Patents

Literature

65results about How to "Stable wear resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

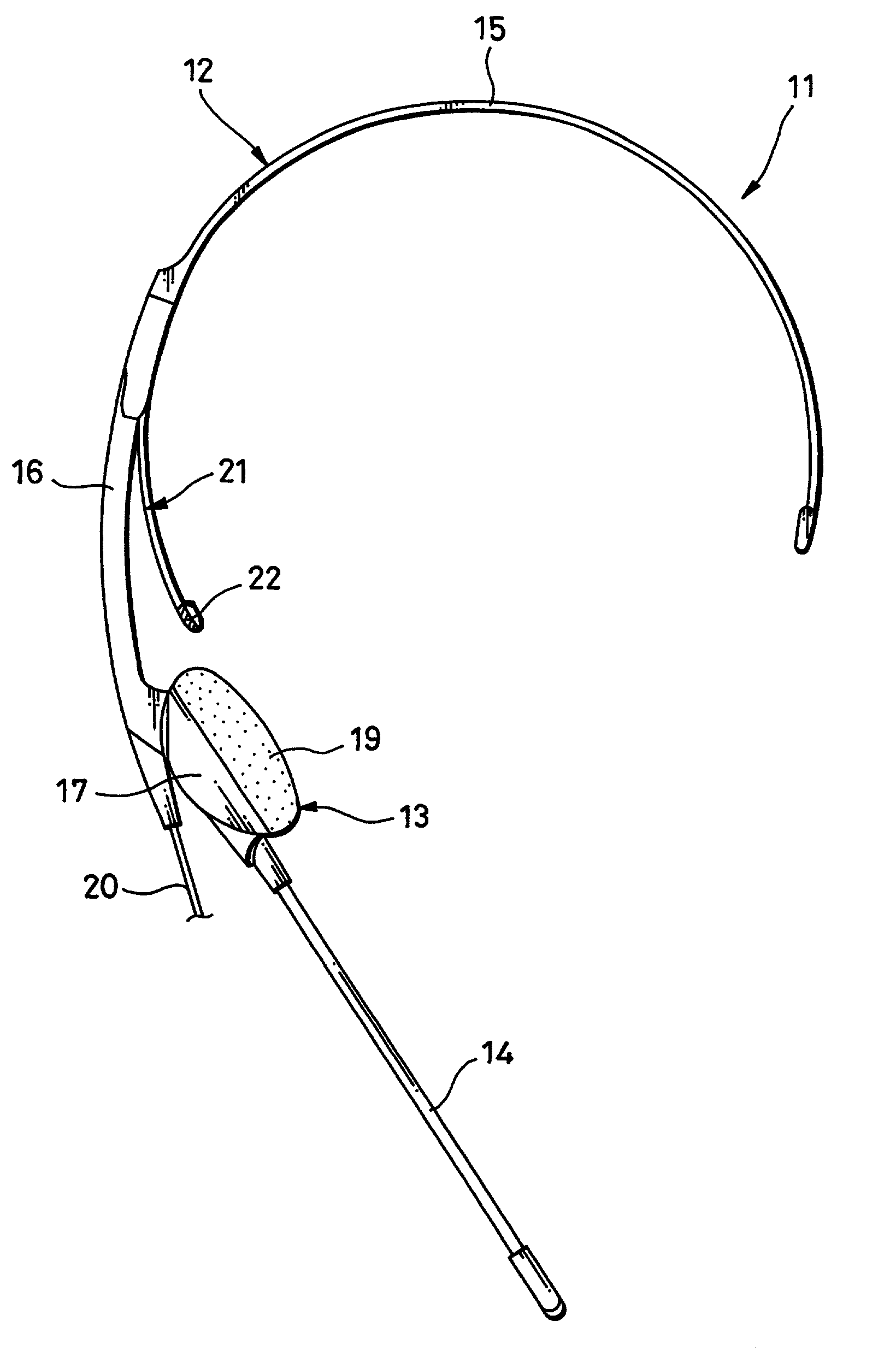

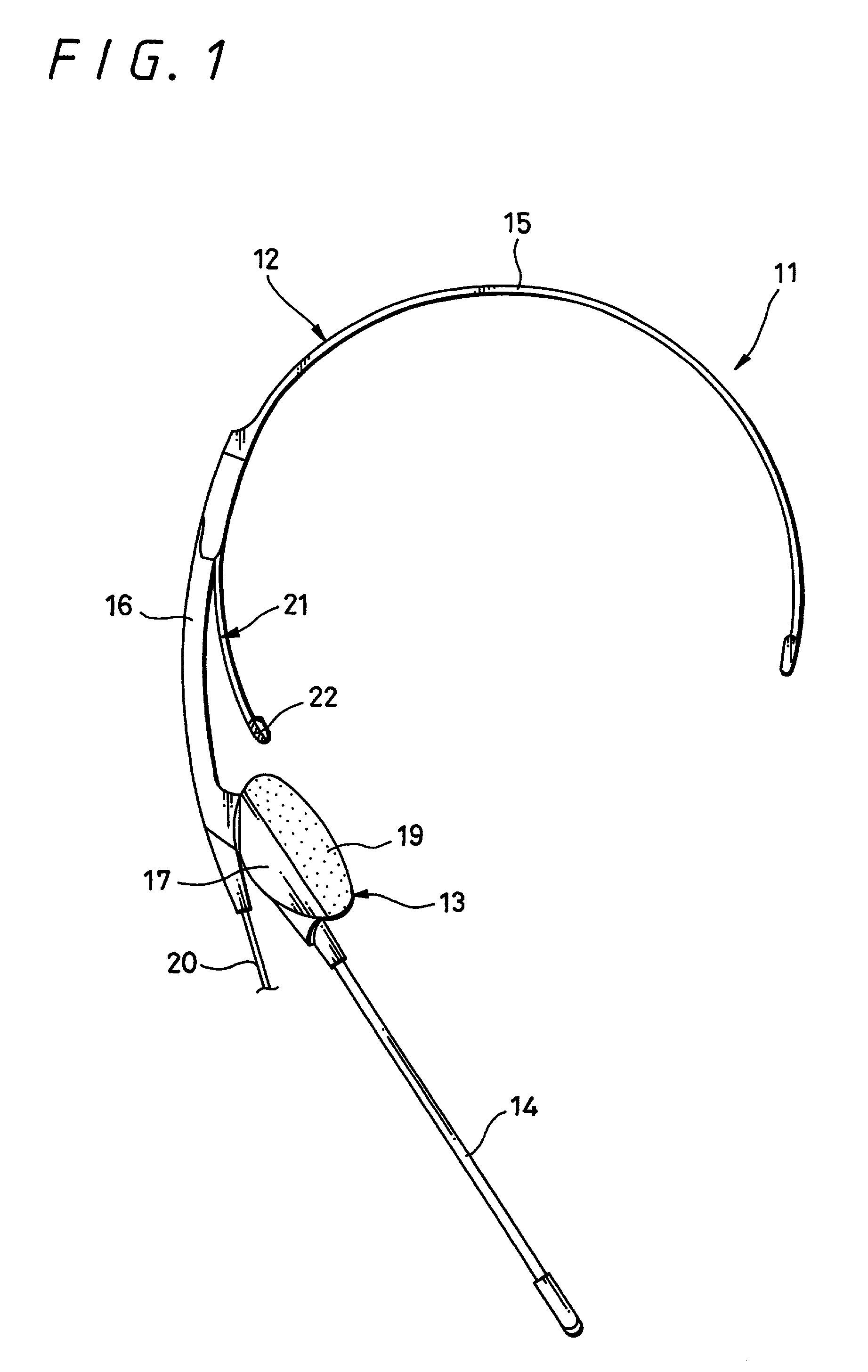

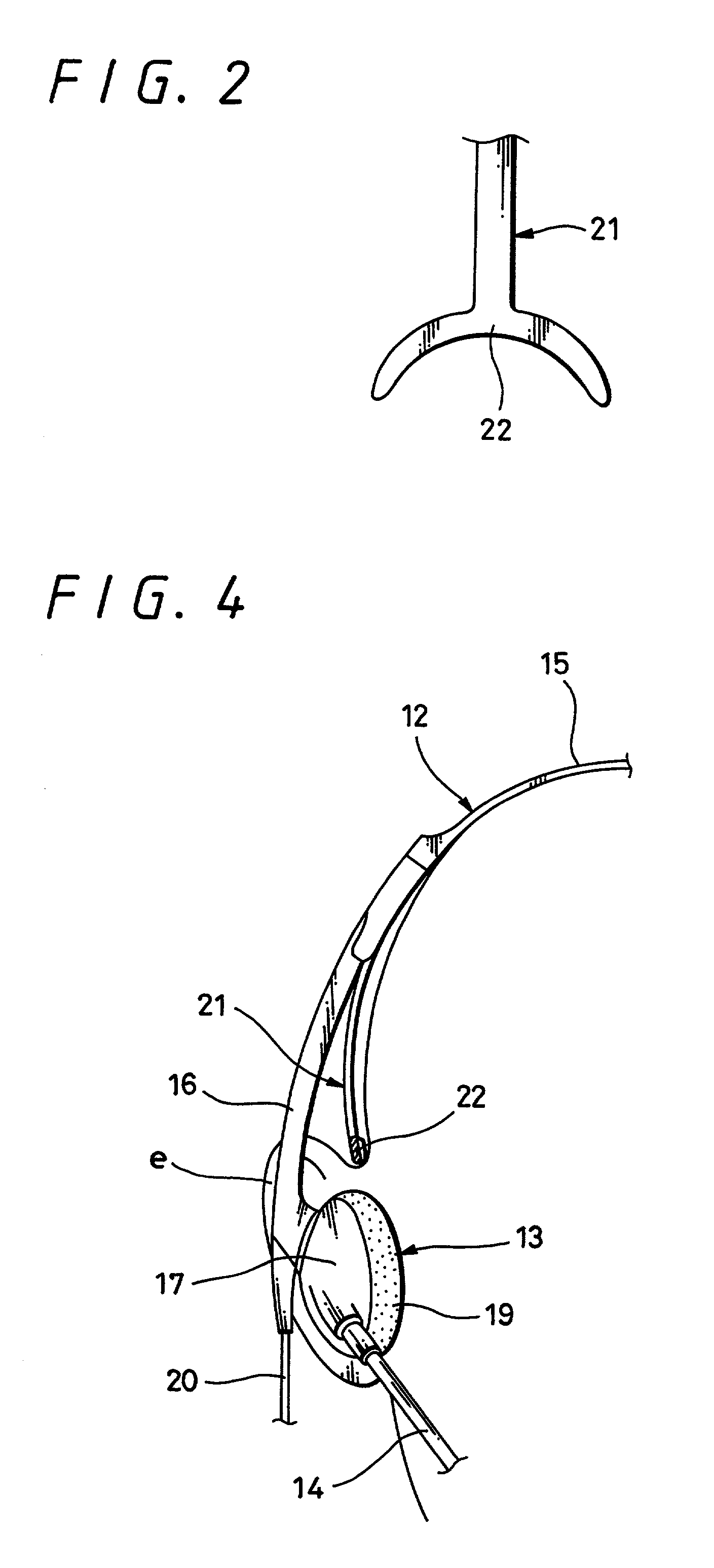

Headphone device

InactiveUS6970572B2Prevent slippingStable wear resistanceSupra/circum aural earpiecesTelephone set constructionsSound qualityEngineering

Owner:SONY CORP

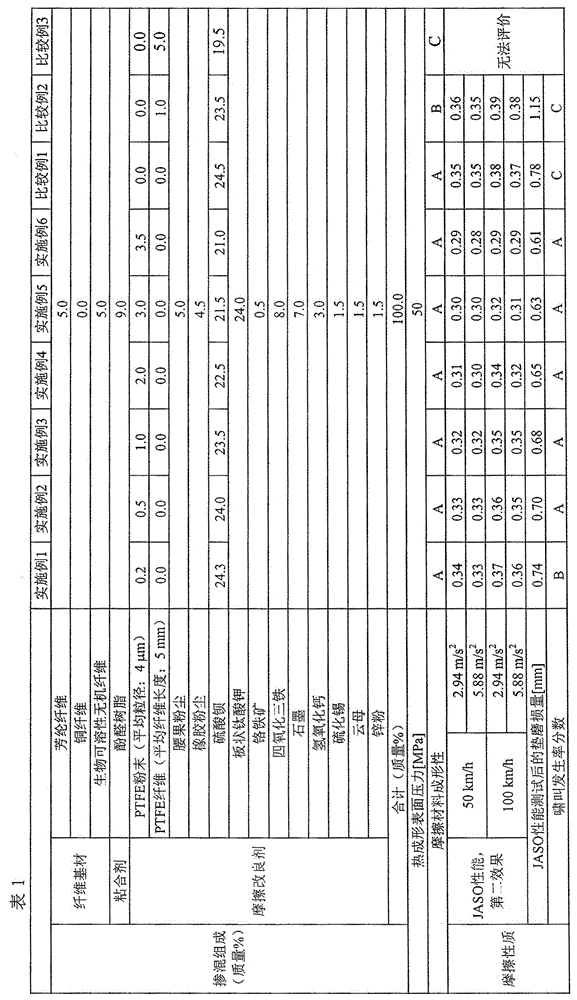

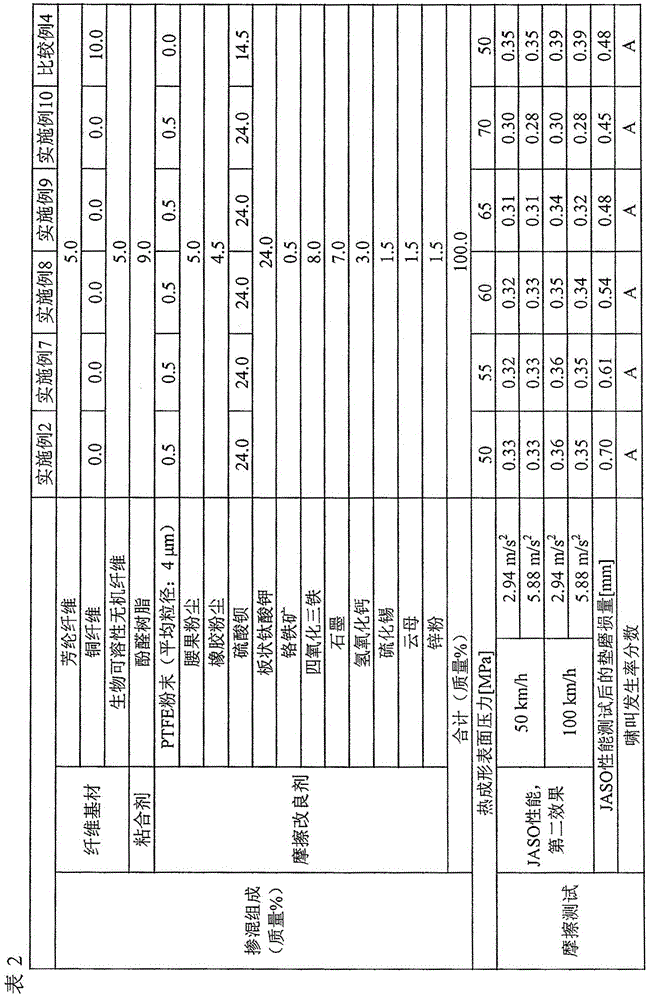

Friction material composition and friction material

InactiveCN105722942AReduce loadStable coefficient of frictionOther chemical processesFriction liningFiberCopper

The present invention provides a friction material having reduced noise after being left in cold conditions when used as a disc brake pad, brake lining, or the like, and copper components are essentially not included in the friction material. The present invention is: a friction material composition including a fiber base material, a binding material, and a friction adjusting material, the copper content of the friction material composition being no more than 0.5% by mass, and the friction material composition containing fluorine-based polymer particles; and a friction material obtained by molding the friction material composition.

Owner:AKEBONO BRAKE IND CO LTD

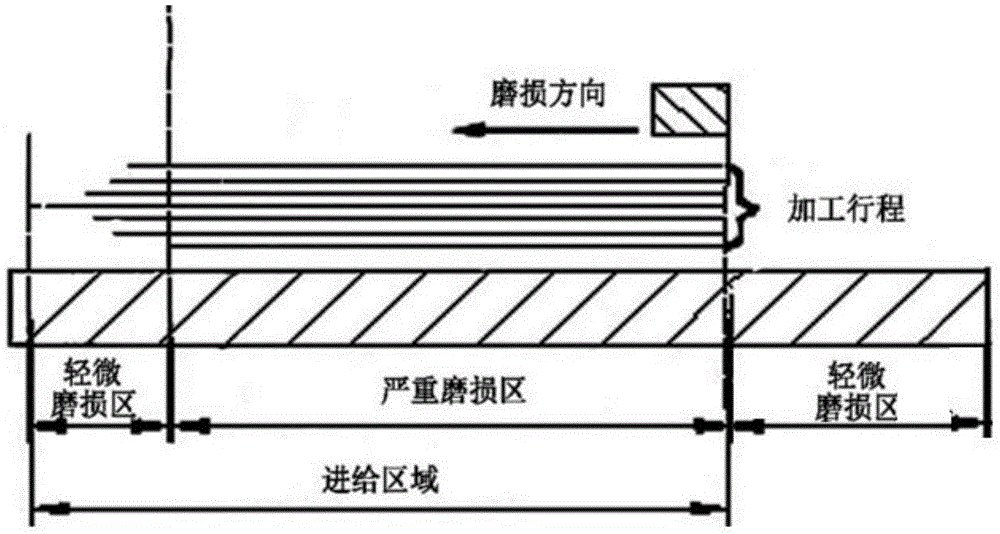

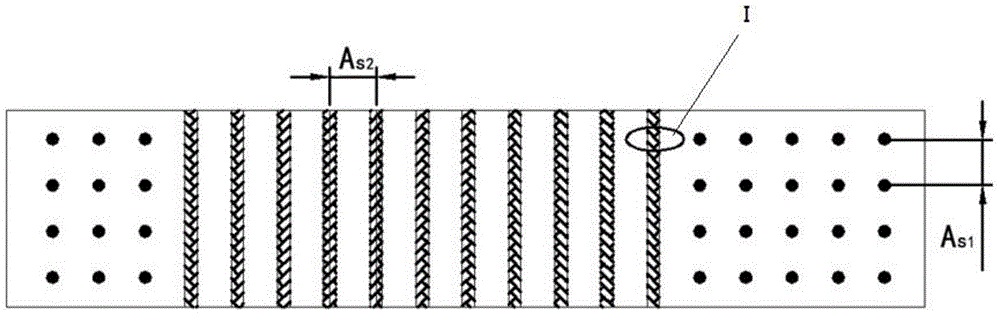

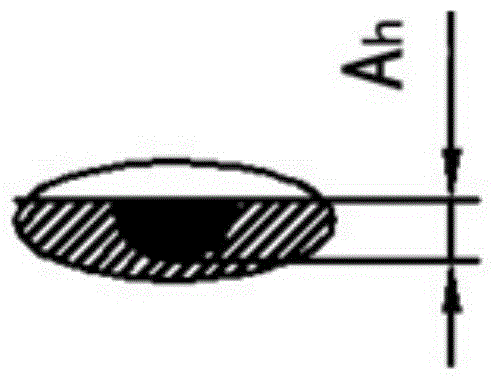

Laser bionic coupling guide rail and regeneration method thereof

ActiveCN105081577ASolve the difficult regeneration problemUniform hardnessLarge fixed membersLaser beam welding apparatusCouplingEngineering

The invention relates to a laser bionic coupling guide rail and a regeneration method thereof. Bionic surfaces different in abrasion resistance are machined in a slight abrasion area and a serious abrasion area on the working face of the guide rail. A point and strip bionic surface combining form or a strip and net bionic surface combining form or a point and net bionic surface combining form is adopted according to the hardness gradient or the stress gradient of the serious abrasion area and the slight abrasion area of the working face of the guide rail. A bionic surface with the overall abrasion resistance being consistent for a long term is formed through the combination of the bionic surfaces different in abrasion resistance, the mechanical performance of the surface with the uneven mechanical performance distribution can be recovered to be evenly distributed, the phenomenon of serious local abrasion caused by large local stress is effectively avoided, and the bionic coupling guide rail is more suitable for the angle of the actual work of the bionic coupling guide rail. A multi-bionic coupling surface combined uneven regeneration repairing manner is directly implemented on the local abrasion surface of a cast iron guide rail on which high-frequency quenching is carried out, and the problem that due to the uneven abrasion of the surface of the scraped guide rail, the scraped guide rail is hard to regenerate is basically solved.

Owner:JILIN UNIV

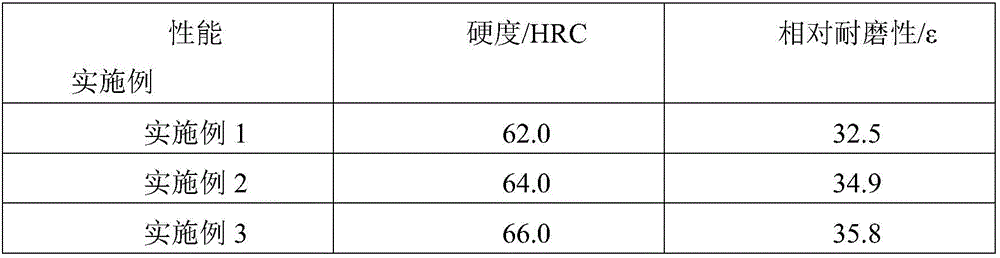

Roll surface material of high-pressure roller mill for crushing ore and preparation method of roll surface

The invention belongs to the field of mining machinery and in particular relates to a roll surface material of a high-pressure roller mill for crushing ore and a preparation method of the roll surface. The roll surface material comprises the following chemical components in percentage by weight: 1.0%-3.0% of C, 2.0%-10.0% of V, 2.0%-10.0% of Mo, 2.0%-7.0% of Cr, 0.3%-6.0% of Nb, 0.1%-3.0% of Ti, 0.7%-1.0% of Si, 0.5%-1.0% of Mn, 0.1%-0.7% of Ni, 0-0.02% of P, 0-0.01% of S and the balance of Fe and inevitable impurities. The preparation method comprises the following steps: firstly smelting molten steel, and molding a high-alloy steel roll surface by centrifugal casting in one step; cooling a casting to room temperature; then carrying out a heating treatment process on the casting; adjusting the rigidity of the roll surface to about 50 HRC; processing blind holes in the roll surface in the manner of staggered distribution; carrying out heat treatment under protection atmosphere; then embedding sintered carboloy studs into the blind holes to obtain a highly wear-resistant composite roll surface. The roll surface material of the high-pressure roller mill is uniform in texture, and a final roll surface has stable strength and wear resistance and longer service life.

Owner:NORTHEASTERN UNIV +1

High-temperature resistant and abrasion-resistant white cast iron piece and production method

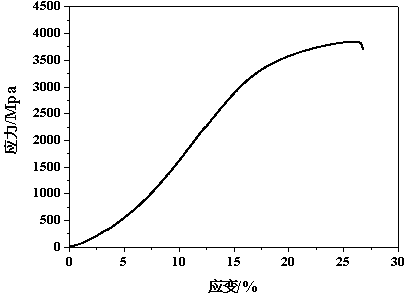

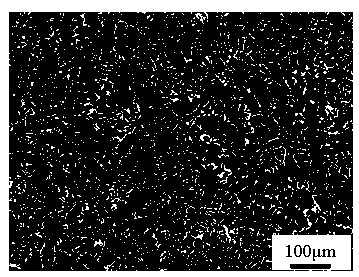

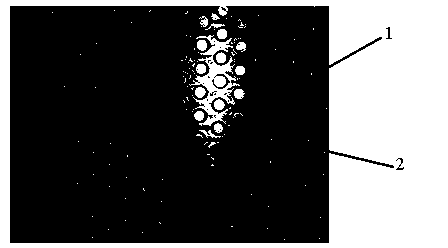

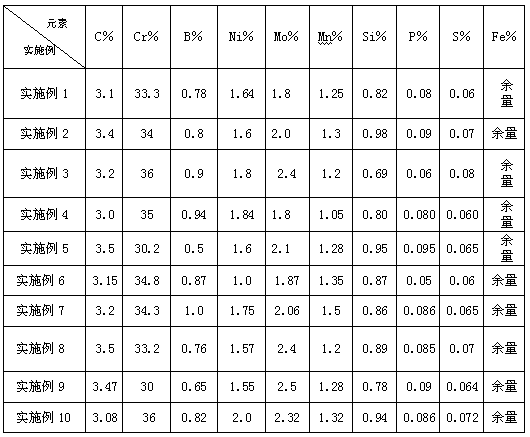

The invention discloses a high-temperature resistant and abrasion-resistant white cast iron piece and a production method to solve the problem in hardness of white cast iron. The high-temperature resistant abrasion-resistant white cast iron piece is characterized in that the white iron casting comprises the following chemical compositions by mass percent: 3.0 to 3.5 percent of C, 30 to 36 percent of Cr, 1.8 to 2.5 percent of Mo, smaller than or equal to 1 percent of Si, 1.0 to 2.0 percent of Ni, 1.05 to 1.5 percent of Mn, 0.5 to 1.0 percent of B, smaller than or equal to 0.10 percent of P, smaller than or equal to 0.08 percent of S, and Fe in balancing amount; and the chromium carbon ratio of the white cast iron is 8.5 to 12. The method comprises the steps of smelting, casting, thermal insulation and cooling. The white cast iron piece has the advantages that casting-state thermal insulation slow cooling hardness HRC is larger than or equal to 61, the hardness HRC after quench tempering is larger than or equal to 66, the hardness HRC can still keep larger than or equal to 61 at 700 DEG C, the corrosion resistance of the white cast iron piece is superior to that of the existing white cast iron piece, and the white cast iron piece is particularly suitable to serve as a wear-resistant part operating under high-temperature condition.

Owner:BAODING FENGFAN PRECISION CASTING

High-ratio methanol fuel composite additive for vehicles

InactiveCN103805300ASolve and improve lubricityAddressing and Improving Reduced MomentumLiquid carbonaceous fuelsFuel additivesMethanol fuelBenzotriazole

The invention discloses a high-ratio methanol fuel composite additive for vehicles. The composite additive is prepared from the following raw materials in percentage by mass: 50-70% of aliphatic ester, 10-30% of nitrate, 5-10% of glycerol, 5-10% of benzotriazole and 5-10% of high carbon alcohol. According to the high-ratio methanol fuel composite additive, the aliphatic ester of which the carbon chain number is about 18 is adopted, and the lubricating property, corrosion resistance and wear resistance of the methanol fuel for vehicles can be greatly improved. The nitrate is an excellent ignition improver and combustion improver, and the glycerol, benzotriazole and high carbon alcohol are excellent corrosion inhibition components and cosolvents. According to the methanol fuel composite additive for vehicles prepared by mixing the substances, the performance of the fuel is greatly improved.

Owner:山西佳新能源化工实业有限公司

Machining process of TP (topaz) bead ring for spinning

ActiveCN103170561AGuaranteed growthEasy to processWire ringsSolid state diffusion coatingFriction reductionChemical plating

The invention discloses a machining process of a TP (topaz) bead ring for spinning. The machining process is characterized by comprising the steps of: 1, selecting materials: selecting an excellent-quality alloy steel wire containing elements of W, V, Ni and Co as a raw material; 2, flaking; 3, annealing; 4, forming; 5, quenching-tempering; 6, polishing; and 7, carrying out surface treatment: nickelling the surface of a bead ring matrix by adopting a chemical plating method, and adding a nano powder body in a plating solution to ensure that the nano powder body is co-deposited on the bead ring matrix; and 8, carrying out surface curing treatment: removing the stress and enhancing the hardness to ensure the surface of the bead ring is golden yellow. The TP bead ring machined by adopting the machining process has relatively good abrasion resistance, friction reduction and corrosion prevention properties, is capable of well meeting the requirement on the existing high-count, high-speed and high-efficiency spinning, is particularly suitable for compact spinning and common high-speed ring spinning, and has a good development prospect and a wide market popularization space.

Owner:CHONGQING JINMAO TEXTILE ACCESSORIES

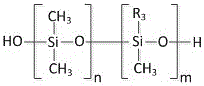

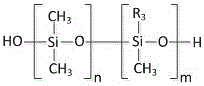

Long-life silicon rubber for peristaltic pump pipes and preparation method of long-life silicon rubber

The invention relates to the field of organic silicon high-polymer materials, in particular to long-life silicon rubber for peristaltic pump pipes and a preparation method of the long-life silicon rubber. The silicon rubber is prepared from raw materials in parts by mass as follows: 50-150 parts of methyl vinyl polysiloxane, 40-60 parts of reinforcing filler, 1-12 parts of a structurized control agent, 0.1-1.0 part of a hydrosilylation catalyst, 0.5-2 parts of a cross-linking agent, 0.05-0.2 parts of an inhibitor and 0.1-0.6 parts of a release agent, wherein the methyl vinyl polysiloxane is a mixture formed by mixing vinyl-terminated methyl vinyl polysiloxane with all side chains being methyl groups and methyl-terminated methyl vinyl polysiloxane with side chains containing vinyl groups in any mass ratio. The silicon rubber for the peristaltic pump pipes has excellent weather resistance, temperature resistance and biocompatibility of silicon rubber, and the molded silicon rubber pipes have very long service life and are good in wear resistance and pressure bearing capability.

Owner:东莞市贝特利新材料有限公司

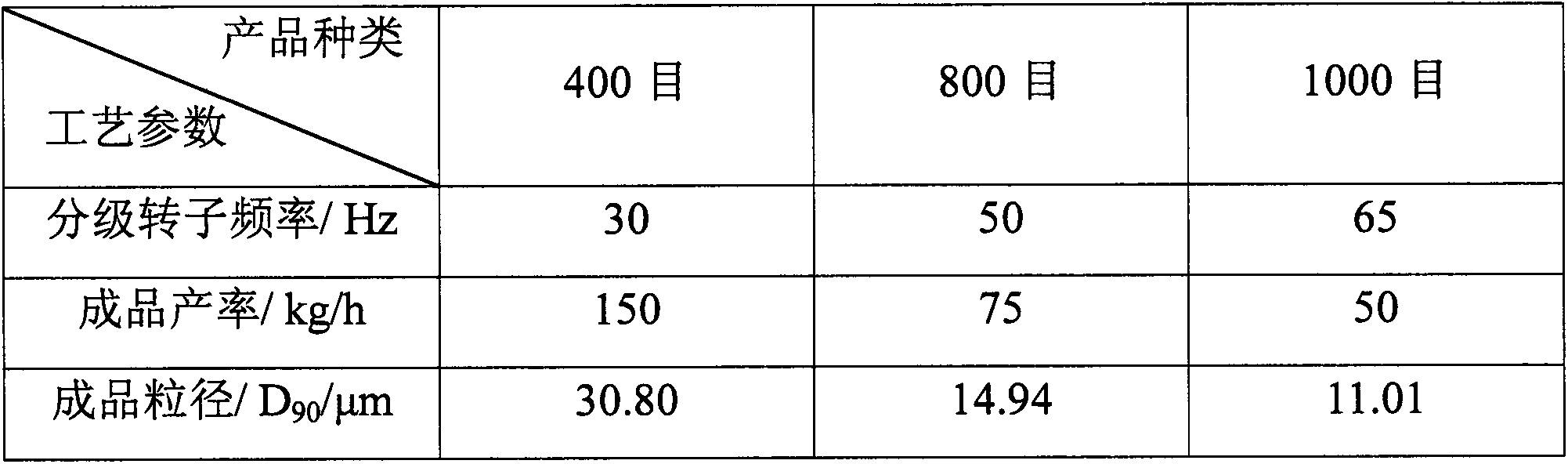

Method for preparing wear-resistant material from tungsten tailings

InactiveCN103952029AImprove use valueSimple processCoatingsWear resistantDistribution characteristic

The invention provides a method for preparing a wear-resistant material from tungsten tailings, belonging to the field of solid waste comprehensive utilization. The preparation method comprises the steps of pre-screening tungsten tailings, carrying out physical sorting, ultra-finely processing to obtain ultrafine tungsten tailings powder, grading and preparing the wear-resistant material from the ultrafine tungsten tailings powder with a specific grade level. The content of garnet in the wear-resistant material is higher than 85% and the utilization rate of tailings is 60-85%. The purposes of purification of garnet and particle size control are achieved by making full use of hardness differences and grain size distribution characteristics of different mineral components in tungsten tailings and selectively grinding and grading. The wear-resistant material disclosed by the invention has the advantages that the particle size is uniform, the purity is high, the requirements of wear-resistant fillers in the coating industry can be met, coating cost is reduced and the wear resistance of the coating is improved. The preparation method has the advantages that sources of raw materials are wide, the preparation method is simple and feasible, the added value of tungsten tailings is greatly improved, and the waste is turned into wealth; the method has good economic and environmental benefits.

Owner:CENT SOUTH UNIV

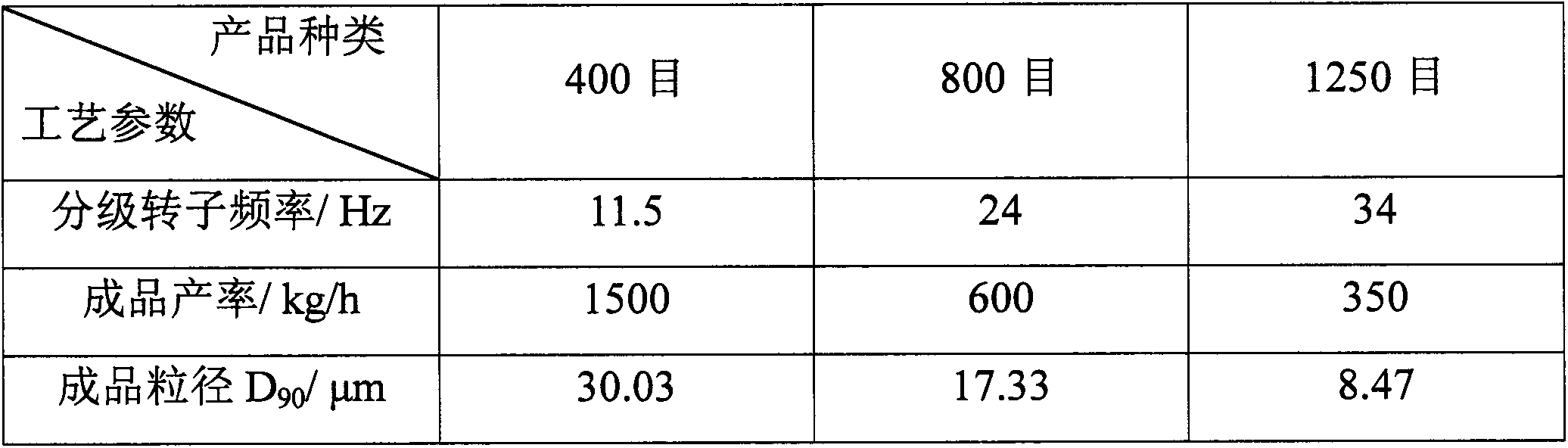

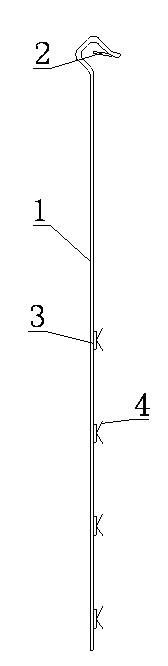

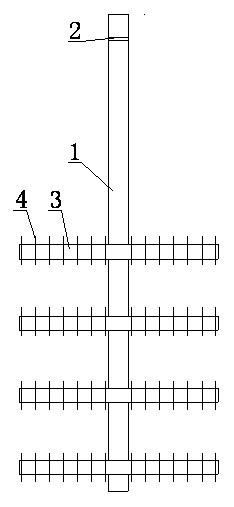

Anode special for oxidation of deep hole aluminum piece hard anode and oxidation method of deep hole aluminum piece hard anode

The invention discloses an anode special for oxidation of a deep hole aluminum piece hard anode and an oxidation method of the deep hole aluminum piece hard anode. According to a machining method of the special anode, a titanium material TA2 with both better conductivity and strength is adopted, so that good conductivity, corrosion resistance and convenience for clamping are guaranteed, and the requirements for oxidation of the deep hole piece hard anode are met. Since the oxidation of the deep hole hard anode is special, the selection of a material which has good selectivity and that a clamp can be soaked into sulfuric acid solution for long time without being easily dissolved or oxidized is particularly important. The treatment of the special clamp is that: a TA2 titanium plate or titanium wire is subjected to treatment such as welding and then used for the deep hole piece hard anode oxidation clamp. The conduction mode is that power is supplied by the anode. The anode provided by the invention is used for oxidation; the qualification rate of products at one time can be increased by over 98 percent; and the consumption and the production cost of the clamp are greatly reduced while the product quality is guaranteed.

Owner:CHONGQING JIANSHE IND GRP

Method for carrying out reinforcing and sealing-protection on wood by using nano cellulose

ActiveCN110181632AImproved dimensional stabilityImprove wood quality and added valueWood treatment detailsPretreatment apparatusElastic modulusFiber

The invention belongs to a method for carrying out reinforcing and sealing-protection on wood by using nano cellulose. The method comprises the following steps: classifying the wood according to waterpermeability of the wood, and performing brushing or immersion treatment on the wood according to classification with a nano-cellulose sealing-protection liquid prepared by a carboxymethyl celluloseor hydroxypropyl cellulose or hydroxyethyl cellulose polymer solution with a concentration of 0.5-2.5%, a cellulose nano crystal with a concentration of 0.5-1.5%, a nano cellulose dispersion liquid ofTEMPO oxidized nano fibers with a concentration of 0.2-0.7%, and a modification liquid of a silica sol with a concentration of 0.5-1.5%. The method can improve dimensional stability, density, flexural modulus and compressive strength of the wood, and has the advantages of significantly improving quality and added values of the wood.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

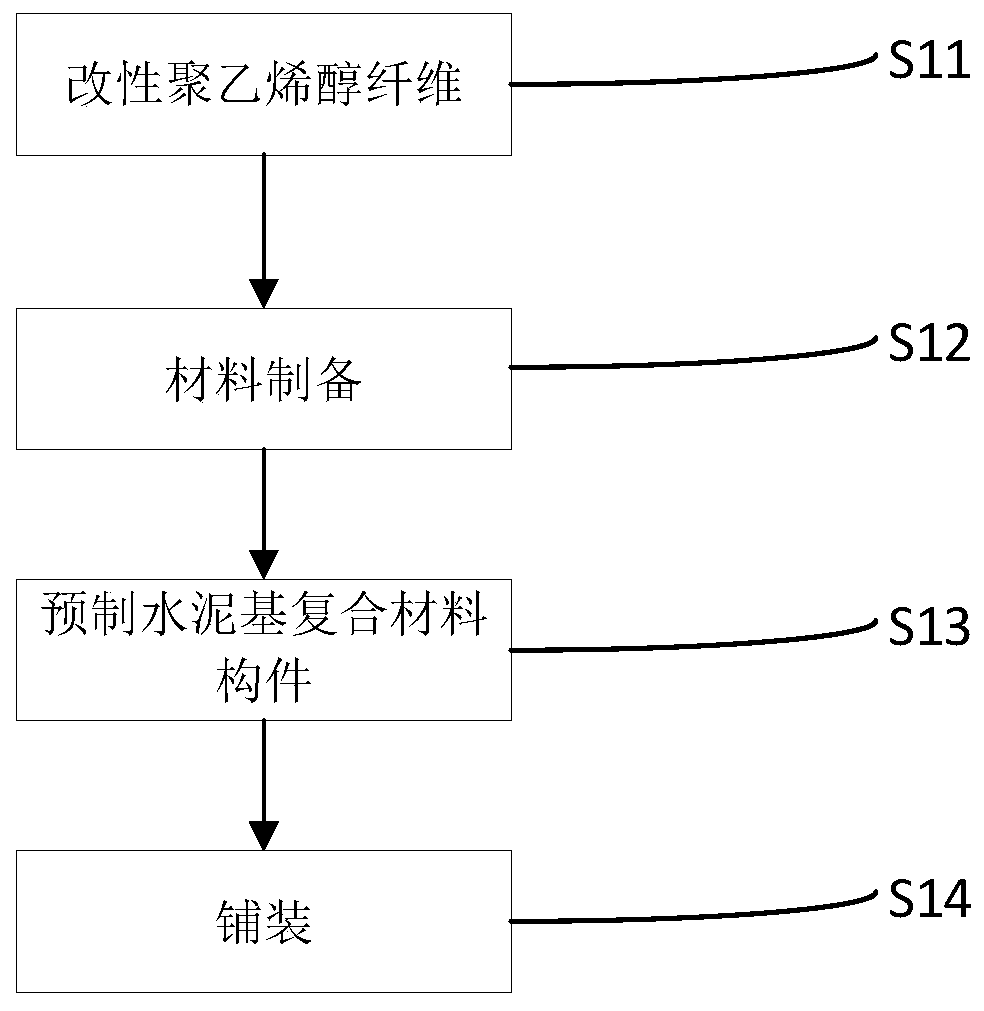

Highway construction and maintenance method based on cement-based composite material

InactiveCN110700041AReduce interface strengthReduce chemical adhesionRoads maintainencePolyvinyl alcoholGraphene flake

The invention discloses a highway construction and maintenance method based on a cement-based composite material. The method comprises the following steps: 1) modifying polyvinyl alcohol fibers; 2) material preparation: firstly, carrying out dry mixing on cement, fly ash and sand for 1-6 minutes; adding water and a water reducing agent, then adding a nano graphene sheet or graphene oxide dispersion liquid, stirring at a low speed for 5-10 minutes, adding modified polyvinyl alcohol fibers while stirring after uniformly flowing cement mortar is obtained, and stirring at a high speed for 5-10 minutes after all the modified polyvinyl alcohol fibers are added; carrying out a flow table fluidity experiment on the slurry in the stirring process until the fluidity of the slurry reaches 200 mm or above and the fibers are uniformly dispersed; 3) precasting cement-based composite material components; and 4) carrying out paving; according to the invention, the construction performance is good, theconstruction cost is low, and construction is convenient.

Owner:维特国际新材料(武汉)有限公司

Modified hardfacing self-shielded flux-cored wire doped with multi-boride and preparation method of modified hardfacing self-shielded flex-cored wire doped with multi-boride

ActiveCN106141495AHigh hardnessImprove thermal stabilityWelding/cutting media/materialsSoldering mediaBorideIron powder

The invention discloses a modified hardfacing self-shielded flux-cored wire doped with multi-boride and a preparation method of the modified hardfacing self-shielded flex-cored wire doped with the multi-boride. The modified hardfacing self-shielded flux-cored wire doped with the multi-boride comprises a low-carbon steel strip and a flux core, wherein the flux core comprises, by mass percentage, 45-55 wt% of high carbon ferro-chrome, 6-16 wt% of B4C, 3-9 wt% of TiB2, 3-9 wt% of ZrB2, 1-3 wt% of graphite, 0.5-1 wt% of cellulose powder with the mesh being 60, 0.5-1 wt% of cellulose powder with the mesh being 200, 1-3 wt% of an aluminum-magnesium alloy with the mesh being 60, 0.5-2 wt% of an aluminum-magnesium alloy with the mesh being 200, 2-7 wt% of an silicon-manganese alloy with the mesh being 60, 1-4 wt% of an silicon-manganese alloy with the mesh being 200 and the balance iron powder, and the flux core accounts for 50-54 wt% of the total mass of the flux-cored wire. According to the flux-cored wire, through addition of the flux core components of different grain sizes, the good welding process performance is guaranteed; through the addition of the multi-boride component, the multi-boride is dispersed and extracted in the welding process; and the flux-cored wire has the beneficial effects of being high and uniform in hardness, good in wear resistance and the like, and few residues are left on the surface of a weld bead, and slag removal is not needed in multi-layer welding.

Owner:JIANGSU UNIV OF SCI & TECH

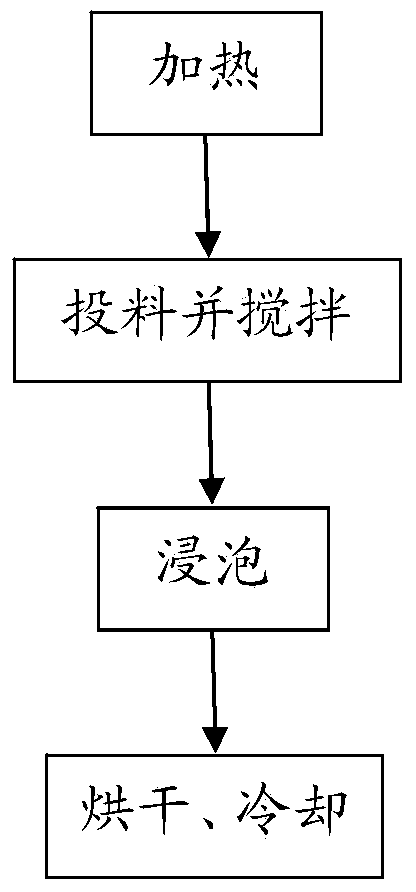

Polyvinyl alcohol size boiling technology and textile fiber sizing technology

InactiveCN103757845AAbrasion resistance remains stableQuality improvementTextile treatment machine partsLiquid/gas/vapor fibres/slivers/rovings treatmentSizingTextile fiber

The invention discloses a polyvinyl alcohol size boiling technology and a textile fiber sizing technology. The polyvinyl alcohol size boiling technology includes the steps that water is heated to 88 DEG C to 92 DEG C, solid polyvinyl alcohol is added into the water at the charging speed of 11.11g / s and is stirred, a polyvinyl alcohol sizing agent is formed after the solid polyvinyl alcohol is completely dissolved. The sizing agent formed through the polyvinyl alcohol size boiling technology does not contain tiny particles, and after textile fibers are covered the sizing agent, particles hindering spinning can not form on the textile fibers, so that abrasion resistance of the textile fibers keeps stable, quality of textile products is improved, and production efficiency of weaving is improved.

Owner:苏州宜新织造有限公司

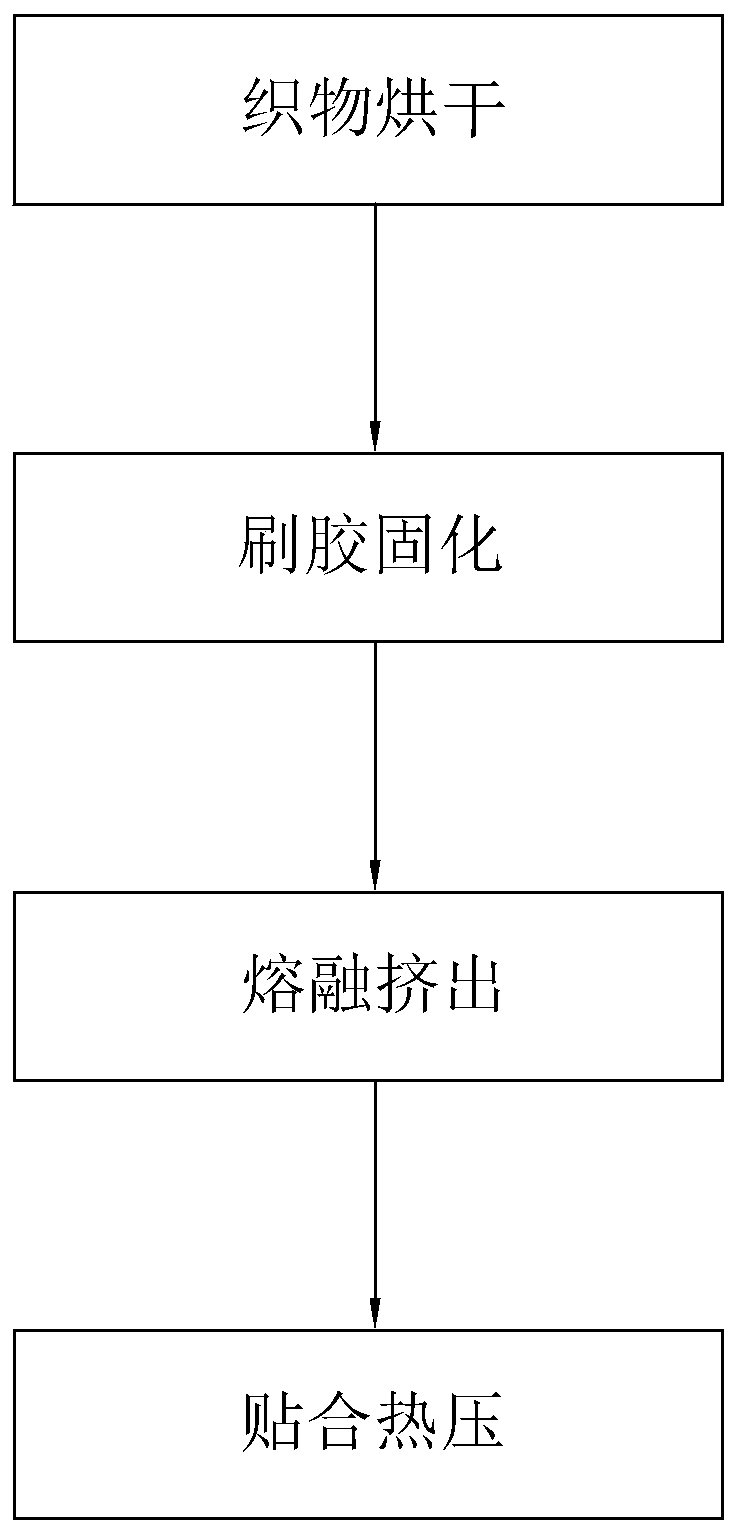

Temperature-change-resistant conveying belt and preparation method thereof

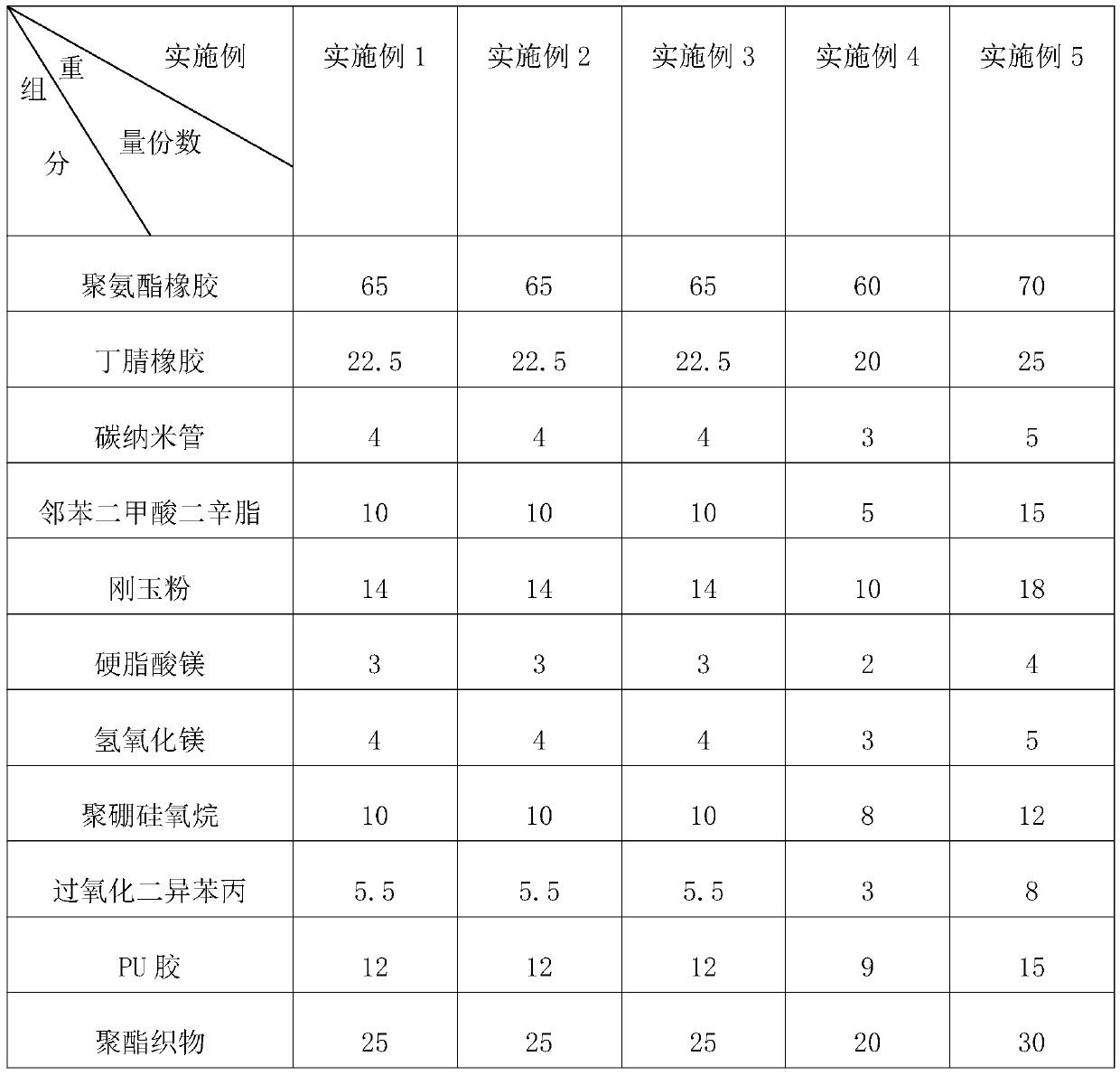

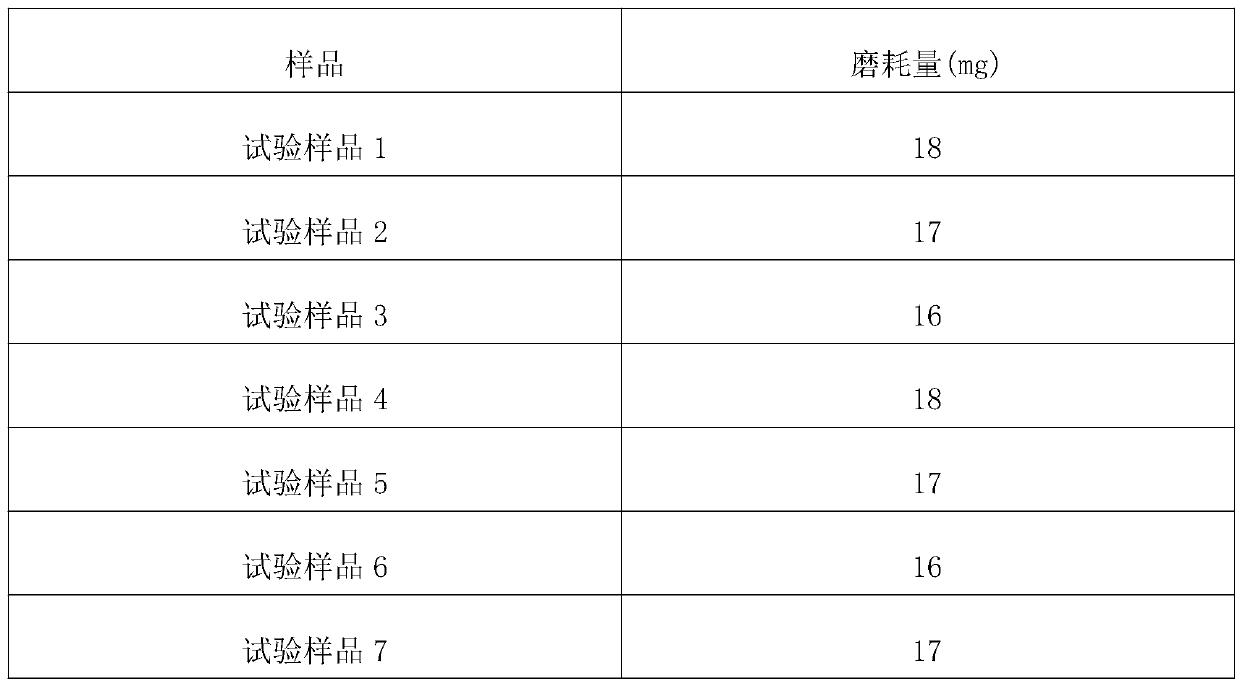

InactiveCN110734640AGood high temperature oxidation resistanceImprove flame retardant performanceConveyorsBeltsPolymer scienceAdhesive

The invention discloses a temperature-change-resistant conveying belt and a preparation method thereof, and relates to the technical field of conveying belts. The problem that the wear resistance of the conveying belt is greatly reduced when the conveying belt is influenced by large temperature change of an external environment due to poor temperature change resistance of the conveying belt is solved. The temperature-change-resistant conveying belt comprises the following components in parts by weight: 60-70 parts of polyurethane rubber; 20-25 parts of butadiene-acrylonitrile rubber; 3 to 5 parts of carbon nanotubes; 5 to 15 parts of dioctyl phthalate; 10-18 parts of a wear-resistant filler; 2-4 parts of a stabilizer; 3-5 parts of a flame retardant; 8 to 12 parts of polyborosiloxane; 3 to8 parts of dicumyl peroxide; 9-15 parts of a PU adhesive; and 20-30 parts of a skeleton fabric. When the temperature-change-resistant conveying belt is affected by large temperature change of the external environment, the abrasion resistance of the temperature-change-resistant conveying belt is not greatly reduced, good structural stability can still be kept, and the whole temperature-change-resistant conveying belt has good temperature change resistance.

Owner:上海米莜凯自动化装备有限公司

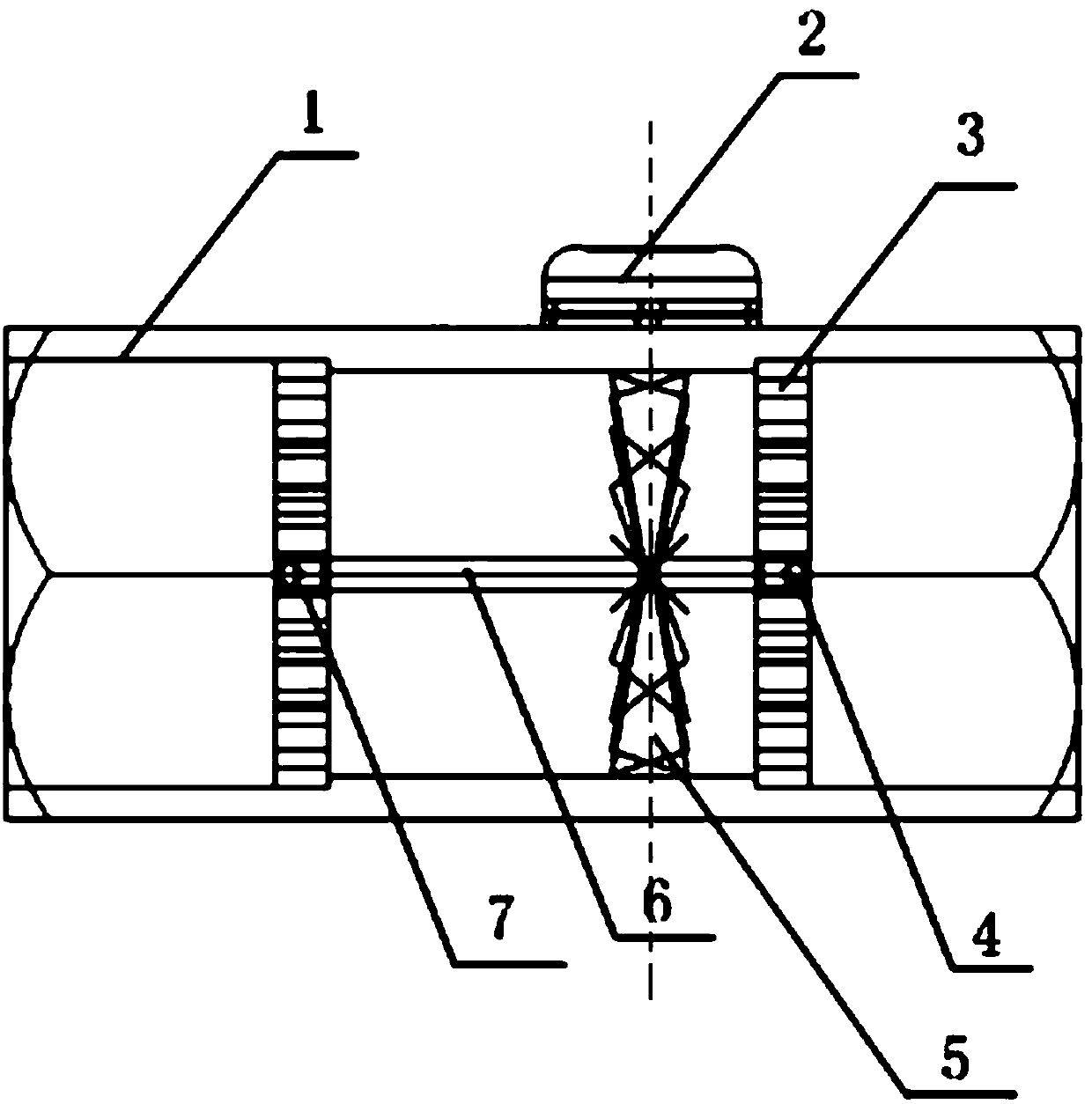

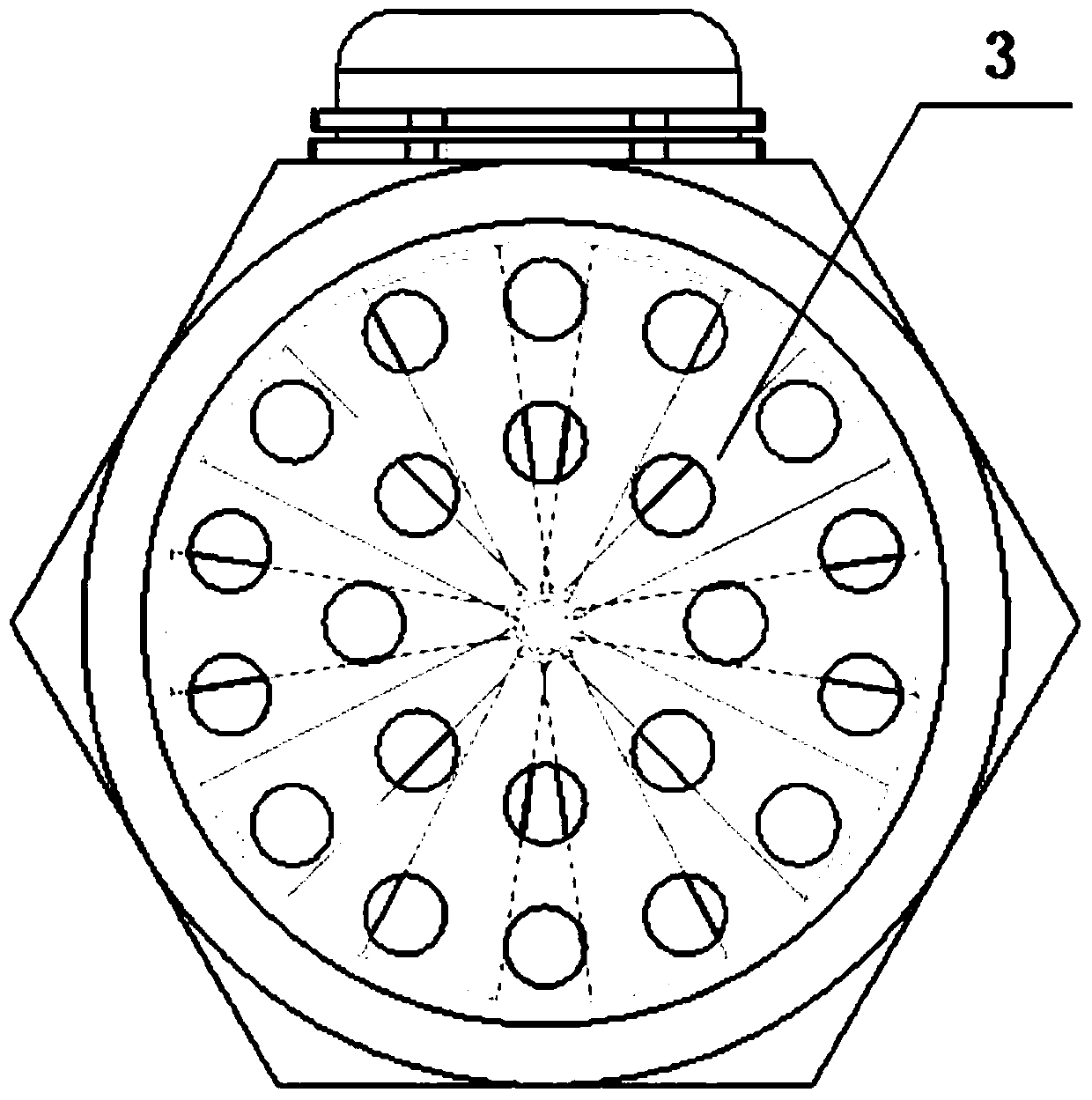

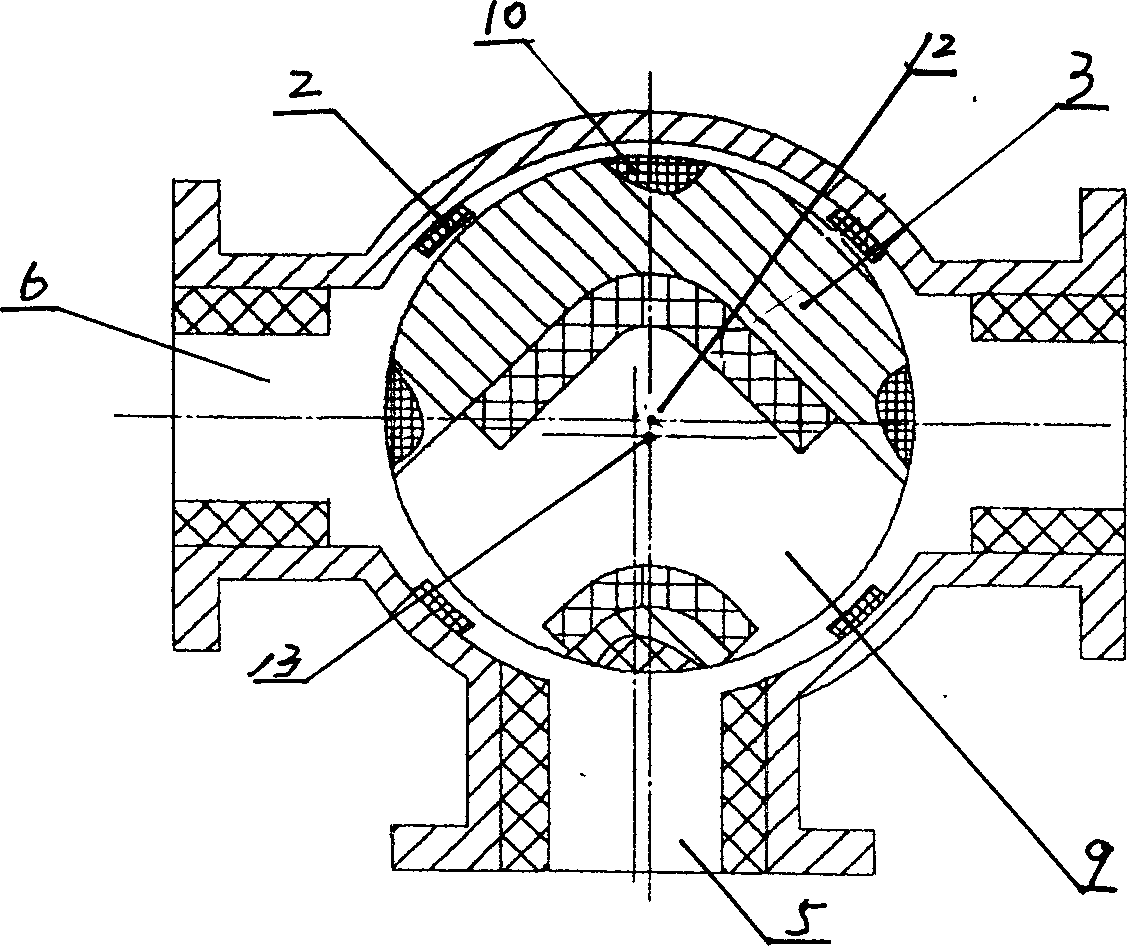

Turbofan flow sensor

InactiveCN103776496AEnsure repeatabilityEnsure consistencyVolume/mass flow by dynamic fluid flow effectEngineeringSteel ball

The invention relates to a turbofan flow sensor and belongs to the technical field of flow measuring devices. The turbofan flow sensor comprises a casing (1), a Hall-effect switch (2), a turbofan rack (3), a steel ball (4), a turbofan (5), a shaft lever (6) and a bearing (7). According to the invention, the flow sensor which is designed by adopting the turbofan is determined to have a relatively stable friction coefficient and abrasive resistance at different angles within a range of 360 degrees due to the design of the structure and the parameters, and the flow measuring repeatability and consistency are ensured.

Owner:CHINA NORTH VEHICLE RES INST

Method for modifying polyvinyl alcohol fiber for high-ductility cement-based composite material

The invention provides a method for modifying polyvinyl alcohol fiber for a high-ductility cement-based composite material. The surface of the polyvinyl alcohol fiber contains a large amount of hydroxyl groups, the hydroxyl groups on the surface of the polyvinyl alcohol fiber react with a cement matrix to form a relatively strong chemical bonding force, and the strong chemical bonding force causesfiber breakage in the pull-out process, so that the ductility is affected. The method comprises the following steps: with the polyvinyl alcohol fiber as a raw material, firstly coating the surface ofthe polyvinyl alcohol fiber with a layer of epoxy resin, and then coating the surface of epoxy resin coating with a layer of fumed silica powder. Due to surface hydrophobicity of the modified polyvinyl alcohol fiber, the interfacial strength between the polyvinyl alcohol fiber and the cement matrix can be effectively weakened and the chemical bonding force can be reduced, so that the polyvinyl alcohol fiber is pulled out of the cement matrix in the stretching process, without breakage; the hydrophobicity and the wear-resistant slip property of a product are more stable, and the coating is more wear-resistant and the original physical and mechanical properties of the PVA fiber are not affected.

Owner:SOUTHEAST UNIV

Processing technique of BS (blue sapphire) traveller used for spinning

InactiveCN103014953AGuaranteed growthEasy to processSolid state diffusion coatingFurnace typesFiberChemical compound

The invention discloses a processing technique of a BS (blue sapphire) traveller used for spinning. The technological process comprises the following steps: (1), selecting material, taking high quality alloy-steel wires containing chemical elements such as W, V, Ni and Co as raw material; (2), tabletting; (3), annealing; (4), forming; (5), quenching and tempering; (6), polishing; (7), surface diffusion treating, melting the chemical compound with transition elements to diffuse and permeate the chemical compound into the base body of the traveller, allowing the surface of the traveller to be blue; and (8), surface curing and treating. The traveller produced by adopting the processing technique has the characters of good wear resistance, anti-friction quality, corrosion resistance and long service life and the like, can obviously reduce the phenomenon of airiness, flying rings and broken ends, can better satisfy the current spinning development requirement of 'high count, high speed and high efficiency', is particularly suitable for compact spinning and common high-speed ring spinning, and also can meet the requirements of novel materials, such as novel fiber, special fiber, carbon fiber, cotton-like fiber and mixed fiber.

Owner:CHONGQING JINMAO TEXTILE ACCESSORIES

Self-repairing multi-soap based composite bearing lubricating grease and preparation method thereof

ActiveCN100412179CReduced antioxidant capacityGuaranteed validityDrill bitsAdditivesStructural ModifierPetroleum

The related composite poly-soap self-repair bearing lubricating grease comprises the basic liquid, composite calcium sulfonate, composite Ca-Li-base thickener, non-oxidizing anti-corrosion additive, metal deactivator, tungsten disulfide extreme pressure additive, wear-well additive, self-repair additive, and structural modifier; has well anti-oxidation ability and bearing capacity, can repair wore part on condition of extreme pressure and high temperature to supply the silver-plating lacking on bearing radial surface effectively, prolongs bearing service time on maximum limit, and has special application in oil drilling exploration.

Owner:SINOPEC OILFIELD EQUIP CORP +1

Tool and mold steel mold casting powder

The invention relates to a tool and mold steel mold casting powder is composed of, by mass percentage, 1.8%-2.2% of sodium carbonate, 1.7%-2.3% of fluorite, 10.5%-17.5% of perlite, 8.3%-12.7% of kieselguhr, 18.5%-21.5% of power plant ash, 28.0%-32.5% of clinker, 4.5%-5.5% of high aluminum powder, 13.5%-16.5% of feldspar powder, 1.8%-2.2% of expanded graphite, and the sum of all the ingredients is 100%. The mold casting powder is high in occluded foreign substance absorption capacity, the occluded foreign substrate formed due to oxidation can be prevented from gathering in the surface of a casting blank, and the problems of longitudinal cracks and pits on the surface of the tool and mold steel are solved; and part of the perlite is replaced with the kieselguhr, so that the mold casting powder is better in spreadability and smaller in surface tension and capable of evenly covering the surface of molten steel and playing the function of preventing secondary oxidation of the molten steel.

Owner:CHANGXING MINGSHENG METALLURGY FURNACE CHARGE

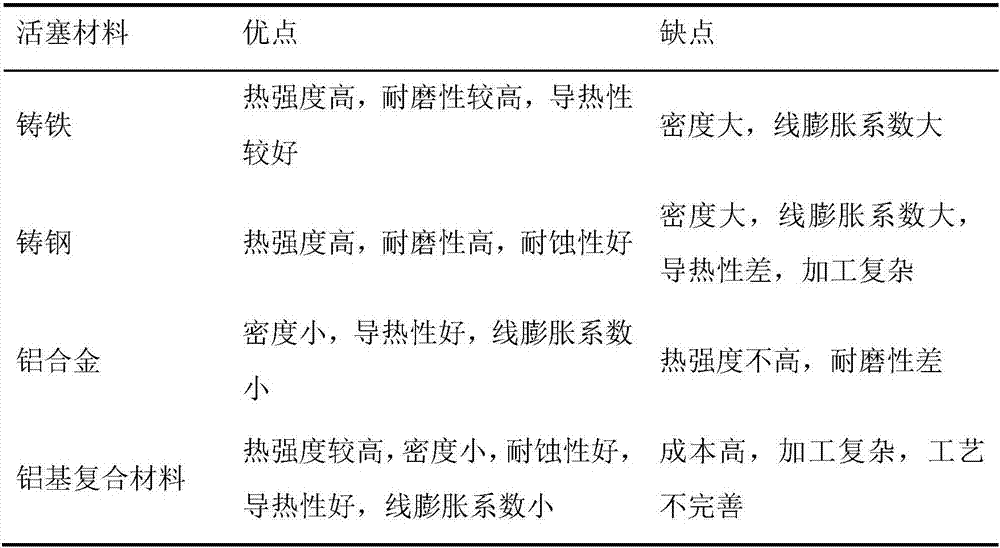

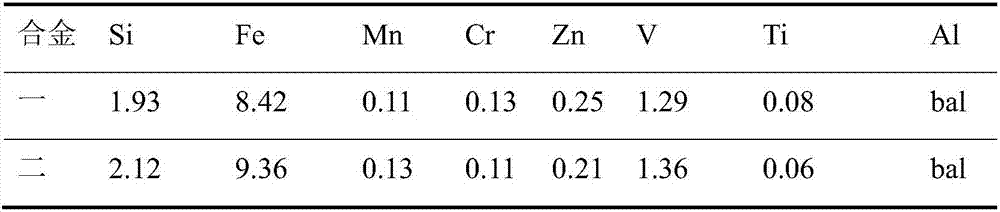

Particle reinforced aluminum matrix composite for automobile piston and preparation method of particle reinforced aluminum matrix composite

InactiveCN107541620AImprove high temperature mechanical propertiesStable wear resistanceMechanical propertyPiston

The invention relates to a particle reinforced aluminum matrix composite for an automobile piston and a preparation method of the particle reinforced aluminum matrix composite. The aluminum matrix composite is prepared from 8-10wt% of Fe, 0.8-1.5wt% of V, 1.4-2.2wt% of Si, the balance 75-91% by volume of aluminum alloy matrix powder of Al, preferentially, 78-89% by volume, 8-25% by volume of silicon carbide, preferentially, 10-20% by volume and 0.5-4% by volume of graphite powder, preferentially, 1-2% by volume. The preparation method of the particle reinforced aluminum matrix composite comprises the steps that aluminum alloy matrix powder, silicon carbide and graphite powder are mixed to be uniform and compacted, a mixture is made to be an extrusion ingot blank, the extrusion ingot blankis heated to 450-520 DEG C, kept at the temperature, extruded according to the extrusion ratio being 8 or more, forged again and optionally machined. The particle reinforced aluminum matrix compositehas the advantages that the process is simple, the content of silicon carbide and graphite is easy to control, a matrix and a reinforcement phase have no interface reaction, and indoor-temperature high-temperature mechanical properties are excellent. The particle reinforcement aluminum matrix composite can be widely applied to manufacturing automobile positions, brake materials and other high-temperature wear resistance parts.

Owner:HUNAN GOLDHORSE ALUMINUM IND +1

Aluminum-magnesium alloy material of stamping part

The invention discloses an aluminum-magnesium alloy material of a stamping part. The aluminum-magnesium alloy material is composed of, by mass, 0-20% of magnesium, 0-0.8% of gold, 0-0.8% of titanium, 0-15% of iron, 0-0.15% of platinum, 0-5% of copper and the balance aluminum. The aluminum-magnesium alloy material has the beneficial effects that the aluminum, magnesium and iron serve as main raw materials, the abrasion resistance of the stamping part is stabilized, meanwhile, the aluminum-magnesium alloy material is composed of the other metal elements, the erosion resistance of parts is improved, the service life is prolonged, the safety is good, and the stability is high.

Owner:太仓明仕金属制造有限公司

Spraying painting material for slide bearing

InactiveCN1163626CCorrosion resistant and stableExtended service lifeMolten spray coatingChemical compositionPlain bearing

A spray material for slide bearing is a self-fused hard alloy powder for the hot galvanizing machine set, and contains Cr (20-26 wt.%), Co (22.8-61), Mo (10-16), W (6-12), Si (1-4), B (2-5), F (less than 14) and C (less than 0.2). Its spayed layer has high anticorrosion and antiwear performance to elongate the service life of slide bearing up to 21-27 days with low cost.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Low-temperature superhigh-toughness wear-resistant copper alloy and preparing method thereof

ActiveCN106916996APlay a role in solid solution strengtheningImprove mechanical propertiesAviationWear resistant

The invention relates to low-temperature superhigh-toughness wear-resistant copper alloy and a preparing method thereof and belongs to the technical fields of metal materials and preparation. The copper alloy consists of the following components in a percent by mass: 25.0-45.0% of nickel, 2-15% of manganese, 1-8% of zinc, 0.1-5.0% of titanium, 0.5-5% of iron, 0.1-3% of chromium and the balance of copper. The preparing method comprises the following preparing steps: preparing materials, carrying out casting, carrying out hot extrusion, carrying out hot forging and obtaining a finished product. The low-temperature comprehensive mechanical properties and the wear resistance of the alloy are improved by adding the elements, such as the manganese, the zinc, the titanium, the iron and the chromium, and at the same time, the alloy is ensured to have great processability. The impact energy of the prepared copper alloy material at the low temperature of -196 DEG C is larger than 170J and is 3-5 times of other common wear-resistant copper alloy materials. The copper alloy material is particularly suitable for manufacturing wear-resistant parts used in low-temperature environments in the fields of aviation, aerospace and the like.

Owner:GRIMAT ENG INST CO LTD

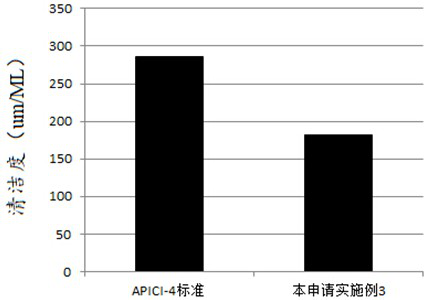

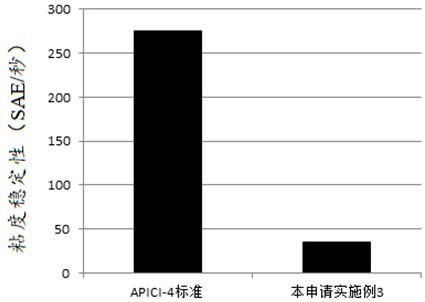

Lubricating oil and preparation method thereof

PendingCN113046161ATight molecular chainStable anti-wear performanceLubricant compositionMechanical equipmentViscosity

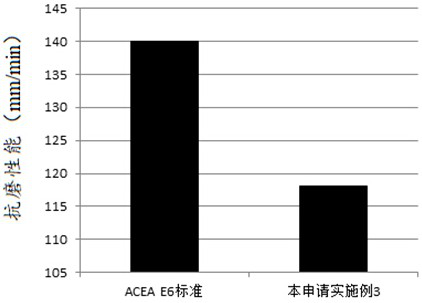

The invention is suitable for the technical field of lubricating oil, and provides lubricating oil and a preparation method thereof. The lubricating oil is prepared from the following raw materials in percentage by weight: 18-25% of polyol ester, 8-10% of alkyl naphthalene, 26.3-40.75% of an additive, and the balance of poly alpha olefin. The lubricating oil disclosed by the invention is more stable in wear resistance, and the wear resistance of the lubricating oil disclosed by the invention exceeds 15% of the ACEA E6 standard requirement; the lubricating oil provided by the invention can better reduce the formation of sediments, and can provide excellent engine cleaning performance which exceeds 36% of the API CI-4 standard requirement; the viscosity stability is high, and the viscosity stability performance exceeds 8 times of the APICI-4 standard requirement; the raw materials of the lubricating oil do not contain corrosive substances, the lubricating oil does not harm the environment or damage mechanical equipment, and the lubricating oil is non-flammable and wide in application range.

Owner:禹城胜牌润滑油有限公司

Lubricating grease compound additive and lubricating grease composition prepared from lubricating grease compound additive

PendingCN114426898AImprove extreme pressure performanceStable anti-wear performanceAdditivesOrganic baseAnoxomer

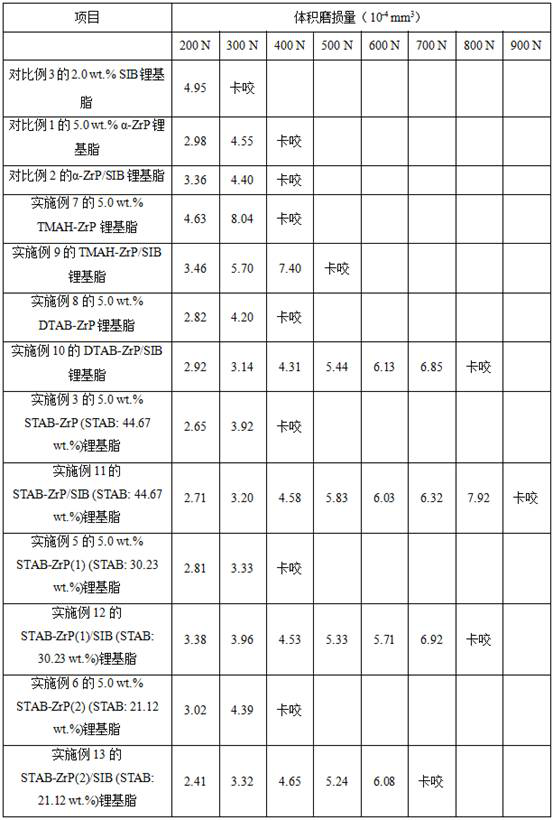

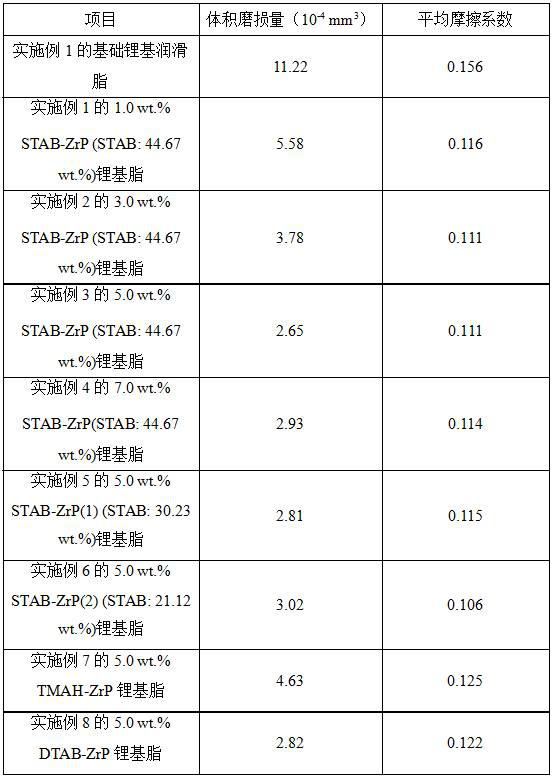

The invention discloses a lubricating grease compound additive and a lubricating grease composition prepared from the lubricating grease compound additive. The lubricating grease compound additive comprises an organic alkali intercalation zirconium phosphate compound and an extreme pressure agent, the organic base intercalation zirconium phosphate compound comprises one or two of organic amine intercalation zirconium phosphate, single-long-chain organic ammonium intercalation zirconium phosphate or double-long-chain organic ammonium intercalation zirconium phosphate. The lubricating grease composition comprises the following components in parts by weight: 90.0 to 98.0 parts of base grease, 1.0 to 7.0 parts of an organic alkali intercalation zirconium phosphate compound, 0 to 3.0 parts of an extreme pressure agent and 0.5 to 1.0 part of an antirust agent, and 0.5 to 2.0 parts of an antioxidant. The additive composition disclosed by the invention combines the advantages of a solid additive and an organic extreme pressure agent, and dual protection of a submicron-sized intercalated zirconium phosphate physical protective film and a nano-sized extreme pressure agent chemical protective film exists on the surface of a friction pair at the same time, so that the extreme pressure property of the lubricating grease is improved, the stable wear resistance is ensured, and the service life of the lubricating grease is prolonged. And the service life of the equipment is effectively prolonged.

Owner:TAIYUAN UNIV OF TECH

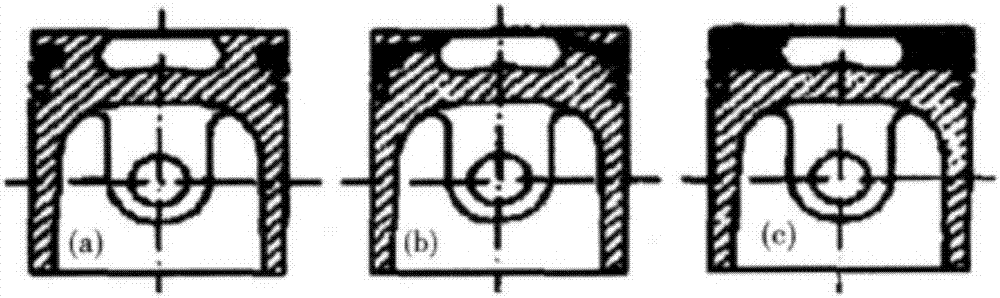

Steam inlet valve of a steam turbine

InactiveCN101109294ATransition eliminationImprove bindingMachines/enginesLift valveInlet valveEngineering

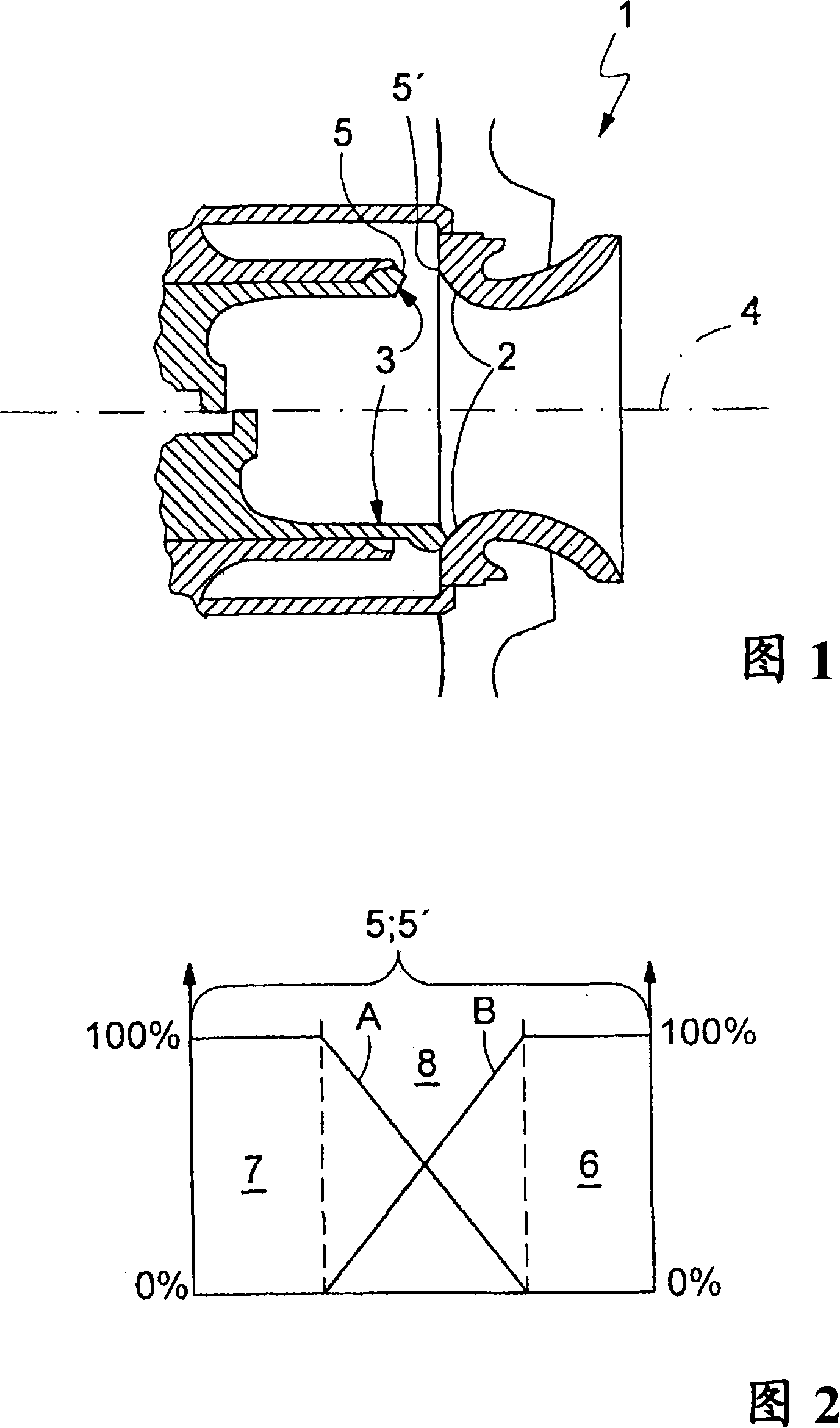

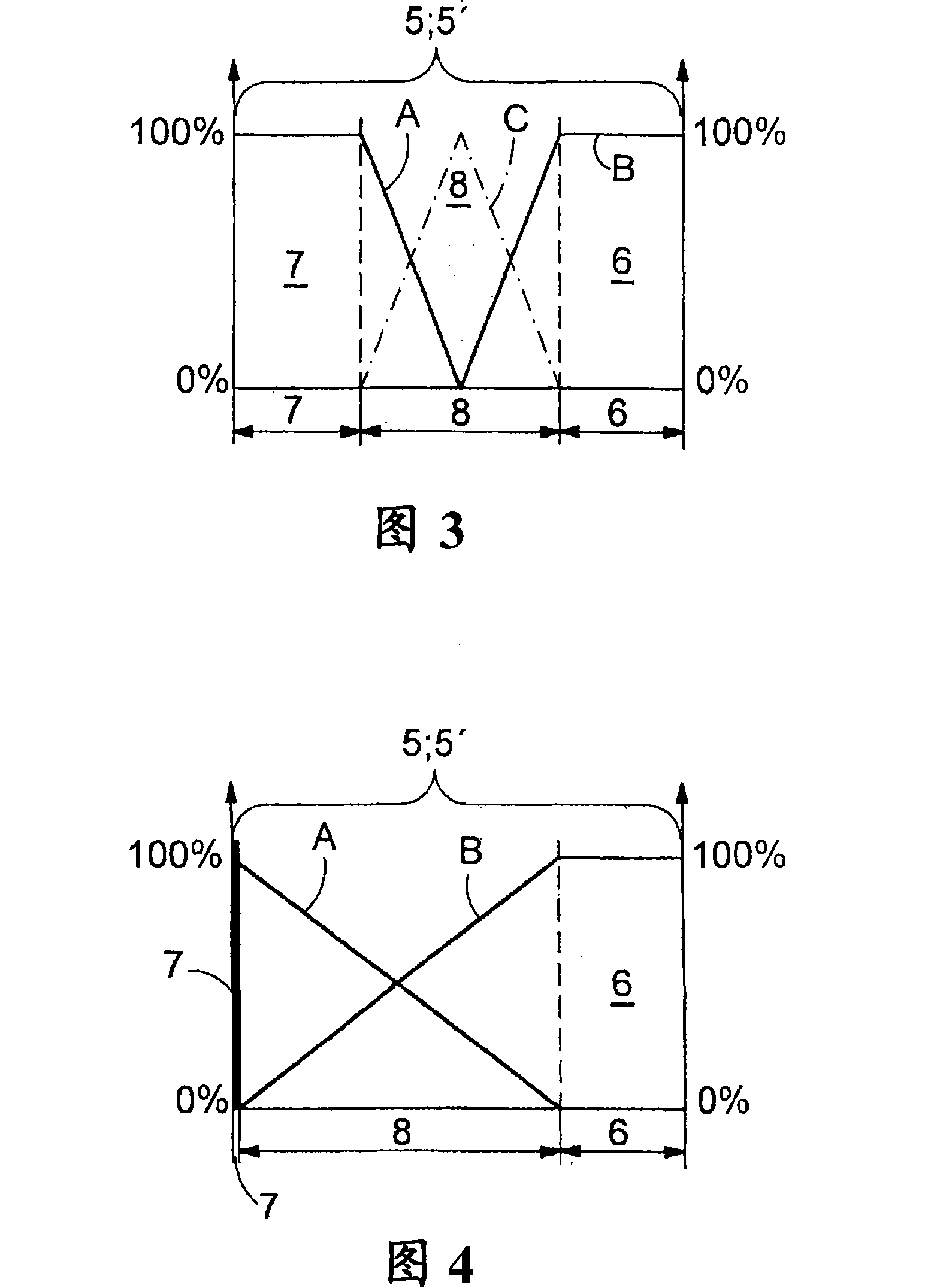

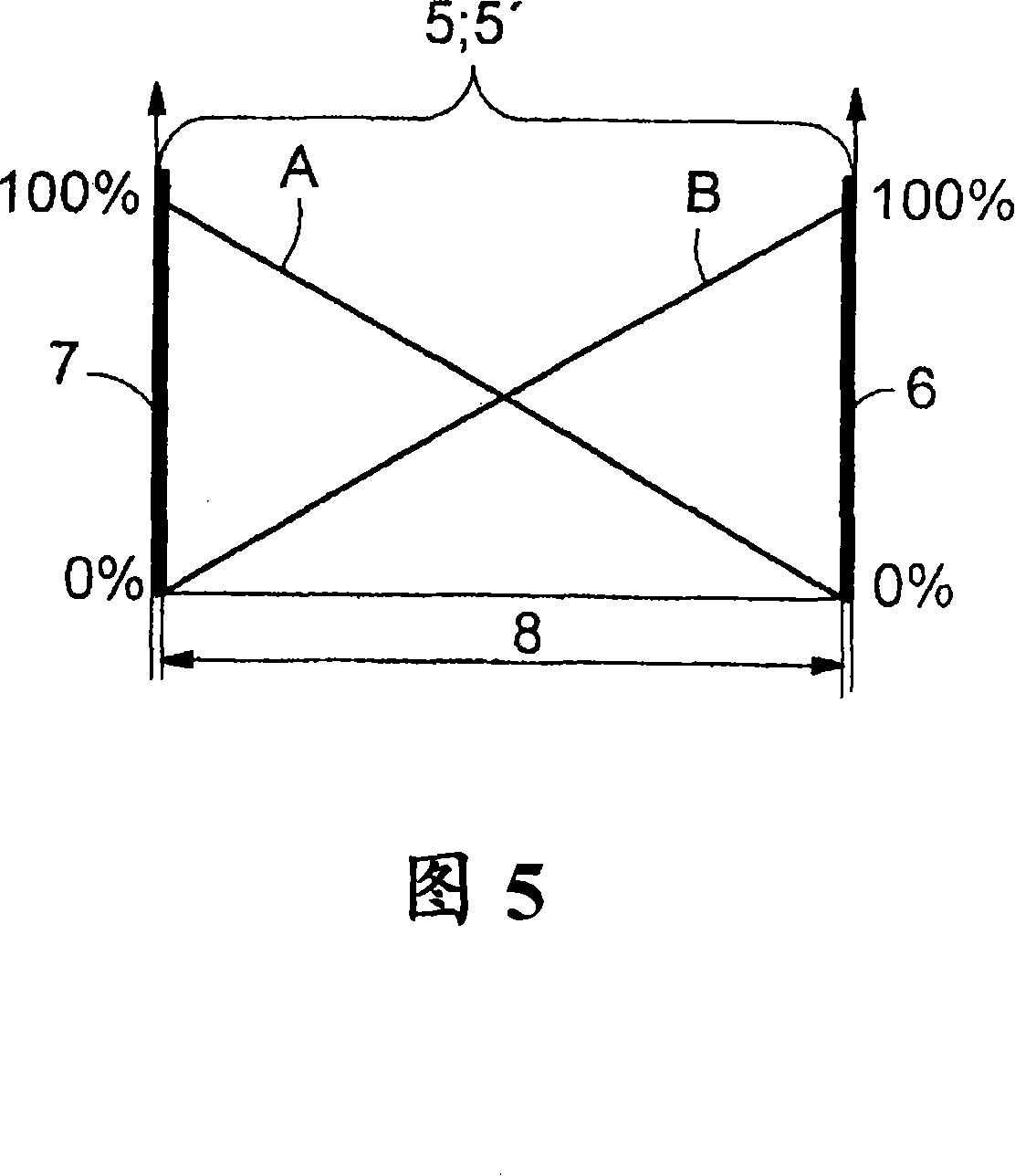

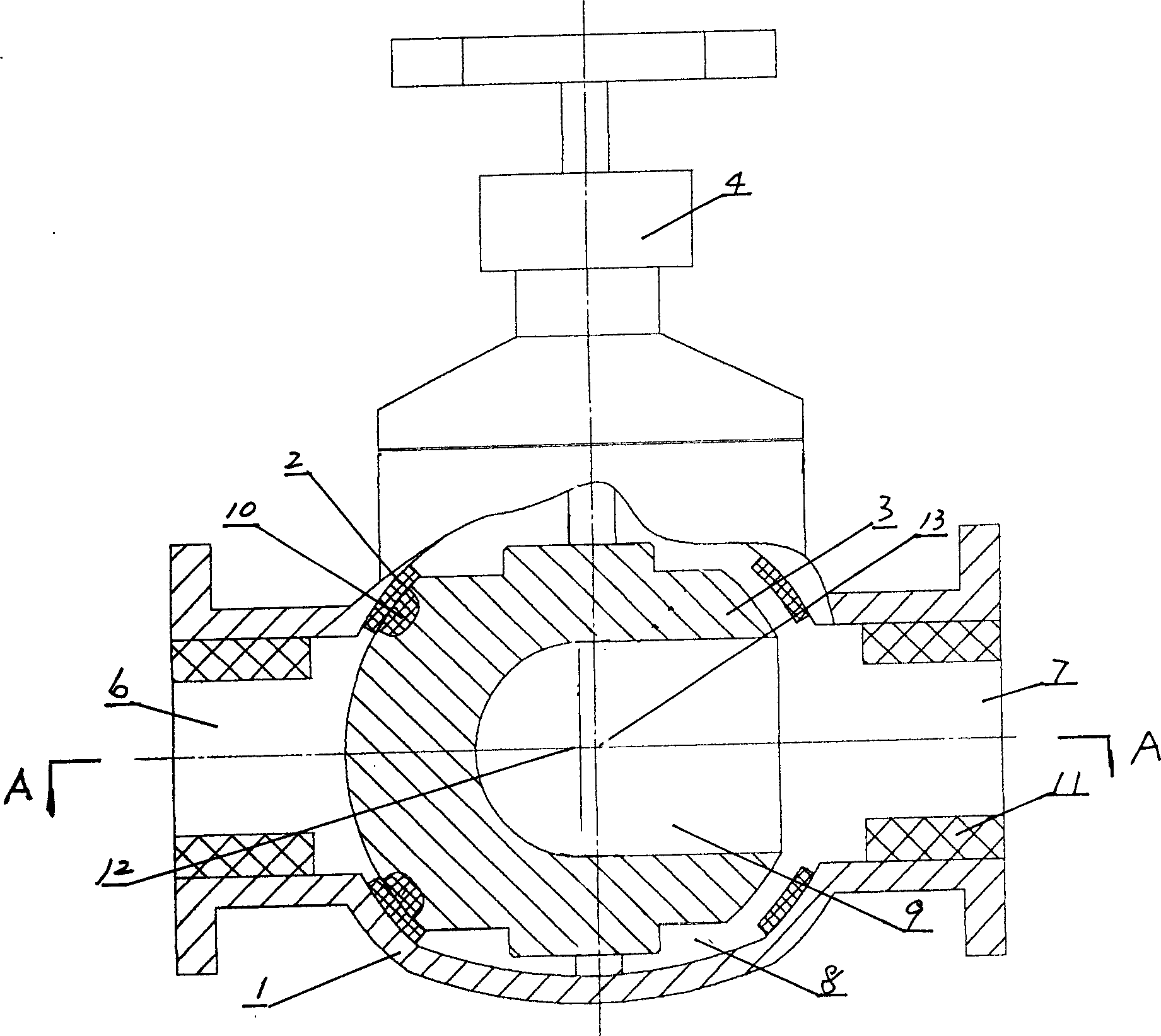

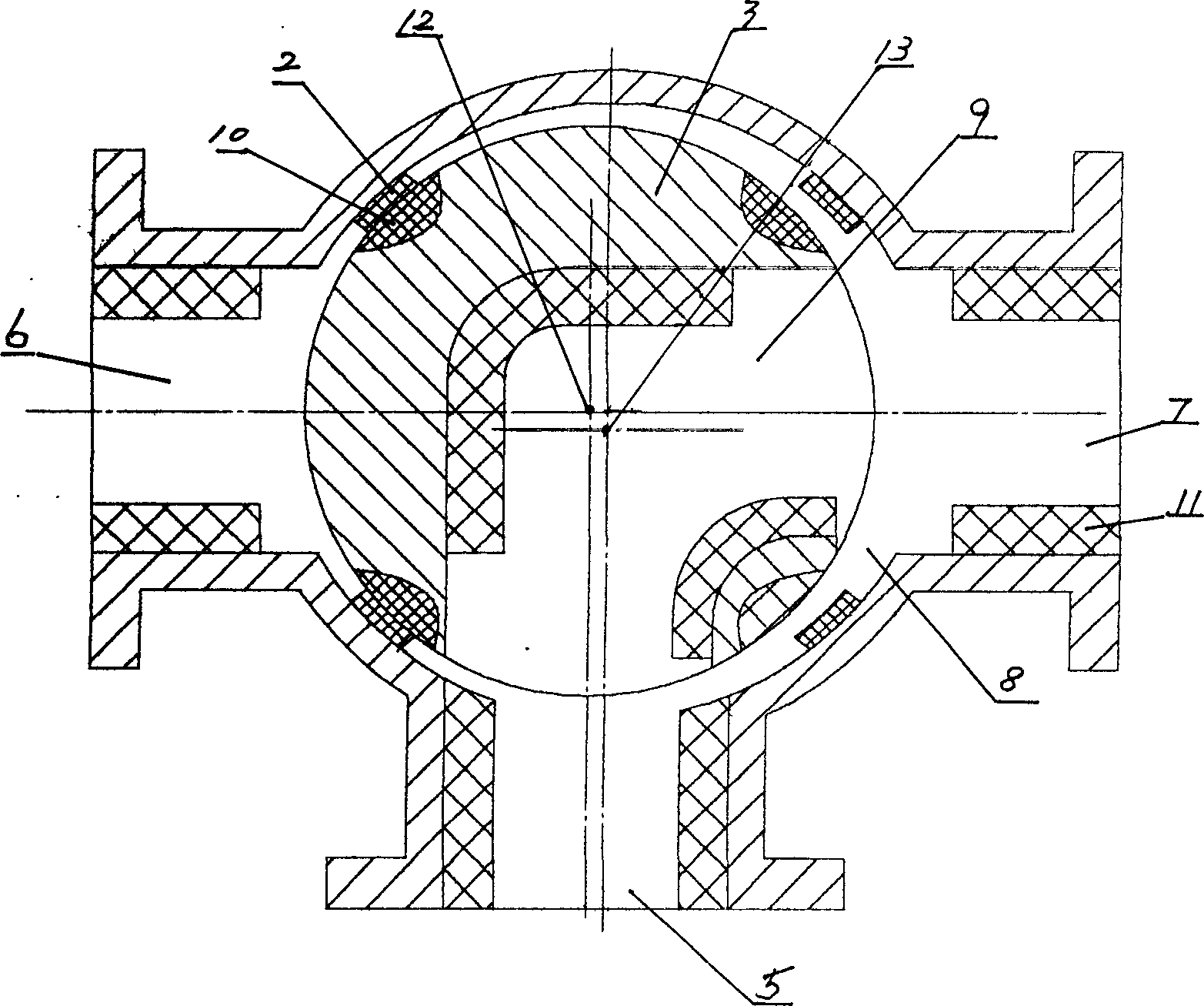

A steam inlet valve ( 1 ) of a steam turbine, with a valve seat ( 2 ) and a valve body ( 3 ) which, when the valve is closed, bears via a contact region ( 5 ) with sealing effect on a contact region ( 5' ) of the valve seat ( 2 ). At least one of the two contact regions ( 5, 5' ) has at least one sealing region ( 6 ) which faces the other contact region ( 5, 5' ), a base region ( 7 ) which faces away from the sealing region ( 6 ), and a transition region ( 8 ) which is situated between them, wherein the sealing region ( 6 ) is formed from a sealing material (B) and the base region ( 7 ) is formed from a base material (A), which the valve seat ( 2 ) or the valve body ( 3 ) also approximately comprises. In order to increase the wear resistance of the contact regions ( 5, 5' ) and of the steam inlet valve ( 1 ) as a result of it, the concentration of the base material (A) reduces from the base region ( 7 ) in the direction towards the sealing region ( 6 ) in the same way as the concentration of the sealing material (B) reduces from the sealing region ( 6 ) in the direction towards the base region ( 7 ), so that both materials (A, B) are to be found in the transition region ( 8 ).

Owner:ALSTOM TECH LTD

New type of ceramic triple change valve

The new-type of ceramic triple change valve can resist scour and wear of medium on the cock, valve body and valve channel and the self-wear of the sealing plane and the sealing pair, and has long service life. The present invention features the sealing ceramic rings in proper positions of cock and valve seat; ceramic lining pipe in the channel, inlet and outlet; the eccentric structure of the cock and the valve body and the connection between central shaft of regulating rotation mechanism and the cock via the valve body axis. The present invention may be used in control and conveyance of medium with particles.

Owner:天津市圣恺工业技术发展有限公司

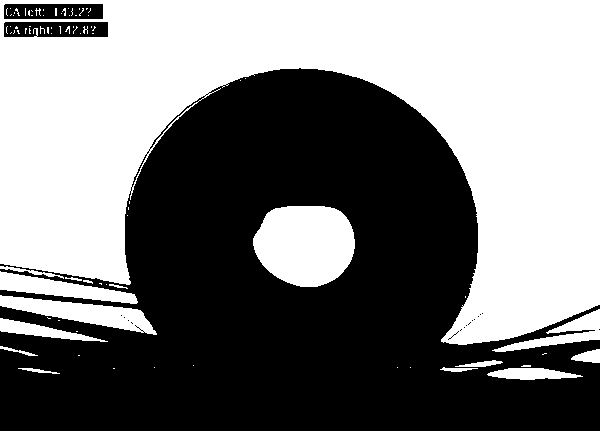

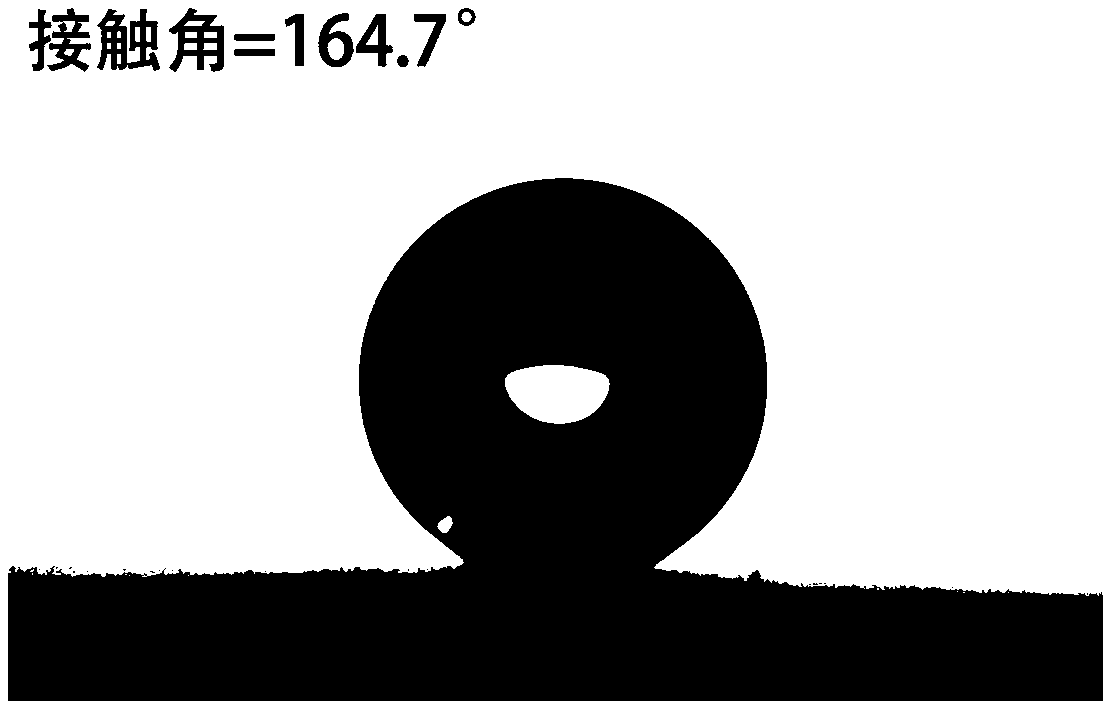

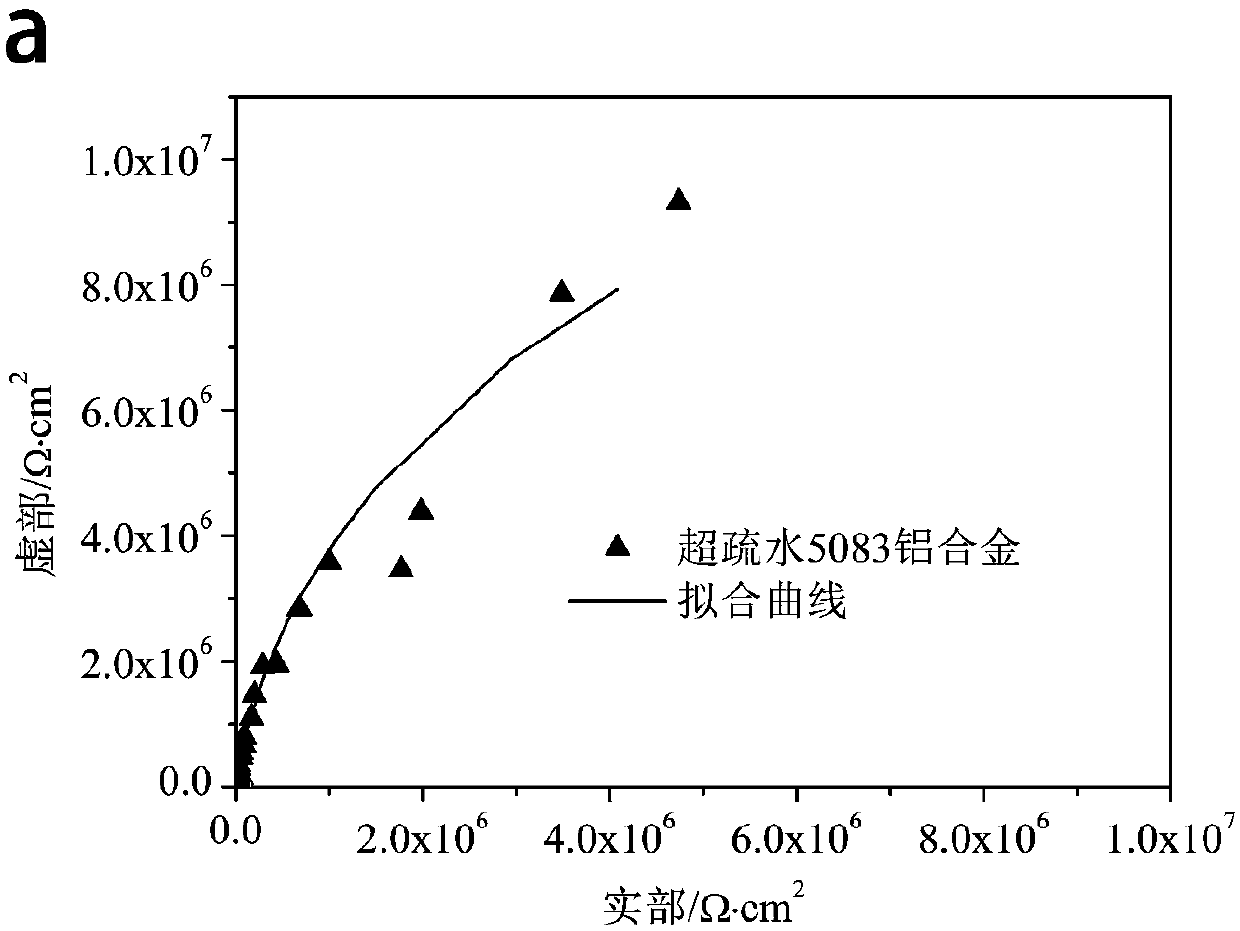

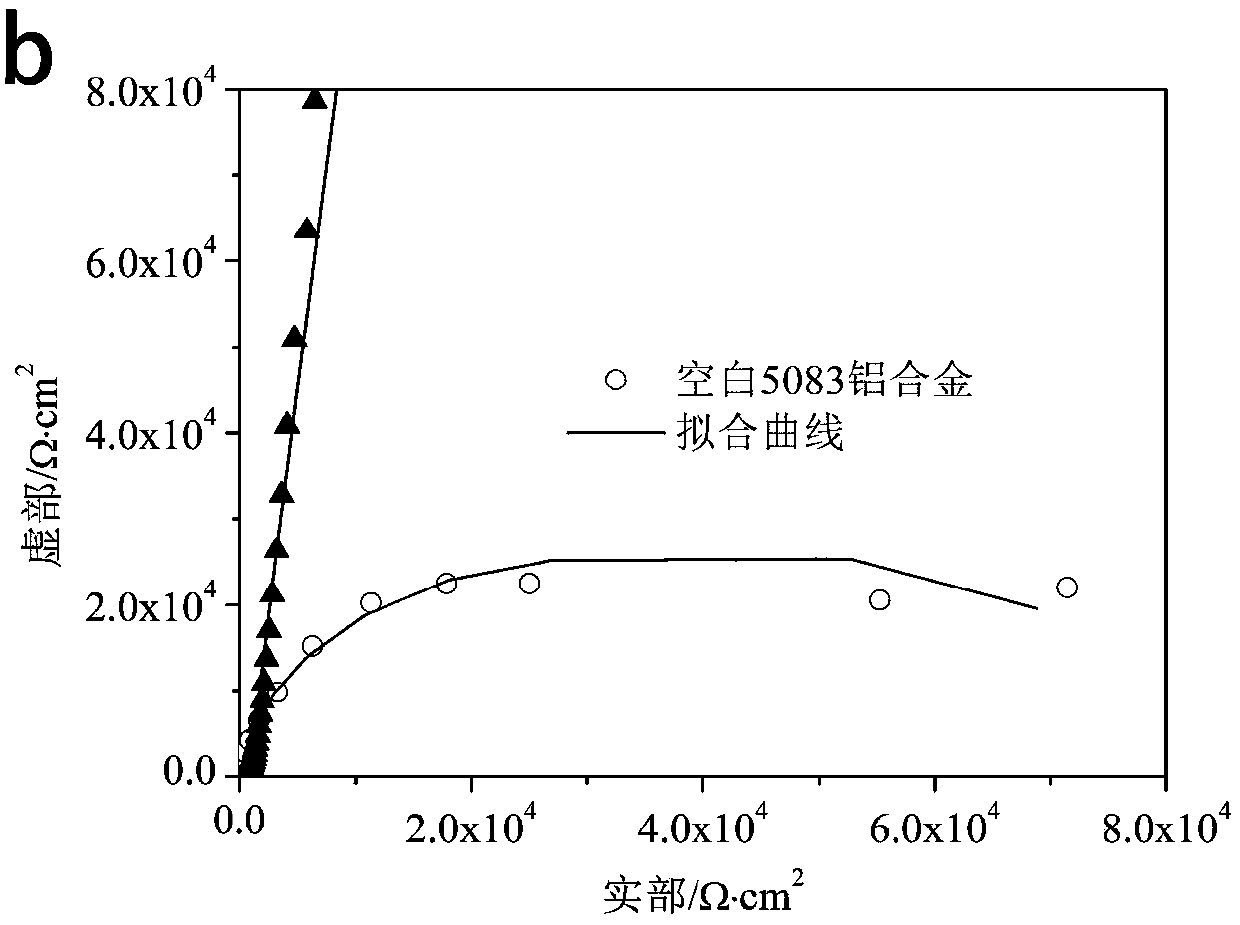

Preparation method for abrasion resistant superhydrophobic surface

InactiveCN109628978AThe preparation process is simpleGood repeatabilitySurface reaction electrolytic coatingElectrolyteHydrophobic surfaces

The invention relates to the field of metal surface treatments and modifications, in particular to a preparation method for an abrasion resistant superhydrophobic surface. A surface-treated substrateis subjected to constant voltage anodization in an aqueous solution with an oxalic acid solution as an electrolyte solution, and then is subjected to low surface energy molecular modification and heattreatment after anodization, so that the abrasion-resistant superhydrophobic surface is formed on the surface of the substrate. The method has the advantages of simple preparation process, good repeatability, low cost and convenient wide promotion, and the obtained superhydrophobic surface has a contact angle reaching 164.7 DEG, has excellent properties of self-cleaning, abrasion resistance and corrosion resistance, and has broad application prospects in ocean corrosion and protection field.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com