Lubricating oil and preparation method thereof

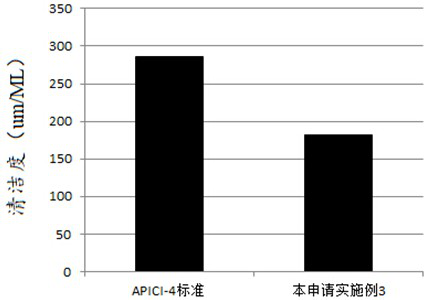

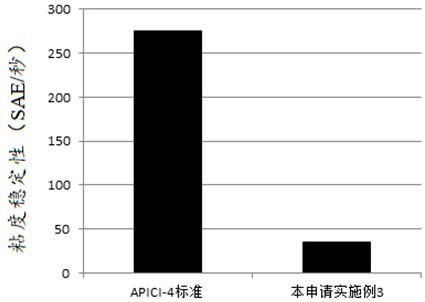

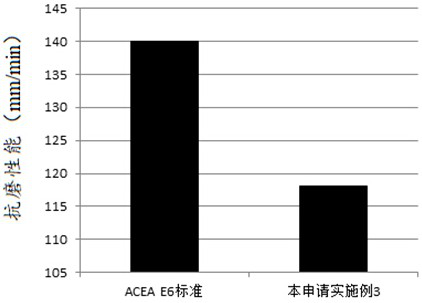

A technology for lubricating oil and raw materials, applied in the field of lubricating oil, can solve the problems of environmental pollution, anti-wear ability, viscosity stability and poor cleaning performance effect, and achieve good fluidity, no damage to machinery and equipment, and a wide range of applications. wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This embodiment provides a kind of lubricating oil, the preparation method of described lubricating oil, comprises the following steps:

[0028] (1) Weigh each raw material and set aside;

[0029] Weigh 100kg of raw materials, including: 10kg of trimethylol alkyl ester, 8kg of pentaerythritol ester, 8kg of alkyl naphthalene, 1kg of surfactant, 1kg of nano-graphene, 6.7kg of borate, 7kg of negative ion material, 0.8kg of fusion agent, 0.4 kg of antiwear agent, 0.8 kg of dispersant, 0.8 kg of extreme pressure agent, 0.8 kg of antioxidant, 6 kg of friction modifier, 1 kg of rust inhibitor; the balance is polyalphaolefin;

[0030] The alkylnaphthalene can be but not limited to methylnaphthalene; the trimethylol alkyl ester can be but not limited to trimethylolpropane trioleate; the anion material can be but not limited to an anion material comprising silicate; The fusion agent adopts rare earth, such as rare earth containing molybdenum or lithium;

[0031] (2) All raw mat...

Embodiment 2

[0033] This embodiment provides a kind of lubricating oil, the preparation method of described lubricating oil, comprises the following steps:

[0034] (1) Weigh each raw material and set aside;

[0035] Weigh 100 kg of raw materials, including: 15 kg of trimethylol alkyl ester, 10 kg of pentaerythritol ester, 10 kg of alkyl naphthalene, 1.25 kg of surfactant, 1.1 kg of nano-graphene, 12 kg of borate, 9 kg of negative ion material, fusion agent 1.2 kg, 0.6 kg of antiwear agent, 1.2 kg of dispersant, 1.2 kg of extreme pressure agent, 1.2 kg of antioxidant, 9 kg of friction modifier, 3 kg of rust inhibitor; the balance is polyalphaolefin;

[0036] The alkylnaphthalene can be but not limited to methylnaphthalene; the trimethylol alkyl ester can be but not limited to trimethylolpropane trioleate; the anion material can be but not limited to an anion material comprising silicate; The fusion agent adopts rare earth, such as rare earth containing molybdenum or lithium;

[0037] (2)...

Embodiment 3

[0039] This embodiment provides a kind of lubricating oil, the preparation method of described lubricating oil, comprises the following steps:

[0040] (1) Weigh each raw material and set aside;

[0041] Weigh 100 kg of raw materials, including: 12 kg of trimethylol alkyl ester, 9 kg of pentaerythritol ester, 8.8 kg of alkyl naphthalene, 1.1 kg of surfactant, 1.05 kg of nano-graphene, 8.3 kg of borate, 8.2 kg of negative ion material, fusion agent 1 kg, 0.5 kg of antiwear agent, 1 kg of dispersant, 1 kg of extreme pressure agent, 1 kg of antioxidant, 8 kg of friction modifier, 2 kg of rust inhibitor; the balance is polyalphaolefin;

[0042] The alkylnaphthalene can be but not limited to methylnaphthalene; the trimethylol alkyl ester can be but not limited to trimethylolpropane trioleate; the anion material can be but not limited to an anion material comprising silicate; The fusion agent adopts rare earth, such as rare earth containing molybdenum or lithium;

[0043] (2) All ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com