Patents

Literature

80results about How to "Reduced deposit formation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermally stable jet prepared from highly paraffinic distillate fuel component and conventional distillate fuel component

InactiveUS6846402B2Improve stabilityReduced deposit formationLiquid organic insulatorsHydrocarbon purification/separationTurbinePetroleum

A stable distillate fuel blend useful as a fuel or as a blending component of a fuel that is suitable for use in turbine engine, said fuel blend prepared from at least one highly paraffinic distillate fuel component having low to moderate branching and at least one conventional petroleum-derived distillate fuel component and a process for preparing same involving the blending of at least two components having antagonistic properties with respect to one another.

Owner:CHEVROU USA INC

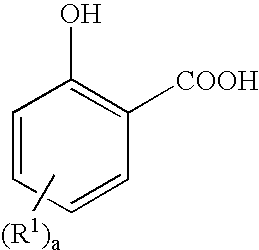

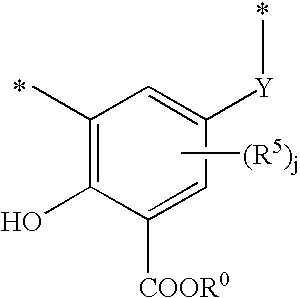

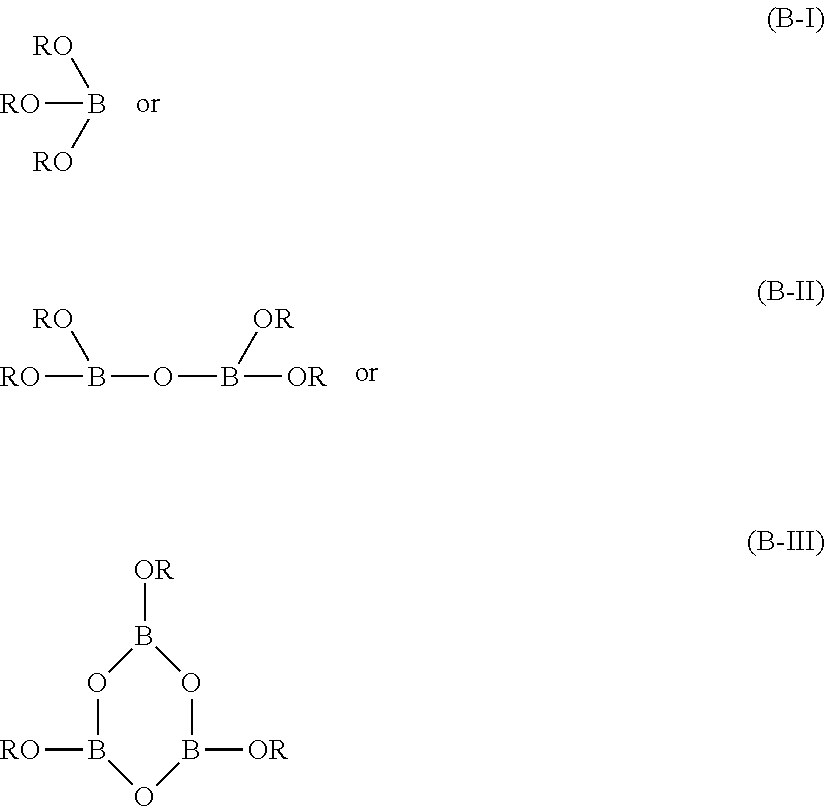

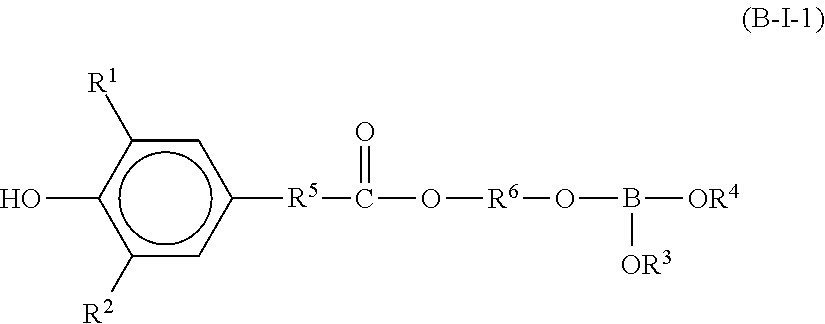

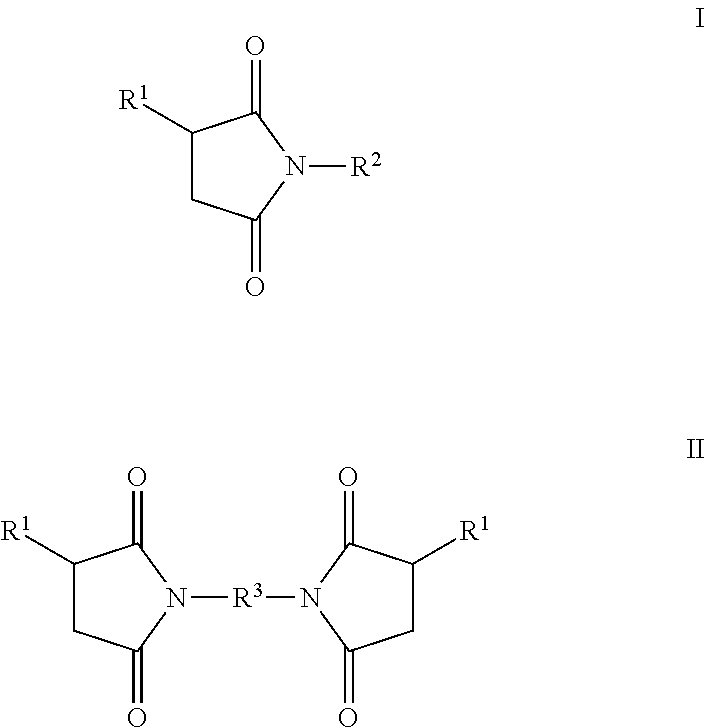

Detergent / anti-oxidant additives for fuels and lubricants

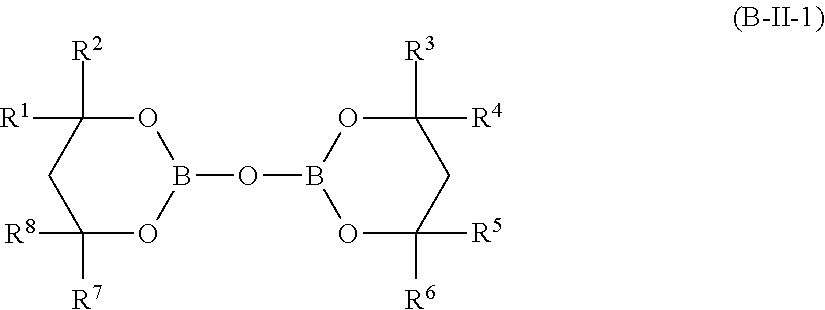

ActiveUS20050172543A1Excellent detergency and cleanliness to an oilImprove antioxidant capacityLiquid carbonaceous fuelsGroup 3/13 element organic compoundsOrganic compoundBoron

A composition is disclosed that comprises the reaction product of an acidic organic compound, a boron compound, and a basic organic compound. The composition is useful as a detergent additive for lubricants and hydrocarbon fuels.

Owner:LANXESS CANADA CO CIE +1

Two-step hydroprocessing method for heavy hydrocarbon oil

ActiveUS20060011510A1Reduce the presence of impuritiesGreat degree of desulfurizationCatalyst activation/preparationHydrocarbon oil crackingHydrogenSulfur

A method is disclosed for hydroprocessing a heavy hydrocarbon oil, comprising a first hydroprocessing step of bringing a heavy hydrocarbon oil into contact with a Catalyst (1) with a certain specific surface area and pore size distribution in the presence of hydrogen in a first reaction zone containing the Catalyst (1), and a second hydroprocessing step of bringing the hydroprocessed oil obtained from the first reaction zone into contact with a Catalyst (2) with a certain specific surface area and pore size distribution in the presence of hydrogen in a second reaction zone containing the Catalyst (2). The method is an improvement in decreasing or inhibiting the sediment formation, while highly hydroprocessing a heavy hydrocarbon oil containing a large amount of impurities such as sulfur, micro carbon residue (MCR), metals, nitrogen and asphaltene, especially a heavy oil containing a large amount of heavy vacuum residue, to adequately remove the impurities.

Owner:EXXON RES & ENG CO

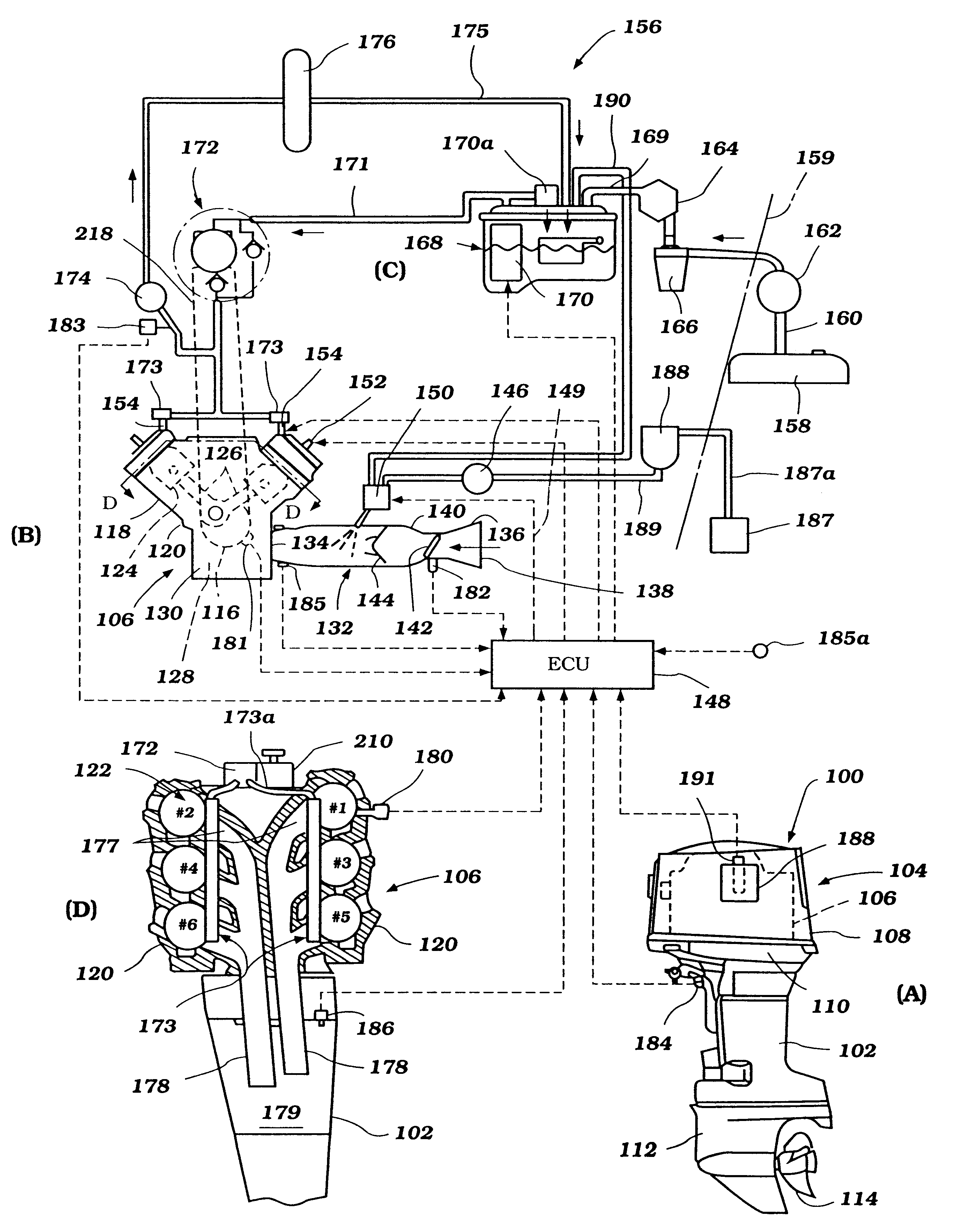

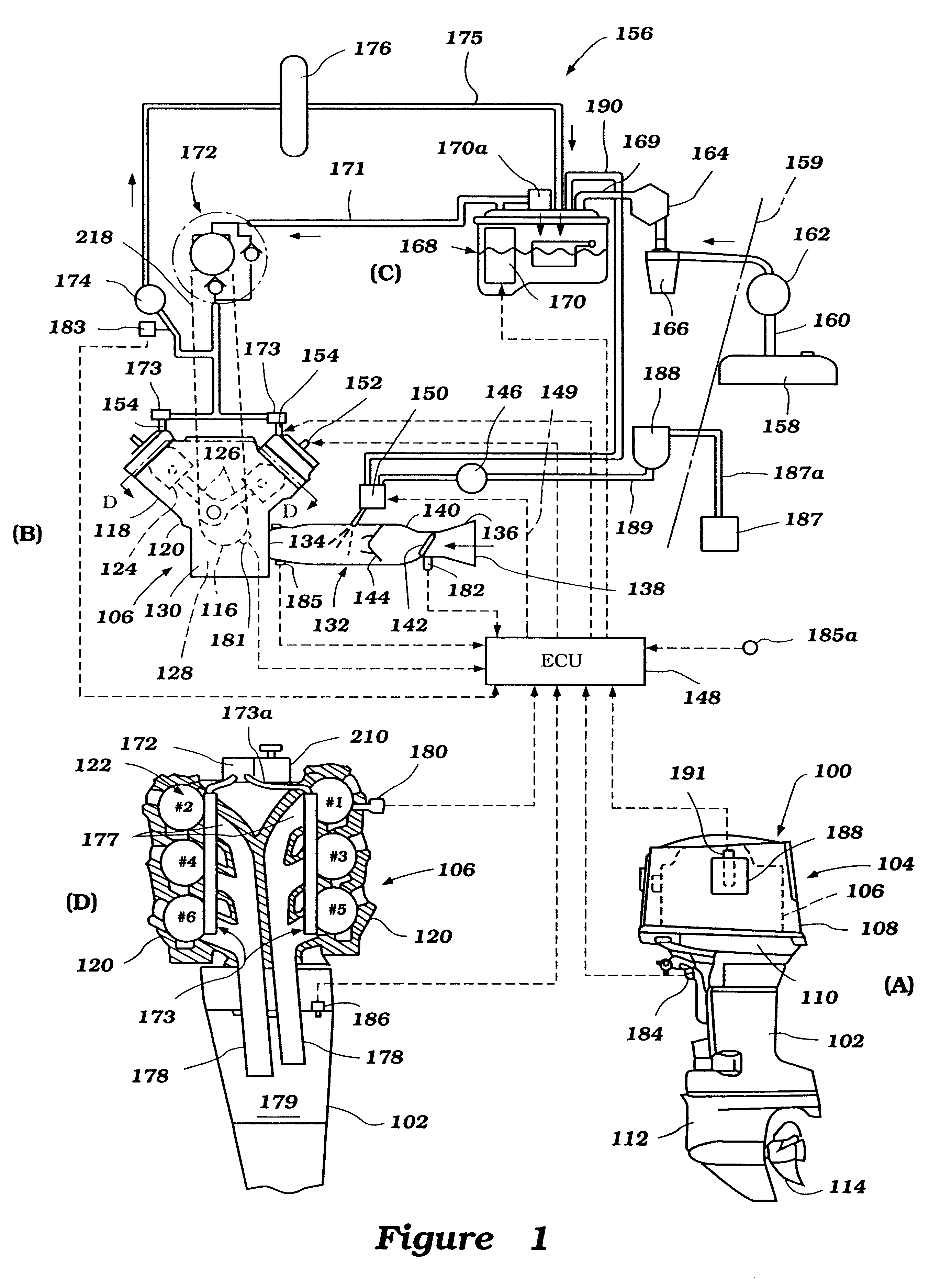

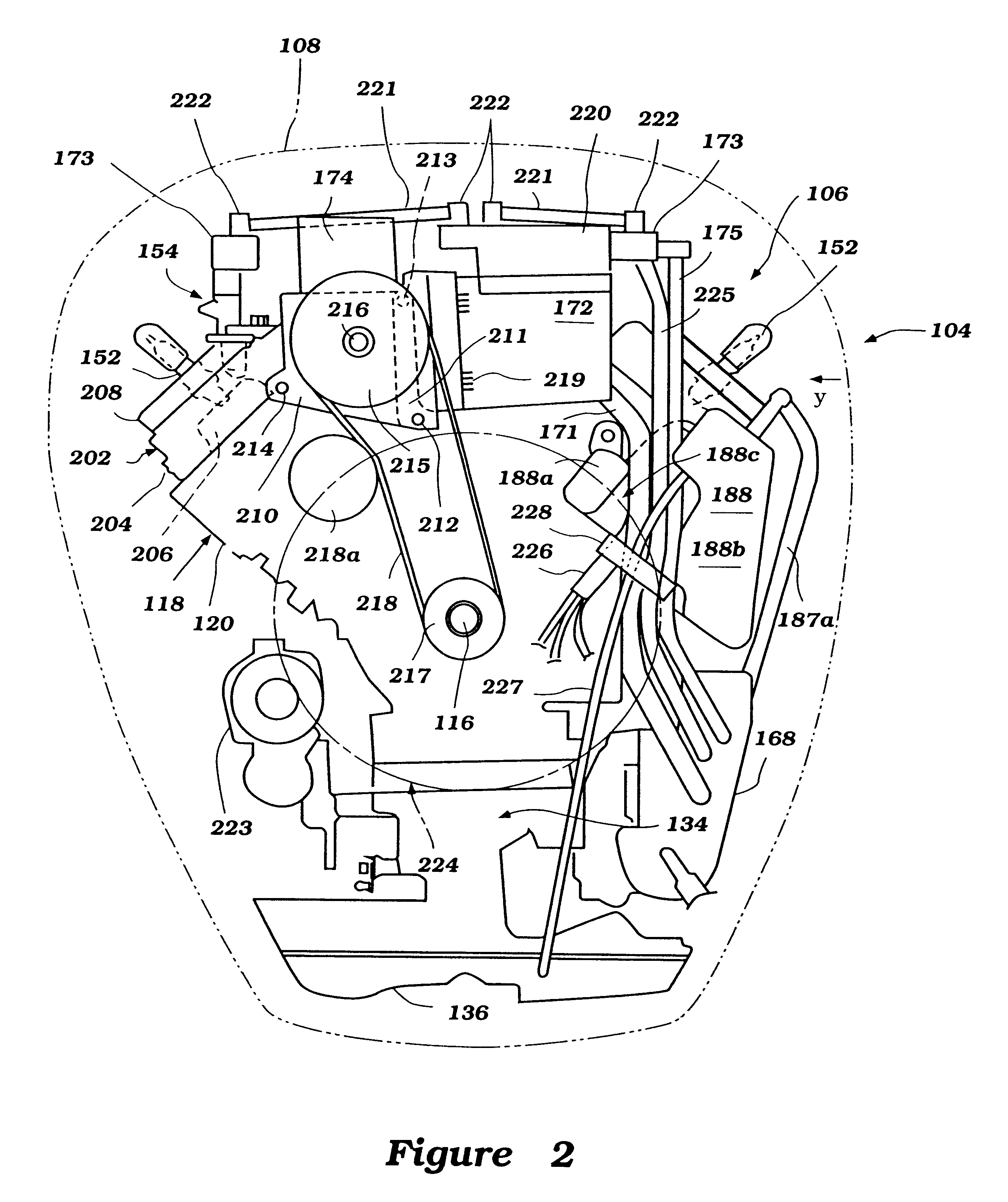

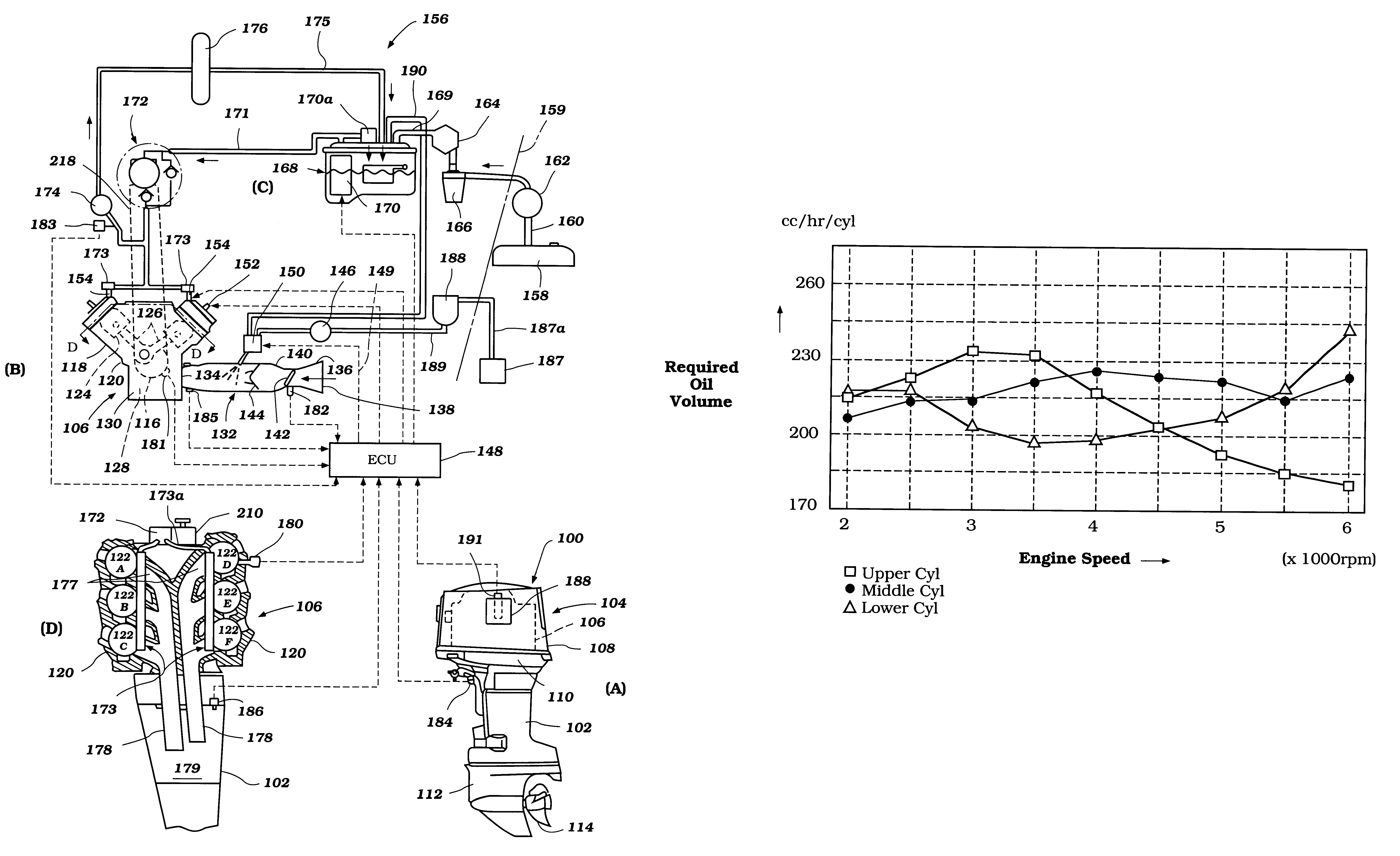

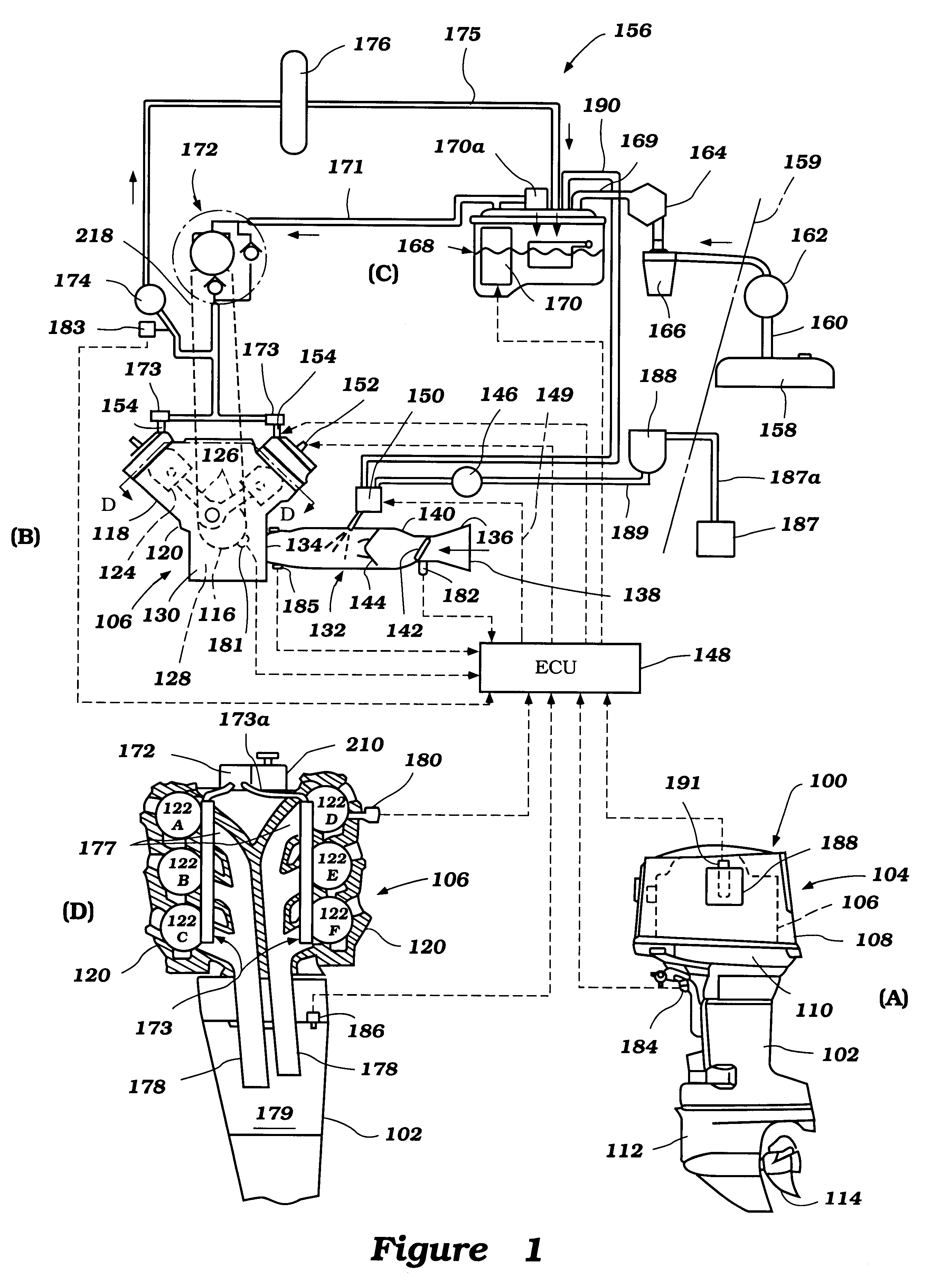

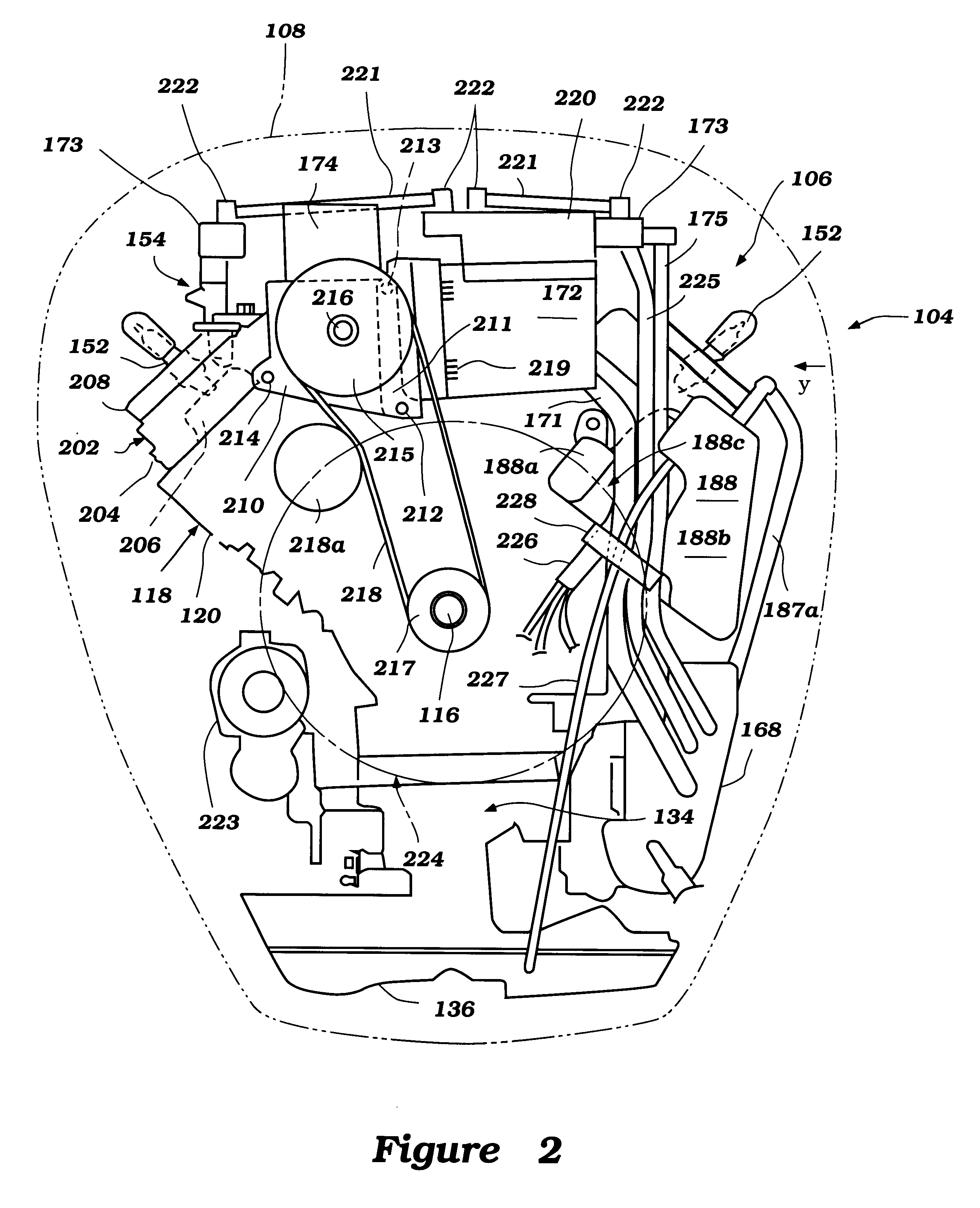

Oil injection lubrication system and methods for two-cycle engines

InactiveUS6422183B1Reduced deposit formationAvoid corrosionCombustion enginesEngine operating parametersSolenoid valveControl signal

The present invention provides an improved oil injection lubrication system for two-cycle engines. The system includes a variable output oil pump, the output of which can be varied in relation to the throttle level. The system also includes a solenoid valve unit containing a plurality of solenoid valves that regulate the flow of oil from the oil pump to each cylinder. The electronic control unit sends control signals to the solenoid valve unit to regulate the flow of oil based upon factors relating to the operation of the engine in accordance with a control scheme. The factors may include those that apply to all of the engine's cylinders (i.e., do not vary between the cylinders), such as intake air temperature, atmospheric pressure, battery voltage, engine break-in period, and load frequency among others.

Owner:SANSHIN KOGYO CO LTD

Thermally stable blends of highly paraffinic distillate fuel component with conventional distillate fuel component

InactiveUS20060049080A1Minimize deposit formationHigh aromatic contentLiquid organic insulatorsHydrocarbon purification/separationProcess engineeringInternal combustion engine

A stable distillate fuel blend useful as a fuel or as a blending component of a fuel that is suitable for use in an internal combustion engine, said fuel blend prepared from at least one highly paraffinic distillate fuel component and at least one highly aromatic petroleum-derived distillate fuel component and a process for preparing same involving the blending of at least two components having antagonistic properties with respect to one another.

Owner:CHEVROU USA INC

Two-step hydroprocessing method for heavy hydrocarbon oil

ActiveUS7491313B2Reduce the presence of impuritiesGreat degreeCatalyst activation/preparationHydrocarbon oil crackingPtru catalystPhysical chemistry

A method is disclosed for hydroprocessing a heavy hydrocarbon oil, comprising a first hydroprocessing step of bringing a heavy hydrocarbon oil into contact with a Catalyst (1) with a certain specific surface area and pore size distribution in the presence of hydrogen in a first reaction zone containing the Catalyst (1), and a second hydroprocessing step of bringing the hydroprocessed oil obtained from the first reaction zone into contact with a Catalyst (2) with a certain specific surface area and pore size distribution in the presence of hydrogen in a second reaction zone containing the Catalyst (2). The method is an improvement in decreasing or inhibiting the sediment formation, while highly hydroprocessing a heavy hydrocarbon oil containing a large amount of impurities such as sulfur, micro carbon residue (MCR), metals, nitrogen and asphaltene, especially a heavy oil containing a large amount of heavy vacuum residue, to adequately remove the impurities.

Owner:EXXON RES & ENG CO

Catalysts having selected pore size distributions, method of making such catalysts, methods of producing a crude product, products obtained from such methods, and uses of products obtained

ActiveUS8114806B2Long useful lifeHigh viscosityRefining with non-metalsLiquid organic insulatorsPore diameterPeriodic table

A catalyst and a method of preparation of said catalyst is described herein. The catalyst includes one or more metals from Columns 6-10 of the Periodic Table and / or one or more compounds of one or more metals from Columns 6-10 of the Periodic Table, a pore size distribution with a median pore diameter ranging from 105 Å to 150 Å, with 60% of the total number of pores in the pore size distribution having a pore diameter within 60 Å of the median pore diameter, with at least 50% of its pore volume in pores having a pore diameter of at most 600 Å, and between 5% and 25% of its pore volume in pores having a pore diameter between 1000 Å and 5000 Å. Methods of producing said catalyst are described herein. Crude products and products made from said crude products are described herein.

Owner:SHELL OIL CO

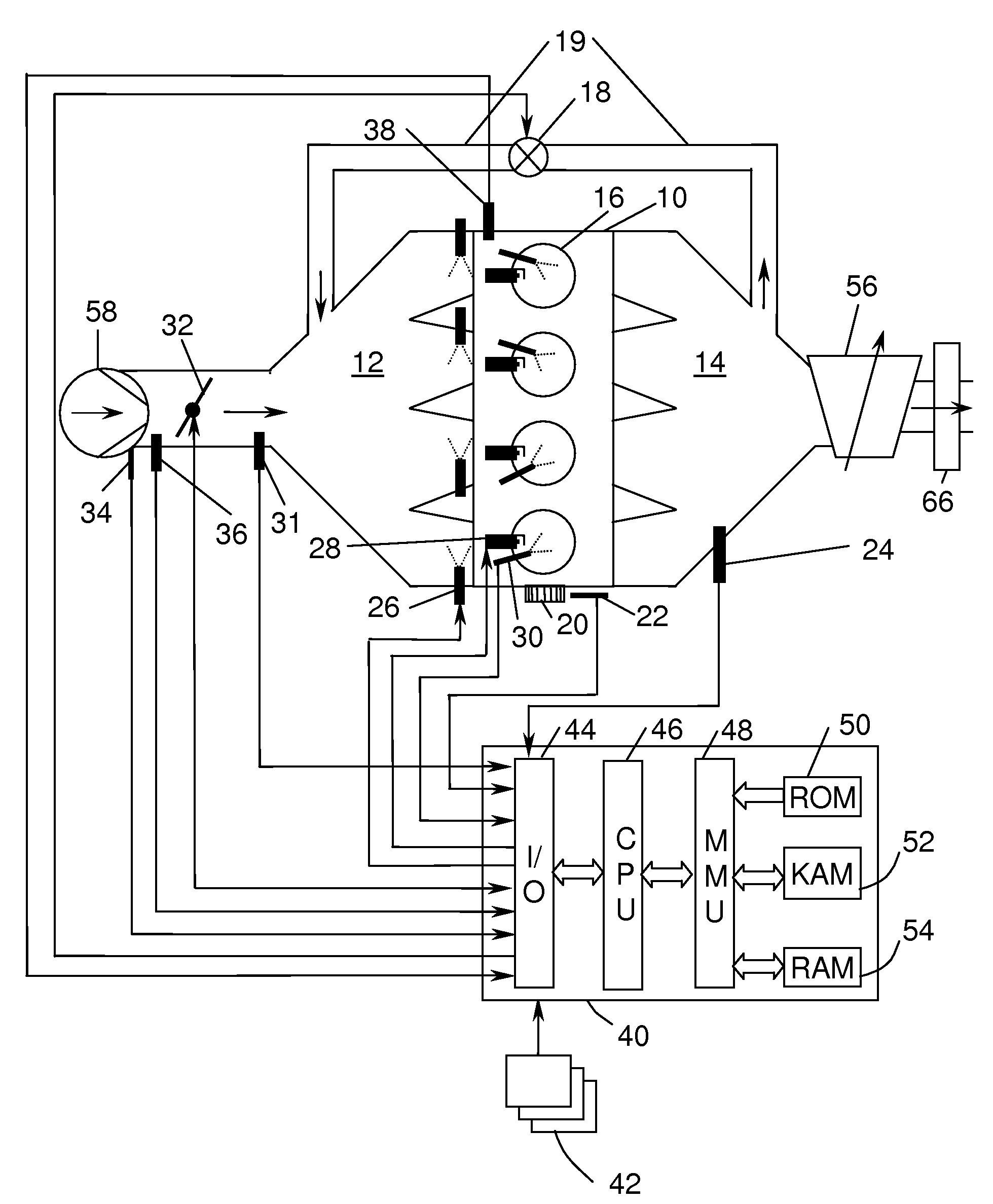

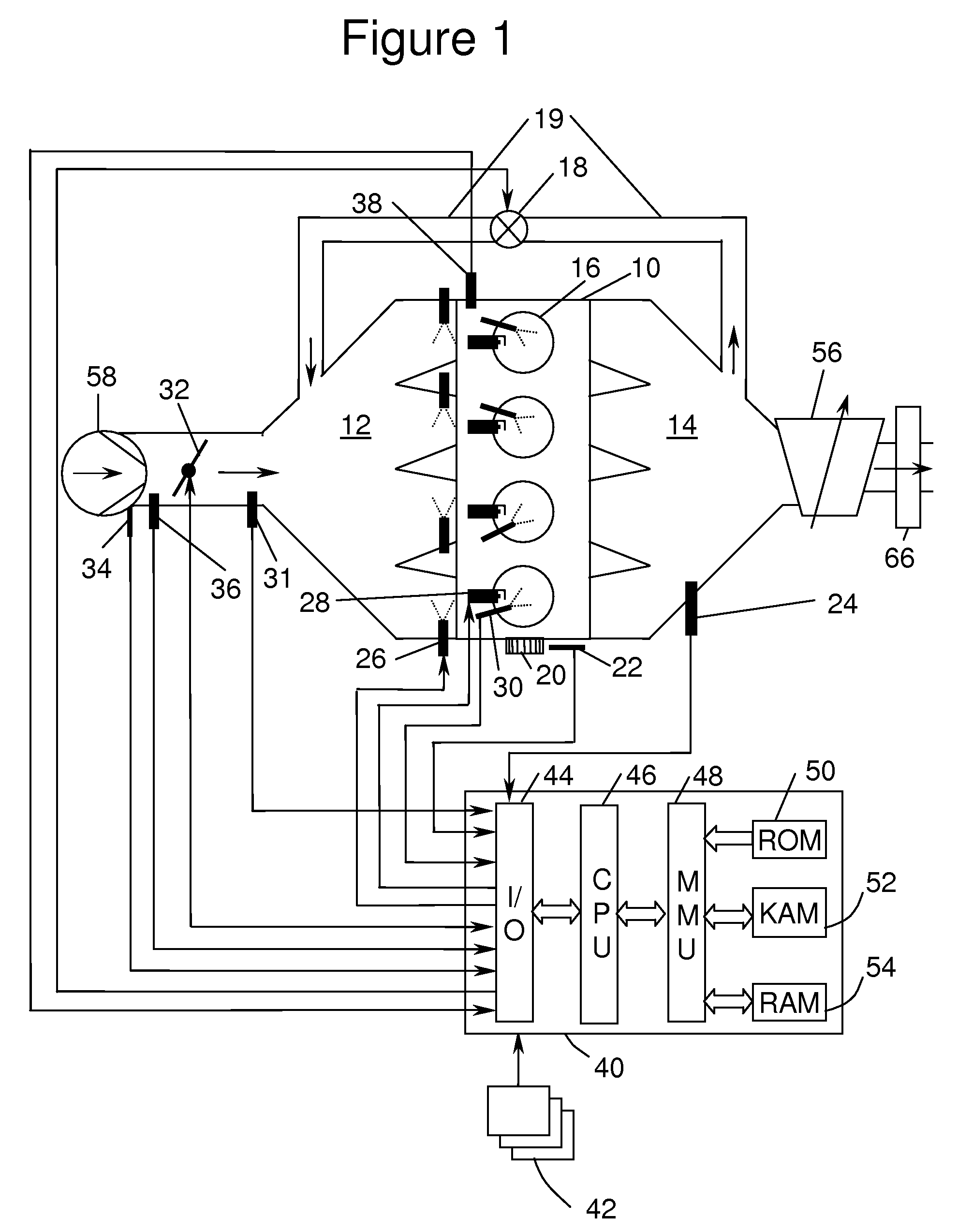

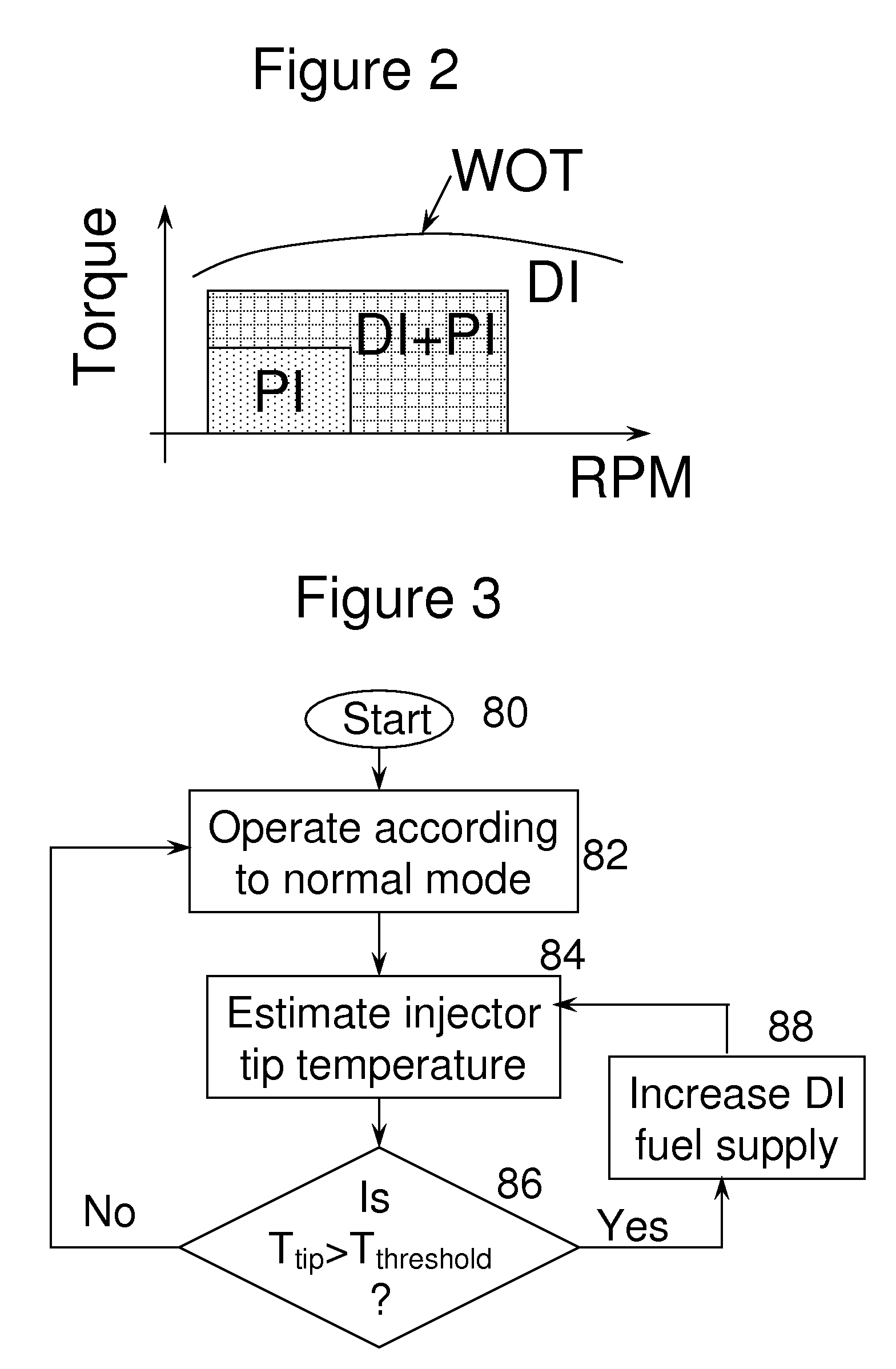

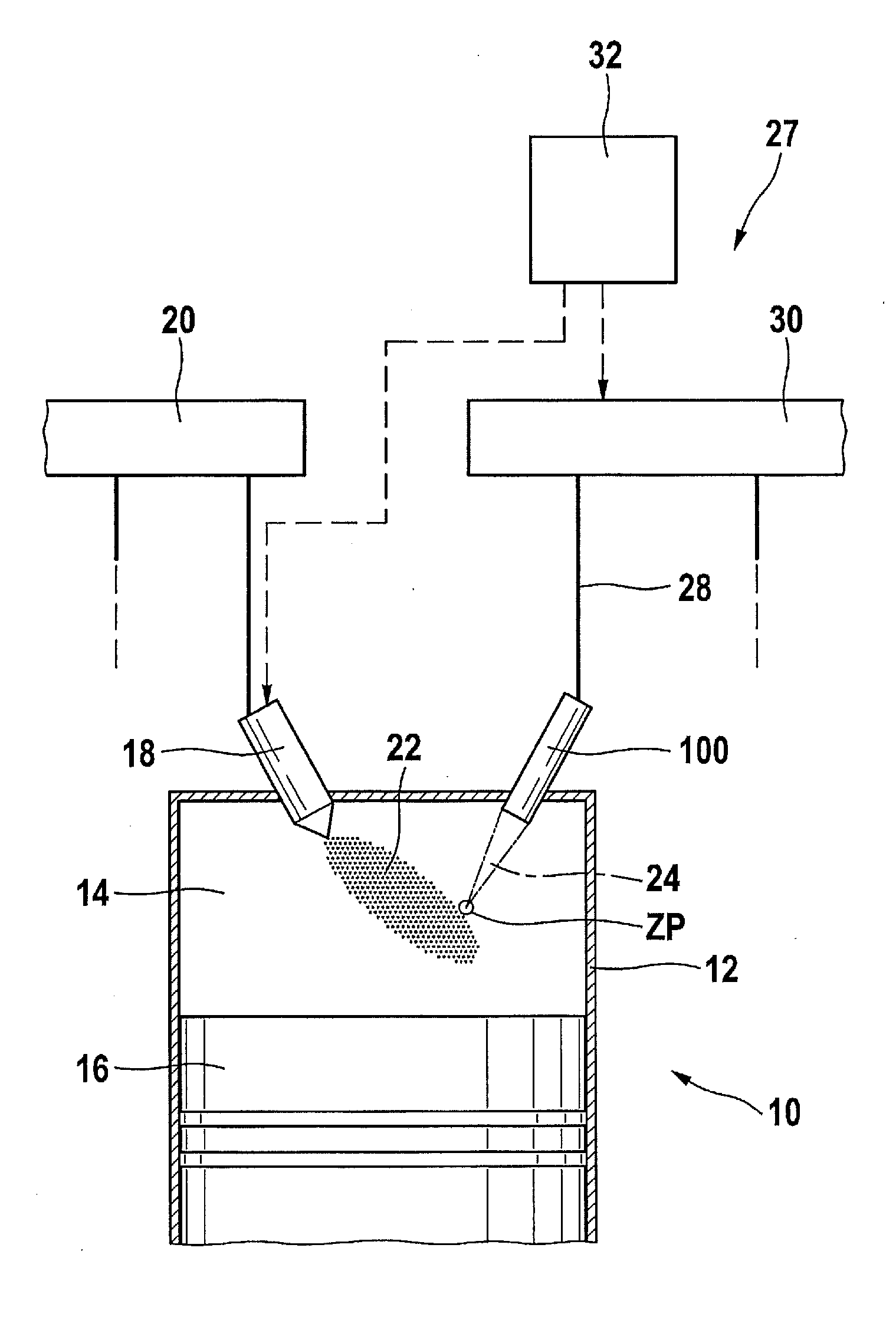

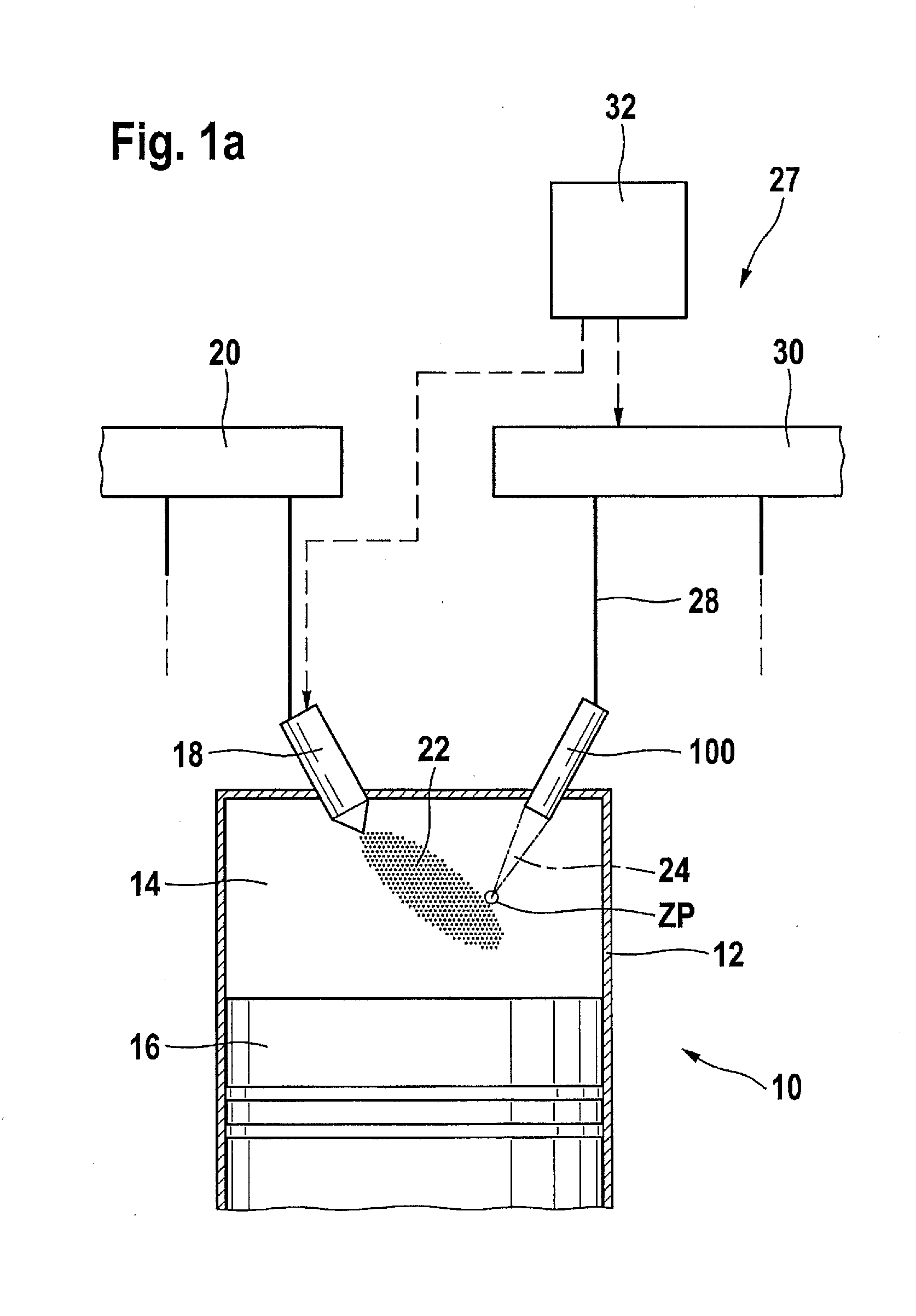

Method and System to Mitigate Deposit Formation on a Direct Injector for a Gasoline-Fuelled Internal Combustion Engine

InactiveUS20090090332A1Reduced deposit formationInhibition formationElectrical controlInternal combustion piston enginesGasoline fuelExternal combustion engine

In an internal combustion engine having both a port injector and a direct injector supplying fuel to a cylinder of the engine, a method is disclosed for avoiding deposit formation on and / or inside the tip of the direct injector. The tip temperature is estimated. When the tip temperature exceeds a threshold temperature at which deposits are formed, the amount of fuel delivered by the direct injector is increase.

Owner:FORD GLOBAL TECH LLC

Method of producing a crude product

InactiveUS20120116145A1Long useful lifeHigh viscosityRefining with metalsCatalyst activation/preparationPore diameterMetal

A method of producing a crude product from a hydrocarbon feed is provided. A hydrocarbon feed is contacted with a catalyst containing a Col. 6-10 metal or compound thereof to produce the crude product, where the catalyst has a pore size distribution with a median pore diameter ranging from 105 Å to 150 Å, with 60% of the total number of pores in the pore size distribution having a pore diameter within 60 Å of the median pore diameter, with at least 50% of its pore volume in pores having a pore diameter of at most 600 Å, and between 5% and 25% of its pore volume in pores having a pore diameter between 1000 Å and 5000 Å.

Owner:SHELL OIL CO

Method of Operating an Engine Using an Ashless Consumable Lubricant

ActiveUS20110297122A1Reduced deposit formationReduce wearElectrical controlNon-fuel substance addition to fuelSulfateEngineering

The present invention relates to methods of using a low sulfur, low phosphorus, low-ash, zinc free consumable lubricating composition in an internal combustion engine equipped with a pilot ignition system, where the composition comprises: an oil of lubricating viscosity; a high TBN succinimide dispersant and where the lubricant composition overall has a sulfated ash value of up to about 0.2, a phosphorus content of up to about 50 to about 800 ppm and a sulfur content of up to about 0.4 percent by weight.

Owner:THE LUBRIZOL CORP

Trunk piston engine lubricating oil compositions

ActiveUS20110077179A1Reduced deposit formationReduce formationOrganic compound preparationLiquid carbonaceous fuelsPistonChemical composition

A trunk piston engine lubricating oil composition is disclosed. The trunk piston engine lubricating oil composition includes at least (a) a major amount of a basestock selected from the group consisting of at least one Group III basestock, at least one Group IV basestock and mixtures thereof; (b) at least one detergent additive; and (c) at least one dispersant additive; wherein the concentration of the at least one dispersant additive in the trunk piston engine lubricating oil composition is at least about 0.1 wt. % on an actives basis, based on the total weight of the lubricating oil composition.

Owner:CHEVRON ORONITE CO LLC

Fuel compositions comprising hydrocarbon oil carriers and methods for using the same

ActiveUS20080034647A1Reduced deposit formationImprove performanceInternal combustion piston enginesLiquid carbonaceous fuelsCombustion chamberInlet valve

The use of fuel compositions comprising selected hydrocarbon oils as carriers for detergents has been found to reduce deposit formation as well as prolong the functionality of fuel injectors. The selection and utilization of particularly characterized hydrocarbon oils as detergent carriers reduces intake valve deposits and combustion chamber deposits, in comparison to conventionally used carrier fluids.

Owner:AFTON CHEMICAL

Fuel compositions comprising hydrocarbon oil carriers and methods for using the same

ActiveUS8231695B2Reduced deposit formationImprove performanceInternal combustion piston enginesLiquid carbonaceous fuelsCombustion chamberInlet valve

The use of fuel compositions comprising selected hydrocarbon oils as carriers for detergents has been found to reduce deposit formation as well as prolong the functionality of fuel injectors. The selection and utilization of particularly characterized hydrocarbon oils as detergent carriers reduces intake valve deposits and combustion chamber deposits, in comparison to conventionally used carrier fluids.

Owner:AFTON CHEMICAL

Heavy feed HPC process using a mixture of catalysts

ActiveUS8012343B2High economic valueEconomic valueRefining with metalsCatalytic crackingSedimentHydrocarbon

The present invention pertains to a process for the hydroprocessing of heavy hydrocarbon feeds, preferably in an ebullating bed process, by contacting the feed with a mixture of two hydroprocessing catalysts meeting specified pore size distribution requirements. The process combines high contaminant removal with high conversion, low sediment formation, and high process flexibility.

Owner:ALBEMARLE NETHERLANDS BV

Fuel compositions

ActiveUS20100075876A1Reduces sediment formationReduced deposit formationLiquid carbonaceous fuelsAdditivesFatty acid methyl esterPhenolic antioxidant

There is disclosed a fuel composition comprising (a) a major amount of a middle distillate fuel comprising from about 0.5% to about 30% by weight fatty acid methyl esters, relative to the total amount of the fuel composition; and (b) a minor amount of an additive composition comprising an antioxidant system comprising at least one cyclic amine antioxidant and at least one phenolic antioxidant, and at least one ashless dispersant, wherein said fuel composition demonstrates reduced sediment formation as compared to a fuel composition devoid of the additive composition, and methods of use thereof.

Owner:ADELL GRP INC +1

Lubricant formulations and methods

The embodiments described herein relate to particular formulations and methods that provide reduced engine deposits. The lubricant composition includes a base oil having a NOACK volatility of from about 5 to about 15 and a zinc dialkyl dithio phosphate composition. The zinc dialkyl dithio phosphate composition has at least about 65 mole percent of zinc dialkyl dithio phosphate compounds derived from all primary alcohols, wherein the zinc dialkyl dithio phosphate composition has greater than about 40 mole percent zinc dialkyl dithio phosphate compounds having alkoxy moieties derived from alcohols having four carbon atoms.

Owner:AFTON CHEMICAL

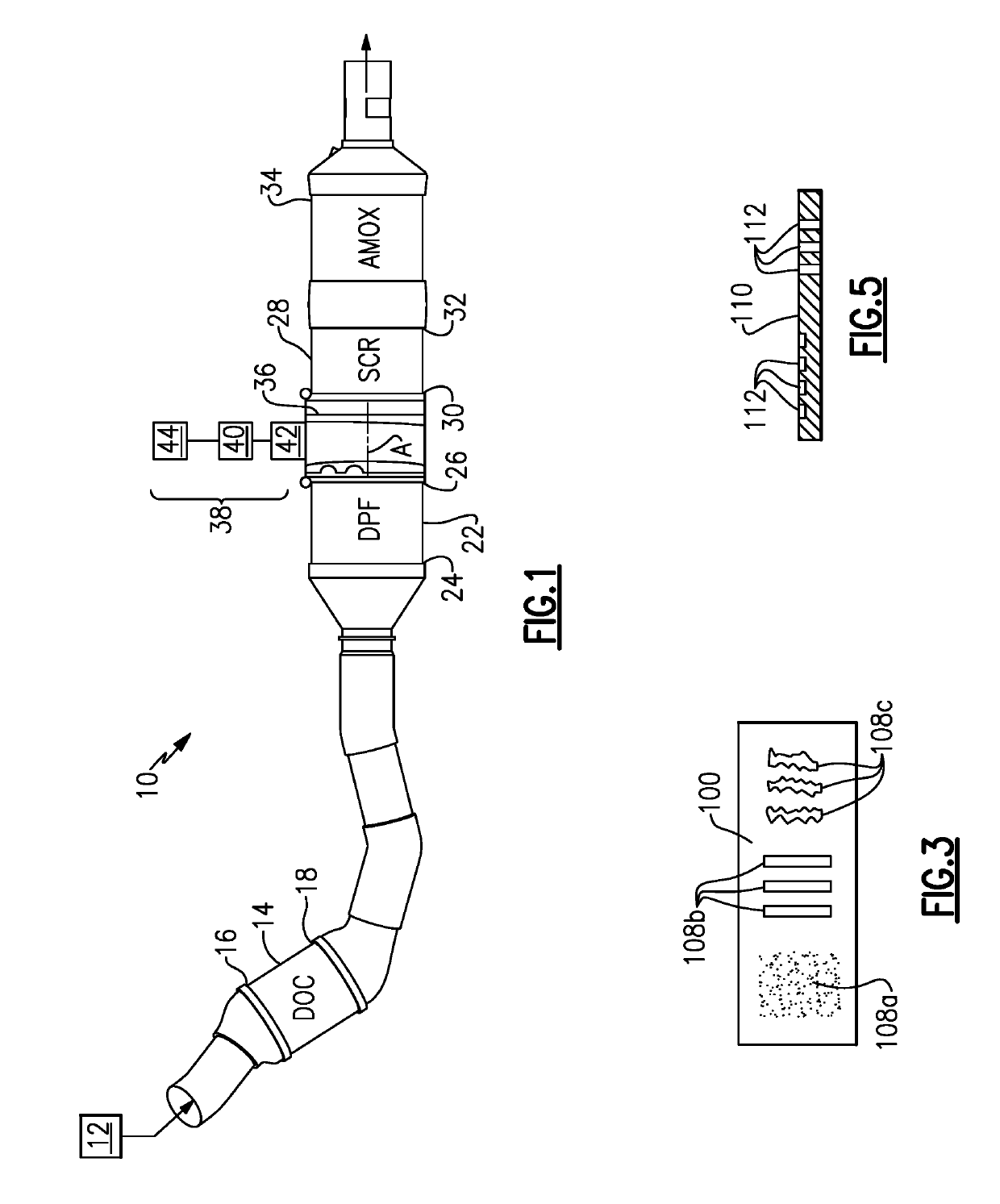

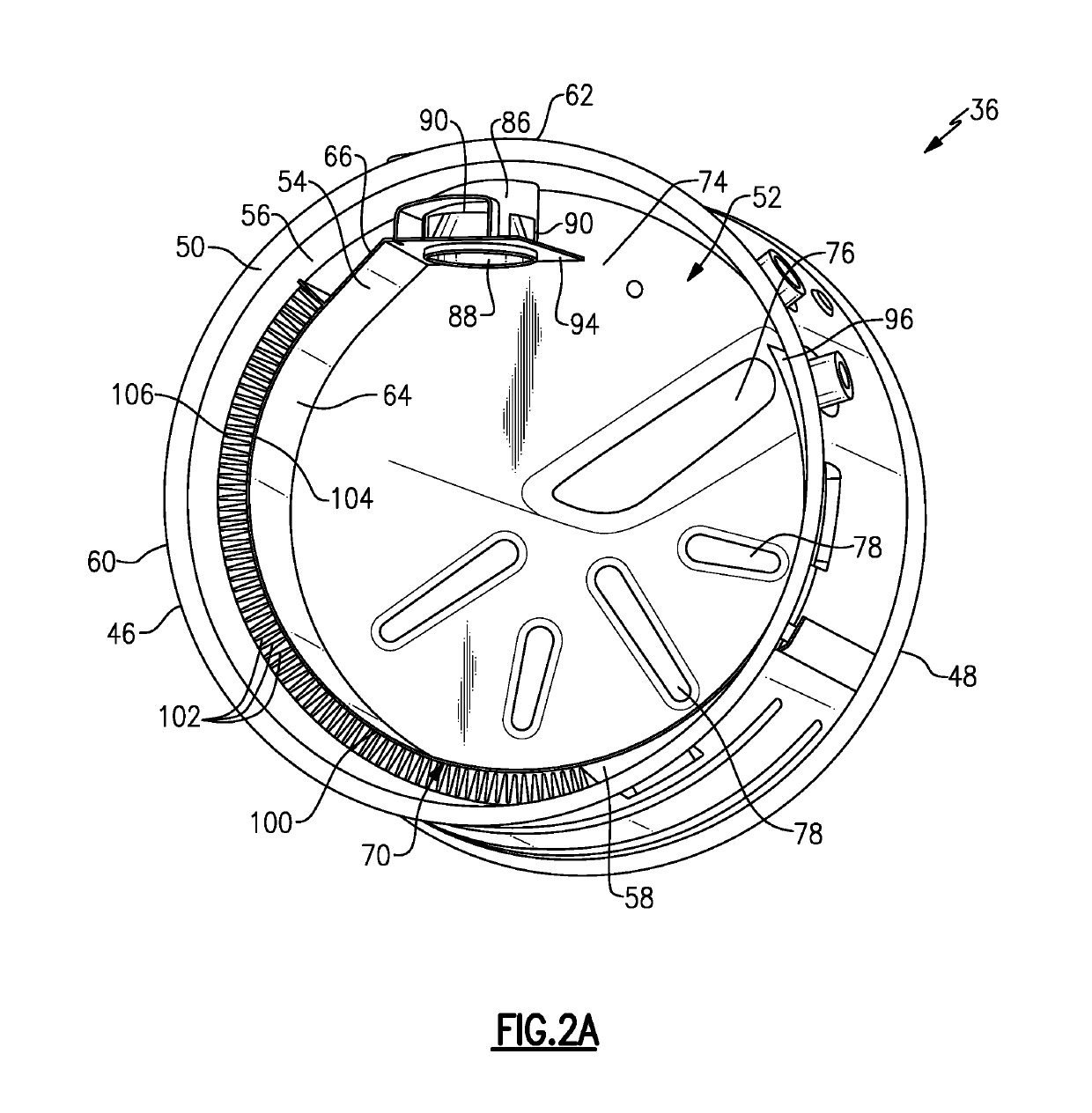

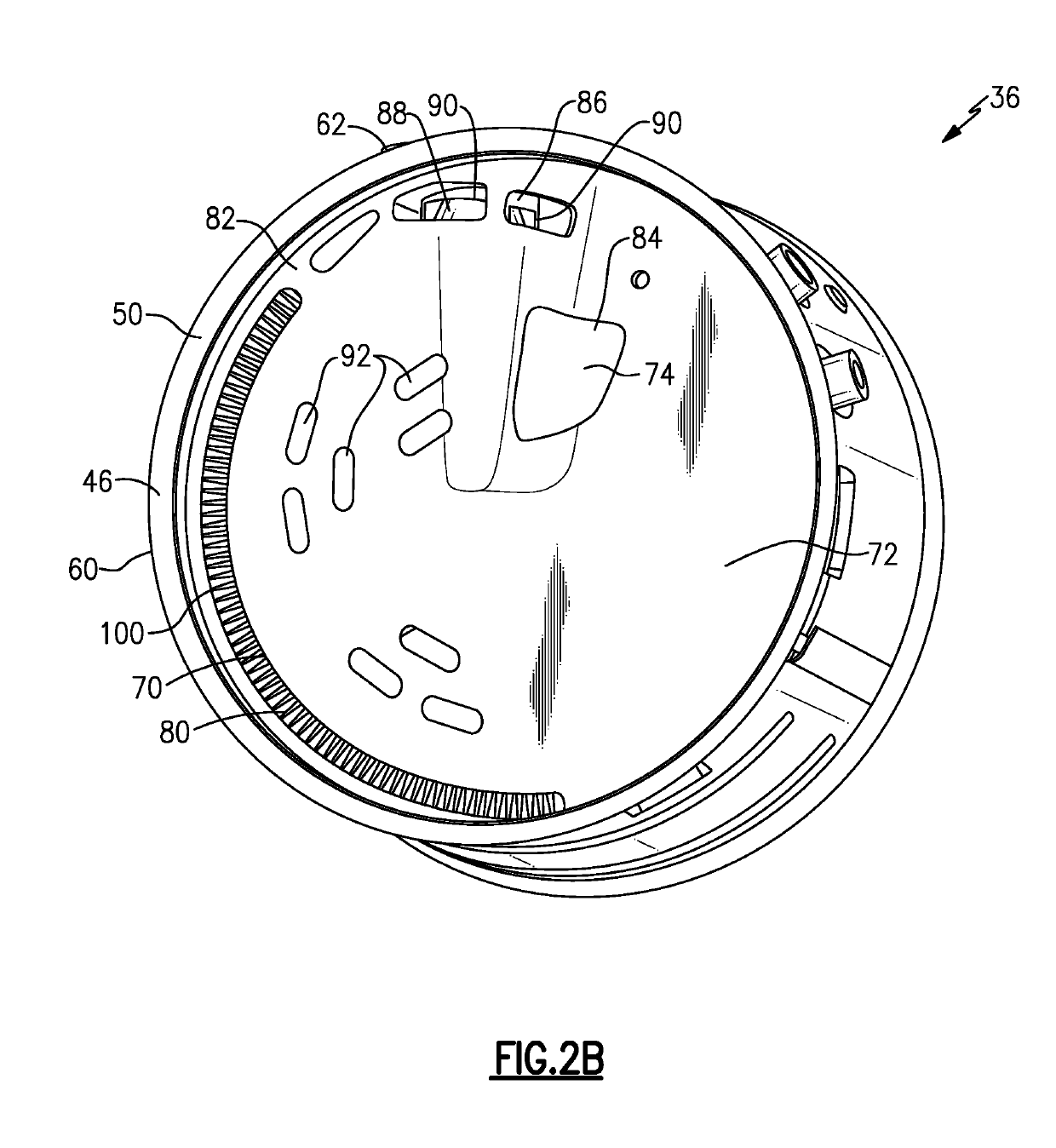

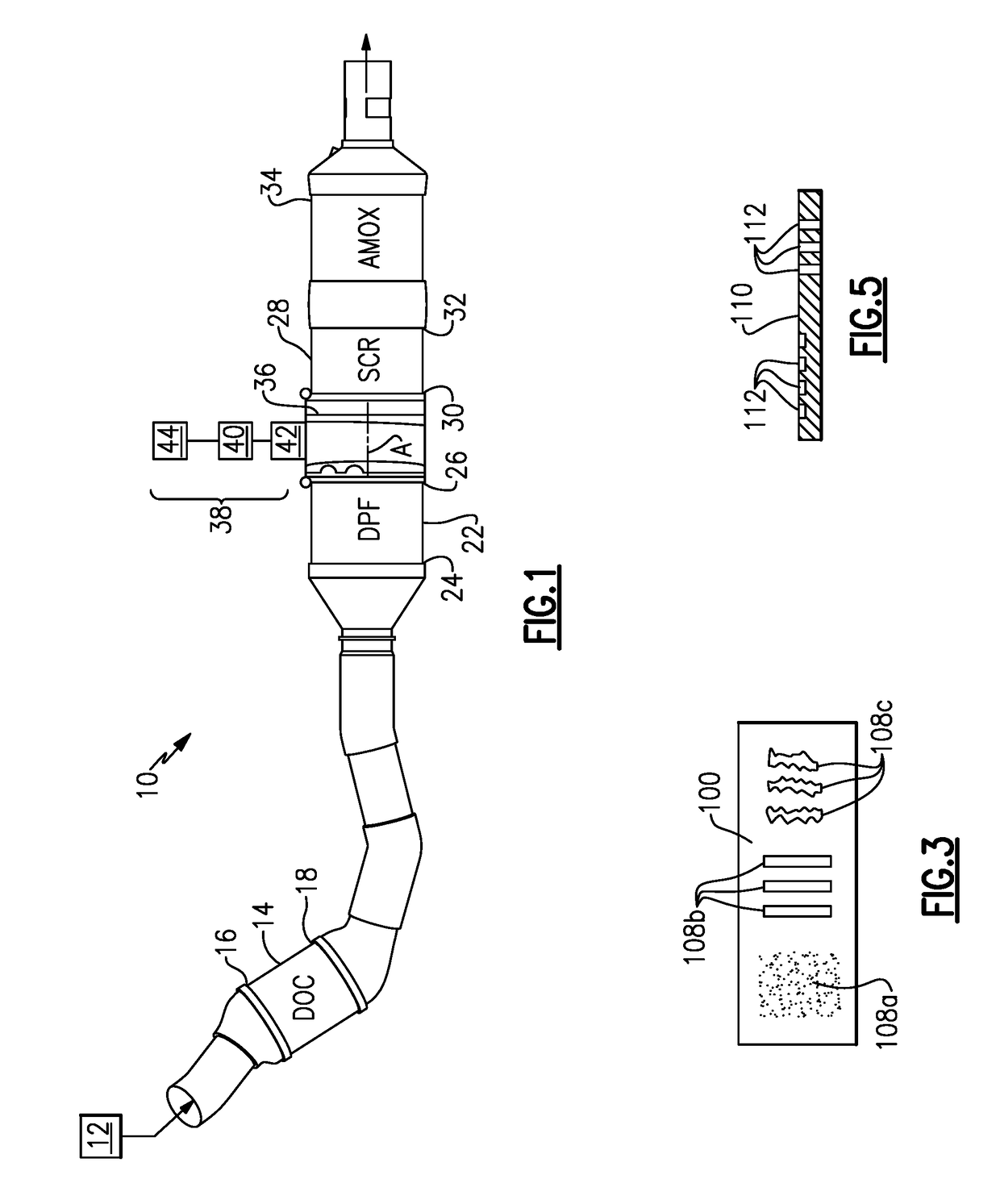

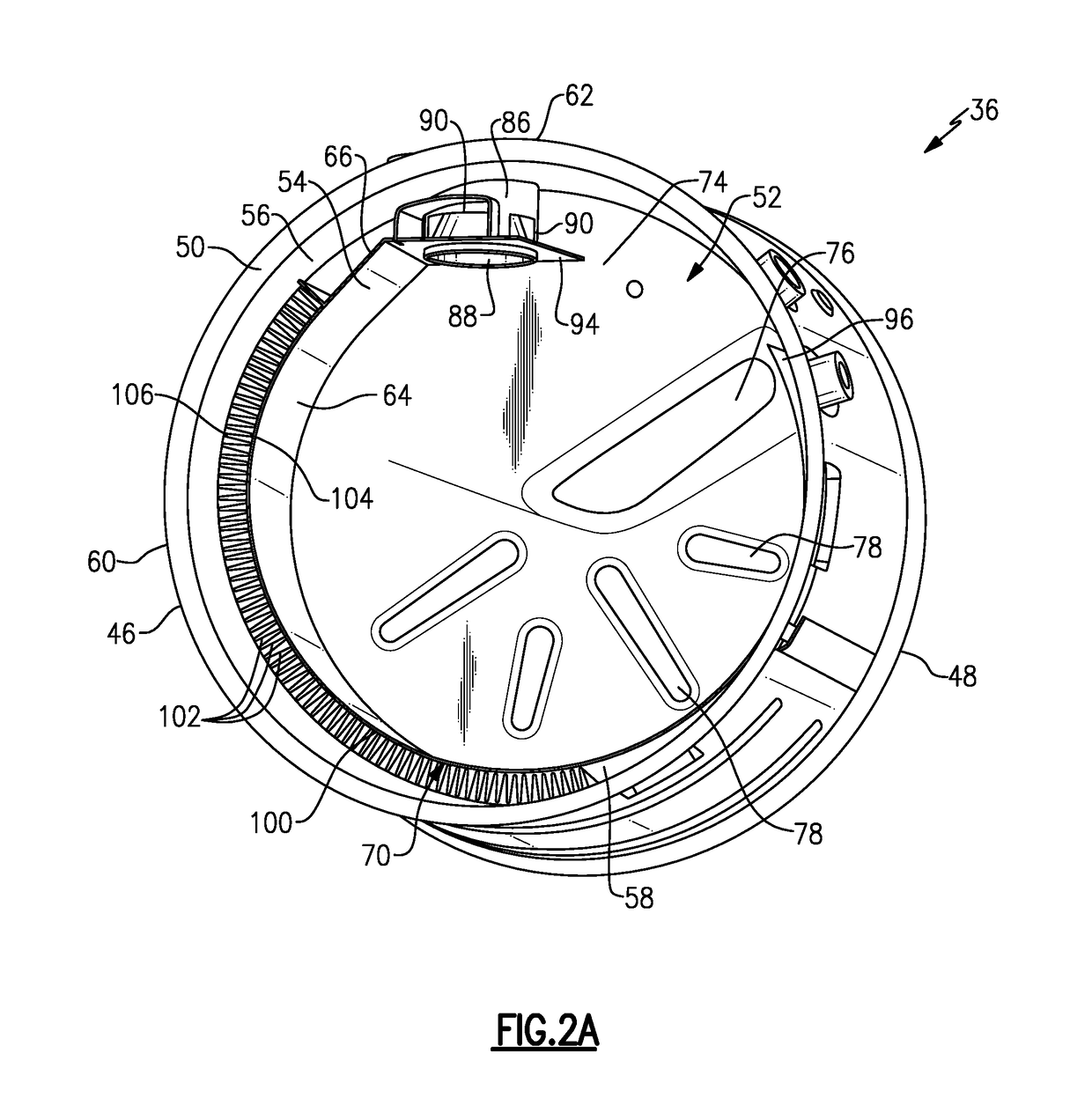

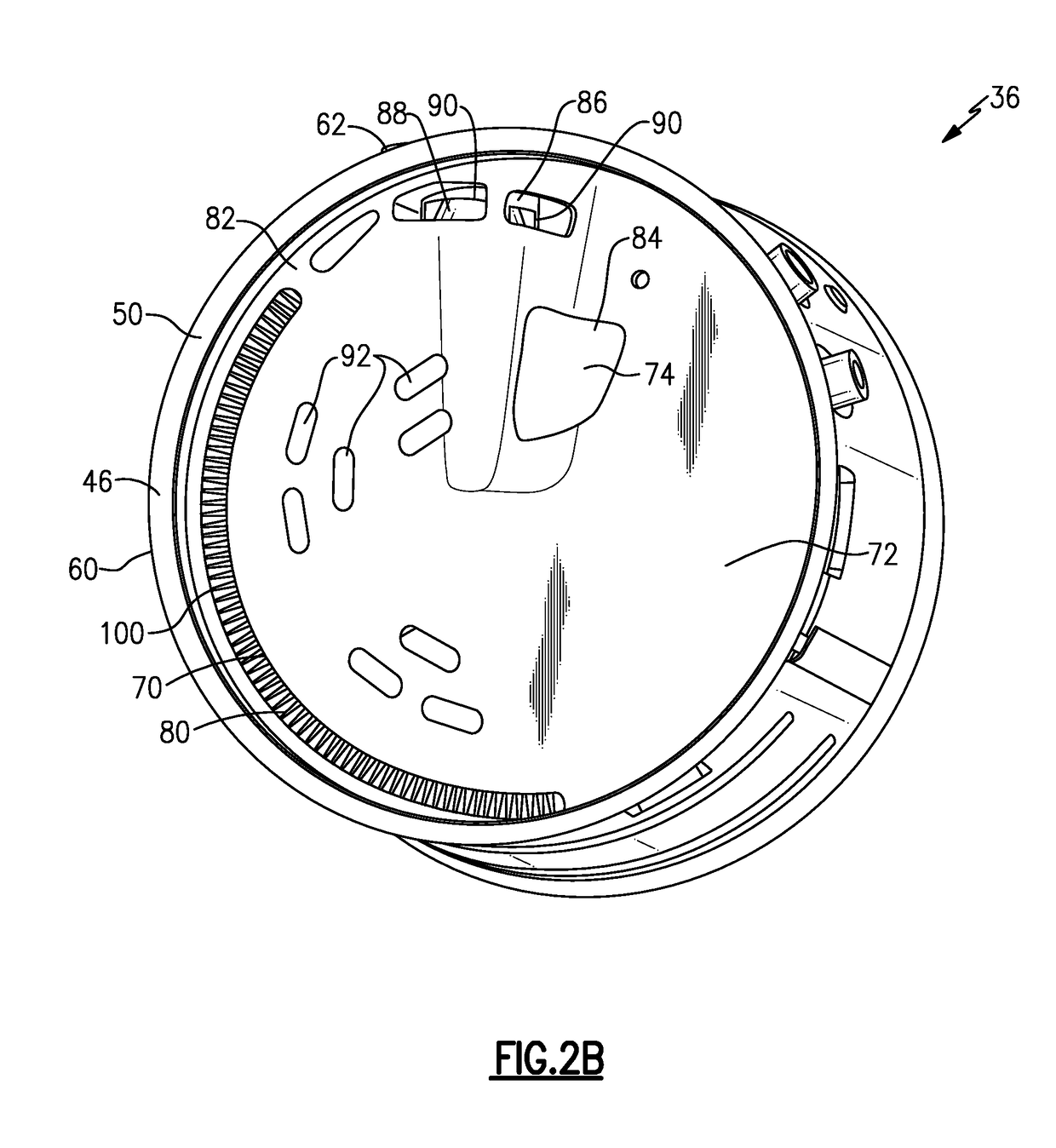

Mixer for a vehicle exhaust system

ActiveUS10337380B2Reduced deposit formationInternal combustion piston enginesFlow mixersInjectorHeat transfer

Owner:FAURECIA EMISSIONS CONTROL TECH GERMANY

Ashless consumable engine oil

The present invention relates to a low sulfur, low phosphorus, low-ash, zinc free consumable lubricant composition suitable for use in an internal combustion engine, comprising: an oil of lubricating viscosity containing less than 0.01 percent by weight of sulfur; a high TBN succinimide dispersant and overall all lubricant composition that has a sulfated ash value of up to about 0.2, a phosphorus content of up to about 50 to about 800 ppm and a sulfur content of up to about 0.4 percent by weight.

Owner:THE LUBRIZOL CORP

Mixer for a vehicle exhaust system

ActiveUS20190010850A1Reduce spray deposit formationReduced deposit formationInternal combustion piston enginesFlow mixersHeat transferExhaust gas

A vehicle exhaust system includes an outer housing defining an internal cavity surrounding an axis, an inlet baffle configured to direct engine exhaust gas into the internal cavity, and an injector that is configured to spray a fluid into the internal cavity to mix with engine exhaust gas. An inner wall is spaced radially inward of an inner surface of the outer housing to define a gap. The inner wall has an impingement side facing the axis and a non-impingement side facing the gap. At least one heat transfer element is positioned within the gap and in is contact with at least one of the inner surface of the outer housing and the non-impingement side of the inner wall to transfer heat through the inner wall to the impingement side to reduce spray deposit formation.

Owner:FAURECIA EMISSIONS CONTROL TECH GERMANY

Oil injection lubrication system for two-cycle engines

InactiveUS6374781B1Reduced deposit formationAvoid corrosionCombustion enginesLubrication pressure controlControl signalSolenoid valve

The invention provides an improved oil injection lubrication system for two-cycle engines. The system includes a variable output oil pump, the output of which can be varied in relation to the throttle level. The system also includes a solenoid valve unit containing a plurality of solenoid valves that further regulates the flow of oil from the oil pump to each cylinder. An electronic control unit sends control signals to the soleniod valve unit to regulate the flow of oil based upon engine operating conditions in accordance with a controle scheme. The combination of the variable output oil pump and the solenoid valve unit enables the solenoid valves to be activated with a lighter duty cycle, which reduces the amount of power consumed by the solenoid valve unit.

Owner:SANSHIN KOGYO CO LTD

Method of lubricating an internal combustion engine

InactiveUS20160326453A1Reduce sootReduce formation of depositAdditivesChemistryInternal combustion engine

The invention provides a method of lubricating a compression-ignition internal combustion engine with a maximum laden mass over 2,700 kg comprising supplying to the engine a lubricating composition comprising: an oil of lubricating viscosity, a 300 TBN or higher alkaline earth metal sulphonate detergent having a metal ratio of 10 to 40, 0.1 wt % to 4 wt % of a borated polyisobutylene succinimide dispersant, wherein the polyisobutylene from which the borated polyisobutylene succinimide is derived has a number average molecular weight of 550 to 1150, and 0.1 wt % to 6 wt % of a polyisobutylene succinimide, wherein the polyisobutylene from which polyisobutylene succinimide is derived has a number average molecular weight of 1550 to 2500, 0 wt % to 0.2 wt % of a phenolic based detergent, wherein the total amount of soap delivered by the alkaline earth metal sulphonate (typically calcium sulphonate) is 0.4 to 1 wt % of the lubricating composition, and wherein the lubricating composition has a sulphated ash content of not more than 1.5 wt %.

Owner:THE LUBRIZOL CORP

Thermoplastically processable polyurethane molding material

Owner:INTIER AUTOMOTIVE EYBL INTERIORS +1

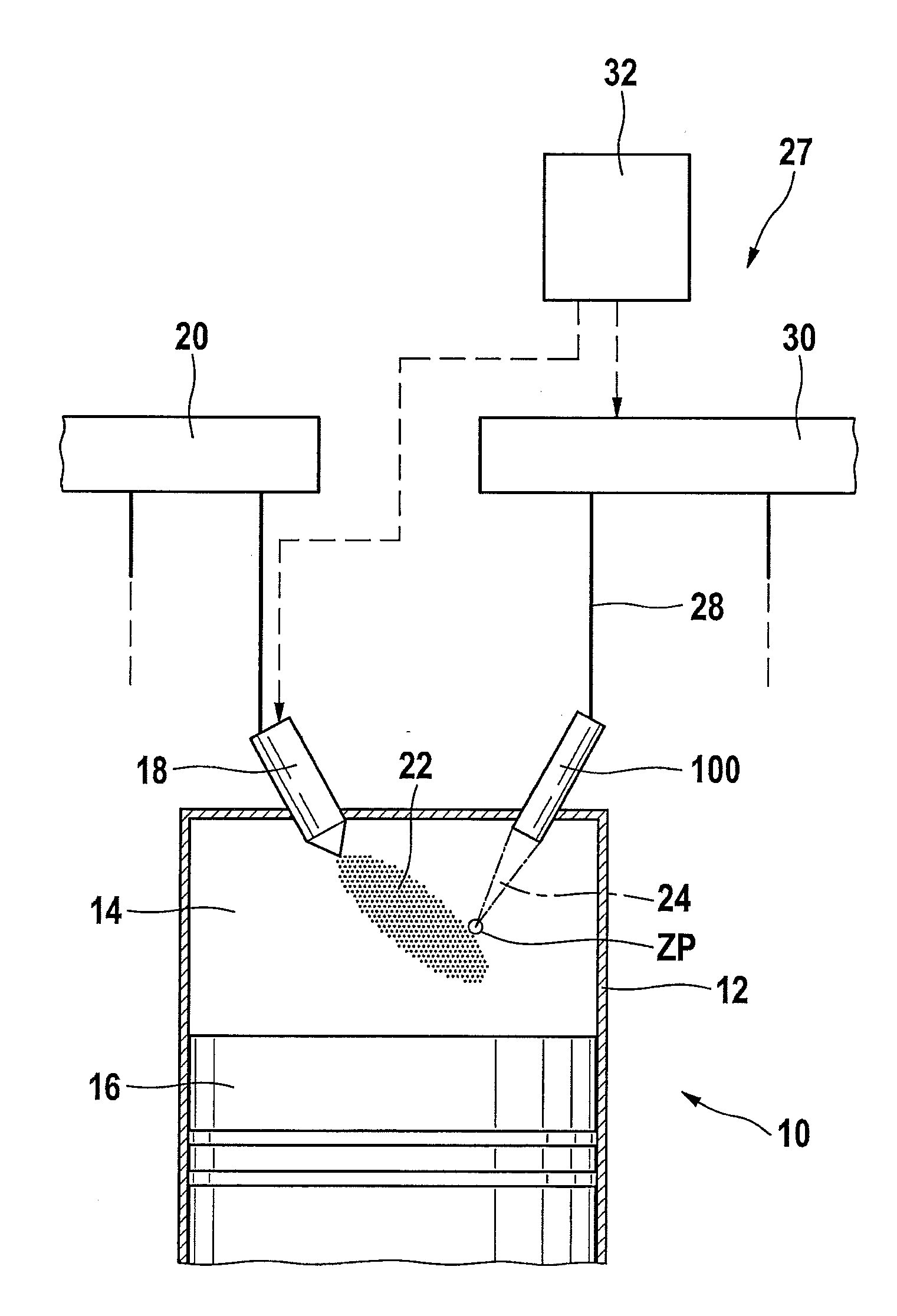

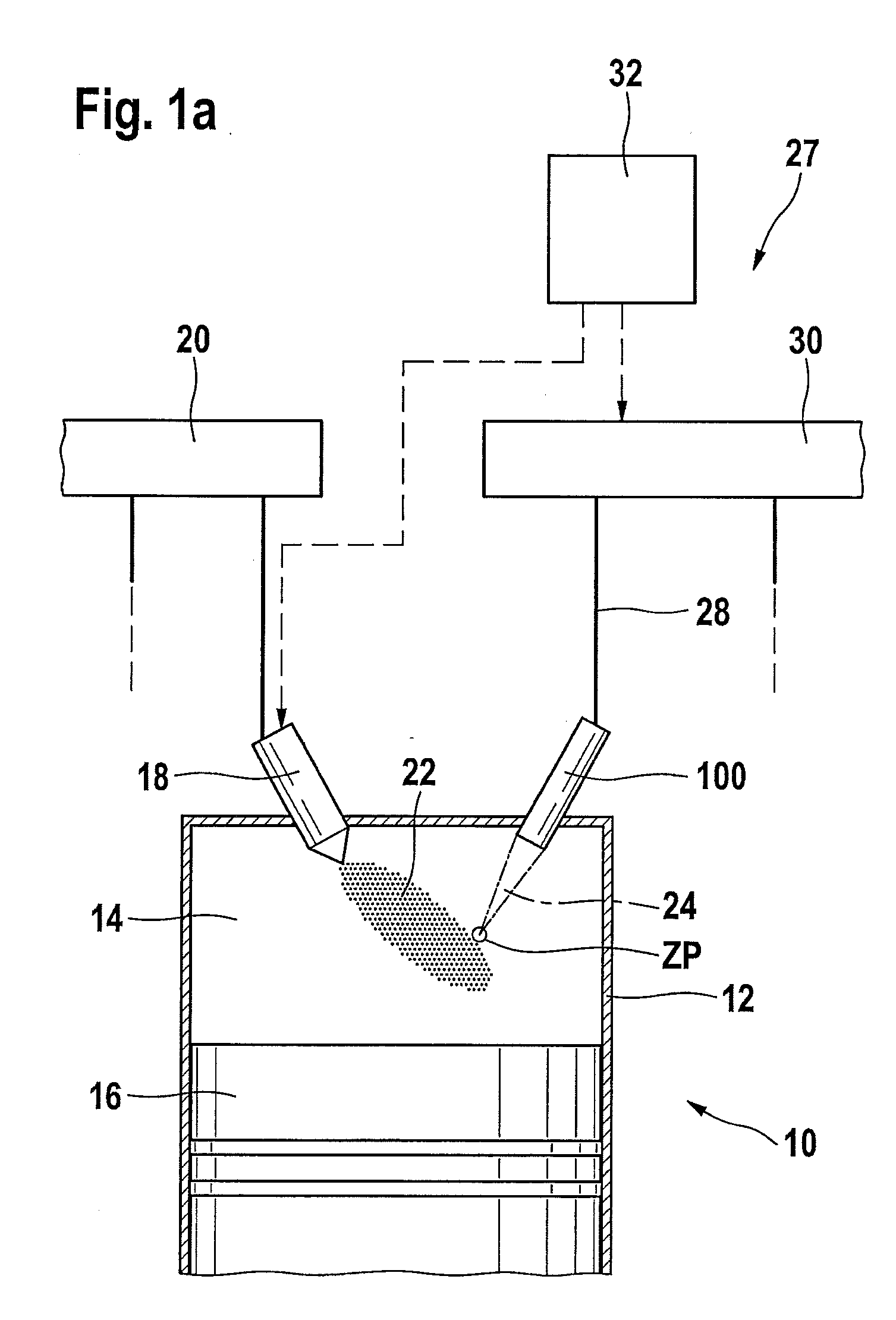

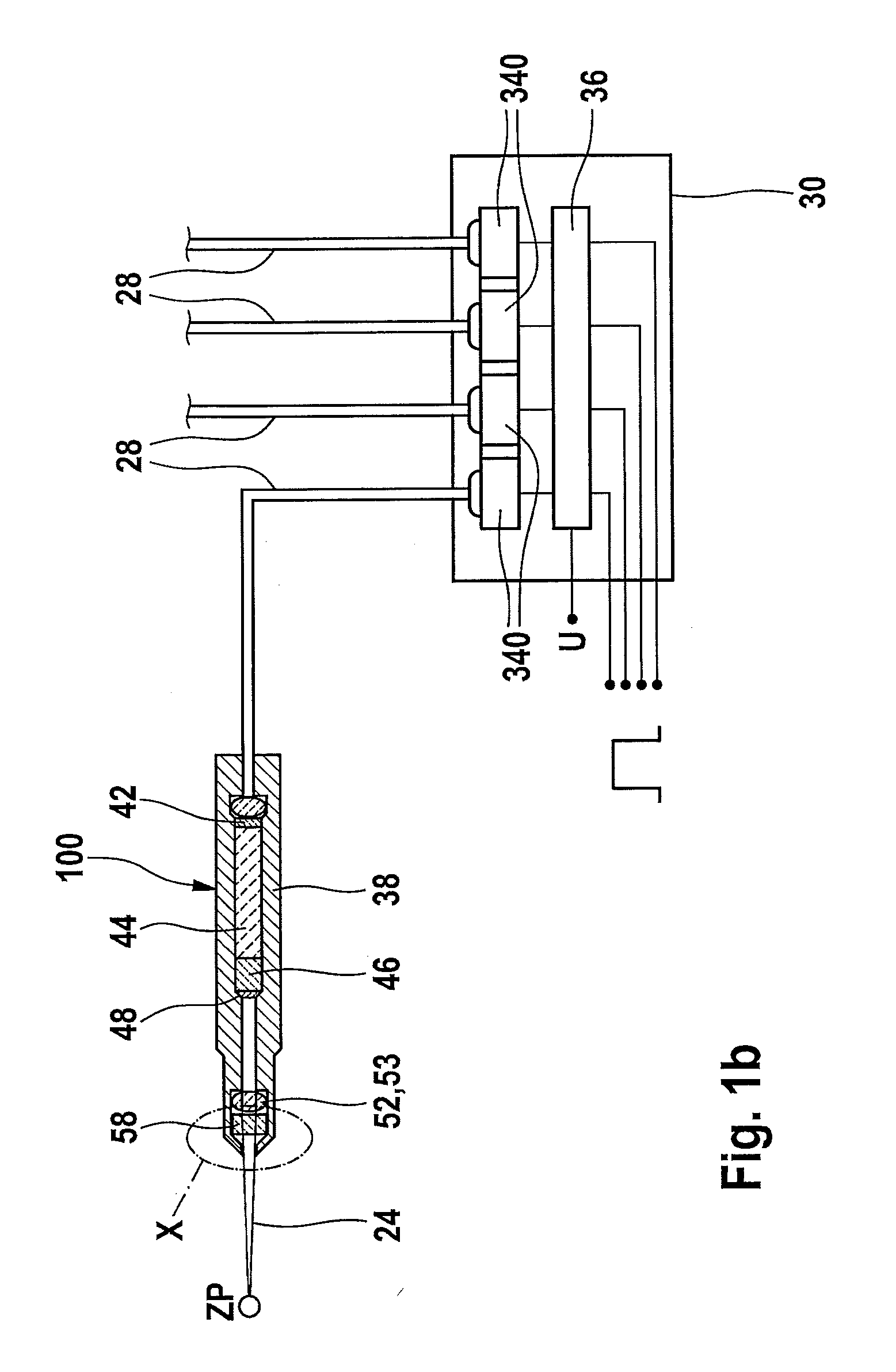

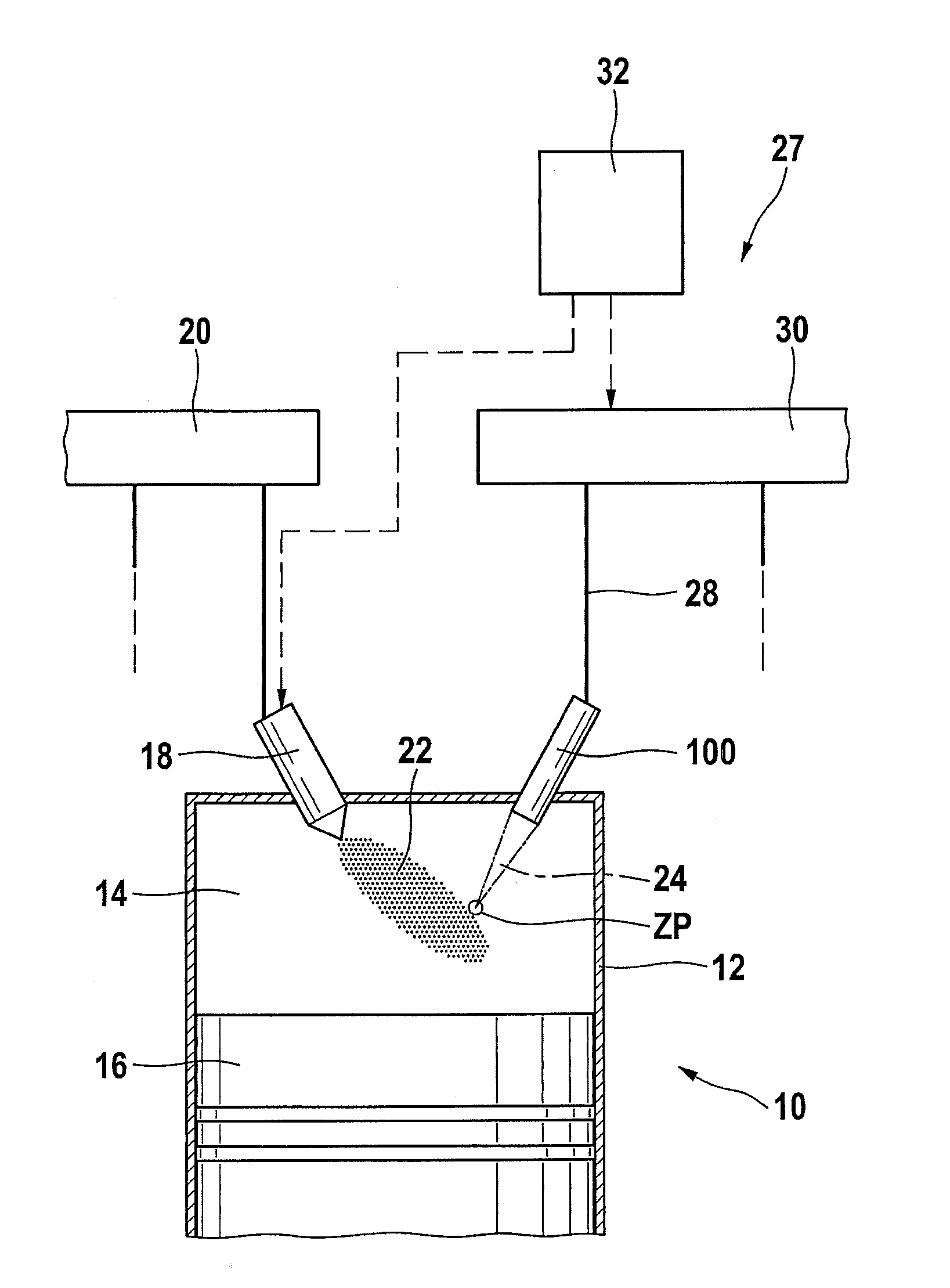

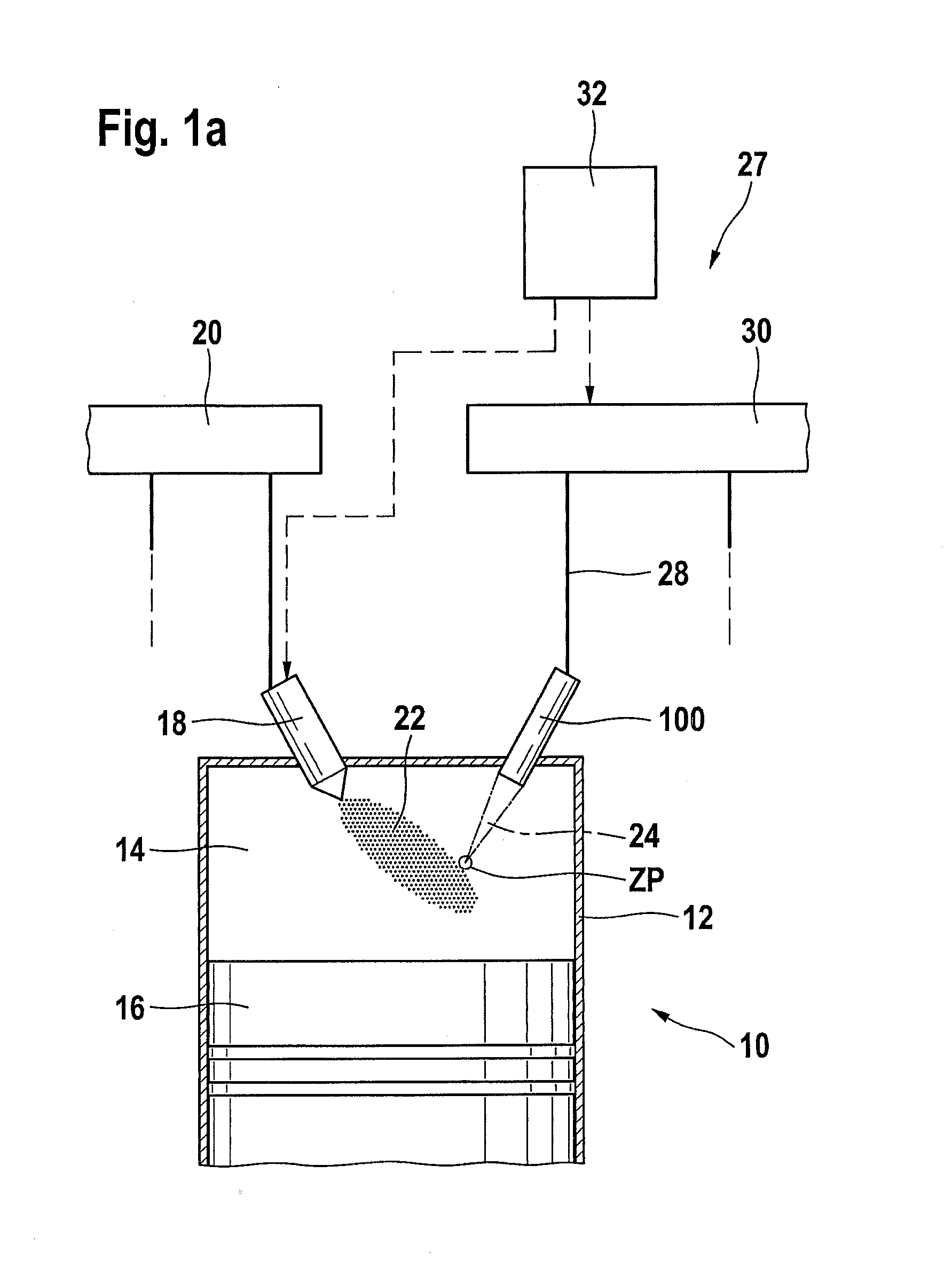

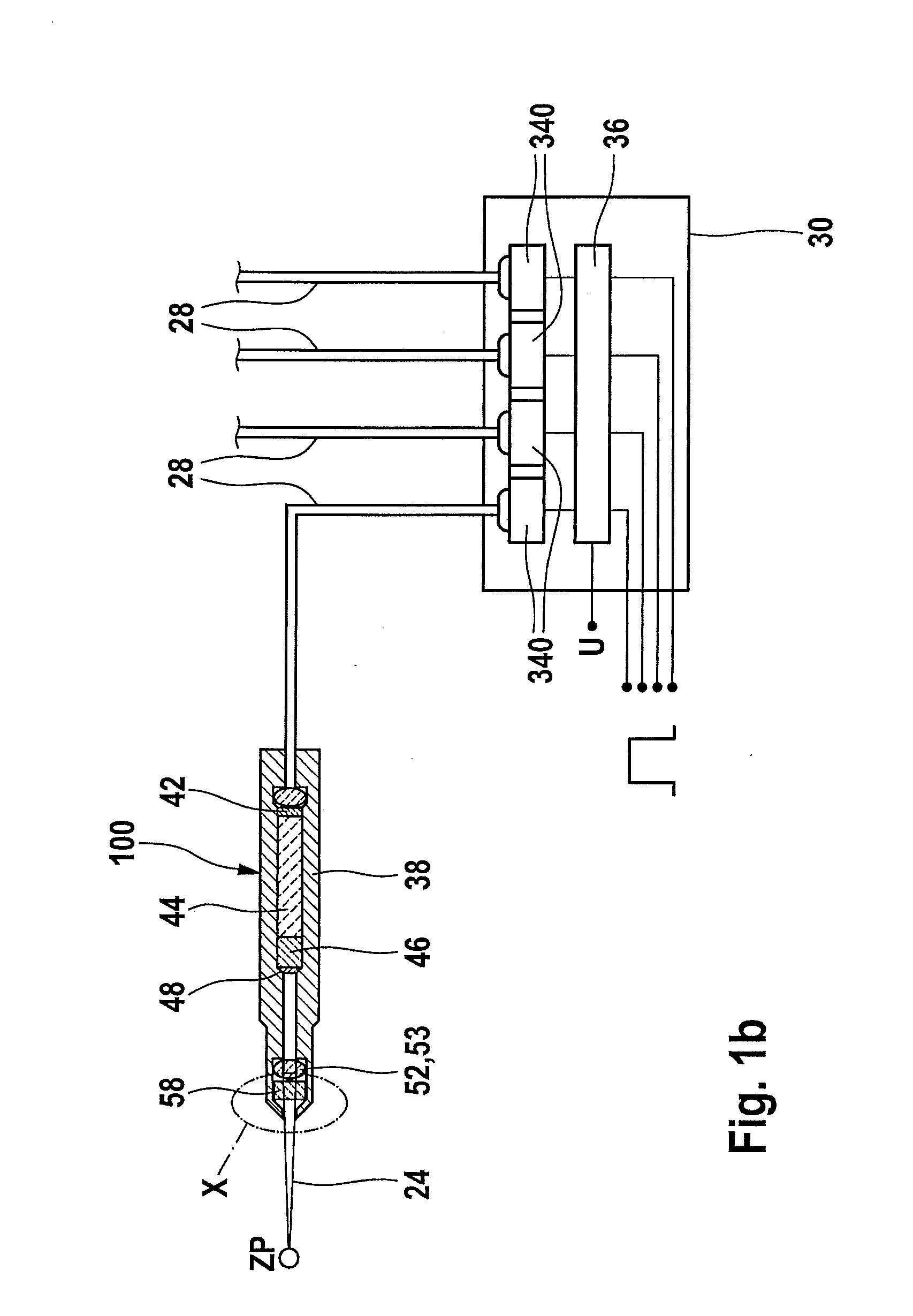

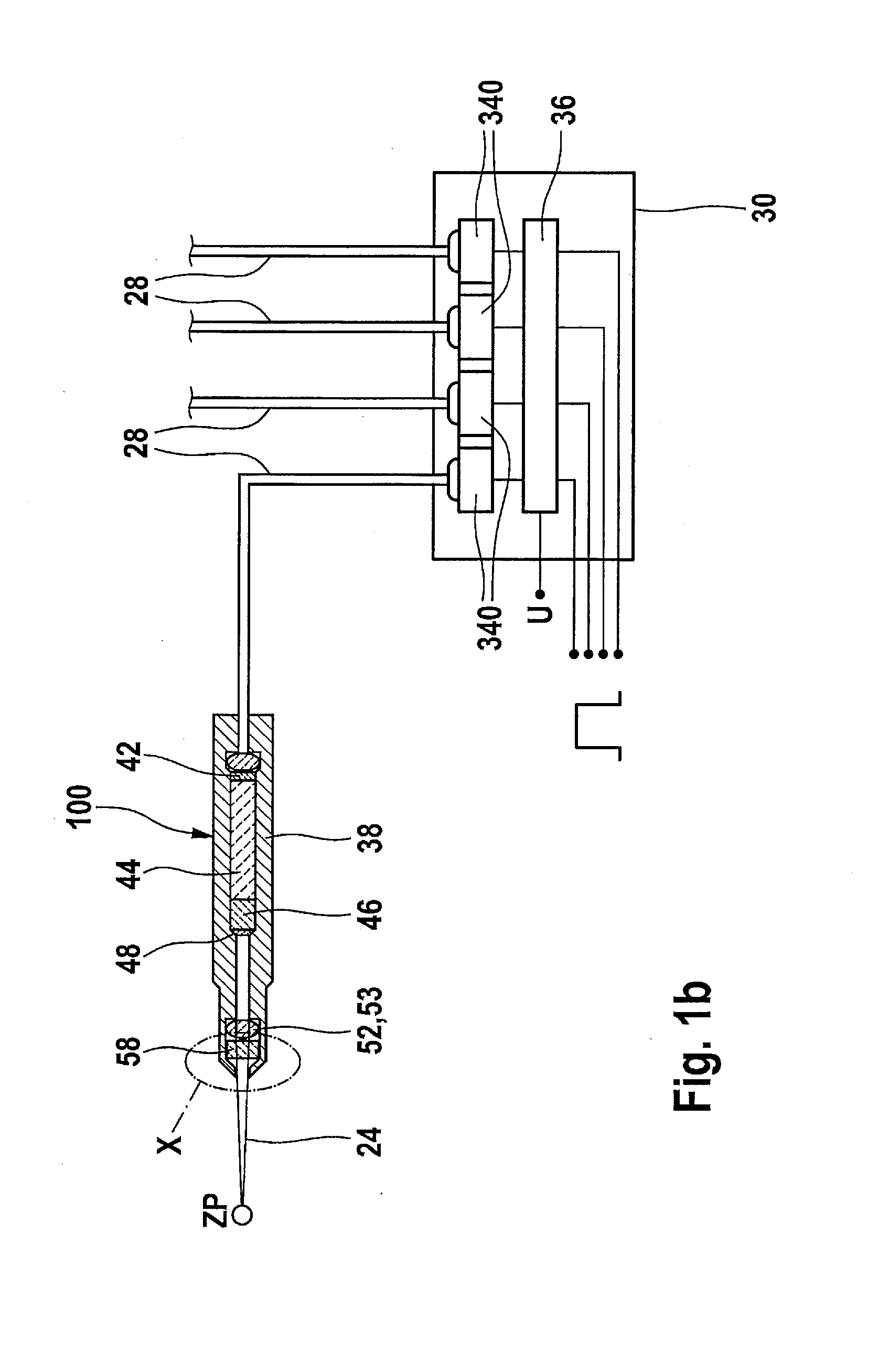

Laser-induced spark ignition for an internal combustion engine

InactiveUS20130104827A1Reduce depositionReduced deposit formationCombustion enginesIgnition sparking plugsExternal combustion engineEngineering

A laser spark plug for an internal combustion engine, including at least one generating arrangement for at least one of guiding, shaping and generating laser radiation, further including a combustion chamber window and a housing, in which the housing has, on the opposite side of the combustion chamber window from the at least one generating arrangement, in particular at an end of the housing on the combustion chamber side, an aperture for the passage of the laser radiation that is at least one of guided, shaped and generated by the at least one generating arrangement into a combustion chamber, the aperture having on the side thereof remote from the combustion chamber window an exit cross-section of 78 mm2 or less, especially 19 mm2 or less.

Owner:ROBERT BOSCH GMBH

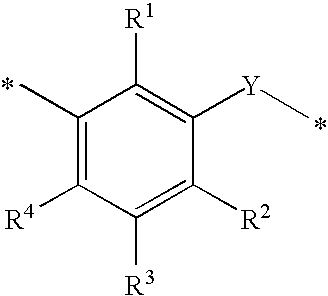

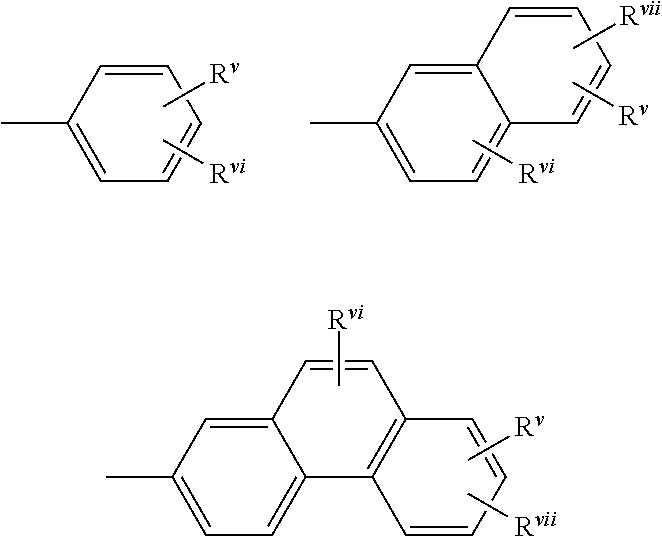

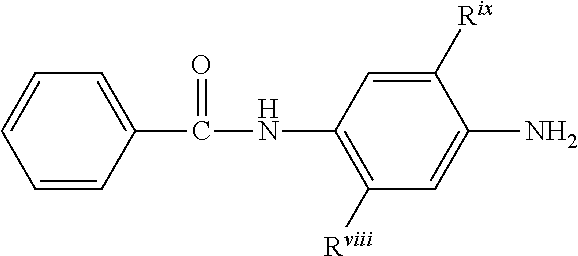

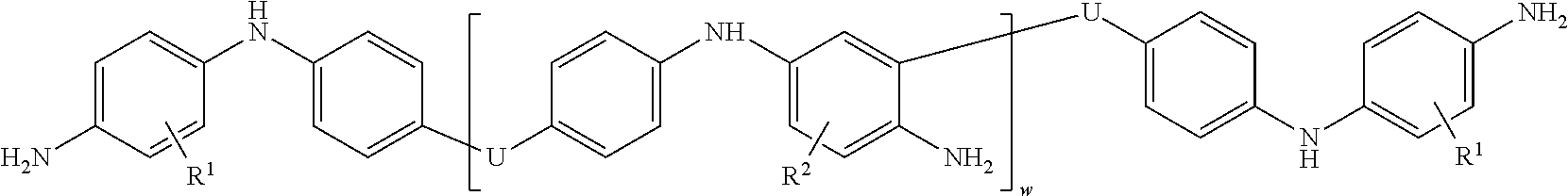

Additive Compositions

ActiveUS20090156448A1Reduced deposit formationReducing metal corrosionOrganic chemistryLiquid carbonaceous fuelsAdductOxygen atom

Compositions in the form of lubricating oil compositions, greases, fuels or functional fluids containing, in the form of Michael adducts, N-substituted phenylenediamine additives in which at least one of the substituents on the N atoms carries a carbonyl group that is connected to an alkyl, alkoxyalkyl, or alkylthioalkyl group either directly or via an oxygen atom.

Owner:INFINEUM INT LTD +1

Thermally stable blends of highly paraffinic distillate fuel component with conventional distillate fuel component

InactiveUS7033484B2Minimize deposit formationHigh aromatic contentLiquid organic insulatorsHydrocarbon purification/separationEngineeringInternal combustion engine

A stable distillate fuel blend useful as a fuel or as a blending component of a fuel that is suitable for use in an internal combustion engine, said fuel blend prepared from at least one highly paraffinic distillate fuel component and at least one highly aromatic petroleum-derived distillate fuel component and a process for preparing same involving the blending of at least two components having antagonistic properties with respect to one another.

Owner:CHEVROU USA INC

Laser-induced spark ignition for an internal combustion engine

InactiveUS20130152893A1Reduce depositionReducing formation of depositCombustion enginesIgnition sparking plugsSpark-ignition engineCombustion chamber

Laser spark plug for an internal combustion engine has at least one laser unit for guiding, shaping and / or generating laser radiation, further including a combustion chamber window, and a housing which has, on the opposite side of the combustion chamber window from the laser unit, an aperture for the passage of the laser radiation guided, shaped and / or generated by the laser unit into a combustion chamber, the length of the aperture being 4 mm or more.

Owner:ROBERT BOSCH GMBH

Method Of Lubricating An Internal Combustion Engine

InactiveUS20180044610A1Avoid serious impactEasy to wearLubricant compositionSulfonateAlkaline earth metal

The disclosed technology provides a method of lubricating a compression-ignition internal combustion engine with a maximum laden mass over 2,700 kg comprising supplying to the engine a lubricating composition comprising: an oil of lubricating viscosity, a 300 TBN or higher alkaline earth metal sulfonate detergent having a metal ratio of 10 to 40, an alkaline earth metal sulfonate detergent having a metal ratio of 3 to 9, and a TBN of 81 to 180 mg KOH / g, wherein the sulfonate detergents provide a total amount of sulfonate substrate of 1 wt % to 3 wt % of the lubricating composition, 0.1 to 1.2 wt % of antioxidant, wherein at least 20 wt % of the antioxidant is a phenolic antioxidant, a borated compound present in an amount to deliver 25 ppm to 300 ppm of boron, the lubricating composition has a sulfated ash content of 0.5 wt % to not more than 1.5 wt %, and the lubricating composition has a TBN of 6.5 to 15 mg KOH / g.

Owner:THE LUBRIZOL CORP

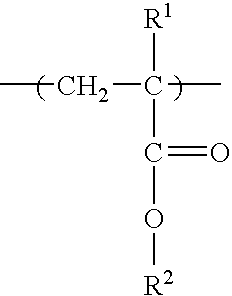

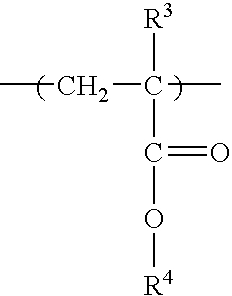

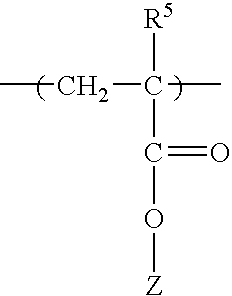

Terpolymer methacrylate dispersant

A methacrylate terpolymer, methods for making the terpolymer, and lubricant compositions containing the terpolymer. The terpolymer is derived from (a) a C4-alkylmethacrylate monomeric unit; (b) a C10-15-alkylmethacrylate monomeric unit; and (c) a di-lower-alkylaminoalkyl methacrylate monomeric unit. Component (a) is in the terpolymer in an amount ranging from about 15 up to less than about 30 percent by weight of the terpolymer. Component (b) is in the terpolymer in an amount ranging from more than about 70 up to about 80 percent by weight of the terpolymer. Component (c) is in the terpolymer in an amount ranging from about 2 to less than about 10 percent by weight of the terpolymer.

Owner:AFTON CHEMICAL

Laser-induced spark ignition for an internal combustion engine

InactiveUS20130139774A1Reduce depositionReduced deposit formationCombustion enginesIgnition sparking plugsCombustion chamberEngineering

A laser spark plug for an internal combustion engine has at least one laser unit for guiding, shaping, and / or for producing laser radiation, a combustion chamber window, and a housing which has, at the side of the combustion chamber window situated opposite the laser unit, a screen for the passage of the laser radiation guided, shaped, and / or produced by the laser unit into a combustion chamber, the screen having a first end facing the combustion chamber and a second end facing away from the combustion chamber, the inner contour of the screen having an extremal cross-section in a region that is situated at a distance both from the first and second ends.

Owner:ROBERT BOSCH GMBH

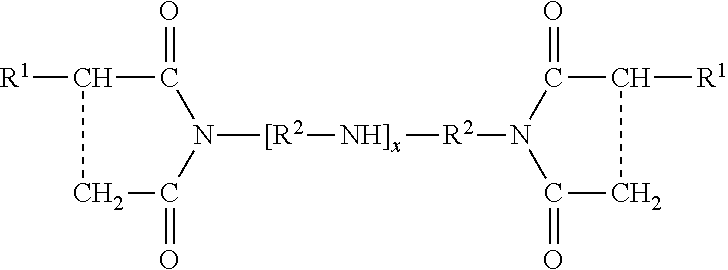

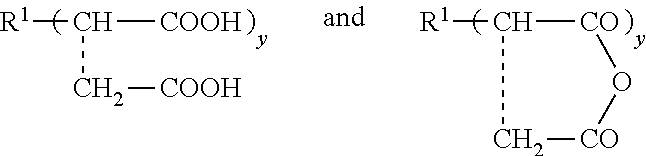

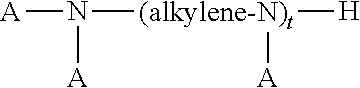

Lubricating oil composition and additive therefor having improved piston deposit control and emulsion stability

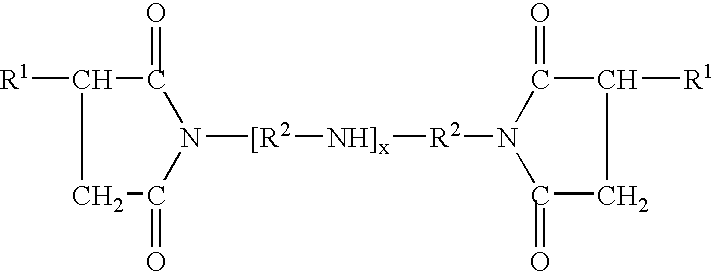

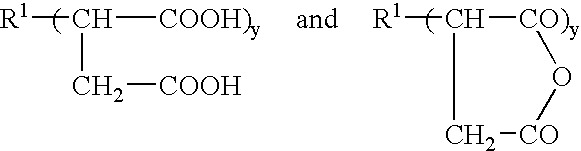

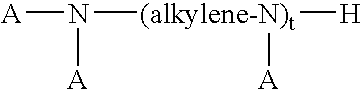

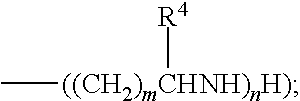

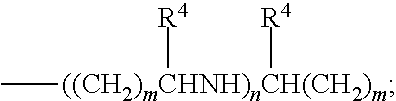

ActiveUS9068135B1Improved performance characteristicsSimple compositionAdditivesOil additivePolyamine

A lubricant additive composition, a method for reducing engine deposit formation and a method for improving emulsion stability of a lubricant composition. The lubricant additive composition includes (a) an organomolybdenum compound contributing from about 20 to no greater than 300 ppm by weight molybdenum to the lubricant composition based on a total weight of the lubricant composition containing the additive composition; (b) a boronated hydrocarbyl substituted succinimide dispersant; and (c) a reaction product of (i) a hydrocarbyl-dicarboxylic acid or anhydride, (ii) a polyamine, (iii) a dicarboxyl-containing fused aromatic compound, and (iv) a non-aromatic dicarboxylic acid or anhydride. The hydocarbyl group of the hydrocarbyl-dicarboxylic acid or anhydride has a number average molecular weight of greater than 1800 Daltons as determined by gel permeation chromatography. A weight ratio of (b) to (c) ranges from about 1:1 to about 4:1.

Owner:AFTON CHEMICAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com