping fabric, wool fiber has the advantages of having elasticity, strong hygroscopicity, good warm-keeping property and the like, the intermolecular force is increased through surface modifying treatment of the fiber, then the fiber is better bonded with other raw materials, the cotton fiber has high strength, the banana fiber has good antibacterial performance, the added polyurethane resin further improves the warm keeping property of the fabric,and the raw materials are appropriately proportioned.

Owner:DONGGUAN POLYTECHNIC

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com