Assembly on paper machines for setting a surface weight cross-section

A paper machine and equipment technology, applied in the paper machine, paper making, wet end of the paper machine, etc., can solve problems such as paper web cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

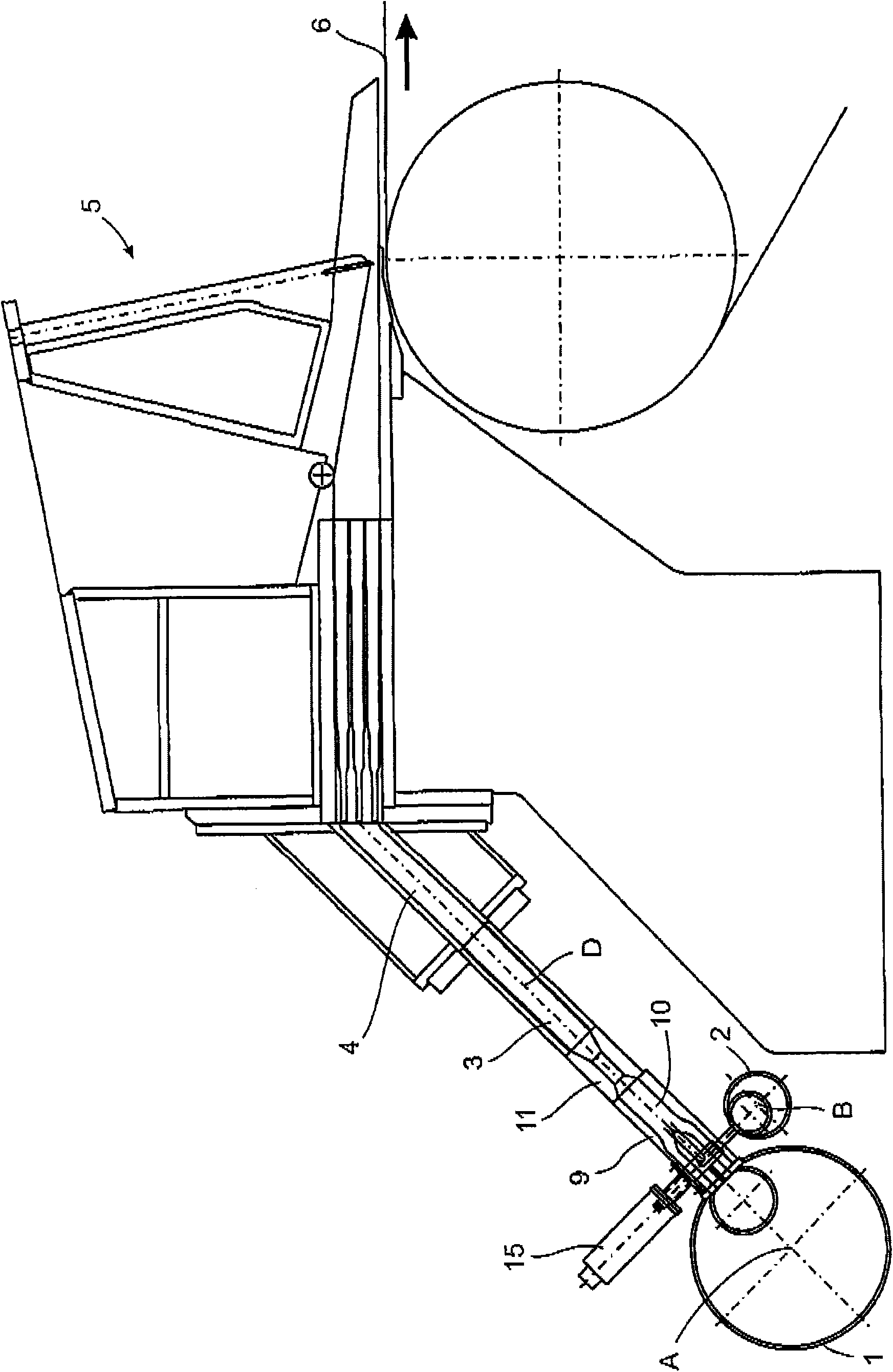

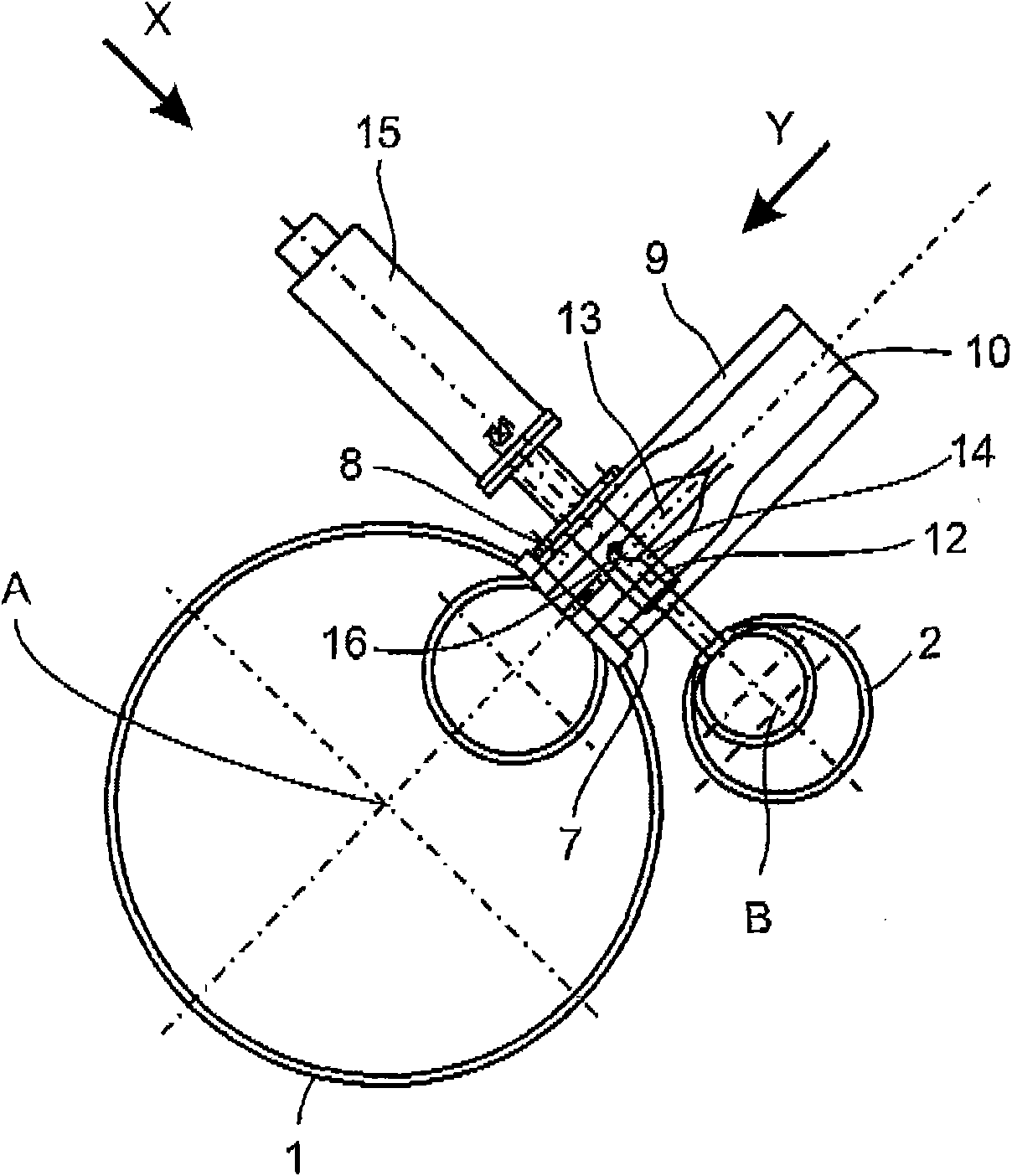

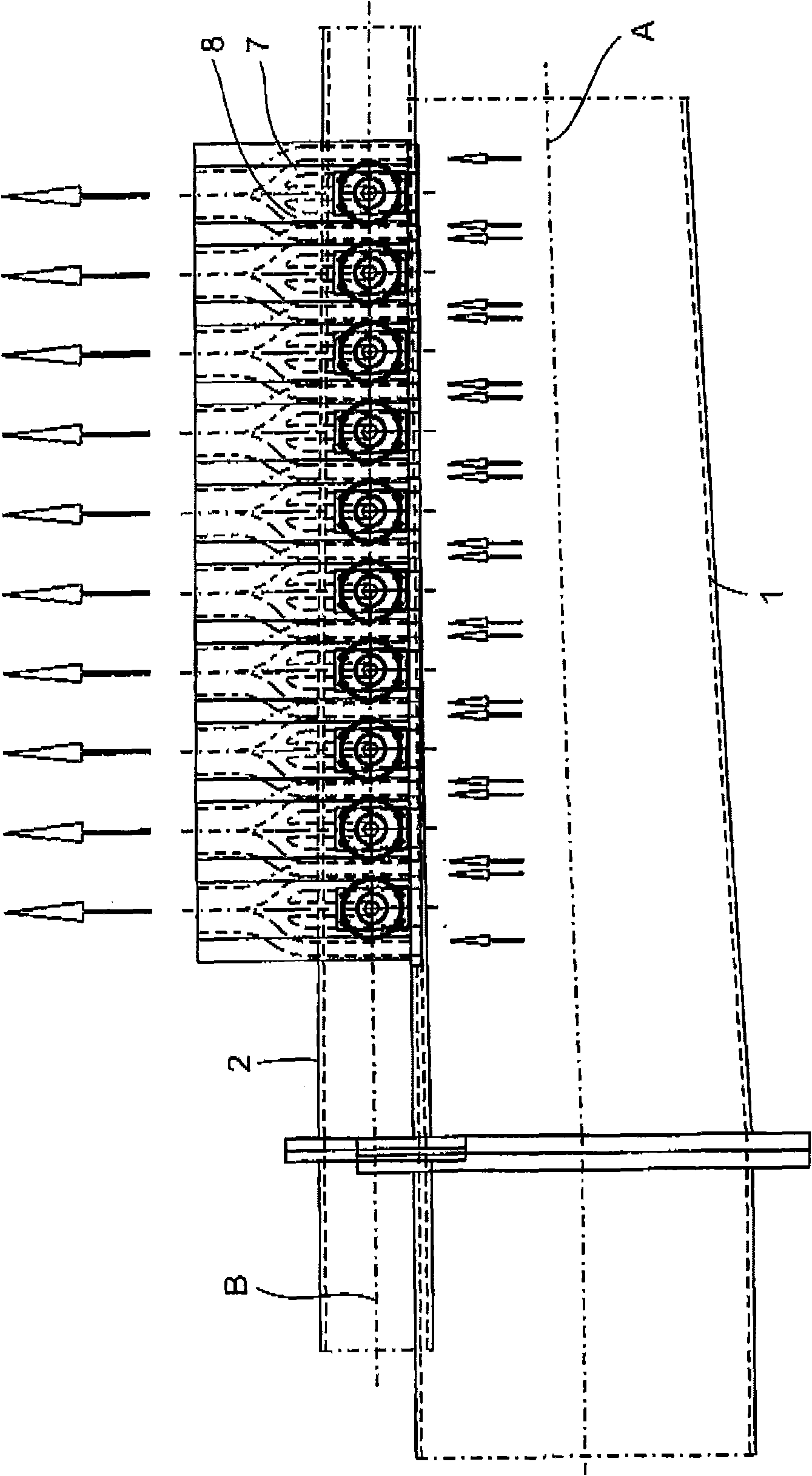

[0018] figure 1 An arrangement on a paper machine for adjusting the basis weight CD profile with dilution water at a hydraulic headbox for paper or board manufacturing is shown.

[0019] The equipment includes a pulp flow cross-flow distributor 1 (cross-flow distributor 1 for the stockstream) and a dilution water cross-flow distributor 2 (cross-flow distributor 2 for dilution water), which distribute the mixed The flow is supplied to the machine width inlet chamber 4 of the hydraulic headbox 5 . The mixed flow from the headbox 5 flows onto a wire 6 . The pulp flow cross-flow distributor 1 has an axis A extending transversely with respect to the machine direction of travel. The dilution water cross-flow distributor 2 has an axis B extending adjacent to the axis A, in particular, the area arranged between the cross-flow distributor 1 and the tube bank 3 . The tube stack 3 defines a plane D oriented transversely with respect to the machine direction.

[0020] Such as Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com