Polyvinyl alcohol size boiling technology and textile fiber sizing technology

A polyvinyl alcohol and textile fiber technology, applied in the textile field, can solve problems such as reducing product quality, affecting weaving efficiency, and increasing the difficulty of weaving in the weaving process, achieving the effect of maintaining stable wear resistance and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

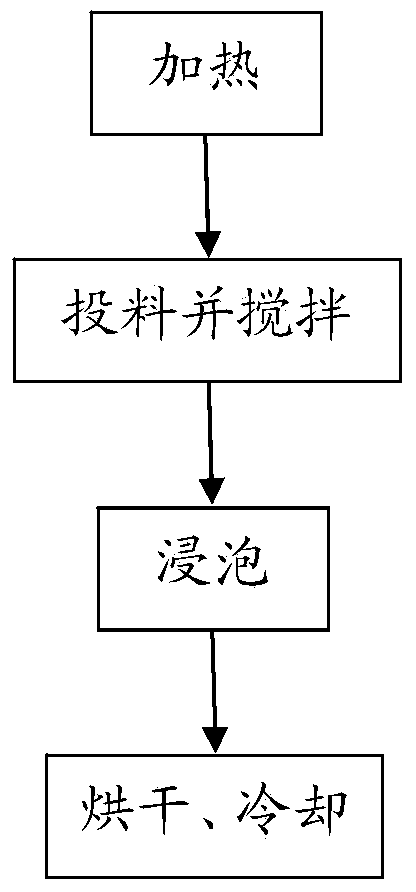

Method used

Image

Examples

Embodiment Construction

[0020] The present invention discloses a process for boiling polyvinyl alcohol, which comprises: after heating water to 88-92°C, adding solid polyvinyl alcohol into the water at a feeding rate of 11.11 g / s, and stirring, After the solid polyvinyl alcohol is completely dissolved, a polyvinyl alcohol slurry is formed.

[0021] Preferably, the water is heated to 90°C.

[0022] Preferably, the stirring step is synchronized with the step of adding solid polyvinyl alcohol.

[0023] As a further improvement of the present invention, the duration of the input of solid polyvinyl alcohol is 30 minutes.

[0024] The present invention also discloses a textile fiber sizing process using the above-mentioned cooking process, which includes: heating the water to 88-92°C, and throwing solid polyethylene into the water at a feeding rate of 11.11g / s After the solid polyvinyl alcohol is completely dissolved, a polyvinyl alcohol slurry is formed, and the spinning fiber is fully immersed in the formed pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com