Method for continuously producing melamine

A technology of melamine and isocyanic acid, applied in organic chemistry and other directions, can solve problems such as cost increase and interference with urea deposits, and achieve the effects of low cost, product yield and product purity optimization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

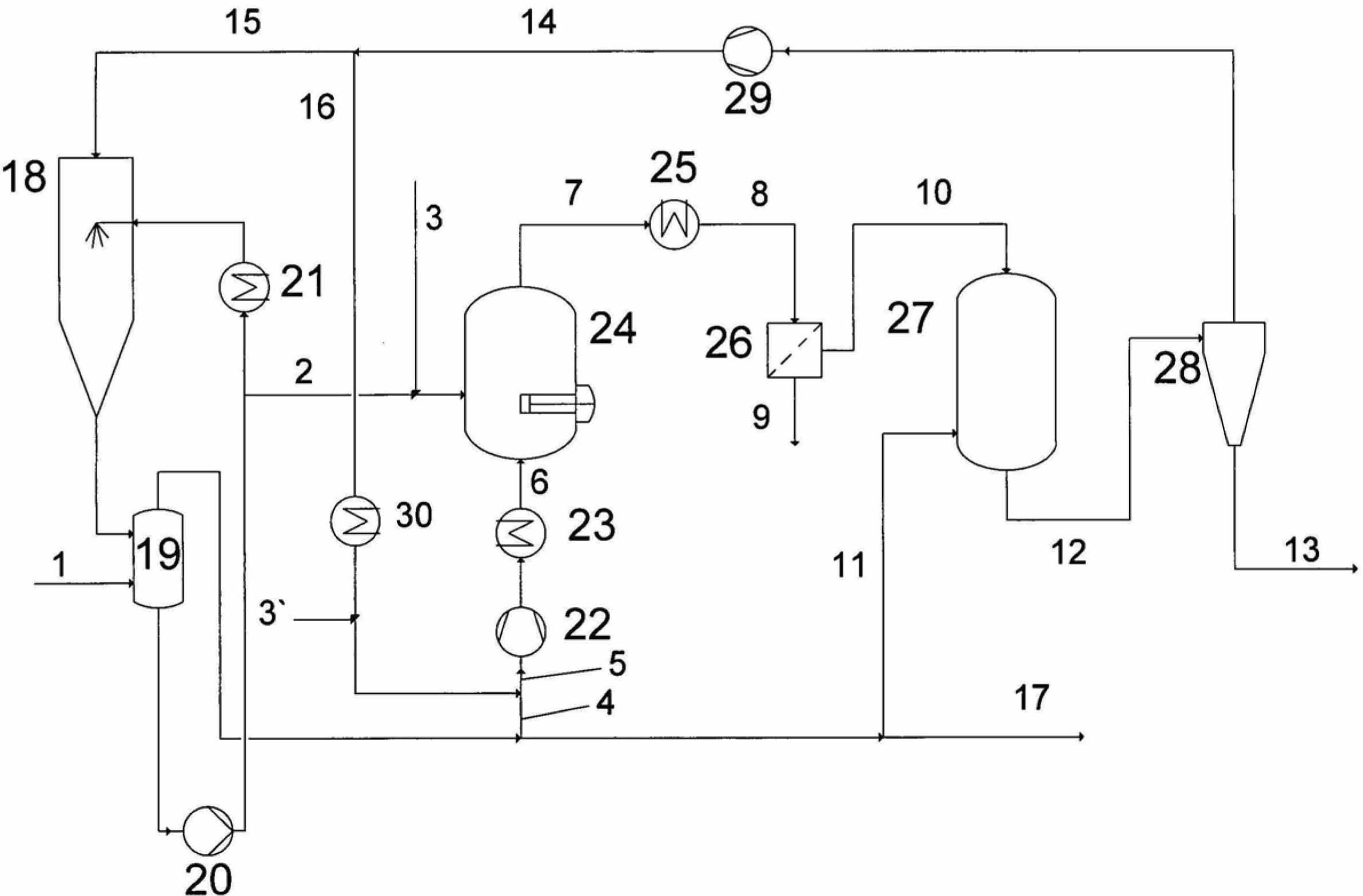

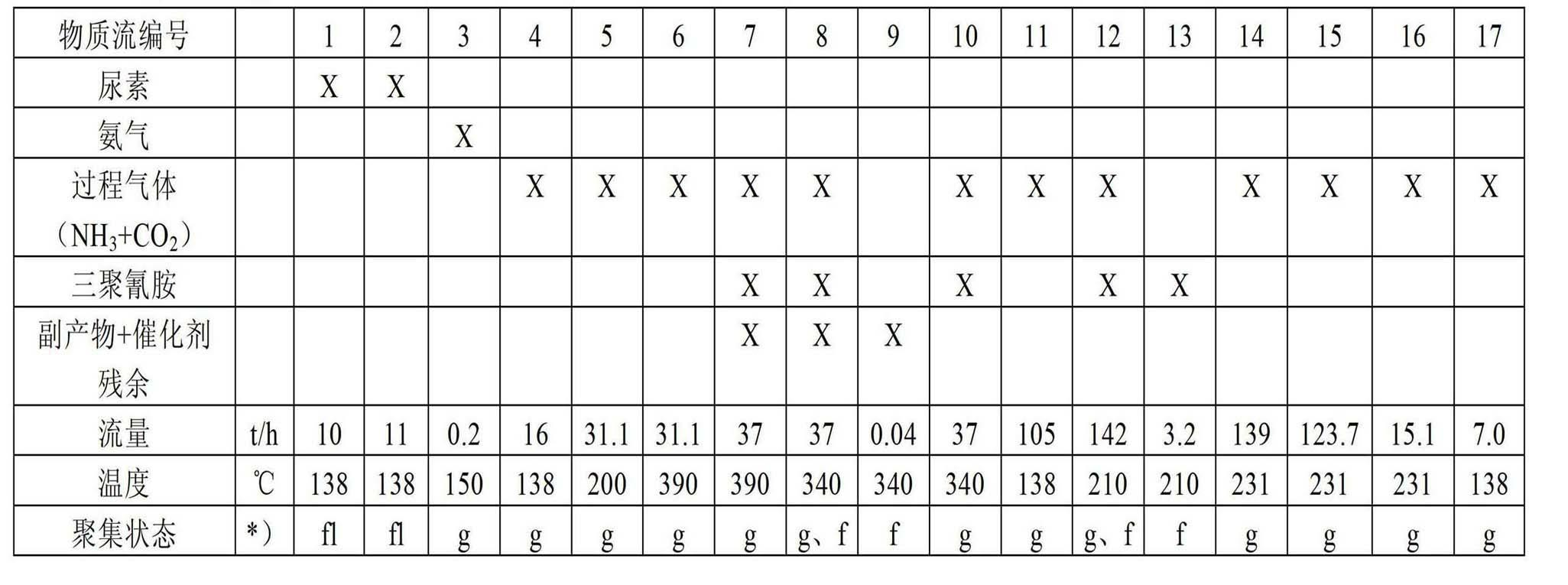

[0031] Liquid urea is fed into the gas separator (19) as raw material for the production of melamine and is led in the circuit through the cooling device (21). In the scrubber ( 18 ), the isocyanic acid residues present in the process gas stream ( 15 ) are converted into urea by an exothermic chemical reaction. The heat of reaction formed here is dissipated from the urea conducted in the circuit by means of a cooler ( 21 ). A urea stream ( 2 ) is branched off from the urea circuit of the scrubber, which is mixed with an ammonia stream ( 3 ) and fed into a fluidized bed reactor ( 24 ). A process gas stream (5) is formed from the process gas stream (4) treated in the scrubber (18) and the process gas stream (16) directed past the scrubber, which is supplied to Compressor or fan (22). In this case, the mixing ratio of the material streams ( 4 ) and ( 16 ) is adjusted such that the process gas stream ( 5 ) with a temperature of 200° C. is supplied to the compressor or fan ( 22 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com