Long-life silicon rubber for peristaltic pump pipes and preparation method of long-life silicon rubber

A silicone rubber and peristaltic pump technology, which is applied in the field of high-life silicone rubber for peristaltic pump tubes and its preparation, can solve the problems of inability to transport fluid, poor elasticity, wear resistance and poor pressure bearing capacity, and achieve improved elasticity and dynamic resistance Fatigue performance, improvement of dynamic fatigue resistance, and uniform distribution of reinforcing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A high-life silicone rubber for peristaltic pump tubes in this embodiment includes the following raw materials in parts by mass:

[0052] 60 parts of methyl vinyl polysiloxane

[0053] 40 parts of reinforcing filler

[0054] Structure control agent 1 part

[0055] 0.2 parts of hydrosilylation catalyst

[0056] 0.5 parts of crosslinking agent

[0057] Inhibitor 0.05 parts

[0058] Release agent 0.1 part.

[0059] Wherein, the mass ratio of the methyl vinyl polysiloxane with vinyl-terminated side chain permethyl to the vinyl-containing methyl vinyl polysiloxane in the methyl-terminated side chain is 1:2 .

[0060] Wherein, the reinforcing filler is a mixture of fumed silica and precipitated silica at a mass ratio of 90:10. The BET method specific surface area of described fumed white carbon black is 200m 2 / g, the BET method specific surface area of the precipitated white carbon black is 150m 2 / g.

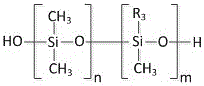

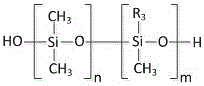

[0061] Wherein, the molecular structure of the structural ...

Embodiment 2

[0070] A high-life silicone rubber for peristaltic pump tubes in this embodiment includes the following raw materials in parts by mass:

[0071] Methyl vinyl polysiloxane 150 parts

[0072] 60 parts of reinforcing filler

[0073] Structure control agent 12 parts

[0074] 1 part of hydrosilylation catalyst

[0075] 2 parts of crosslinking agent

[0076] Inhibitor 0.2 parts

[0077] 0.6 parts of mold release agent.

[0078] Wherein, the mass ratio of the methyl vinyl polysiloxane of the vinyl-terminated side chain permethyl to the vinyl-containing methyl vinyl polysiloxane of the methyl-terminated side chain is 3:1 .

[0079] Wherein, the reinforcing filler is a mixture of fumed silica and precipitated silica at a mass ratio of 95:5. The BET method specific surface area of described fumed white carbon black is 300m 2 / g, the BET method specific surface area of the precipitated white carbon black is 150m 2 / g.

[0080] Wherein, the molecular structure of the structu...

Embodiment 3

[0089] A high-life silicone rubber for peristaltic pump tubes in this embodiment includes the following raw materials in parts by mass:

[0090] Methyl vinyl polysiloxane 80 parts

[0091] 45 parts of reinforcing filler

[0092] Structure control agent 3 parts

[0093] 0.3 parts of hydrosilylation catalyst

[0094] 0.6 parts of crosslinking agent

[0095] Inhibitor 0.08 part

[0096] Release agent 0.3 part

[0097] Additive 0.05 part.

[0098] Wherein, the mass ratio of the vinyl-terminated side chain permethyl methyl vinyl polysiloxane to the methyl-terminated side chain vinyl-containing methyl vinyl polysiloxane is 1:1 .

[0099] Wherein, the additive is a six-membered ring compound containing a carbon-nitrogen unsaturated bond.

[0100] Wherein, the reinforcing filler is a mixture of fumed silica and precipitated silica at a mass ratio of 91:9. The BET method specific surface area of described fumed white carbon black is 220m 2 / g, the BET method specific surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com