Wet dust removal equipment for underground coal mine

A technology of wet dust removal and equipment, which is applied in the field of dust removal equipment, can solve the problems of slow dust removal speed and achieve the effects of increasing contact area, fast speed and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

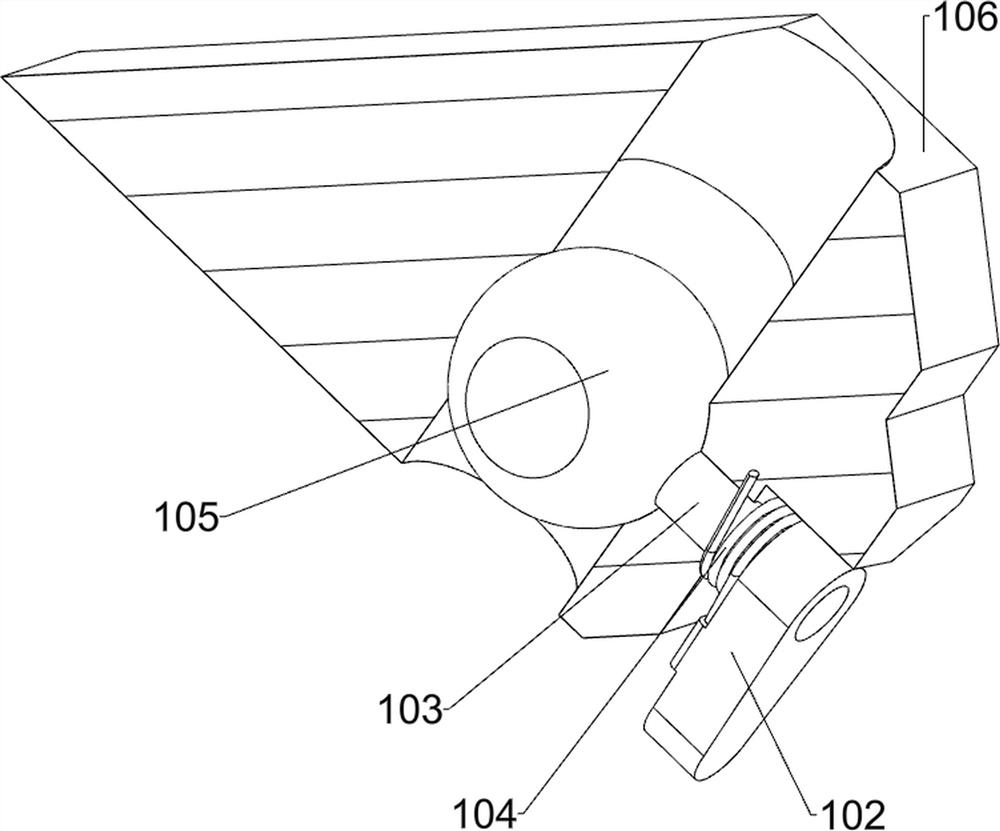

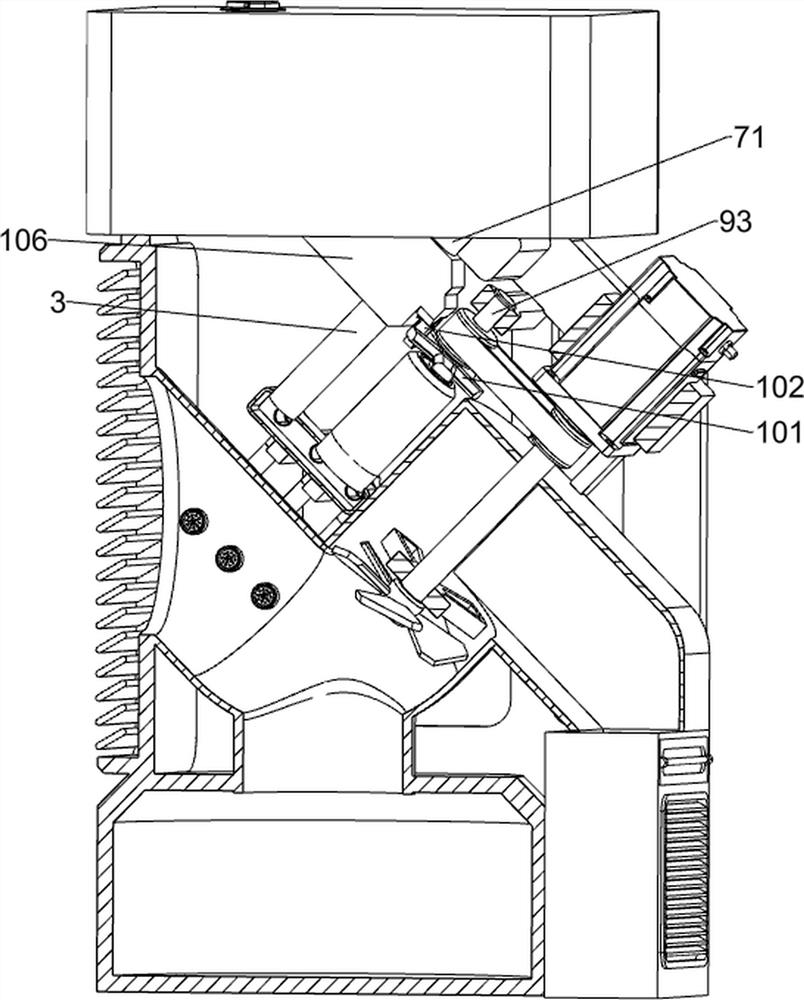

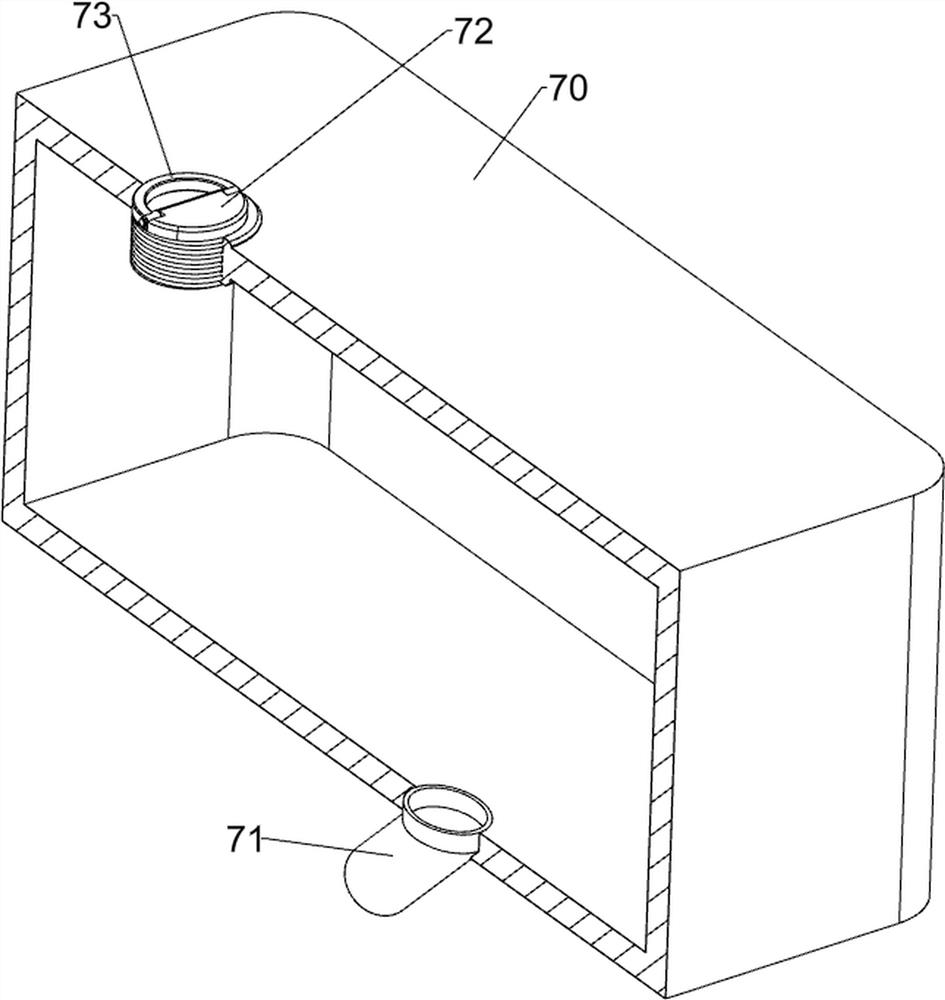

[0035] A kind of wet dust removal equipment used in underground coal mines, such as Figure 1-14 As shown, it includes a mounting bracket 1, a distribution box 2, a first conduit 3, a second conduit 4, a nozzle 5, a protective grille 6, a storage mechanism 7 and an air suction mechanism 8. There are two mounting brackets 1, the left one The right side of the mounting bracket 1 is a hollow structure, the left side of the mounting bracket 1 on the left is fixedly connected with a protective grille 6, and a storage mechanism 7 is arranged between the top of the mounting bracket 1, and the front and rear sides of the left mounting bracket 1 are equally spaced. There are three second conduits 4 fixedly connected to the ground, and the upper part of the second conduits 4 is fixedly connected to the shunt box 2, and the top of the shunt box 2 is fixedly connected to the first conduit 3. Three nozzles 5 are fixedly connected to the ground, and the nozzles 5 are used to spray water mis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com