Patents

Literature

36results about How to "Avoid sediment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Two-step hydroprocessing method for heavy hydrocarbon oil

ActiveUS20060011510A1Reduce the presence of impuritiesGreat degree of desulfurizationCatalyst activation/preparationHydrocarbon oil crackingHydrogenSulfur

A method is disclosed for hydroprocessing a heavy hydrocarbon oil, comprising a first hydroprocessing step of bringing a heavy hydrocarbon oil into contact with a Catalyst (1) with a certain specific surface area and pore size distribution in the presence of hydrogen in a first reaction zone containing the Catalyst (1), and a second hydroprocessing step of bringing the hydroprocessed oil obtained from the first reaction zone into contact with a Catalyst (2) with a certain specific surface area and pore size distribution in the presence of hydrogen in a second reaction zone containing the Catalyst (2). The method is an improvement in decreasing or inhibiting the sediment formation, while highly hydroprocessing a heavy hydrocarbon oil containing a large amount of impurities such as sulfur, micro carbon residue (MCR), metals, nitrogen and asphaltene, especially a heavy oil containing a large amount of heavy vacuum residue, to adequately remove the impurities.

Owner:EXXON RES & ENG CO

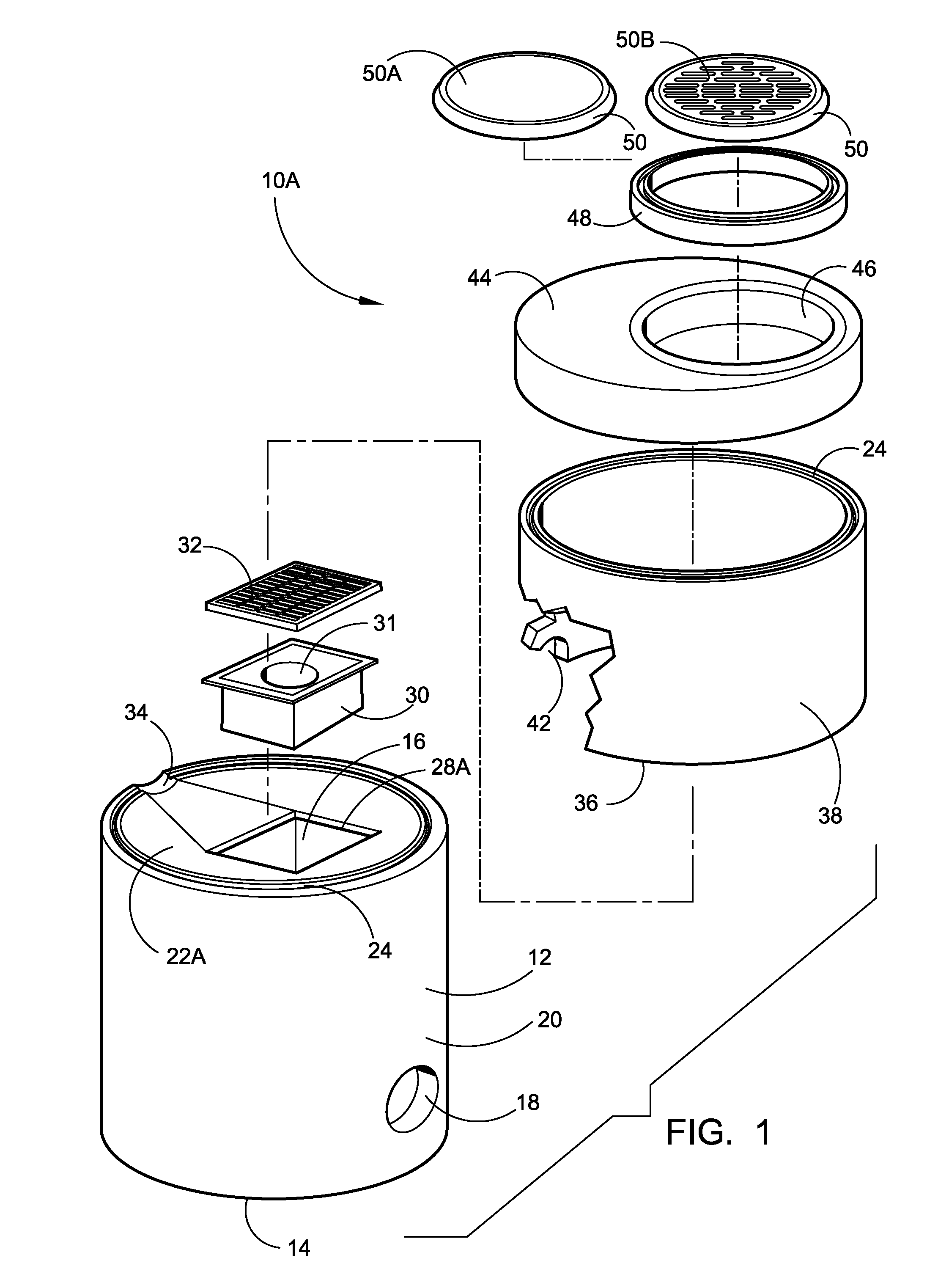

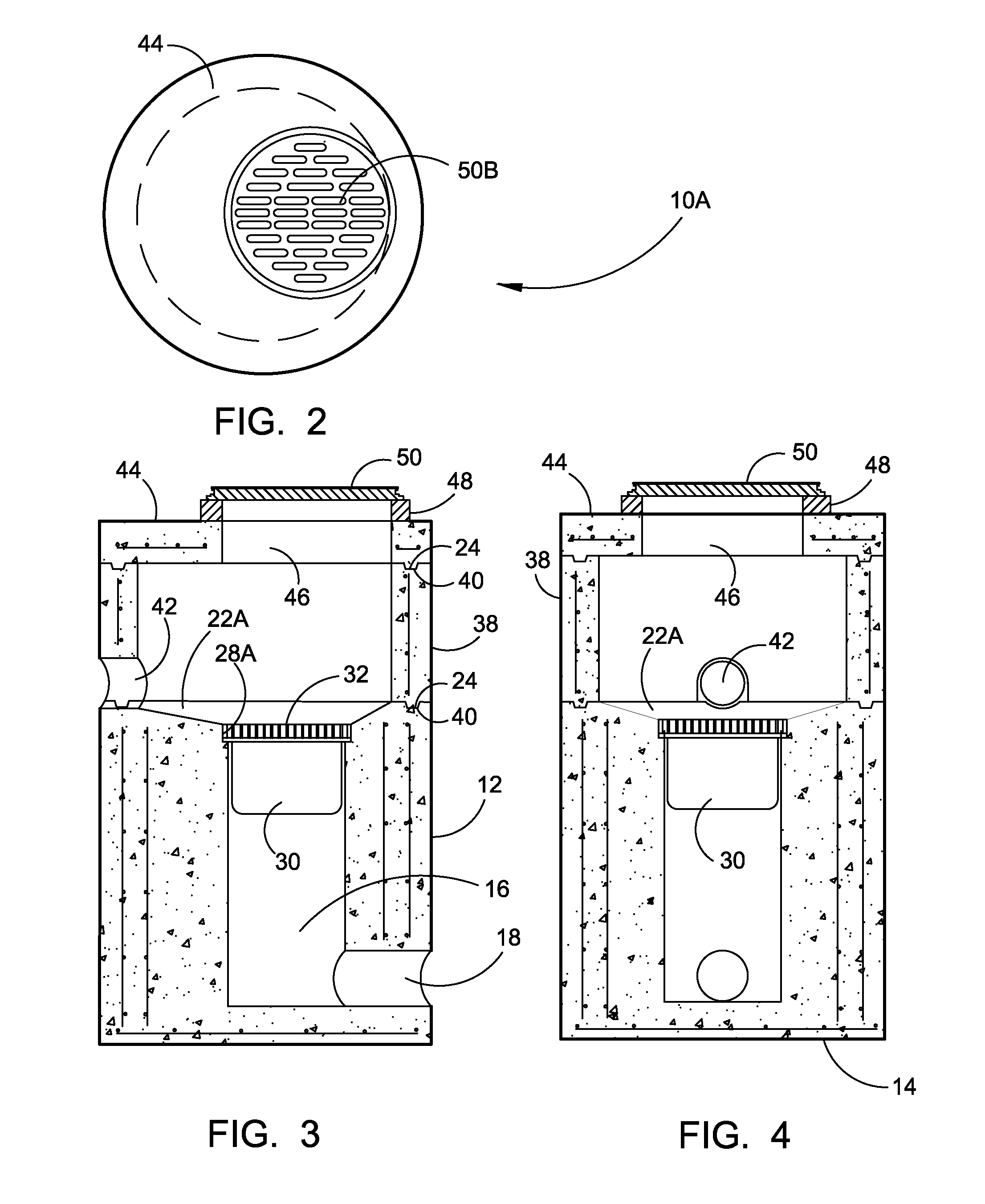

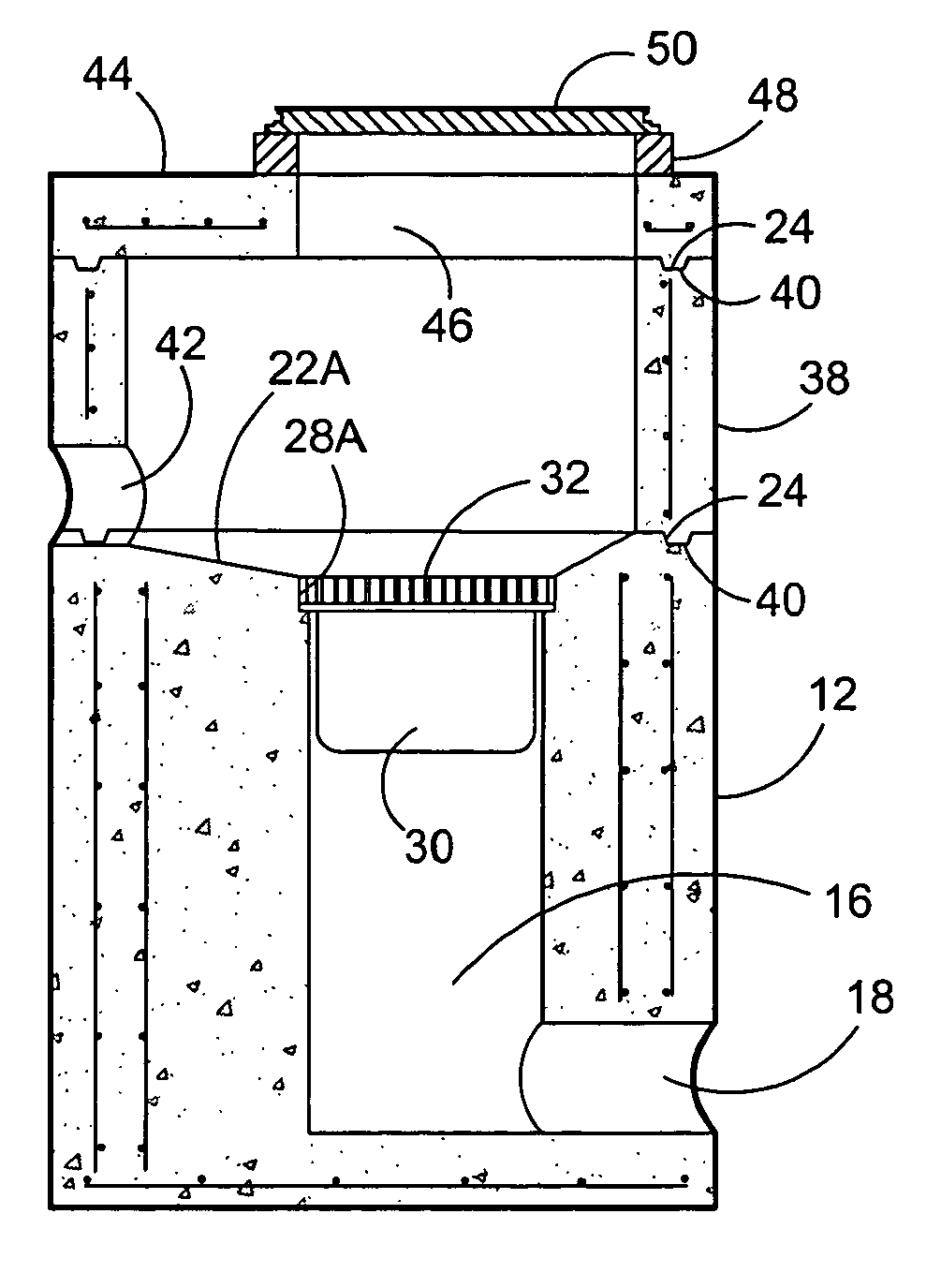

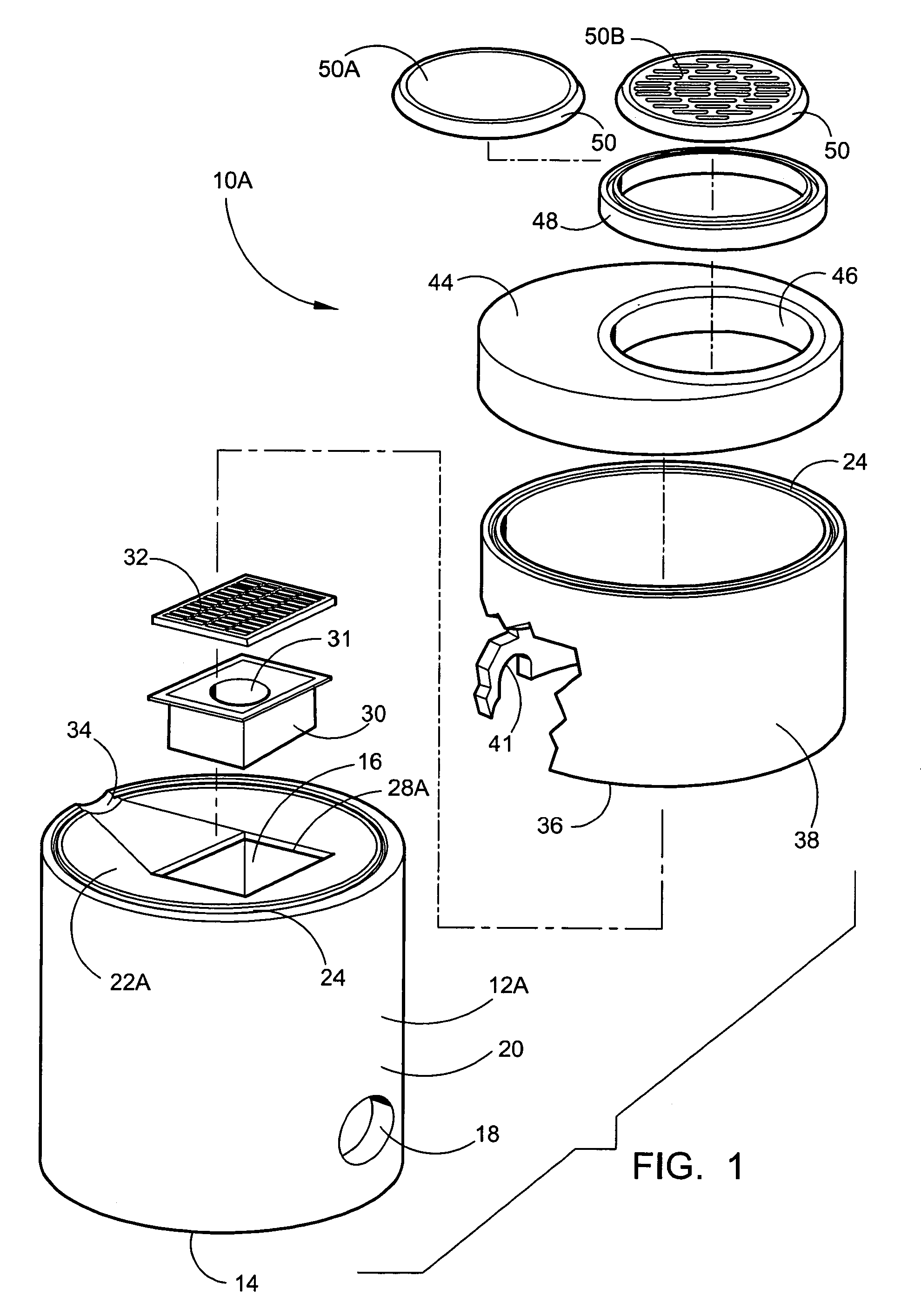

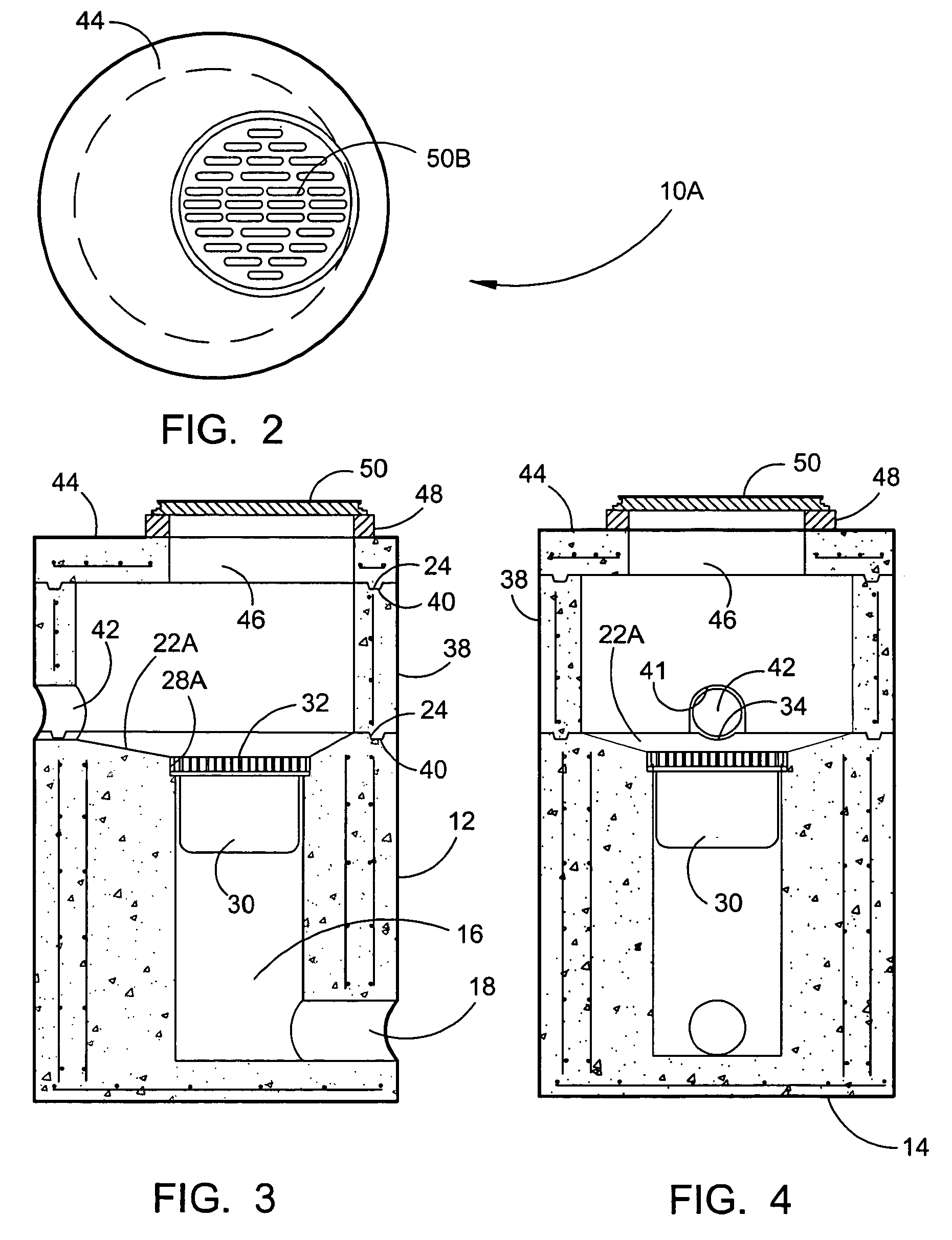

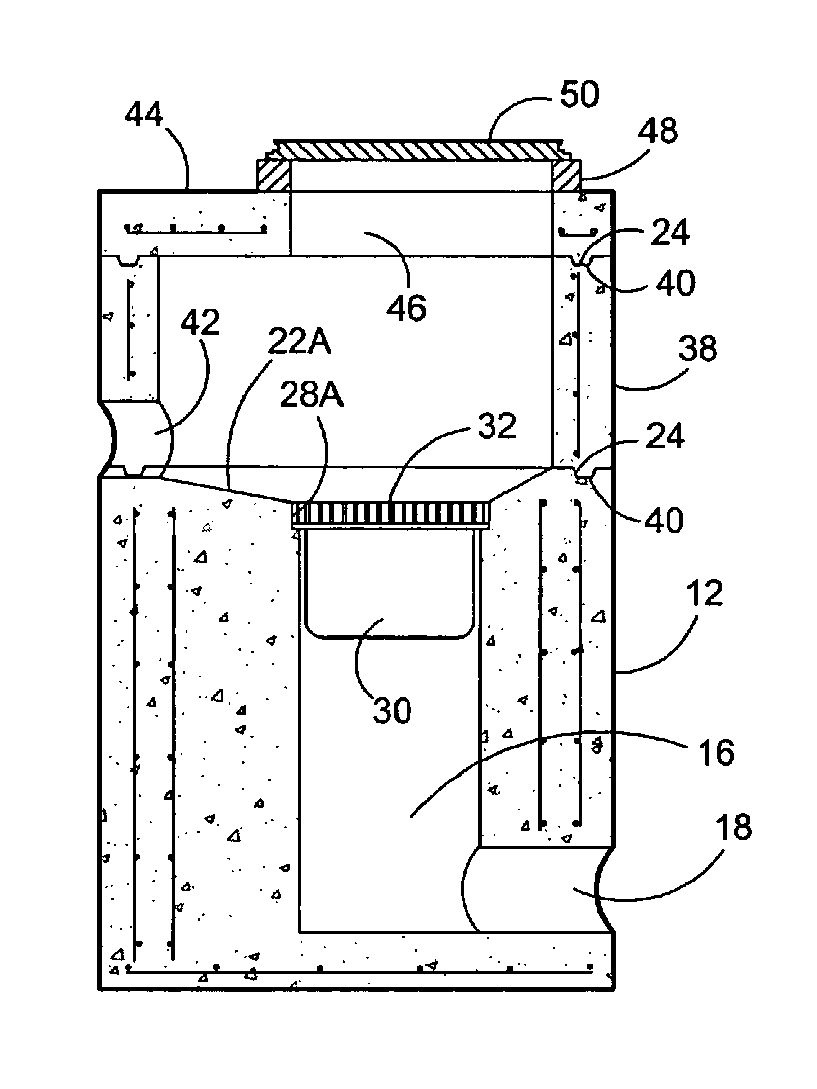

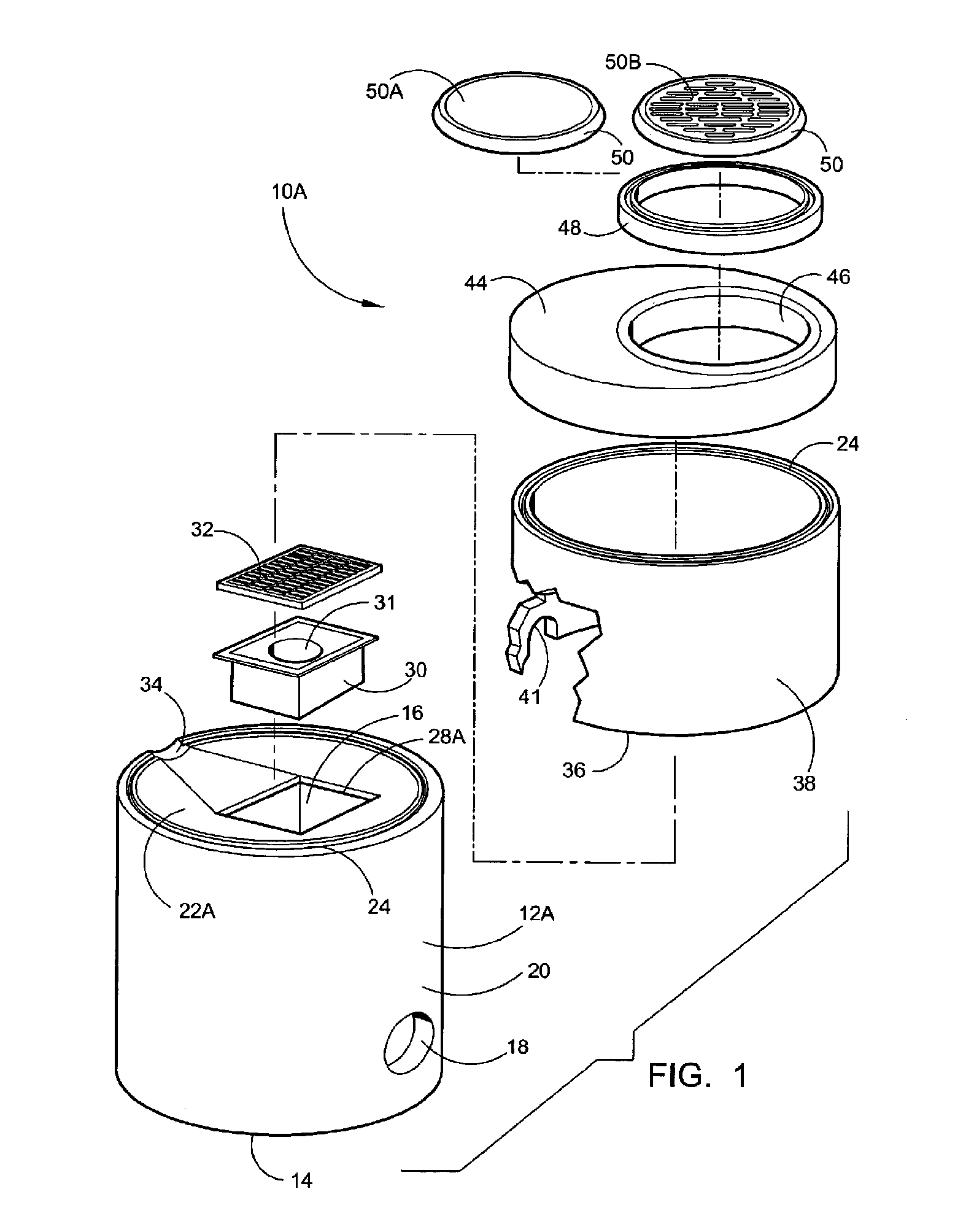

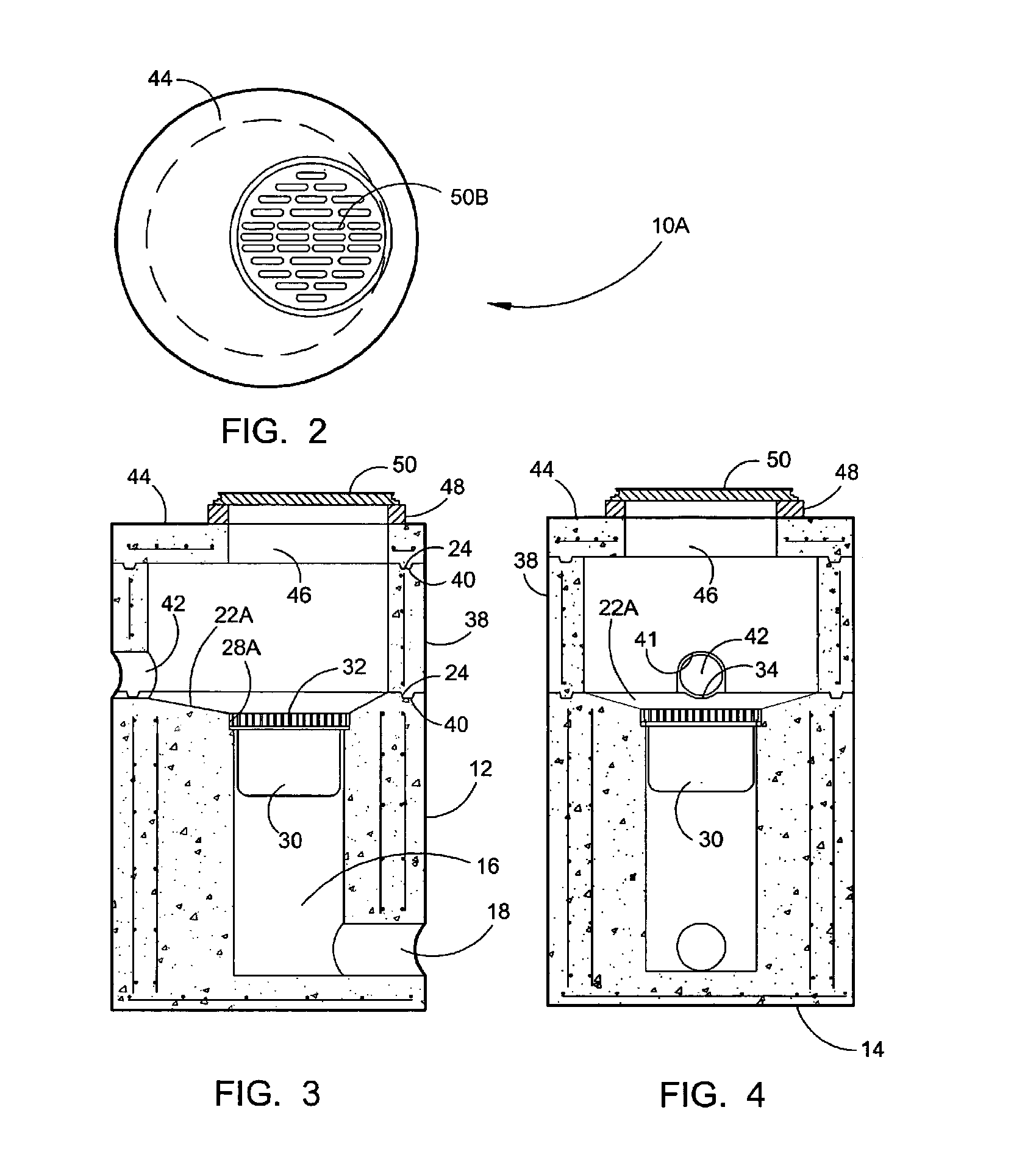

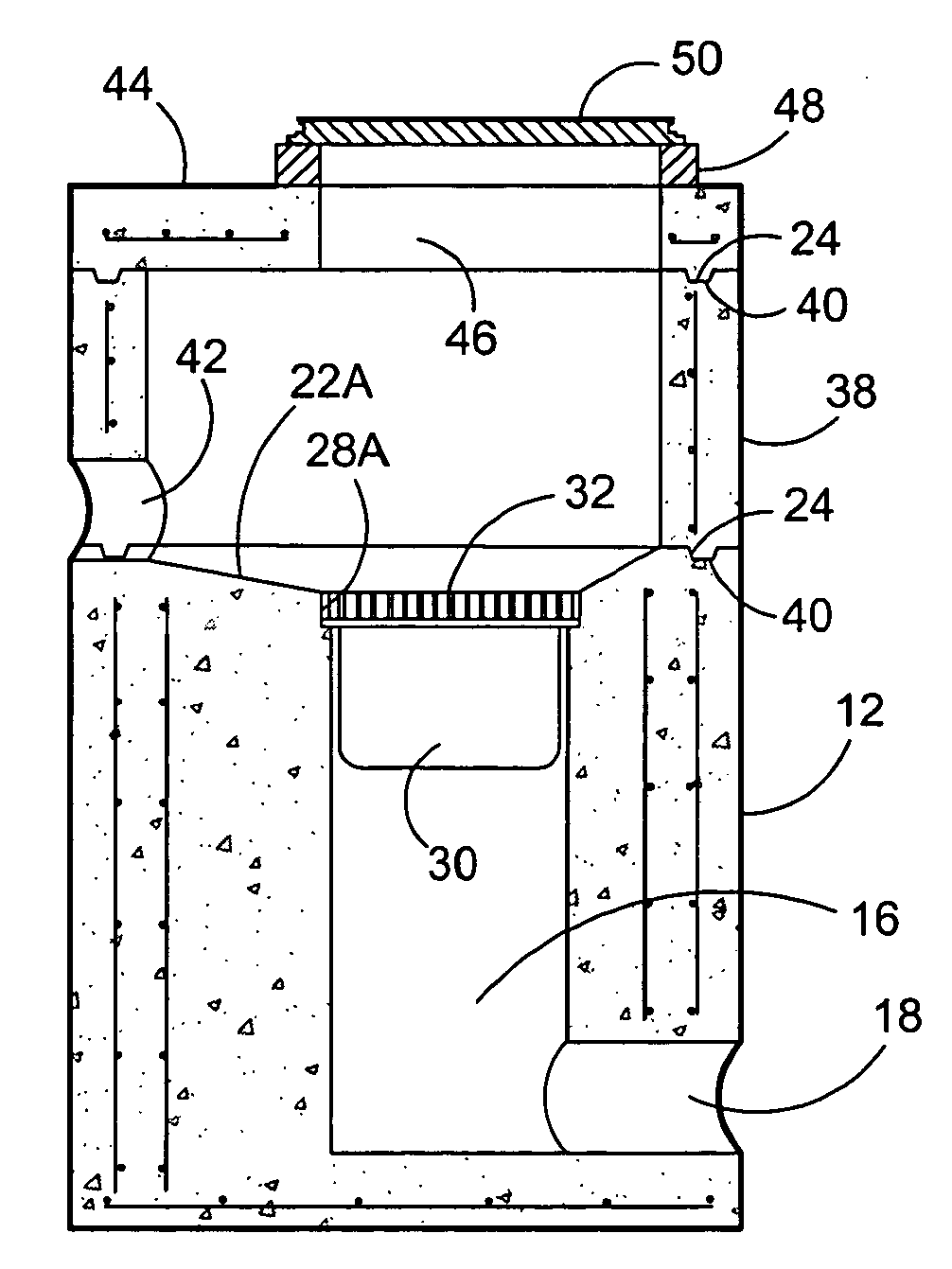

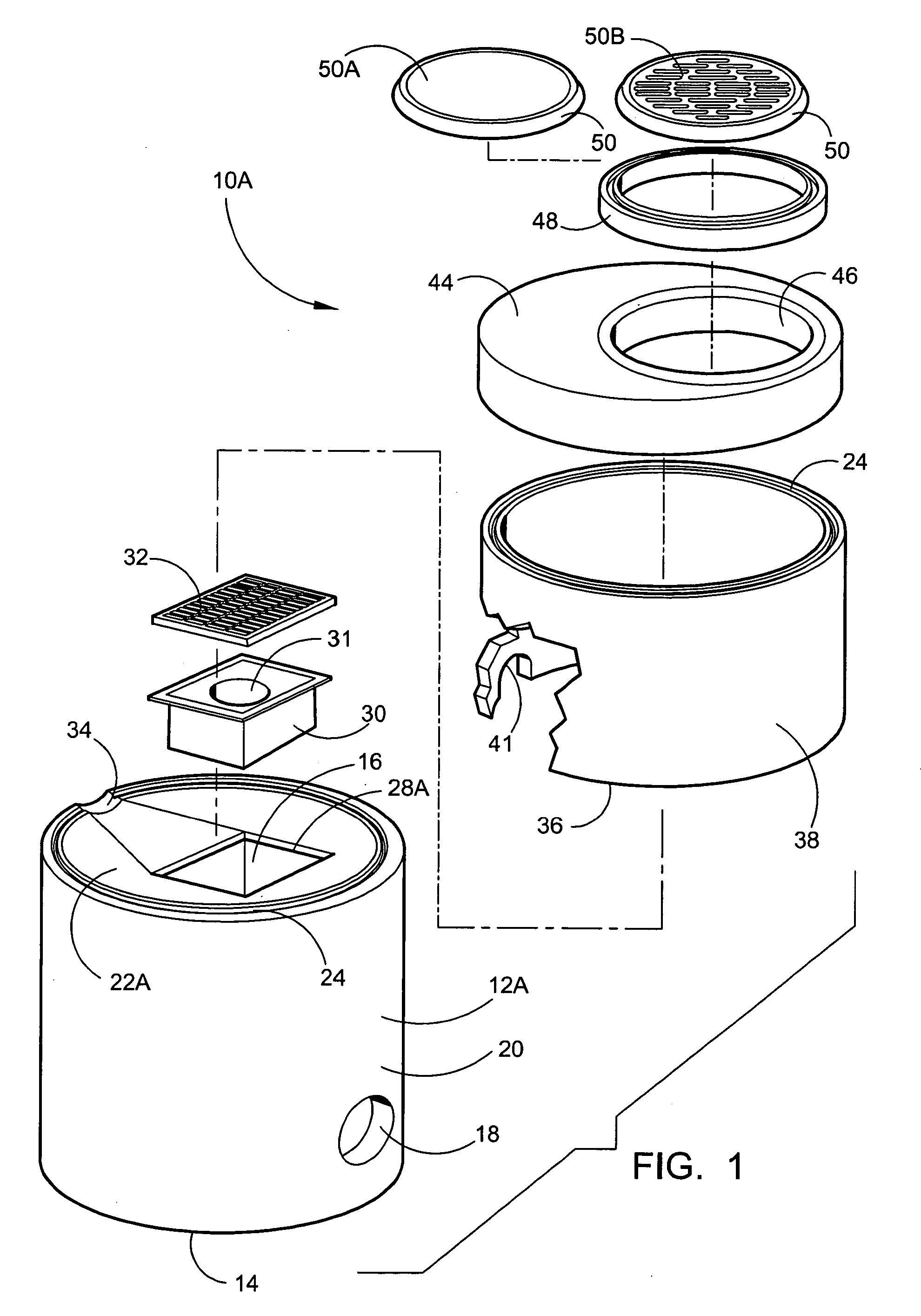

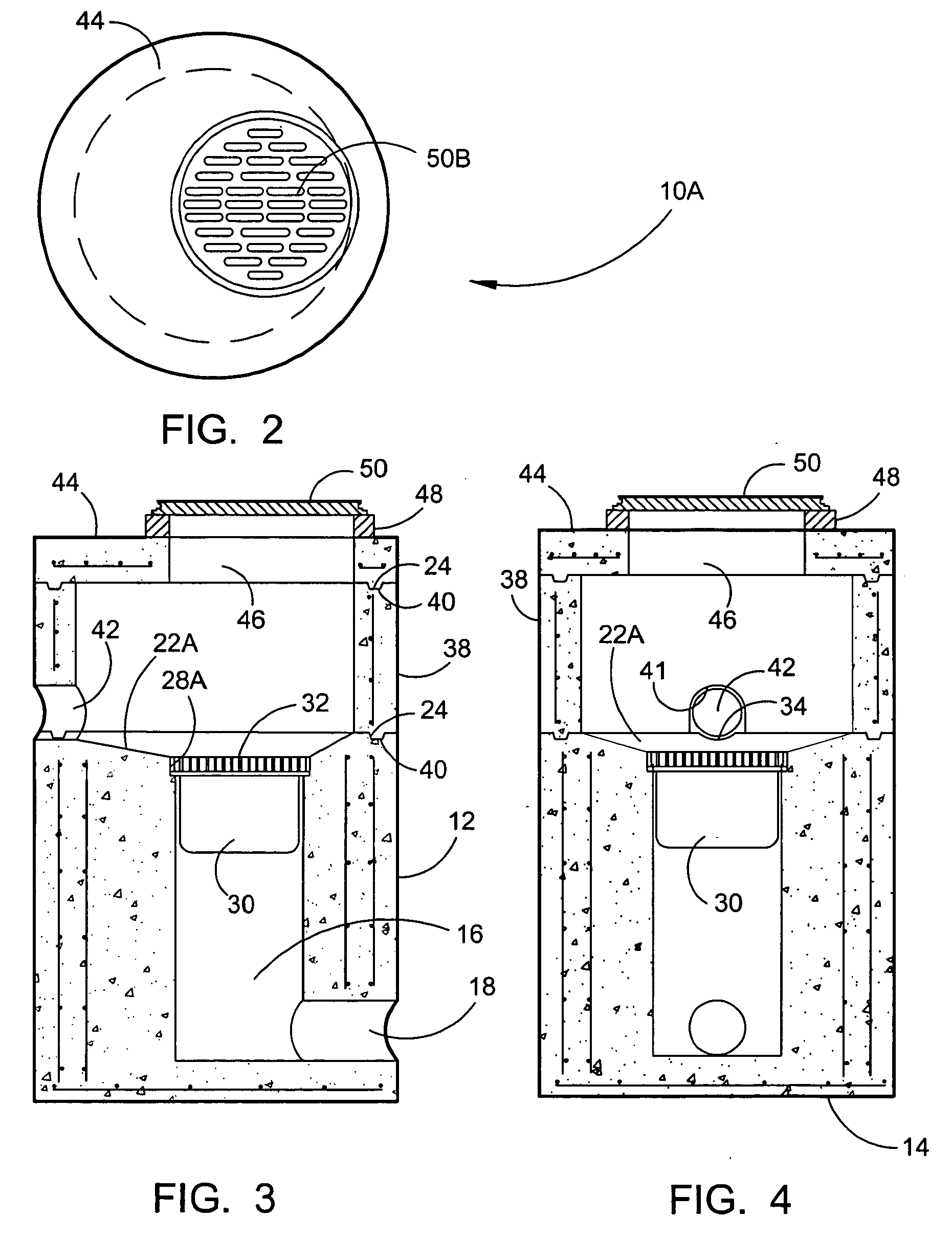

Integrated below-ground vault with a filtered catch basin

InactiveUS7540953B2Improve handlingImprove purification effectPaving gutters/kerbsTreatment involving filtrationControl systemStreamflow

The invention relates to an integrated belowground vault with filter catch basin, that allows the runoff water to enter into a belowground two-part vault passing through a commercially available replaceable filter before being transferred out to the sewer, Rood control system or out through a French drain consisting of a cavity below the device that is filled with drain gravel. A layer of filter cloth can optionally be placed over the drain gravel. This device will be manufactured in variety of sizes and shapes and made from several different materials. The device has the unique ability of being capable of filtering low flow water runoff while allowing high volume to pass through with the added benefit of not retaining water that can become a mosquito breeding ground.

Owner:FITZGERALD JAMES

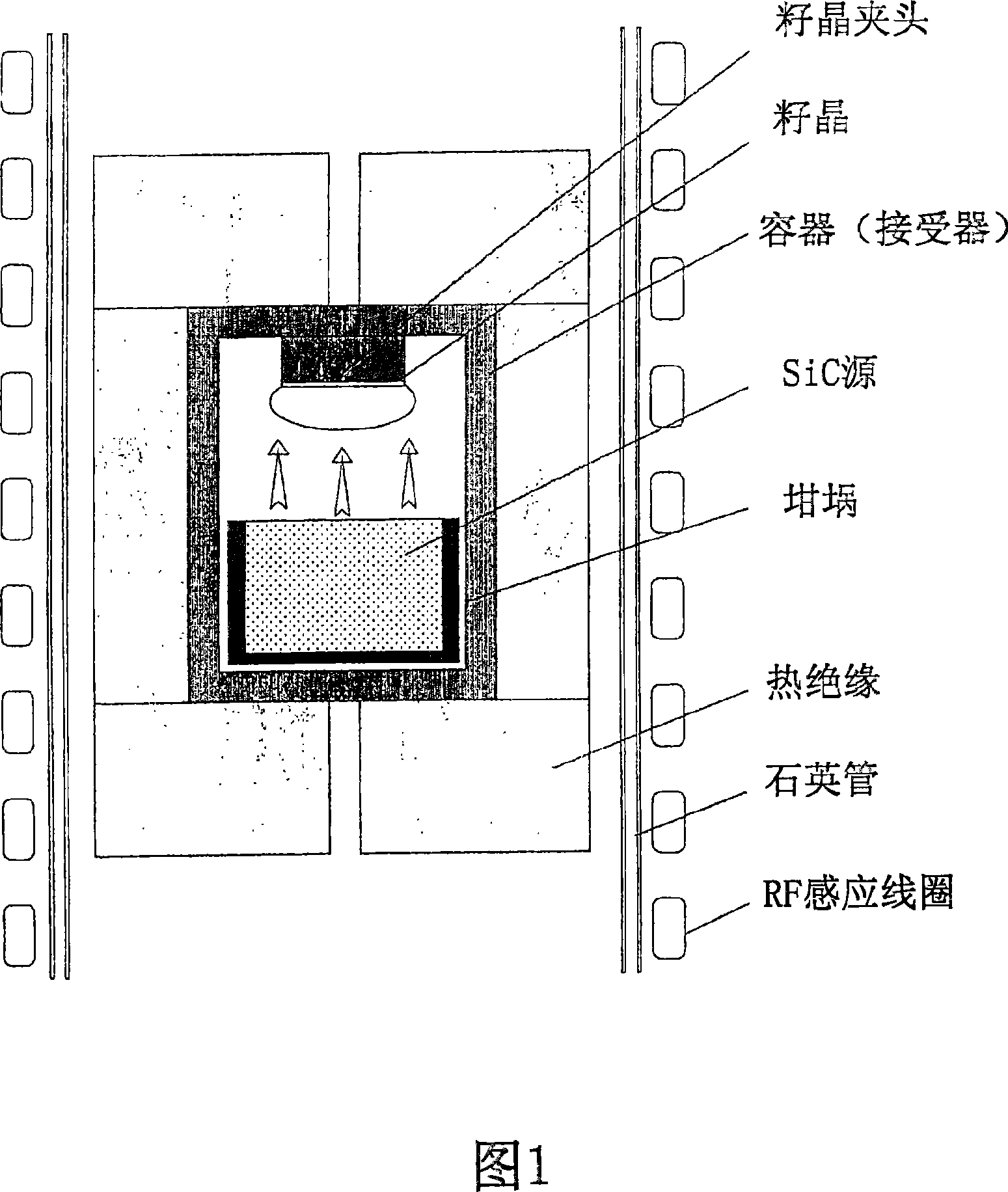

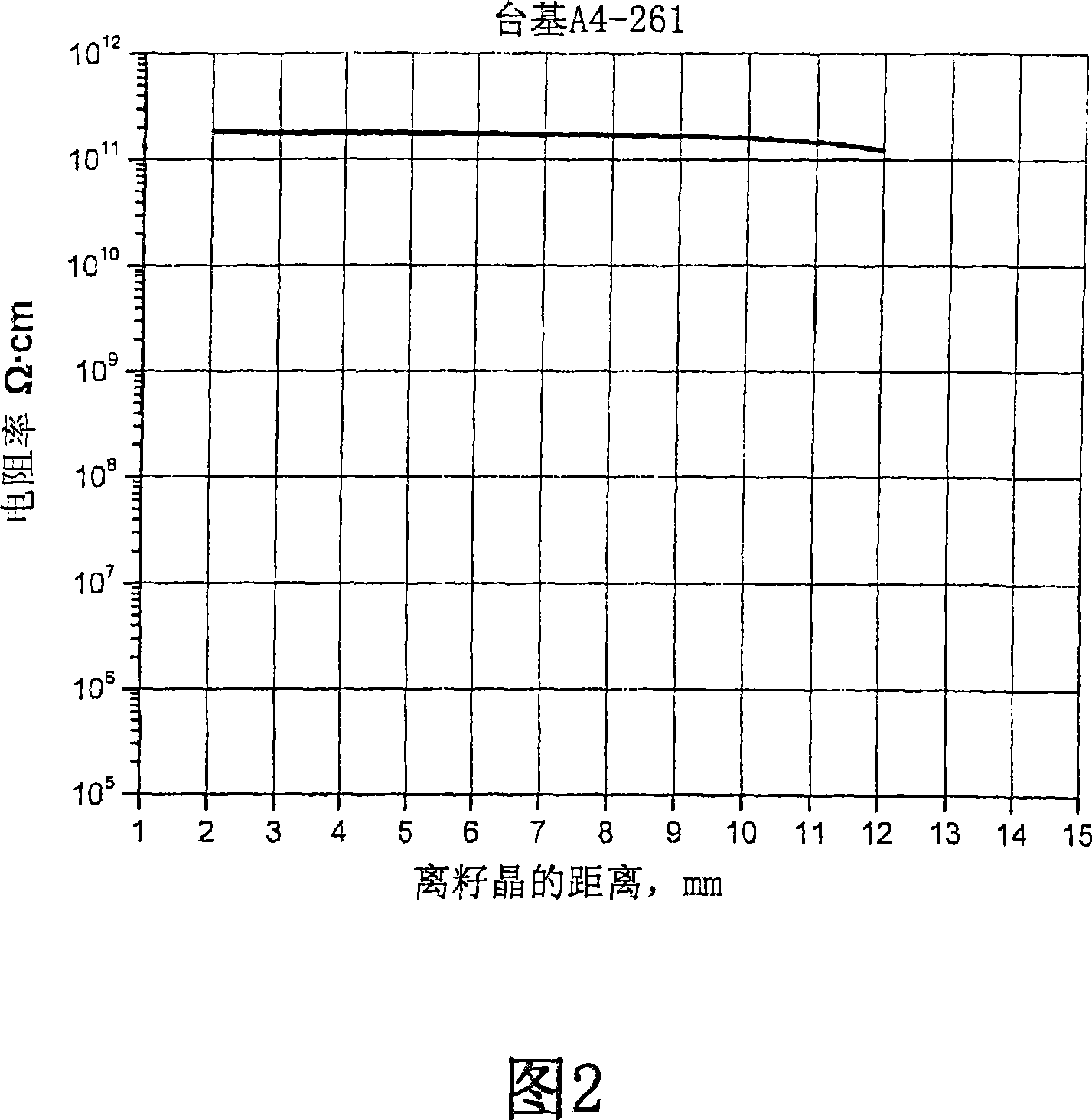

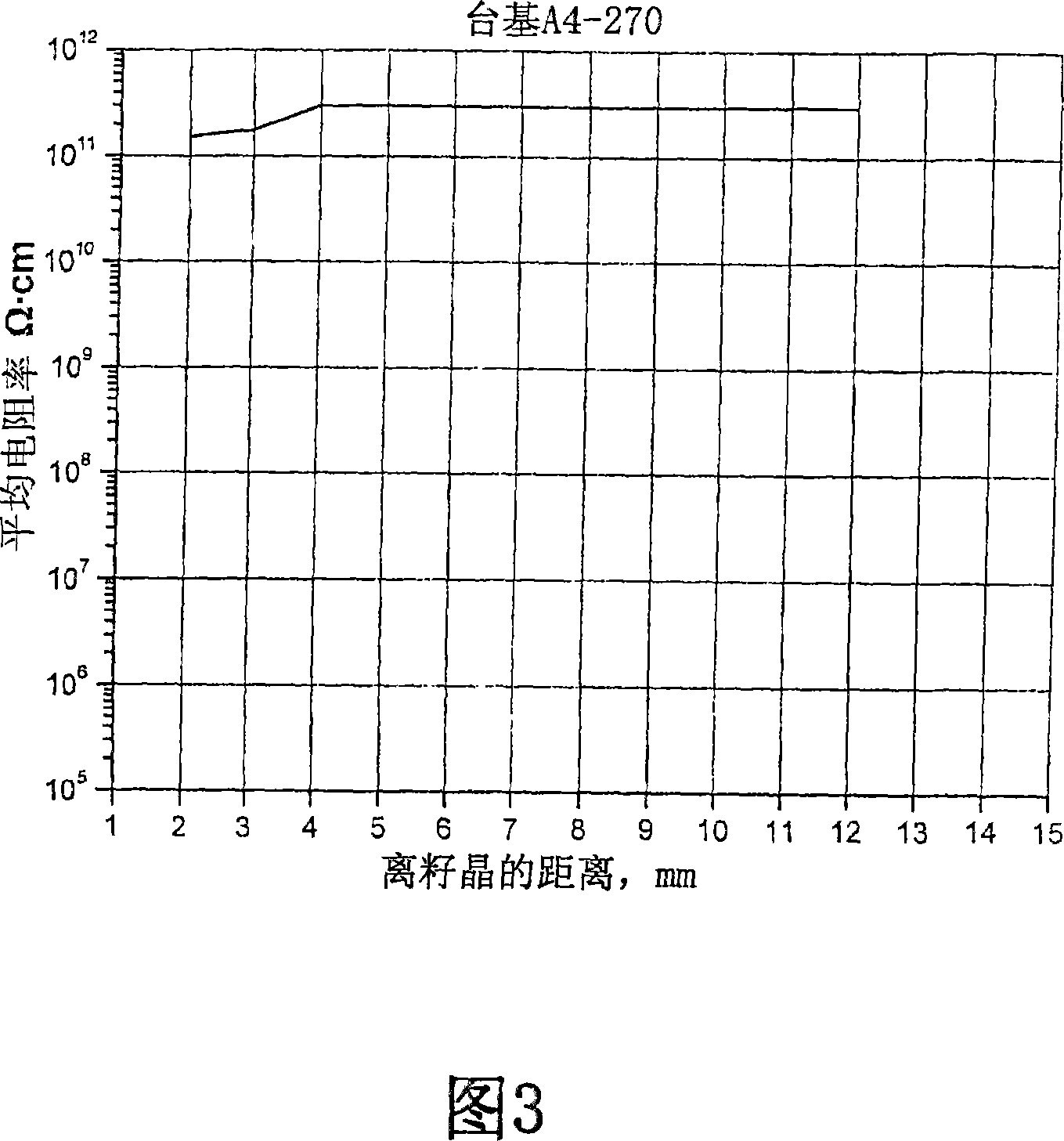

Low-doped semi-insulating SIC crystals and method

InactiveCN1985029AIncrease concentrationAvoid sedimentPolycrystalline material growthSemiconductor/solid-state device manufacturingCapacitanceShallow donor

The invention relates to substrates of semi-insulating silicon carbide used for semiconductor devices and a method for making the same. The substrates have a resistivity above 106 Ohm-cm, and preferably above 108 Ohm-cm, and most preferably above 109 Ohm-cm, and a capacitance below 5 pF / mm2 and preferably below 1 pF / mm2. The electrical properties of the substrates are controlled by a small amount of added deep level impurity, large enough in concentration to dominate the electrical behavior, but small enough to avoid structural defects. The substrates have concentrations of unintentional background impurities, including shallow donors and acceptors, purposely reduced to below 5 DEG 1016 cm-3, and preferably to below 1 DEG 1016 cm-3, and the concentration of deep level impurity is higher, and preferably at least two times higher, than the difference between the concentrations of shallow acceptors and shallow donors. The deep level impurity comprises one of selected metals from the periodic groups IB, IIB, IIIB, IVB, VB, VIB, VIIB and VIIIB. Vanadium is a preferred deep level element. In addition to controlling the resistivity and capacitance, a further advantage of the invention is an increase in electrical uniformity over the entire crystal and reduction in the densityof crystal defects.

Owner:II VI

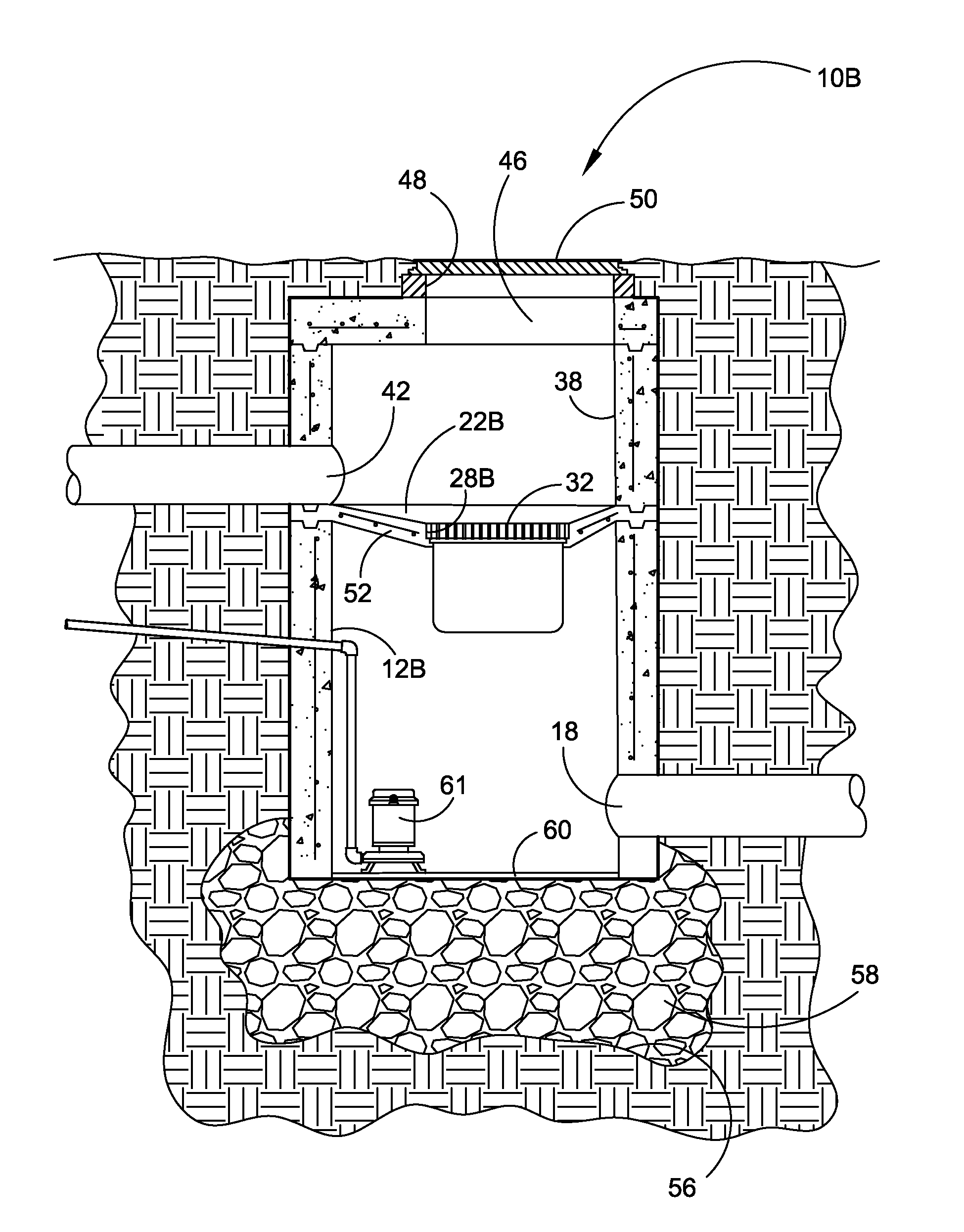

Integrated below-ground vault with a filtered catch basin

InactiveUS7163635B2Improve handlingImprove purification effectPaving gutters/kerbsLoose filtering material filtersFlood controlStreamflow

The invention relates to an integrated belowground vault with filter catch basin, that allows the runoff water to enter into a belowground two-part vault passing through a commercially available replaceable filter before being transferred out to the sewer, flood control system or out through a French drain consisting of a cavity below the device that is filled with drain gravel. A layer of filter cloth can optionally be placed over the drain gravel. This device will be manufactured in variety of sizes and shapes and made from several different materials. The device has the unique ability of being capable of filtering low flow water runoff while allowing high volume to pass through with the added benefit of not retaining water that can become a mosquito breeding ground.

Owner:FITZGERALD JAMES

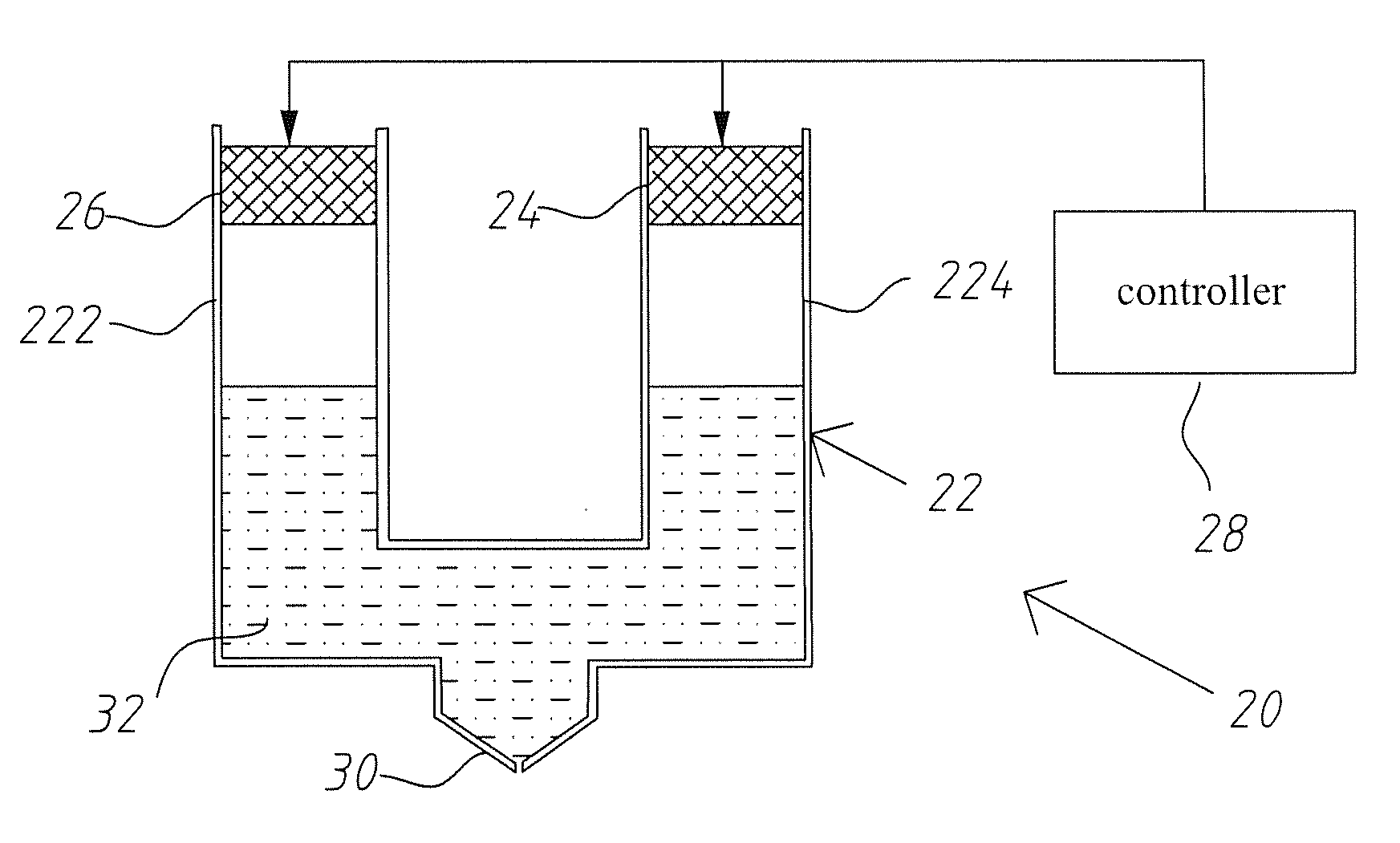

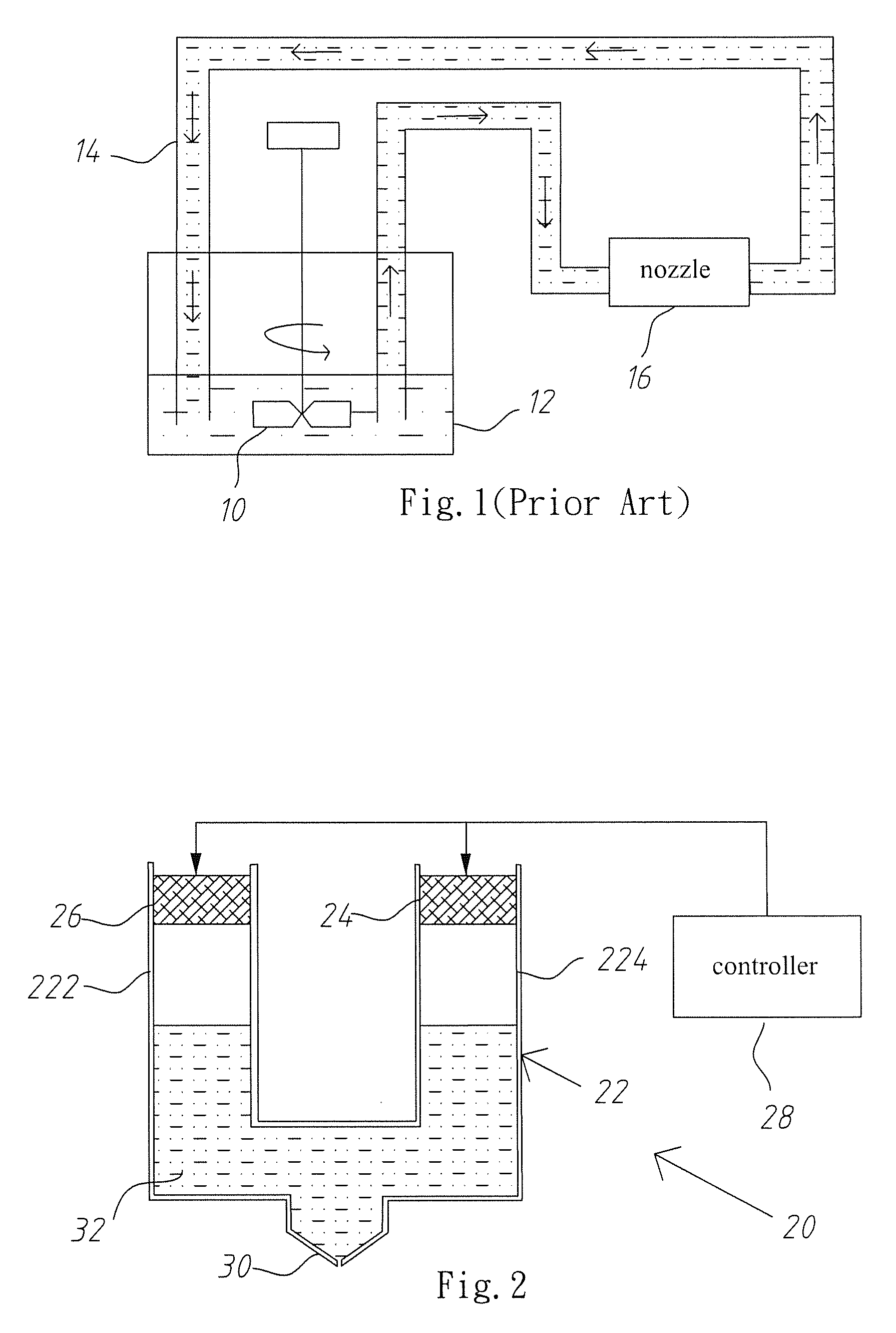

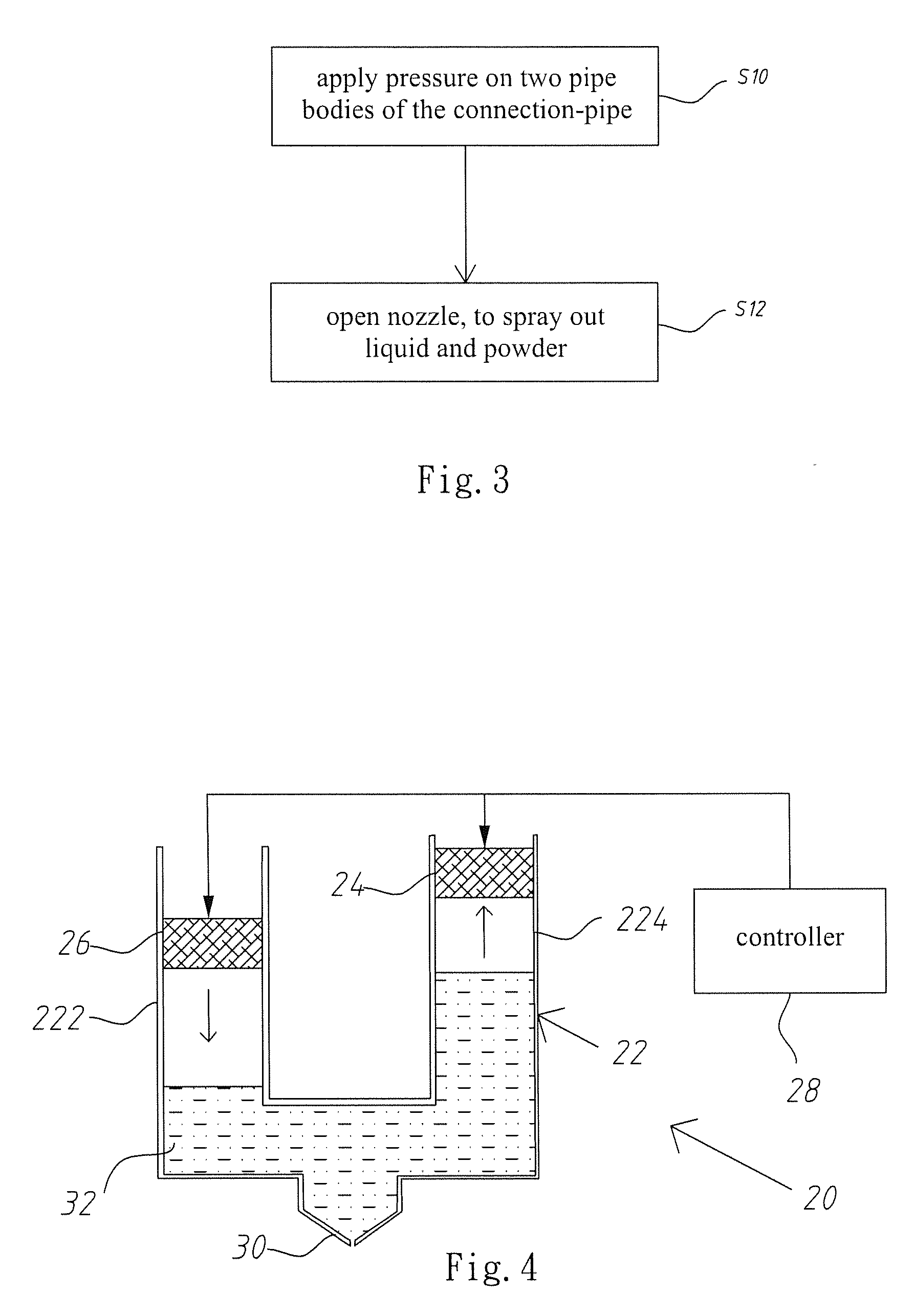

Connection-pipe sediment prevention device and method

InactiveUS20120286064A1Equally distributedAvoid sedimentShaking/oscillating/vibrating mixersTransportation and packagingReciprocating motionEngineering

A connection-pipe sediment prevention device and method. In said connection-pipe sediment prevention device, at least a pressuring element is disposed at an opening of a pipe body of said connection-pipe, and a controller controls reciprocal movements of said pressuring elements, to make suspension liquid to flow in said connection-pipe and not to produce sediment. A nozzle is provided at bottom of said connection-pipe, to spray out said suspension liquid. Said connection-pipe sediment prevention method utilizes same means to make powder distribute evenly in said suspension liquid, so that said suspension liquid is sprayed out evenly from said nozzle. A connection-pipe principle is used, such that said suspension liquid having insoluble powder will not produce sediment, in achieving uniform spray. In addition, it is not required to put in large amount of powder and liquid at one time, thus saving production cost.

Owner:CHANG GUNG UNIVERSITY

Integrated below-ground vault with a filtered catch basin

InactiveUS20070262009A1Improve handlingImprove purification effectPaving gutters/kerbsTreatment involving filtrationControl systemEngineering

The invention relates to an integrated belowground vault with filter catch basin, that allows the runoff water to enter into a belowground two-part vault passing through a commercially available replaceable filter before being transferred out to the sewer, Rood control system or out through a French drain consisting of a cavity below the device that is filled with drain gravel. A layer of filter cloth can optionally be placed over the drain gravel. This device will be manufactured in variety of sizes and shapes and made from several different materials. The device has the unique ability of being capable of filtering low flow water runoff while allowing high volume to pass through with the added benefit of not retaining water that can become a mosquito breeding ground.

Owner:FITZGERALD JAMES

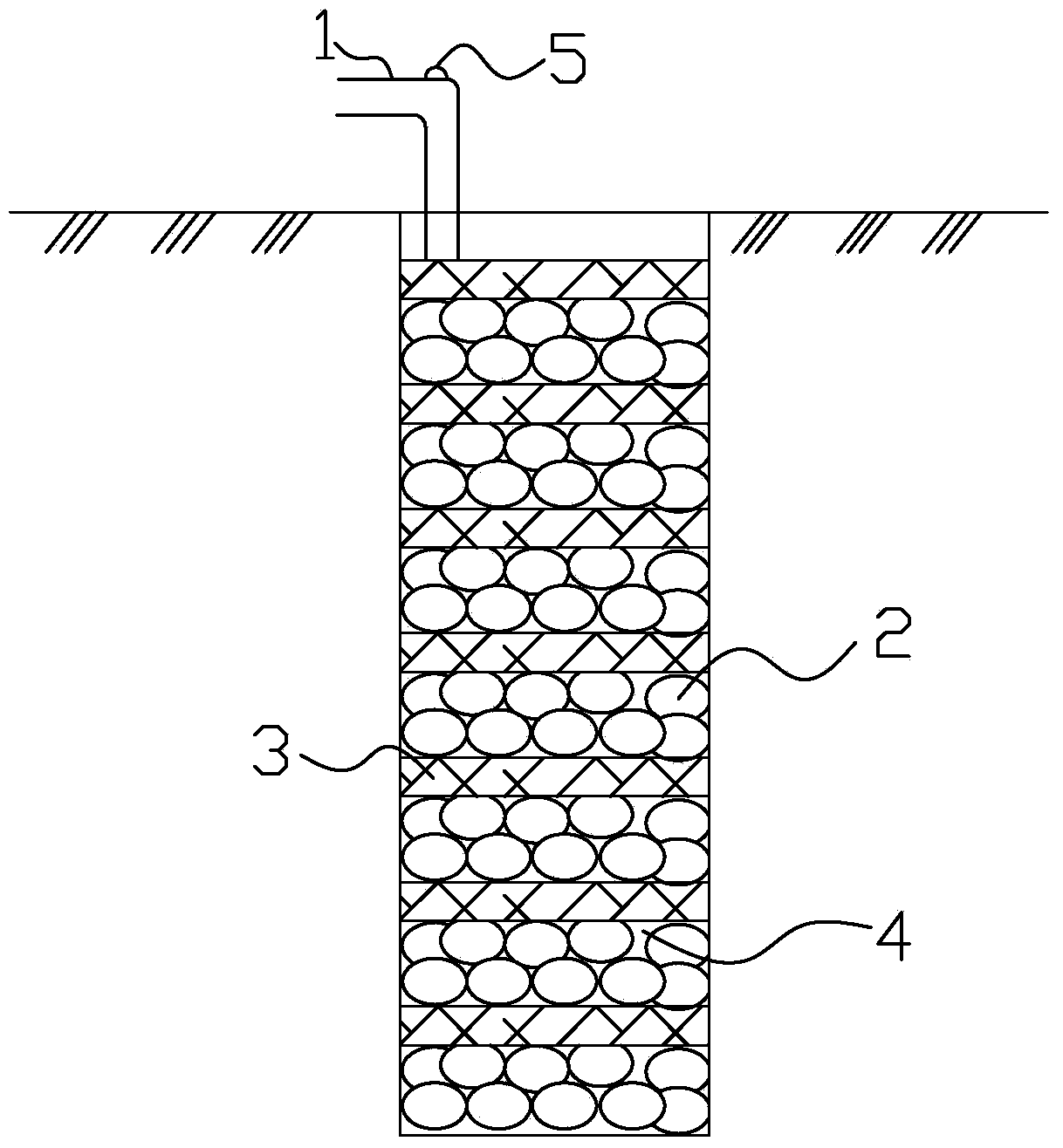

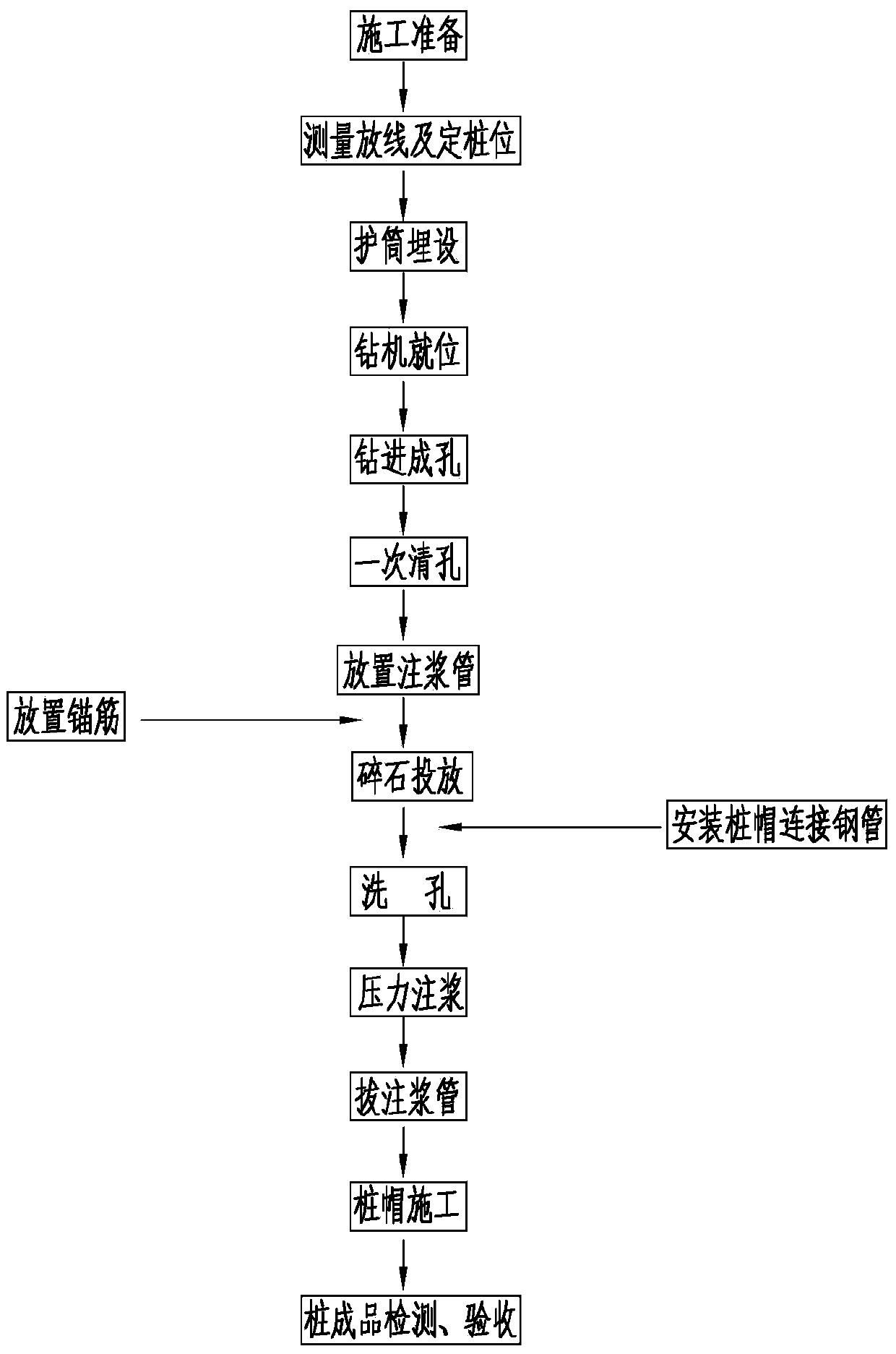

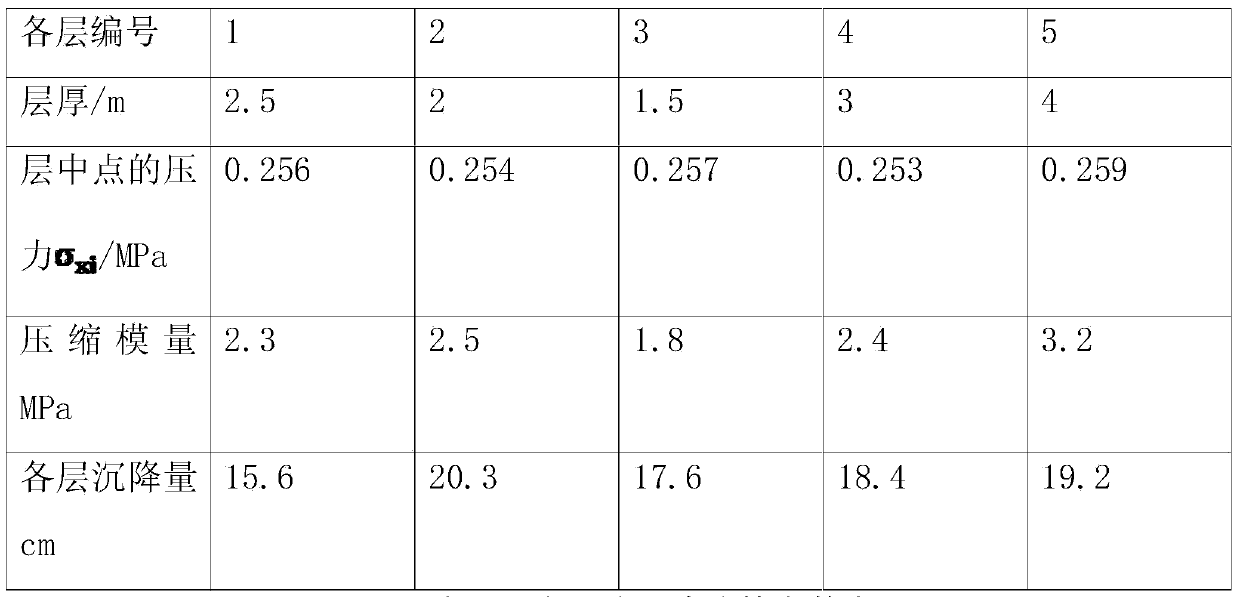

Construction method of gravel grouting pile

The invention discloses a construction method of a gravel grouting pile. The construction method comprises the following steps: (1) preparing for construction, (2) conducting measurement, paying off and positioning of the pile, (3) embedding a protective canister, (4) placing a drilling machine in place, (5) forming a hole by drilling, (6) cleaning the hole at a time, (7) placing a grouting pipe, (8) placing an anchor bar, (9) putting gravels in the hole, (10) installing a pile cap connecting steel pipe, (11) cleaning the hole, (12) conducting pressure grouting, (13) pulling the grouting pipe out, (14) constructing a pile cap, and (15) conducting detection and acceptance inspection on the finished pile. According to the construction method of the gravel grouting pile, the construction speed is high, the construction period is shortened, and compared with soft foundation treatment such as a prestressed pipe pile and a Y-type pile, the engineering investment is saved; the labor intensity is low, the construction is safe, and the construction method can be widely popularized and used; the gravel pile formed by cement and gravels is high in integrality and stability. The engineering drilling machine is adopted in a soft foundation to drill the hole in a rotating and cycling mode to form the pile, the disturbance to the foundation and the surrounding buildings is small, ground depression is controlled, and the construction method is small in vibration and low in noise during the construction and has good social benefits.

Owner:NINGBO SHENGHONG CONSTR ENG

Separation and refining method of 1,3-methyl glycol in ferment liquor

ActiveCN1880290AReduce energy consumptionNo cloggingOrganic compound preparationHydroxy compound preparation1-PentanolFiltration

This invention relates to a method for separating and purifying 1,3-dihydroxypropane from microbial fermentation liquor, comprising: after the sterilization and dehydration of fermentation liquor, add in 1-pentanol or isoamyl alcohol, n-butanol and n-hexanol, then remove the sediment in the fermentation liquor by filtration or settlement followed by washing; add in appropriate amount of glycerol or 1,4-butylene glycol to the supernatant to recover 1-pentanol or isoamyl alcohol, n-butanol and n-hexanol, by decompression or normal pressure distillation, so as to produce high-purity 1,3-dihydroxypropane, with more than 95% recovering rate. This invention is characterized of simple separation process, mature technique, low separation cost, and little additional introduced agent with easy recovery. Besides, the crystallization sediment in the fermentation liquor can be efficiently separated, which overcomes the problems of foaming, agglomerating and pipe clogging during distillation, so as to realize continuous operation.

Owner:PETROCHINA CO LTD

Integrated below-ground vault with a filtered catch basin

InactiveUS20060169648A1Improve handlingImprove purification effectPaving gutters/kerbsLoose filtering material filtersTraffic volumeSewerage

The invention relates to an integrated belowground vault with filter catch basin, that allows the runoff water to enter into a belowground two-part vault passing through a commercially available replaceable filter before being transferred out to the sewer, flood control system or out through a French drain consisting of a cavity below the device that is filled with drain gravel. A layer of filter cloth can optionally be placed over the drain gravel. This device will be manufactured in variety of sizes and shapes and made from several different materials. The device has the unique ability of being capable of filtering low flow water runoff while allowing high volume to pass through with the added benefit of not retaining water that can become a mosquito breeding ground.

Owner:FITZGERALD JAMES

Automobile gasoline composite modifying agent

ActiveCN103194284ANot poisonedNo carbon depositionLiquid carbonaceous fuelsFuel additivesAntioxidantSolvent

The invention relates to an automobile gasoline composite modifying agent. The raw material of the modifying agent is prepared from the following components in percentage by weight: 25-50% of an octane value promoter, 30-50% of a combustion improver and 20-25% of a latent solvent, wherein the octane value promoter comprises the following components in percentage by weight: 20-45% of sec-butyl acetate, 30-40% of diisopropyl ether, 5-10% of absolute ethyl alcohol and 20-30% of methyl tert-butyl ether; the combustion improver comprises the following components in percentage by weight: 10-20% of cyclopentane, 47-50% of mixed light arene, 30-40% of alkylate and 3-6% of 1# jet fuel; and the latent solvent comprises the following components in percentage by weight: 10-30% of acetone, 25-30% of dimethoxy ethane, 20-25% of industrial isobutyl alcohol, 22.5-28% of industrial isopropyl alcohol, 1-4% of trinitromethane, 1-2% of glycol ethylene ether, 0.1-0.2% of a clearing agent polyisobutene succinimide, 0.2-0.4% of a metal deactivator T1201 and 0.2-0.4% of an antioxidant. By adopting the automobile gasoline composite modifying agent, a three-way catalyst of an organic ashless exhaust system cannot be poisoned, a fuel spray nozzle and a cylinder exhaust valve cannot be abraded, and carbon deposition and abrasive particles cannot be generated in a machine body.

Owner:ENERGY & ENVIRONMENT RES INST OF HEILONGJIANG PROVINCE +2

Process for the recovery of oil

InactiveUS6264398B1Inhibited DiffusionImprove lipophilicityFatty/oily/floating substances removal devicesWater cleaningFuel oilOil spill

Heavy oil or crude oil spills in sea water are recovered without polluting environment. A natural rubber latex and a coagulant are scattered around lumps of oil spills to coagulate the latex with the coagulant, so that a membrane of the latex is formed around the oil lumps.

Owner:YUGENKAISHA FAMS +1

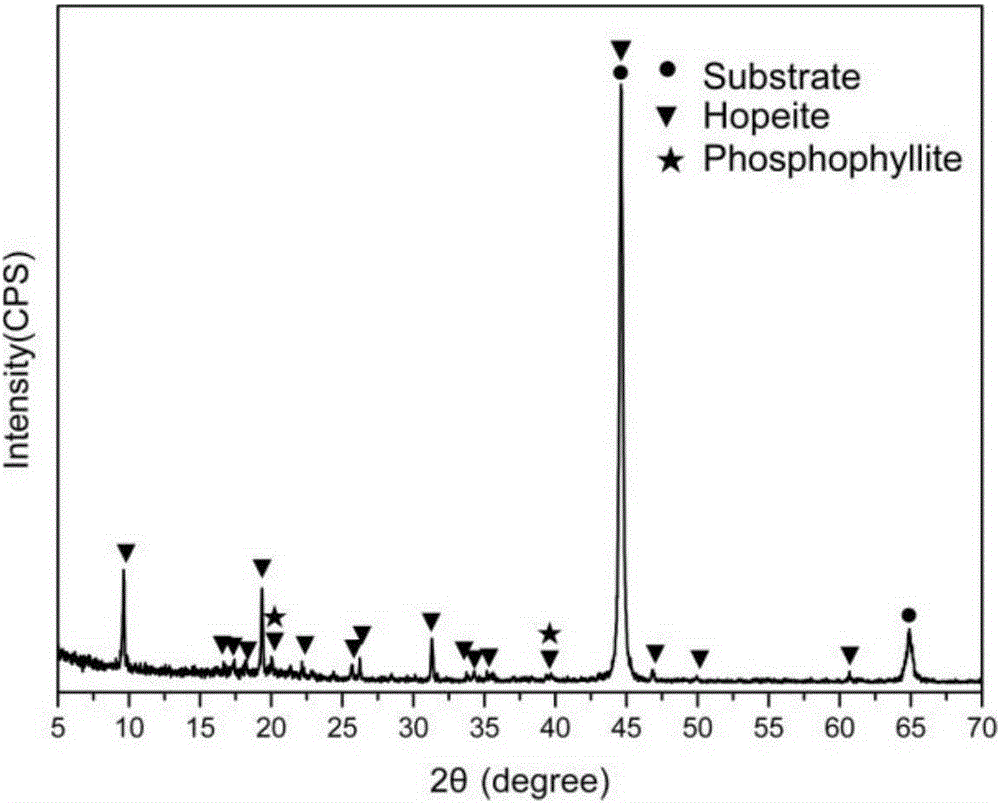

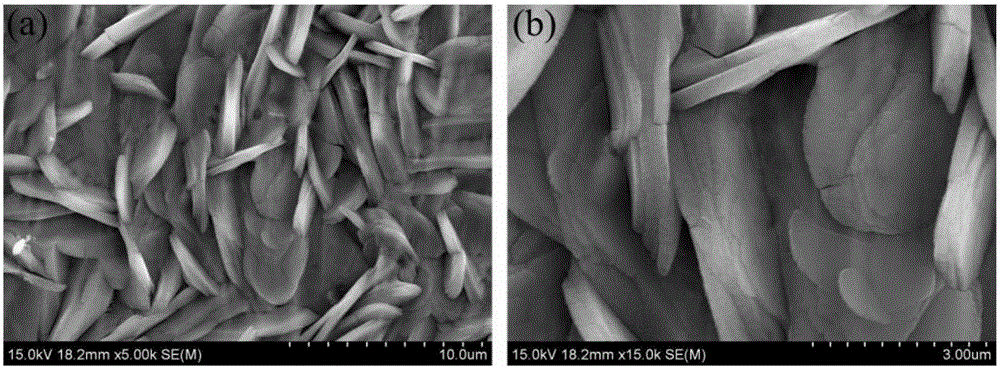

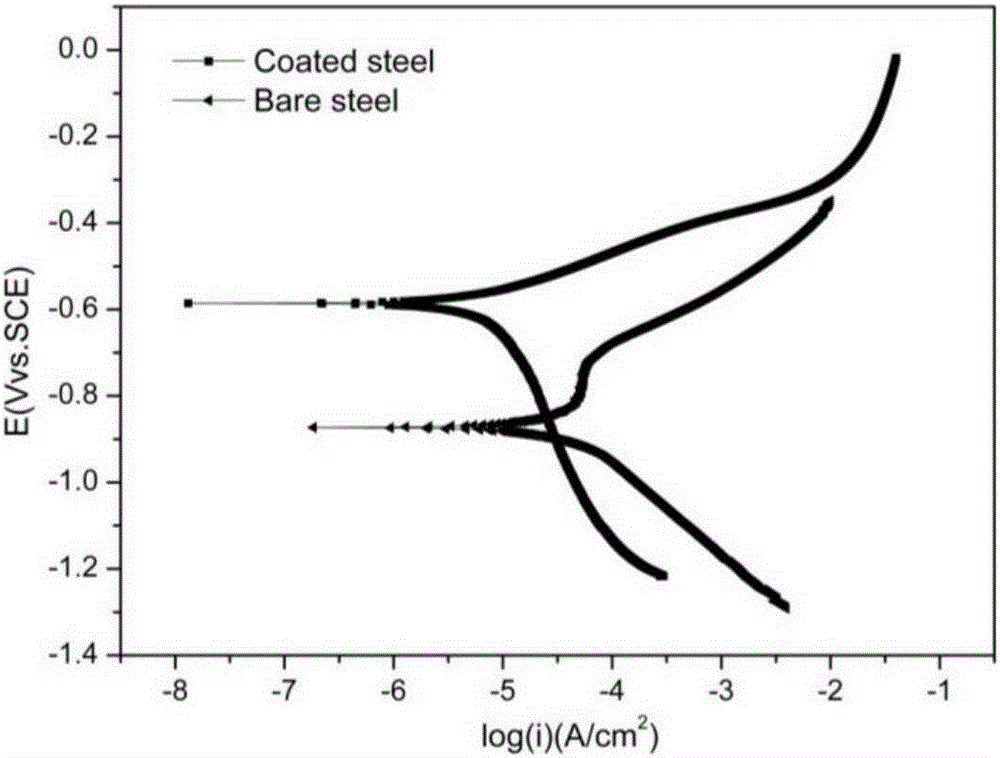

Normal/low-temperature chemical conversion solution for 35CrMnSi steel and preparing method thereof

ActiveCN105256296AReduce energy costsReduce manufacturing costMetallic material coating processesO-Phosphoric AcidChlorate salt

The invention discloses a normal / low-temperature chemical conversion solution for 35CrMnSi steel and a preparing method thereof. The conversion solution consists of the following components in percents by weight: 10-30% of nitric acid, 5-15% of phosphoric acid, 15-25% of zinc oxide, 1-5% of iron powder, 5-10% of a compound accelerant and the balance of water, wherein the compound accelerant is prepared from citric acid and chlorate. The preparing method comprises the following steps: (1), dissolving the zinc oxide in the nitric acid and the phosphoric acid; (2), then, adding the compound accelerant, and after fully dissolving, adding the water; and (3), adding the iron powder into a solution obtained in step (2), taking out the iron powder after curing, and regulating the pH value to 2.0 to 3.0. The normal / low-temperature chemical conversion solution for 35CrMnSi steel does not contain toxic components, the use method is simple and is easy to operate, energy consumption and production cost are low, one layer of even and dense conversion film consisting of 2-5mum flaky zinc phosphate crystals can be formed on the surface of a base body, and the corrosion resistance is great.

Owner:SHANDONG UNIV

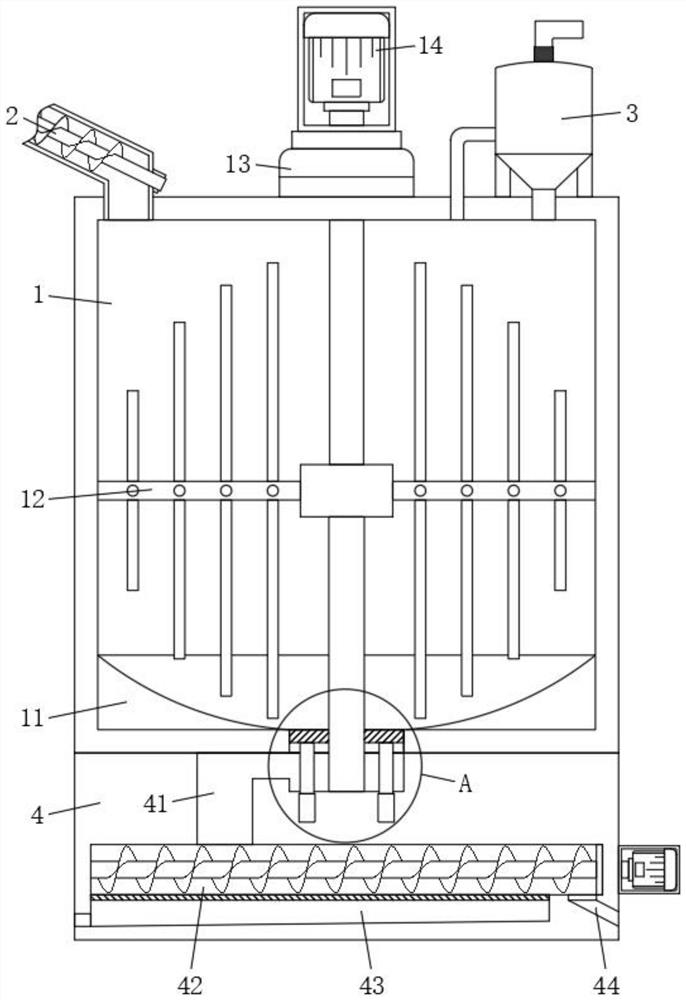

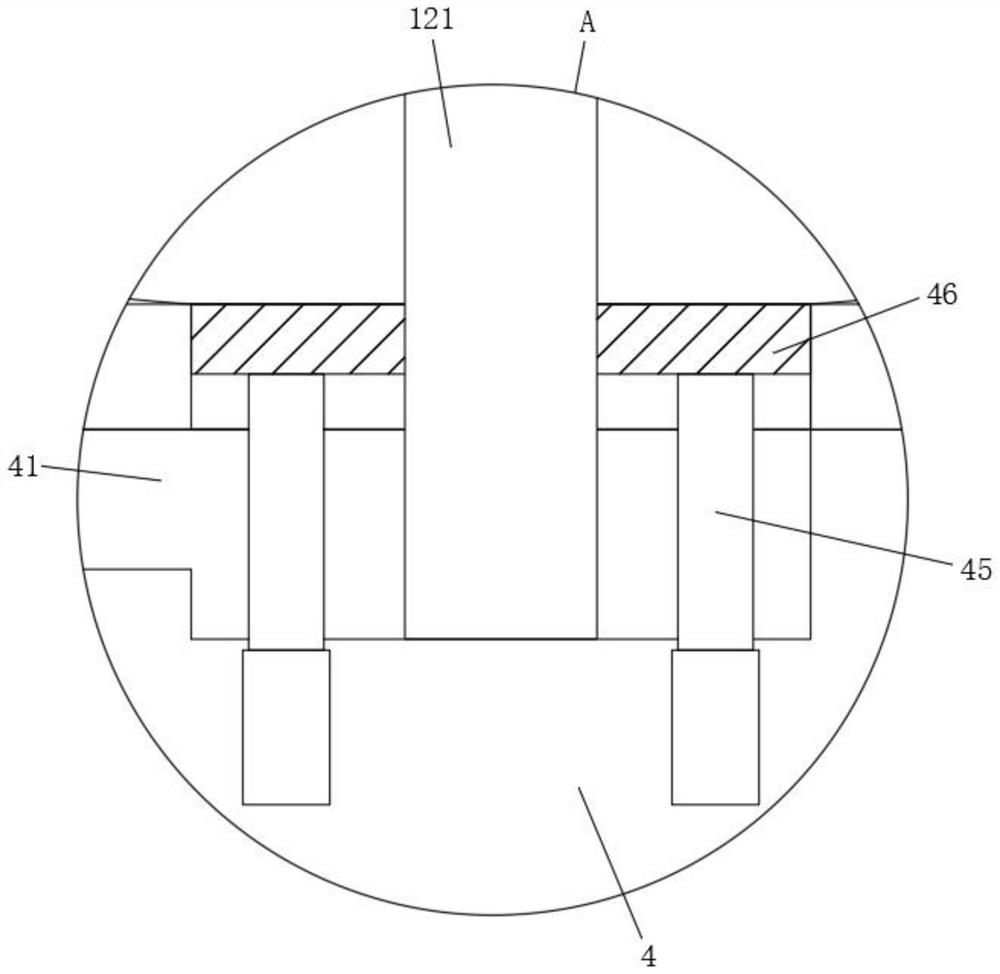

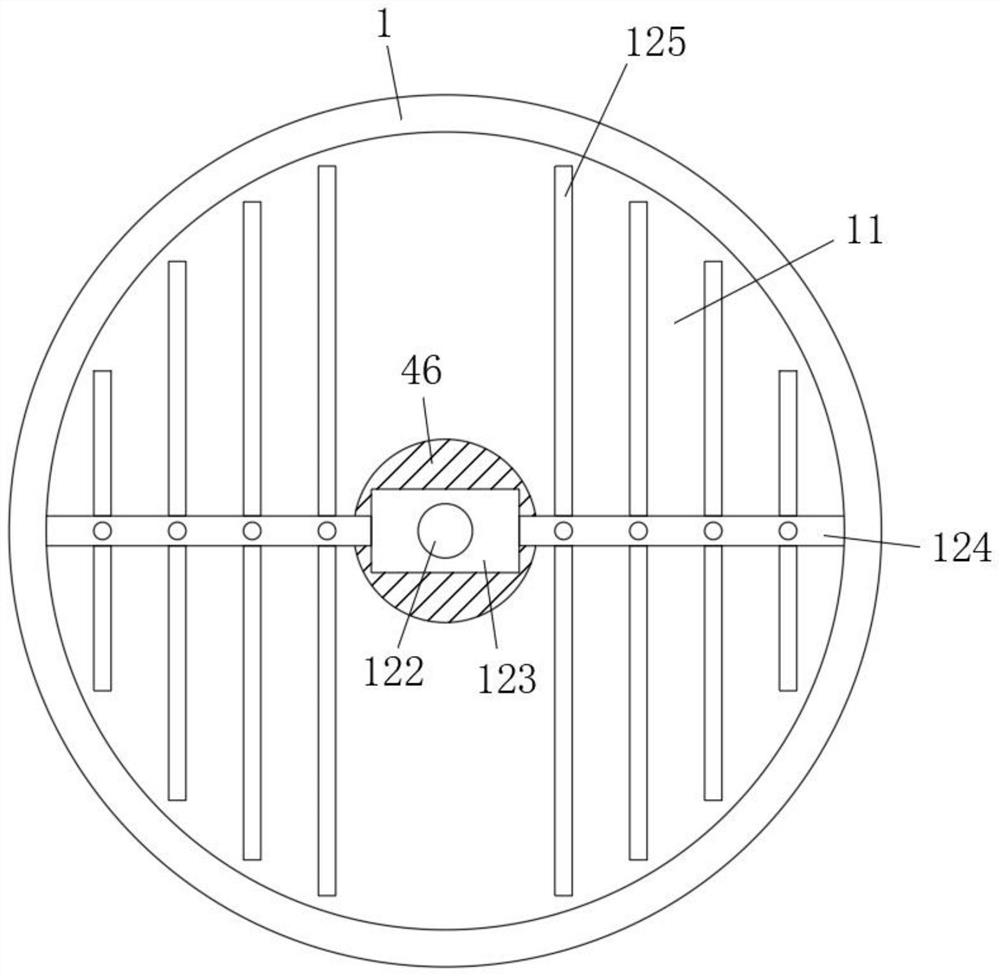

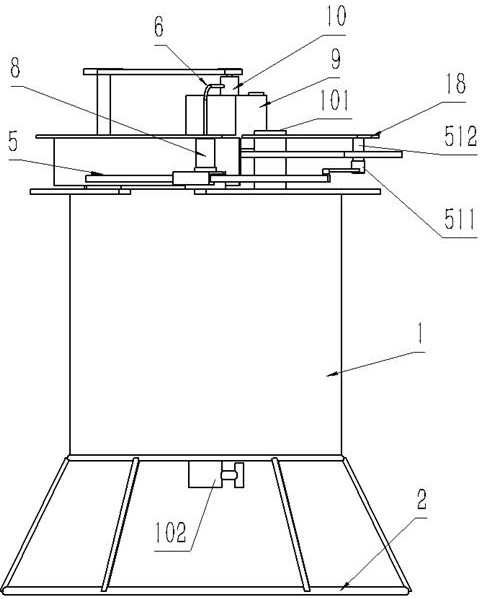

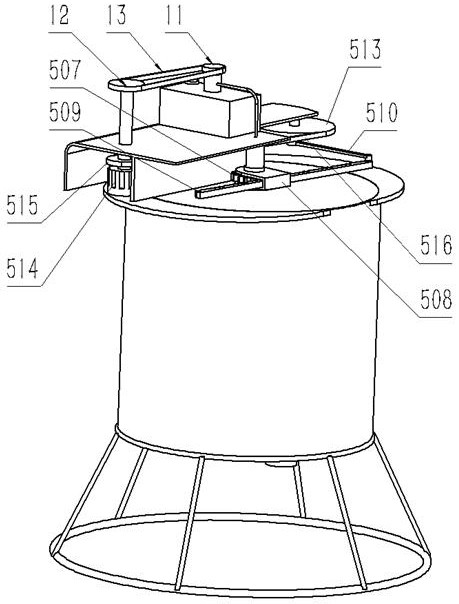

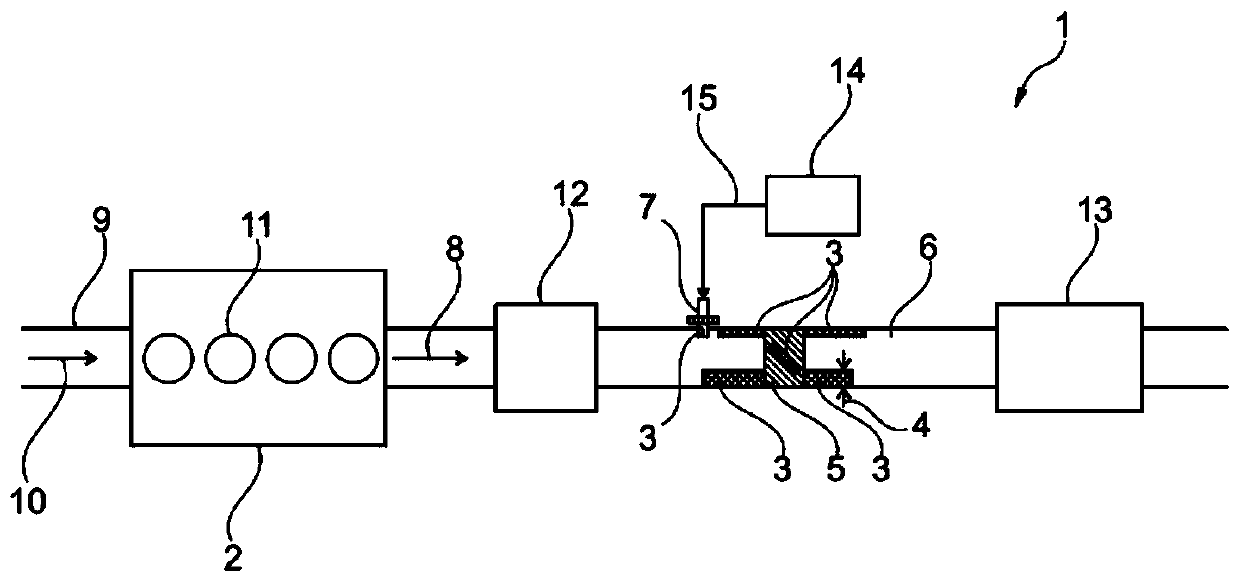

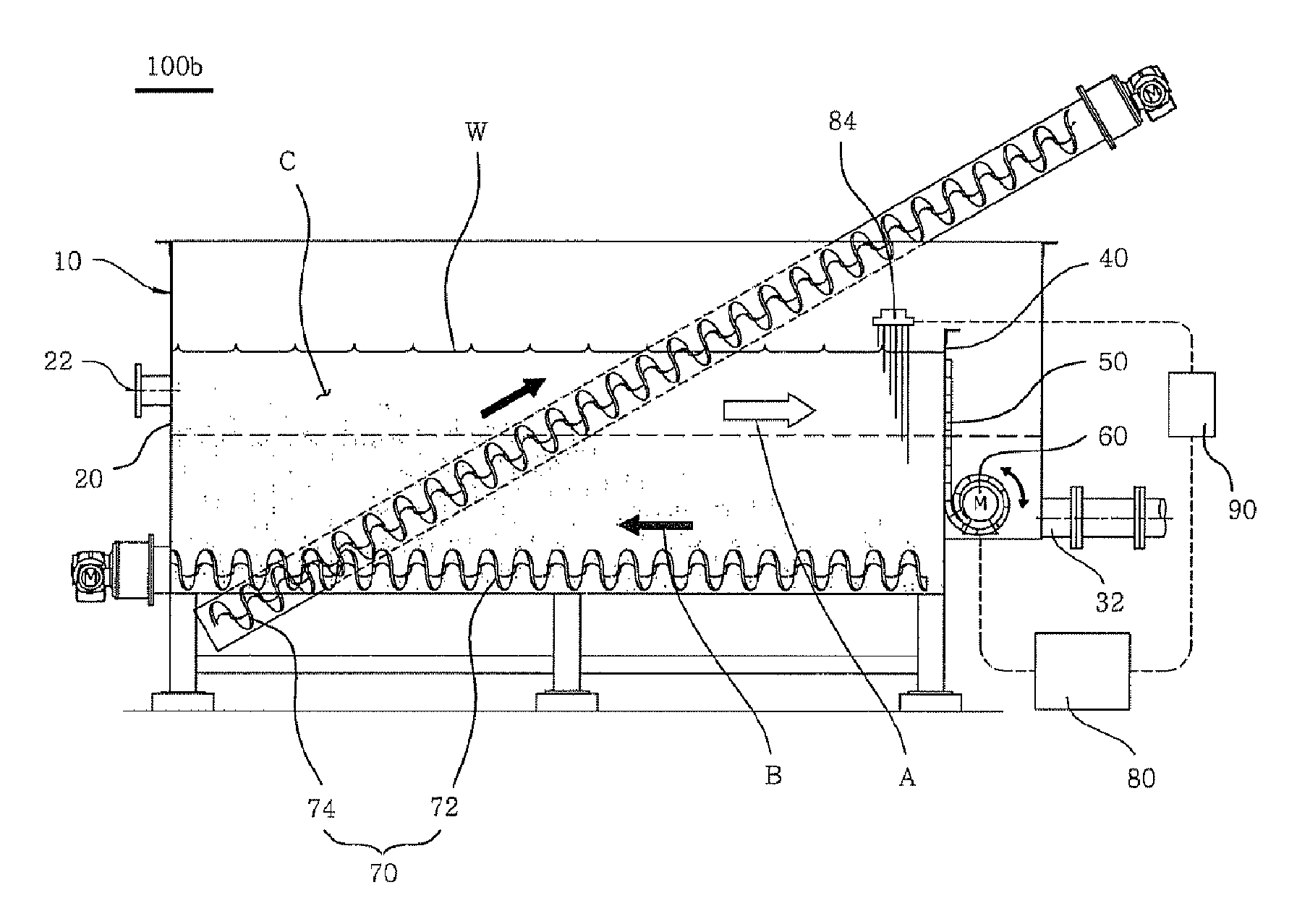

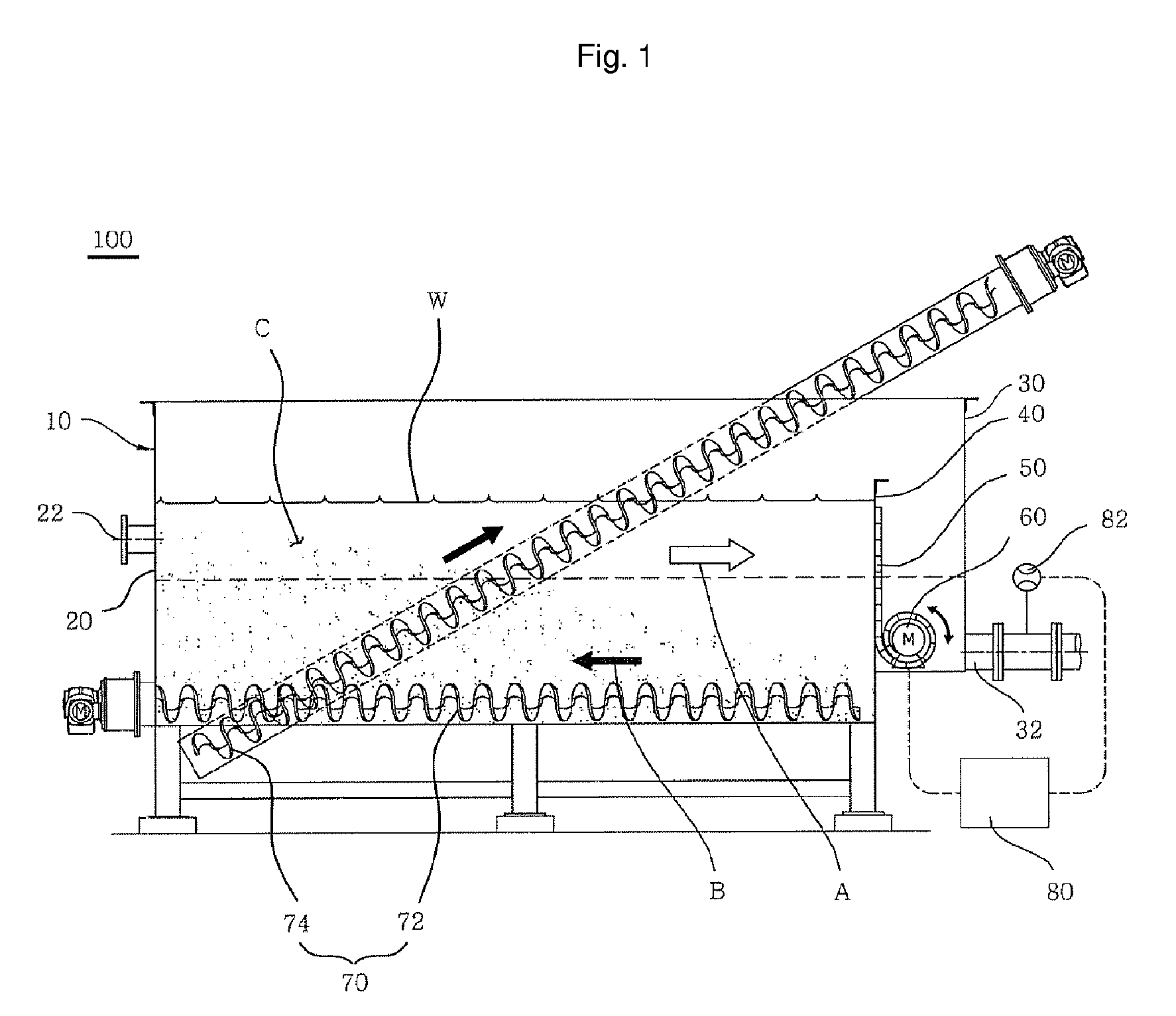

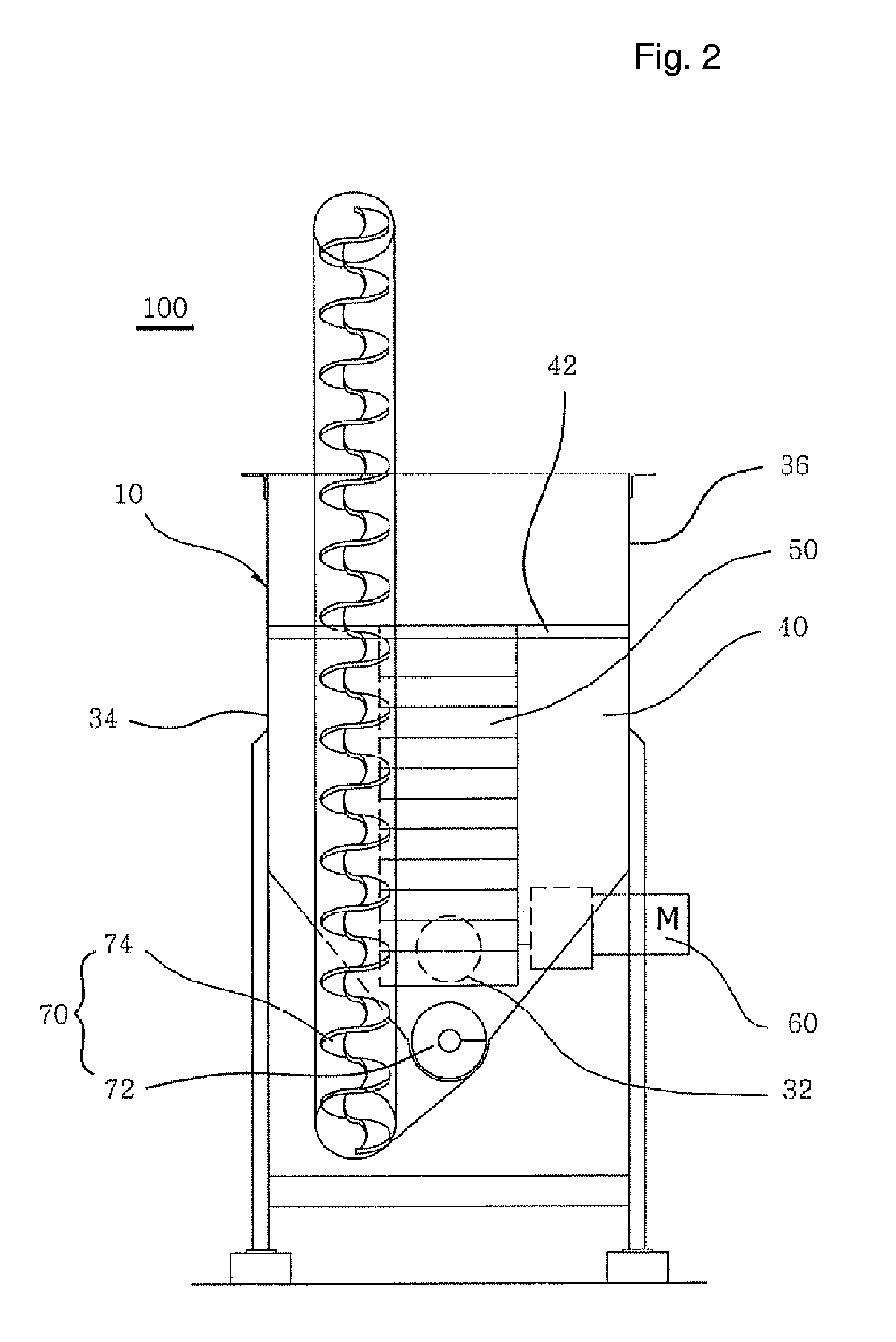

Method and equipment for producing biogas through anaerobic fermentation of biomass

PendingCN112080400AImprove conversion efficiencyAvoid sedimentBioreactor/fermenter combinationsBiological substance pretreatmentsVapor–liquid separatorElectric machinery

The invention belongs to the technical field of biogas production, and discloses a method and equipment for producing biogas through anaerobic fermentation of biomass. The equipment includes a fermentation tank; a screw feeding device and a gas-liquid separator are installed on the top of the fermentation tank, and a dehydration discharging device is installed at the bottom; a heating material-guiding base and a multi-angle agitator are successively installed inside the fermentation tank from bottom to top; the top of the multi-angle agitator is successively connected to a decelerator and an agitator motor; and the decelerator and the agitator motor are fixed between the screw feeding device and the gas-liquid separator on the top of the fermentation tank. Thus, based on the arrangement ofthe multi-angle agitator, continuous stirring without dead angles can be carried out during overall anaerobic fermentation, so that raw materials in the fermentation tank can be fully mixed, and phenomenon such as sediment and scum during fermentation can be effectively avoided; and therefore, the conversion efficiency of biogas and the stability of the overall operation of the equipment can be enhanced, and the problems of equipment blocking can be avoided as well.

Owner:山东中润生物质能源有限公司

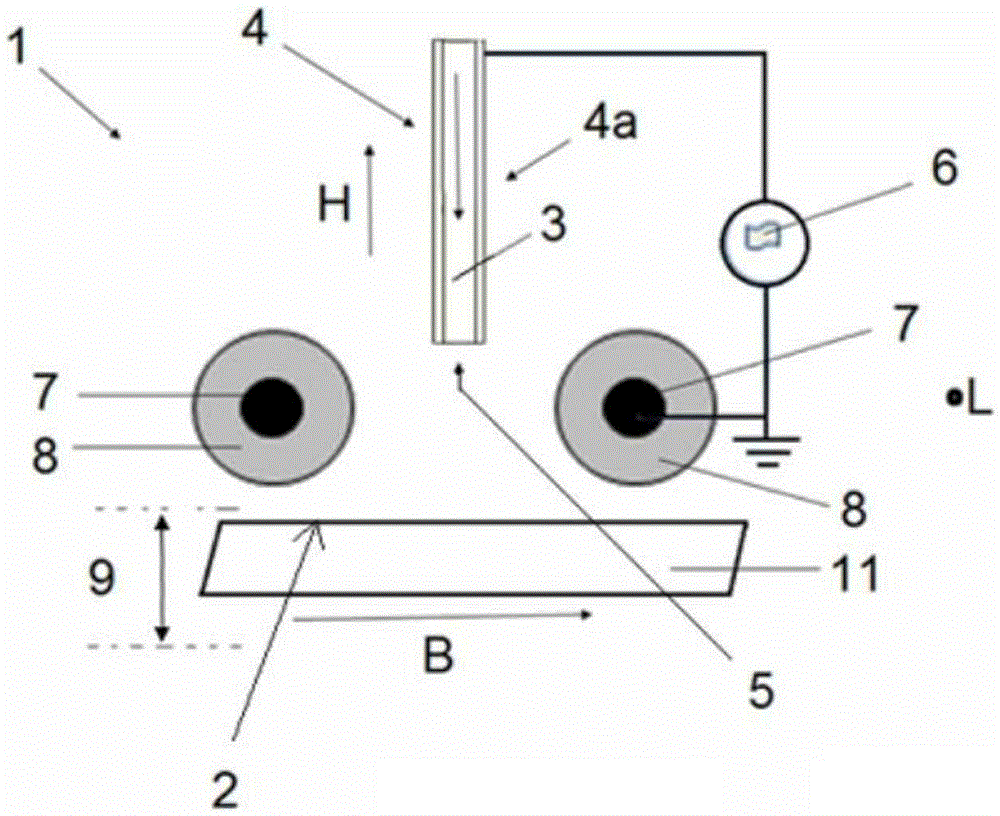

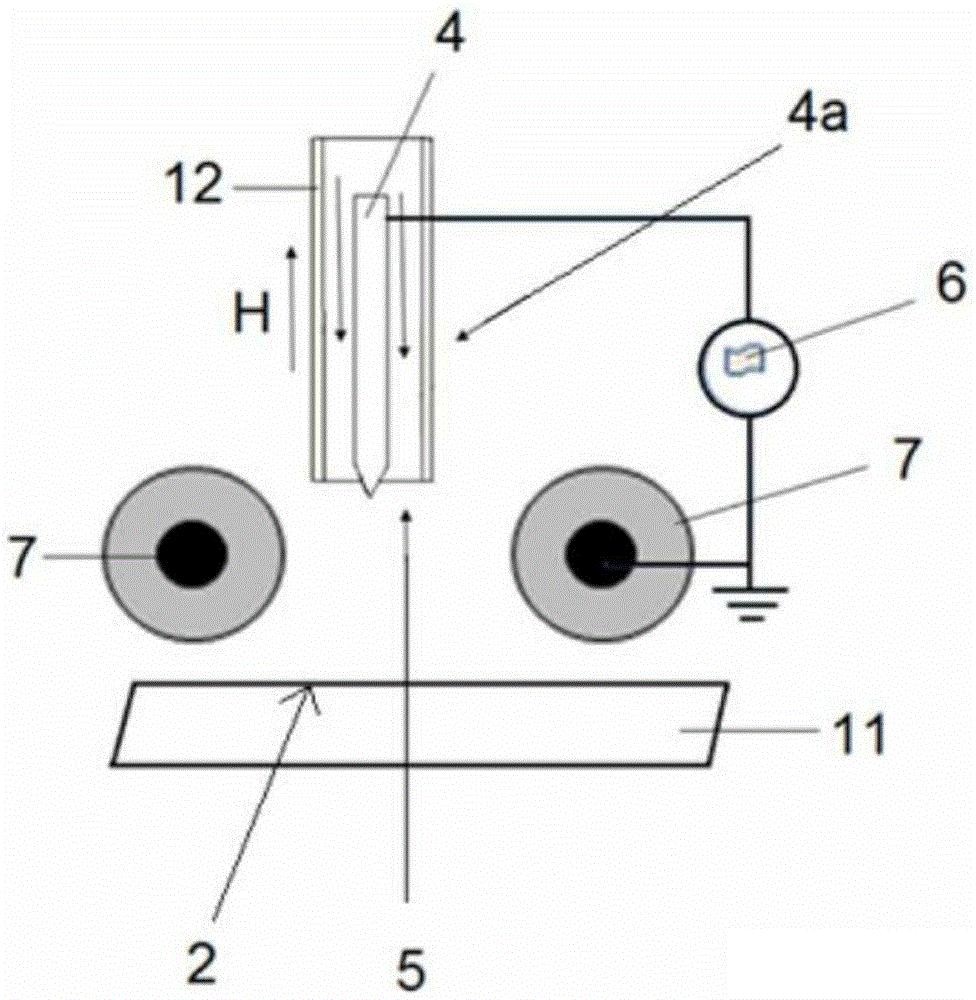

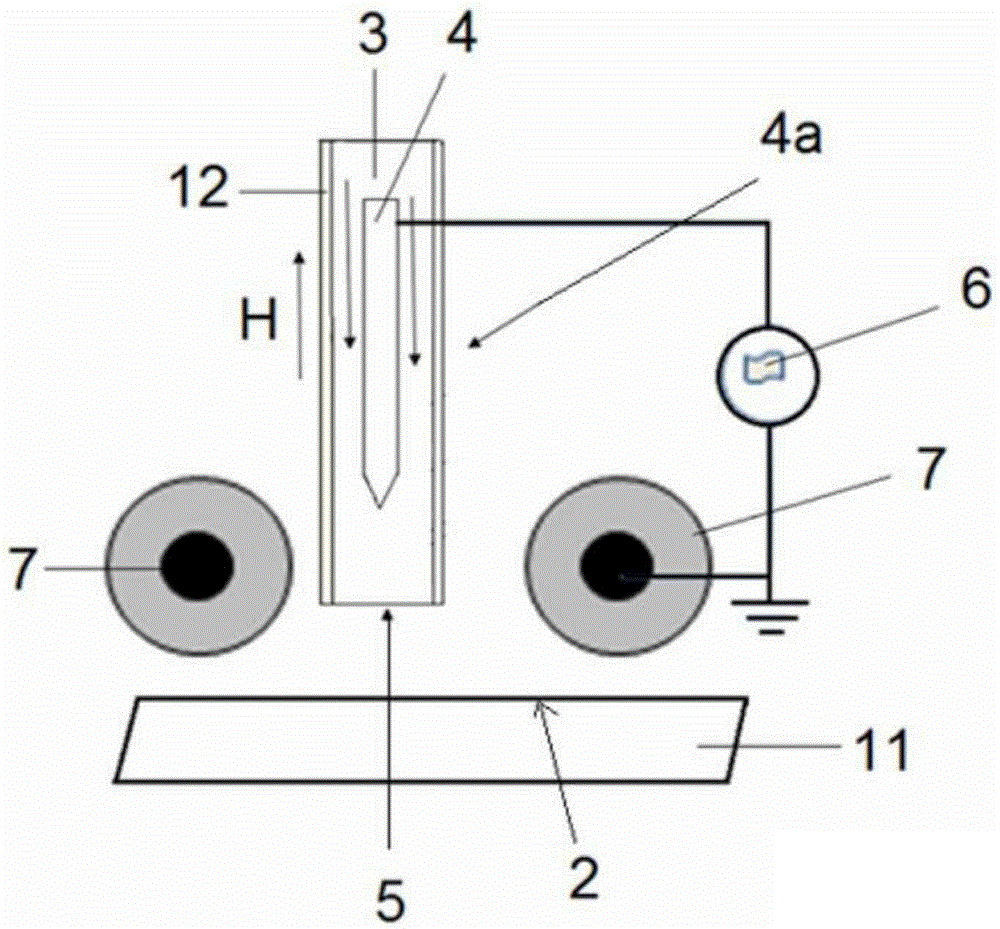

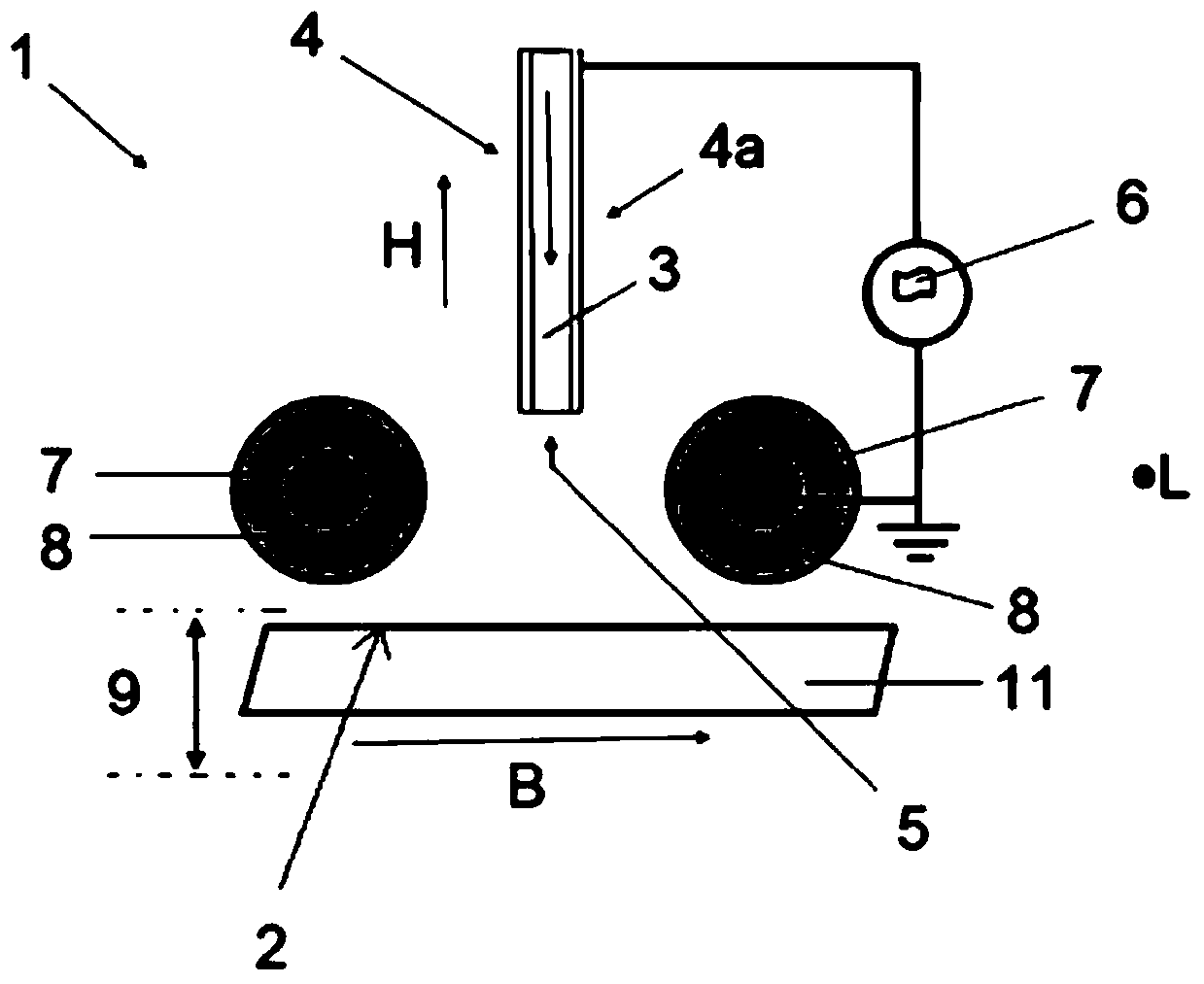

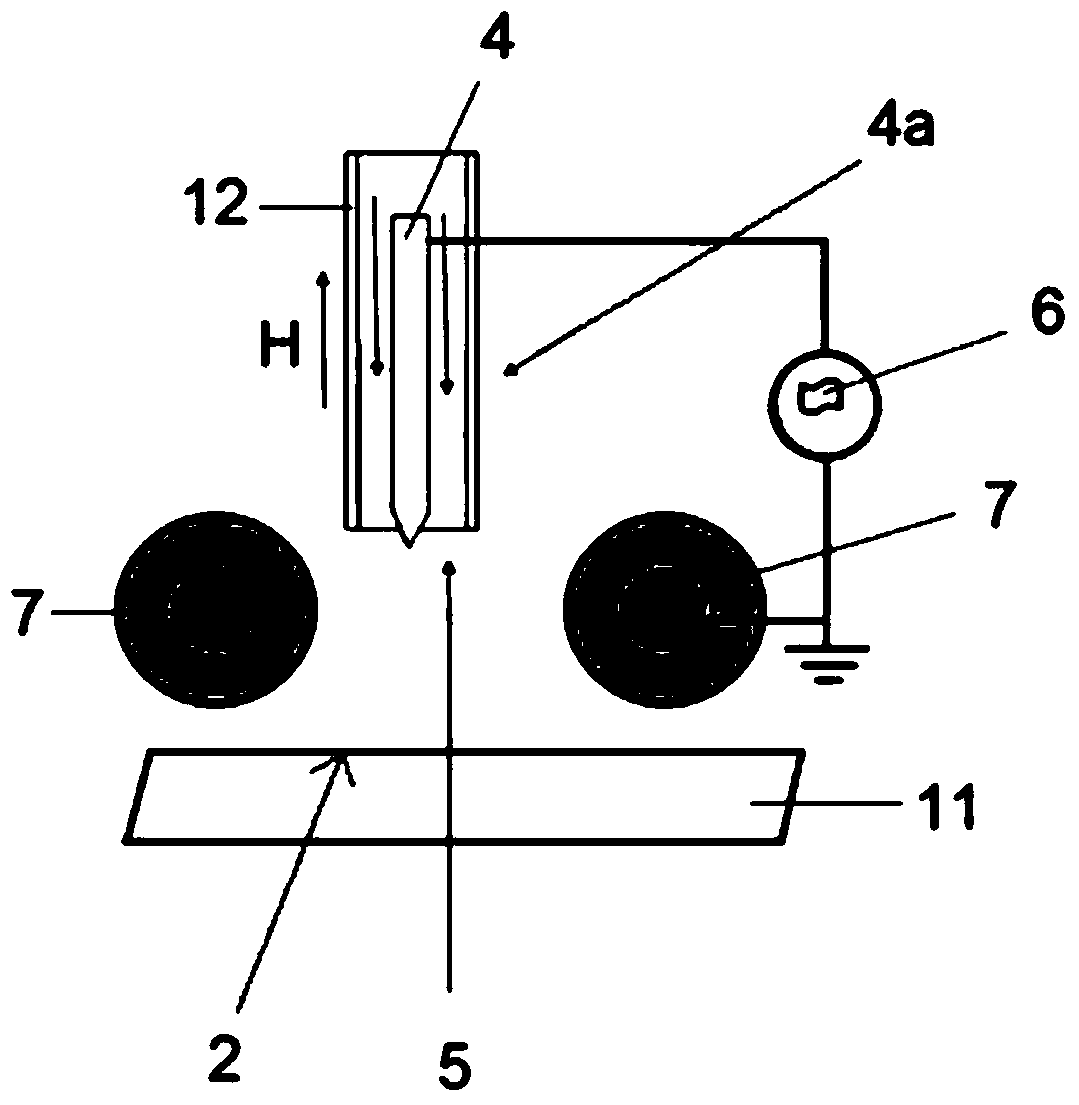

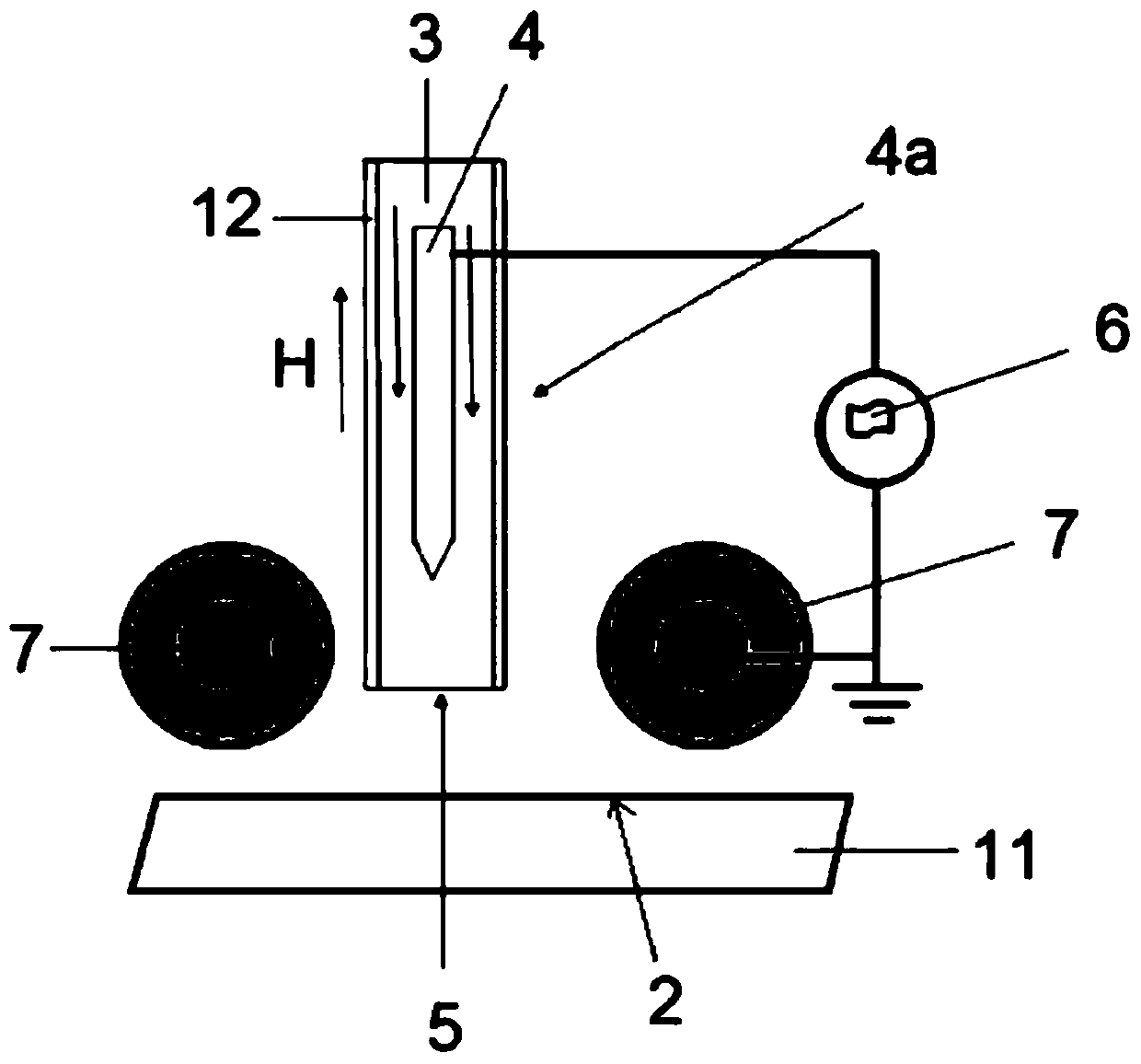

Apparatus for the plasma treatment of surfaces and a method for treating surfaces with plasma

InactiveCN105551924AAvoid sedimentElectric discharge tubesAdhesive processes with surface pretreatmentVoltage sourceElectric field

Apparatus for the plasma treatment of surfaces (2) with a first electrode (4) and a second electrode (7) and an alternating voltage source (6) between the first electrode (4) and the second electrode (7), and an electrical field, forming at least between the first electrode (4) and the second electrode (7), an effective area (9), which is arranged in front of the first electrode (4) and in which the surface (2) to be treated can be positioned, and the second electrode (7) is arranged closer to the effective area (9) than the first electrode (4), characterized in that at least one process gas channel (3) for at least one stream of process gas with at least one outlet (5) at the first electrode (4) is provided and the at least one outlet (5) points in the direction of the effective area (9); and the at least one stream of process gas impinges on the electrical field and the electrical field converts the at least one stream of process gas into a stream of plasma and the stream of plasma impinges on the effective area (9).

Owner:TESA SE

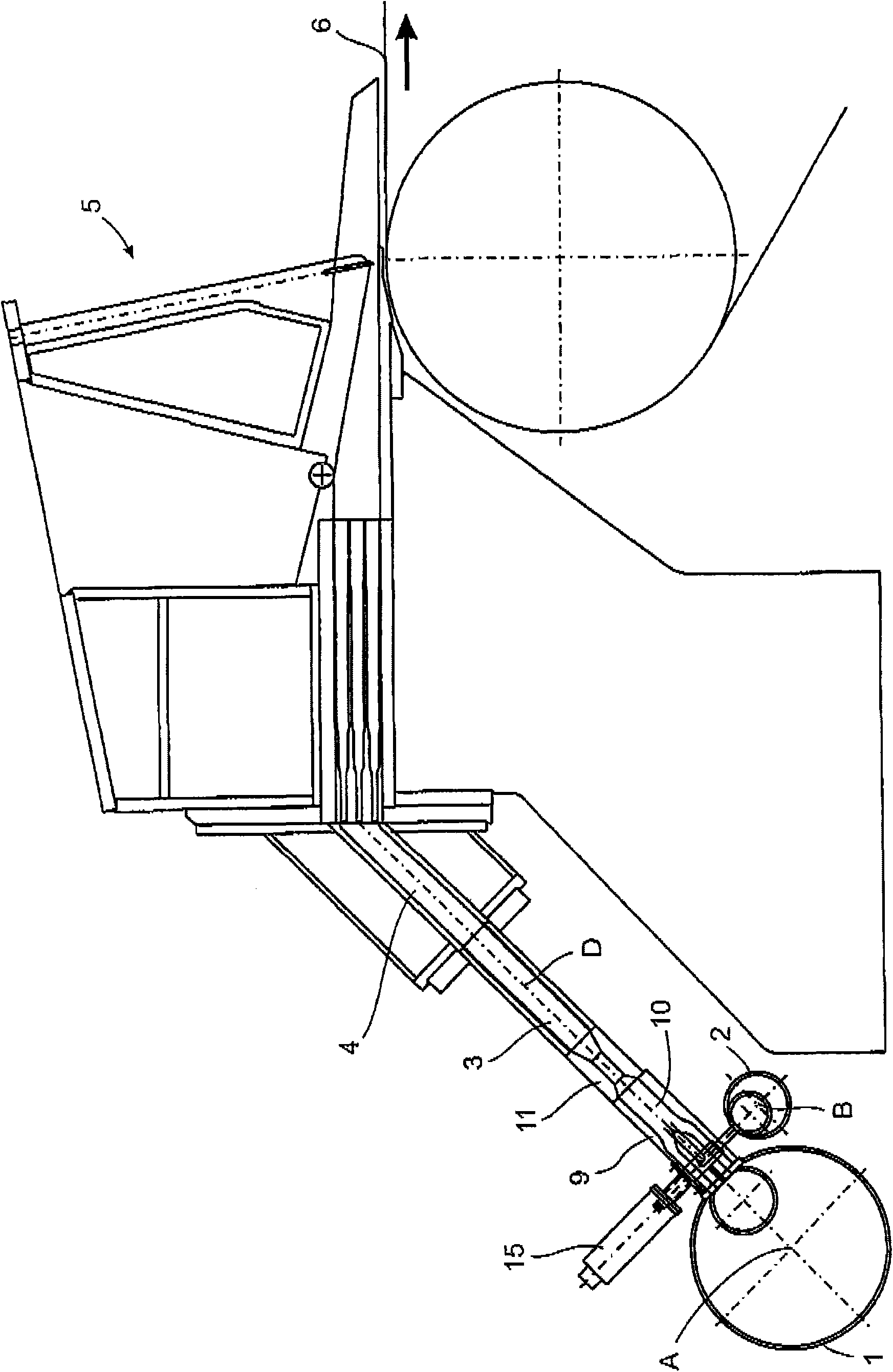

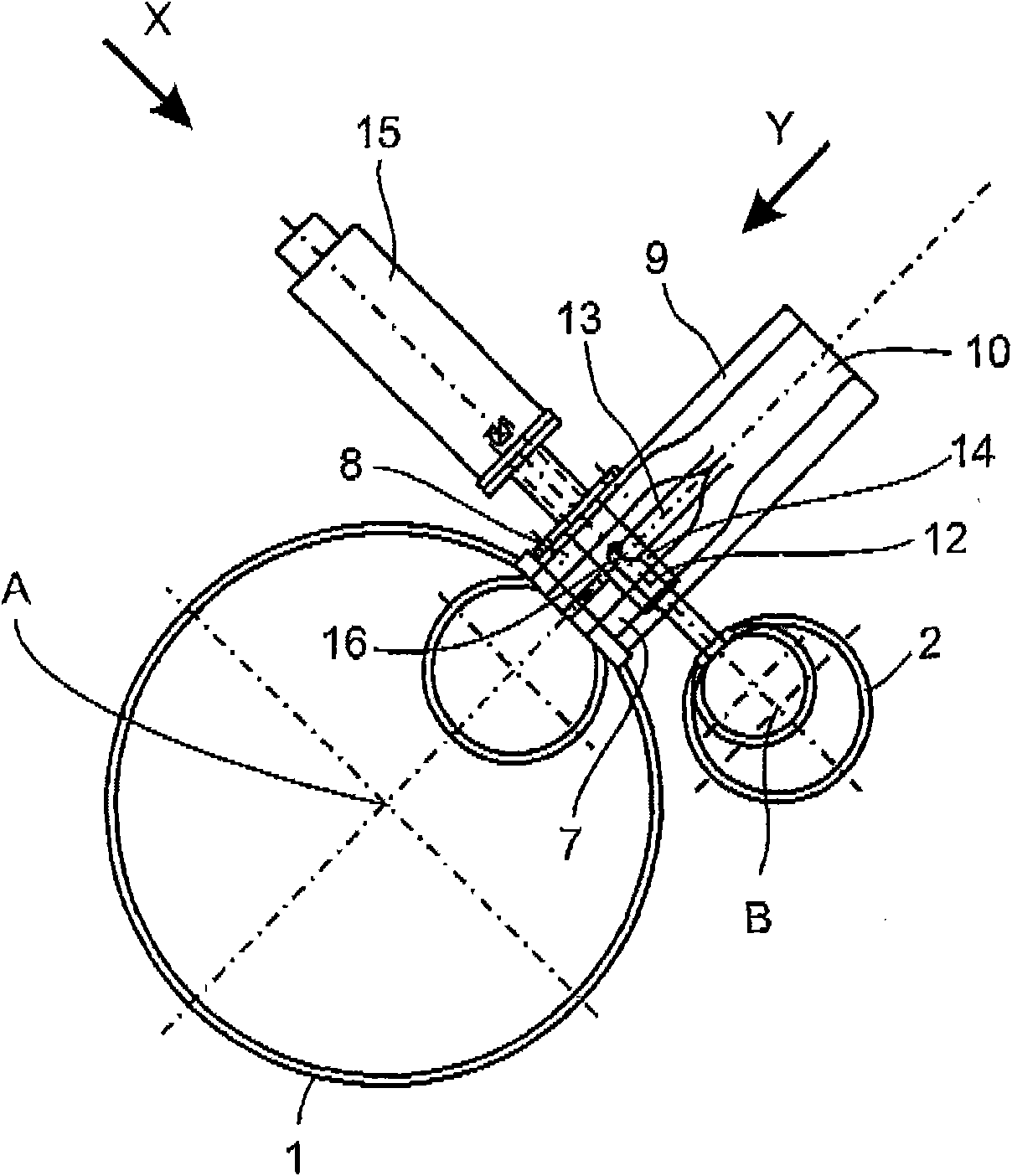

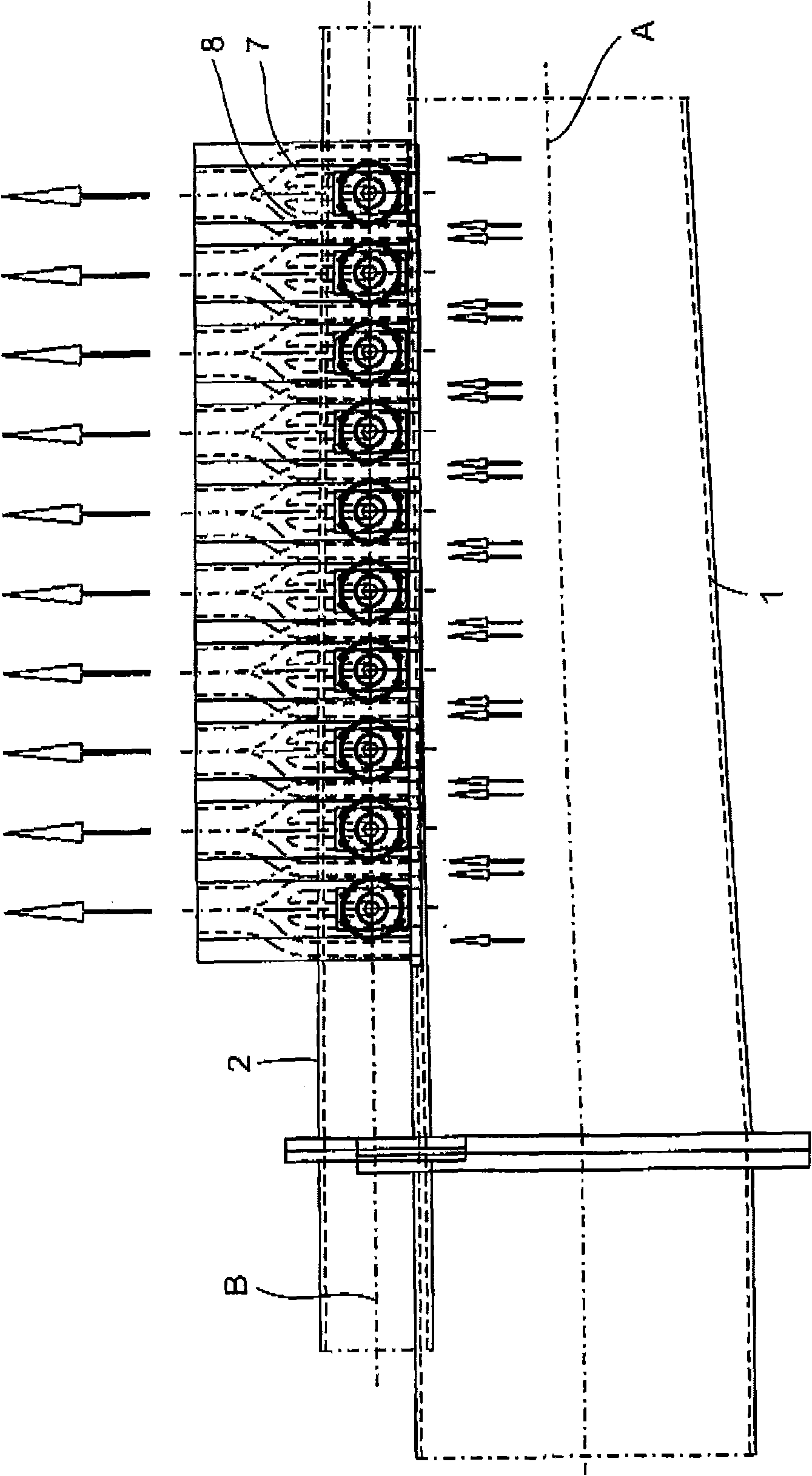

Assembly on paper machines for setting a surface weight cross-section

InactiveCN101838949ADirect regulationAvoid sedimentFlow mixersTransportation and packagingDistributorWater supply

A facility on the paper making machine modulates the quantitative transverse distribution of the diluted water at the stock discharge box for paper making or plate making, includes a machine width entering chamber including a paper pulp stream cross flow distributor, a diluted water cross flow distributor and a stock discharge box; the paper pulp stream cross flow distributor is connected to n cross section volume stream supply channel that can be divided by 2, wherein two of which are respectively connected to a mixing device; at an export side, each mixing device has a mixing cross section volume stream discharging pipe connected to entering chamber; the flow resistances respectively connected to the cross section volume stream supply channel of mixing device are about equally to each other, and are smaller than the flow resistance of the mixed cross section volume stream discharged tube; the diluted water cross flow distributor has n / 2 diluted water supply channels; each mixing device has a centre hole, for mounting diluted water supply channels with controllable input variable at various instances, and is arranged between two cross section volume stream supply channel; a valve for passing diluted water with controllable input variable is provided at the centre hole of each mixing device.

Owner:ANDRITZ KUESTERS GMBH & CO KG

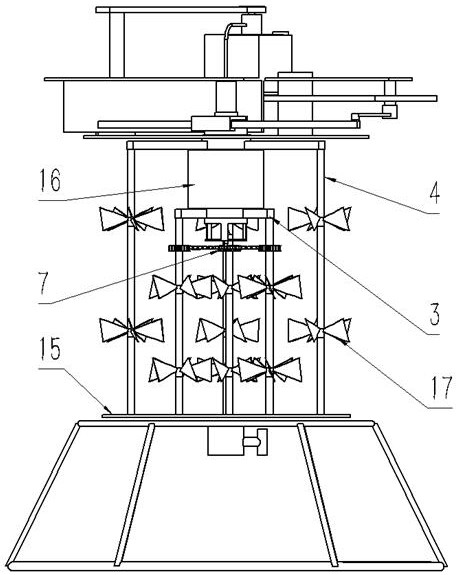

Efficient stirring device for aviation fuel oil

PendingCN114345197AStir fully and evenlyAvoid sedimentRotary stirring mixersTransportation and packagingAutomotive engineeringProcess engineering

The invention provides an efficient stirring device for aviation fuel oil, belongs to the technical field of aviation fuel production, and effectively solves the problems that in the aviation fuel production process, stirring of an additive and fuel is not uniform, the efficiency is low, and precipitates are likely to be generated. According to the technical scheme, the efficient aviation fuel oil stirring device comprises a stirring barrel, an inner rotating frame and an outer rotating frame are arranged in the stirring barrel, the inner rotating frame and the outer rotating frame are connected with a driving mechanism and are both provided with main stirring blades, and the interior of the stirring barrel communicates with the output end of an additive guide pipe; a pre-stirring mechanism is arranged close to the lower part of the output end of the additive guide pipe, is arranged on the inner rotating frame and is matched with the inner rotating frame to rotate. The stirring device has the beneficial effect that the stirring device capable of efficiently and fully stirring aviation fuel and additives to prevent precipitates from being generated is provided.

Owner:DONGYING HUAYA GUOLIAN AVIATION FUEL CO LTD

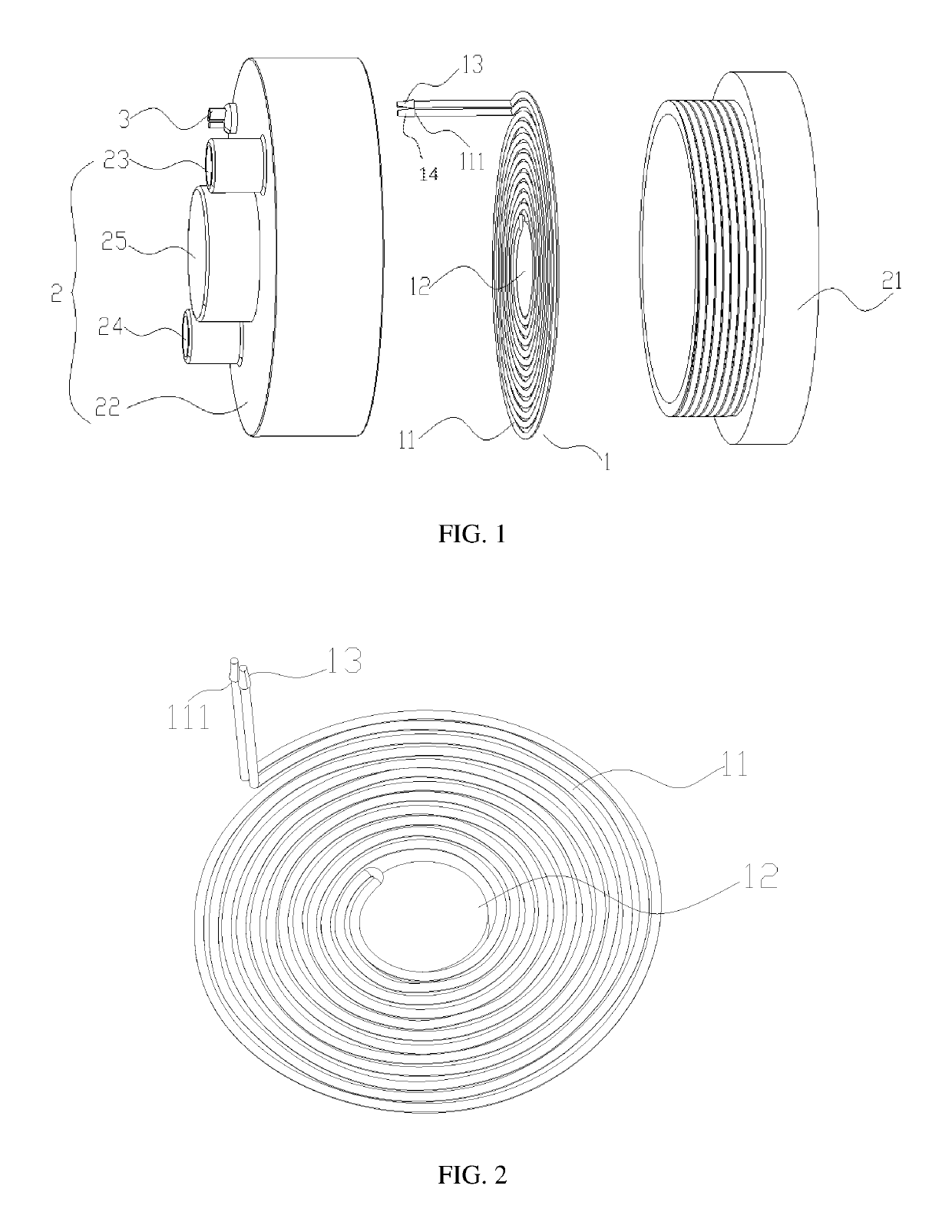

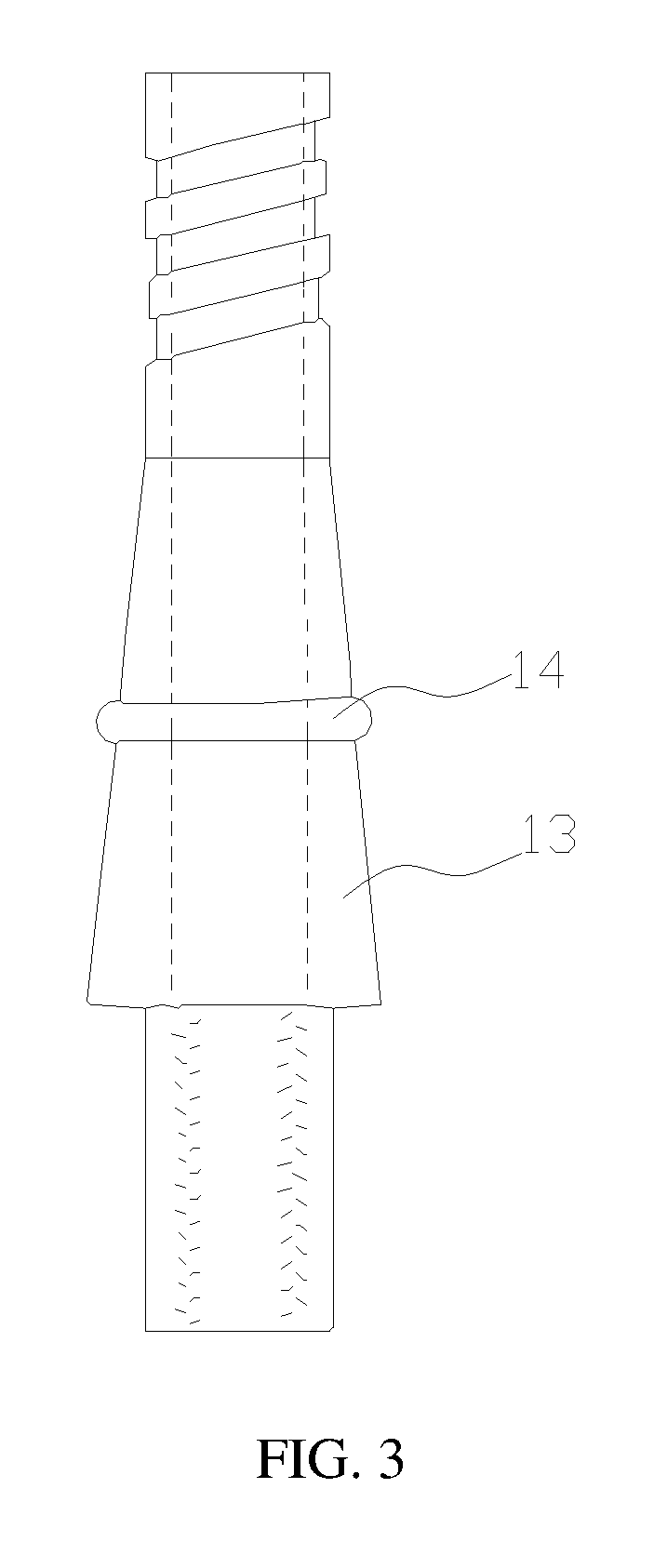

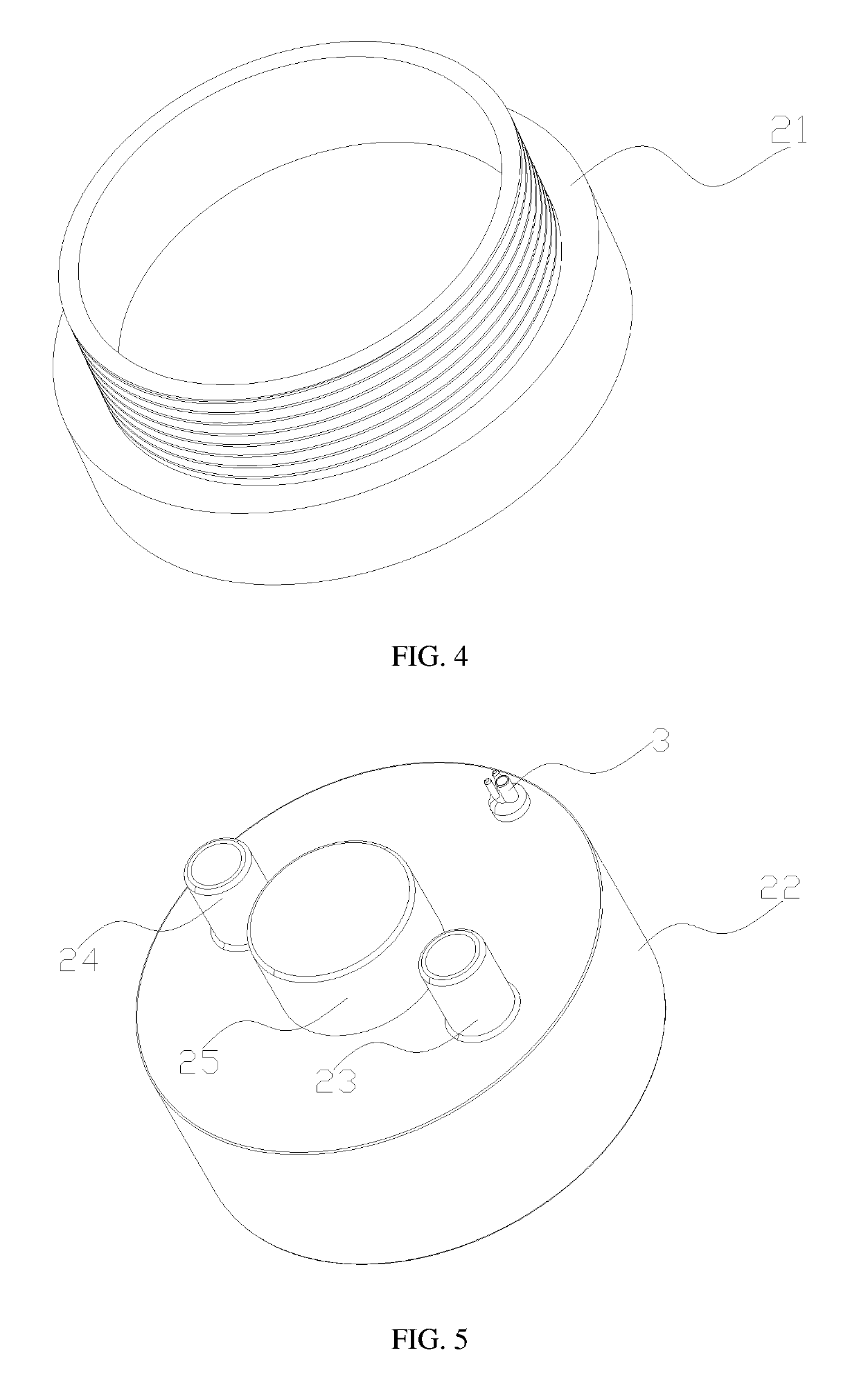

Spring tube type flexible micro chemical reactor

ActiveUS10252241B1Simple structureEasy to adjustChemical/physical/physico-chemical microreactorsChemical/physical/physico-chemical stationary reactorsChemical reactorProcess engineering

The present invention provides a spring tube type flexible micro chemical reactor. It comprises a reactor body, a thermal control device, and a gas generating device. The spring tube type flexible micro chemical reactor enhances the heat and mass transfer using the scroll spring tube, which is able to achieve accurate mixing and dynamic adjustment of the heat and mass transfer and is able to effectively solve the problems of blocking of channels by solid reactant, the poor portability of the reaction, etc.

Owner:DONGGUAN UNIV OF TECH

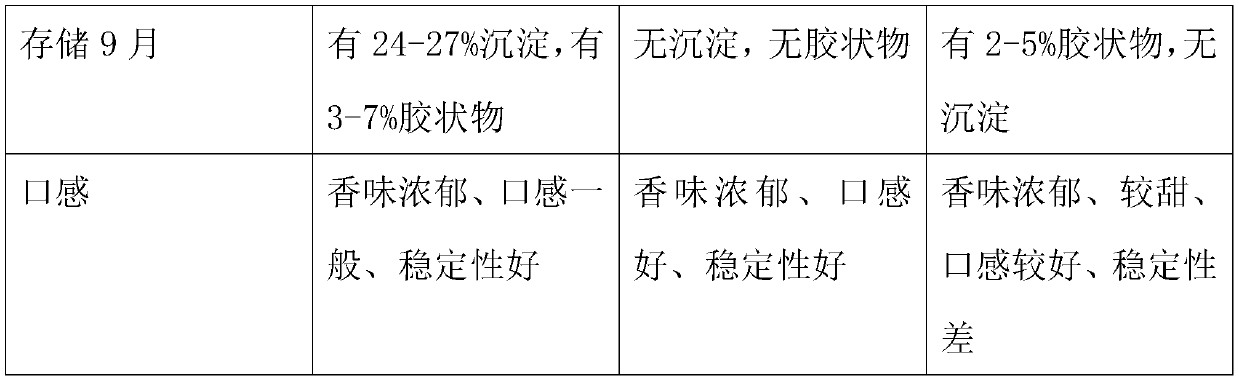

Honey beverage

InactiveCN108157718AAvoid sedimentQuality assuranceFood scienceNutrientSodium carboxymethylcellulose

The invention discloses a honey beverage. The honey beverage comprises the following components in percentage by weight: 82-86% of purified water, 6-10% of honey, 2-3% of maltose, 1-3% of menthol, 0.5-1% of aspartame, 0.5-1% of edible essence, 0.5-1% of sodium carboxymethyl cellulose and 0.5-1% of table salt. Compared with the prior art, the honey beverage achieves the technical beneficial effects: the honey beverage can better avoid precipitate appearing in the beverage, ensures the quality of the honey beverage and improves the quality of the honey beverage. In addition, the honey beverage contains rich nutrient elements, has high nutritional value and good mouthfeel, and better meets the requirements of people for honey beverages.

Owner:高炳秀

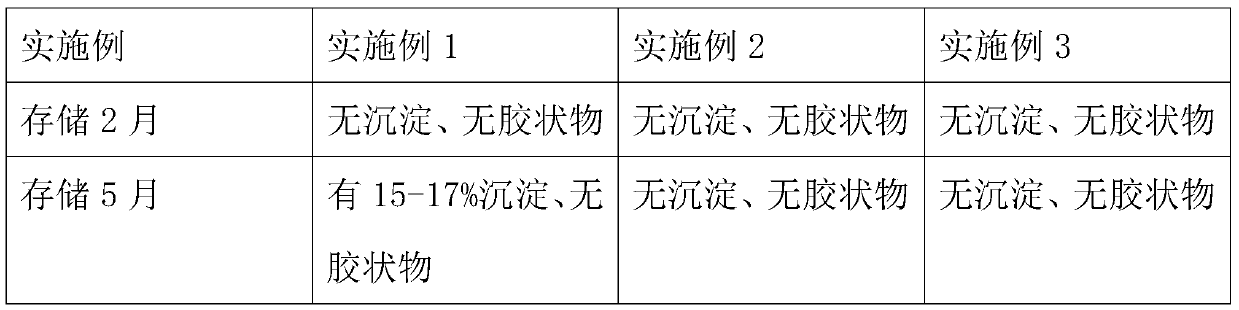

Preparation method of enzymolysis buckwheat flour

The invention discloses a preparation method of enzymolysis buckwheat flour in the technical field of buckwheat processing. The preparation method comprises the following steps: step 1, preparing following raw materials in parts by weight: 10-30 parts of buckwheat flour, 0.01-0.03 part of beta-amylase, 0.01-0.03 part of lactic acid, 0.01-0.03 part of hydrochloric acid, 0.01-0.03 part of sodium hydroxide, 0.2-0.6 part of 3,5-dinitrosalicylic acid and 0.2-0.6 part of glucose; 2, mixing the buckwheat flour with water, and performing fine grinding and stirring to form slurry; step 3, cooking a slurry mixture; and step 4, stopping heating, adding the the beta-amylase, the lactic acid, the hydrochloric acid and the sodium hydroxide, and performing stirring so as to obtain the pasty enzymolysis buckwheat flour. According to the application, the buckwheat flour is subjected to enzymolysis by selecting an optimal scheme, and the buckwheat flour subjected to the enzymolysis is added into a beverage, so that the problem that jelly and precipitate appear in buckwheat flour in an existing beverage is effectively prevented, and the storage time is prolonged.

Owner:GUIZHOU UNIV OF ENG SCI

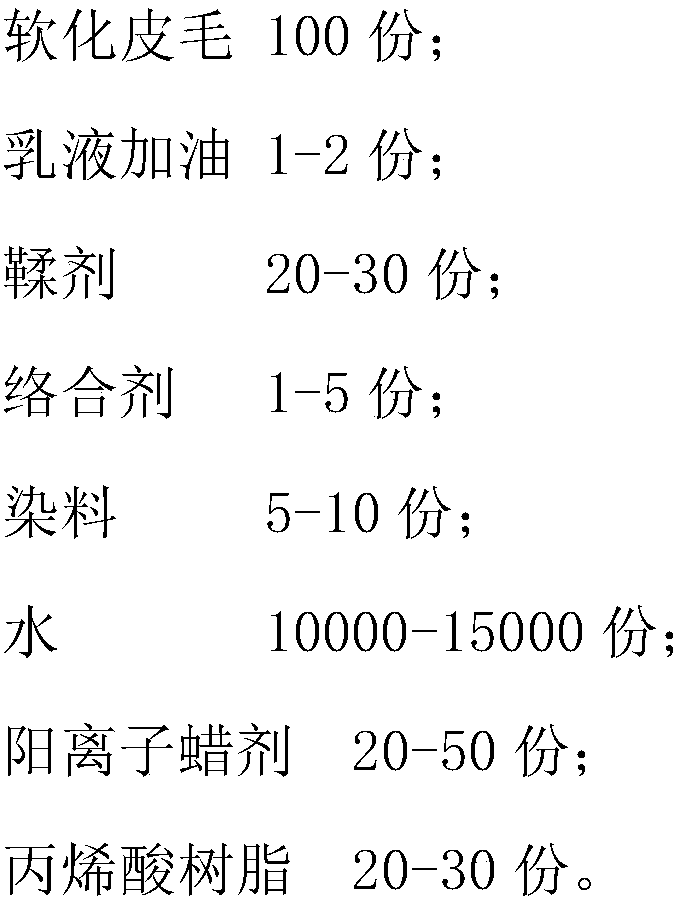

Environment-friendly leather bag with high smoothness and manufacturing method of environment-friendly leather bag

InactiveCN108179233ASimple methodAvoid sedimentTanning treatmentScale removal and water softeningEmulsionChromium

The invention discloses an environment-friendly leather bag with high smoothness and a manufacturing method of the environment-friendly leather bag. The environment-friendly leather bag comprises softened leather, emulsion added oil, a tanning agent and a complexing agent and further comprises dye and water. The environment-friendly leather bag comprises, by mass percent, 100 parts of the softenedleather, 1-2 parts of the emulsion added oil, 10-20 parts of the tanning agent, 1-5 parts of the complexing agent, 5-10 parts of the dye and 10,000-15,000 parts of the water. The three edges of two pieces of same leather dried in the fifth step are sewn, and a zipper is sewn on the other side. The method is simple, one or more of acrylic resin, a polyurethane resin tanning agent, an amino resin synthetic tanning agent and an aromatic synthetic tanning agent are adopted as the tanning agent instead of the tanning agent containing the chromium element, and the leather is more comfortable, morehealth, greener, more ecological and more environment-friendly.

Owner:GUANGZHOU PANYU POLYTECHNIC

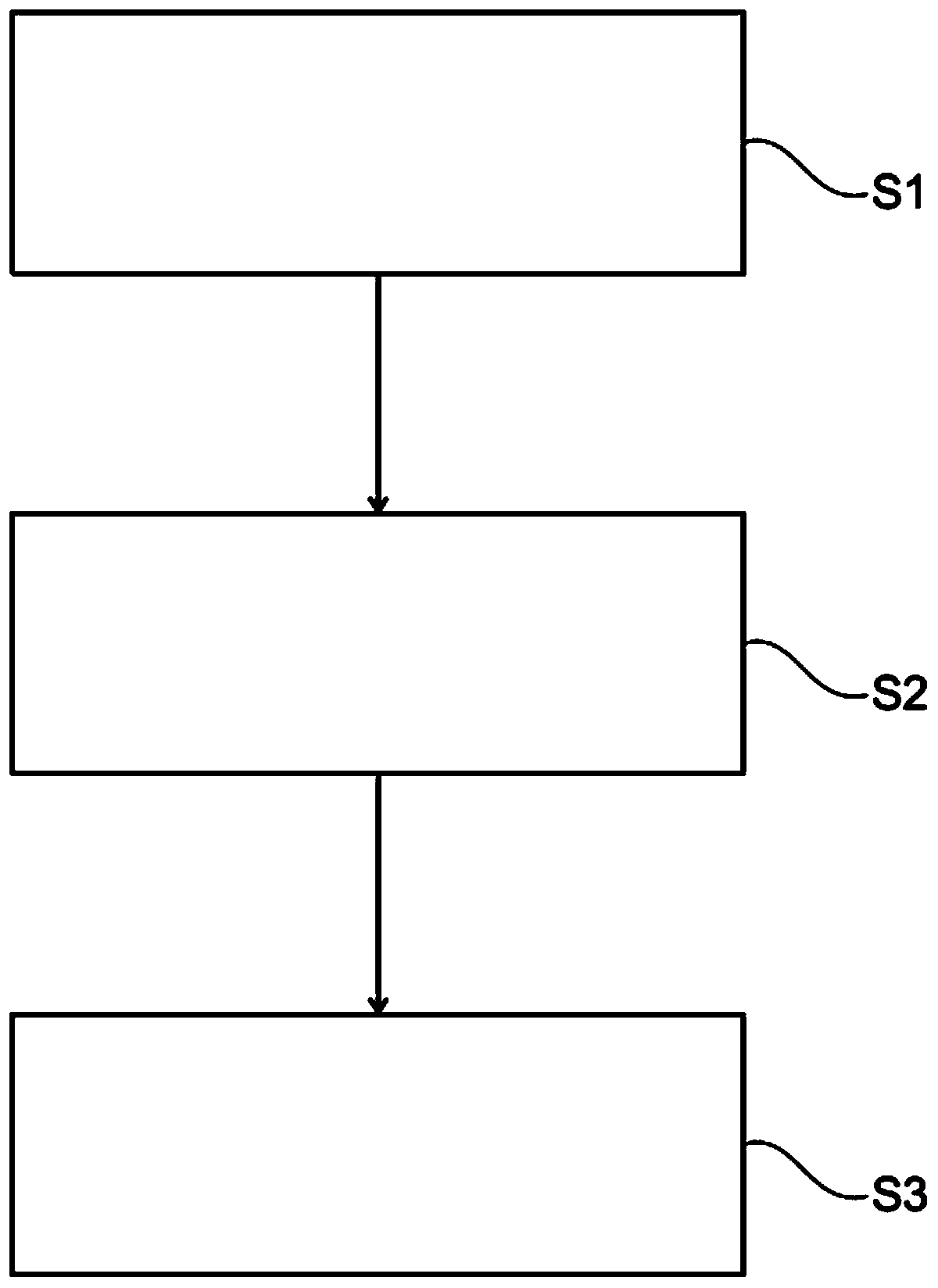

Method for preventing formation of urea-based deposits and exhaust passage having coating

PendingCN111441845AImprove effectivenessExtended service lifeExhaust apparatusSilencing apparatusCatalytic decompositionInternal combustion engine

The invention relates to a method for preventing the formation of urea-based deposits in an exhaust duct 1 of an internal combustion engine 2. The method comprises identifying a region (S1) of the exhaust duct 1 at risk of urea-based deposit formation, determining a degree of spatial resolution of the risk of urea-based deposit formation in the identified region (S2), and applying a coating 3 formed for catalytically decomposing an aqueous urea solution and / or urea-based deposits to the identified region (S3) according to the determined degree. Furthermore, an exhaust duct 1 for an internal combustion engine 2 has a coating 3, which is configured for catalytically decomposing urea-based deposits, in the region of the exhaust duct 1 at risk of urea-based deposit formation, the coating 3 having a varying layer thickness 4 and / or varying composition.

Owner:FORD GLOBAL TECH LLC

Anti-wear and friction-inducing agent used in lubricating oil

The invention relates to a lubricating oil additive and particularly relates to an anti-wear and friction-inducing agent used in lubricating oil. The anti-wear and friction-inducing agent used in lubricating oil is prepared from sulfurized alkylphenol, alkyl salicylate, maleic anhydride, acrylic acid higher alcohol ester, polyisobutylene amine, tetrahydrofurfuryl nitrate, alkyl naphthalene and polymethacrylate according to a specific ratio. By the anti-wear and friction-inducing agent, the deposits generated during the application of the lubricating oil can be effectively prevented, the anti-wear and friction-inducing agent has excellent wear resistance, friction modification and corrosion resistance and when the anti-wear and friction-inducing agent, which is disclosed by the invention, is applied in the lubricating oil according to the amount of 200-600ppm, the fuel consumption of the motor vehicle can be decreased, the noise can be reduced, the exhaust gas emission can meet the standard and the service life of the entire motor vehicle can be prolonged.

Owner:王智

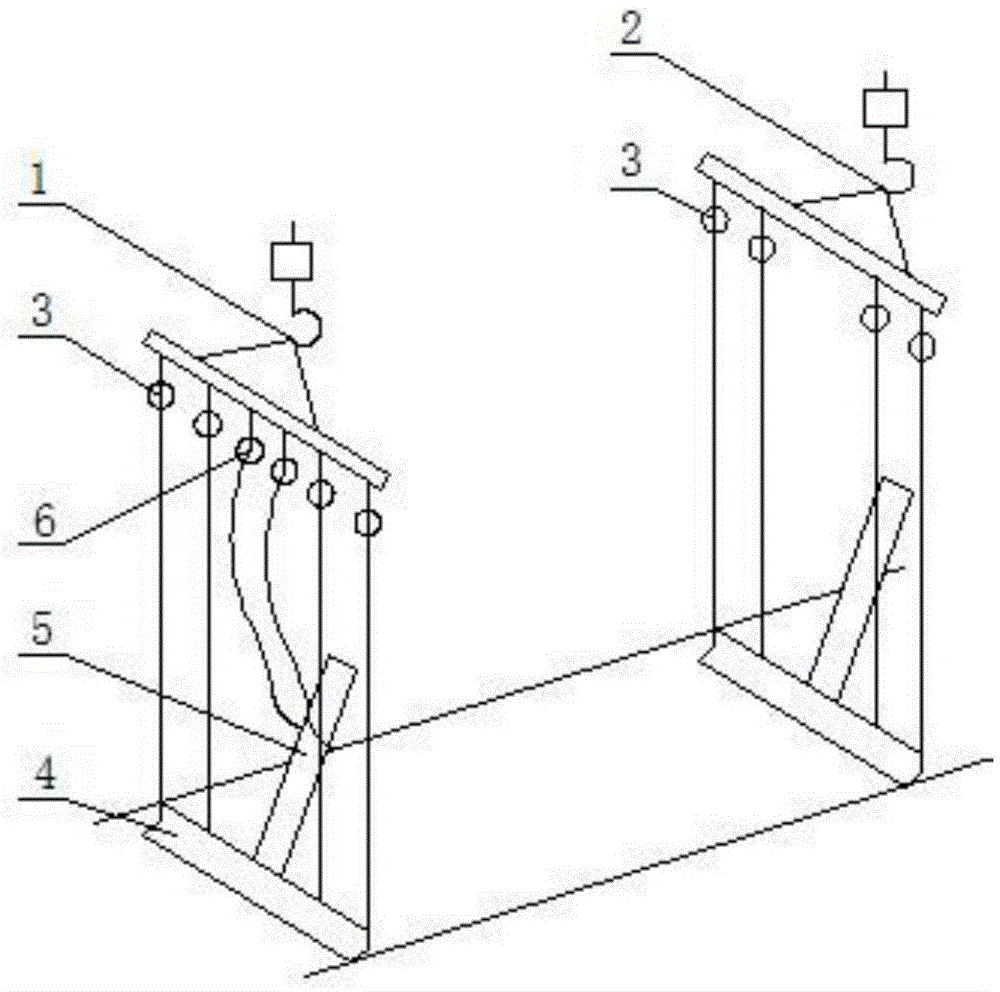

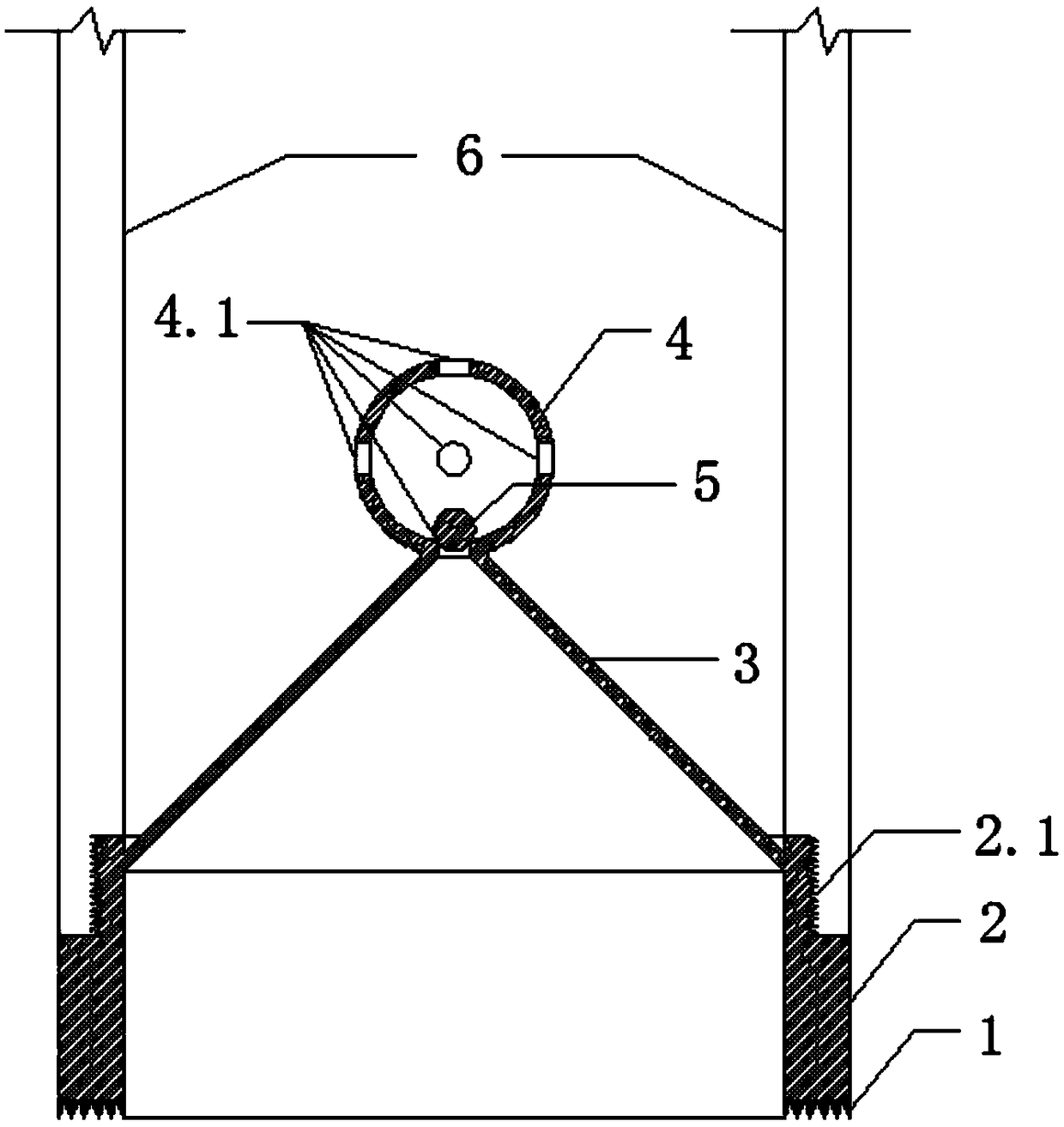

Concentric hoisting method for T-shaped reinforcement cage with diaphragm walls

The invention provides a concentric hoisting method for a T-shaped reinforcement cage with diaphragm walls. According to the technical scheme, a concentric hoisting device comprises a main hoisting rope and an auxiliary hoisting rope, wherein four hoisting fasteners are arranged on two sides of the main hoisting rope; the two hoisting fasteners are arranged on the left side of the main hoisting rope; the other two hoisting fasteners are arranged on the right side of the main hoisting rope; two control fasteners are arranged in the center of the main hoisting rope; the auxiliary hoisting rope is provided with a hoisting fastener; the hoisting fasteners of the main hoisting rope are hoisting ropes tied on wing walls; the control fasteners are hoisting ropes tied on an abdominal wall; the hoisting fasteners are stressed simultaneously, but the control fasteners are not stressed; and after the main hoisting rope overturns until the control fasteners are stressed, the reinforcement cage is vertical. By the technical scheme, the main hoisting rope is only provided with the two control fasteners, and the economic input is low. The concentric hoisting device is easy to operate; and after the reinforcement cage is hoisted, a cage body is vertical, so that the reinforcement cage enters a groove conveniently, walls of the groove are prevented from being scratched by the cage body, sediments on the bottom of the groove are avoided, secondary slag removal is avoided, the engineering quality is ensured, extra objects are not required to be hoisted, the hoisting device only needs to meet requirements on hoisting of the reinforcement cage, the cost is low, and the economic benefit is high.

Owner:NO 5 ENG CO LTD OF CCCC FIRST HARBOR ENG

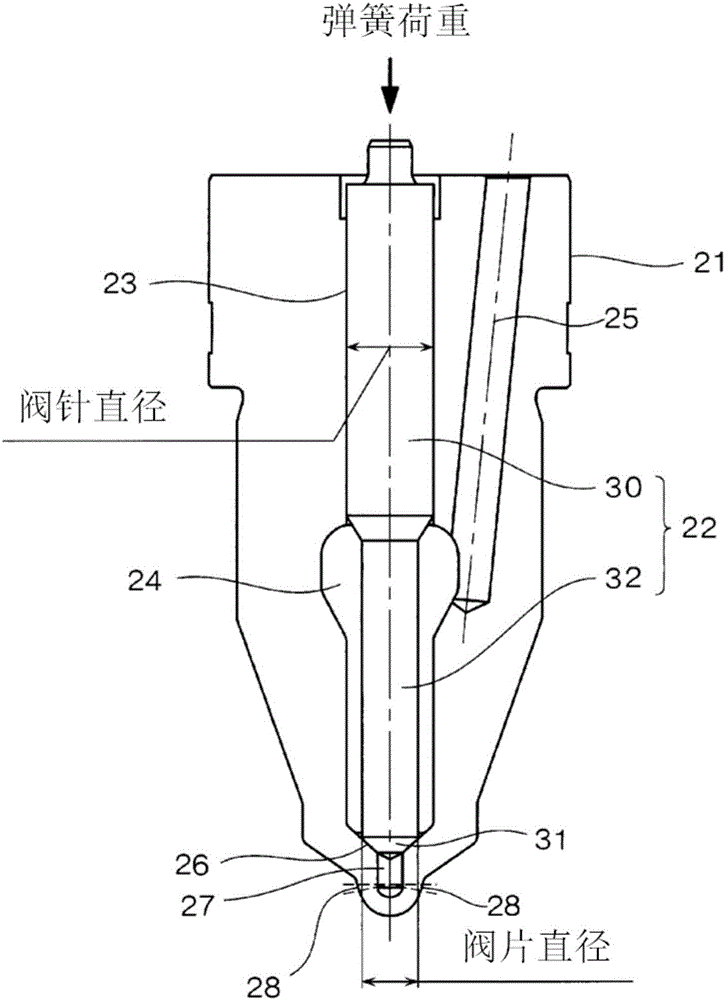

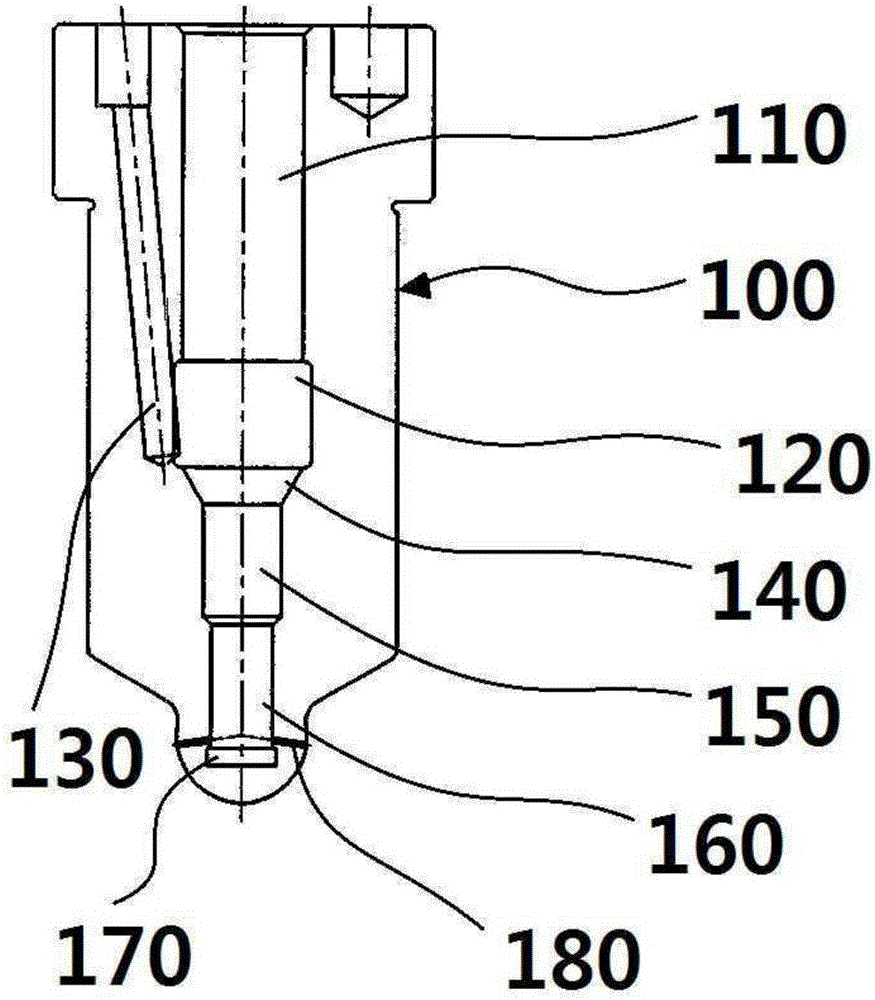

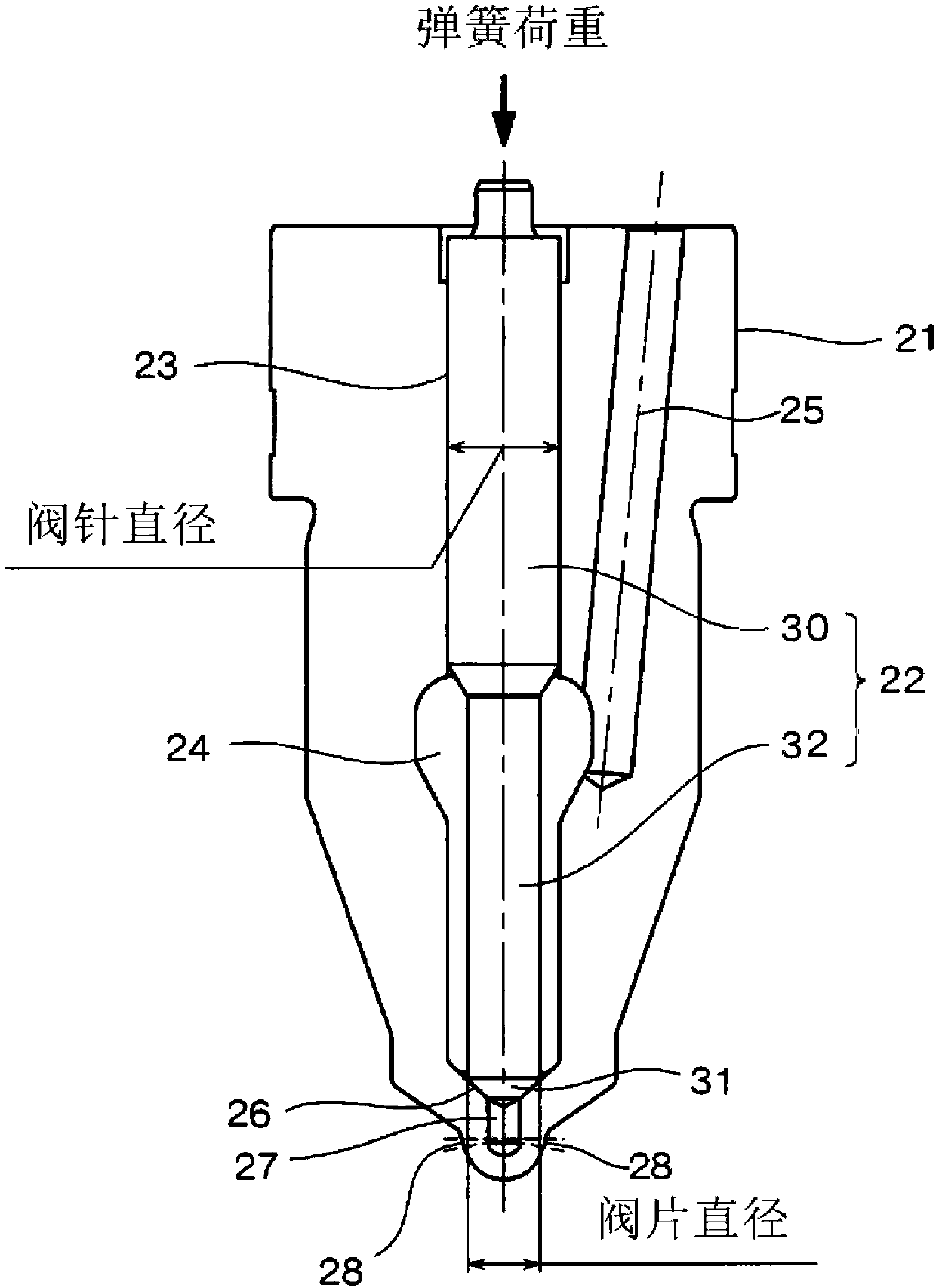

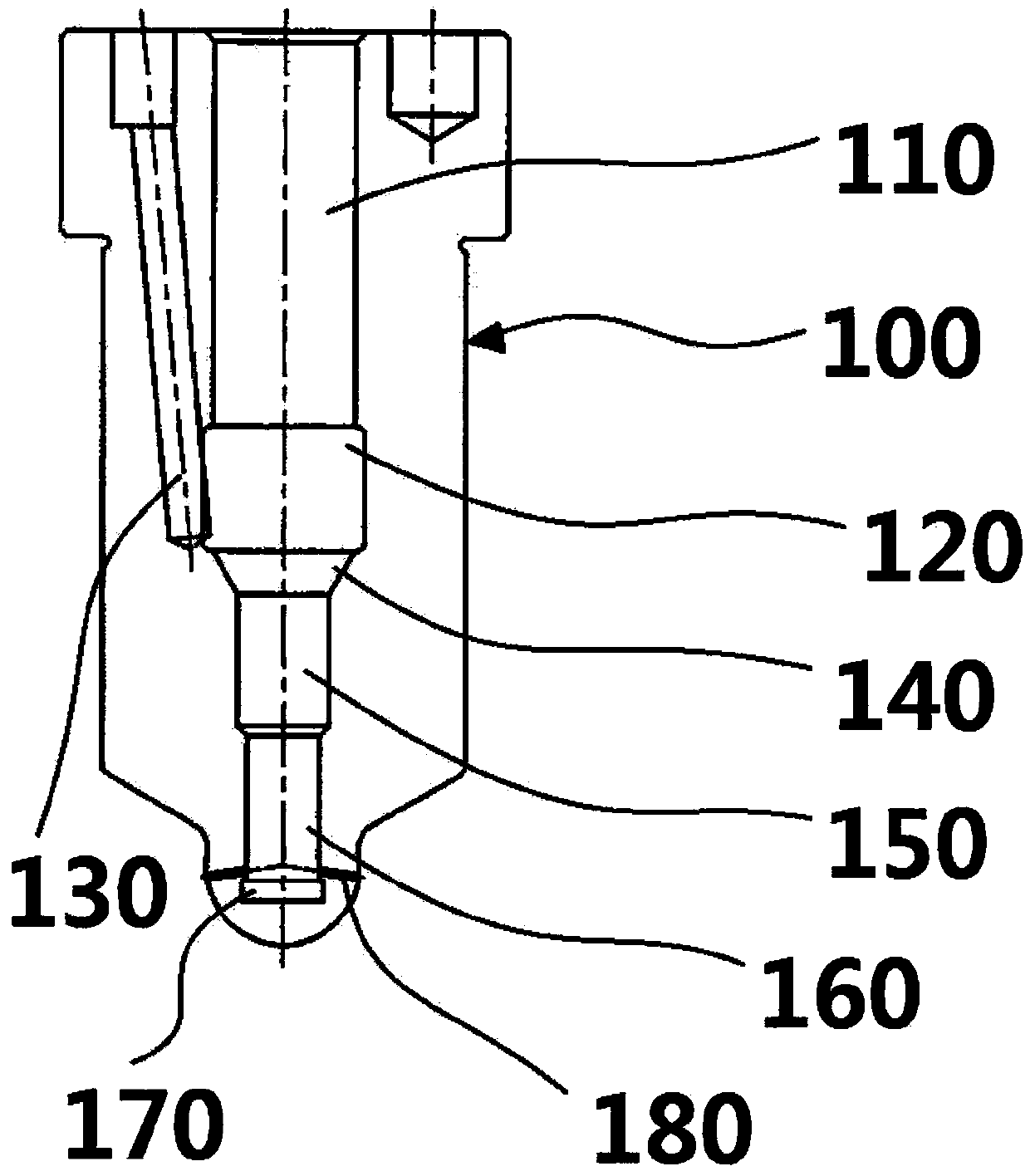

Injection valve for 4 stroke engine

InactiveCN106762304ABlock counterflowImprove wear resistanceFuel injection apparatusMachines/enginesFour-stroke engineEngineering

The invention relates to an injection valve for four-stroke engine. The injection valve is capable of stopping un-injected fuels from flowing reversely towards a first fuel chamber and a fuel supply flow path with reliability. When volume of an oil injection nozzle pressure chamber can be reduced, fuels can be stably injected to injection holes.

Owner:HANVIT JEONGGONG

Four stroke injection valve

InactiveCN106762304BBlock counterflowImprove wear resistanceFuel injection apparatusMachines/enginesFour-stroke engineFuel supply

The invention relates to an injection valve for four-stroke engine. The injection valve is capable of stopping un-injected fuels from flowing reversely towards a first fuel chamber and a fuel supply flow path with reliability. When volume of an oil injection nozzle pressure chamber can be reduced, fuels can be stably injected to injection holes.

Owner:HANVIT JEONGGONG

Device for plasma treatment of surfaces and method for treating surfaces with plasma

InactiveCN105551924BAvoid sedimentElectric discharge tubesAdhesive processes with surface pretreatmentVoltage sourceElectric field

The invention discloses a device for plasma treatment of surfaces and a method for treating surfaces with plasma. A device for plasma treatment of a surface (2) has a first electrode (4) and a second electrode (7) and an alternating voltage source ( 6), and at least the electric field formed between the first electrode (4) and the second electrode (7), the active area arranged in front of the first electrode (4) and in which the surface (2) to be treated can be located ( 9), and the second electrode (7) is arranged closer to the active area (9) than the first electrode (4), characterized in that the outlet with at least one outlet (5) arranged at the first electrode (4) At least one process gas channel (3) for at least one process gas stream, and the at least one outlet (5) is directed in the direction of the active area (9), and the at least one process gas stream impinges on an electric field and the electric field The at least one process gas stream is converted into a plasma stream and the plasma stream impinges on the active area (9).

Owner:TESA SE

Catalytic oxidation method of desulfurizing liquid

ActiveCN102872717BIncrease oxidation rateReduce depositionDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsRare earthCatalytic oxidation

The invention discloses a catalytic oxidation method of a desulfurizing liquid. According to the method, a SO2 absorbed desulfurizing liquid and air continuously pass through a fixed bed reactor filled with a catalyst and react in the presence of the catalyst and under a proper oxidation condition, wherein the catalyst is a supported catalyst; a carrier is titanium dioxide; and an active metal component is rare-earth oxide. By the adoption of the method, oxidation rate and oxygenation efficiency of sulfite are significantly raised. During the application of the catalyst, there is no loss of active components. Therefore, operation cost is reduced, and secondary pollution caused by loss of active components is also effectively avoided. In addition, the solid catalyst used also has advantages of high mechanical strength, wear resistance, long service life and the like. The method provided by the invention provides an effective processing method for the discharge of a wet flue gas desulfurizing liquid to reach the standard.

Owner:CHINA PETROLEUM & CHEM CORP +1

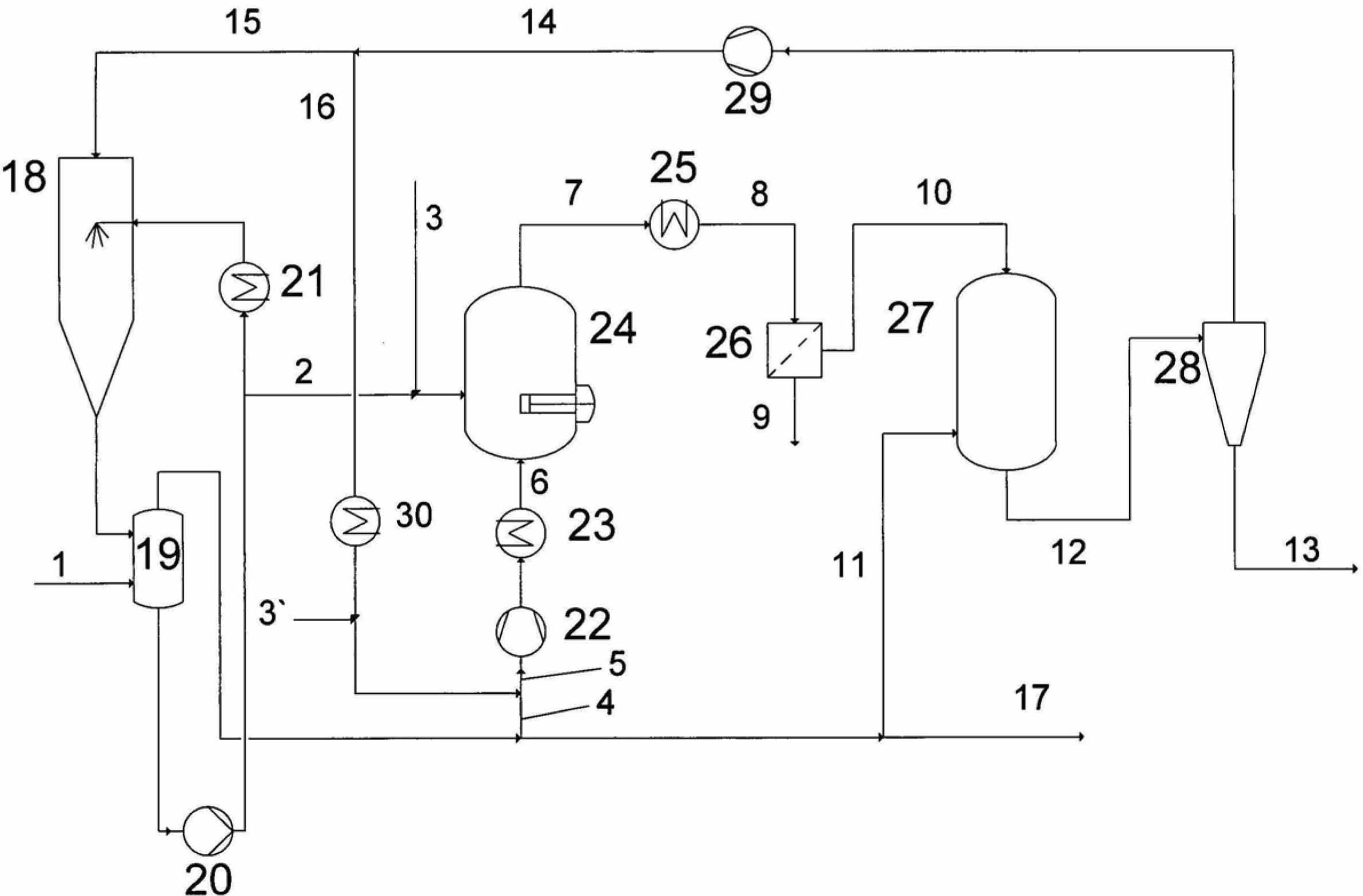

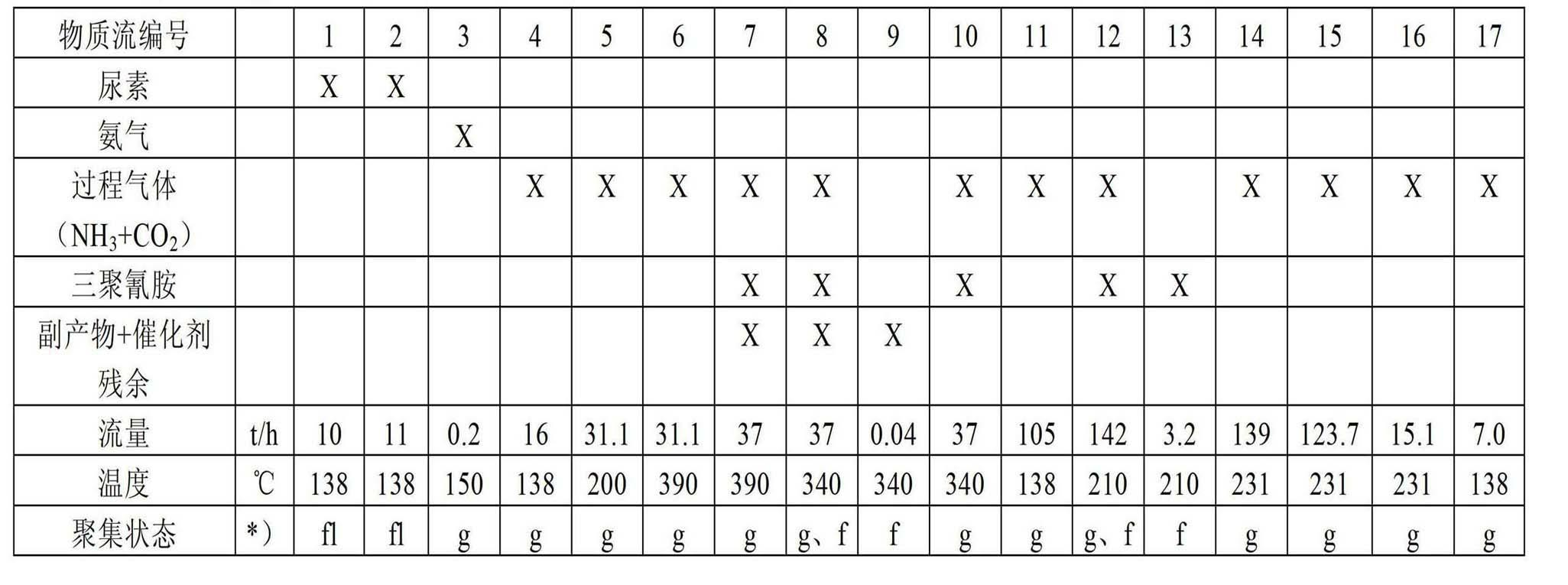

Method for continuously producing melamine

ActiveCN102596920AGas temperature can be adjustedAdjust the gas temperatureOrganic chemistryFluidized bedProduct gas

The invention relates to a method for continuously producing melamine from urea by means of a fluidized bed reactor, wherein process gas conducted in the process circuit is used as the fluidizing gas, and wherein the temperature of the process gas at the inlet of the conveying element for the fluidizing gas is adjusted by adjusting the mixture ratio of a process gas flow conducted through a scrubber and a process gas flow conducted past the scrubber.

Owner:LURGI

Grit chamber for wastewater treatment plant, capable of preventing sedimentation of organic material

InactiveUS7638043B2Constant flow velocity of wastewaterPrevent precipitationSedimentation regulating devicesLiquid displacementDrive motorOrganic matter

A grit chamber for a wastewater treatment plant. A vertical floodgate is installed on a partitioning wall and is driven in a vertical direction to be opened downwardly from a top toward a bottom. A floodgate driving motor is coupled to one end of the vertical floodgate to directly drive the vertical floodgate. An inflow amount measurement sensor functions to stepwisely measure a flow amount of wastewater which passes through a wastewater tank. A control section is connected to the floodgate driving motor and the inflow amount measurement sensor to control the floodgate driving motor in response to a measurement result of the inflow amount measurement sensor. A wastewater level is adjusted within a predetermined range through operation of the vertical floodgate to maintain a constant flow velocity of wastewater which passes through a sand sedimentation zone, thereby preventing organic material which is contained in the wastewater and is other than sand, from sedimenting.

Owner:BLUE WHALE SCREEN

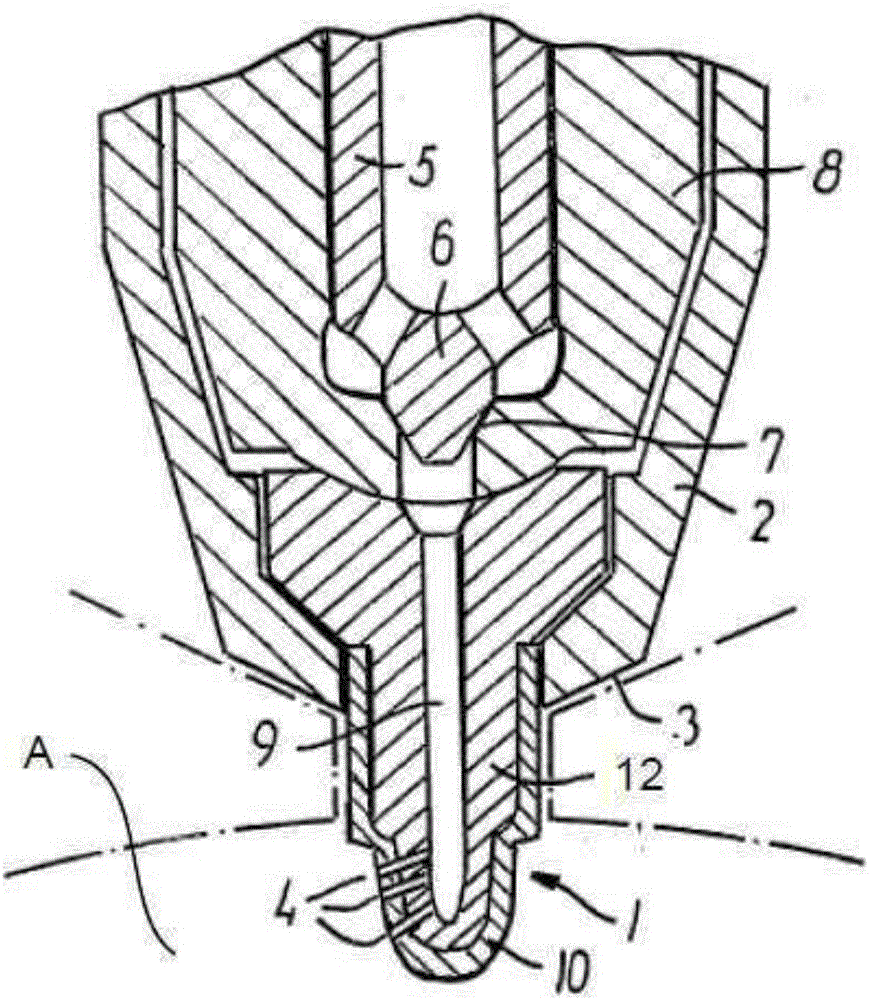

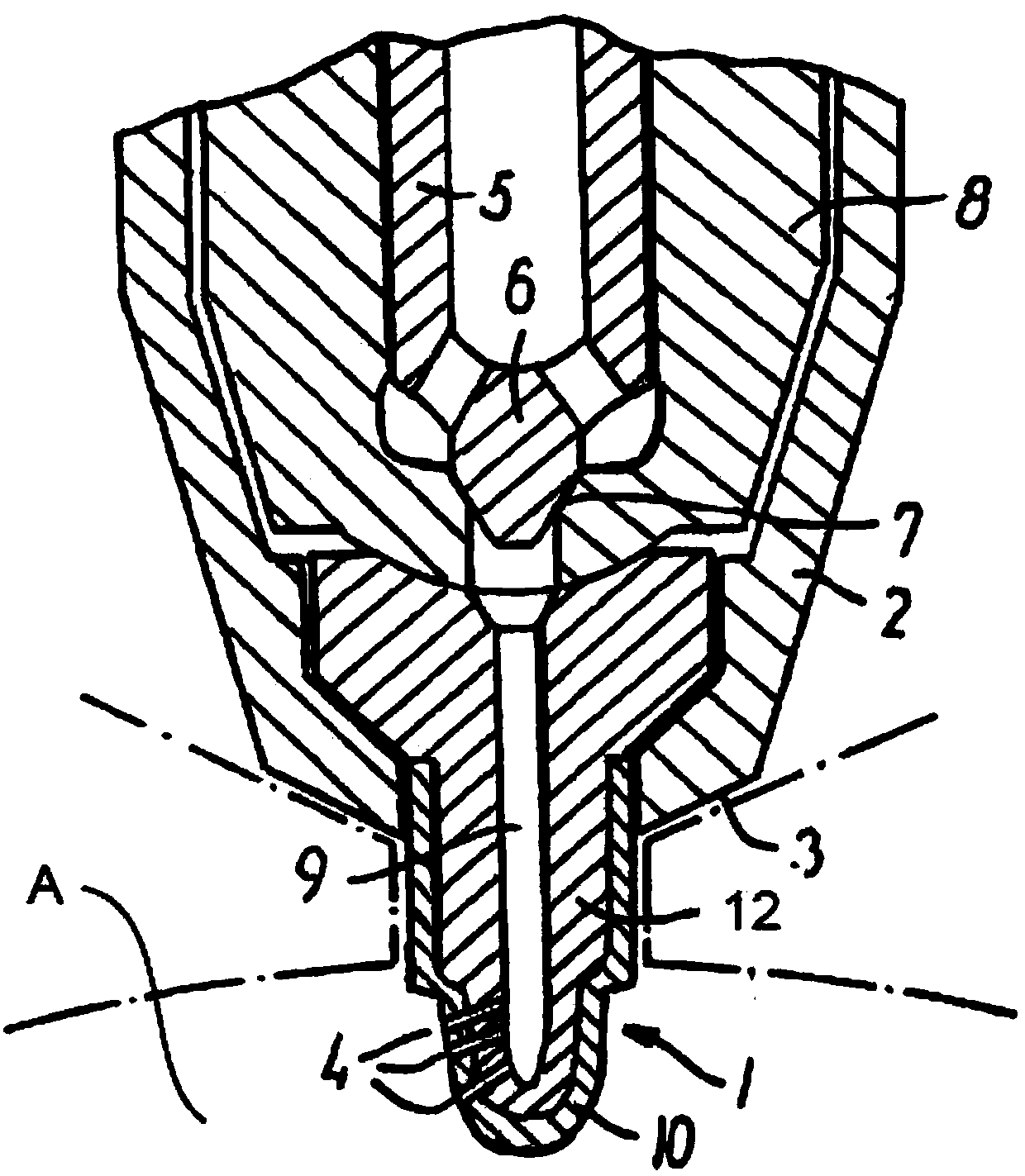

Drill bits suitable for drilling in silt and fine sand formations below the water table

ActiveCN106194090BEasy inflowEasy to overflowConstructionsWell/borehole valve arrangementsWell drillingEngineering

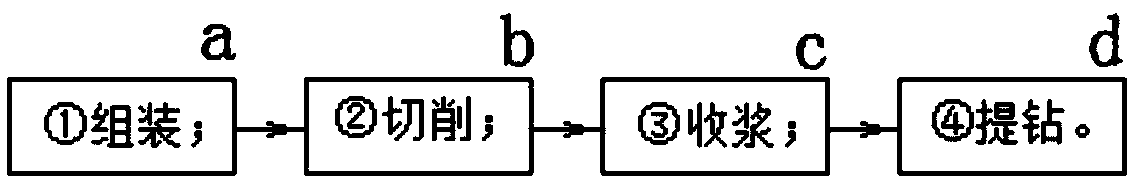

The invention discloses a drill suitable for drilling in a silty-fine sand stratum below the underground water level, and relates to the well drilling technology in engineering investigation. The drill comprises alloy drill teeth (1), a connecting barrel (2), a conical fairing (3), a spherical overflow valve (4), a ball valve (5) and a drill barrel (6). The drill teeth (1), the connecting barrel (2) and the drill barrel (6) are sequentially connected from bottom to top to form a main body structure. The conical fairing (3) and the spherical overflow valve (4) are sequentially arranged at the top of the connecting barrel (2). The ball valve (5) is arranged in the spherical overflow valve (4). A drilling method includes the steps of (1) assembling, (2) cutting, (3) slurry collecting and (4) drill lifting. When the drill drills in the silty-fine sand stratum below the underground water level, silty-fine sand can be effectively extracted, sediment is prevented from forming at the bottom of a drill hole, the expected drilling depth is achieved, and the hole forming quality is guaranteed. Meanwhile, the drill can realize multiple times of industrial copying.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com