Closed cooling system for soft water of blast furnace body and blast furnace cooling method

A soft water sealing and cooling system technology, applied in the direction of cooling devices, etc., can solve the problems of cooling intensity blast furnace thickening, low practicability, inability to achieve adjustment, etc., to prevent furnace wall thickening, prevent slag skin instability, and effectively adjust. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

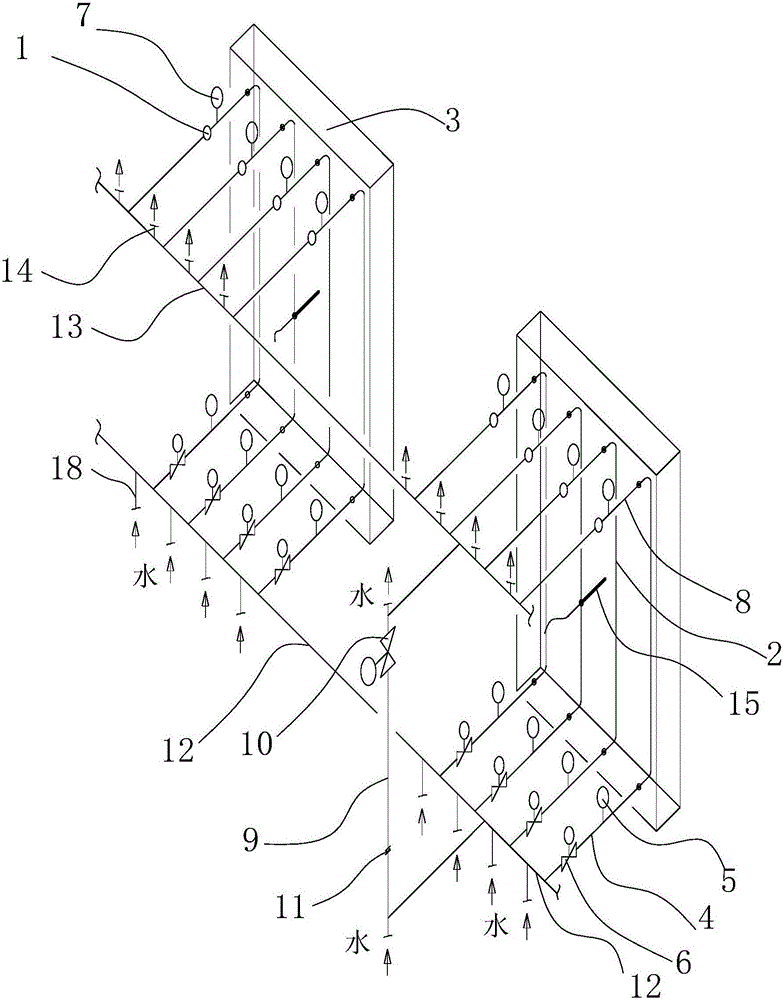

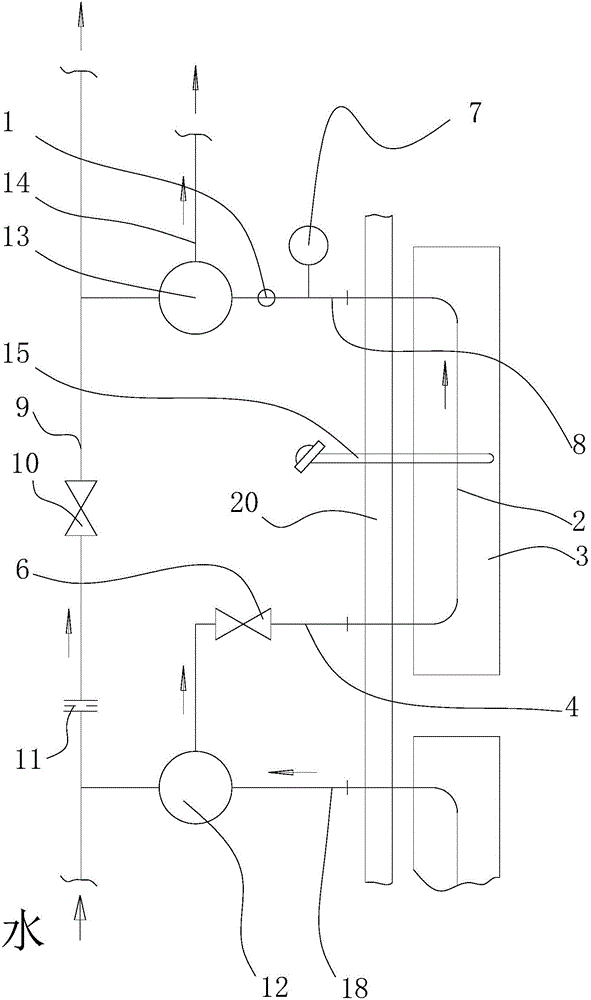

[0048] Such as figure 1 , image 3 As shown, a soft water closed cooling system for a blast furnace body includes a number of stave bodies 3 fixed to the inner wall of the blast furnace shell 20 with bolts. 48 cooling stave bodies are arranged in each layer, and each cooling stave body 3 is provided with four cooling water flow channels 2. Out of the blast furnace shell 20, and the first temperature sensor 5 and the second temperature sensor 7 are respectively installed on the water inlet pipe 4 and the water outlet pipe 8, the flow sensor 1 is arranged on the water inlet pipe 4 or the water outlet pipe 8, and the stave body 3 A third temperature measuring sensor 15 is installed on it, and the third temperature measuring sensor 15 penetrates the furnace shell 20 and goes deep into the stave body 3 . Every 6 stave bodies on the same floor are divided into 8 groups. The 24 water inlet pipes of each group of cooling wall bodies are connected with the water inlet concentration ...

Embodiment 2

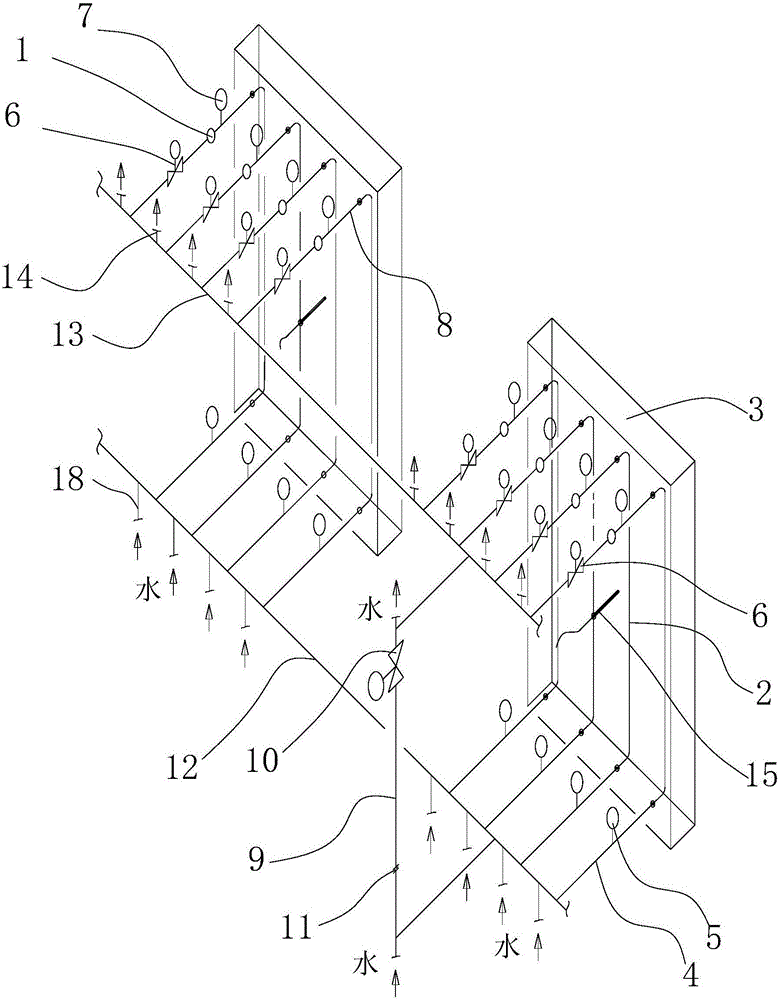

[0055] The other structures of this embodiment are the same as those of Embodiment 1, the only difference being that all the water inlet pipes 4 of the stave body on the same floor are in communication with the water inlet concentration pipe 12, and the water inlet concentration pipe 12 is a ring pipe surrounding the blast furnace body. All the water outlet pipes 8 of the stave body on the same layer are connected with the water outlet centralized pipe 13, and the water outlet centralized pipe 13 is a ring pipe surrounding the blast furnace body. The outlet pipe 8 is provided with a first regulating valve 6, and the opening degree of the first regulating valve 6 is controlled to control the flow of water passing through the cooling wall as required, and at the same time, the opening of the second regulating valve 10 on the same group of bypass pipes 9 is changed. to avoid affecting the water flow in other parts of the flow channel.

[0056] The core of the present invention is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com