Drill bits suitable for drilling in silt and fine sand formations below the water table

A groundwater level and silty sand technology, which is applied in the field of drilling, can solve the problems of inability to extract sand and slag at the bottom of the hole, and achieve the effects of convenient assembly and disassembly, ensuring the quality of the hole and reducing the water consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

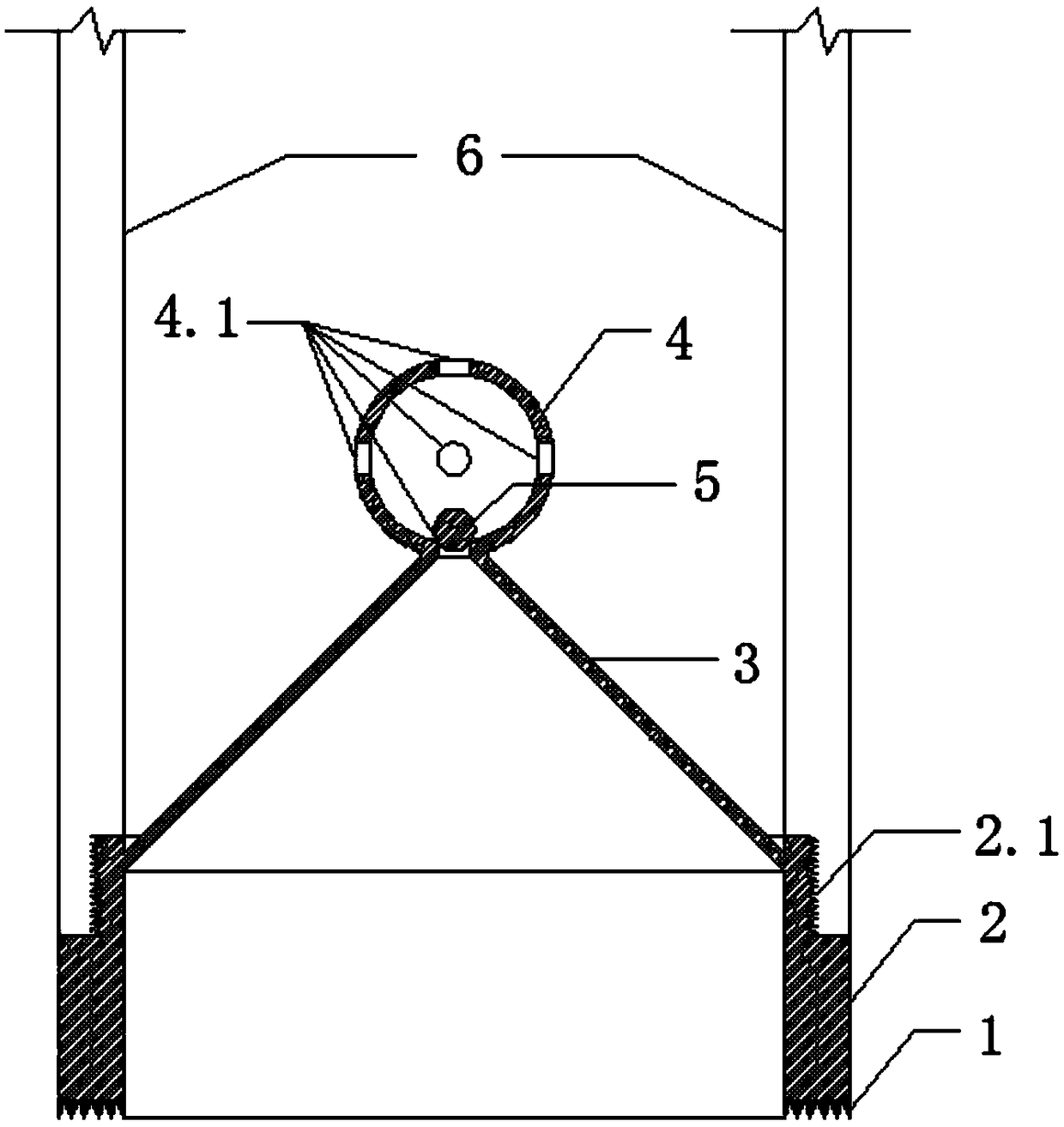

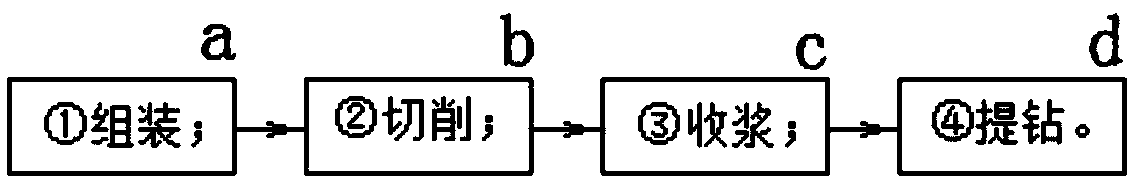

[0046] Below in conjunction with accompanying drawing and embodiment describe in detail:

[0047] 1. Drill bit

[0048] 1. Overall

[0049] Such as figure 1 , the drill bit includes alloy drill teeth 1, connecting cylinder 2, conical shroud 3, spherical overflow valve 4, ball valve 5 and drill cylinder 6;

[0050] Its location and connection relationship are:

[0051] From bottom to top, the alloy drill tooth 1, the connecting cylinder 2 and the drill cylinder 6 are sequentially connected to form the main structure;

[0052] On the top of the connecting cylinder 2, a cone-shaped shroud 3 and a spherical overflow valve 4 are sequentially arranged, and a ball valve 5 is arranged inside the spherical overflow valve 4.

[0053] 2. Functional components

[0054] 01) Alloy drill tooth 1

[0055] The alloy drill tooth 1 is a circle in which the drill teeth made of alloy material are evenly distributed;

[0056] It is arranged on the bottom surface of the connecting cylinder 2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com